An Integrated Health Monitoring Method for Structural Fatigue Life Evaluation Using Limited Sensor Data

Abstract

:1. Introduction

- Perform statistical analysis for the results from the rainflow analysis to create a histogram of cyclic stress and form a fatigue damage spectrum.

- For each stress level in the fatigue damage spectrum, calculate the degree of cumulative damage using the S-N curve (of the material).

- Combine the damage contributions of each stress level using Miner’s rule.

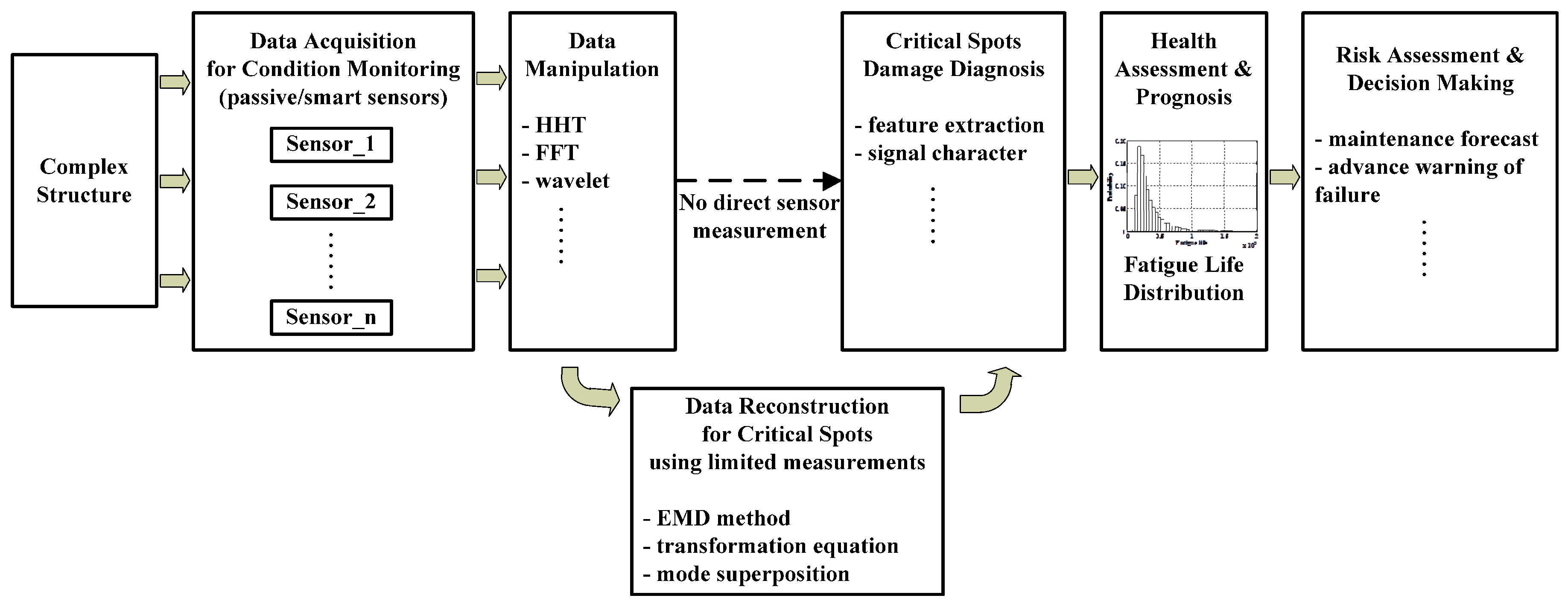

2. Integrated Health Monitoring Method Development

