Thermoelectric Responsive Shape Memory Graphene/Hydro-Epoxy Composites for Actuators

Abstract

:1. Introduction

2. Experimental

2.1. Materials and Preparation

2.2. Sample Preparation

2.3. Measurements

2.3.1. Mechanical Properties

2.3.2. Electrical Properties

2.3.3. Scanning Electron Micrsocopy (SEM)

2.3.4. Dynamic Mechanical Analysis (DMA)

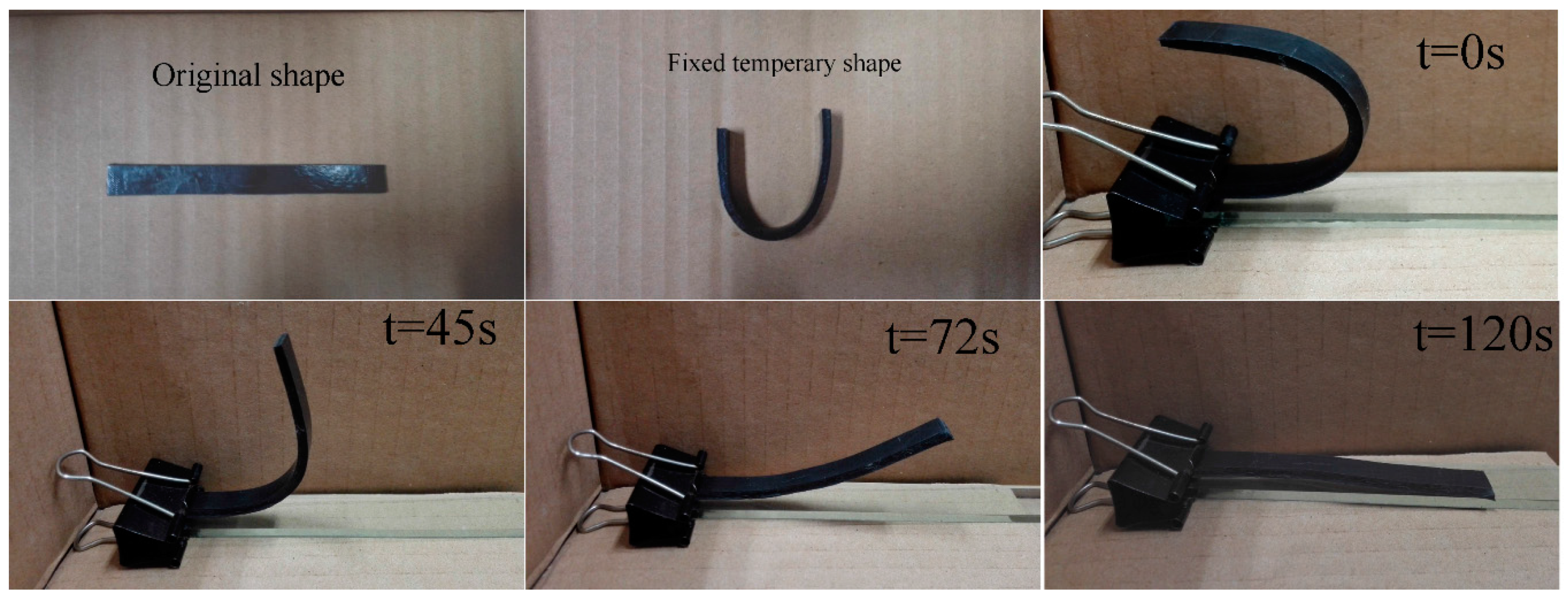

2.3.5. Thermo-Active Shape Memory Property

