Separated Type Atmospheric Pressure Plasma Microjets Array for Maskless Microscale Etching

Abstract

:1. Introduction

2. Materials and Methods

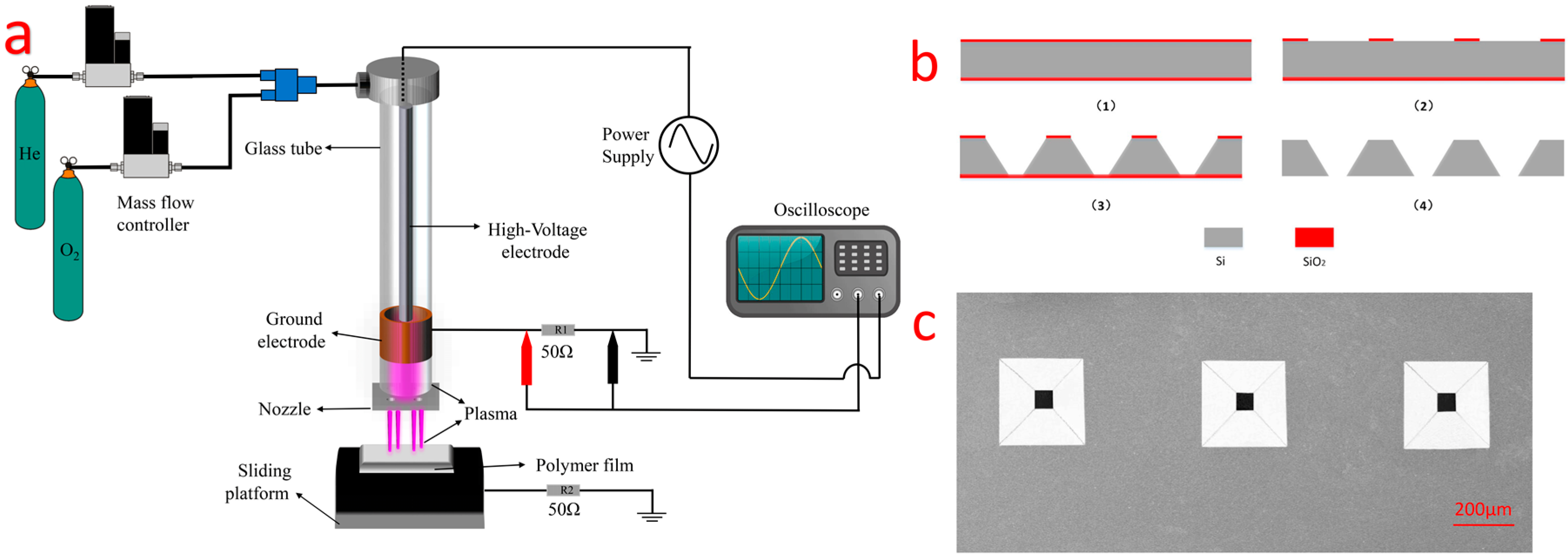

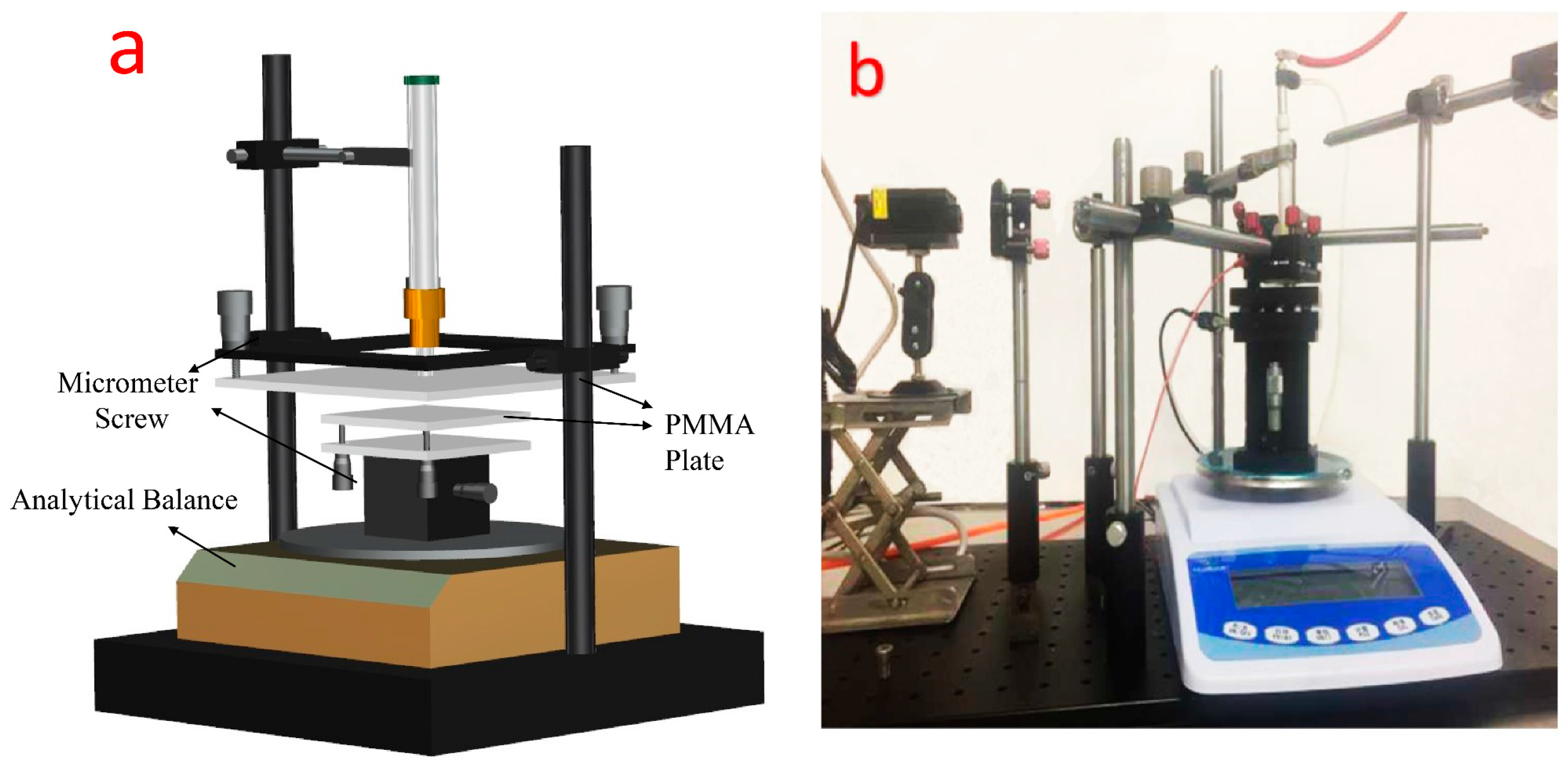

2.1. Main Components of Separated Type Atmospheric Pressure Plasma Microjets Array System

2.2. Etching and Characterization

