Optimization of Wavy-Channel Micromixer Geometry Using Taguchi Method †

Abstract

:1. Introduction

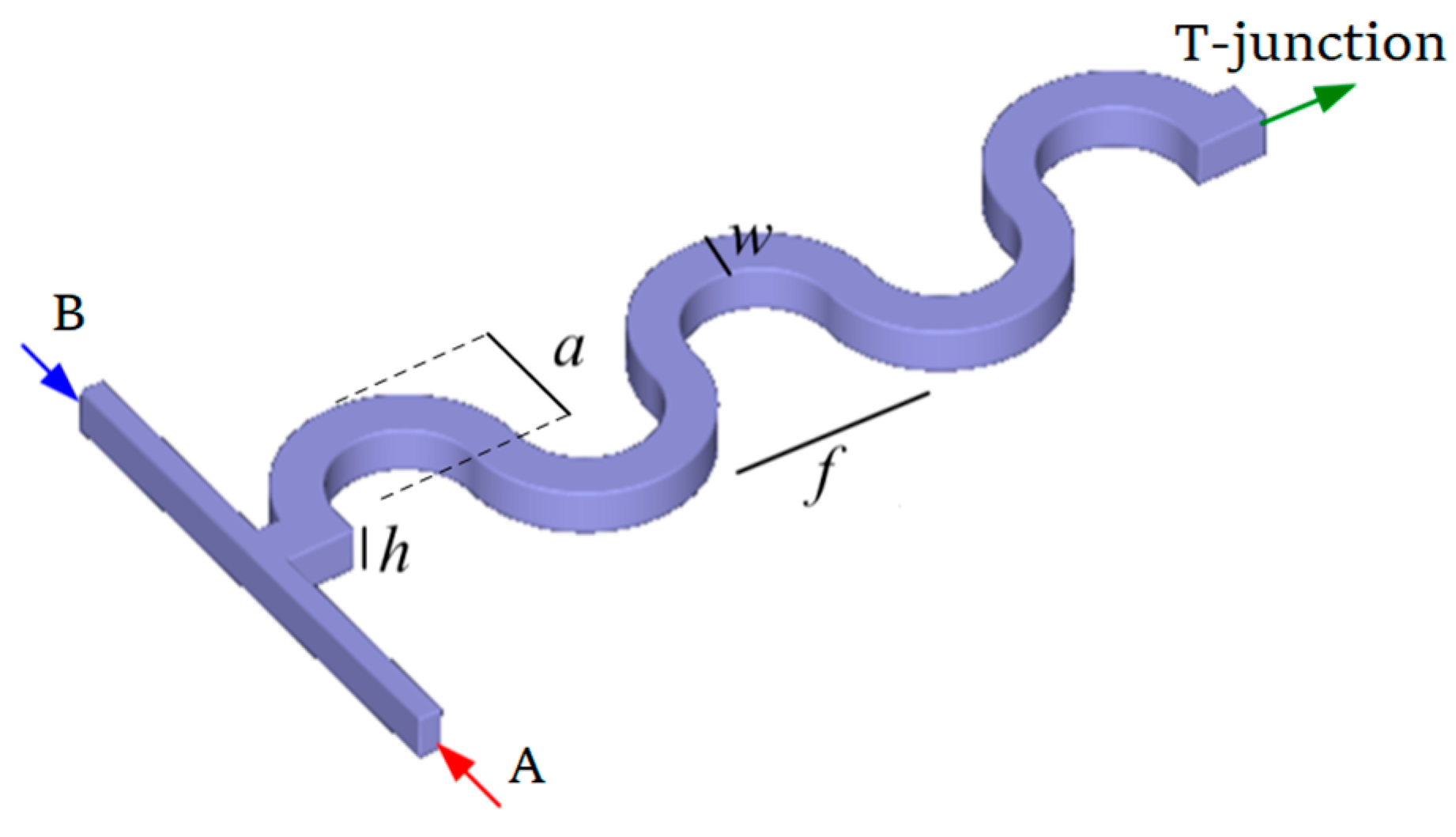

2. Model Development

2.1. Governing Equations

2.2. Boundary Conditions

2.3. Taguchi Statistical Method

