SU-8 Electrothermal Actuators: Optimization of Fabrication and Excitation for Long-Term Use

Abstract

:1. Introduction

2. Actuator Design Approach and Fabrication Process Using Surface Micromachining

2.1. The Pseudo-Bimorph Actuator Design

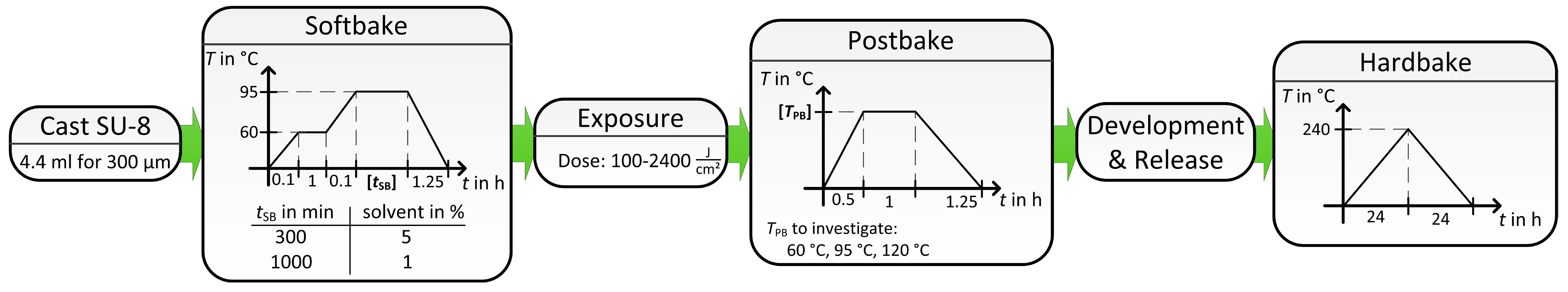

2.2. The Fabrication Process

3. Optimization of the SU-8 Process for Maximum Mechanical and Temperature Stability

3.1. Analysis of SU-8 Fabrication and Deduction of Test Parameters

| Set | mSolv in % | ϑPB in °C |

|---|---|---|

| I | 1 | 60 |

| II | 5 | 60 |

| III | 1 | 95 |