3. Results and Discussions

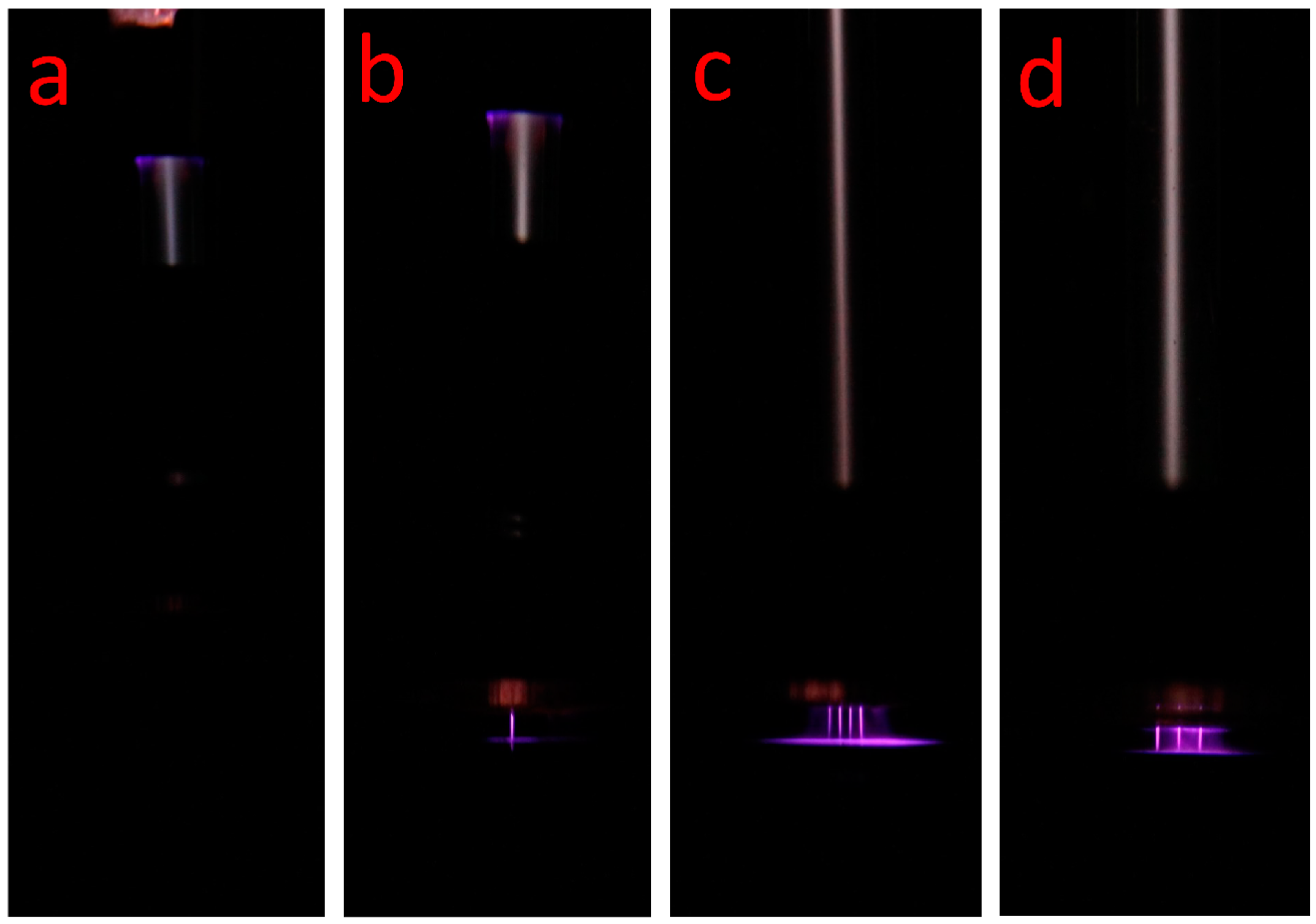

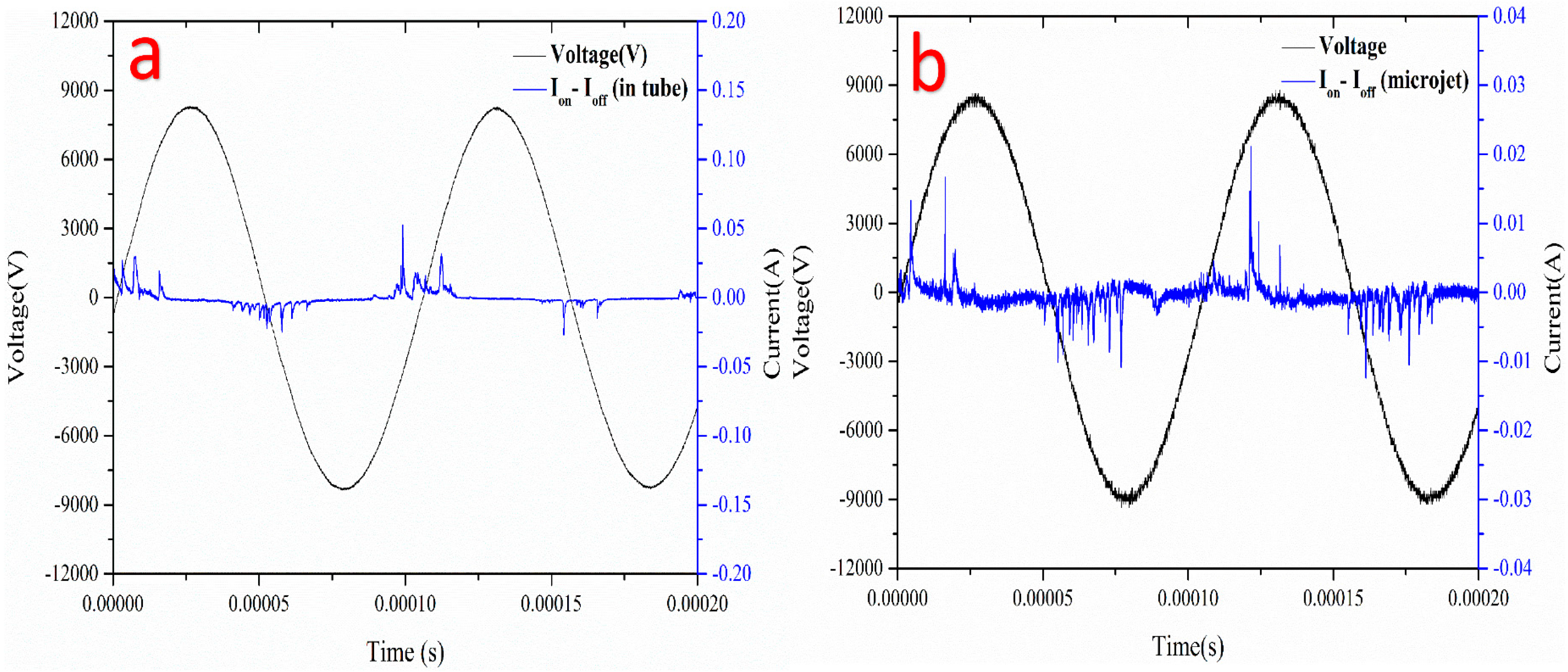

3.1. The Electrical Characteristics of the Atmospheric Pressure Plasma Microjet

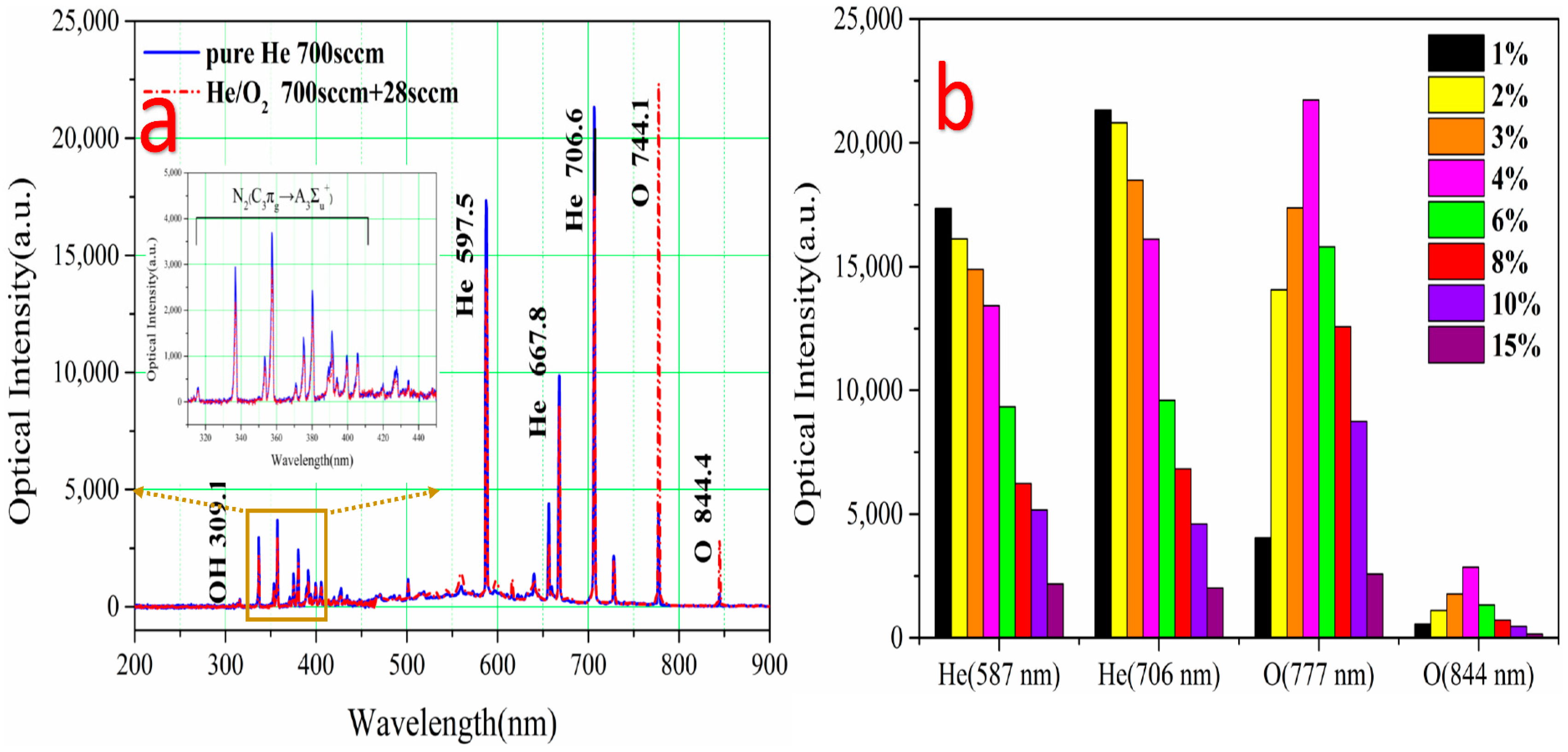

3.2. The Spectral Characteristics of Atmospheric Pressure Plasma Microjet

3.3. The Maskless Etching of Photoresist

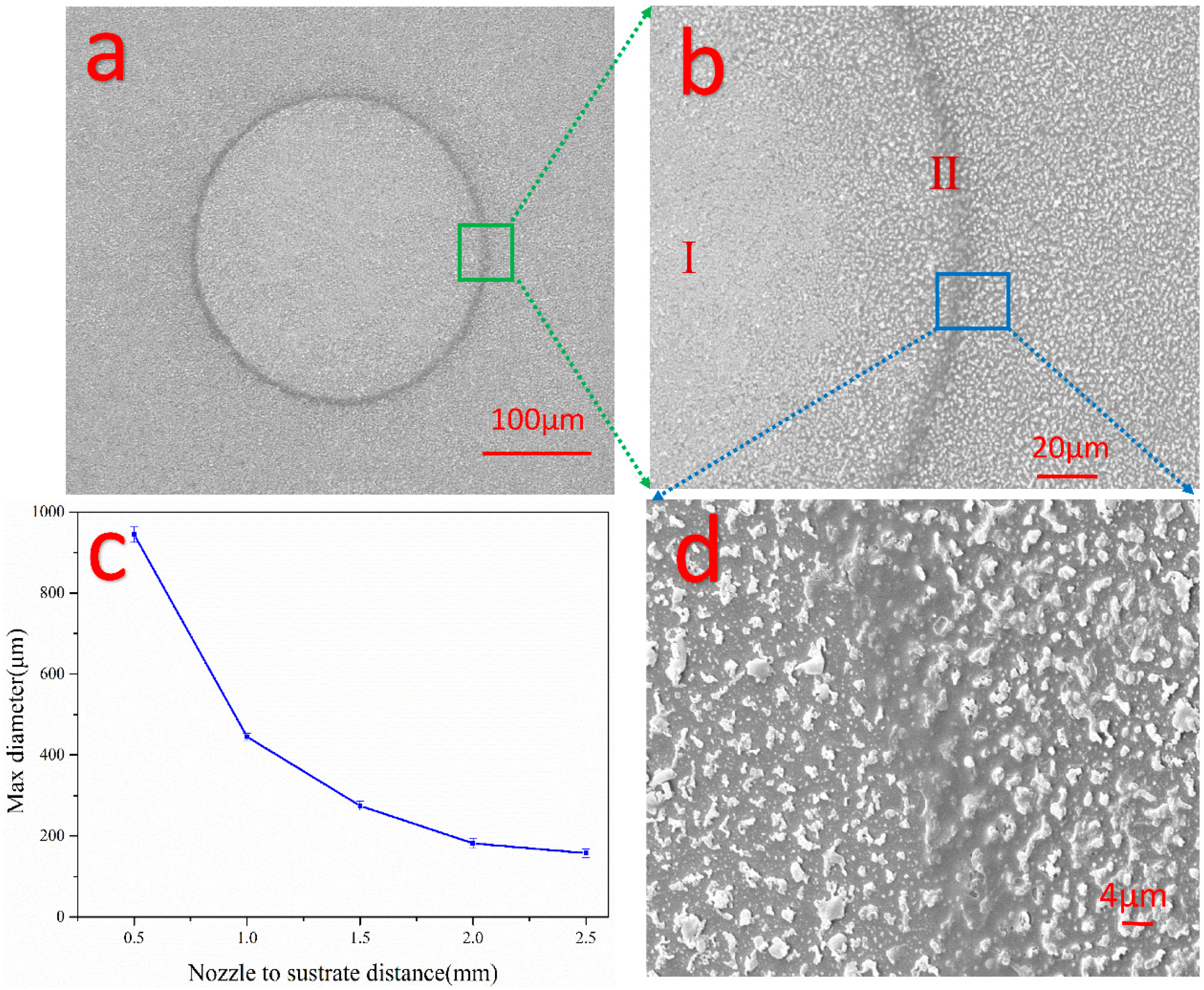