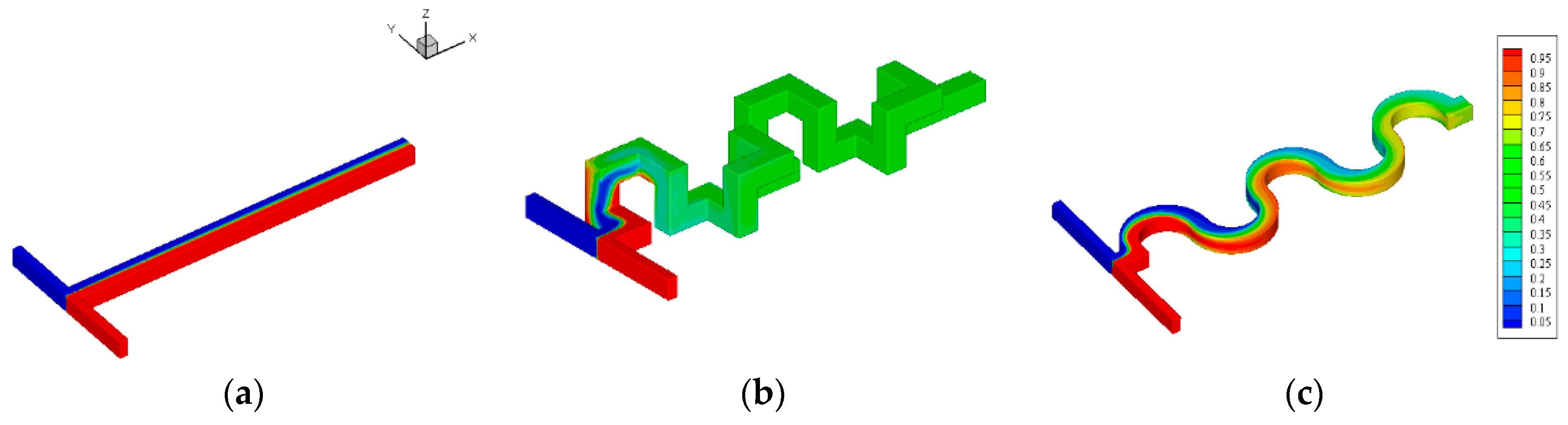

3. Numerics

4. Results and Discussion

4.1. Effect of Channel Geometries

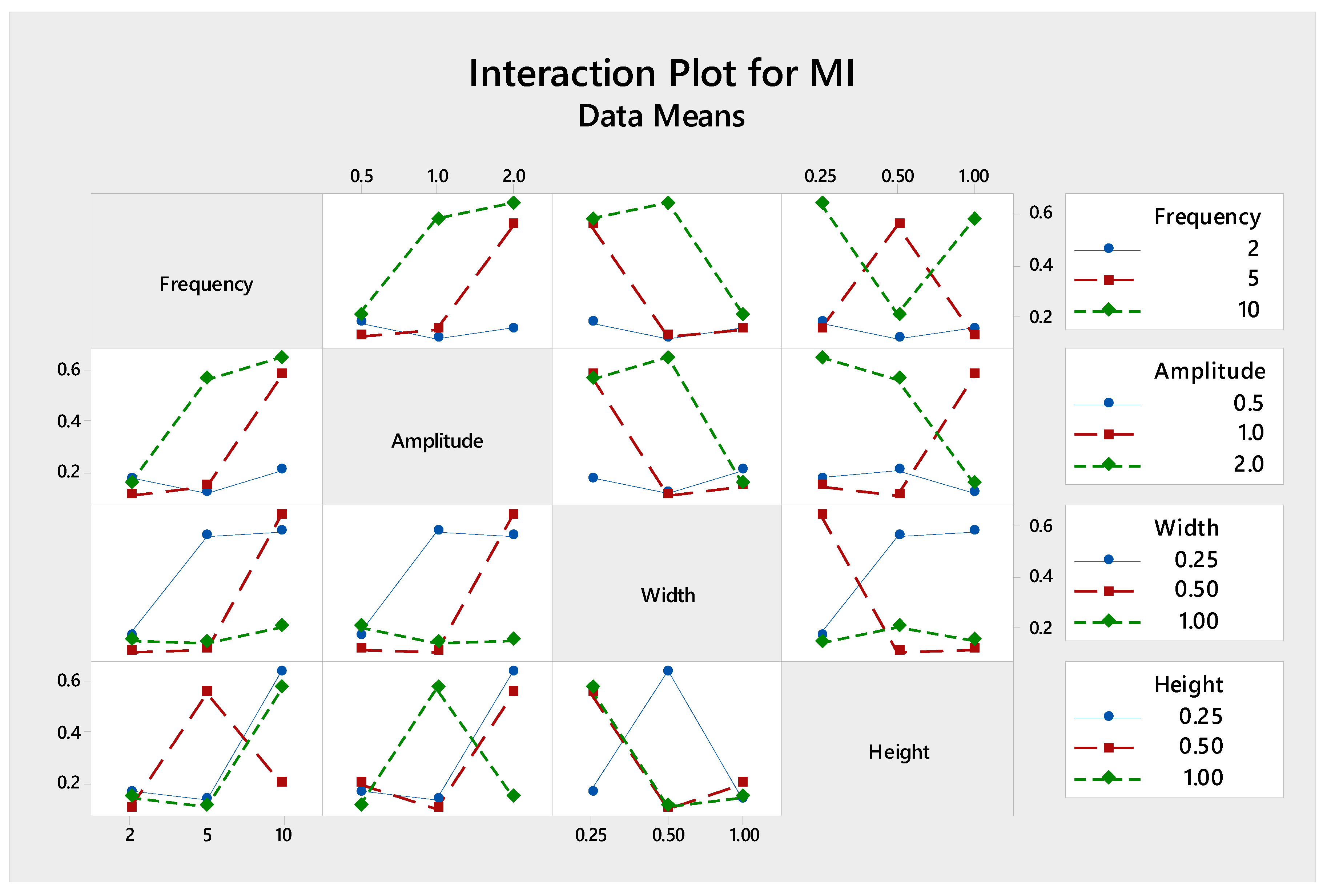

4.2. Mixing Performance

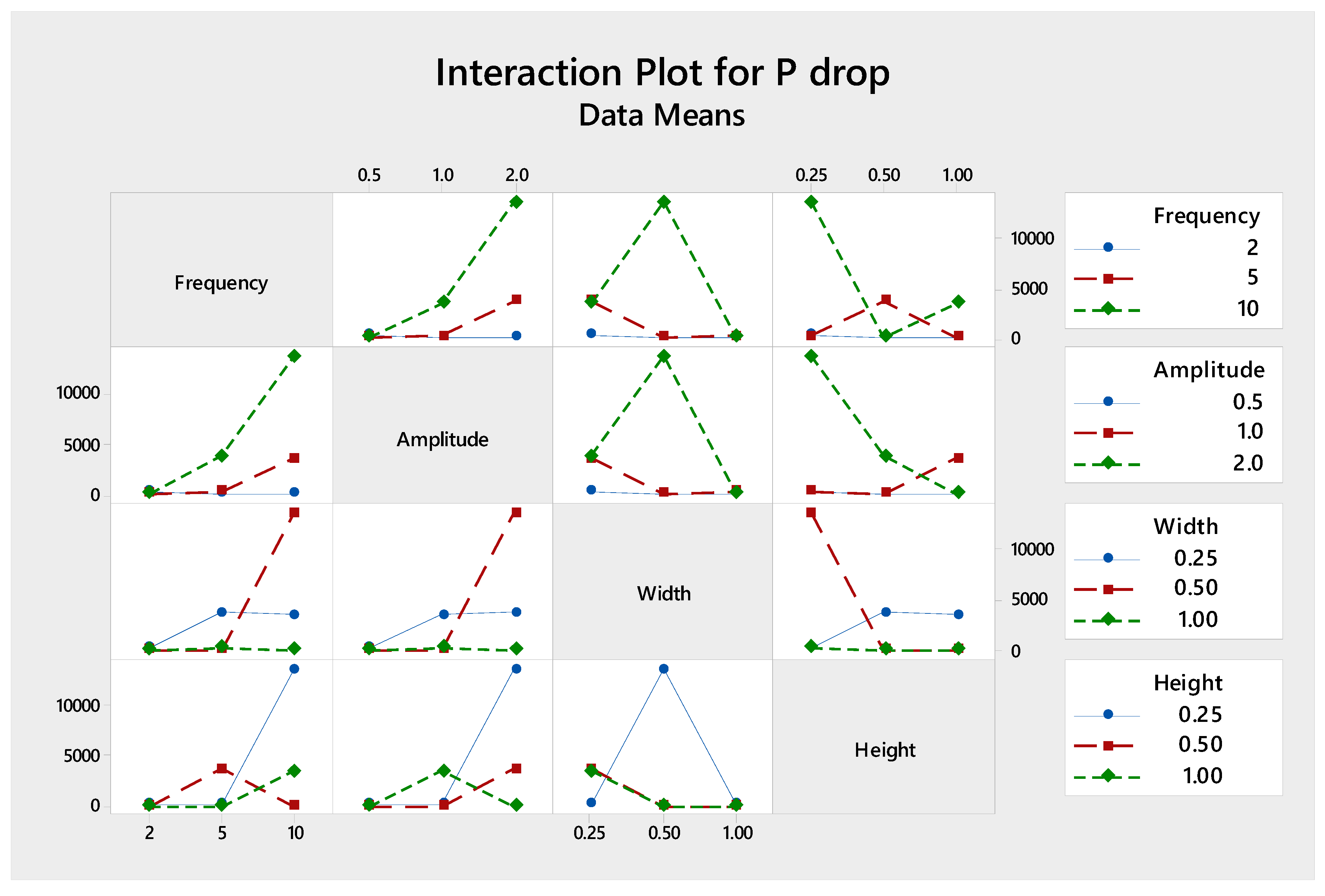

4.3. Pumping Power

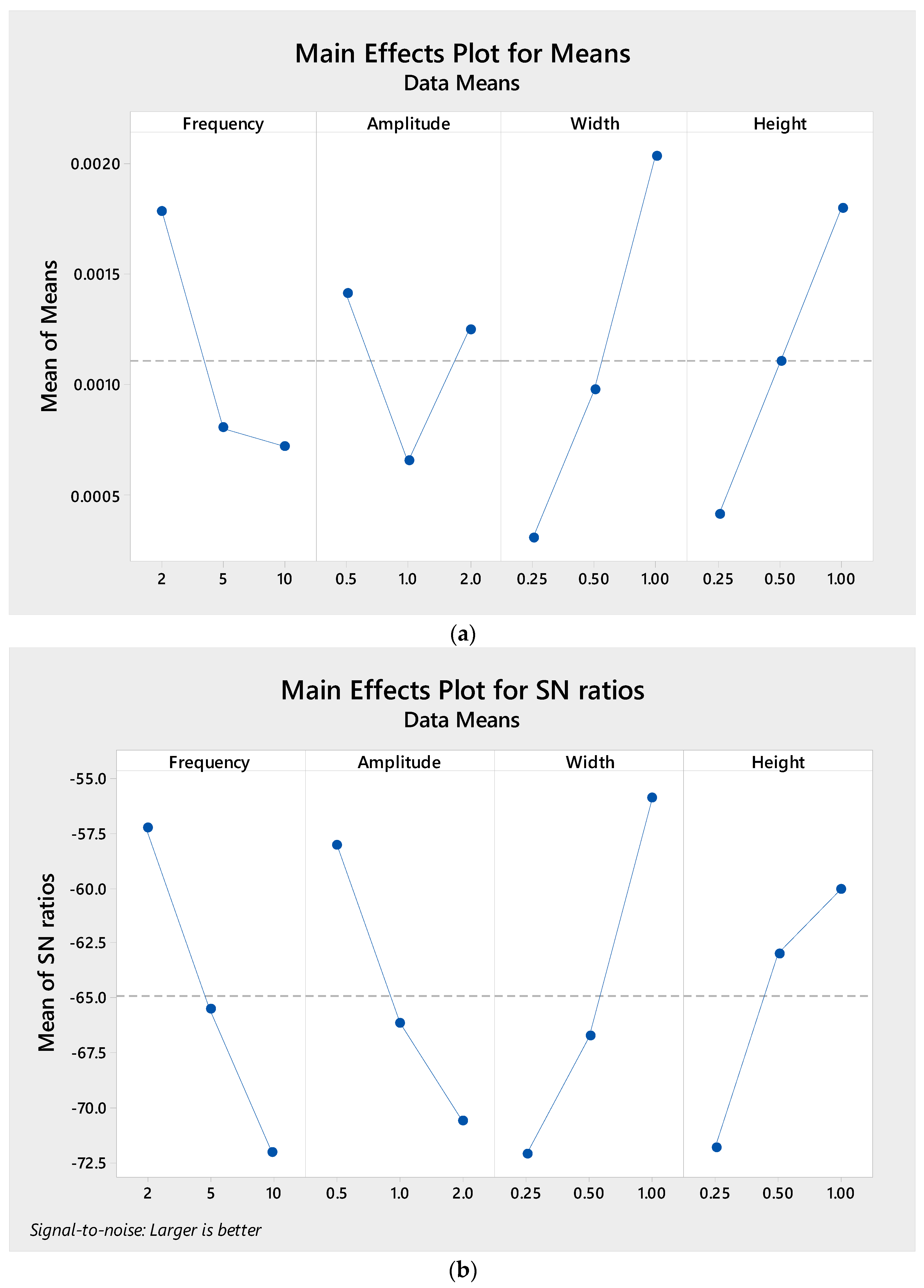

