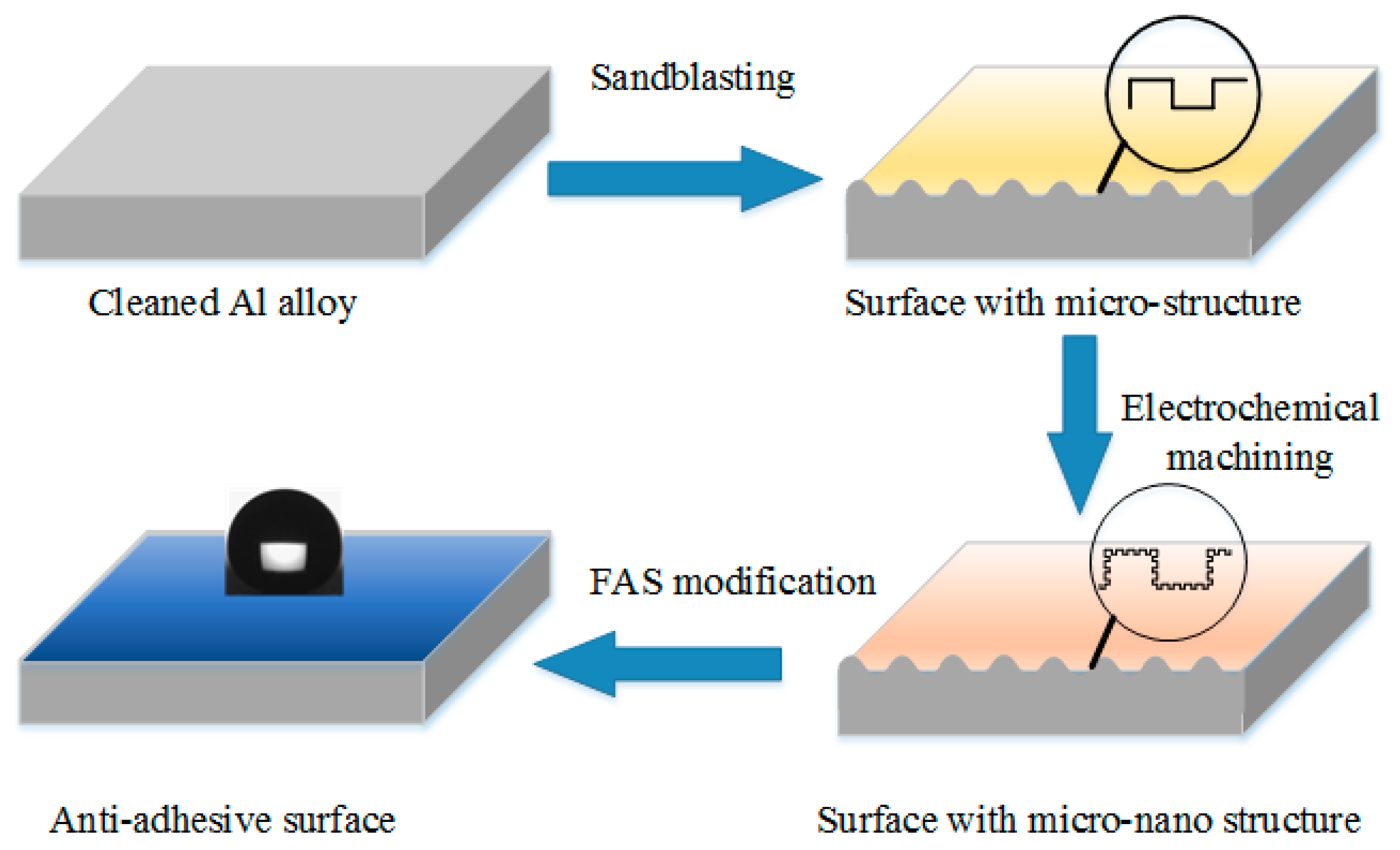

3.1. Surface Morphology and Wettability

The original morphology of shot-free surfaces is shown in

Figure 2. Before sandblasting, the sample surfaces exhibited a roughness value of 0.24 μm and a water contact angle (CA) value of 98.5°. Treated for 2 min by sandblasting with an 80 mesh sand size, the morphology of the aluminum alloy surface can be obtained from

Figure 3.

Figure 4 shows images of the SEM, AFM spectra of the sample surfaces, treated by electrochemical machining in 0.5 mol/L Na

3PO

4 aqueous solution with the application of 50 V voltage for 5 min, as well as the profile of one water droplet on the sample surface.