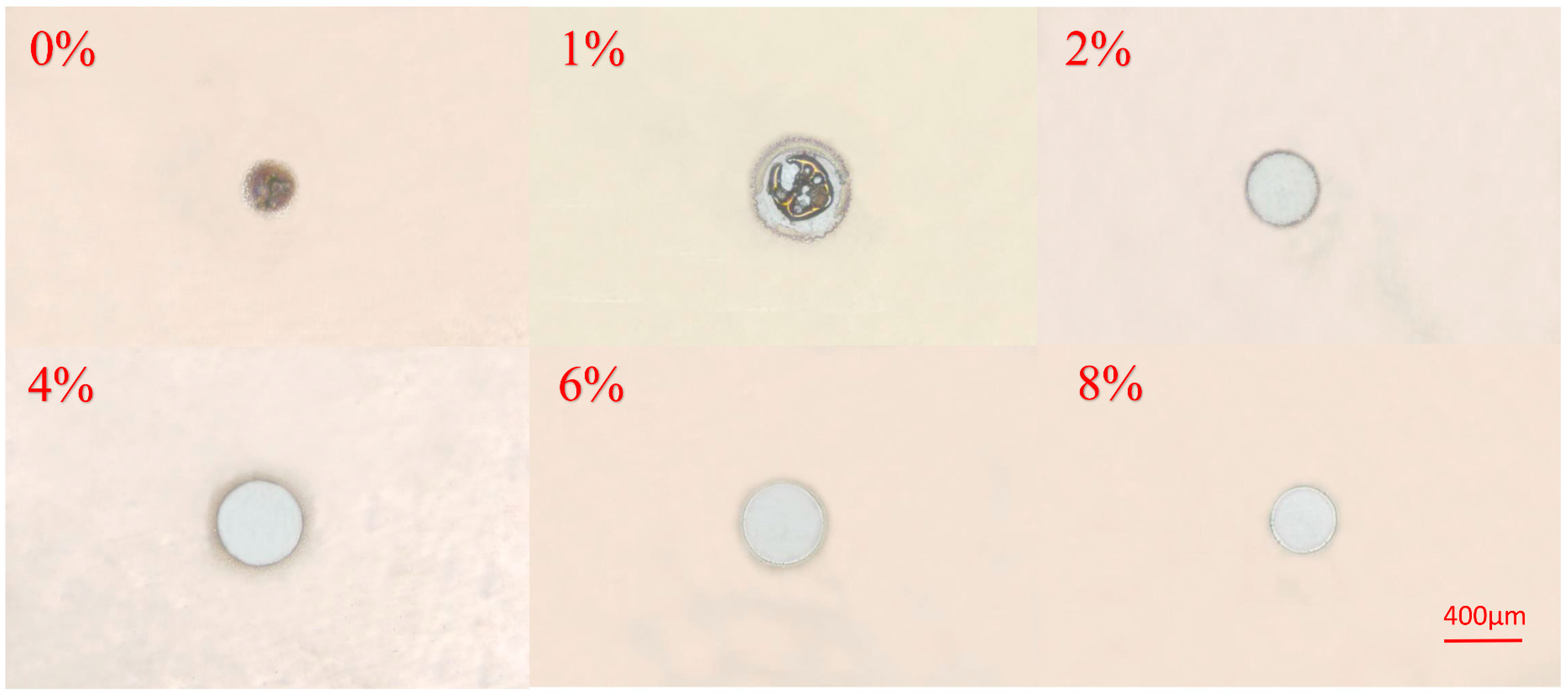

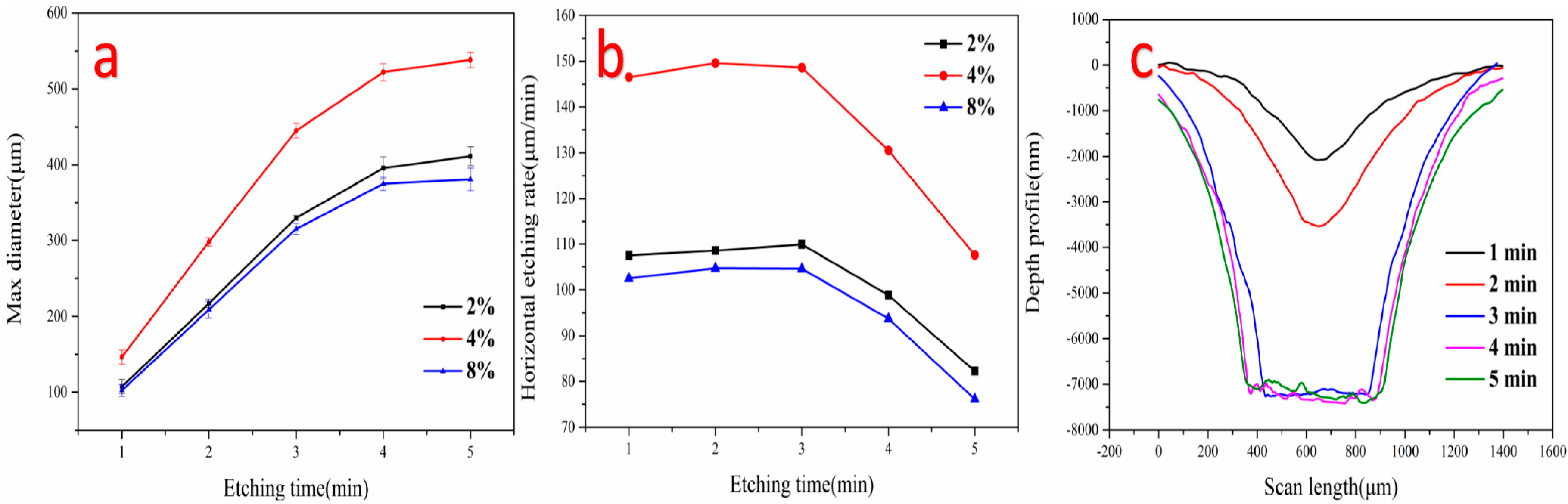

3.3.1. Maskless Etching of Photoresist Using Single-Hole Plasma Microjet

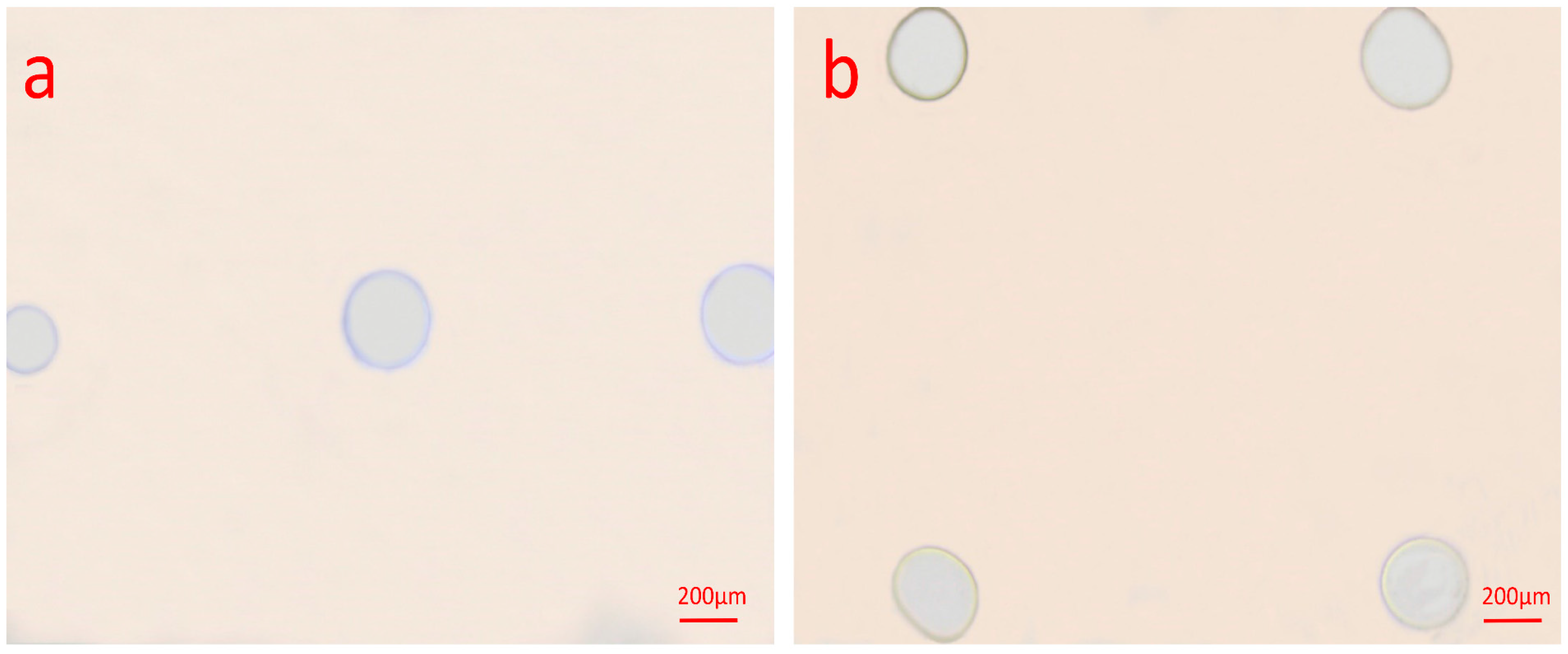

3.3.2. Maskless Etching of Photoresist Using Array-Holes Plasma Microjet

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bange, A.; Halsall, H.B.; Heineman, W.R. Microfluidic