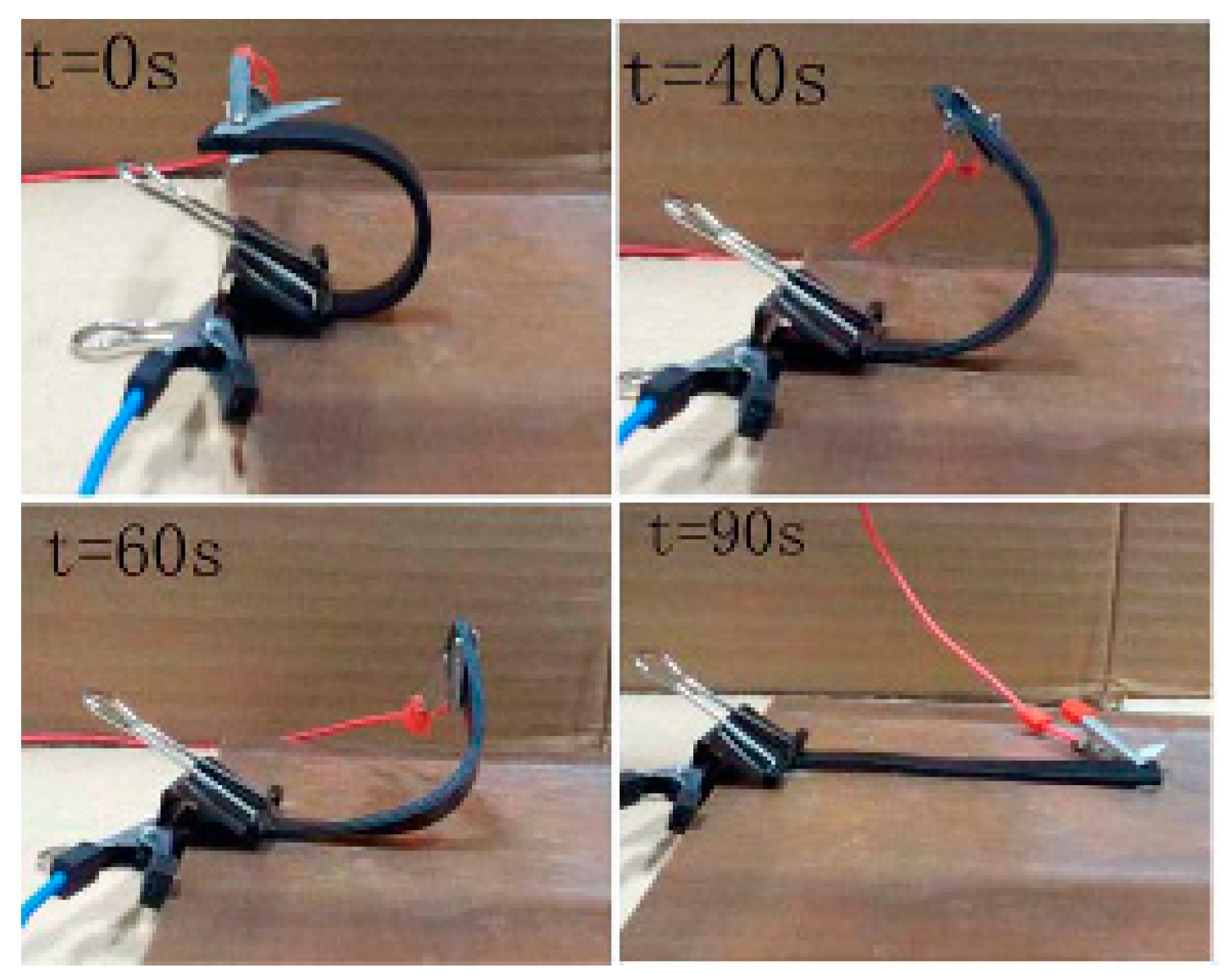

2.3.6. Electroactive Shape Memory Behavior Test

3. Results and Discussions

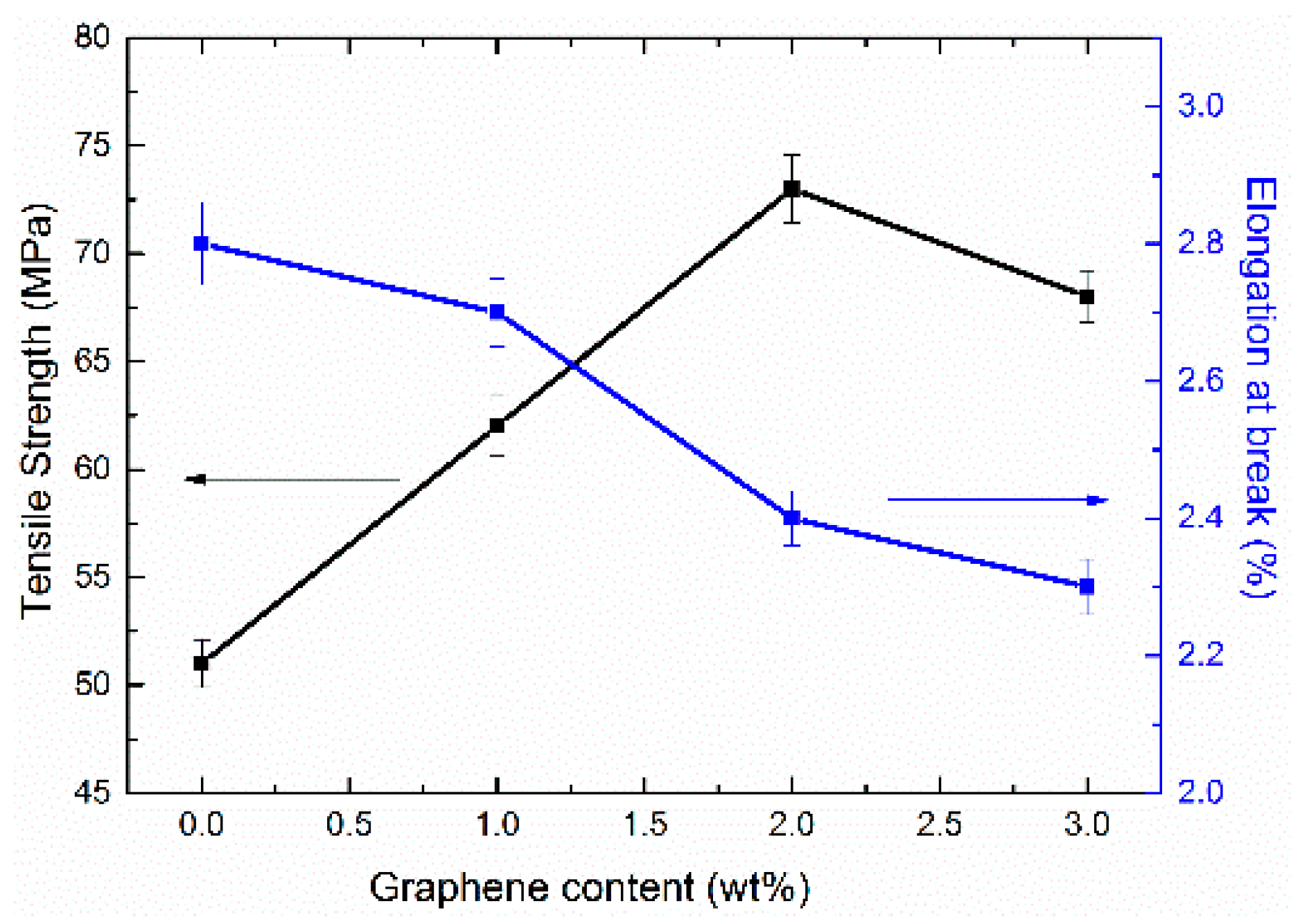

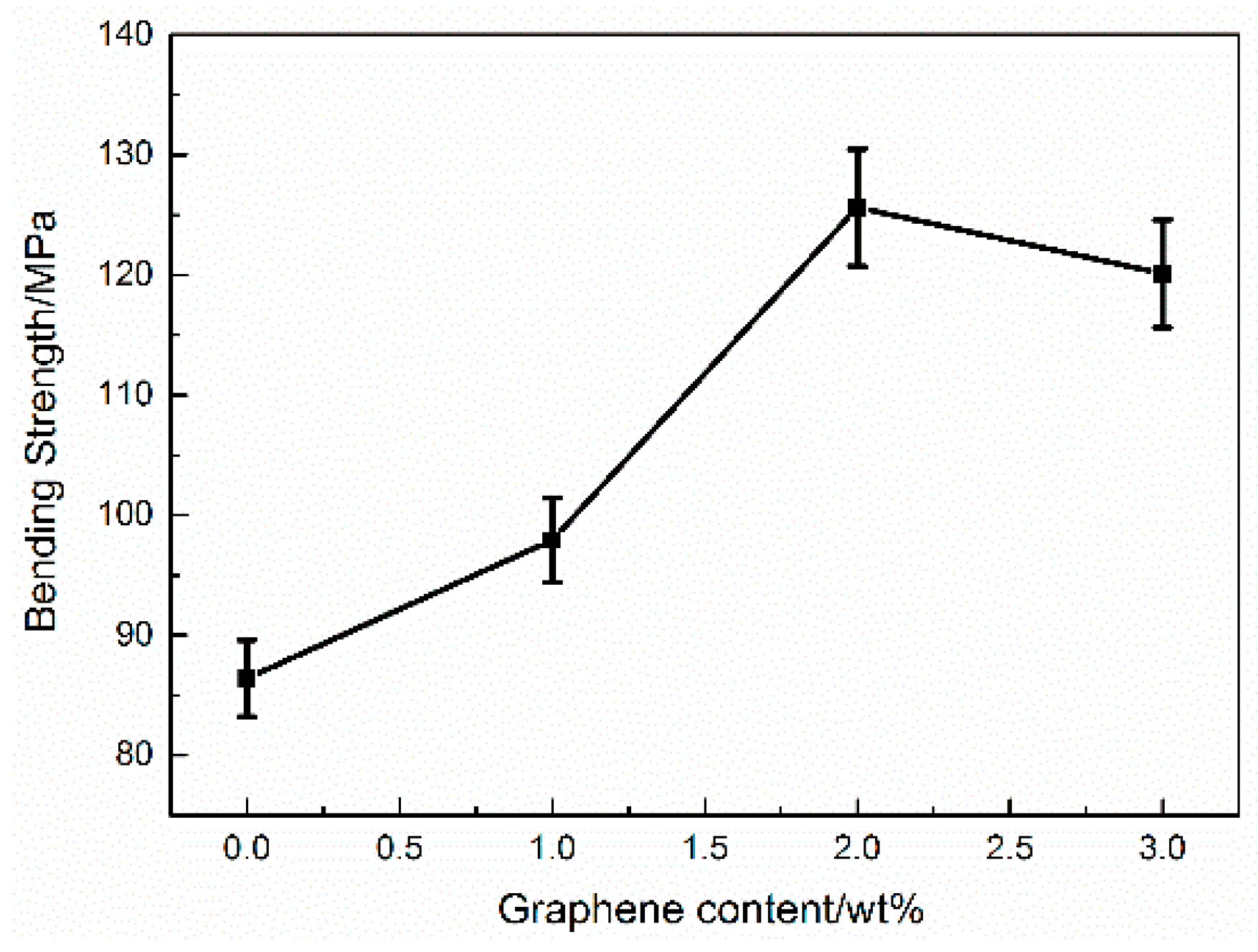

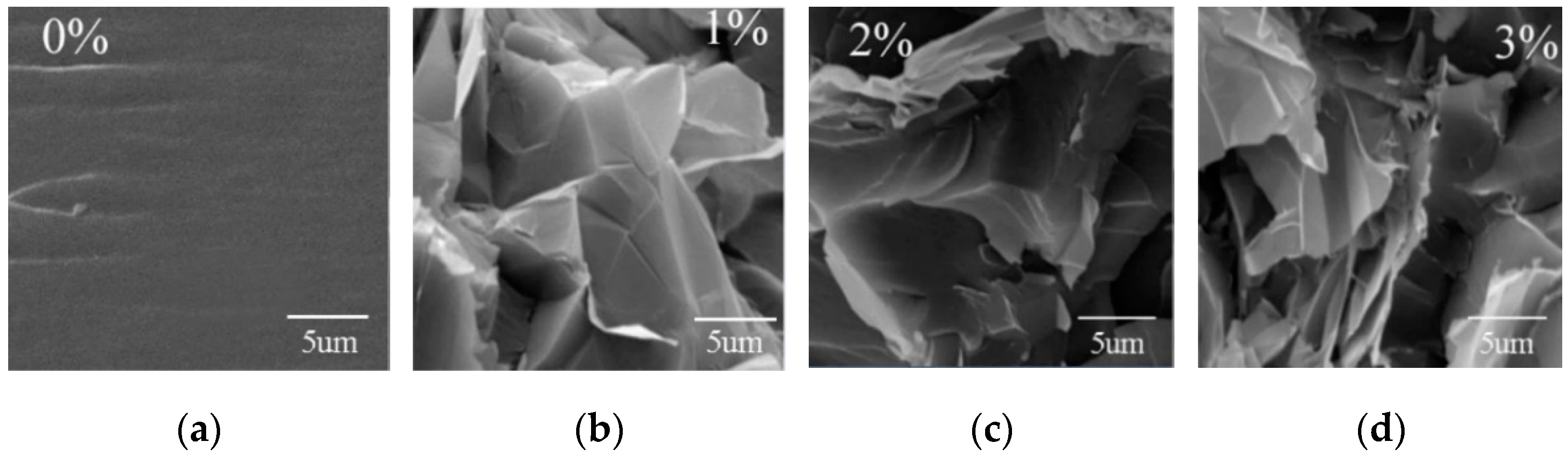

3.1. Mechanical Properties and SEM

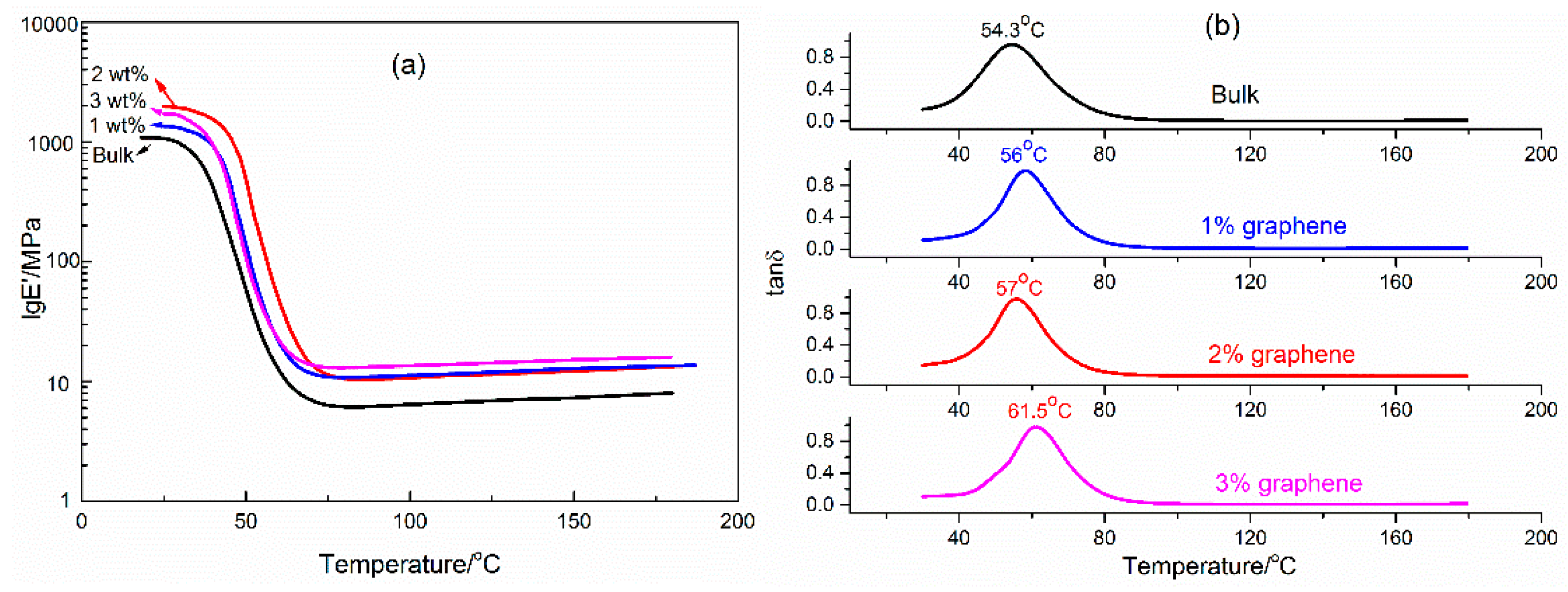

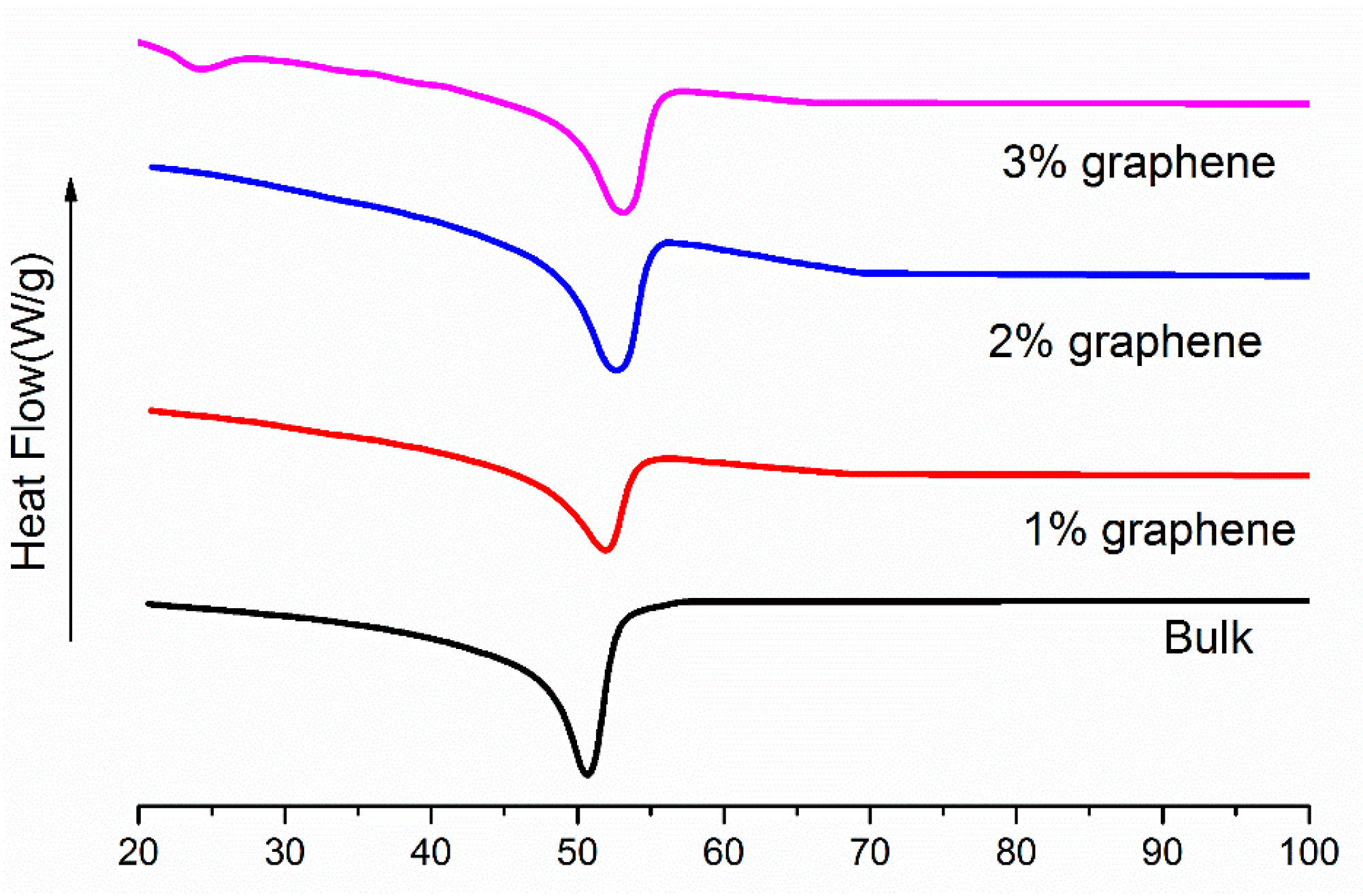

3.2. Thermal Properties Analyses

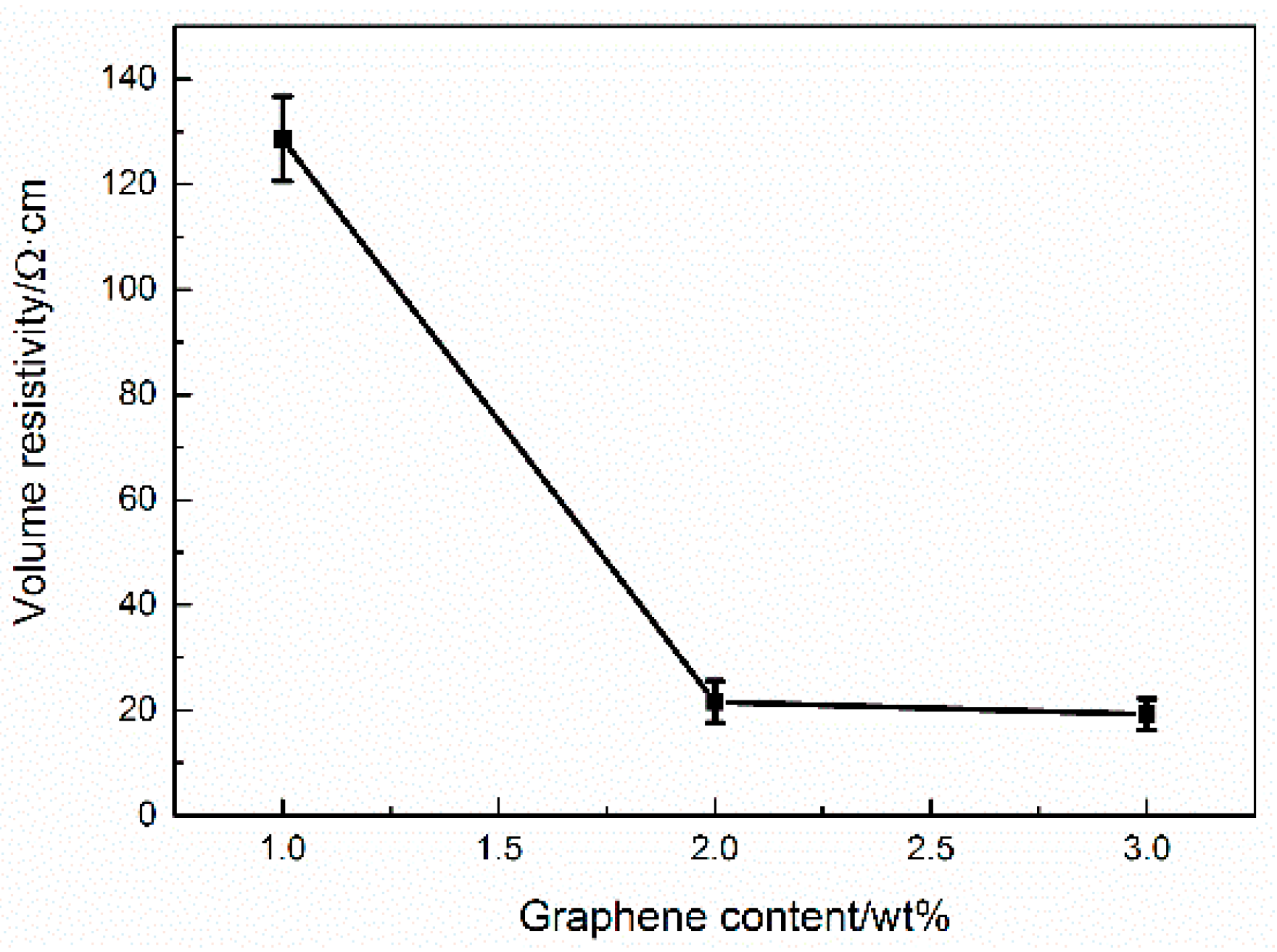