Figure 3a,b are the images with 200×, 2000× magnification, respectively. It can be seen that many pits with sizes of 10–40 µm are distributed on the aluminum alloy surface. The microstructure with the above pits was formed on the aluminum alloy surface by sandblasting. From

Figure 4a,b, it can be found that many porous honeycombs with sizes of 50−250 nm were fabricated on the microstructure by electrochemical machining. Consequently, binary micro-nano structures are formed by the combination of sandblasting and electrochemical machining.

Figure 3c and

Figure 4c show the AFM images of the sample surface processed by sandblasting and electrochemical machining. In

Figure 3c, the average roughness

Ra is 0.48 μm on the roughened surface of the aluminum alloy sample after sandblasting and FAS modification. In

Figure 4c, the average roughness

Ra is 0.95 μm on the treated surface of the aluminum alloy sample after electrochemical machining.

In

Figure 3b, besides micro-scale pits, a few nano-scale cavities existed in the sample surface treated by sandblasting. Compared with

Figure 3b,

Figure 4b shows a large number of nano-scale porous honeycombs dispersed uniformly on the whole surface fabricated by electrochemical machining. The roughness of the sample surface increased from 0.24 to 0.48 μm after sandblasting. As shown in

Figure 4c, the roughness increased to 0.95 μm. After electrochemical machining, the aluminum surfaces exhibited superhydrophilic properties before fluorination, and water droplets spread on the surface completely with a contact angle of about 0°, as shown in

Figure 4d. This phenomenon conforms to Wenzel’s theory that roughness enhances the hydrophilicity of hydrophilic surfaces. Micro-level protrusions and pits, as well as nano-level caves and mastoids in the pits, appeared to form the binary micro-nano structure of the sample surface.

From

Figure 3c to

Figure 4c, it can be seen that the average roughness of the latter is less than the former. This is because the Na

3PO

4 aqueous solution in this study is a neutral electrolyte. It is a non-linear electrolyte with a low current efficiency, which results in an oxygen evolution reaction occurring with the anode dissolution. Peaks of the rough microstructure are prone to being flatted by electrochemical machining. Consequently, the micro-nano structure with low roughness can be fabricated by sandblasting and electrochemical machining.

