Research of a Novel Ultra-High Pressure Sensor with High-Temperature Resistance †

Abstract

:1. Introduction

2. Materials and Methods

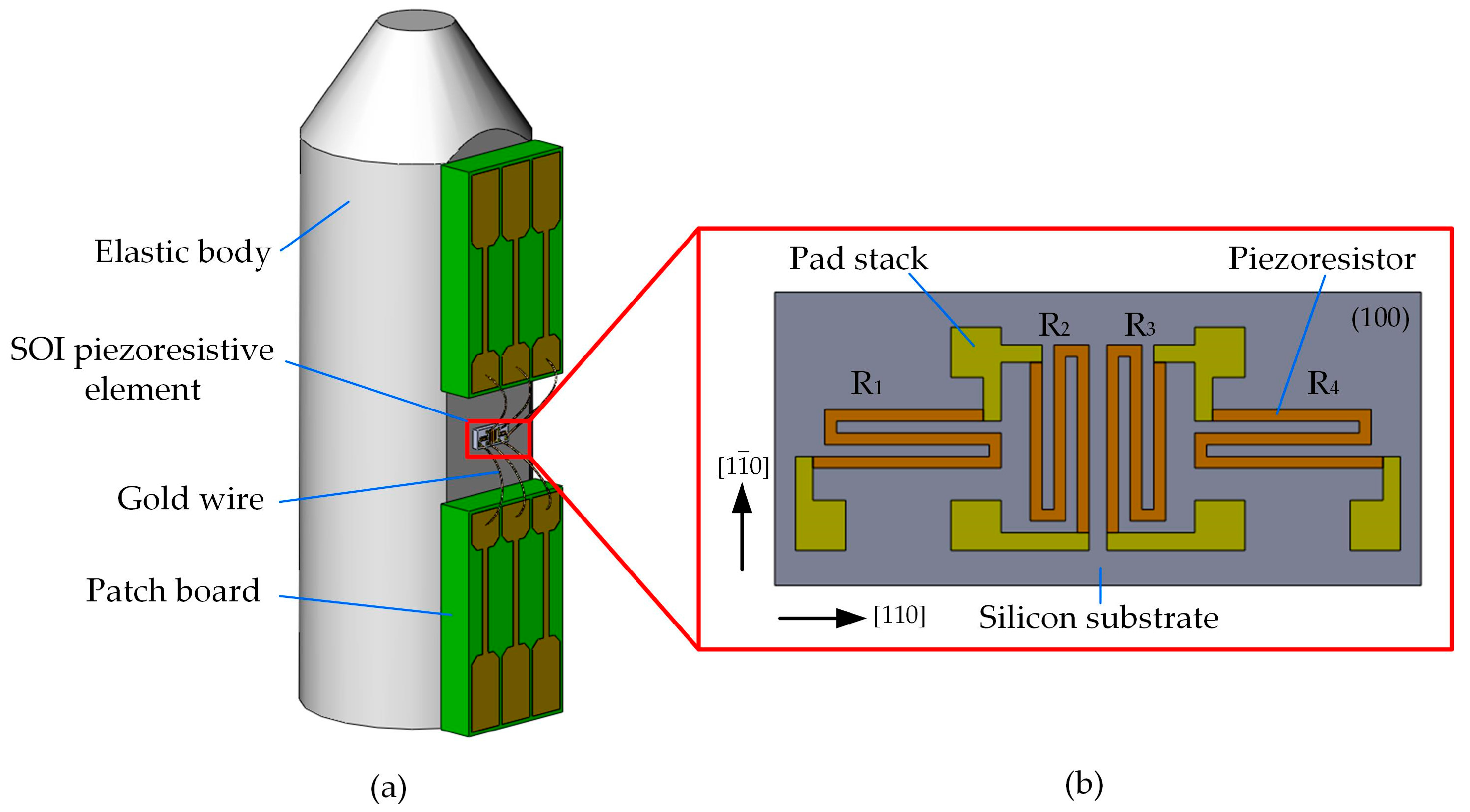

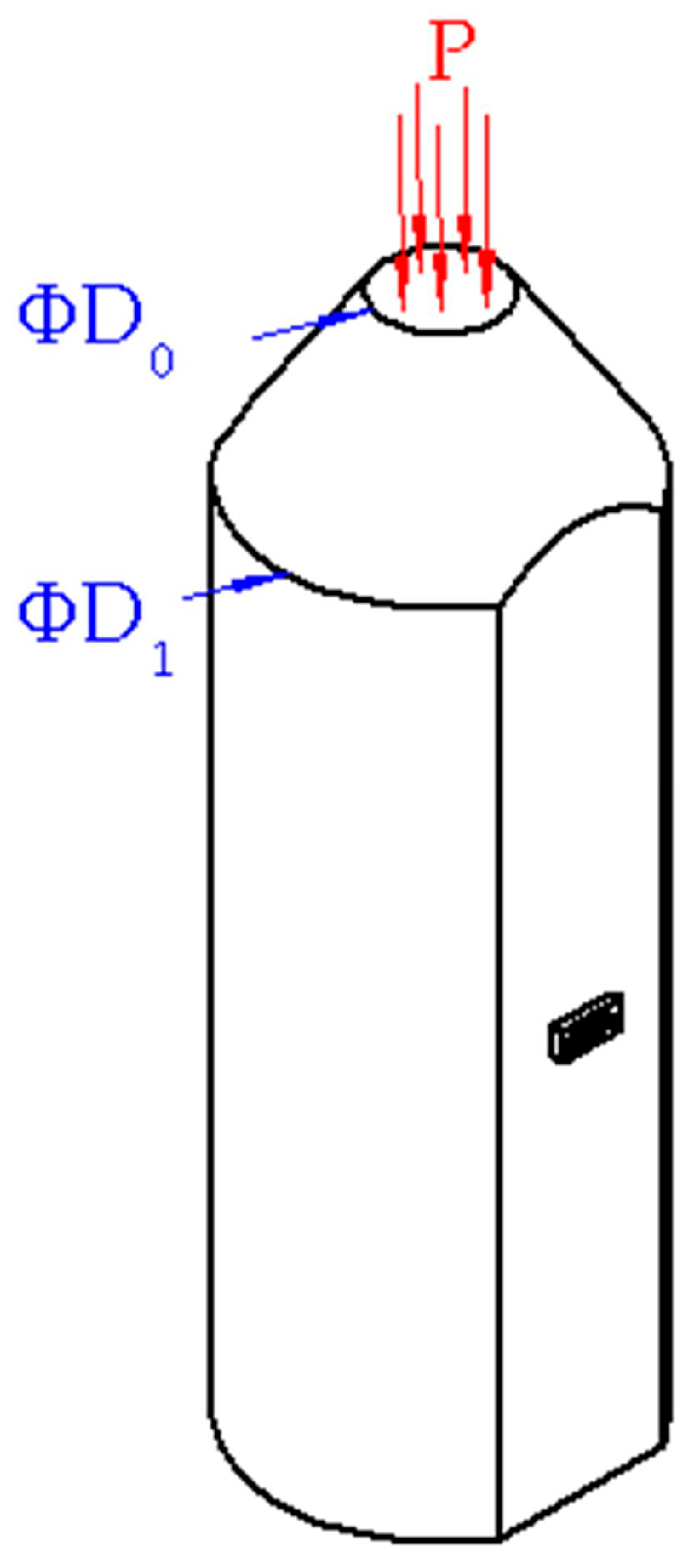

2.1. Structure of the Sensor