| IV | 5 | 95 |

| V | 1 | 120 |

| VI | 5 | 120 |

3.2. Degree of Cross-Linking

3.3. Glass Transition Temperature

3.4. Discussion

4. Long-term Stability of Electrothermal Actuators and Limits of Operation

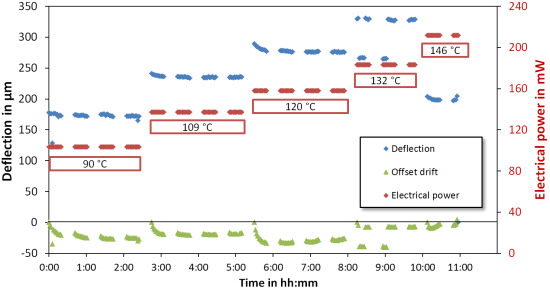

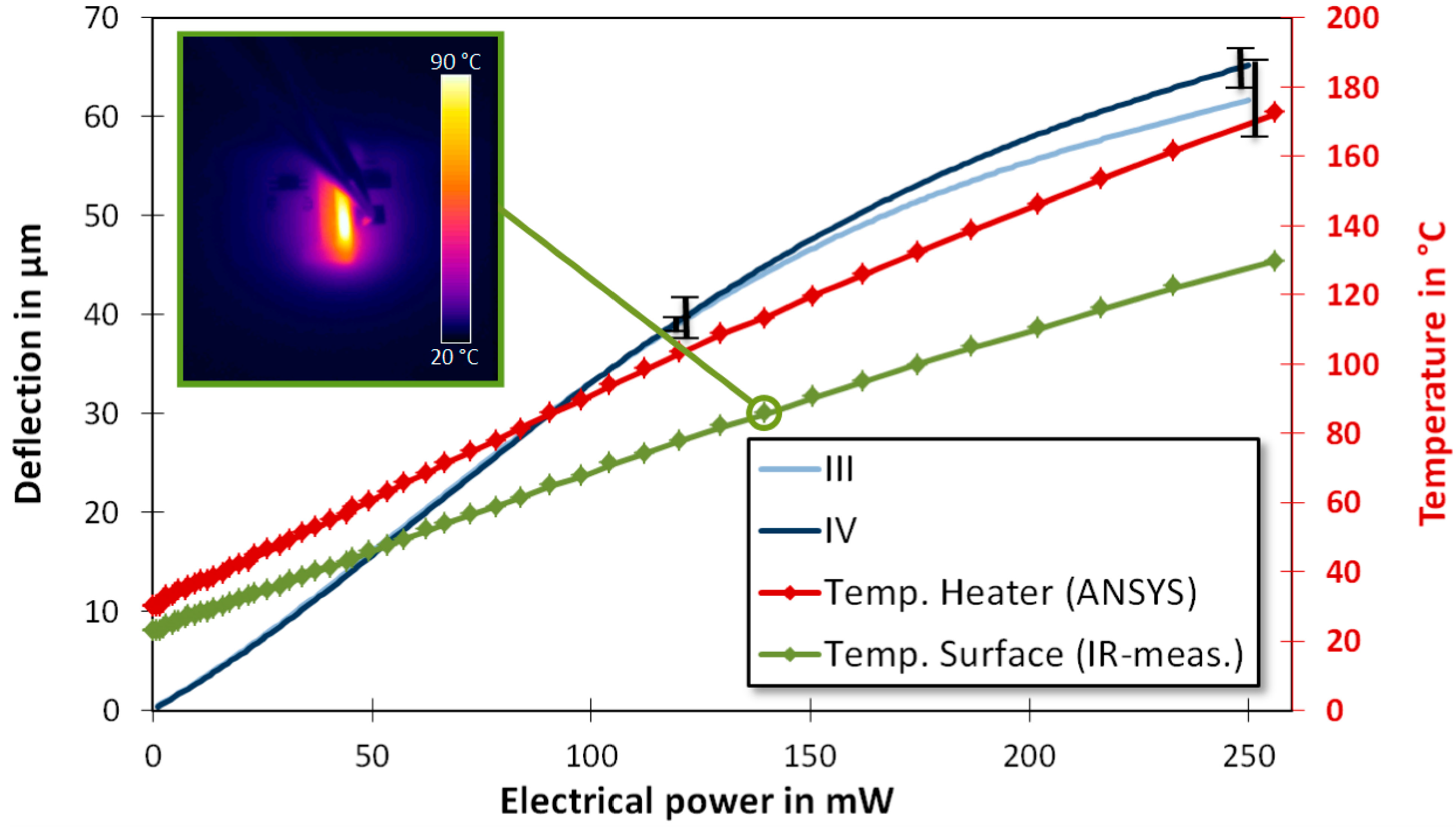

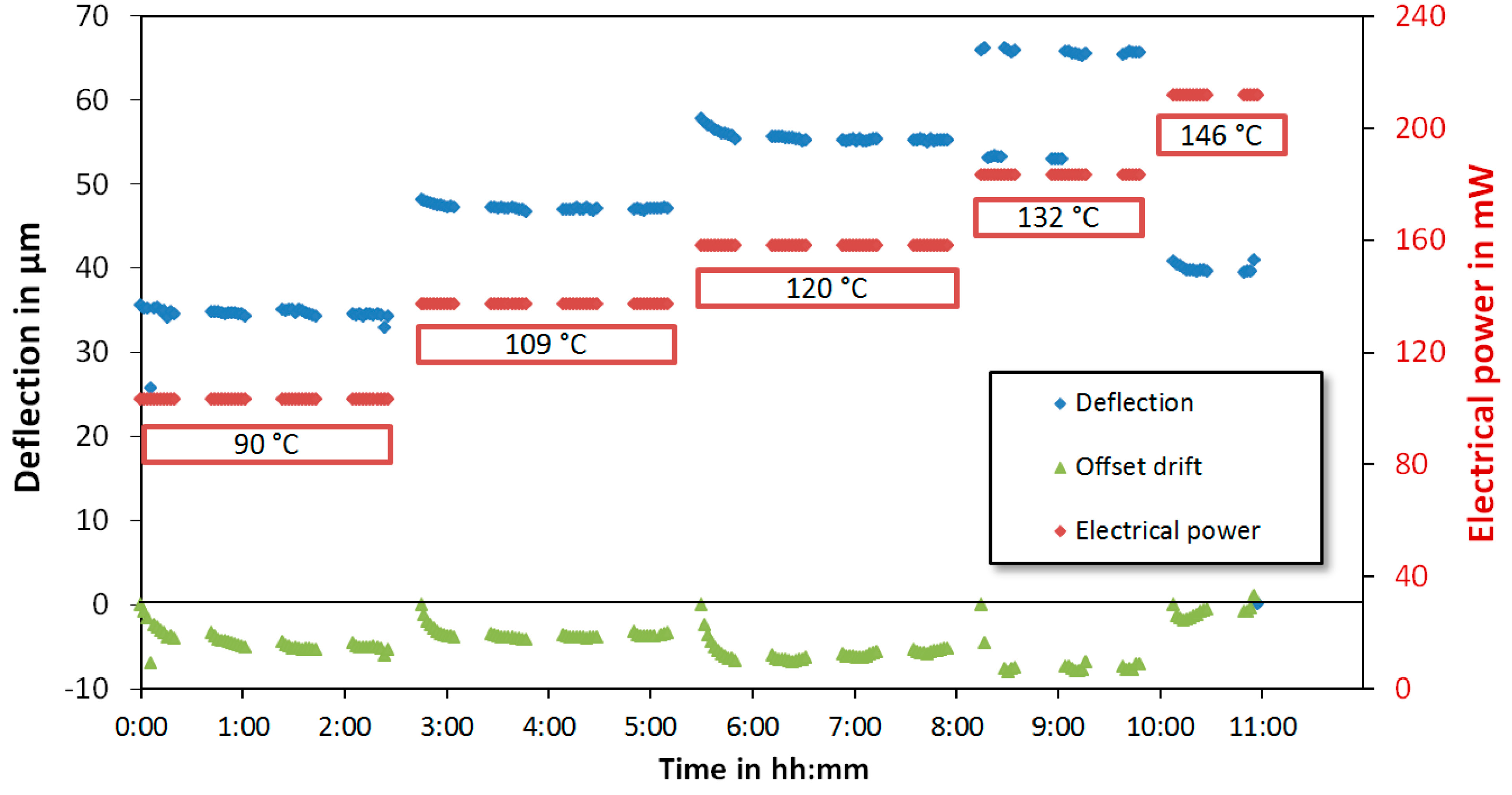

4.1. Static Actuator Operation

4.2. Dynamic Actuator Operation

5. Conclusions and Outlook

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Park, D.S.W.; Nallani, A.K.; Cha, D.; Lee, G.S.; Kim, M.J.; Skidmore, G.; Lee, J.B.; Lee, J.S. A sub-micron metallic electrothermal gripper. Microsyst. Technol. 2010, 16, 367–373. [Google Scholar] [CrossRef]

- Lee, J.S.; Park, D.S.W.; Nallani, A.K.; Lee, G.S.; Lee, J.B. Sub-micron metallic electrothermal actuators. J. Micromech. Microeng. 2005, 15, 322–327. [Google Scholar] [CrossRef]

- Carlson, K.; Andersen, K.N.; Eichhorn, V.; Petersen, D.H.; Mølhave, K.; Bu, I.Y.Y.; Teo, K.B.K.; Milne, W.I.; Fatikow, S.; Bøggild, P. A carbon nanofibre scanning probe assembled using an electrothermal microgripper. Nanotechnology 2007, 18, 345501. [Google Scholar] [CrossRef]

