On-Chip Transportation and Measurement of Mechanical Characteristics of Oocytes in an Open Environment

Abstract

:1. Background

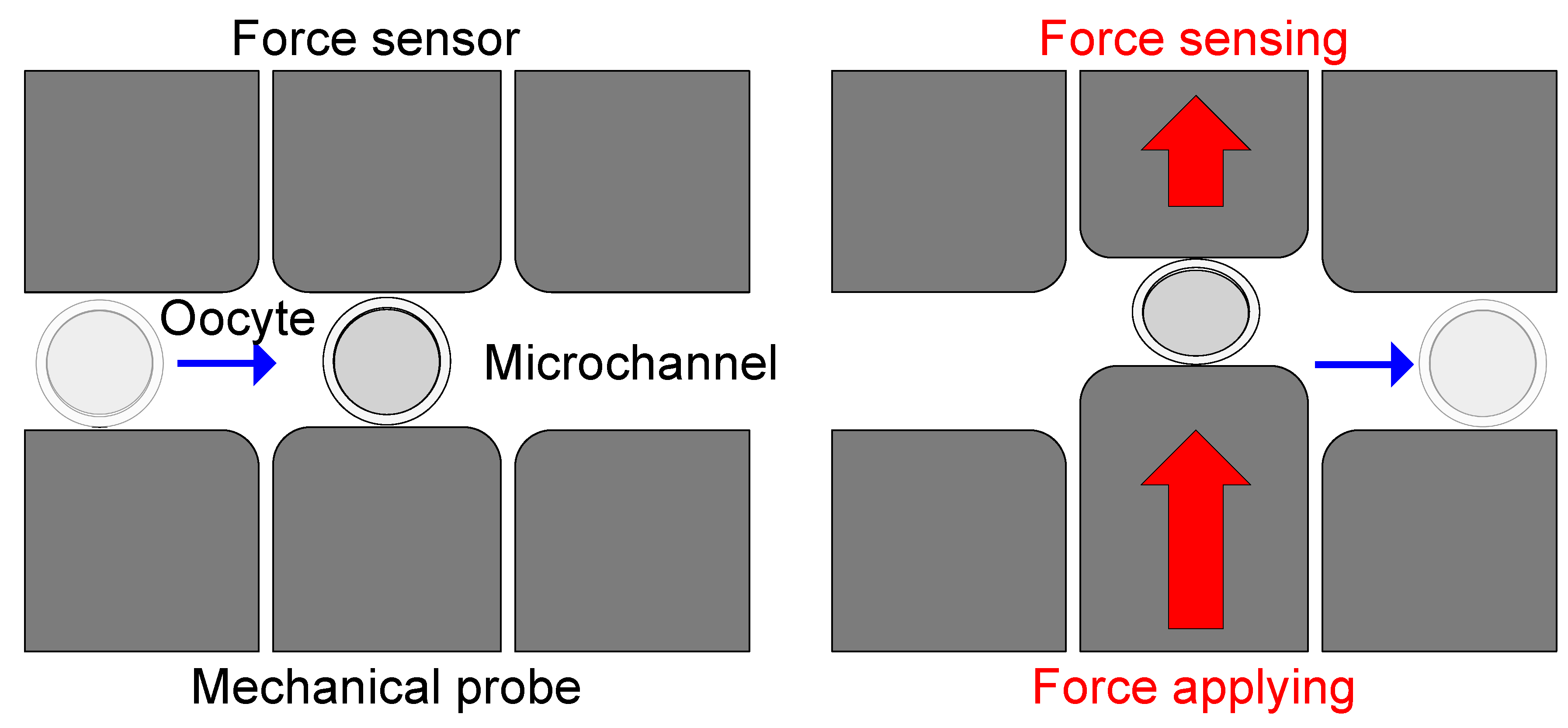

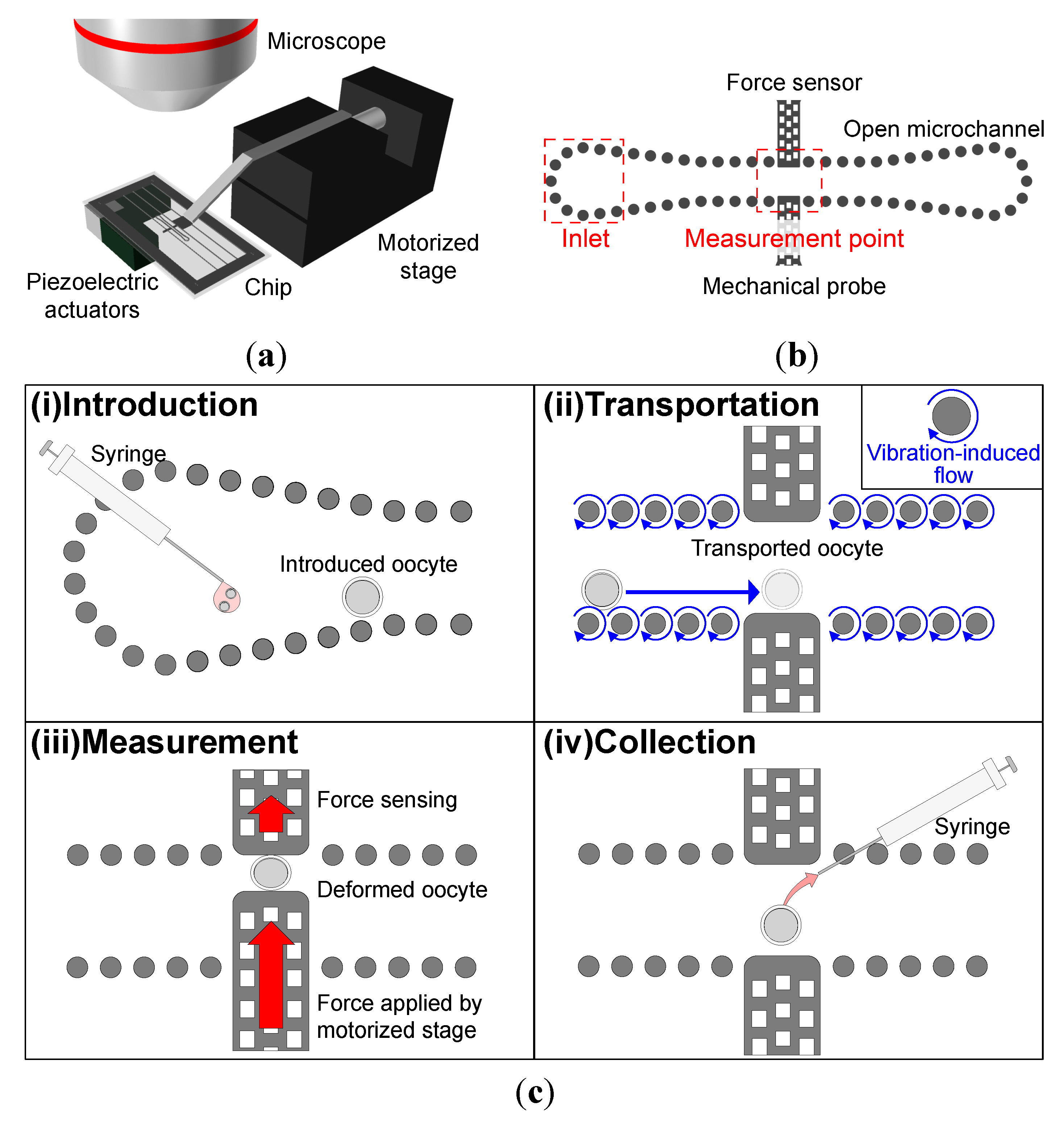

2. Concept

- (i)

- Introduction: An oocyte is introduced to the chip. By virtue of the open microchannel, oocytes can be introduced by merely dropping the oocyte-containing culture medium into the channel.

- (ii)

- Transportation: By applying circular vibration to the chip, local flow can be generated around each micropillar. Thus, we can transport the oocyte by patterning micropillar array on the chip and applying circular vibration to the chip. We can transport the oocyte along micropillar array towards the measurement point by a vibration-induced flow. By stopping the circular vibration when the oocyte reaches the measurement point, we can introduce the oocyte to the measurement point.

- (iii)