2.2. Working Principle of the Sensor

2.3. Design Details of the Sensor

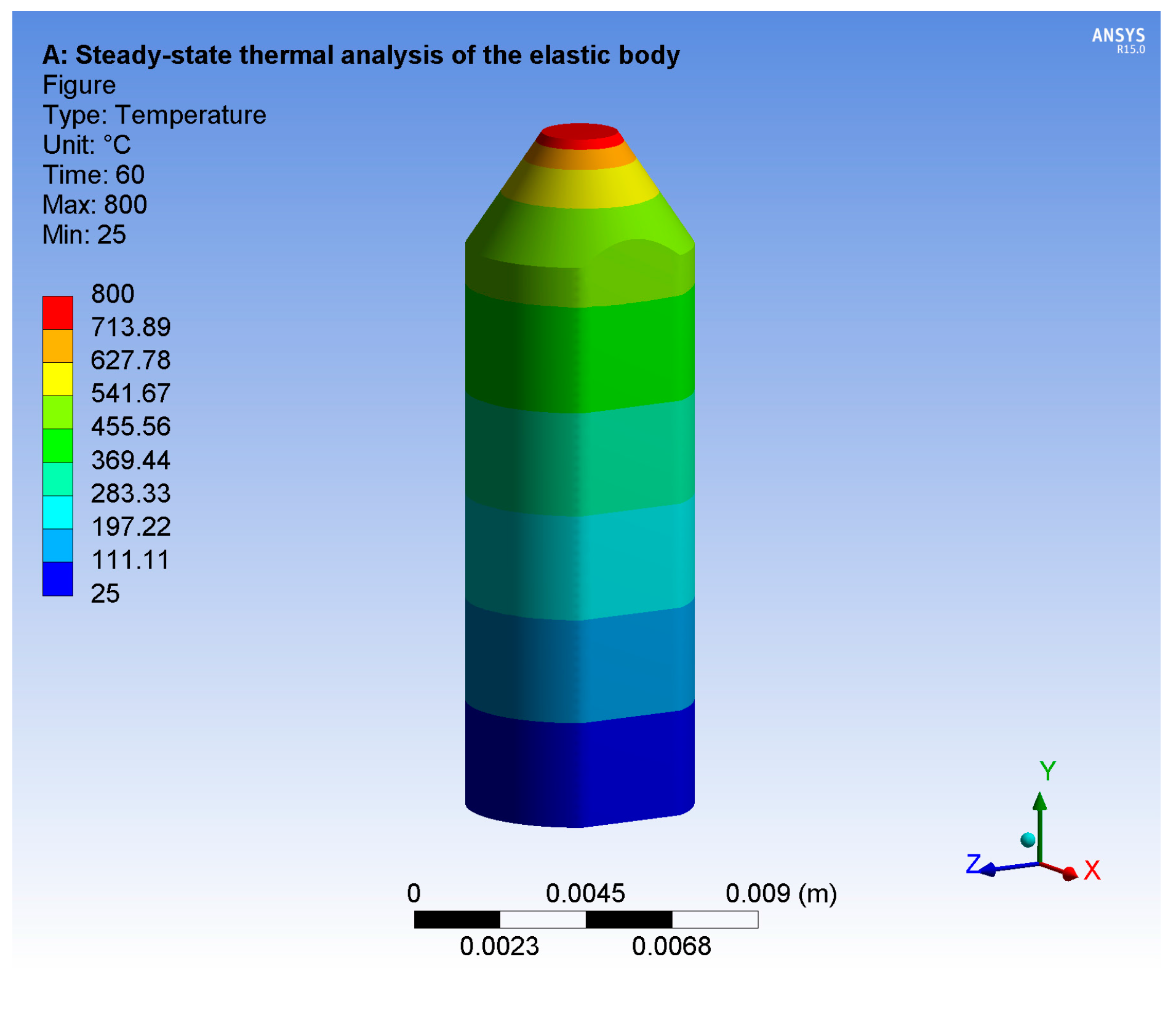

2.4. Analysis of High-Temperature Resistance

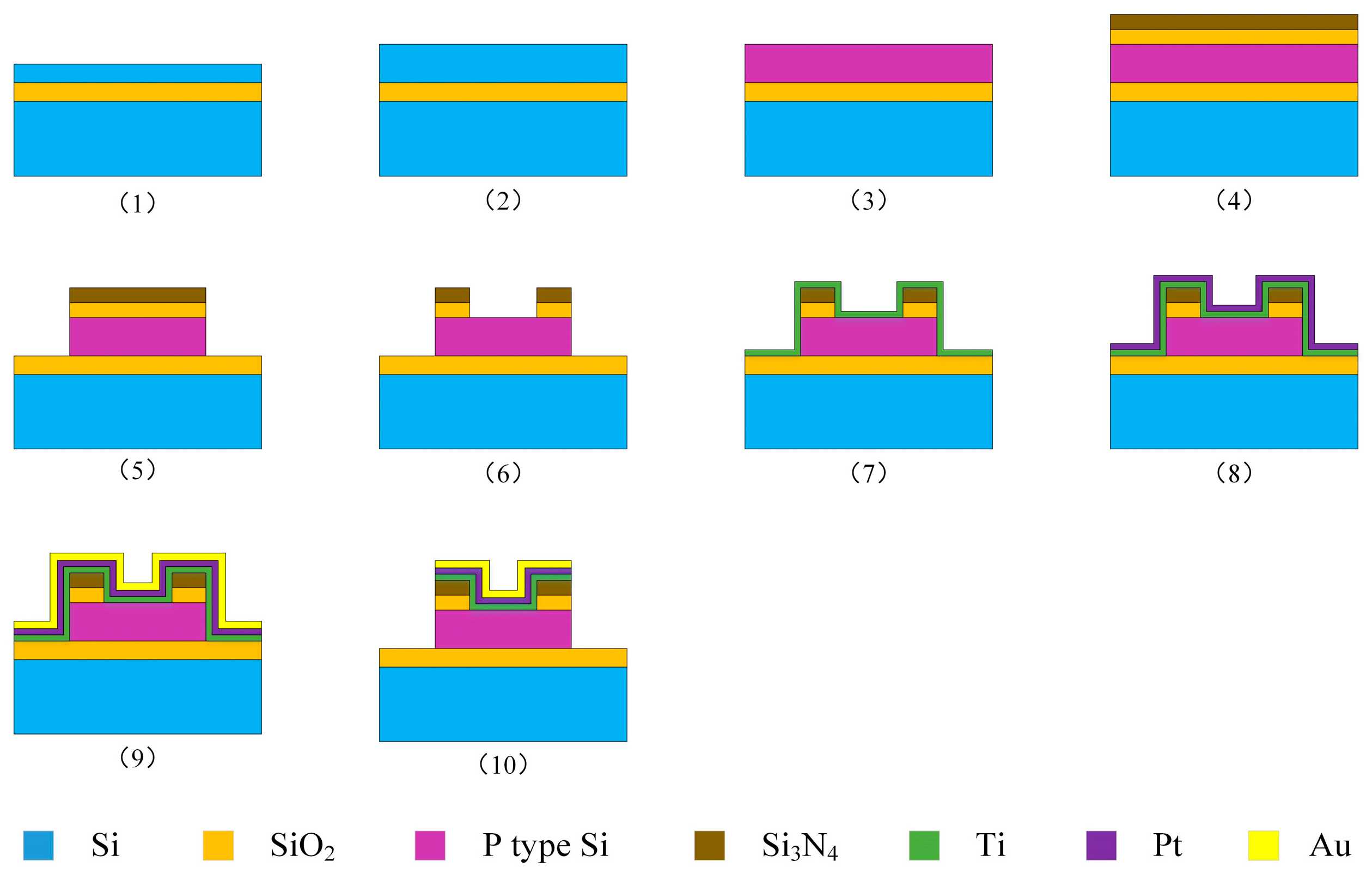

2.5. Fabrication of the Sensor

2.6. Static Calibration

2.7. Temperature Experiment