- Akiyama, T.; Staufer, U.; de Rooij, N.F.; Lange, D.; Hagleitner, C.; Brand, O.; Baltes, H.; Tonin, A.; Hidber, H.R. Integrated atomic force microscopy array probe with metal-oxide-semiconductor field effect transistor stress sensor, thermal bimorph actuator, and on-chip complementary metal-oxide-semiconductor electronics. J. Vac. Sci. Technol. B 2000, 18, 2669–2675. [Google Scholar] [CrossRef]

- Ebefors, T.; Kälvesten, E.; Stemme, G. Dynamic actuation of polyimide V-groove joints by electrical heating. Sens. Actuators A Phys. 1998, 67, 199–204. [Google Scholar] [CrossRef]

- Nakic, C.; Staab, M.; Dörr, R.; Schlaak, H.F. Polymer in-plane electrothermal actuators fabricated by UV-lithography versus micro-milling of PEEK. In Proceedings of 14th International Conference on New Actuators and 8th International Exhibition on Smart Actuators and Drive Systems, Bremen, Germany, 23–25 June 2014; pp. 398–401.

- Kopka, P.; Hoffmann, M.; Voges, E. Coupled U-shaped cantilever actuators for 1 × 4 and 2 × 2 optical fibre switches. J. Micromech. Microeng. 2000, 10, 260–264. [Google Scholar] [CrossRef]

- Chronis, N.; Lee, L.P. Electrothermally activated SU-8 microgripper for single cell manipulation in solution. J. Microelectromechan. Syst. 2005, 14, 857–863. [Google Scholar] [CrossRef]

- Lee, J.S.; Park, D.S.; Nallani, A.K.; Yonghao, C.; Skoyles, A.; Lee, J.B. High-Aspect Ratio Metallic Nano Grippers. In Proceedings of International Conference on Nano/Micro Engineered and Molecular Systems, Zhuhai, China, 18–21 January 2006; pp. 682–686.

- Mackay, R.E.; Le, H.R.; Keatch, R.P. Design optimisation and fabrication of SU-8 based electro-thermal micro-grippers. J. Micro-Nano Mechatron. 2011, 6, 13–22. [Google Scholar] [CrossRef]

- Qui, J.; Lang, J.H.; Slocum, A.H.; Strumpler, R. A high-current-current electrothermal bistable MEMS relay. In Proceedings of 6th IEEE International Conference on Micro Electro Mechanical Systems, Kyoto, Japan, 23 January 2003; pp. 64–67.

- Staab, M.; Schlaak, H.F. Novel electrothermally actuated magnetostatic bistable microrelay for telecommunication applications. In Proceedings of 24th IEEE International Conference on Micro Electro Mechanical Systems, Cancun, Mexico, 23–27 January 2011; pp. 1261–1264.

- Girbau, D.; Roldan, A.M.; Pradell, L. RF MEMS switches based on the buckle-beam thermal actuator. In Proceedings of 33th European Microwave Conference, Munich, Germany, 9 October 2003; Volum 2, pp. 651–654.

- Winterstein, T.; Schlaak, H.F. Normally latched linear inchworm drive with electrothermal actuation for fluidic applications. In Proccedings of ACTUATOR12, 13th International Conference on New Actuators and 7th International Exhibition on Smart Actuators and Drive Systems, Bremen, Germany, 18–20 June 2012; pp. 713–716.

- Lorenz, H.; Laudon, M.; Renaud, P. Mechanical characterization of a new high-aspect-ratio near UV-photoresist. Microelectron. Eng. 1998, 41–42, 371–374. [Google Scholar] [CrossRef]

- Staab, M.; Schlaak, H.F. Indirectly Heated Electrothermal Actuator for a Magnetostatic Bistable Micro Actuator System. In Proceedings of 12th International Conference on New Actuators and 6th International Exhibition on Smart Actuators and Drive Systems, Bremen, Germany, 14–16 June 2010; pp. 356–360.