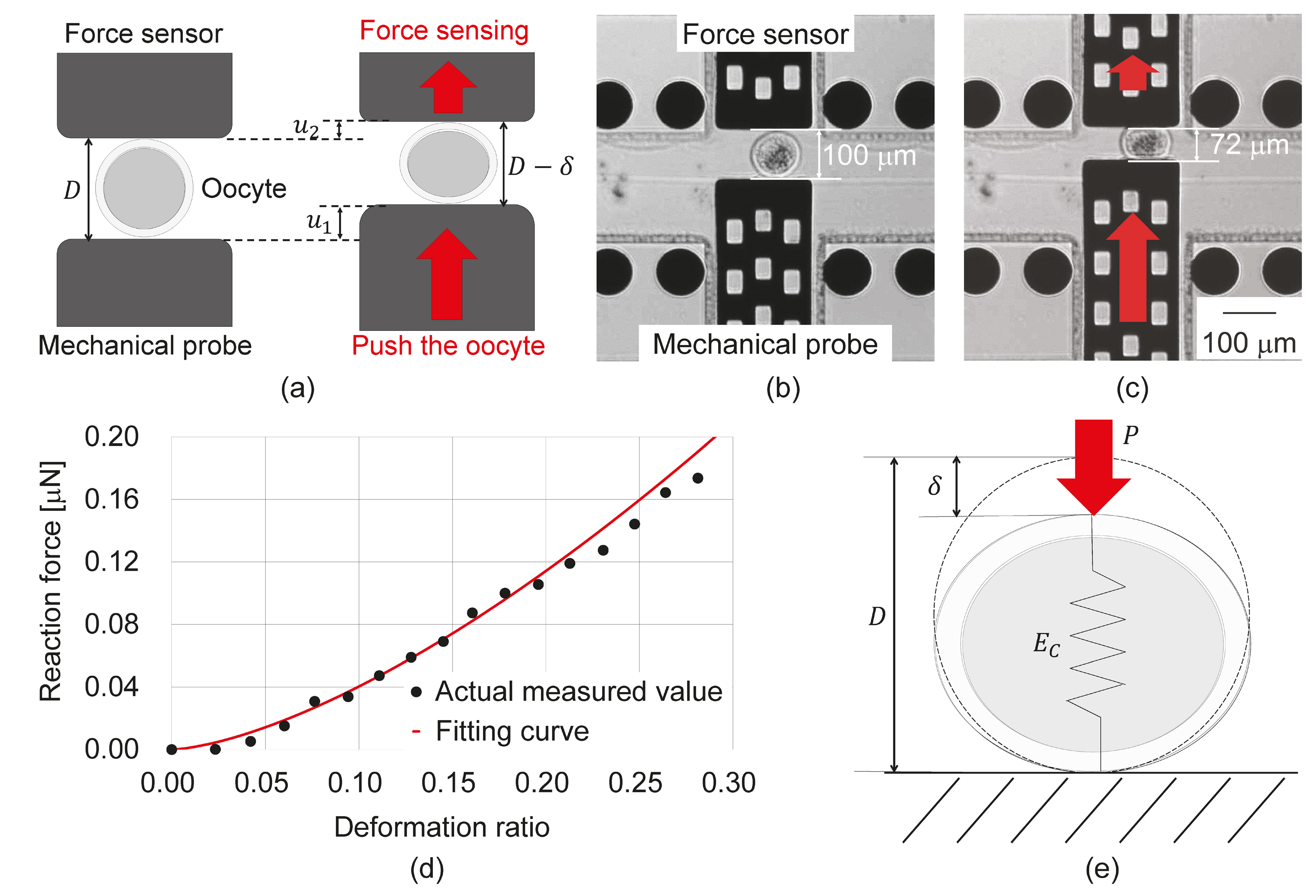

- Measurement: A mechanical probe and a force sensor are installed at the measurement point. The mechanical probe is driven by an external single-axis motorized stage, and the probe pushes the oocyte toward the force sensor. The mechanical characteristics of the oocyte are calculated from the displacement of the force sensor and the oocyte deformation.

- (iv)

- Collection: The oocyte is collected after measurement. Similar to step (i), the oocyte can be collected by aspirating it with a syringe.