3. Results and Discussions

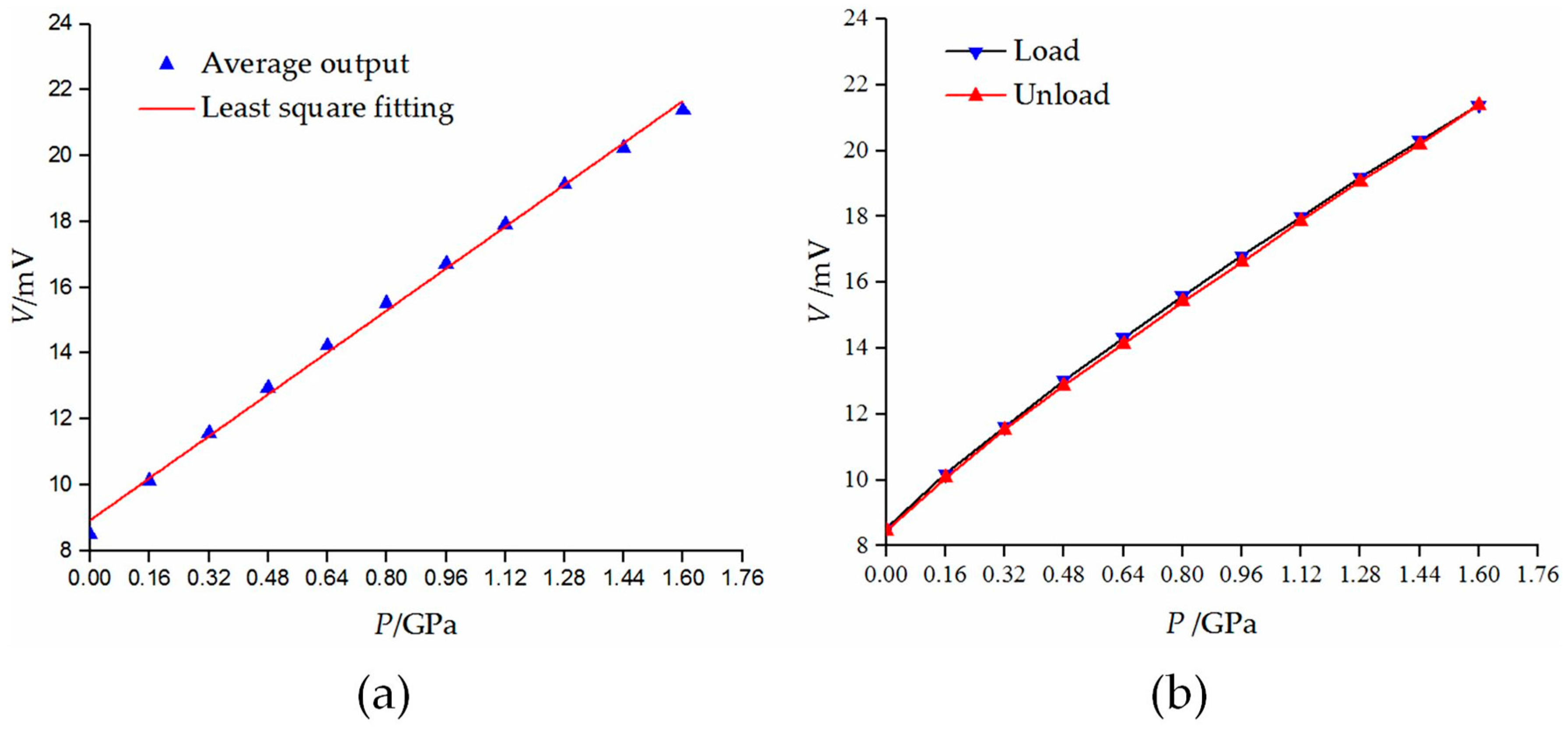

3.1. Static Calibration

3.2. Temperature Experiment

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Fraden, J. Handbook of Modern Sensors, 4th ed.; Springer: New York, NY, USA; Heidelberg, Germany; Dordrecht, The Netherlands; London, UK, 2010; pp. 375–398. [Google Scholar]

- Morten, B.; de Cicco, G.; Prudenziati, M. Resonant pressure sensor based on piezoelectric properties of ferroelectric thick films. Sens. Actuators A Phys. 1992, 31, 153–158. [Google Scholar] [CrossRef]

- Mitrakos, V.; Macintyre, L.; Denison, F.; Hands, P.; Desmulliez, M. Design, manufacture and testing of capacitive pressure sensors for low-pressure measurement ranges. Micromachines 2017, 8, 41. [Google Scholar] [CrossRef]