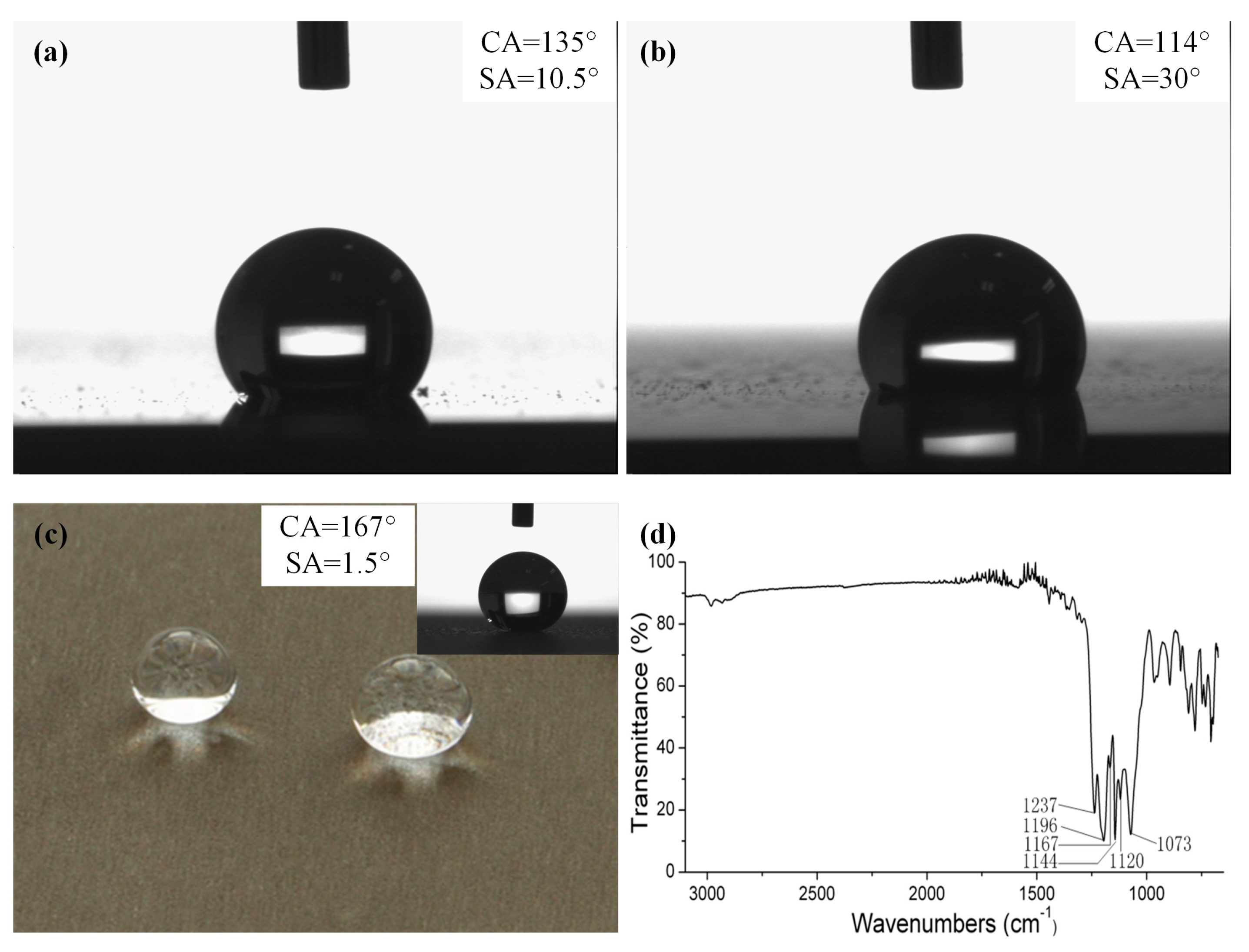

Figure 5 shows the characterization and wettability performance of the sample surface, treated by sandblasting, electrochemical machining and FAS modification. From

Figure 5a, it can be observed that the water droplets can form a hemisphere (apparent contact angle of 135°) on the sample surface after treatment by sandblasting and FAS modification. However, with the secondary nanostructures (

Figure 4b) being embedded on the surfaces of micro-scale caves (

Figure 3b), the shape of the water droplets on the surfaces converts to a spherical shape instead (

Figure 5c). After modification with FAS, compared with

Figure 3,

Figure 4 and

Figure 5, the wettability changes from hydrophilicity to hydrophobicity. However, sliding angles (SA) in

Figure 5a,b are much higher than the SAs in

Figure 5c. As shown in

Figure 5c, a water droplet cannot stably stick to the low-wettability surface. It rolls off immediately without any adhesion, indicating that the SA of the treated surface is as low as 1.5°. Hence, the addition of the secondary nanostructures and FAS modification play an important role in enhancing the low wettability and adhesive resistance.

Figure 5d shows the Fourier transform infrared spectroscopy (FTIR) spectra of the sample surfaces after the treatment by sandblasting, electrochemical machining and FAS modification. It can be seen that the absorption bands of 1073 cm

−1 are assigned to Si–O–Si stretching, indicating that the aluminum surfaces have been uniformly covered by the fluoroalkylsilane polymer coating, not the monolayer. It can be seen that the intense absorption bands between 1237 and 1120 cm

−1 are assigned to the C–F stretching of the –CF

3 and –CF

2 groups of the fluoroalkylsilane molecules, indicating that the low-surface-energy –CF

3 and –CF

2 groups have been successfully grafted onto the treated surface after modification with FAS.