2.1. Strain/Stress Reconstruction Method Based on Empirical Mode Decomposition

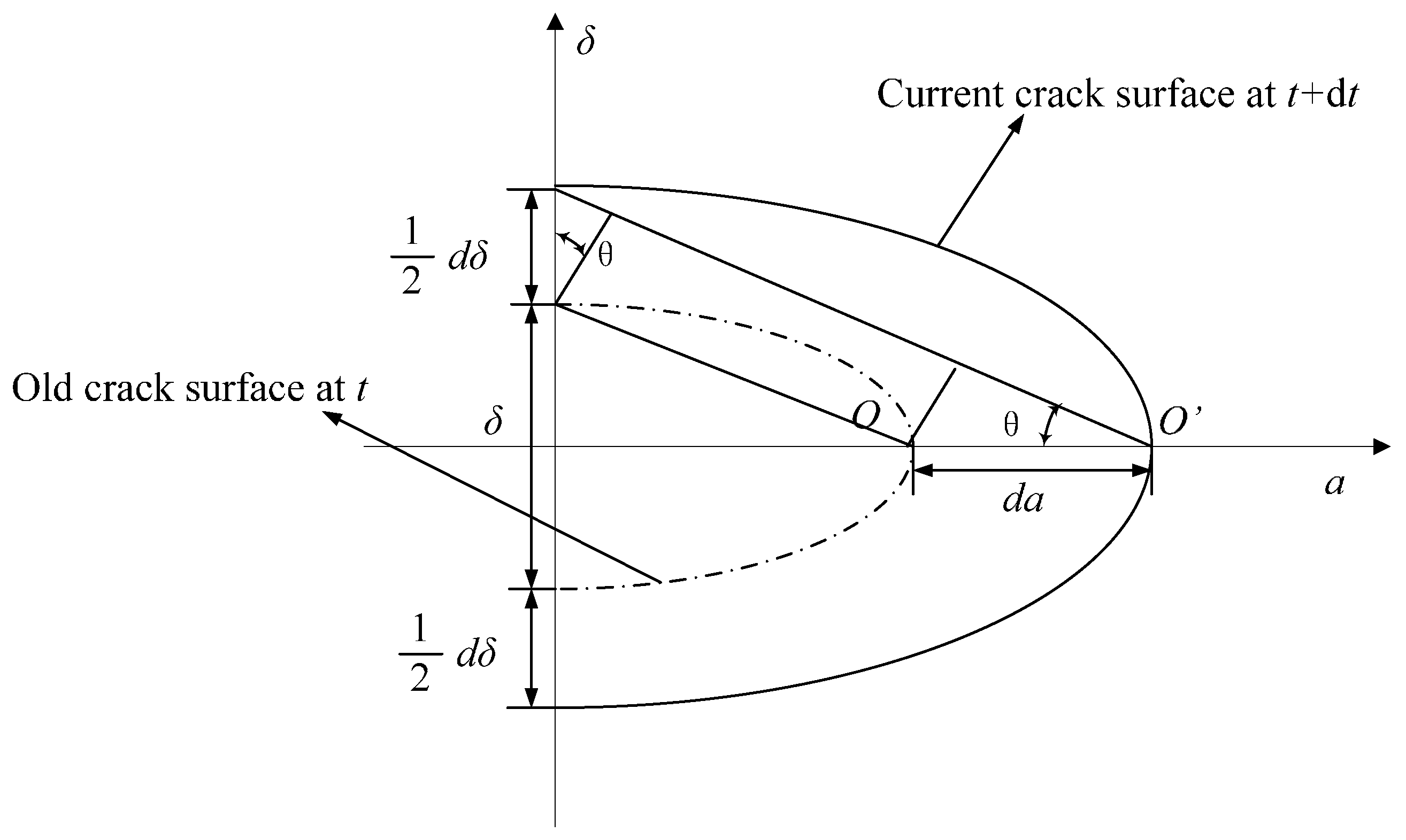

2.2. Fatigue Life Prediction Integrating Strain and Stress Reconstruction Method

3. Example Validation

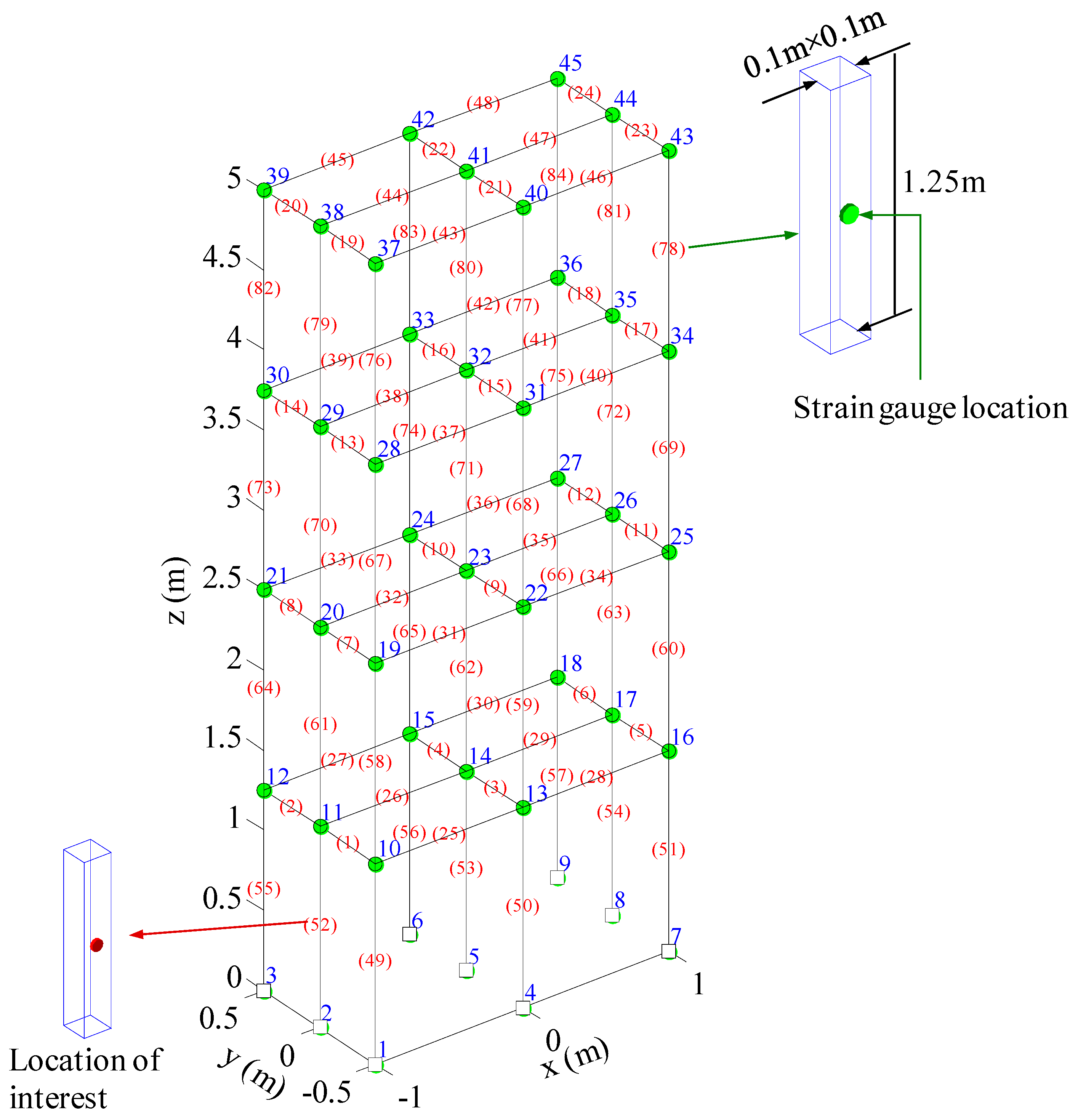

3.1. A Three-Dimensional Frame Structure Example