- Bock, W.J.; Eftimov, T.; Molinar, G.F.; Wisniewski, R. Free active element bulk-modulus high-pressure transducer based on fiber-optic displacement sensor. In Proceedings of the IEEE Instrumentation and Measurement Technology Conference, Ottawa, ON, Canada, 19–21 May 1997. [Google Scholar]

- Cunningham, B.; Vandersall, K.S.; Niles, A.M.; Greenwood, D.W.; Garcia, F.; Forbes, J.W.; Wilson, W.H. Carbon resistor pressure gauge calibration at low stresses. In Proceedings of the 12th International Conference of the American Physical Society Topical Group on Shock Compression of Condensed Matter, Atlanta, GA, USA, 24–29 June 2001. [Google Scholar]

- Grady, D.E.; Ginsberg, M.J. Piezoresistive effects in ytterbium stress transducers. J. Appl. Phys. 1977, 48, 2179–2181. [Google Scholar] [CrossRef]

- Du, X.S.; Yang, B.C.; Zhou, H.R. Piezoresistive response of thin film manganin gauges in the 50–100-GPa range. Thin Solid Films 2002, 410, 167–170. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Zhao, L.B.; Jiang, Z.D. A novel high temperature pressure sensor on the basis of SOI layers. Sens. Actuators A Phys. 2003, 108, 108–111. [Google Scholar] [CrossRef]

- Choi, W.; Lee, J.; Yoo, Y.K.; Kang, S.; Kim, J.; Lee, J.H. Enhanced sensitivity of piezoelectric pressure sensor with microstructured polydimethylsiloxane layer. Appl. Phys. Lett. 2014, 104, 7808–7826. [Google Scholar] [CrossRef]

- Singh, R.; Ngo, L.L.; Seng, H.S.; Mok, F.N.C. A silicon piezoresistive pressure sensor. In Proceedings of the IEEE International Workshop on Electronic Design, Test and Application, Christchurch, New Zealand, 29–31 January 2002. [Google Scholar]

- Hamdana, G.; Bertke, M.; Doering, L.; Frank, T.; Brand, U.; Wasisto, H.S.; Peiner, E. Transferable micromachined piezoresistive force sensor with integrated double-meander-spring system. J. Sens. Sens. Syst. 2017, 6, 121–133. [Google Scholar] [CrossRef]

- Hamdana, G.; Wasisto, H.S.; Doering, L.; Yan, C.L.; Zhou, L.; Brand, U.; Peiner, E. Double-meander spring silicon piezoresistive sensors as microforce calibration standards. Opt. Eng. 2016, 55, 091409. [Google Scholar] [CrossRef]

- Fu, J.Q.; Fan, M.J.; Shan, Y.Y.; Qu, Y.X. 400Mpa F.S. Piezoresistive pressure transducer. J. Transducer Technol. 1995, 1, 13–16. [Google Scholar] [CrossRef]

- Zhao, L.B.; Guo, X.; Meng, X.W.; Hebibul, R.; Zhao, Y.L.; Wang, J.Z.; Jiang, Z.D. An ultra-high pressure sensor with cylinder structure. J. Mech. Sci. Technol. 2013, 27, 2383–2389. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Fang, X.D.; Jiang, Z.D.; Zhao, L.B. An ultra-high pressure sensor based on SOI piezoresistive material. J. Mech. Sci. Technol. 2010, 24, 1655–1660. [Google Scholar] [CrossRef]

- Cavanough, G.; Onederra, I. Development of pressure and temperature gauges to monitor performance of commercial explosives. Inst. Mater. Miner. Min. 2013, 120, 74–79. [Google Scholar] [CrossRef]

- Brazhkin, V.V. High-pressure synthesized materials: A chest of treasure and hints. Physics 2006, 27, 333–351. [Google Scholar] [CrossRef]

- Xin, J.; Yang, W.T.; Zhao, B.Y.; An, G.P. Design of interior off-line temperature detector for the ultrahigh pressure vessel. Appl. Mech. Mater. 2012, 229–231, 1206–1212. [Google Scholar] [CrossRef]

- Zhao, Y.L. Study on High Temperature Pressure Sensor. Ph.D. Thesis, Xi’an Jiaotong University, Xi’an, China, 2003. [Google Scholar]