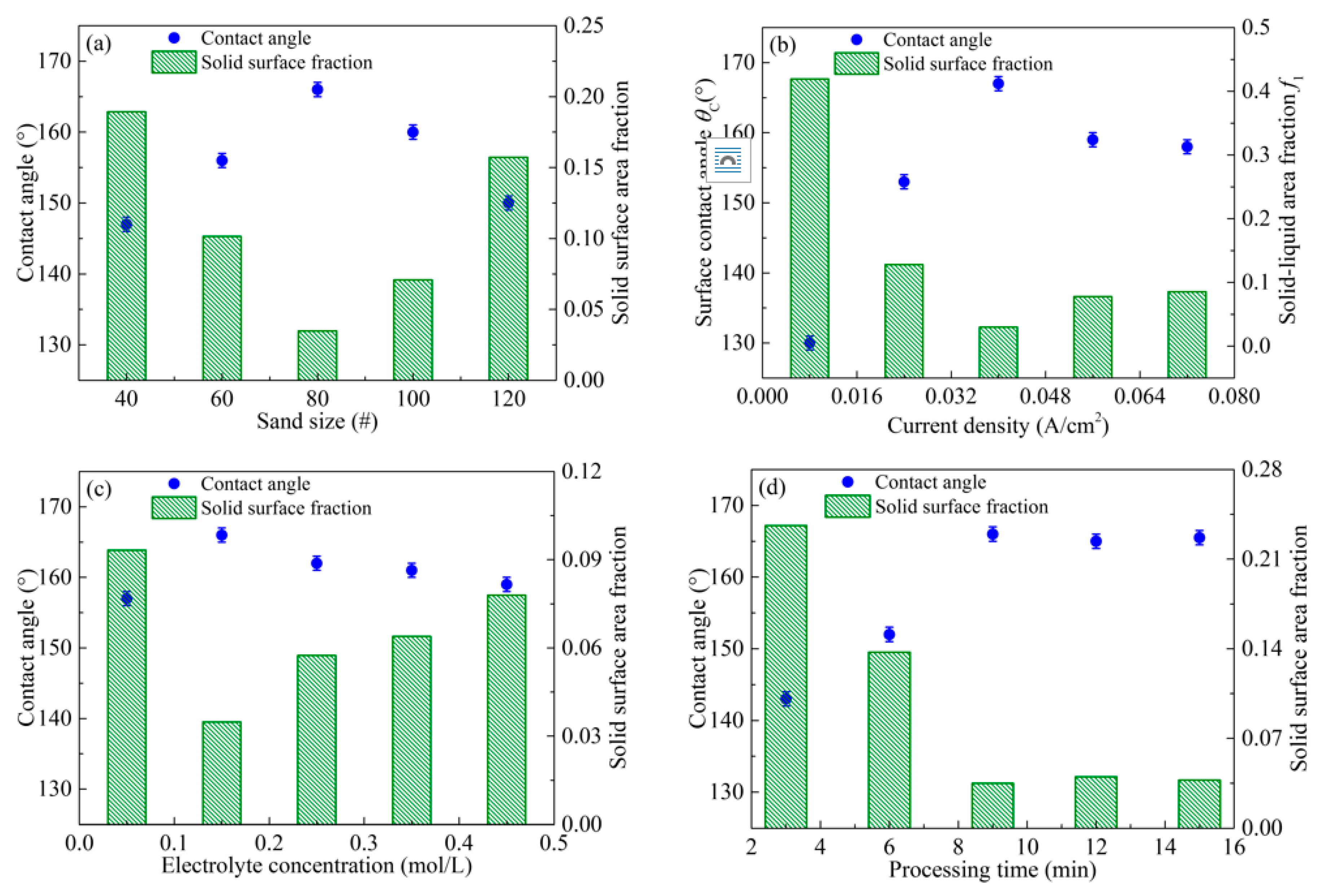

3.2. Effect of Processing Parameters on Surface Wettablity

As shown in

Figure 5c, a water droplet of 5 µL exhibits a typical spherical shape with a maximum contact angle of 167° and a tilting angle of 1.5° on the formed surface by sandblasting and electrochemical machining, followed by FAS modification. The low wettability of the fabricated surface on the aluminum alloy can be explained in terms of the Cassie-Baxter theory [

14], which is described as follows:

where θ

c and θ are the contact angles on the rough and smooth surfaces, respectively;

f1 and

f2 (

f1 +

f2 = 1) are the area fractions of the solid surface

f1 and trapped air in the voids among the micro-nano structures, respectively. This model indicates that the solid surface fraction is particularly important in determining the low wettability of the rough surface;

f1 would decrease with the increase of the contact angle. According to the model, when a water droplet is placed on the formed surface by sandblasting, electrochemical machining and FAS modification, only about 3% serves as the contact area of the water droplet and the solid surface, but the remaining 97% serves as the contact area of the water droplet and air, respectively. This means that air pockets trapped between the solid and liquid can prevent direct contact between the water droplets and the aluminum alloy surface formed by sandblasting, electrochemical machining and FAS modification.

The variations of the contact angles and the area fraction of the solid surface

f1 obtained on aluminum alloy surfaces by sandblasting and electrochemical machining, depending on the process parameters, such as sand size, processing current, electrolyte concentration, and processing time, are shown in

Figure 6.