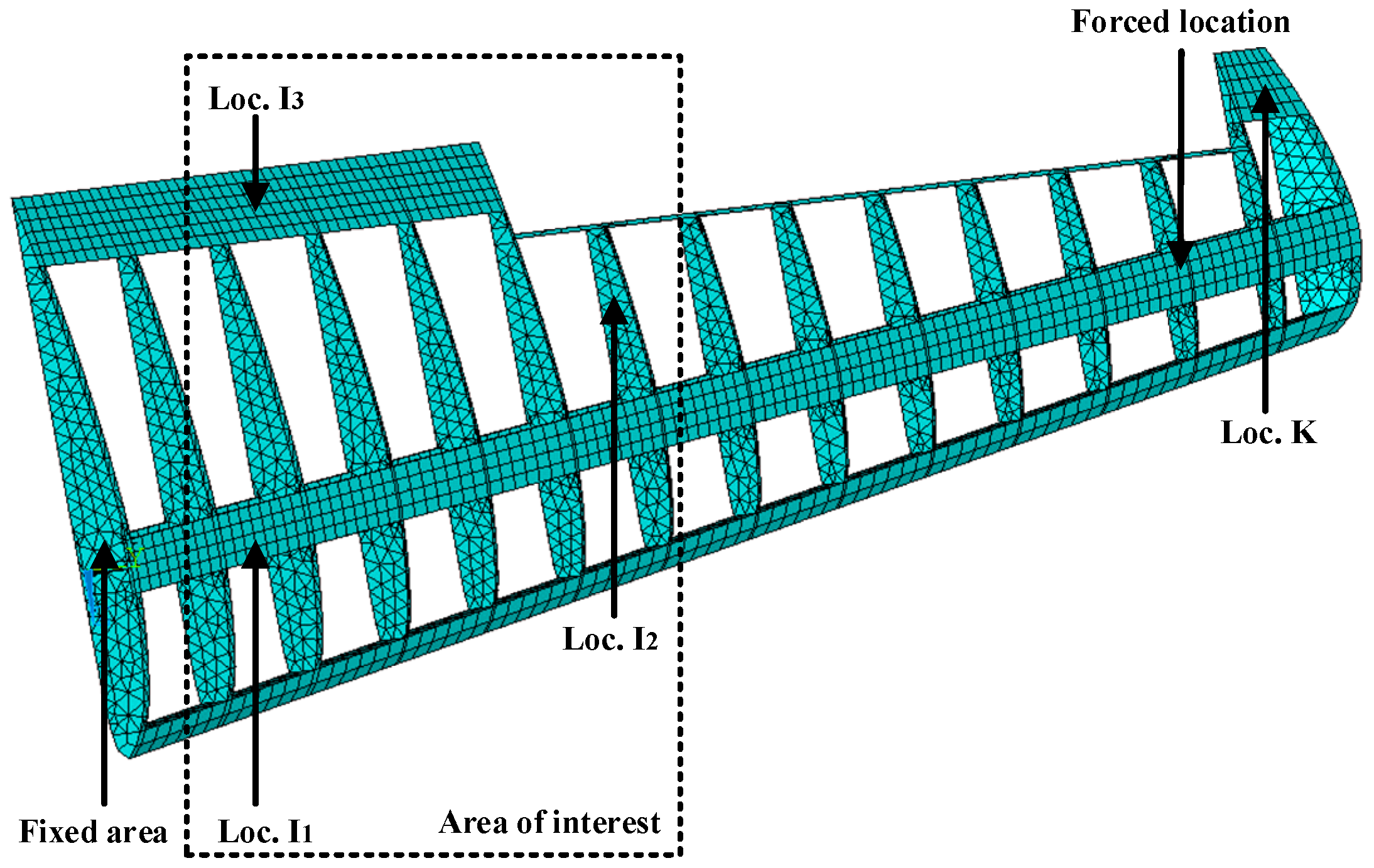

3.2. A Simplified Airfoil Structure Model Example

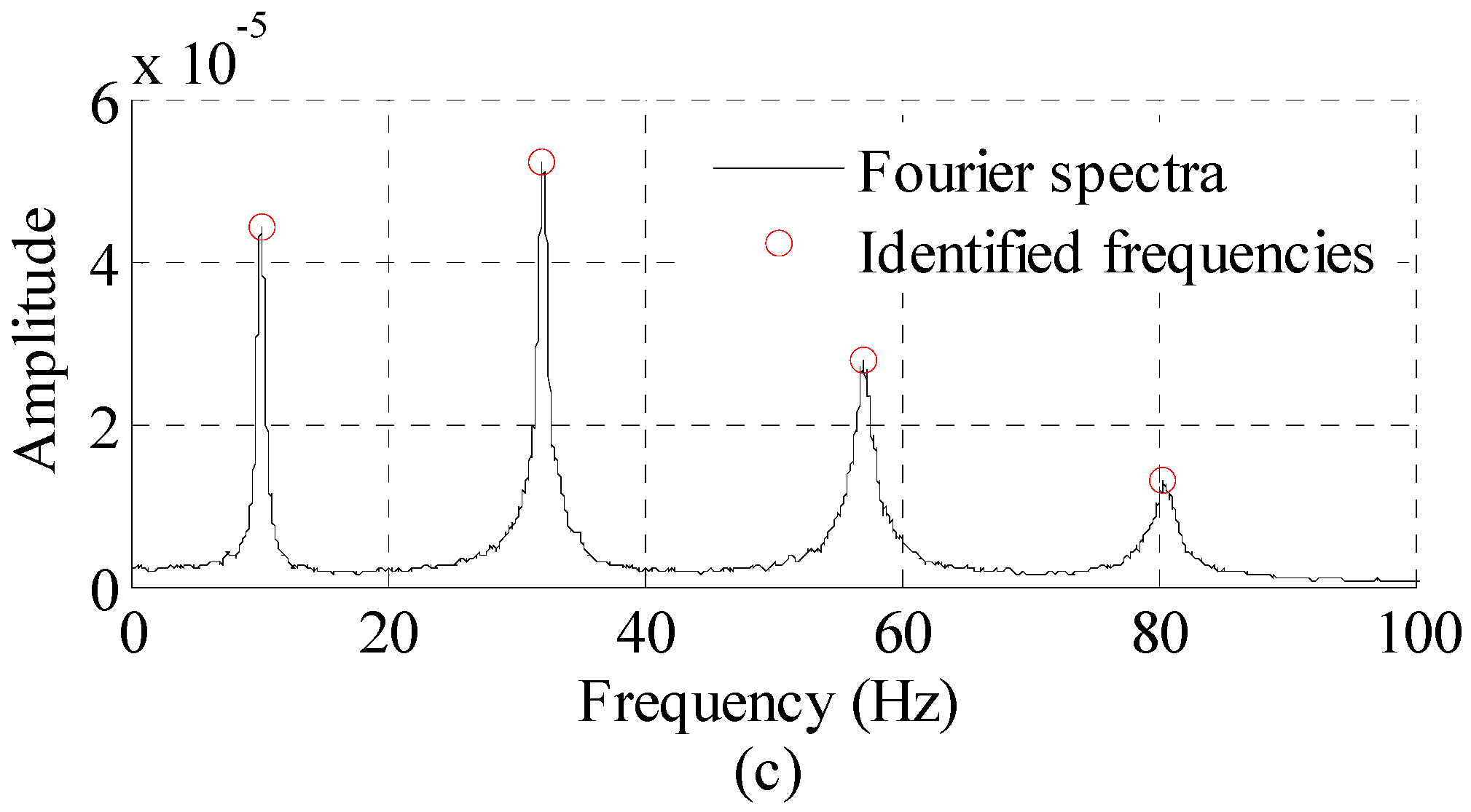

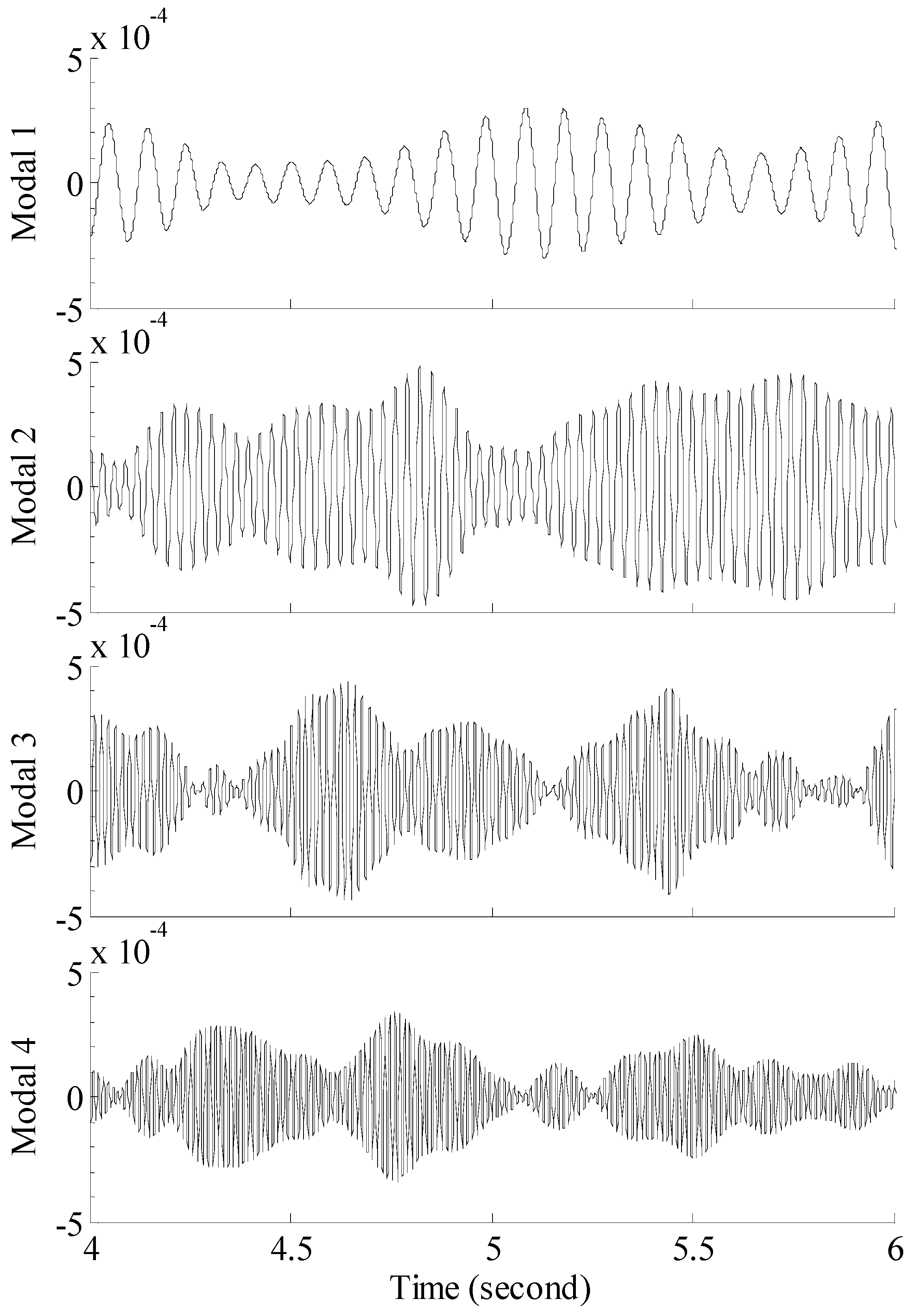

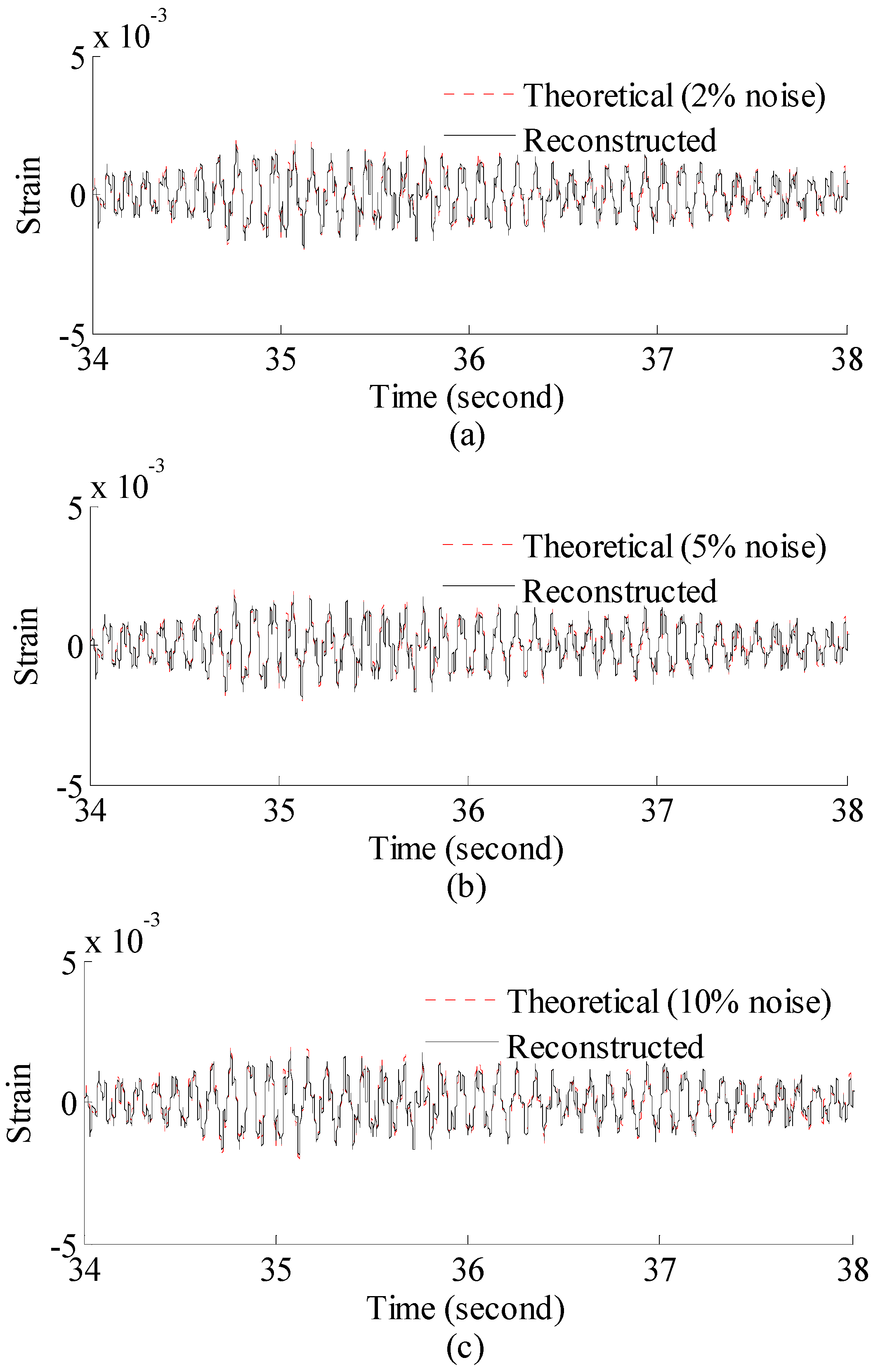

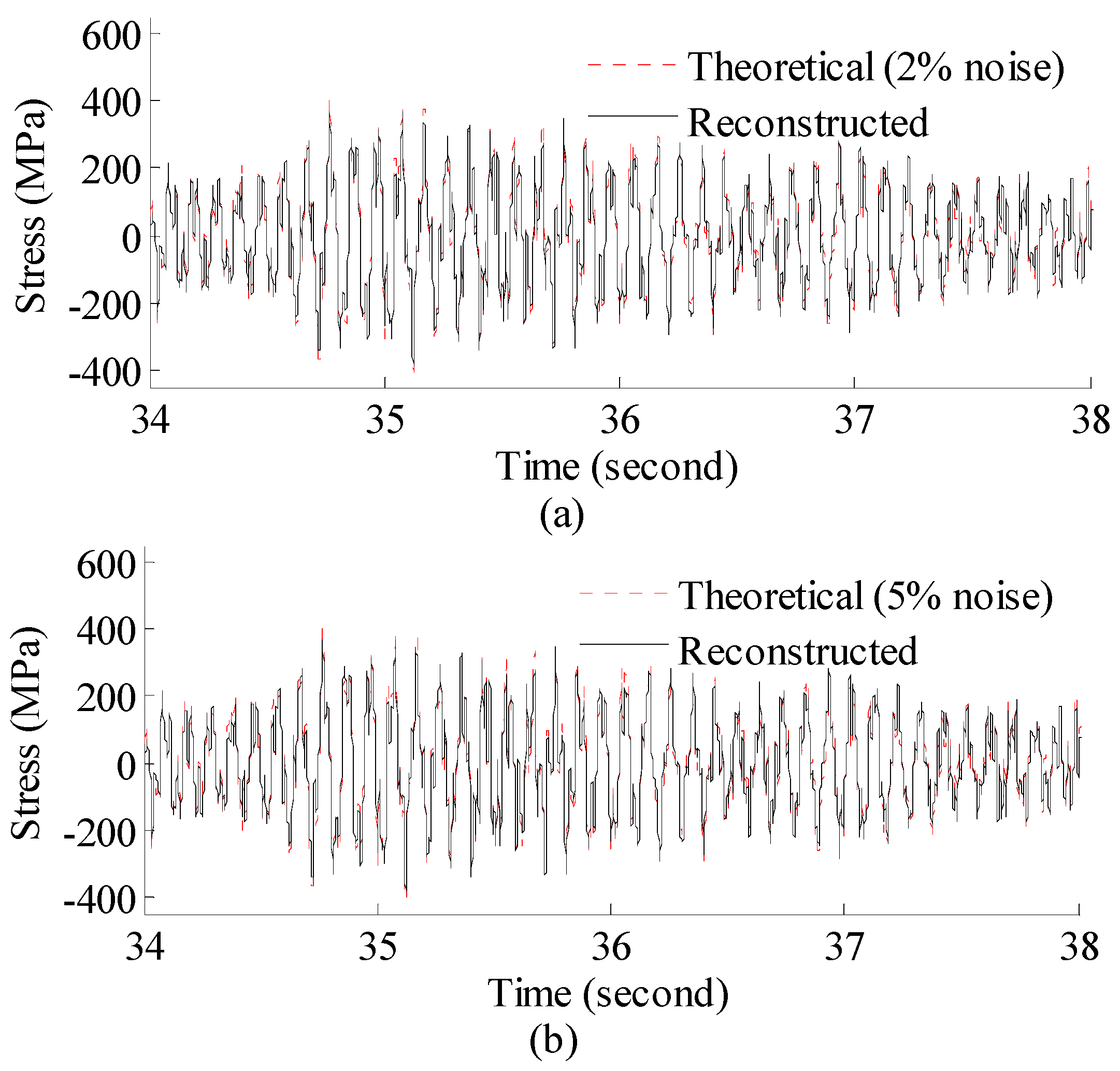

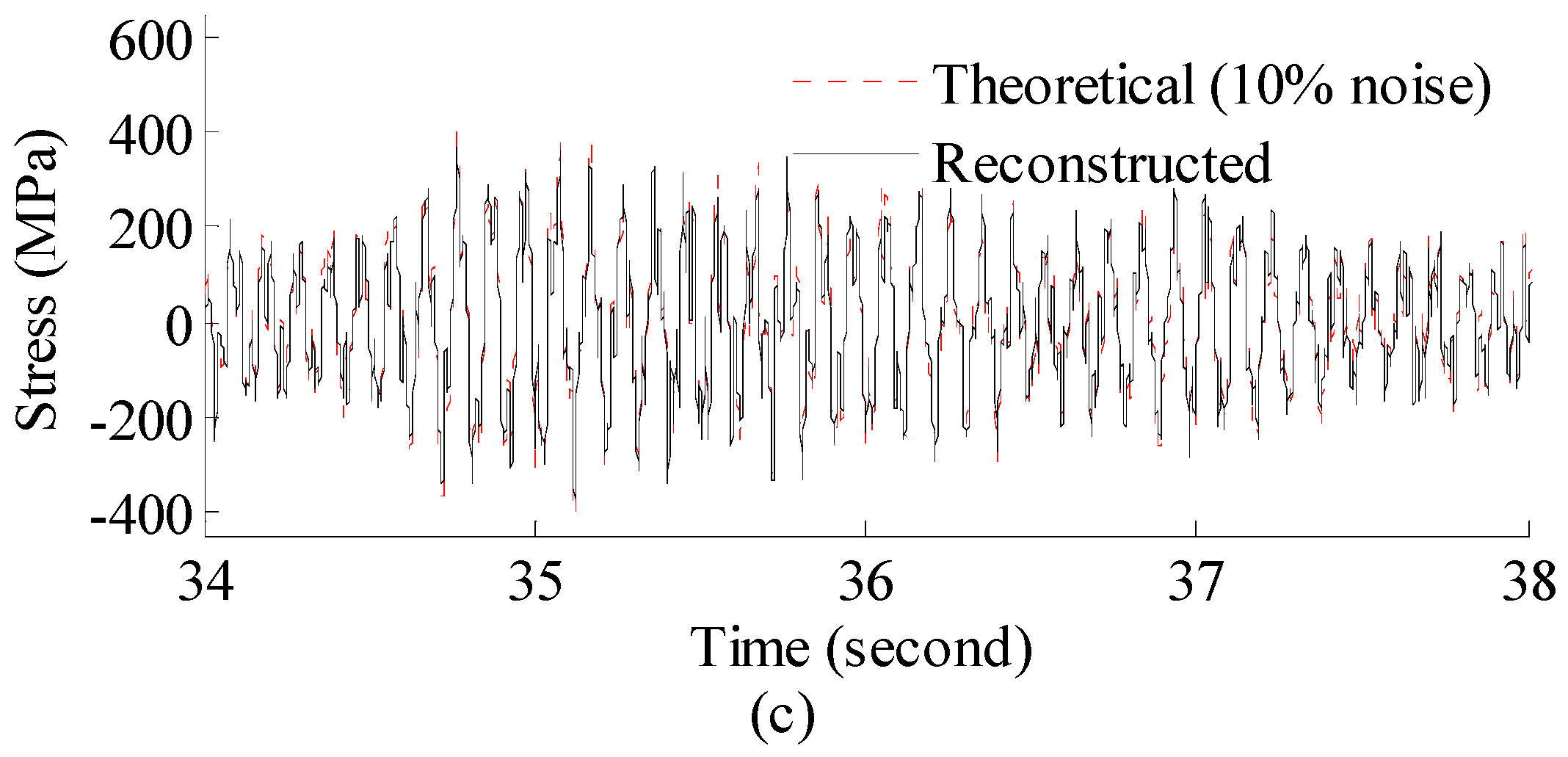

