Influence of Temperature on the Performance of a Full-Scale Activated Sludge Process Operated at Varying Solids Retention Times Whilst Treating Municipal Sewage

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

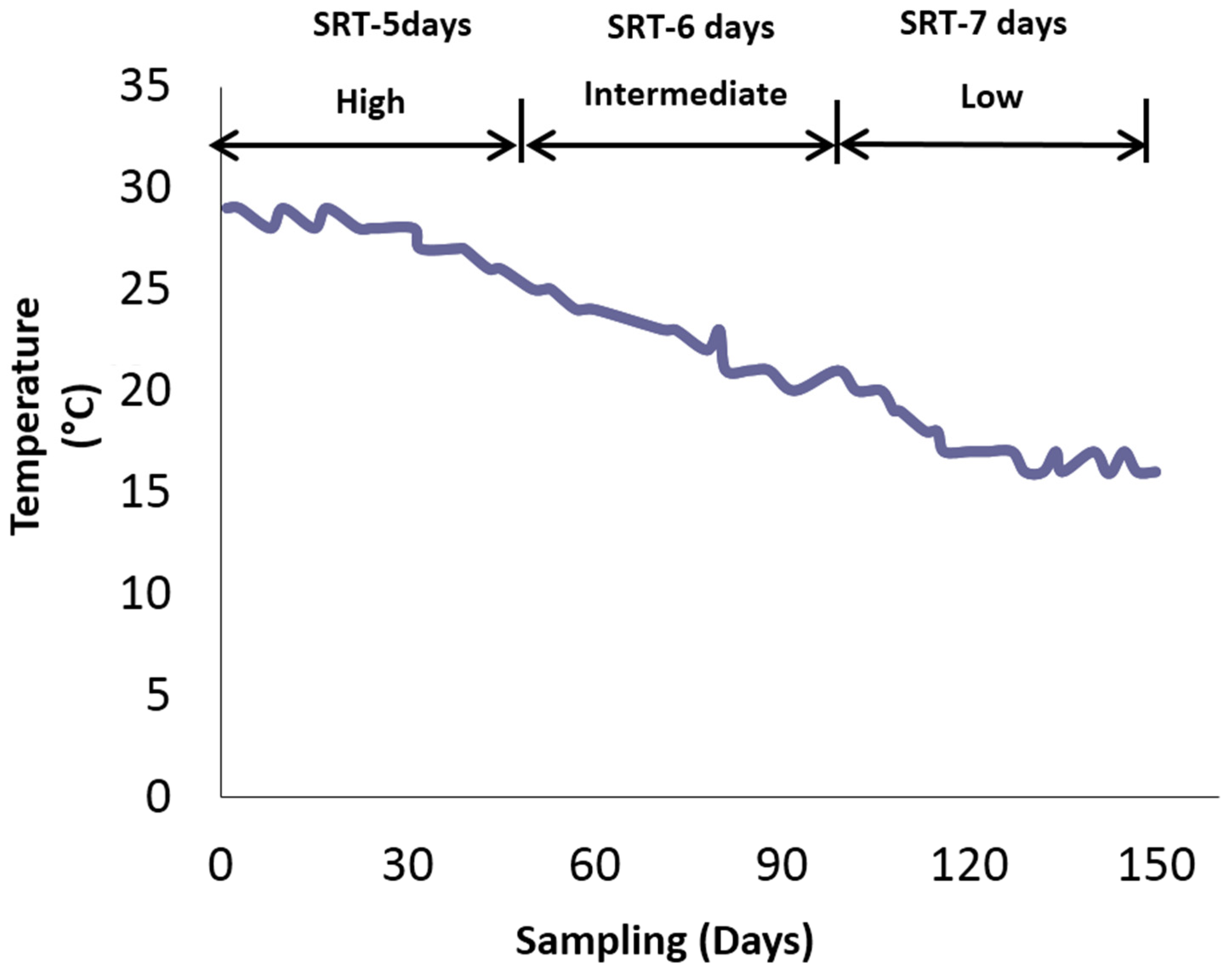

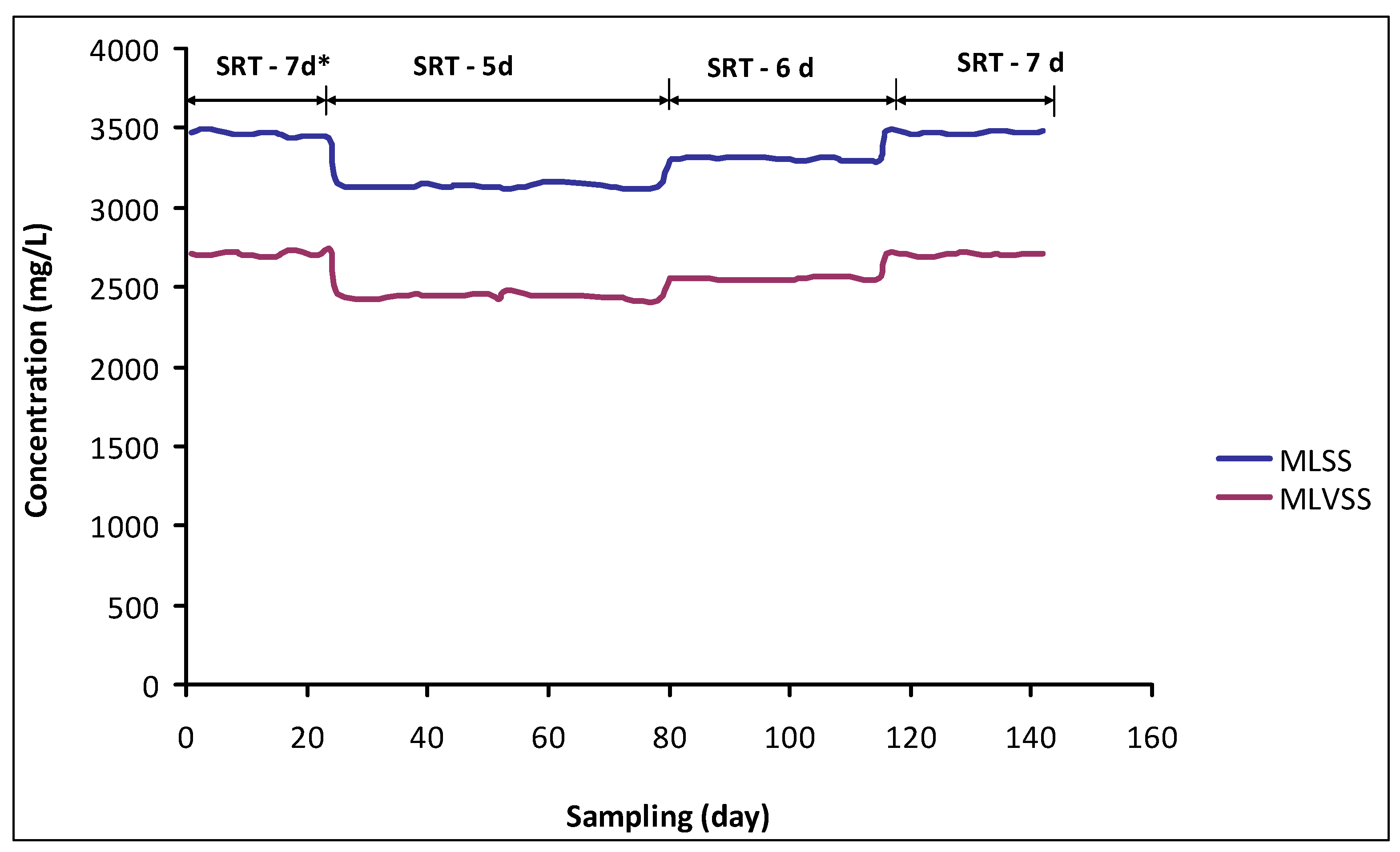

3.1. Selection of Solids Retention Time (SRT) Based upon Liquid Temperature Ranges

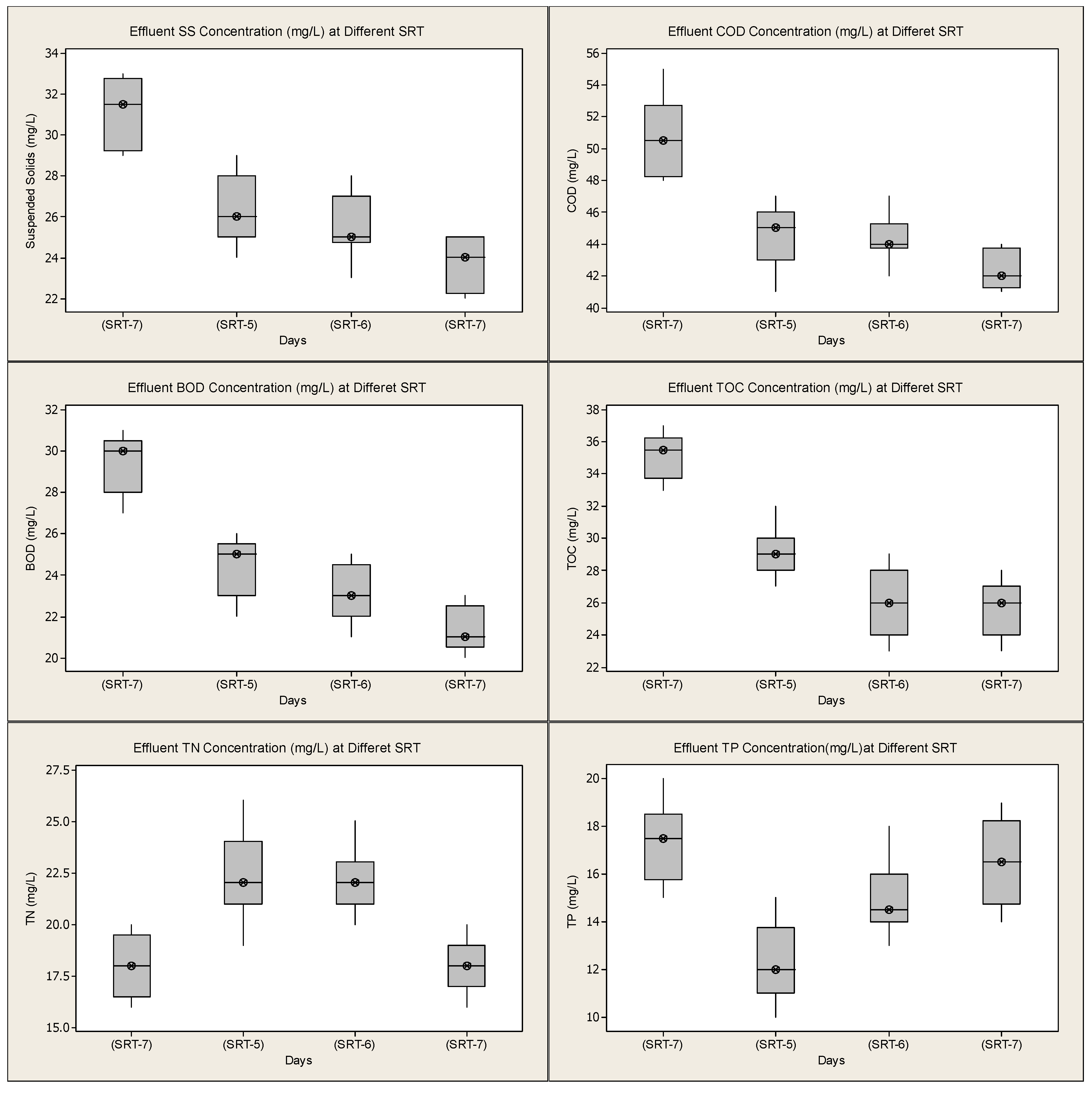

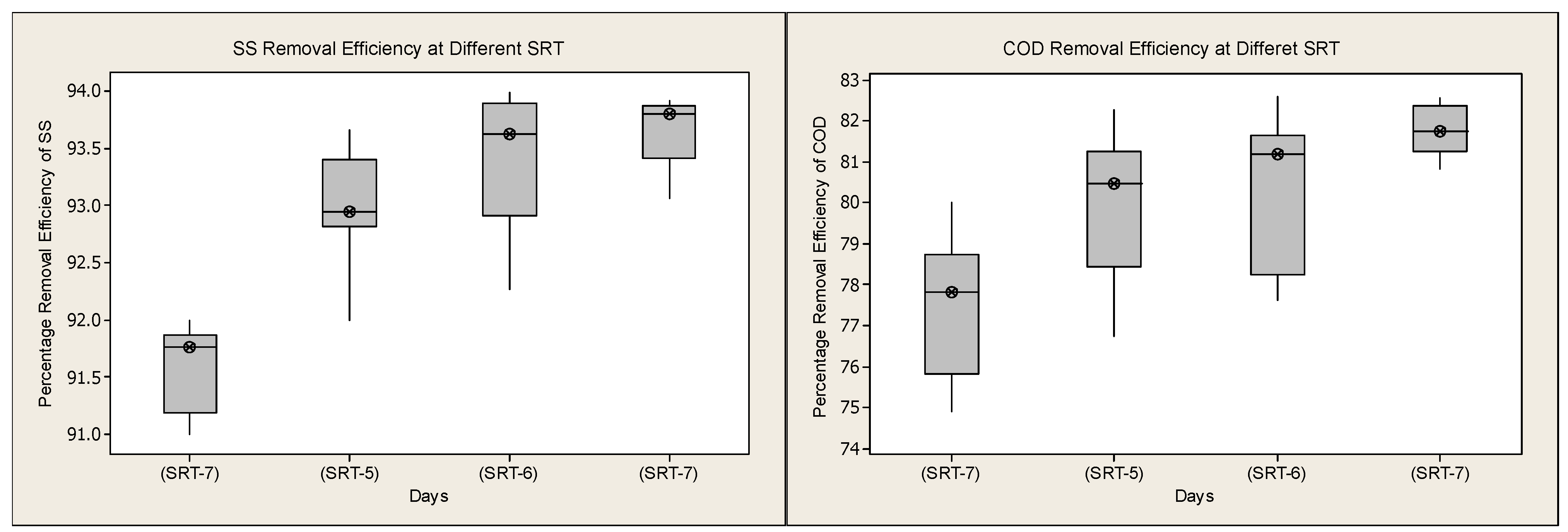

3.2. Influence of Solids Retention Time (SRT) on Organic and Nutrients Removal

| Parameter | Sampling Point (Units) | 7 Days a | 5 Days | 6 Days | 7 Days |

|---|---|---|---|---|---|

| TSS | Influent (mg/L) | 370 | 386 | 382 | 384 |

| Effluent (mg/L) | 31 | 27 | 26 | 24 | |

| Removal efficiency (%) | 91 | 93 | 93 | 94 | |

| BOD | Influent (mg/L) | 133 | 131 | 135 | 132 |

| Effluent (mg/L) | 29 | 24 | 23 | 21 | |