Figure 6a shows the variation of the contact angle and

f1 with the sand size. The contact angle increases significantly with the decrease of the sand size from 40 to 80 mesh. It can reach 166° after the sample surfaces are treated by sandblasting with a sand size of 80#, electrochemical machining and FAS modification. The reason is that the rough microstructures become ever more uniform, and are prone to entrapping air to prevent direct contact between the treated surface and the water droplets. When the sand size is more than 80#, the contact angle decreases, because the less rough microstructure results in the increase of the fractional interfacial areas. Contrarily, the area fraction decreases to 0.035 with the increasing sand size from 40 to 80#, due to the well-distributed microstructures with proper roughness. As shown in

Figure 6b, the contact angle increases and

f1 decreases with the enhancement of the current density from 0.008 to 0.04 A/cm

2. When the current density is more than 0.04 A/cm

2, the contact angle decreases and

f1 increases. The reason is that an excessive current density leads to the increase of the removal amount, and decreases the roughness of the binary micro-nano structures. Consequently, the increase of the contact area between the water droplets and the fabricated surface results in the decrease of the contact angle.

Figure 6c shows the variation of the contact angle and

f1 with the Na

3PO

4 concentration. The increase of the electrolyte concentration leads to the improvement of the contact angles and the decrease of

f1 until the concentration reaches 0.15 mol/L. It is because the conductivity and electrolytic corrosion increases with the electrolyte concentration. When the electrolyte concentration is greater than 0.15 mol/L, the interaction between the positive and negative ions increases, which results in the decline of the ion’s migration rate and the solution conductivity. Consequently, the contact angle and

f1 are affected slightly by the Na

3PO

4 concentration in the range from 0.15 to 0.45 mol/L. As shown in

Figure 6d, the contact angle increases and

f1 decreases significantly with the processing time increasing from 3 to 9 min. The reason is that the oxide film obtained by electrochemical machining should be too thin to cover the original surface roughness. When the processing time is more than 9 min, the contact angle and

f1 remain stable. This is because the grooves are completely covered by the oxide films, and the density and size of the pores increase with the anodic oxidation progress. Consequently, a large air fraction is generated on the formed surfaces with the fractal morphology.

