A Study on the Influence of the Nozzle Lead Angle on the Performance of Liquid Metal Electromagnetic Micro-Jetting

Abstract

:1. Introduction

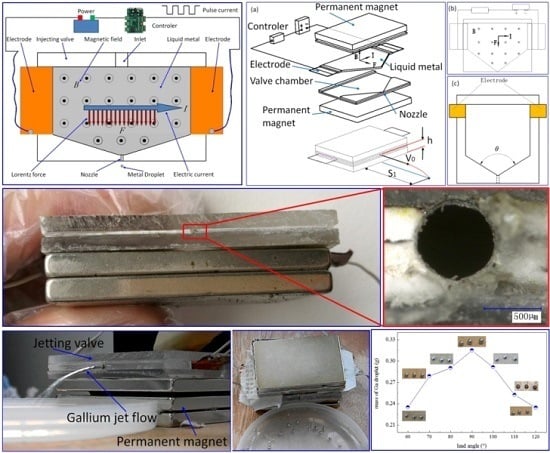

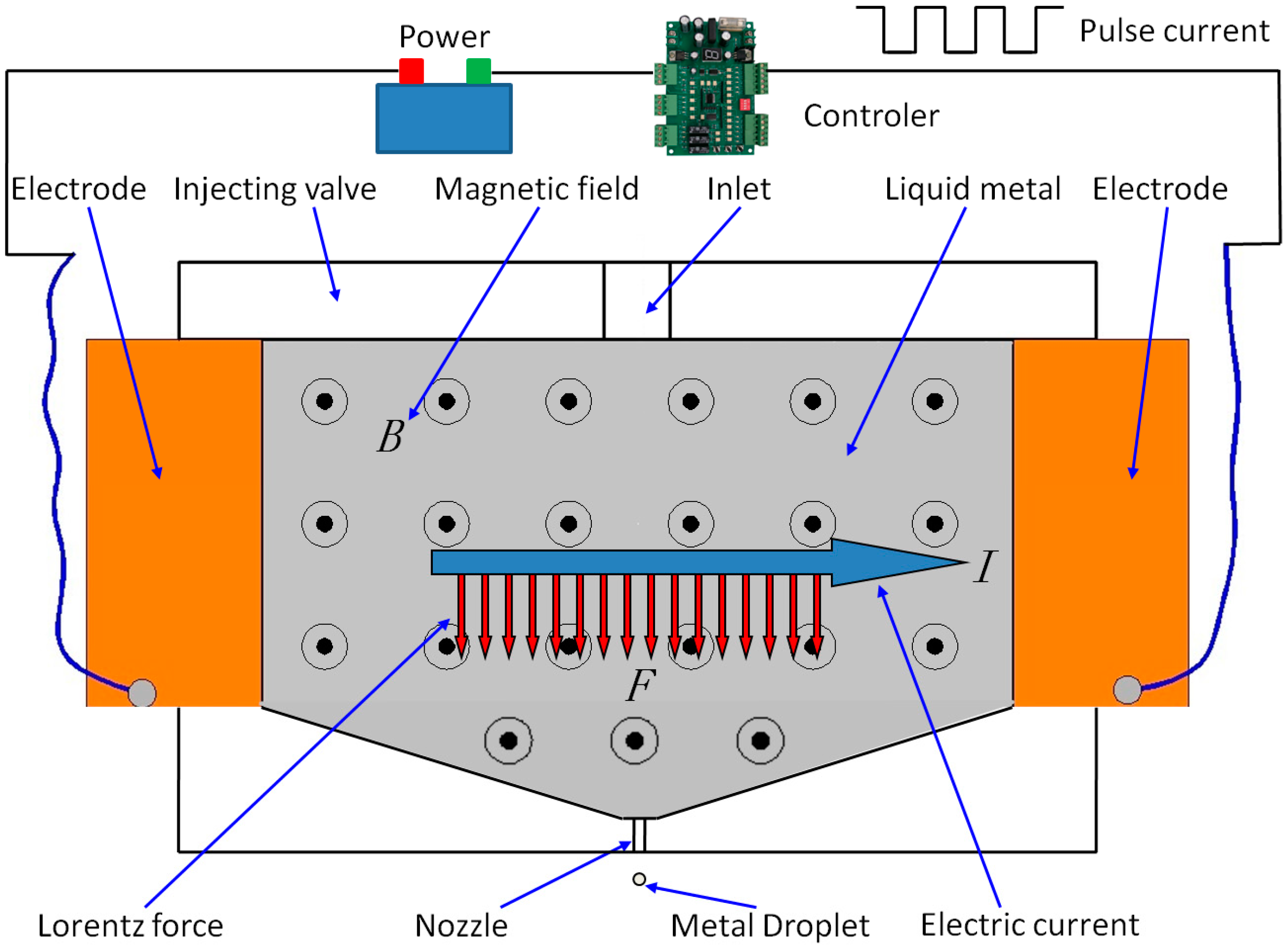