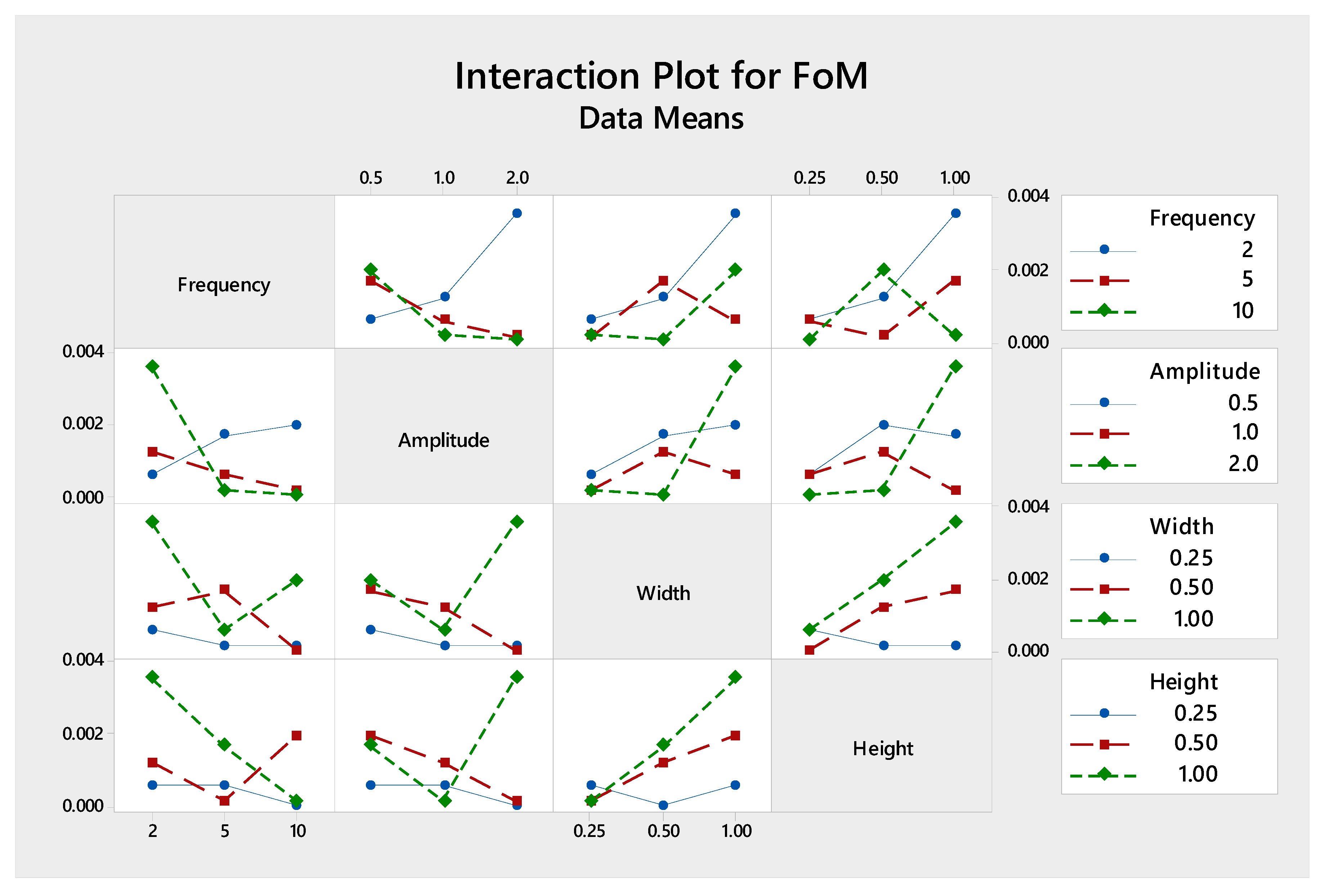

4.4. Figure of Merit

5. Concluding Remarks

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Liu, H.; Li, P.; Lew, J.V. CFD study on flow distribution uniformity in fuel distributors having multiple structural bifurcations of flow channels. Int. J. Hydrog. Energy 2010, 35, 9186–9198. [Google Scholar] [CrossRef]

- Kumar, V.; Paraschivoiu, M.; Nigam, K.D.P. Single-phase fluid flow and mixing in microchannels. Chem. Eng. Sci. 2011, 66, 1329–1373. [Google Scholar] [CrossRef]

- Nguyen, N.T.; Wu, Z. Micromixers—A review. J. Micromech. Microeng. 2005, 15, R1–R16. [Google Scholar] [CrossRef]

- Hessel, V.; Lowe, H.; Schonfeld, F. Micromixers—A review on passive and active mixing principles. Chem. Eng. Sci. 2005, 60, 2479–5501. [Google Scholar] [CrossRef]

- Cai, G.; Xue, L.; Zhang, H.; Lin, J. A review on micromixers. Micromachines 2017, 8, 274. [Google Scholar] [CrossRef]

- Lee, C.Y.; Wang, W.T.; Liu, C.C.; Fu, L.M. Passive mixers in microfluidic systems: A review. Chem. Eng. J. 2016, 288, 146–160. [Google Scholar] [CrossRef]