3. Experimental Section

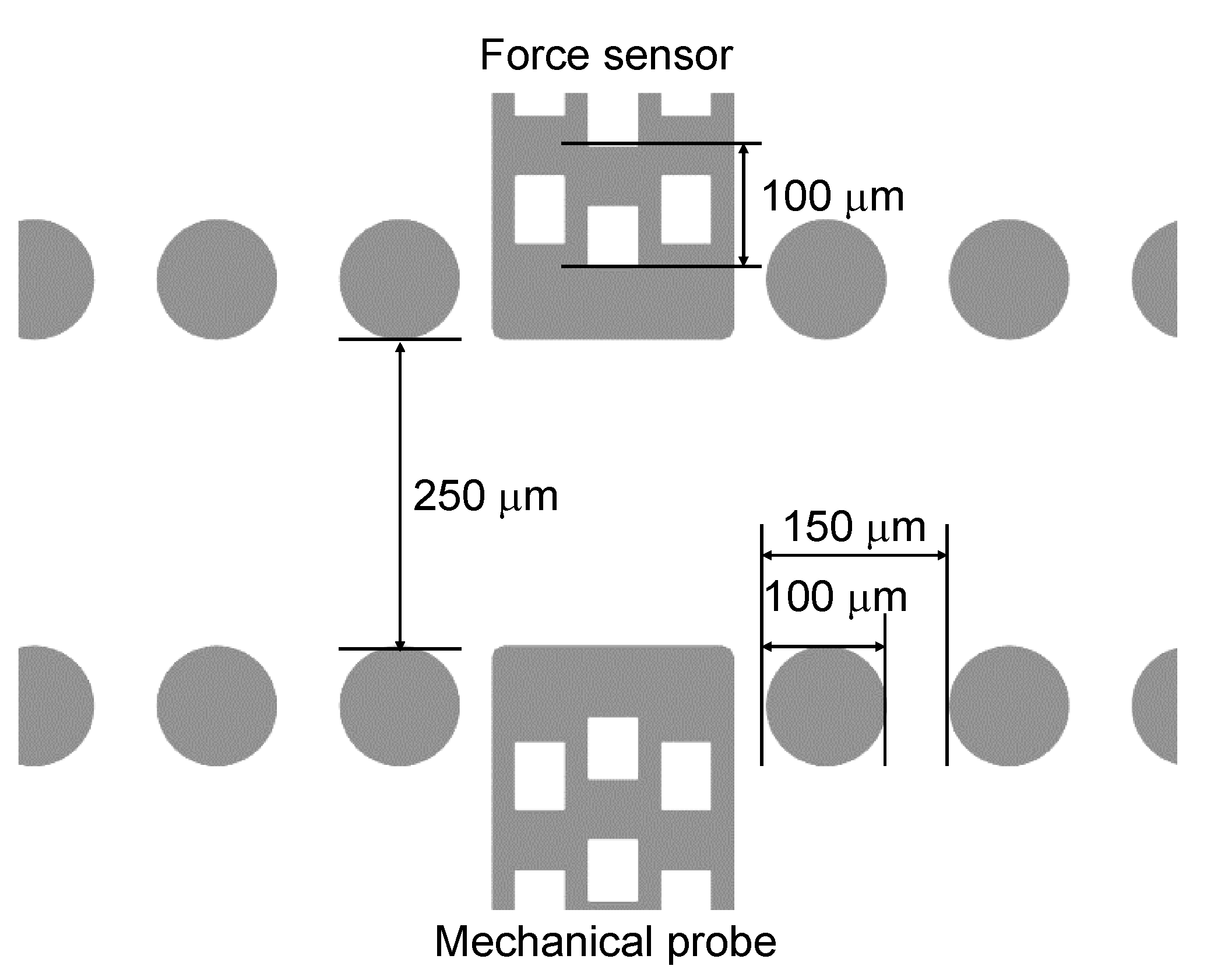

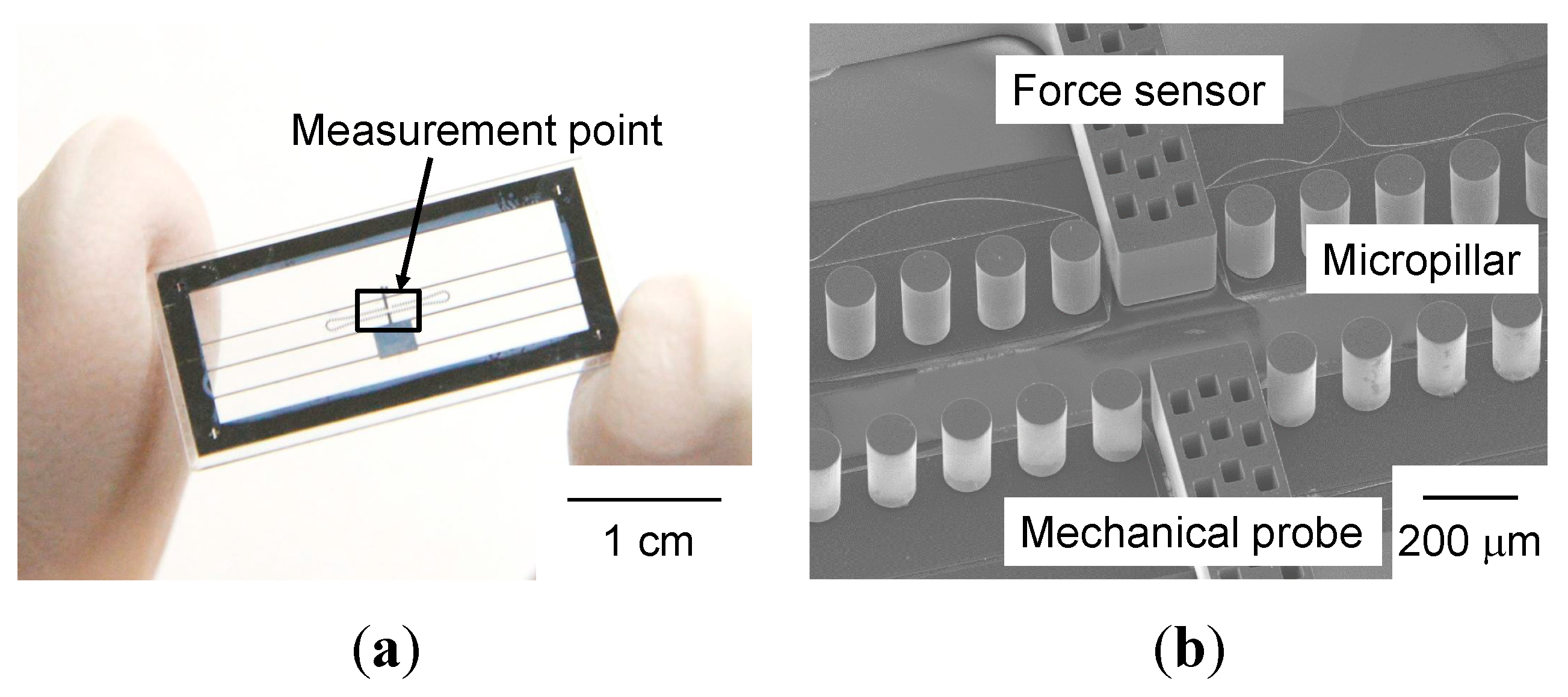

3.1. Chip Design

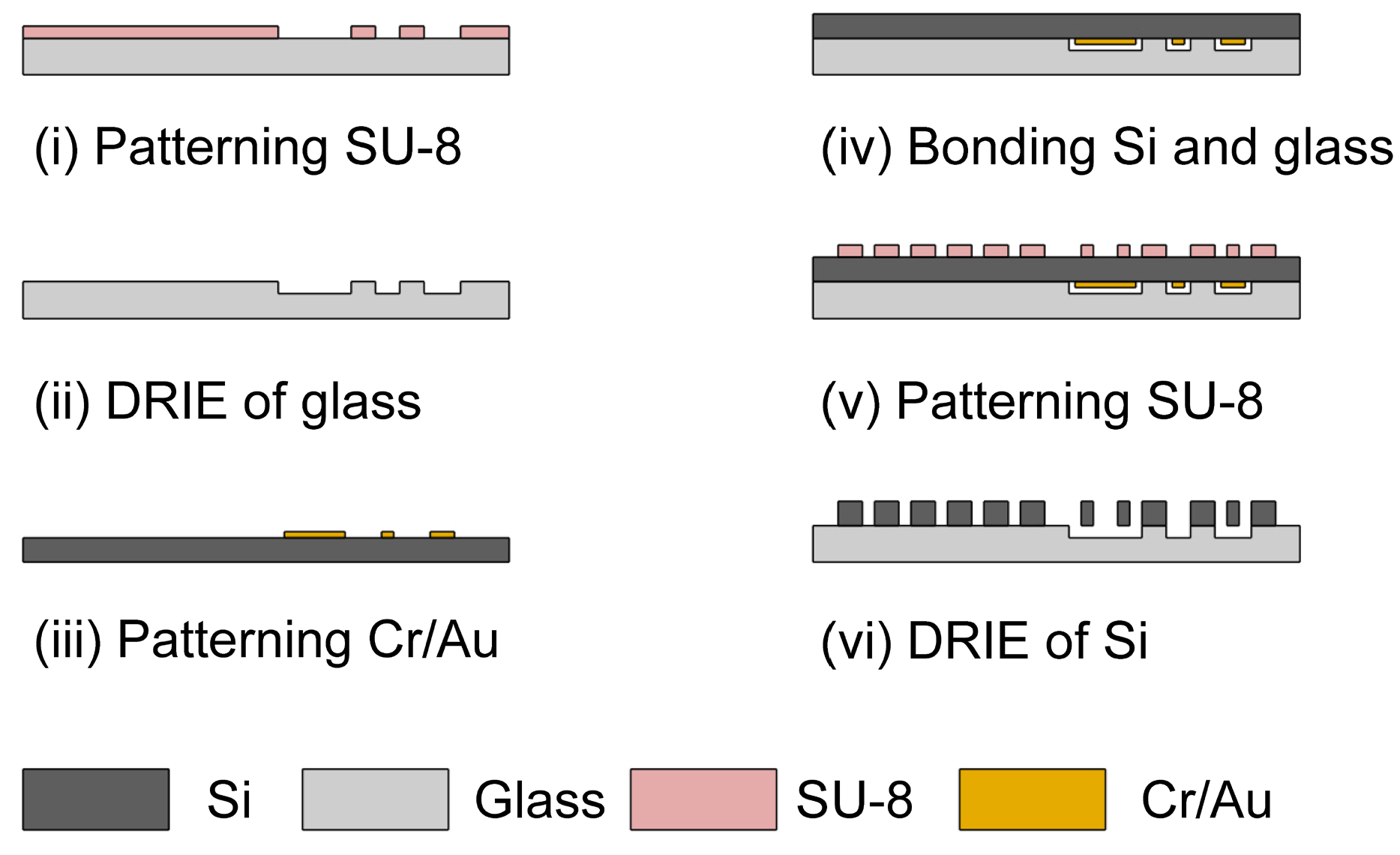

3.2. Chip Fabrication

3.3. System Setup

3.4. Sample Cell Preparation

4. Results

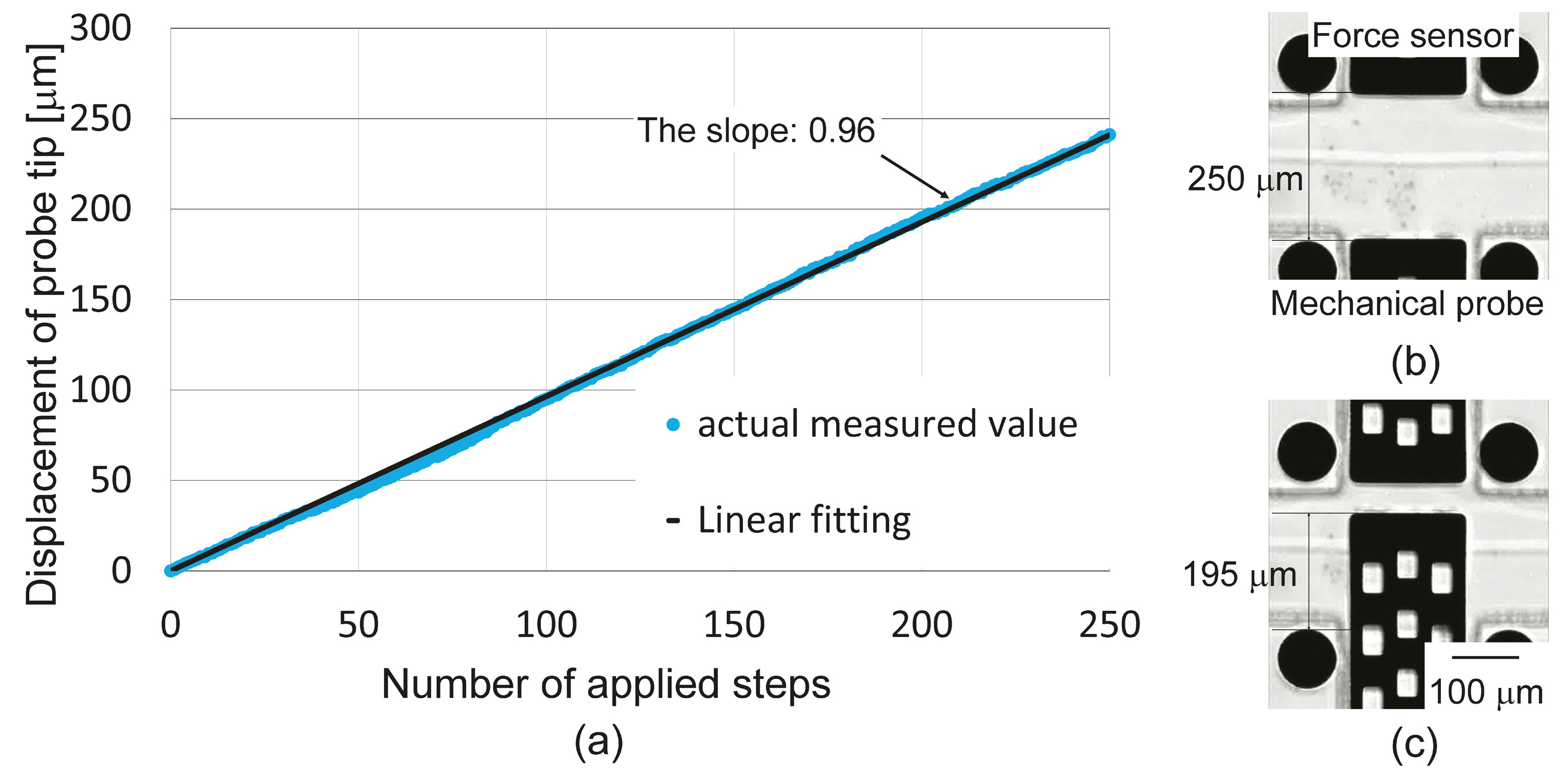

4.1. Evaluation of Mechanical Probe

4.2. Introduction of Oocytes

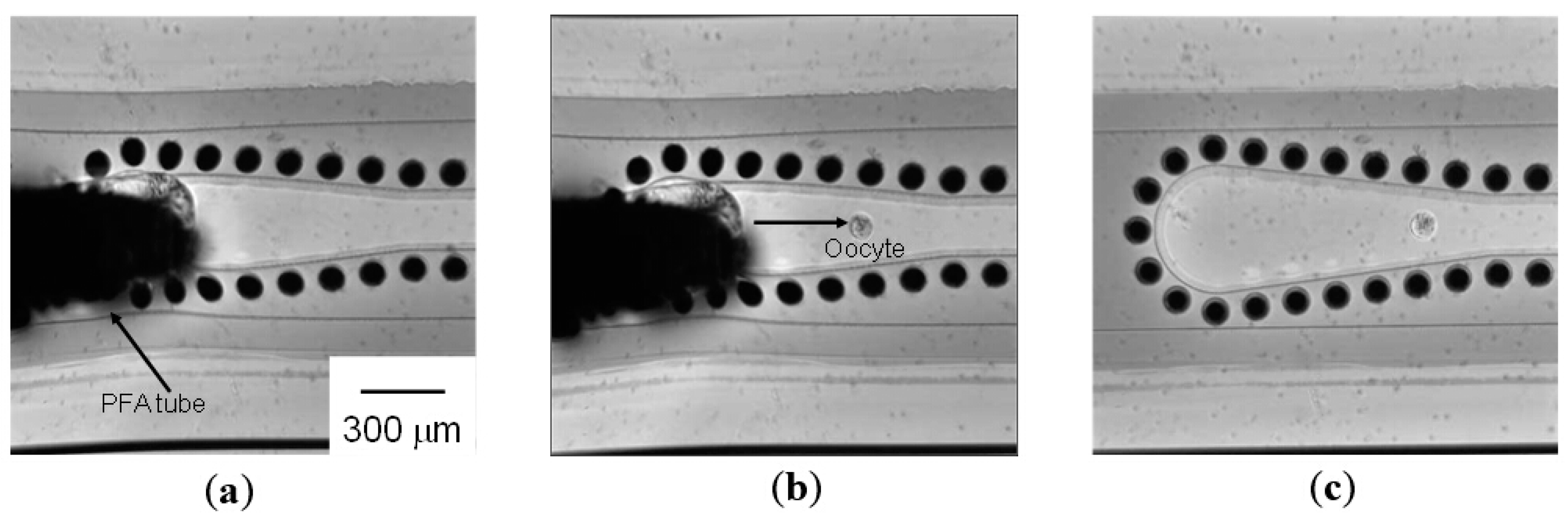

4.3. Transportation of Oocytes

4.4. Measurement of Mechanical Characteristics of Oocytes

| Sample No. | Diameter (μm) | Ec (Pa) |

|---|---|---|

| 1 | 100 | 203.2 |

| 2 | 96 | 404.6 |

| 3 | 97 | 367.5 |

| 4 | 108 | 222.0 |

| 5 | 96 | 381.8 |

| 6 | 99 | 224.2 |

| 7 | 97 | 406.0 |

| 8 | 97 | 332.8 |

| 9 | 102 | 281.4 |

4.5. Oocyte Viability Evaluation

5. Conclusions

Acknowledgments

Author Contributions

Supplementary Materials

Conflicts of Interest

References