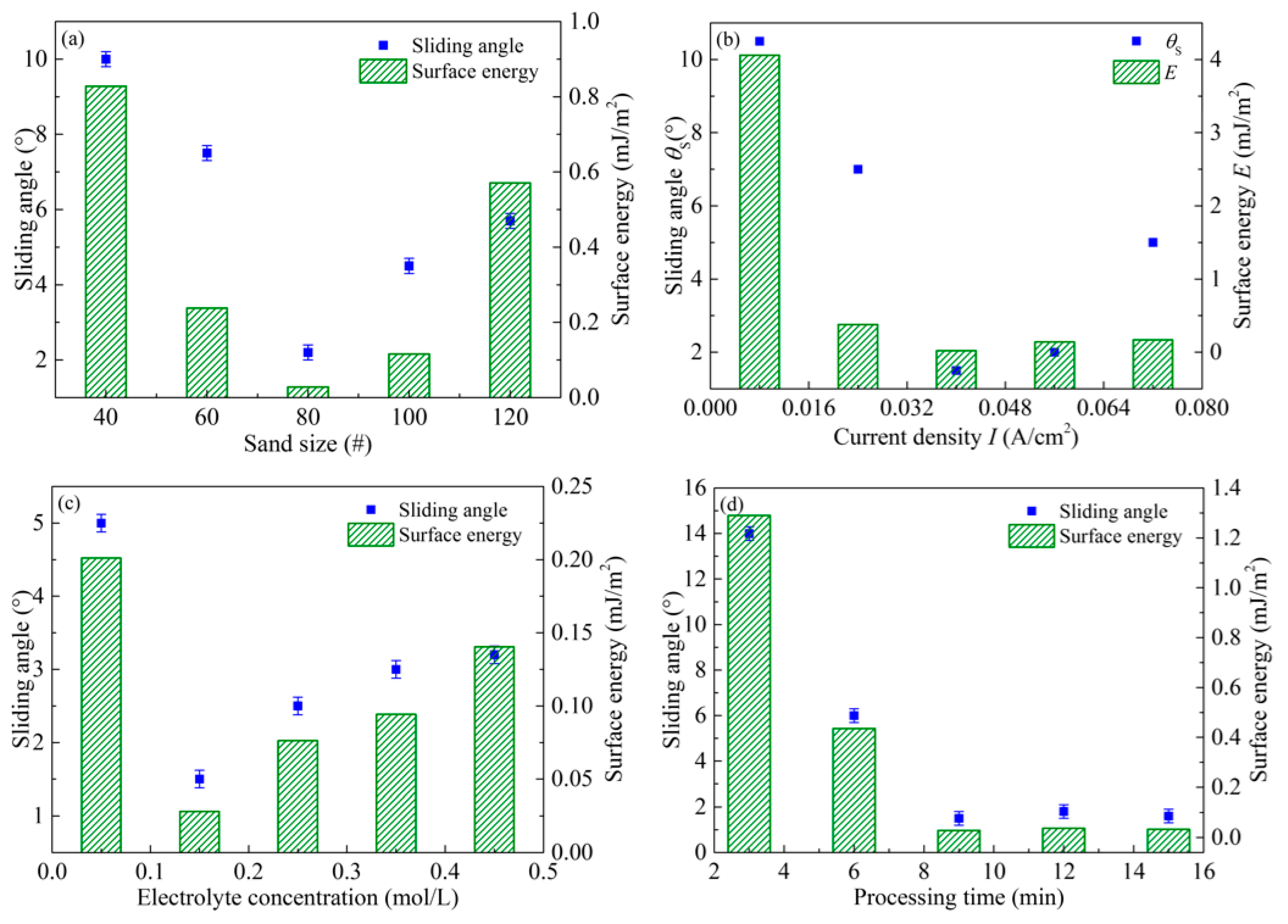

3.3. Surface Anti-Adhesive Performance

Low adhesive forces are essential for improving the adhesive resistance of an aluminum alloy. However, it is difficult to directly measure the adhesive force of aluminum alloy surfaces. As is well known, anti-adhesive surfaces are dependent on the surface energy and the sliding angle [

15,

16]. In this paper, the sliding angle and solid surface energy are used to investigate the adhesive resistance of aluminum alloy surfaces prepared by sandblasting and electrochemical machining. The sliding angle can be measured by the DSA100 optical contact angle meter, and the solid surface energy can be calculated by the geometric mean method, which is written as:

where γ is the total surface-free energy,

is the London attraction of the van der Waals force, and

is the other type of non-dispersive component for physical interactions [

17,

18]. Further,

and

are the dispersive component and the specific component of liquid surface free energy (γ

L) [

19,

20], respectively. The liquid used here is re-distillation water. The surface-free energy of the anti-adhesive surfaces on aluminum alloys can be obtained using Equations (2) and (3) with the measured contact angles.

Their changes are presented in

Figure 7.

From

Figure 7a, it can be seen that surface energy first decreases with the decrement of the sand size. When the sand size is 80 mesh, the surface energy is lowest. With further decrement of the sand size, the surface energy enhances. This is due to binary structures entrapping air to reduce the contact area between the droplet and aluminum alloy surface. As shown in

Figure 7b, the surface energy decreases with the increment of the current density, and it is down to 0.0209 mJ/m

2 under the current density of 0.04 A/cm

2. When the current density further increases, the surface energy increases instead. This reason is that the roughness of the fabricated surface is not high enough under the low current density, which is not in favor of the formation of steady air film reducing the adhesive force.

As shown in

Figure 7c, the surface energy first decreases with the increase of the electrolyte concentration. When the Na

3PO

4 concentration is 0.15 mol/L, the surface energy is 0.02806 mJ/m

2. Contrarily, the surface energy increases with the further increment of the electrolyte concentration. The reason is that there are few nano-level protrusions formed by electrochemical machining on the micro-level structure obtained from sandblasting, when the electrolyte concentration is less than 0.15 mol/L. From

Figure 7d, it can be found that the surface energy first decreases with the increment of the processing time. When the time is 9 min, the surface energy decreases to 0.02806 mJ/m

2. With the further increment of the processing time to 15 min, the surface energy is still 0.03277 mJ/m

2. This is because the dynamic equilibrium between the dissolution of the anodized film and its formation is reached after 9 min during the processing of the aluminum alloy sample treated by electrochemical machining.

Furthermore, the changes of the sliding angle with different process parameters, such as sand size, current density, electrolyte concentration, and processing time, are also presented in

Figure 6. The result is attributed to the combined effects of binary structures and chemical compositions. The former is a rough surface with micro-nano structures, which can trap air and reduce the contact between the aluminum alloy surfaces and liquid droplets. On the other hand, with low-surface-energy compounds, the rough surface is modified to render artificial adhesive resistance. During the modification, a polymerization reaction occurs between the surface groups and silanol groups, which can improve the adhesive resistance of the aluminum alloy surfaces.