3.3. Electrical Property Analysis

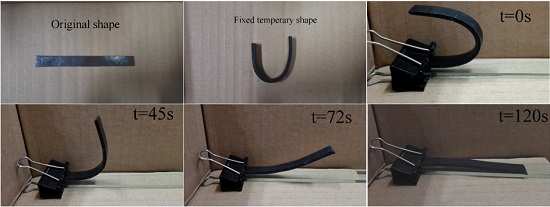

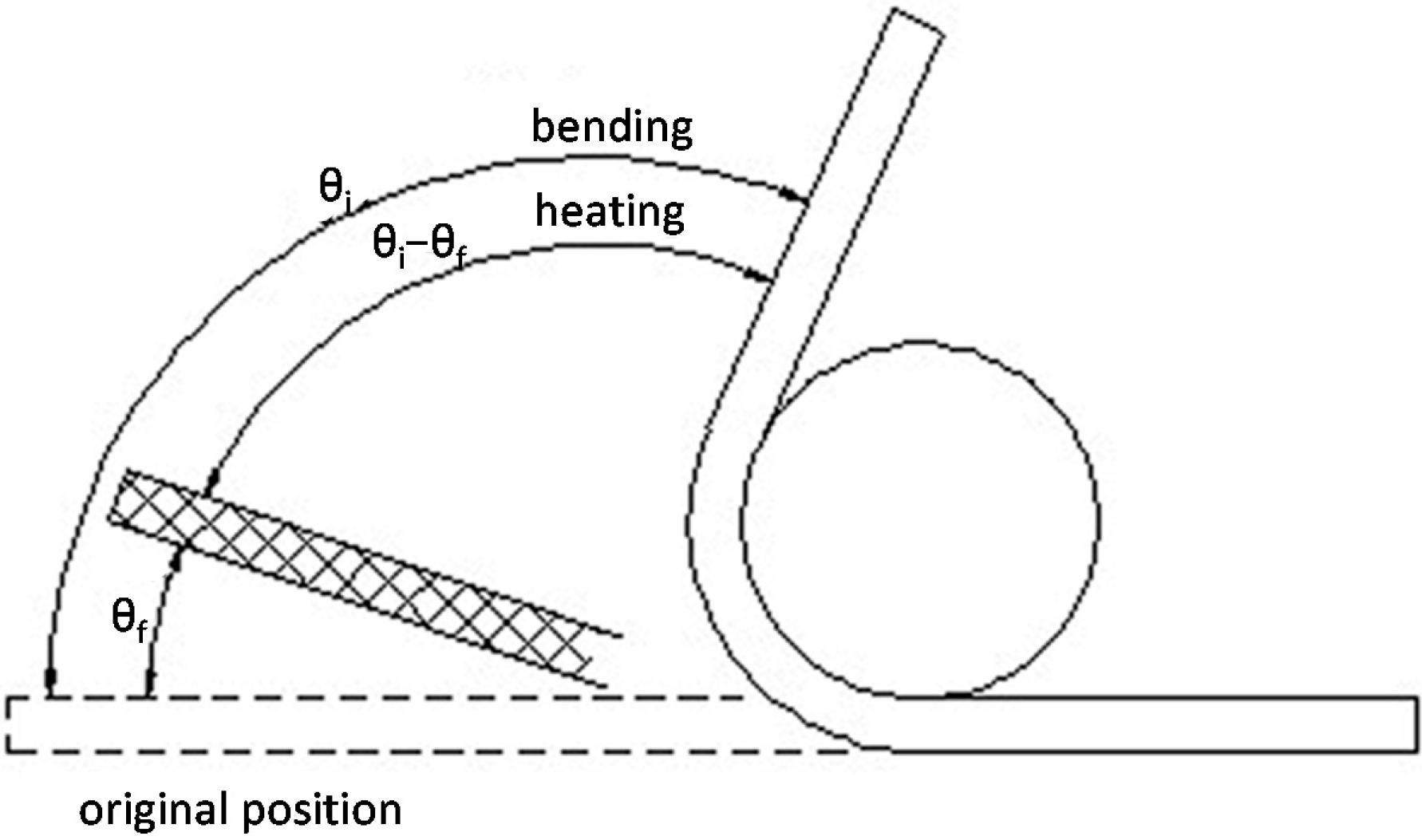

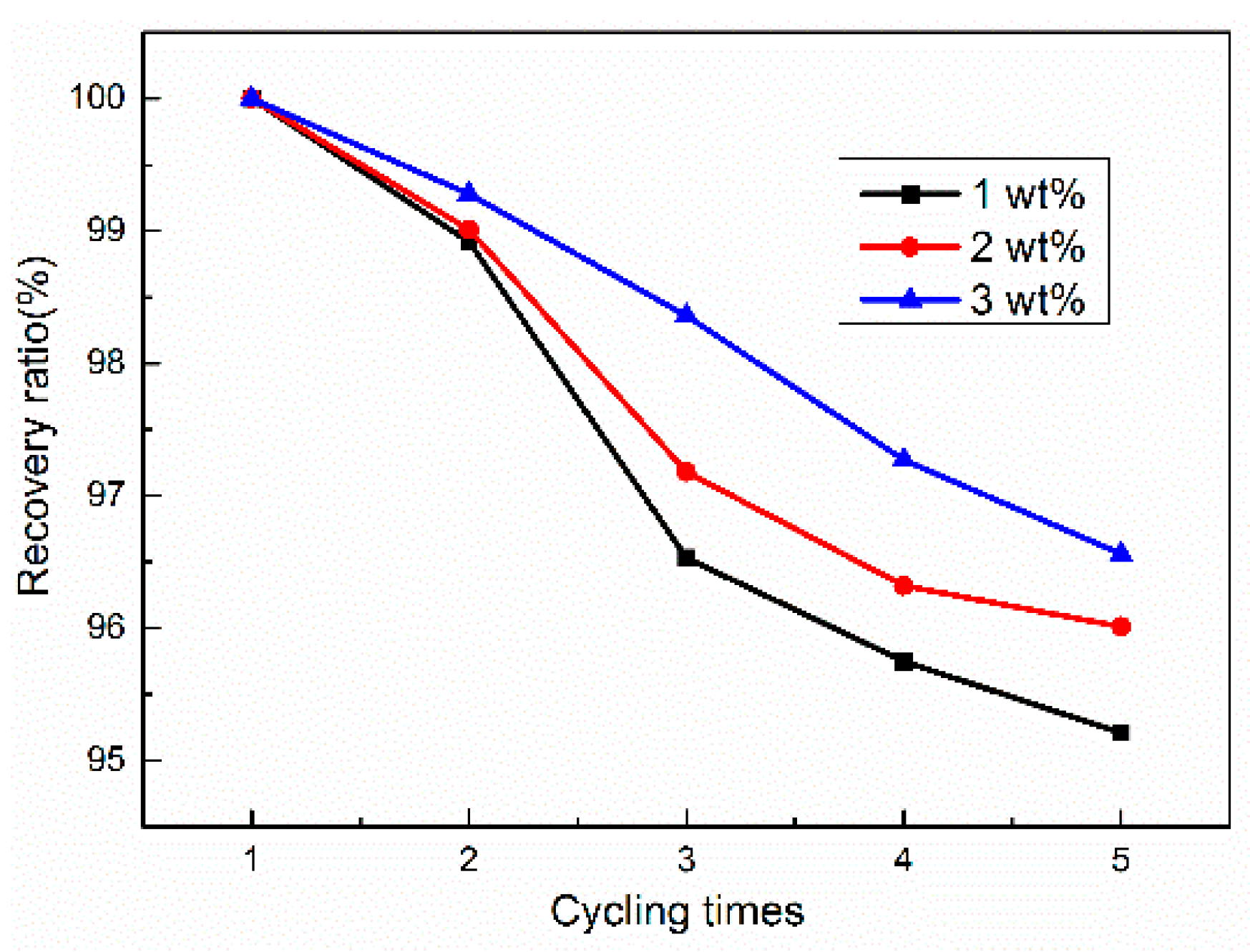

3.4. Thermo-Active Shape Memory Property Analysis

3.5. Electro-Active Shape Memory Property Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Huang, Y.; Liang, J.; Chen, Y. The application of graphene based materials for actuators. J. Mater. Chem. 2012, 22, 3671–3679. [Google Scholar] [CrossRef]