- Sun, Y.; Wan, K.-T.; Roberts, K.P.; Bischof, J.C.; Nelson, B.J. Mechanical property characterization of mouse zona pellucida. IEEE Trans. Nanobiosci. 2003, 2, 279–286. [Google Scholar] [CrossRef]

- Jaasma, M.J.; Jackson, W.M.; Keaveny, T.M. Measurement and characterization of whole-cell mechanical behavior. Ann. Biomed. Eng. 2006, 34, 748–758. [Google Scholar] [CrossRef] [PubMed]

- Wacogne, B.; Pieralli, C.; Roux, C.; Gharbi, T. Measuring the mechanical behavior of human oocytes with a very simple SU-8 micro-tool. Biomed. Microdevices. 2008, 10, 411–419. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Fernandes, R.; Jurisicova, A.; Casper, R.F.; Sun, Y. In situ measurement of mechanical characteristics of mouse oocytes using a cell holding device. Lab Chip 2010, 10, 2154–2161. [Google Scholar] [CrossRef] [PubMed]

- Khalilian, M.; Navidbakhsh, M.; Valojerdi, M.R.; Chizari, M.; Yazdi, P.E. Estimating young’s modulus of zona pellucida by micropipette aspiration in combination with theoretical models of ovum. J. R. Soc. Interface 2010, 7, 687–694. [Google Scholar] [CrossRef] [PubMed]