- Huang, P.H.; Xie, Y.; Ahmed, D.; Rufo, J.; Nama, N.; Chen, Y.; Chan, C.Y.; Huang, T.J. An acoustofluidic micromixer based on oscillating sidewall sharp-edhes. Lab Chip 2013, 13, 3847. [Google Scholar] [CrossRef] [PubMed]

- Nama, N.; Huang, P.H.; Huang, T.J.; Costanzo, F. Investigation of micromixing by acoustically oscillated sharp-edges. Biomicrofluidics 2016, 10, 024124. [Google Scholar] [CrossRef] [PubMed]

- Tseng, W.K.; Lin, J.L.; Sung, W.C.; Chen, S.H.; Lee, G.B. Active micro-mixers using surface acoustic waves on Y-cut 128° LiNbO3. J. Micromech. Microeng. 2006, 16, 539–548. [Google Scholar] [CrossRef]

- Tovar, A.R.; Lee, A.P. Lateral cavity acoustic transducer. Lab Chip 2009, 9, 41–43. [Google Scholar] [CrossRef] [PubMed]

- Tonkovich, A.; Kuhlmann, D.; Rogers, A.; McDaniel, J.; Fitzgerald, S.; Arora, R.; Yuschak, T. Microchannel technology scale-up to commercial capacity. Chem. Eng. Res. Des. 2005, 83, 634–639. [Google Scholar] [CrossRef]

- Lim, W.S.; Choi, H.S.; Ahn, S.Y.; Kim, B.M. Cooling channel design of hot stamping tools for uniform high-strength components in hot stamping process. Int. J. Adv. Manuf. Technol. 2014, 10, 1189–1203. [Google Scholar] [CrossRef]

- Yoon, D.H.; Tanaka, D.; Sekiguchi, T.; Shoji, S. Microfluidic stamping on sheath flow. Small 2016, 24, 3224–3228. [Google Scholar] [CrossRef] [PubMed]

- Bong, H.J.; Lee, J.; Kim, J.H.; Barlat, F.; Lee, M.G. Two-stage forming approach for manufacturing ferritic stainless steel bipolar plates in PEM fuel cell: Experiments and numerical simulations. Int. J. Hydrog. Energy 2017, 42, 6965–6977. [Google Scholar] [CrossRef]

- Choi, J.H.; Oh, C.M.; Jang, J.W. Micro- and nano-patterns fabricated by emboseed microscale stamp with trenched edges. RSC Adv. 2017, 7, 32058. [Google Scholar] [CrossRef]

- Hossain, S.; Lee, I.; Kim, S.M.; Kim, K.Y. A micromixer with two-layer serpentine crossing channels having excellent mixing performance at low Reynolds numbers. Chem. Eng. J. 2017, 327, 268–277. [Google Scholar] [CrossRef]

- Hossain, S.; Kim, K.Y. Mixing analysis in a three-dimensional serpentine split-and-recombine micromixer. Chem. Eng. Res. Des. 2015, 100, 95–103. [Google Scholar] [CrossRef]

- Ahmed, F.; Kim, K.Y. Parametric study of an electroosmotic micromixer with heterogeneous charged surface patches. Micromachines 2017, 8, 199. [Google Scholar] [CrossRef]

- Xie, T.; Xu, C. Numerical and experimental investigations of chaotic mixing behavior in an oscillating feedback micromixer. Chem. Eng. Sci. 2017, 171, 303–317. [Google Scholar] [CrossRef]

- Solehati, N.; Bae, J.; Sasmito, A.P. Numerical investigation of mixing performance in microchannel T-junction with wavy structure. Comput. Fluids 2014, 96, 10–19. [Google Scholar] [CrossRef]

- Solehati, N.; Bae, J.; Sasmito, A.P. Numerical investigation of multi-scale mixing in microchannel T-junction with wavy structure. In Proceedings of the ASME 2012 International Mechanical Engineering Congress and Exposition, Houston, TX, USA, 9–15 November 2012. [Google Scholar] [CrossRef]