- Wasisto, H.S.; Merzsch, S.; Waag, A.; Uhde, E.; Salthammer, T.; Peiner, E. Airborne engineered nanoparticle mass sensor based on a silicon resonant cantilever. Sens. Actuators B Chem. 2013, 180, 77–89. [Google Scholar] [CrossRef]

- Wasisto, H.S.; Merzsch, S.; Uhde, E.; Waag, A.; Peiner, E. Handheld personal airborne nanoparticle detector based on microelectromechanical silicon resonant cantilever. Microelectron. Eng. 2015, 145, 96–103. [Google Scholar] [CrossRef]

- Kanda, Y. Piezoresistance effect of silicon. Sens. Actuators A Phys. 1991, 28, 83–91. [Google Scholar] [CrossRef]

- Sahin, Y. Recent progress in processing of tungsten heavy alloys. J. Powder Technol. 2014, 2014, 22. [Google Scholar] [CrossRef]

| Young’s Modulus (GPa) | Yield Strength (GPa) | Melting Point (°C) | Coefficient of Thermal Expansion (1 × 10–6/°C) |

|---|---|---|---|

| 345 | 1.6 | 3410 | 4.5 |

| Force (N) | Corresponding Pressure (GPa) | Average Output Data (mV) |

|---|---|---|

| 0 | 0 | 8.495 |

| 500 | 0.16 | 10.125 |

| 1000 | 0.32 | 11.571 |

| 1500 | 0.48 | 12.949 |

| 2000 | 0.64 | 14.234 |

| 2500 | 0.8 | 15.511 |

| 3000 | 0.96 | 16.712 |

| 3500 | 1.12 | 17.917 |

| 4000 | 1.28 | 19.126 |

| 4500 | 1.44 | 20.243 |

| 5000 | 1.6 | 21.388 |

| Pressure (GPa) | Loading (mV) | Unloading (mV) |

|---|---|---|

| 0 | 8.532 | 8.458 |

| 0.16 | 10.182 | 10.068 |

| 0.32 | 11.622 | 11.520 |

| 0.48 | 13.028 | 12.870 |

| 0.64 | 14.324 | 14.144 |

| 0.80 | 15.598 | 15.424 |

| 0.96 | 16.804 | 16.620 |

| 1.12 | 17.980 | 17.854 |

| 1.28 | 19.188 | 19.064 |

| 1.44 | 20.299 | 20.186 |

| 1.60 | 21.380 | 21.388 |

| Time (min) | Zero Output at 25 °C (mV) | Zero Output at 200 °C (mV) |

|---|---|---|

| 0 | 8.505 | 7.947 |

| 15 | 8.518 | 7.934 |

| 30 | 8.526 | 7.912 |

| 45 | 8.513 | 7.938 |

| 60 | 8.507 | 7.951 |

| Temperature (°C) | Zero Output (mV) |

|---|---|

| 25 | 8.513 |

| 50 | 8.532 |

| 75 | 8.545 |

| 100 | 8.372 |

| 125 | 8.121 |

| 150 | 7.968 |

| 175 | 7.942 |

| 200 | 7.936 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.-D.; Zhao, Y.-L.; Zhao, Y.; Wang, X.-C.; Wei, X.-Y. Research of a Novel Ultra-High Pressure Sensor with High-Temperature Resistance. Micromachines 2018, 9, 5. https://doi.org/10.3390/mi9010005

Zhang G-D, Zhao Y-L, Zhao Y, Wang X-C, Wei X-Y. Research of a Novel Ultra-High Pressure Sensor with High-Temperature Resistance. Micromachines. 2018; 9(1):5. https://doi.org/10.3390/mi9010005

Chicago/Turabian StyleZhang, Guo-Dong, Yu-Long Zhao, Yun Zhao, Xin-Chen Wang, and Xue-Yong Wei. 2018. "Research of a Novel Ultra-High Pressure Sensor with High-Temperature Resistance" Micromachines 9, no. 1: 5. https://doi.org/10.3390/mi9010005