- Murayama, Y.; Mizuno, J.; Kamakura, H.; Fueta, Y.; Nakamura, H.; Akaishi, K.; Anzai, K.; Watanabe, A.; Inui, H.; Omata, S. Mouse zona pellucida dynamically changes its elasticity during oocyte maturation, fertilization and early embryo development. Hum. Cell 2006, 19, 119–125. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Nelson, B.J.; Greminger, M.A. Investigating protein structure change in the zona pellucida with a microrobotic system. Int. J. Robot. Res. 2005, 24, 211–218. [Google Scholar] [CrossRef]

- Lyons, A.B. Analysing cell division in vivo and in vitro using flow cytometric measurement of CFSE dye dilusion. J. Immunol. Methods 2000, 243, 147–154. [Google Scholar] [CrossRef] [PubMed]

- Cillo, F.; Brevini, A.L.; Antonini, S.; Paffioni, A.; Ragni, G.; Gandolfi, F. Assocaiation between human oocyte developmental competence and expression levels of some cumulus genes. Reproduction 2007, 134, 645–650. [Google Scholar] [CrossRef] [PubMed]

- Beer, D.D.; Stoodley, P.; Lewandowski, Z. Measurement of local diffusion coefficients in biofilms by microinjection and confocal microscopy. Biotechnol. Bioeng. 1997, 53, 151–158. [Google Scholar] [CrossRef] [PubMed]

- Lyng, H.; Haraldseth, O.; Rofstad, E.K. Measurement of cell density and necrotic fraction in human melanoma xenografts by diffusion weighted magnetic resonance imaging. Magnet Reson. Med. 2000, 43, 828–836. [Google Scholar] [CrossRef]

- Rizos, D.; Ward, F.; Duffy, P.; Boland, M.P.; Lonergan, P. Consequences of bovine oocyte maturation, fertilization or early embryo development in vitro versus in vivo: Implications for blastocyst yield and blastocyst quality. Mol. Reprod. Dev. 2002, 61, 234–248. [Google Scholar] [CrossRef] [PubMed]