- Solehati, N.; Bae, J.; Sasmito, A.P. Optimization of operating parameters for liquid-cooled PEM fuel cell stakcs using Taguchi method. J. Ind. Eng. Chem. 2012, 18, 1039–1050. [Google Scholar] [CrossRef]

- Sasmito, A.P.; Kurnia, J.C.; Shamim, T.; Mujumdar, A.S. Optimization of an open-cathode polymer electrolyte fuel cells stack utilizing Taguchi method. Appl. Energy 2017, 185, 1225–1232. [Google Scholar] [CrossRef]

- Barker, T.A. Quality by Experimental Design; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Fowlkes, W.Y.; Creveling, C.M. Engineering Methods for Robust Product Design Using Taguchi Methods in Technology and Product Development; Addison-Wesley Publishing Company: Boston, MA, USA, 1995. [Google Scholar]

| No. | Frequency (π) | Amplitude (mm) | Width (mm) | Height (mm) |

|---|---|---|---|---|

| 1 | 2 | 0.5 | 0.25 | 0.25 |

| 2 | 2 | 1 | 0.5 | 0.5 |

| 3 | 2 | 2 | 1 | 1 |

| 4 | 5 | 0.5 | 0.5 | 1 |

| 5 | 5 | 1 | 1 | 0.25 |

| 6 | 5 | 2 | 0.25 | 0.5 |

| 7 | 10 | 0.5 | 1 | 0.5 |

| 8 | 10 | 1 | 0.25 | 1 |

| 9 | 10 | 2 | 0.5 | 0.25 |

| Parameter | Value | Unit |

|---|---|---|

| Channel length | 10 | mm |

| Liquid density | 998 | kg/m3 |

| Viscosity | 1 × 10−3 | kg/m∙s |

| Diffusivity | 2.2 × 10−9 | m2/s |

| Velocity inlet A | 0.04 | m/s |

| Velocity inlet B | 0.04 | m/s |

| No. | Mixing Index | Pressure Drop (Pa) | Figure of Merit |

|---|---|---|---|

| 1 | 0.171 | 286.76 | 5.98 × 10−4 |

| 2 | 0.105 | 87.2 | 1.21 × 10−3 |

| 3 | 0.149 | 41.85 | 3.56 × 10−3 |

| 4 | 0.115 | 68.36 | 1.68 × 10−3 |

| 5 | 0.142 | 238.73 | 5.93 × 10−4 |

| 6 | 0.563 | 3747.13 | 1.50 × 10−4 |

| 7 | 0.203 | 103.58 | 1.96 × 10−3 |

| 8 | 0.582 | 3506.95 | 1.66 × 10−4 |

| 9 | 0.649 | 13,729 | 4.73 × 10−5 |

| Parameter | Mixing Index | Pressure Drop | Figure of Merit |

|---|---|---|---|

| Frequency | 10 | 2 | 2 |

| Amplitude | 2 | 0.5 | 0.5 |

| Width | 0.25 | 1 | 1 |

| Height | 0.25 | 1 | 1 |

| Optimized design | 0.8 | 21.75 | 3.77 × 10−3 |

| CI (%) | 94.6% | 93.8 | 95.8 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Solehati, N.; Bae, J.; Sasmito, A.P. Optimization of Wavy-Channel Micromixer Geometry Using Taguchi Method. Micromachines 2018, 9, 70. https://doi.org/10.3390/mi9020070

Solehati N, Bae J, Sasmito AP. Optimization of Wavy-Channel Micromixer Geometry Using Taguchi Method. Micromachines. 2018; 9(2):70. https://doi.org/10.3390/mi9020070

Chicago/Turabian StyleSolehati, Nita, Joonsoo Bae, and Agus P. Sasmito. 2018. "Optimization of Wavy-Channel Micromixer Geometry Using Taguchi Method" Micromachines 9, no. 2: 70. https://doi.org/10.3390/mi9020070