| Removal Efficiency (%) | 77 | 82 | 82 | 82 | |

| COD | Influent (mg/L) | 224 | 220 | 229 | 232 |

| Effluent (mg/L) | 51 | 44 | 44 | 42 | |

| Removal Efficiency (%) | 77 | 80 | 80 | 81 | |

| TOC | Influent (mg/L) | 111 | 108 | 111 | 110 |

| Effluent (mg/L) | 35 | 29 | 26 | 26 | |

| Removal Efficiency (%) | 67 | 74 | 75 | 76 | |

| TN | Influent (mg/L) | 38 | 39 | 43 | 38 |

| Effluent (mg/L) | 18 | 22 | 21 | 18 | |

| Removal Efficiency (%) | 52 | 46 | 48 | 53 | |

| TP | Influent (mg/L) | 40 | 41 | 42 | 38 |

| Effluent (mg/L) | 20 | 15 | 18 | 19 | |

| Removal Efficiency (%) | 57 | 68 | 62 | 59 |

| Parameter | Source | Effluent Concentration Range | Removal Efficiency Range |

|---|---|---|---|

| TSS (mg/L) | Literature a | 20 to 40 | 87 to 93 |

| Actual b | 22 to 33 | 90 to 93 | |

| BOD (mg/L) | Literature a | 10 to 40 | 85 to 97 |