immune sensor systems. Biosens. Bioelectron. 2005, 20, 2488–2503. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Wang, X.; Cheng, C.; Wang, L.; Zhao, E.; Wang, X.; Wen, W. Selective modification for polydimethylsiloxane chip by micro-plasma. J. Mater. Sci. 2012, 48, 1310–1314. [Google Scholar] [CrossRef]

- Penache, C.; Gessner, C.; Betker, T.; Bartels, V.; Hollaender, A.; Klages, C.P. Plasma printing: Patterned surface functionalisation and coating at atmospheric pressure. IEE Proc. Nanobiotechnol. 2004, 151, 139–144. [Google Scholar] [CrossRef] [PubMed]

- Gandhiraman, R.P.; Nordlund, D.; Jayan, V.; Meyyappan, M.; Koehne, J.E. Scalable low-cost fabrication of disposable paper sensors for DNA detection. ACS Appl. Mater. Interfaces 2014, 6, 22751–22760. [Google Scholar] [CrossRef] [PubMed]

- Priest, C.; Gruner, P.J.; Szili, E.J.; Al-Bataineh, S.A.; Bradley, J.W.; Ralston, J.; Steele, D.A.; Short, R.D. Microplasma patterning of bonded microchannels using high-precision “injected” electrodes. Lab Chip 2011, 11, 541–544. [Google Scholar] [CrossRef] [PubMed]