- Kong, L.; Chen, W. Carbon Nanotube and Graphene-based Bioinspired Electrochemical Actuators. Adv. Mater. 2014, 26, 1025–1043. [Google Scholar] [CrossRef] [PubMed]

- Jeon, J.H.; Cheng, T.H.; Oh, I.K. Snap-through dynamics of buckled IPMC actuator. Sens. Actuat. A Phys. 2010, 158, 300–305. [Google Scholar] [CrossRef]

- Chen, S.J.; Hu, J.L.; Zhuo, H.T. Properties and mechanism of two-way shape memory polyurethane composites. Compos. Sci. Technol. 2010, 70, 1437–1443. [Google Scholar] [CrossRef]

- Jung, M.; An, J.Y.; Park, Y.; Yang, S.; Lee, J.H. A movable polymeric microneedle array actuated by thermopneumatic force. Sens. Actuat. A Phys. 2016, 237, 128–135. [Google Scholar] [CrossRef]

- Lu, J.; Kim, S.G.; Lee, S.; Oh, I.K. A Biomimetic Actuator Based on an Ionic Networking Membrane of Poly(styrene-alt-maleimide)-Incorporated Poly(vinylidene fluoride). Adv. Funct. Mater. 2008, 18, 1290–1298. [Google Scholar] [CrossRef]

- Imai, S.; Sakurai, K. An actuator of two-way behavior by using two kinds of shape memory polymers with different Tgs. Precis. Eng. 2013, 37, 572–579. [Google Scholar] [CrossRef]

- Wang, Y.K.; Zhu, G.M.; Xie, J.Q.; Men, Q.N.; Liu, T.T.; Ren, F. An investigation on shape memory behavior of glass fiber/SBS/LDPE composites. J. Polym. Res. 2014, 21, 1–8. [Google Scholar] [CrossRef]

- Wang, Y.K.; Zhu, G.M.; Tang, Y.S.; Liu, T.T.; Xie, J.Q.; Ren, F. Short glass fiber reinforced radiation crosslinked shape memory SBS/LLDPE blends. J. Appl. Polym. Sci. 2014, 131, 40691. [Google Scholar]

- Lan, X.; Wang, X.H.; Lu, H.B.; Liu, Y.J.; Leng, J.S. Shape recovery performances of a deployable hinge fabricated by fiber-reinforced shape-memory polymer. Proc. SPIE 2009, 7289, 728910. [Google Scholar]