- Winterstein, T.; Schlaak, H.F. Electrothermal pseudo bimorph actuators made of SU-8 with improved mechanical performance. In Proceedings of ACTUATOR14,14th International Conference on New Actuators and 8th International Exhibition on Smart Actuators and Drive Systems, Bremen, Germany, 23–25 June 2014; pp. 609–612.

- Feng, R.; Farris, R.J. Influence of processing conditions on the thermal and mechanical properties of SU-8 negative photoresist coatings. J. Micromech. Microeng. 2003, 13, 80–88. [Google Scholar] [CrossRef]

- Barber, R.L.; Ghantasala, M.K.; Divan, R.; Vora, K.D.; Harvey, E.C.; Mancini, D.C. Optimisation of SU-8 processing parameters for deep X-ray lithography. Microsyst. Technol. 2005, 11, 303–310. [Google Scholar] [CrossRef]

- Kouba, J.; Bednarzik, M.; Engelke, R.; Ahrens, G.; Miller, H.; Haase, D. Optimizing SU-8 resist to fabricate micro-metallic structures. Solid State Technol. 2006, 49, 39–44. [Google Scholar]

- Sameoto, D.; Tsang, S.H.; Foulds, I.G.; Lee, S.W.; Parameswaran, M. Control of the out-of-plane curvature in SU-8 compliant microstructures by exposure dose and baking times. J. Micromech. Microeng. 2007, 17, 1093–1098. [Google Scholar] [CrossRef]

- Tan, T.L.; Wong, D.; Lee, P.; Rawat, R.S.; Springham, S.; Patran, A. Characterization of chemically amplified resist for X-ray lithography by Fourier transform infrared spectroscopy. Thin Solid Films 2006, 504, 113–116. [Google Scholar] [CrossRef]

- Ehrenstein, G.W.; Riedel, G.; Trawiel, P. Thermal Analysis of Plastics: Theory and Practice; Carl Hanser Verlag GmbH Co KG: Munich, Germany, 2012. [Google Scholar]

- Vogel, J.; Feige, H.-J.; Saupe, J.; Schubert, S.; Grimm, J. In Experimental analysis of thermo-mechanical material properties of photosensitive polymers. In Proceedings of 11th Youth Symposium on Experimental Solid Mechanics, Brasov, Romania, 30 May–02 June 2014; pp. 61–66.

- Vogel, J.; Feige, H.-J.; Saupe, J.; Schubert, S.; Grimm, J. Mechanical material characterization of photosensitive polymers. Microsyst. Technol. 2014, 20, 1975–1979. [Google Scholar] [CrossRef]

- Robin, C.J.; Vishnoi, A.; Jonnalagadda, K.N. Mechanical behavior and anisotropy of spin-coated SU-8 thin films for MEMS. J. Microelectromech. Syst. 2014, 23, 168–180. [Google Scholar] [CrossRef]

- Wouters, K.; Puers, R. Diffusing and swelling in SU-8: Insight in material properties and processing. J. Micromech. Microeng. 2010, 20, 095013. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Winterstein, T.; Staab, M.; Nakic, C.; Feige, H.-J.; Vogel, J.; Schlaak, H.F. SU-8 Electrothermal Actuators: Optimization of Fabrication and Excitation for Long-Term Use. Micromachines 2014, 5, 1310-1322. https://doi.org/10.3390/mi5041310

Winterstein T, Staab M, Nakic C, Feige H-J, Vogel J, Schlaak HF. SU-8 Electrothermal Actuators: Optimization of Fabrication and Excitation for Long-Term Use. Micromachines. 2014; 5(4):1310-1322. https://doi.org/10.3390/mi5041310

Chicago/Turabian StyleWinterstein, Thomas, Matthias Staab, Christian Nakic, Hans-Jürgen Feige, Jürgen Vogel, and Helmut F. Schlaak. 2014. "SU-8 Electrothermal Actuators: Optimization of Fabrication and Excitation for Long-Term Use" Micromachines 5, no. 4: 1310-1322. https://doi.org/10.3390/mi5041310