- Hu, S.W.; Xu, B.Y.; Ye, W.K.; Xia, X.H.; Chen, H.Y.; Xu, J.J. Versatile microfluidic droplets array for bioanalysis. ACS Appl. Mater. Interfaces 2015, 7, 935–940. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.; Song, J.; Lu, Y.; Chen, F.; Zheng, H.; Yang, X.; Liu, X.; Sun, J.; Carmalt, C.J.; Parkin, I.P.; et al. Underwater spontaneous pumpless transportation of nonpolar organic liquids on extreme wettability patterns. ACS Appl. Mater. Interfaces 2016, 8, 2942–2949. [Google Scholar] [CrossRef] [PubMed]

- Poulsen, R.G. Plasma etching in integrated circuit manufacture—A review. J. Vac. Sci. Technol. 1977, 14, 266–274. [Google Scholar] [CrossRef]

- Sankaran, R.M.; Giapis, K.P. Maskless etching of silicon using patterned microdischarges. Appl. Phys. Lett. 2001, 79, 593–595. [Google Scholar] [CrossRef]

- Uwe, S.; Dohse, A.; Hoppe, P.; Gehringer, A.; Thomas, M.; Klages, C.-P.; Reinecke, H. Porous Photoresist Stamps for Selective Plasma Treatment. Plasma Process. Polym. 2010, 7, 9–15. [Google Scholar]

- Al-Bataineh, S.A.; Szili, E.J.; Gruner, P.J.; Priest, C.; Griesser, H.J.; Voelcker, N.H.; Short, R.D.; Steele, D.A. Fabrication and operation of a microcavity plasma array device for microscale surface modification. Plasma Process. Polym. 2012, 9, 638–646. [Google Scholar] [CrossRef]

- Yang, Y.-J.; Hsu, C.-C. A flexible paper-based microdischarge array device: A novel route to cost-effective and simple setup microplasma generation devices. IEEE Trans. Plasma Sci. 2014, 42, 3756–3759. [Google Scholar] [CrossRef]

- Hsu, C.-C.; Tsai, J.-H.; Yang, Y.-J.; Liao, Y.-C.; Lu, Y.-W. A foldable microplasma-generation device on a paper substrate. J. Microelectromech. Syst. 2012, 21, 1013–1015. [Google Scholar] [CrossRef]

- Sakaguchi, T.; Sakai, O.; Tachibana, K. Photonic bands in two-dimensional microplasma arrays. II. Band gaps observed in millimeter and subterahertz ranges. J. Appl. Phys. 2007, 101, 073305. [Google Scholar] [CrossRef]

- Yoshiki, H.; Taniguchi, K.; Horiike, Y. Localized removal of a photoresist by atmospheric pressure micro-plasma jet using RF corona discharge. Jpn. J. Appl. Phys. 2002, 41, 5797–5798. [Google Scholar] [CrossRef]

- Guo, H.; Liu, J.; Yang, B.; Chen, X.; Yang, C. Localized etching of polymer films using an atmospheric pressure air microplasma jet. J. Micromech. Microeng. 2015, 25, 015010. [Google Scholar] [CrossRef]

- Wang, T.; Liu, J.; Yang, B.; Chen, X.; Wang, X.; Yang, C. Optimization of micropipette fabrication by laser micromachining for application in an ultrafine atmospheric pressure plasma jet using response surface methodology. J. Micromech. Microeng. 2016, 26, 065001. [Google Scholar] [CrossRef]

- Kakei, R.; Ogino, A.; Iwata, F.; Nagatsu, M. Production of ultrafine atmospheric pressure plasma jet with nano-capillary. Thin Solid Films 2010, 518, 3457–3460. [Google Scholar] [CrossRef]

- Morimatsu, D.; Sugimoto, H.; Nakamura, A.; Ogino, A.; Nagatsu, M.; Iwata, F. Development of a scanning nanopipette probe microscope for fine processing using atmospheric pressure plasma jet. Jpn. J. Appl. Phys. 2016, 55, 08NB15. [Google Scholar] [CrossRef]

- Abuzairi, T.; Okada, M.; Mochizuki, Y.; Poespawati, N.R.; Purnamaningsih, R.W.; Nagatsu, M. Maskless functionalization of a carbon nanotube dot array biosensor using an ultrafine atmospheric pressure plasma jet. Carbon 2015, 89, 208–216. [Google Scholar] [CrossRef]

- Shimane, R.; Kumagai, S.; Hashizume, H.; Ohta, T.; Ito, M.; Hori, M.; Sasaki, M. Localized plasma irradiation through a micronozzle for individual cell treatment. Jpn. J. Appl. Phys. 2014, 53, 11RB03. [Google Scholar] [CrossRef]

- Jõgi, I.; Talviste, R.; Raud, J.; Piip, K.; Paris, P. The influence of the tube diameter on the properties of an atmospheric pressure He micro-plasma jet. J. Phys. D Appl. Phys. 2014, 47, 415202. [Google Scholar] [CrossRef]

- Inomata, K.; Koinuma, H.; Oikawa, Y.; Shiraishi, T. Open air photoresist ashing by a cold plasma torch: Catalytic effect of cathode material. Appl. Phys. Lett. 1995, 66, 2188–2190. [Google Scholar] [CrossRef]

- Hopf, C.; Schlüter, M.; Schwarz-Selinger, T.; von Toussaint, U.; Jacob, W. Chemical sputtering of carbon films by simultaneous irradiation with argon ions and molecular oxygen. New J. Phys. 2008, 10, 093022. [Google Scholar] [CrossRef]