- Gall, K.; Kreiner, P.; Turner, D.; Hulse, M. Shape-memory polymers for microelectromechanical systems. J. IEEE Microelectromech. Syst. 2004, 13, 472–483. [Google Scholar] [CrossRef]

- Takashima, K.; Rossiter, J.; Mukai, T. McKibben artificial muscle using shapememory polymer. Sens. Actuator A Phys. 2010, 164, 116–124. [Google Scholar] [CrossRef]

- Raccichini, R.; Varzi, A.; Passerini, S.; Scrosati, B. The role of graphene for electrochemical energy storage. Nat. Mater. 2015, 14, 271–279. [Google Scholar] [CrossRef] [PubMed]

- Bonaccorso, F.; Colombo, L.; Yu, G.H.; Stoller, M.; Tozzini, V.; Ferrari, A.C.; Ruoff, R.S.; Pellegrini, V. Graphene, related two-dimensional crystals, and hybrid systems for energy conversion and storage. Science 2015, 347, 1246501. [Google Scholar] [CrossRef] [PubMed]

- Shao, Y.; El-Kady, M.F.; Wang, L.J.; Zhang, Q.; Li, Y.; Wang, H.; Mousavi, M.F.; Kaner, R.B. Graphene-based materials for flexible supercapacitors. Chem. Soc. Rev. 2015, 44, 3639–3665. [Google Scholar] [CrossRef] [PubMed]

- Yoonessi, M.; Shi, Y.; Scheiman, D.A.; Lebron-Colon, M.; Tigelaar, D.M.; Weiss, R.A.; Meador, M. Graphene polyimide nanocomposites; thermal, mechanical, and high-temperature shape memory effects. ACS Nano. 2012, 6, 7644–7655. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.T.; Jeong, H.J.; Park, H.C.; Jeong, H.M.; Bae, S.Y.; Kim, B.K. Electroactive shape memory performance of polyurethane/graphene nanocomposites. React. Funct. Polym. 2015, 88, 1–7. [Google Scholar] [CrossRef]

- American Society for Testing Materials. Standard Test Method for Tensile Properties of Plastics; ASTM D638-14; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- American Society for Testing Materials. Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials; ASTM D7264/D7264M-15; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Wang, Y.K.; Zhu, G.M.; Cui, X.P.; Liu, T.T.; Liu, Z.; Wang, K. Electroactive shape memory effect of radiation cross-linked SBS/LLDPE composites filled with carbon black. Colloid Polym. Sci. 2014, 292, 2311–2317. [Google Scholar] [CrossRef]

- Ye, J.J.; Qiu, Y.Y.; Chen, X.F.; Ma, J. Initial and final failure strength analysis of composites based on a micromechanical method. Compos. Struct. 2015, 125, 328–335. [Google Scholar] [CrossRef]

- Ye, J.J.; Qiu, Y.Y.; Chen, X.F.; Ma, J.; Zhai, Z. Working temperature variation effect on nonlinear and failure envelope of fiber-reinforced composites. Compos. Interface 2015, 22, 531–542. [Google Scholar] [CrossRef]

- Du, F.P.; Ye, E.Z.; Yang, W.; Shen, T.H.; Tang, C.Y.; Xie, X.L.; Zhou, X.P.; Law, W.C. Electroactive shape memory polymer based on optimized multi-walled carbon nanotubes/polyvinyl alcohol nanocomposites. Compos. Part B Eng. 2015, 68, 170–175. [Google Scholar] [CrossRef]

- Young, R.J.; Kinloch, I.A. Graphene and graphene-based nanocomposites. Nanosci. Nanostruct. Chem. 2012, 1, 145. [Google Scholar]

- Wei, K.; Zhu, G.M.; Tang, Y.S.; Li, X.M.; Liu, T.T. The effects of carbon nanotubes on electroactive shape-memory behaviors of hydro-epoxy/carbon black composite. Smart. Mater. Struct. 2012, 21, 085016. [Google Scholar] [CrossRef]

| Samples | 60 V | 80 V | 100 V | 120 V | 140 V | 160 V |

|---|---|---|---|---|---|---|

| 1.0 wt % graphene/H-EP | - | - | - | 196 s | 138s | 87 s |

| 2.0 wt % graphene/H-EP | 158 s | 90 s | 56 s | 21 s | 5 s | 0.8 s |

| 3.0 wt % graphene/H-EP | 136 s | 72 s | 29 s | 3 s | 0.6 s | 0.2 s |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Tian, W.; Xie, J.; Liu, Y. Thermoelectric Responsive Shape Memory Graphene/Hydro-Epoxy Composites for Actuators. Micromachines 2016, 7, 145. https://doi.org/10.3390/mi7080145

Wang Y, Tian W, Xie J, Liu Y. Thermoelectric Responsive Shape Memory Graphene/Hydro-Epoxy Composites for Actuators. Micromachines. 2016; 7(8):145. https://doi.org/10.3390/mi7080145

Chicago/Turabian StyleWang, Yongkun, Wenchao Tian, Jianqiang Xie, and Yan Liu. 2016. "Thermoelectric Responsive Shape Memory Graphene/Hydro-Epoxy Composites for Actuators" Micromachines 7, no. 8: 145. https://doi.org/10.3390/mi7080145

APA StyleWang, Y., Tian, W., Xie, J., & Liu, Y. (2016). Thermoelectric Responsive Shape Memory Graphene/Hydro-Epoxy Composites for Actuators. Micromachines, 7(8), 145. https://doi.org/10.3390/mi7080145