| Actual b | 21 to 30 | 77 to 85 | |

| COD (mg/L) | Literature a | 30 to120 | 80 to 93 |

| Actual b | 41 to 55 | 76 to 82 | |

| TN (mg/L) | Literature a | >15 | <60 |

| Actual b | 16 to 26 | 43 to 53 | |

| TP (mg/L) | Literature a | >04 | <60 |

| Actual b | 11 to 20 | 52 to 70 |

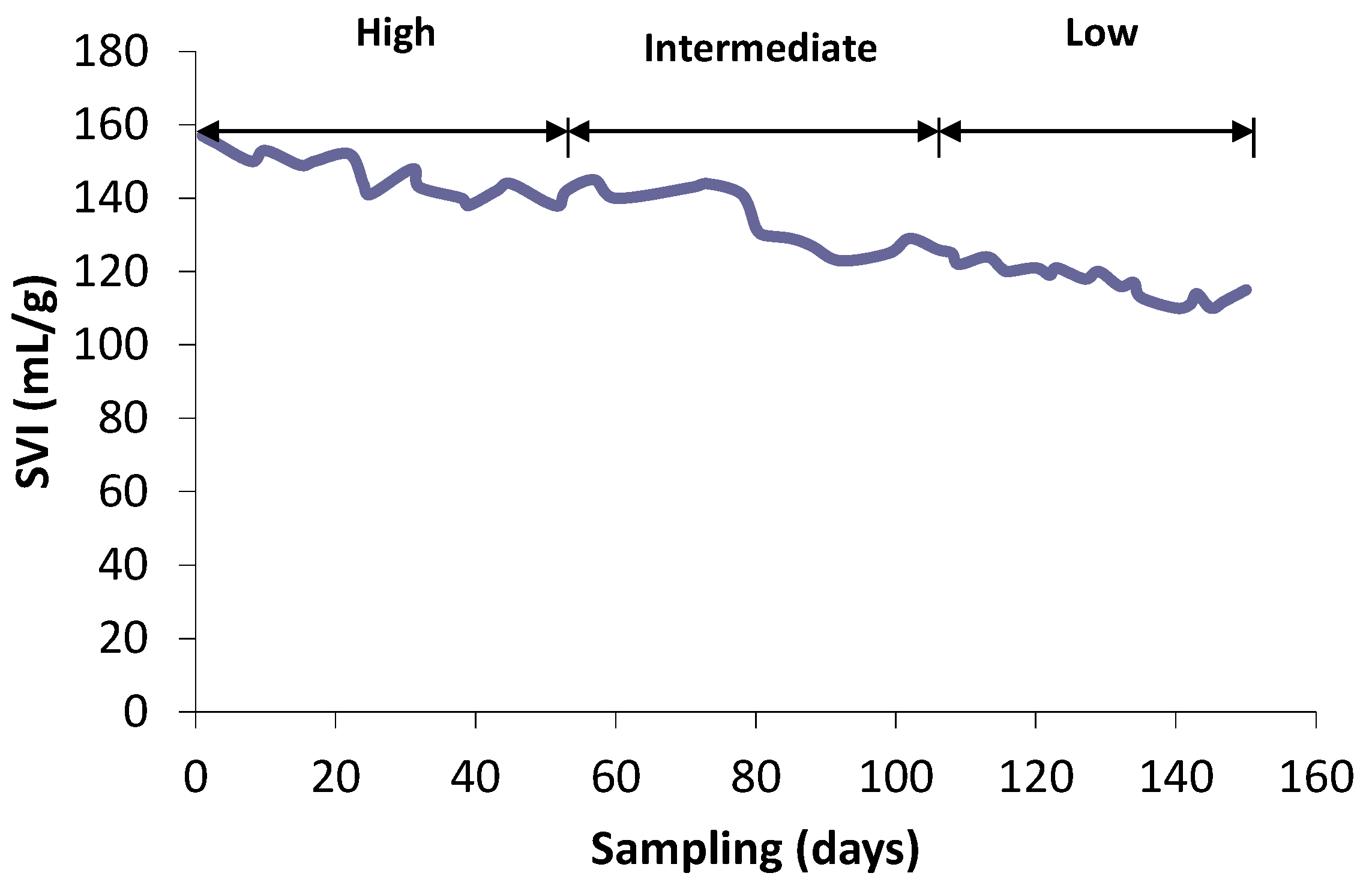

3.3. Influence of Solids Retention Time (SRT) on Sludge Settling Properties

| Temperature Variation (°C) | SRT (Days) | MLSS (g/m3) | Wastage (Hour) | SVI (mL/g) |

|---|---|---|---|---|

| 29–30 a | 7 | 3450 | 08 | 152 |

| 25–29 | 5 | 3130 | 11 | 143 |

| 20–24 | 6 | 3305 | 09 | 126 |

| 15–19 | 7 | 3470 | 08 | 116 |

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wiesmann, U.; Choi, I.S.; Dombrowski, E.M. Fundamentals of Biological Wastewater Treatment: Fundamentals, Microbiology, Industrial Process Integration; Wiley-VCH Verlag GmbH: Weinheim, Germany, 2006. [Google Scholar]