- Wang, L.; Zheng, Y.; Wu, C.; Jia, S. Experimental investigation of photoresist etching by kHz AC atmospheric pressure plasma jet. Appl. Surf. Sci. 2016, 385, 191–198. [Google Scholar] [CrossRef]

- Li, X.; Yuan, N.; Jia, P.; Chen, J. A plasma needle for generating homogeneous discharge in atmospheric pressure air. Phys. Plasmas 2010, 17, 093504. [Google Scholar] [CrossRef]

- Lu, X.; Laroussi, M. Dynamics of an atmospheric pressure plasma plume generated by submicrosecond voltage pulses. J. Appl. Phys. 2006, 100, 063302. [Google Scholar] [CrossRef]

- Walsh, J.L.; Olszewski, P.; Bradley, J.W. The manipulation of atmospheric pressure dielectric barrier plasma jets. Plasma Sources Sci. Technol. 2012, 21, 034007. [Google Scholar] [CrossRef]

- Lu, X.; Laroussi, M.; Puech, V. On atmospheric-pressure non-equilibrium plasma jets and plasma bullets. Plasma Sources Sci. Technol. 2012, 21, 034005. [Google Scholar] [CrossRef]

- Zhang, C.; Shao, T.; Zhou, Y.; Fang, Z.; Yan, P.; Yang, W. Effect of O2 additive on spatial uniformity of atmospheric-pressure helium plasma jet array driven by microsecond-duration pulses. Appl. Phys. Lett. 2014, 105, 044102. [Google Scholar]

- Joh, H.M.; Choi, J.Y.; Kim, S.J.; Chung, T.H.; Kang, T.H. Effect of additive oxygen gas on cellular response of lung cancer cells induced by atmospheric pressure helium plasma jet. Sci. Rep. 2014, 4, 6638. [Google Scholar] [CrossRef] [PubMed]

- Ellerweg, D.; Benedikt, J.; von Keudell, A.; Knake, N.; Schulz-von der Gathen, V. Characterization of the effluent of a He/O2 microscale atmospheric pressure plasma jet by quantitative molecular beam mass spectrometry. New J. Phys. 2010, 12, 013021. [Google Scholar] [CrossRef]

- Park, G.; Lee, H.; Kim, G.; Lee, J.K. Global model of He/O2 and Ar/O2 atmospheric pressure glow discharges. Plasma Process. Polym. 2008, 5, 569–576. [Google Scholar] [CrossRef]

- Sun, L.; Huang, X.; Zhang, J.; Zhang, J.; Shi, J.J. Discharge dynamics of pin-to-plate dielectric barrier discharge at atmospheric pressure. Phys. Plasmas 2010, 17, 113507. [Google Scholar] [CrossRef]

- Wang, T.; Yang, B.; Chen, X.; Wang, X.; Yang, C.; Liu, J. Nonhomogeneous surface properties of parylene-C film etched by an atmospheric pressure He/O2 micro-plasma jet in ambient air. Appl. Surf. Sci. 2016, 383, 261–267. [Google Scholar] [CrossRef]

- Fricke, K.; Steffen, H.; von Woedtke, T.; Schröder, K.; Weltmann, K.-T. High Rate Etching of Polymers by Means of an Atmospheric Pressure Plasma Jet. Plasma Process. Polym. 2011, 8, 51–58. [Google Scholar] [CrossRef]

- Weltmann, K.D.; Brandenburg, R.; von Woedtke, T.; Ehlbeck, J.; Foest, R.; Stieber, M.; Kindel, E. Antimicrobial treatment of heat sensitive products by miniaturized atmospheric pressure plasma jets (APPJs). J. Phys. D Appl. Phys. 2008, 41, 194008. [Google Scholar] [CrossRef]

- Ghasemi, M.; Olszewski, P.; Bradley, J.W.; Walsh, J.L. Interaction of multiple plasma plumes in an atmospheric pressure plasma jet array. J. Phys. D Appl. Phys. 2013, 46, 052001. [Google Scholar] [CrossRef]

- Sun, P.P.; Cho, J.H.; Park, C.H.; Park, S.J.; Eden, J.G. Close-Packed Arrays of Plasma Jets Emanating from Microchannels in a Transparent Polymer. IEEE Trans. Plasma Sci. 2012, 40, 2946–2950. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, Y.; Zhang, M.; Li, Q.; Wen, L.; Wang, H.; Chu, J. Separated Type Atmospheric Pressure Plasma Microjets Array for Maskless Microscale Etching. Micromachines 2017, 8, 173. https://doi.org/10.3390/mi8060173

Dai Y, Zhang M, Li Q, Wen L, Wang H, Chu J. Separated Type Atmospheric Pressure Plasma Microjets Array for Maskless Microscale Etching. Micromachines. 2017; 8(6):173. https://doi.org/10.3390/mi8060173

Chicago/Turabian StyleDai, Yichuan, Man Zhang, Qiang Li, Li Wen, Hai Wang, and Jiaru Chu. 2017. "Separated Type Atmospheric Pressure Plasma Microjets Array for Maskless Microscale Etching" Micromachines 8, no. 6: 173. https://doi.org/10.3390/mi8060173

APA StyleDai, Y., Zhang, M., Li, Q., Wen, L., Wang, H., & Chu, J. (2017). Separated Type Atmospheric Pressure Plasma Microjets Array for Maskless Microscale Etching. Micromachines, 8(6), 173. https://doi.org/10.3390/mi8060173