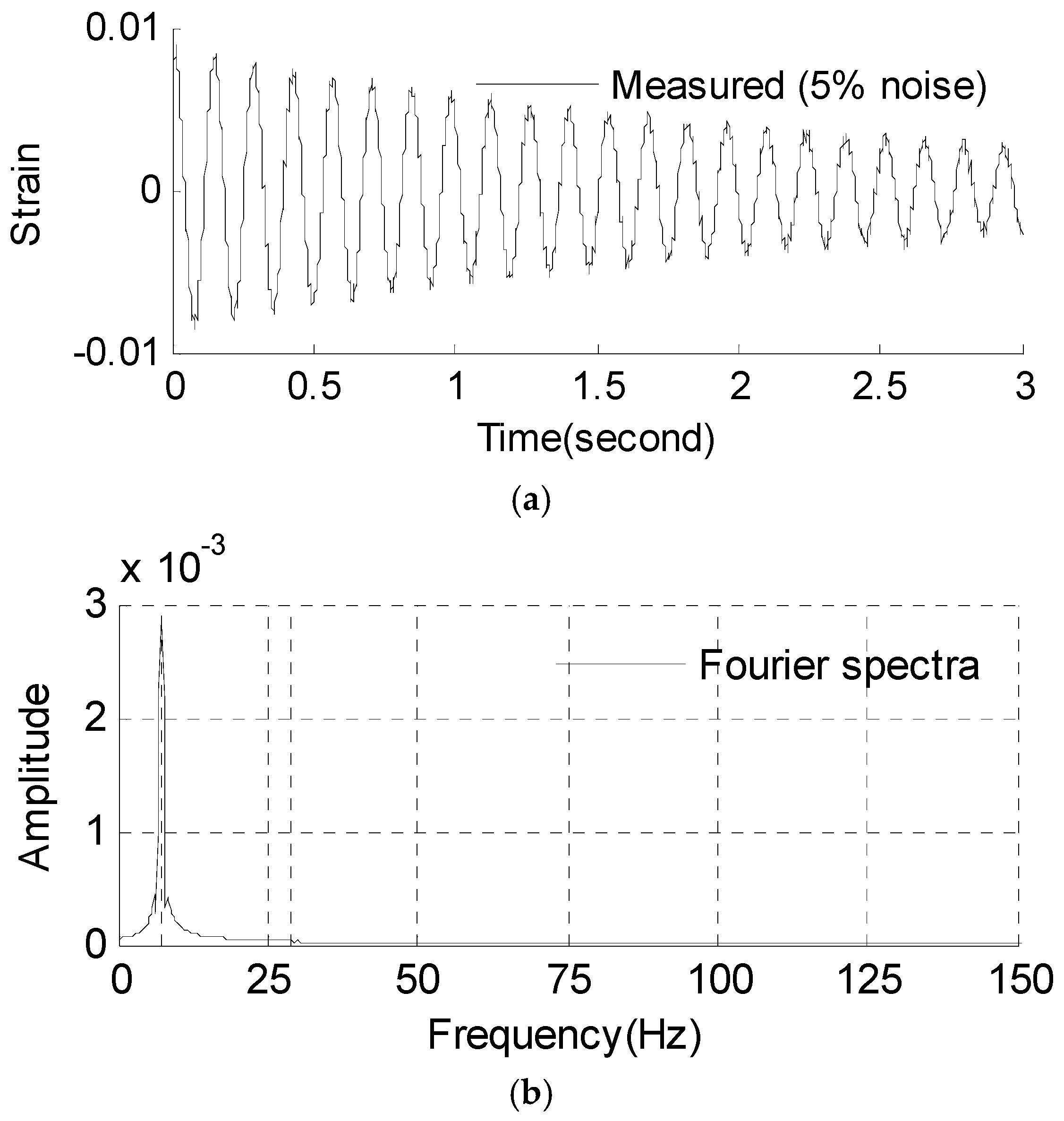

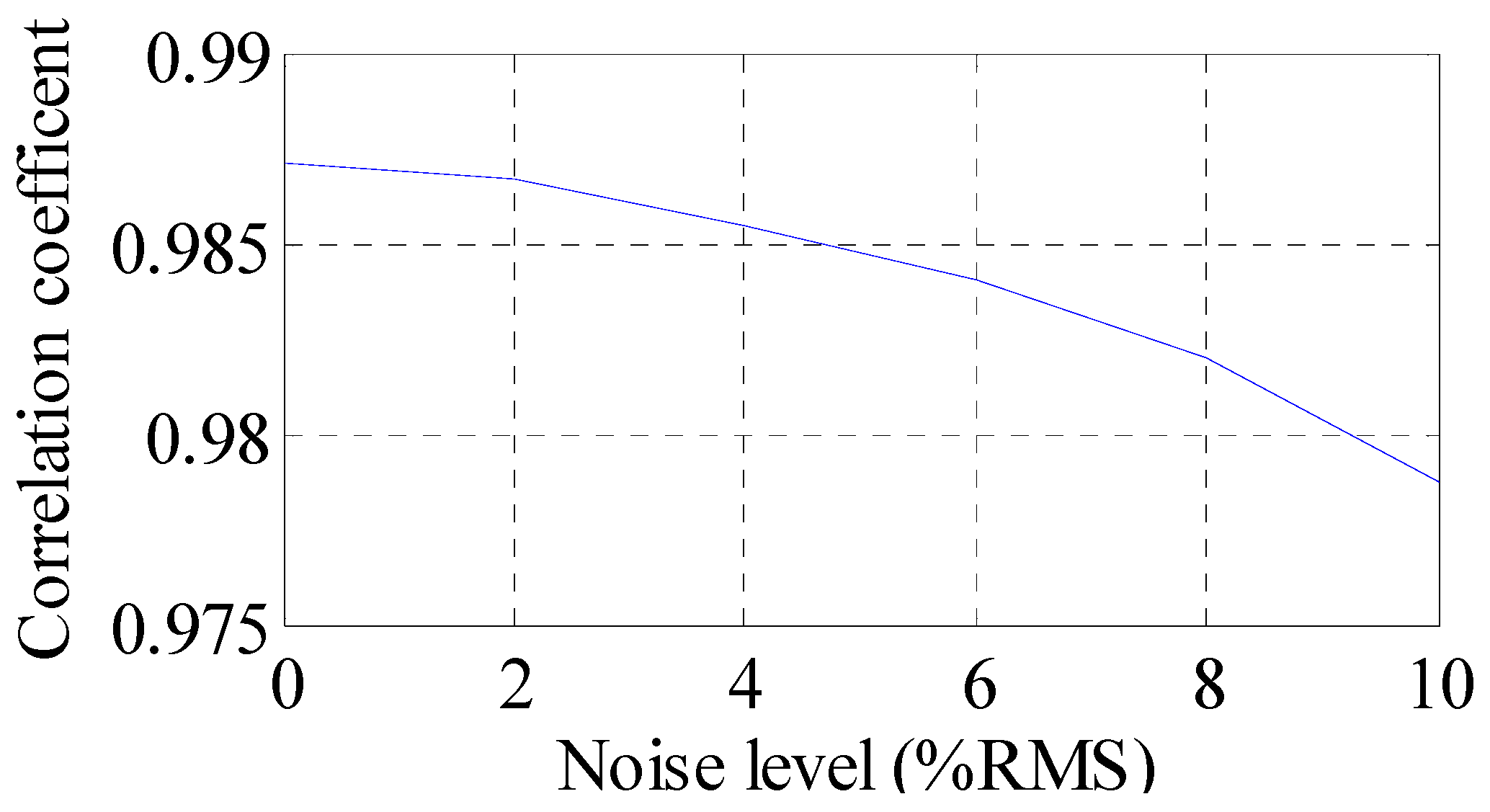

3.2.1. Strain and Stress Response Reconstruction

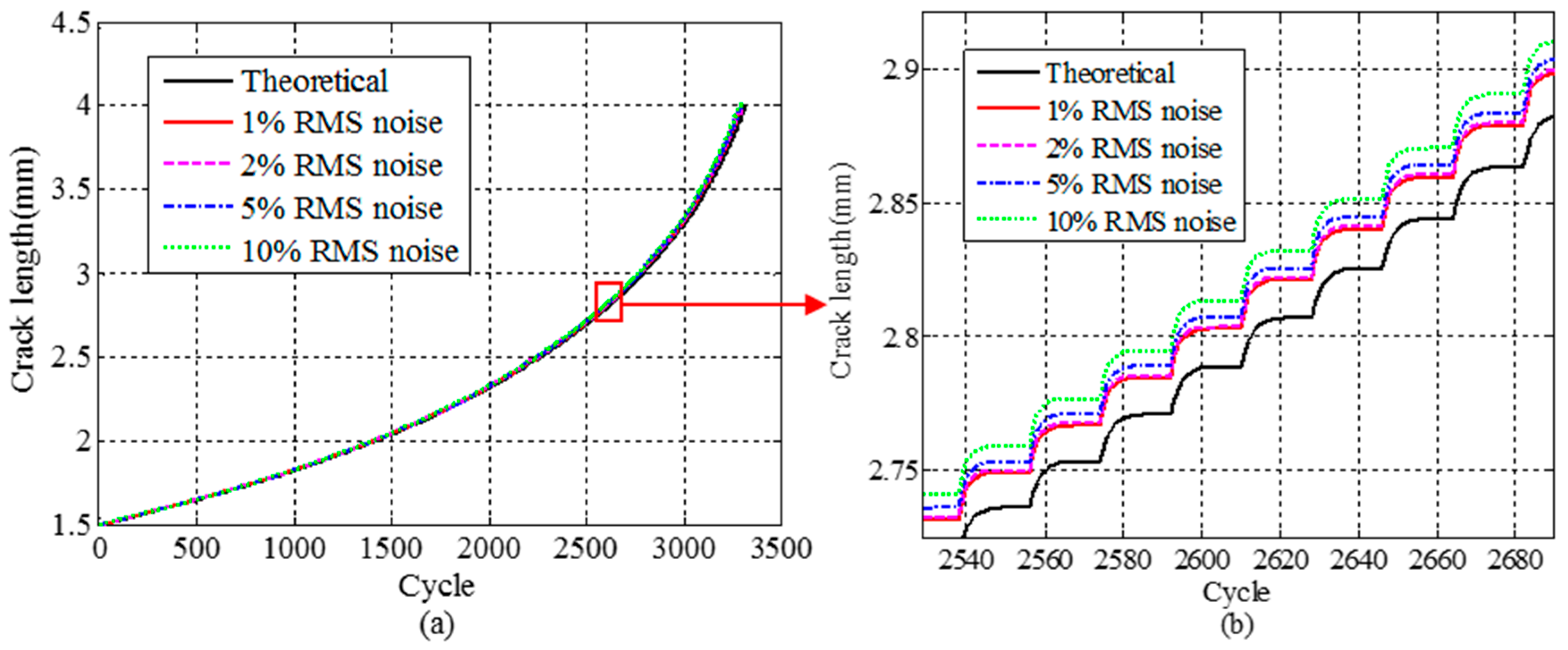

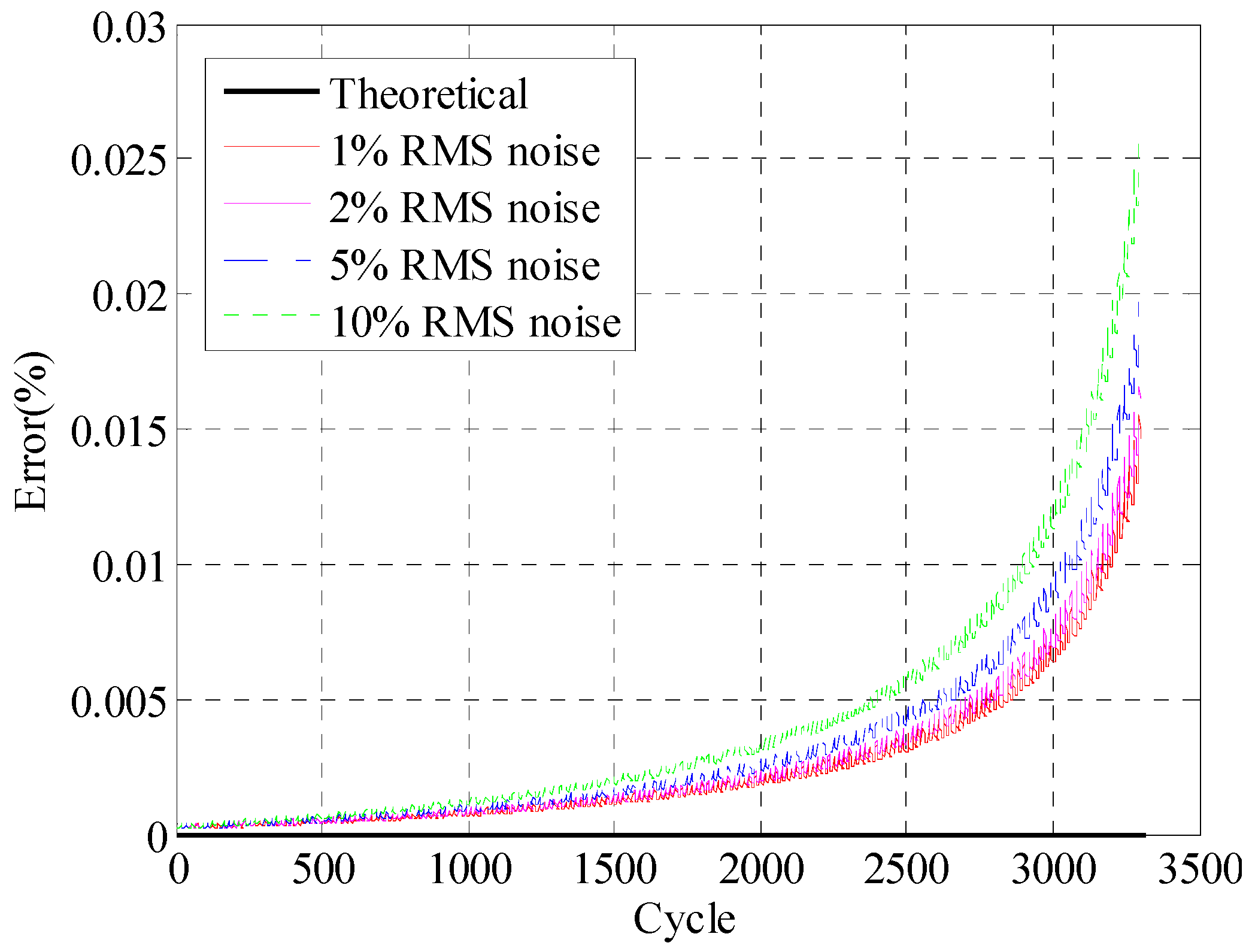

3.2.2. Fatigue Life Evaluation Using the Reconstructed Stress Responses

4. Conclusions

- In this study, a novel structural fatigue life evaluation method is proposed to provide prompt, informed fatigue damage predictions of the structures based on limited strain gauge measurement. Using this method, the evolution of fatigue damage within structures can be performed using the limited strain gauge measurement.

- According to numerical analysis results, the proposed method can produce results which are very close to theoretical solutions considering a practical noisy measurement system. The reconstructed results have an overall correlation coefficient larger than 0.975 under 10% RMS noise settings.