- Fatima, S.S.; Khan, S.J. Evaluating the treatment performance of a full scale Activated Sludge Plant in Islamabad. Water Pract. Technol. 2012, 7, 1. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, H.; Zhu, J.; Weiping, L.; Xin, X. Improvement strategy on enhanced biological phosphorus removal for municipal wastewater treatment plants: Full-scale operating parameters, sludge activities, and microbial features. Bioresour. Technol. 2011, 102, 4646–4653. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, S.C.; Sperling, M. Performance evaluation of different wastewater treatment technologies operating in a developing country. J. Water Sanit. Hyg. Dev. 2011, 1, 37–56. [Google Scholar] [CrossRef]

- Sato, T.; Qadir, M.; Yamamoto, S.; Endo, T.; Zahoor, A. Global, regional, and country level need for data on wastewater generation, treatment, and reuse. Agric. Water Manag. 2013, 130, 1–13. [Google Scholar] [CrossRef]

- Ensink, J.H.J.; van Der Hoek, W.; Mara, D.D.; Cairncross, S. Waste stabilization pond performance in Pakistan and its implications for wastewater use in agriculture. Urban Water J. 2007, 4, 261–267. [Google Scholar] [CrossRef]

- Peng, G.; Ye, F.; Li, Y. Investigation of extracellular polymer substances (EPS)and physicochemical properties of activated sludge from different municipal and industrial wastewater treatment plants. Environ. Technol. 2012, 33, 857–863. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.M.; Cho, H.U.; Lee, D.S.; Park, D.; Park, J.M. Influence of operational parameters on nitrogen removal efficiency and microbial communities in a full-scale activated sludge process. Water Res. 2011, 45, 5785–5795. [Google Scholar] [CrossRef] [PubMed]

- Sürücü, G.; Çetin, F.D. Effects of temperature, pH and D.O. concentration on settleability of activated sludge. Environ. Technol. 1990, 11, 205–212. [Google Scholar]

- Lippi, S.; Rosso, D.; Lubello, C.; Canziani, R.; Stenstrom, M.K. Temperature modelling and prediction for activated sludge systems. Water Sci. Technol. 2009, 59, 125–131. [Google Scholar] [CrossRef] [PubMed]

- Clara, M.; Kreuzinger, N.; Strenn, B.; Gans, O.; Kroiss, H. The solids retention time—A suitable design parameter to evaluate the capacity of wastewater treatment plants to remove micropollutants. Water Res. 2005, 39, 97–106. [Google Scholar] [CrossRef] [PubMed]

- Leu, S.Y.; Chan, L.; Stenstrom, M.K. Toward long solids retention time of activated sludge processes: Benefits in energy saving, effluent quality, and stability. Water Environ. Res. 2012, 84, 42–53. [Google Scholar] [CrossRef] [PubMed]