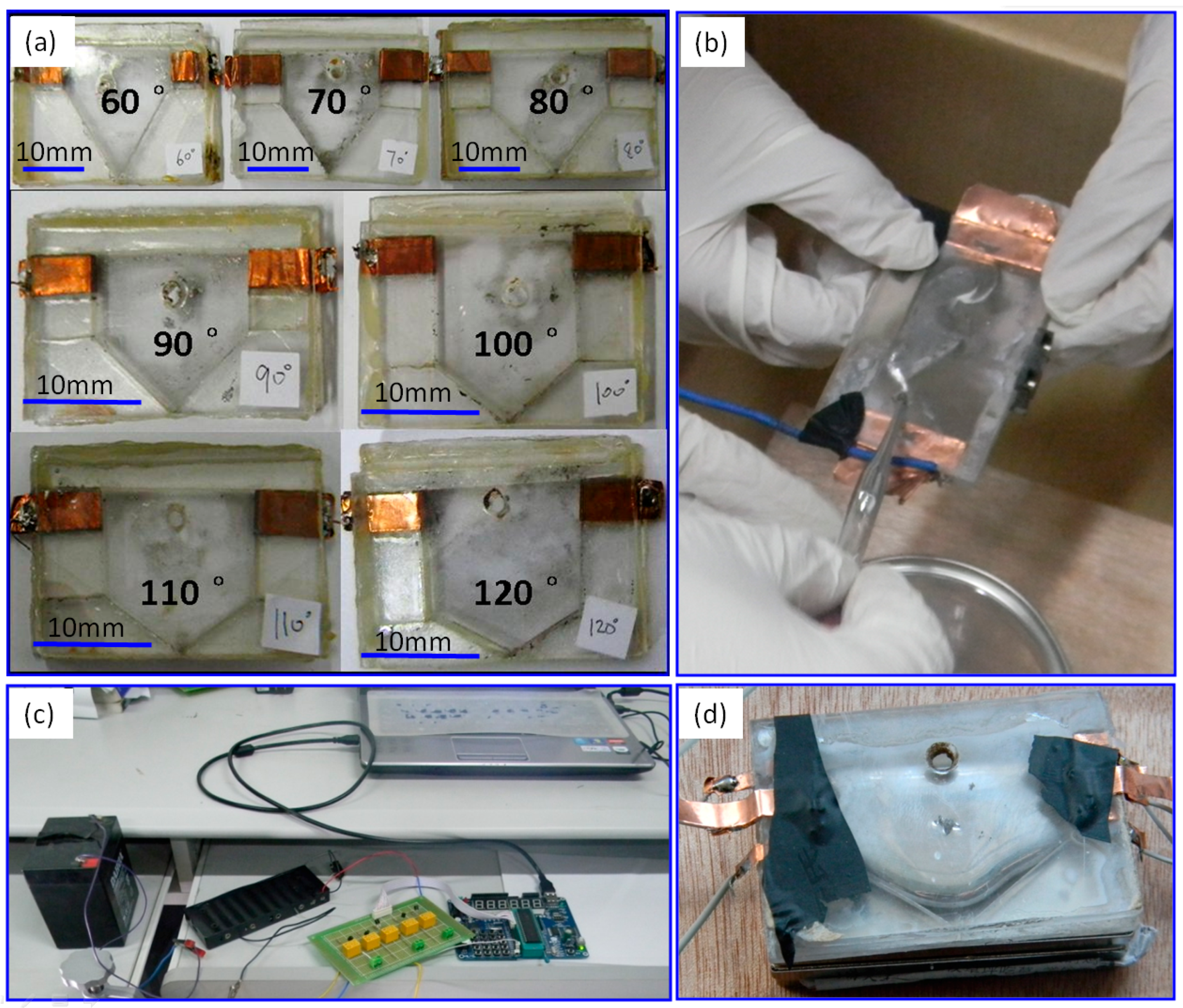

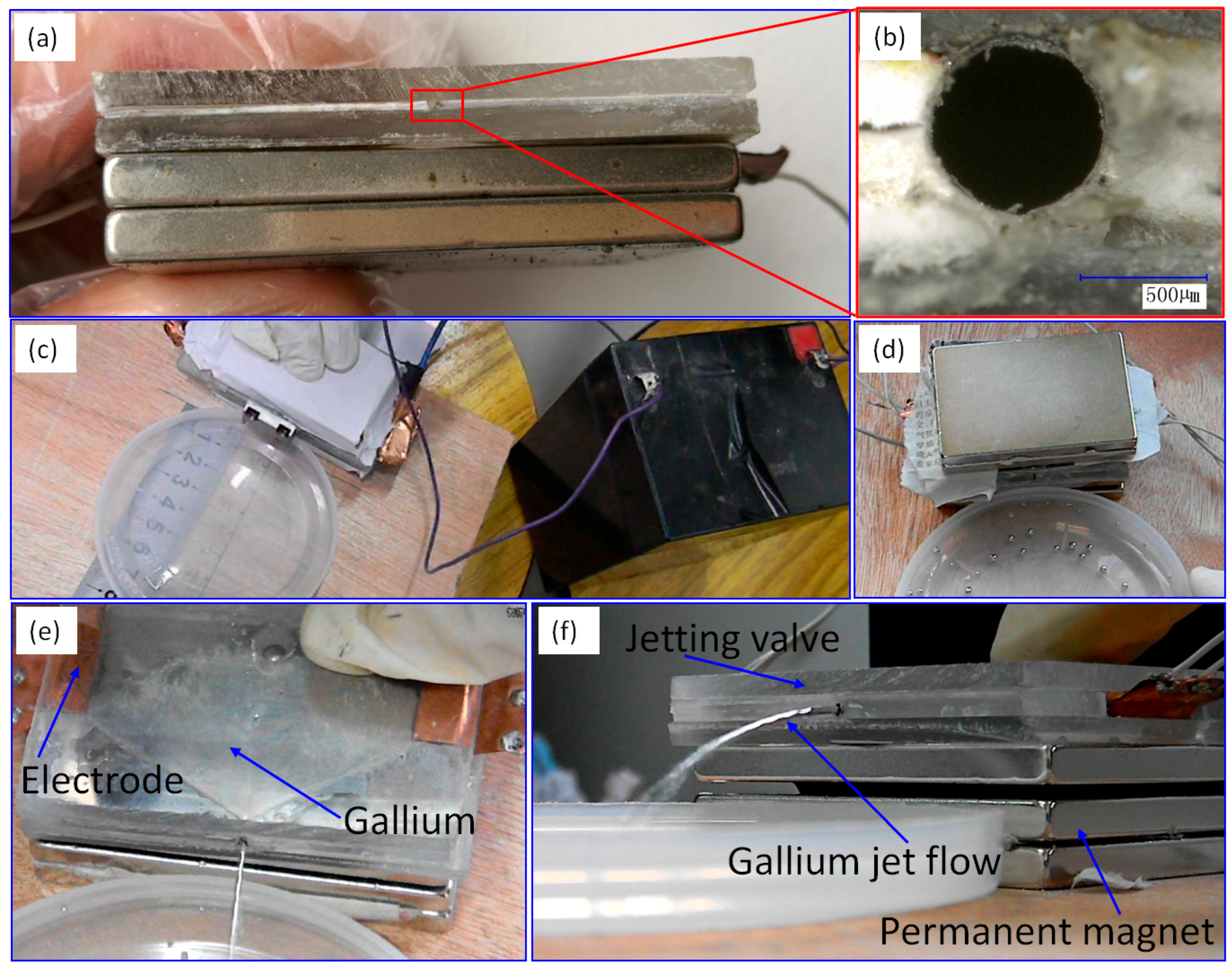

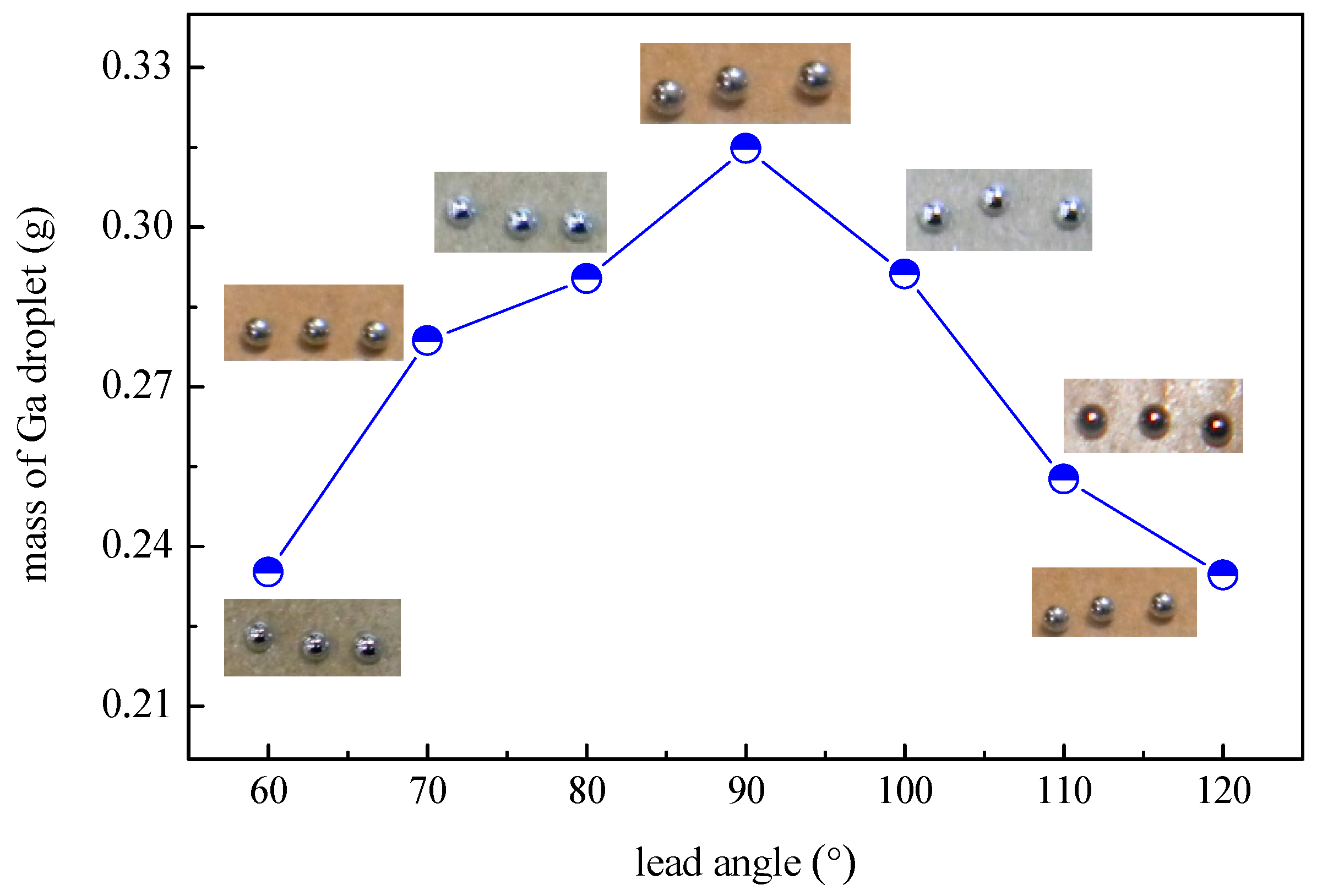

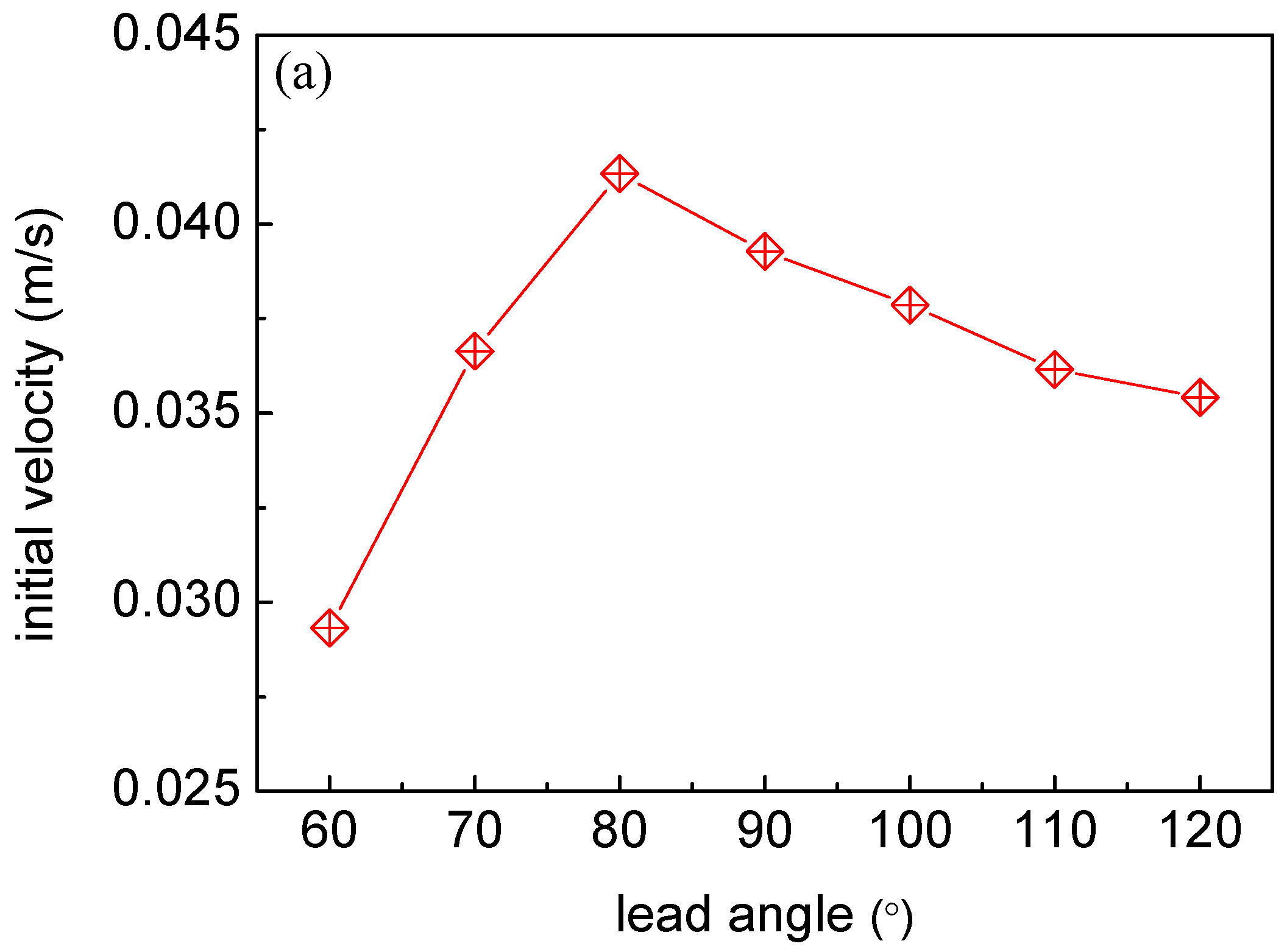

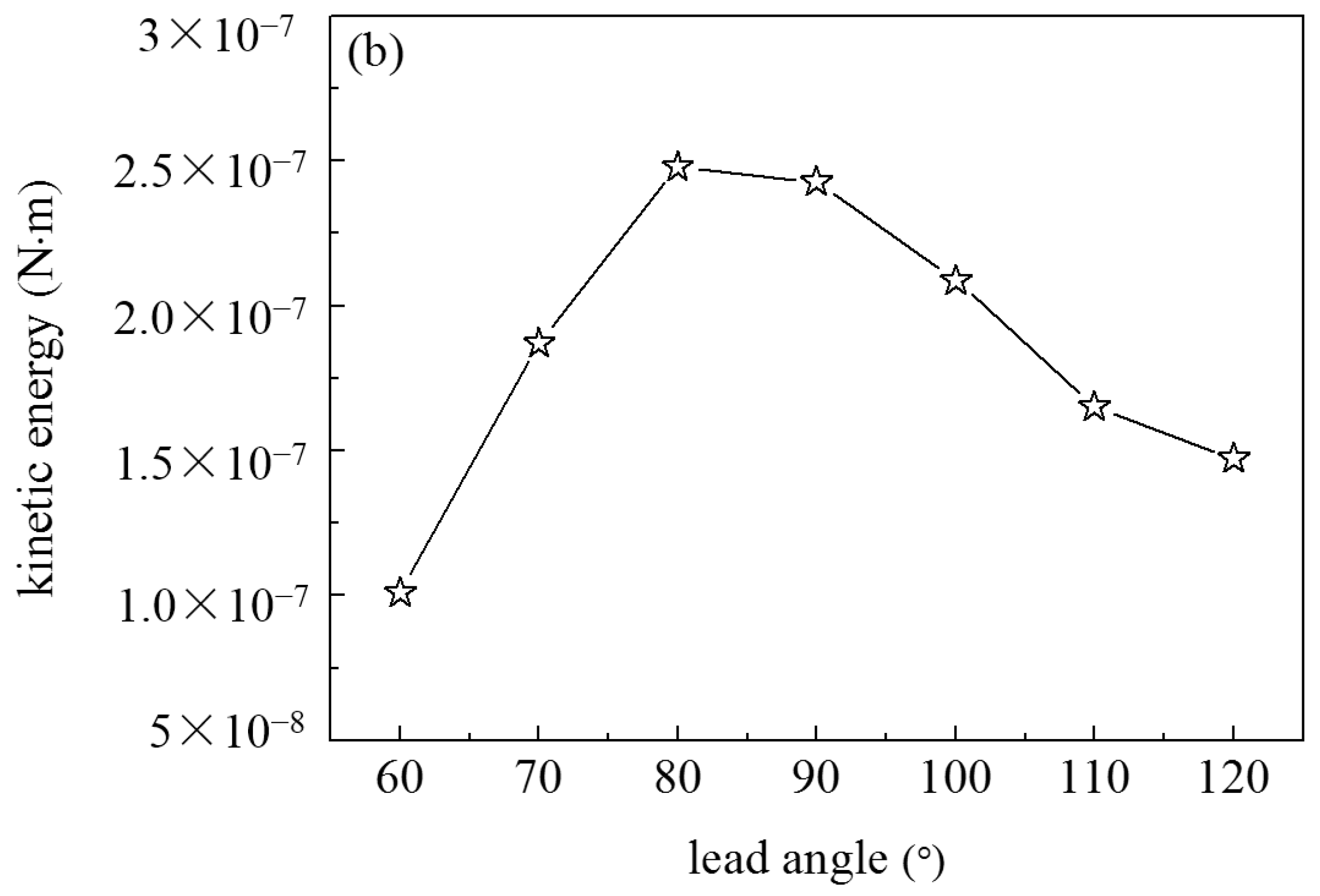

2. Experiment

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Orme, M. A novel technique of rapid solidification net-form materials synthesis. J. Mater. Eng. Perform. 1993, 2, 399–405. [Google Scholar] [CrossRef]

- Xu, L.; Wang, X.; Lei, T.; Sun, D.; Lin, L. Electrohydrodynamic deposition of polymeric droplets under low-frequency pulsation. Langmuir 2011, 27, 6541–6548. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Qi, L.; Zeng, X.; Yang, F. Principle of micro-feeding powders by ultrasonic vibration and influence of amplitude on rate of micro-feeding powders. Chin. J. Mech. Eng. 2009, 1, 267–272. [Google Scholar] [CrossRef]

- Park, B.K.; Kim, D.; Jeong, S.; Moon, J.; Kim, J.S. Direct writing of copper conductive patterns by ink-jet printing. Thin Solid Films 2007, 515, 7706–7711. [Google Scholar] [CrossRef]

- Šturm, R.; Grum, J.; Božič, S. Influence of the alloying elements in Al-Si alloys on the laser remelting process. Lasers Eng. (Old City Publ.) 2012, 22, 47–61. [Google Scholar]