- Fujino, Y.; Ozaki, K.; Yamamasu, S.; Ito, F.; Matsuoka, I.; Hayashi, E.; Nakamura, H.; Ogita, S.; Sato, E.; Inoue, M. DNA fragmentation of oocytes in aged mice. Hum. Reprod. 1996, 11, 1480–1483. [Google Scholar] [CrossRef] [PubMed]

- Sakuma, S.; Kuroda, K.; Tsai, C.-H.D.; Fukui, W.; Arai, F.; Kaneko, M. Red blood cell fatigue evaluation based on the close-encountering point between extensibility and recoverability. Lab. Chip 2014, 14, 1135–1141. [Google Scholar] [CrossRef] [PubMed]

- Gossett, D.R.; Tse, H.T.K.; Lee, S.A.; Ying, Y.; Lindgren, A.G.; Yang, O.O.; Rao, J.; Clark, A.T.; Carlo, D.D. Hydrodynamic stretching of single cells for large population mechanical phenotyping. Proc. Natl. Acad. Sci. USA 2012, 109, 7630–7635. [Google Scholar] [CrossRef] [PubMed]

- Sakuma, S.; Turan, B.; Arai, F. High throughput measurement of mechanical characteristics of oocyte using robot integrated microfluidic chip. In Proceedings of 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Tokyo, Japan, 3–7 November 2013; pp. 2047–2052.

- Sakuma, S.; Arai, F. Cellular force measurement using a nanometric-probe-integrated microfluidic chip with a displacement reduction mechanism. J. R. M. 2013, 25, 277–284. [Google Scholar]

- Ashkin, A.; Dziedzic, J.M. Optical trapping and manipulation of viruses and bacteria. Science 1987, 235, 1517–1520. [Google Scholar] [CrossRef] [PubMed]

- Ashkin, A.; Dziedzic, J.M.; Yamane, T. Optical trapping and manipulation of single cells using infrared laser beams. Nature 1987, 330, 769–771. [Google Scholar] [CrossRef] [PubMed]

- Yeo, L.Y.; Friend, J.R. Ultrafast microfluidics using surface acoustic waves. Biomicrofluidics 2009, 3, 012002. [Google Scholar] [CrossRef]

- Voldman, J.; Gray, M.L.; Toner, M.; Schmidt, M.A. A microfabrication-based dynamic array cytometer. Anal. Chem. 2002, 74, 3984–3990. [Google Scholar] [CrossRef] [PubMed]

- Chiou, P.Y.; Ohta, A.T.; Wu, M.C. Massively parallel manipulation of single cells and microparticles using optical images. Nature 2005, 436, 370–372. [Google Scholar] [CrossRef] [PubMed]

- Hayakawa, T.; Sakuma, S.; Fukuhara, T.; Yokoyama, Y.; Arai, F. A single cell extraction chip using vibration-induced whirling flow and a thermo-responsive gel pattern. Micromachines 2014, 5, 681–696. [Google Scholar] [CrossRef]

- Sugiura, H.; Sakuma, S.; Kaneko, M.; Arai, F. On-chip measurement of cellular mechanical properties using moiré fringe. In Proceedings of 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015.

- Ri, S.; Fujigaki, M.; Morimoto, Y. Sampling moiré method for accurate small deformation distribution measurement. Exp. Mech. 2010, 50, 501–508. [Google Scholar] [CrossRef]

- Nakao, K.; Nakagata, N.; Katsuki, M. Simple and efficient vitrification procedure for cryopreservation of mouse embryos. Exp. Anim. 1997, 46, 231–234. [Google Scholar] [CrossRef] [PubMed]

- Bacabac, R.G.; Mizuno, D.; Schmidt, C.F.; MacKintosh, F.C.; van Loon, J.J.; Klein-Nulend, J.; Smit, T.H. Round versus flat: Bone cell morphology, elasticity, and mechanosensing. J. Appl. Biomech. 2008, 41, 1590–1598. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nakahara, K.; Sakuma, S.; Hayakawa, T.; Arai, F. On-Chip Transportation and Measurement of Mechanical Characteristics of Oocytes in an Open Environment. Micromachines 2015, 6, 648-659. https://doi.org/10.3390/mi6050648

Nakahara K, Sakuma S, Hayakawa T, Arai F. On-Chip Transportation and Measurement of Mechanical Characteristics of Oocytes in an Open Environment. Micromachines. 2015; 6(5):648-659. https://doi.org/10.3390/mi6050648

Chicago/Turabian StyleNakahara, Kou, Shinya Sakuma, Takeshi Hayakawa, and Fumihito Arai. 2015. "On-Chip Transportation and Measurement of Mechanical Characteristics of Oocytes in an Open Environment" Micromachines 6, no. 5: 648-659. https://doi.org/10.3390/mi6050648