- Liao, B.Q.; Droppo, I.G.; Leppard, G.G.; Liss, S.N. Effect of solids retention time on structure and characteristics of sludge flocs in sequencing batch reactors. Water Res. 2006, 40, 2583–2591. [Google Scholar] [CrossRef] [PubMed]

- Gerardi, M.H. Wastewater Bacteria; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Ekster, A.; Ignasi, R.R. The effect of sludge age in the operational cost of Activated Sludge Systems. In Proceedings of the Water Environment Federation, WEFTEC 2003: Session 31 through 40; Water Environment Federation: Los Angeles, CA, USA, 2003; pp. 402–410. [Google Scholar]

- Andreadakis, A.D. Nitrification-denitrification and activated sludge settlement. Environ. Technol. 1993, 14, 615–627. [Google Scholar] [CrossRef]

- Chan, L.; Leu, S.Y.; Rosso, D.; Stenstrom, M.K. The relationship between mixed-liqour particle size and solids retention time in the activated sludge process. Water Environ. Res. 2011, 83, 2178–2186. [Google Scholar] [CrossRef] [PubMed]

- Falas, P.; Andersen, H.R.; Ledin, A.; la Cour Jansen, J. Impact of solid retention time and nitrification capacity on the ability of activated sludge to remove pharmaceuticals. Environ. Technol. 2012, 33, 865–872. [Google Scholar] [CrossRef] [PubMed]

- Arceivala, S.J.; Asolerkar, S.R. Wastewater Treatment for Pollution Control and Reuse; Tata McGraw-Hill: New Delhi, India, 2007. [Google Scholar]

- Kim, D.; Kim, K.Y.; Ryu, H.; Min, K.K.; Lee, S. Long term operation of pilot-scale biological nutrient removal process in treating municipal wastewater. Bioresour. Technol. 2009, 100, 3180–3184. [Google Scholar] [CrossRef] [PubMed]

- APHA. Standard Methods for the Examination of Water and Wastewater, 21st ed.; American Public Health Association (APHA): Washington, DC, USA, 2005. [Google Scholar]

- Arceivala, S.J. Wastewater Treatment and Disposal: Engineering and Ecology in Pollution Control; Marcel Dekker Inc.: New York, NY, USA, 1981. [Google Scholar]

- Qasim, S.R. Wastewater Treatment Plants: Planning, Design and Operation; Holt, Rinehart and Winston: New York, NY, USA, 1985. [Google Scholar]

- Design of Municipal Wastewater Treatment Plants; Water Environment Federation/American Society of Civil Engineers: Alexandria, VA, USA, 1982.

- Mara, D. Domestic Wastewater Treatment in Developing Countries; Earthscan: London, UK, 2003. [Google Scholar]

- Metcalf & Eddy. Wastewater Engineering: Treatment and Reuse, 4th ed.; Metcalf & Eddy, Inc.: New York, NY, USA, 2003. [Google Scholar]

- Von Sperling, M.V.; Chernicharo, C.A.L. Biological Wastewater Treatment in Warm Climate Regions; IWA Publishing: London, UK, 2005; Volume 1. [Google Scholar]

- Spellman, F.R. Handbook of Water and Wastewater Treatment Plant Operation; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shahzad, M.; Khan, S.J.; Paul, P. Influence of Temperature on the Performance of a Full-Scale Activated Sludge Process Operated at Varying Solids Retention Times Whilst Treating Municipal Sewage. Water 2015, 7, 855-867. https://doi.org/10.3390/w7030855

Shahzad M, Khan SJ, Paul P. Influence of Temperature on the Performance of a Full-Scale Activated Sludge Process Operated at Varying Solids Retention Times Whilst Treating Municipal Sewage. Water. 2015; 7(3):855-867. https://doi.org/10.3390/w7030855

Chicago/Turabian StyleShahzad, Moazzam, Sher Jamal Khan, and Parneet Paul. 2015. "Influence of Temperature on the Performance of a Full-Scale Activated Sludge Process Operated at Varying Solids Retention Times Whilst Treating Municipal Sewage" Water 7, no. 3: 855-867. https://doi.org/10.3390/w7030855