- Fatigue crack growth analysis using the reconstructed stress responses agrees well with the crack size predictions using the original stress responses. The crack size prediction using the reconstructed stress responses is not sensitive to the introduced noise.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kulkarni, S.; Achenbach, J. Structural health monitoring and damage prognosis in fatigue. Struct. Health Monit. 2008, 7, 37–49. [Google Scholar] [CrossRef]

- Beral, B.; Speckmann, H. Structural health monitoring (SHM) for aircraft structures: A challenge for system developers and aircraft manufactures. In Structural Health Monitoring 2003: From Diagnostics & Prognostics to Structural Health Management: Proceedings of the 4th International Workshop on Structural Health Monitoring, Stanford University, Stanford, CA, September 15–17, 2003; Chang, F.K., Ed.; Stanford University: Stanford, CA, USA, 2003; pp. 12–29. [Google Scholar]

- Chang, P.C.; Flatau, A.; Liu, S. Review paper: Health monitoring of civil infrastructure. Struct. Health Monit. 2003, 2, 257–267. [Google Scholar] [CrossRef]

- Giurgiutiu, V.; Cuc, A. Embedded non-destructive evaluation for structural health monitoring, damage detection, and failure prevention. Shock Vib. Dig. 2005, 37, 83–105. [Google Scholar] [CrossRef]

- Katsikeros, C.E.; Labeas, G. Development and validation of a strain-based structural health monitoring system. Mech. Syst. Signal Process. 2009, 23, 372–383. [Google Scholar] [CrossRef]

- Farrar, C.R.; Worden, K. An introduction to structural health monitoring. Philos. Trans. R. Soc. A 2007, 365. [Google Scholar] [CrossRef] [PubMed]

- Law, S.; Li, J.; Ding, Y. Structural response reconstruction with transmissibility concept in frequency domain. Mech. Syst. Signal Process. 2011, 25, 952–968. [Google Scholar] [CrossRef]

- Kammer, D.C. Estimation of structural response using remote sensor locations. J. Guid. Control Dyn. 1997, 20, 501–508. [Google Scholar] [CrossRef]

- Ribeiro, A.; Silva, J.; Maia, N. On the generalisation of the transmissibility concept. Mech. Syst. Signal Process. 2000, 14, 29–36. [Google Scholar] [CrossRef]

- He, J.; Guan, X.; Liu, Y. Structural response reconstruction based on empirical mode decomposition in time domain. Mech. Syst. Signal Process. 2012, 28, 348–366. [Google Scholar] [CrossRef]

- Stephens, R.I.; Fuchs, H.O. Metal Fatigue in Engineering, 2nd ed.; John Wiley & Sons, Inc.: New York, NY, USA, 2001. [Google Scholar]

- Miner, M.A. Cumulative damage in fatigue. J. Appl. Mech. 1945, 12, A159–A164. [Google Scholar]

- Matsuishi, M.; Endo, T. Fatigue of metals subjected to varying stress. Jpn. Soc. Mech. Eng. 1968, 68, 37–40. [Google Scholar]

- Downing, S.D.; Socie, D. Simple rainflow counting algorithms. Int. J. Fatigue 1982, 4, 31–40. [Google Scholar] [CrossRef]

- Colombo, D.; Giglio, M. A methodology for automatic crack propagation modelling in planar and shell Fe models. Eng. Fract. Mech. 2006, 73, 490–504. [Google Scholar] [CrossRef]

- Giglio, M.; Manes, A. Crack propagation on helicopter panel: Experimental test and analysis. Eng. Fract. Mech. 2008, 75, 866–879. [Google Scholar] [CrossRef]

- Luo, C.T.; Mohanty, S.; Chattopadhyay, A. Fatigue damage prediction of cruciform specimen under biaxial loading. J. Intell. Mater. Syst. Struct. 2013, 24, 2084–2096. [Google Scholar] [CrossRef]

- Colombo, D.; Giglio, M.; Manes, A. 3d fatigue crack propagation analysis of a helicopter component. Int. J. Mater. Prod. Technol. 2007, 30, 107–123. [Google Scholar] [CrossRef]

- Sbarufatti, C.; Corbetta, M.; Manes, A.; Giglio, M. Sequential monte-carlo sampling based on a committee of artificial neural networks for posterior state estimation and residual lifetime prediction. Int. J. Fatigue 2016, 83, 10–23. [Google Scholar] [CrossRef]

- Newman, J.C., Jr. A crack-closure model for predicting fatigue crack growth under aircraft spectrum loading. ASTM Int. 1981, 748, 53–84. [Google Scholar]

- He, J.; Lu, Z.; Liu, Y. New method for concurrent dynamic analysis and fatigue damage prognosis of bridges. J. Bridge Eng. 2012, 17, 396–408. [Google Scholar] [CrossRef]

- De Koning, A. A simple crack closure model for prediction of fatigue crack growth rates under variable-amplitude loading. ASTM Int. 1981, 743, 63–85. [Google Scholar]

- Bao, C.; Hao, H.; Li, Z.X.; Zhu, X. Time-varying system identification using a newly improved HHT algorithm. Comput. Struct. 2009, 87, 1611–1623. [Google Scholar] [CrossRef]

- Huang, N.E.; Shen, Z.; Long, S.R. A new view of nonlinear water waves: The hilbert spectrum 1. Annu. Rev. Fluid Mech. 1999, 31, 417–457. [Google Scholar] [CrossRef]

- Lu, Z.; Liu, Y. Small time scale fatigue crack growth analysis. Int. J. Fatigue 2009, 32, 1306–1321. [Google Scholar] [CrossRef]

- Janssen, M.; Zuidema, J.; Wanhill, R.J.H. Fracture Mechanics, 1st ed.; VSSD: Delft, The Netherlands, 2004; p. 378. [Google Scholar]

- Skorupa, M. Load interaction effects during fatigue crack growth under variable amplitude loading—A literature review. Part II: Qualitative interpretation. Fatigue Fract. Eng. Mater. Struct. 1999, 22, 905–926. [Google Scholar] [CrossRef]

- Huang, N.E.; Shen, Z.; Long, S.R.; Wu, M.C.; Shih, H.H.; Zheng, Q.; Yen, N.-C.; Tung, C.C.; Liu, H.H. The empirical mode decomposition and the hilbert spectrum for nonlinear and non-stationary time series analysis. Proc. R. Soc. Lond. A 1998, 454, 903–995. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Cross-section area B (m2) | 0.01 |

| Moment of inertia Iy (m4) | 8.3333 × 10−6 |

| Moment of inertia Iz (m4) | 8.3333 × 10−6 |

| Torsion constant J (m4) | 6.6667 × 10−5 |

| Young’s modulus E (GPa) | 200 |

| Poisson’s ratio ν | 0.3 |

| Shear modulus G (GPa) | E/(2 + 2ν) |

| Mass per unit volume ρ (kg/m3) | 7.8 × 10−3 |

| Property | Value |

|---|---|

| Material | aluminum 7075 |

| Element type | solid185 |

| Young’s modulus E (GPa) | 72 |

| Poisson’s ratio ν | 0.33 |

| Mass per unit volume ρ (kg/m3) | 2.81 × 103 |

| Number of element | 14951 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, J.; Zhou, Y.; Guan, X.; Zhang, W.; Wang, Y.; Zhang, W. An Integrated Health Monitoring Method for Structural Fatigue Life Evaluation Using Limited Sensor Data. Materials 2016, 9, 894. https://doi.org/10.3390/ma9110894

He J, Zhou Y, Guan X, Zhang W, Wang Y, Zhang W. An Integrated Health Monitoring Method for Structural Fatigue Life Evaluation Using Limited Sensor Data. Materials. 2016; 9(11):894. https://doi.org/10.3390/ma9110894

Chicago/Turabian StyleHe, Jingjing, Yibin Zhou, Xuefei Guan, Wei Zhang, Yanrong Wang, and Weifang Zhang. 2016. "An Integrated Health Monitoring Method for Structural Fatigue Life Evaluation Using Limited Sensor Data" Materials 9, no. 11: 894. https://doi.org/10.3390/ma9110894