- Yokoyama, Y.; Endo, K.; Iwasaki, T.; Fukumoto, H. Variable-size solder droplets by a molten-solder ejection method. J. Microelectromech. Syst. 2009, 18, 316–321. [Google Scholar] [CrossRef]

- Song, Q.; Zhu, W.; Zhang, W.; Ren, M.; Chia, E.; Liu, A. Tunable thz filter based on random access metamaterial with liquid metal droplets. In Proceedings of the 2014 IEEE 27th International Conference on Micro Electro Mechanical Systems (MEMS), San Francisco, CA, USA, 26–30 January 2014; pp. 664–667.

- Sun, J.; Fuh, J.; Thian, E.; Hong, G.; Wong, Y.; Yang, R.; Tan, K. Fabrication of electronic devices with multi-material drop-on-demand dispensing system. Int. J. Comput. Integr. Manuf. 2013, 26, 897–906. [Google Scholar] [CrossRef]

- Glynne-Jones, P.; Coletti, M.; White, N.M.; Gabriel, S.; Bramanti, C. A feasibility study on using inkjet technology, micropumps, and MEMS as fuel injectors for bipropellant rocket engines. Acta Astronaut. 2010, 67, 194–203. [Google Scholar] [CrossRef]

- Kim, B.-H.; Kim, S.-I.; Lee, J.-C.; Shin, S.-J.; Kim, S.-J. Dynamic characteristics of a piezoelectric driven inkjet printhead fabricated using MEMS technology. Sens. Actuators A Phys. 2012, 173, 244–253. [Google Scholar] [CrossRef]

- Vaezi, M.; Chua, C.K. Effects of layer thickness and binder saturation level parameters on 3D printing process. Int. J. Adv. Manuf. Technol. 2011, 53, 275–284. [Google Scholar] [CrossRef]

- Lijun, L.J.L. Experimental study on fabrication of thin-wall metallic features by laser cladding. Chin. J. Mech. Eng. 2004, 10, 036. [Google Scholar]

- Xiao, Y.; Qi, L.; Huang, H.; Zeng, X.-H.; Yang, F. Design and implement of pneumatic drop-on-demand generator for metal droplet production. Trans. Beijing Inst. Technol. 2010, 30, 780–784. [Google Scholar]

- Zeng, X.; Qi, L.; Huang, H.; Li, Y.; Yang, F. Control system development and experimental study on ultrasonic vibration feeding. Chin. J. Mech. Eng. 2011, 24, 1083–1088. [Google Scholar] [CrossRef]

- Cheng, S.X.; Li, T.; Chandra, S. Producing molten metal droplets with a pneumatic droplet-on-demand generator. J. Mater. Process. Technol. 2005, 159, 295–302. [Google Scholar] [CrossRef]

- Cao, W.; Miyamoto, Y. Freeform fabrication of aluminum parts by direct deposition of molten aluminum. J. Mater. Process. Technol. 2006, 173, 209–212. [Google Scholar] [CrossRef]

- Chun, J.-H.; Passow, C.H. Production of Charged Uniformly Sized Metal Droplets. U.S. Patent 5266098, 30 November 1993. [Google Scholar]

- Orme-Marmerelis, M.; Smith, R.F. High-Speed Fabrication of Highly Uniform Metallic Microspheres. U.S. Patent 6562099, 18 May 2003. [Google Scholar]

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, Z.; Zheng, G.; Wang, L. A Study on the Influence of the Nozzle Lead Angle on the Performance of Liquid Metal Electromagnetic Micro-Jetting. Micromachines 2016, 7, 220. https://doi.org/10.3390/mi7120220

Luo Z, Zheng G, Wang L. A Study on the Influence of the Nozzle Lead Angle on the Performance of Liquid Metal Electromagnetic Micro-Jetting. Micromachines. 2016; 7(12):220. https://doi.org/10.3390/mi7120220

Chicago/Turabian StyleLuo, Zhiwei, Gaofeng Zheng, and Lingyun Wang. 2016. "A Study on the Influence of the Nozzle Lead Angle on the Performance of Liquid Metal Electromagnetic Micro-Jetting" Micromachines 7, no. 12: 220. https://doi.org/10.3390/mi7120220