Interior Fracture Mechanism Analysis and Fatigue Life Prediction of Surface-Hardened Gear Steel under Axial Loading

Abstract

:1. Introduction

2. Experimental Procedure

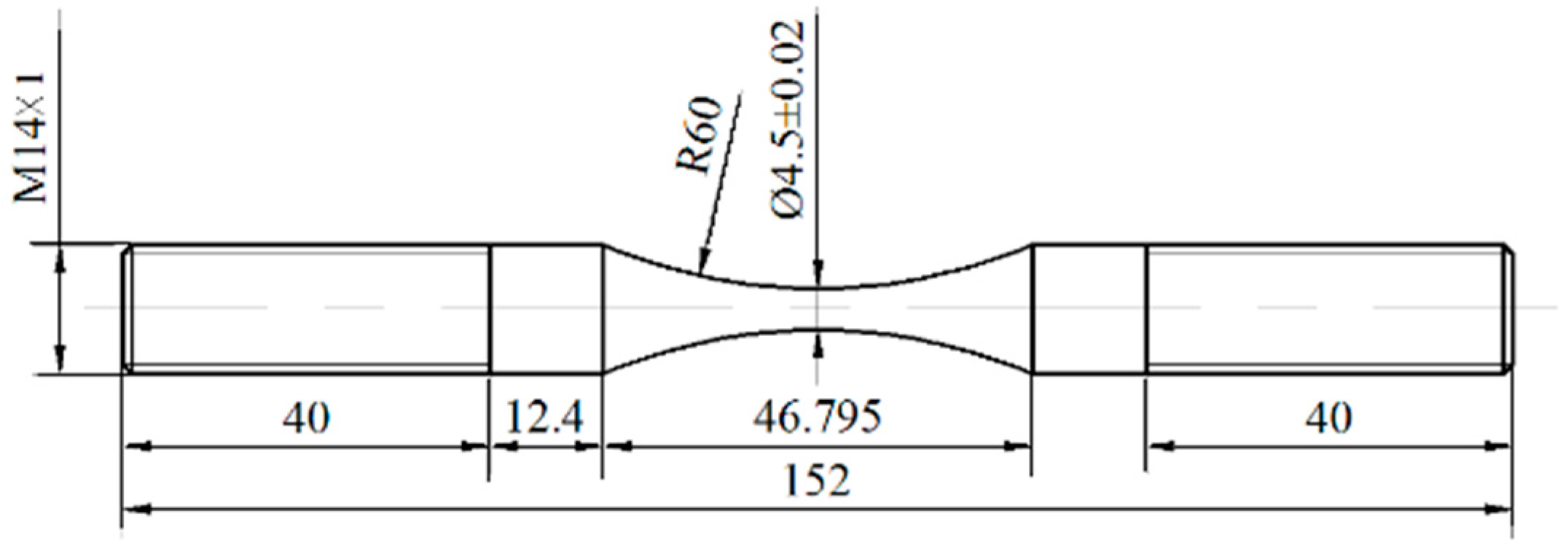

2.1. Material and Specimen

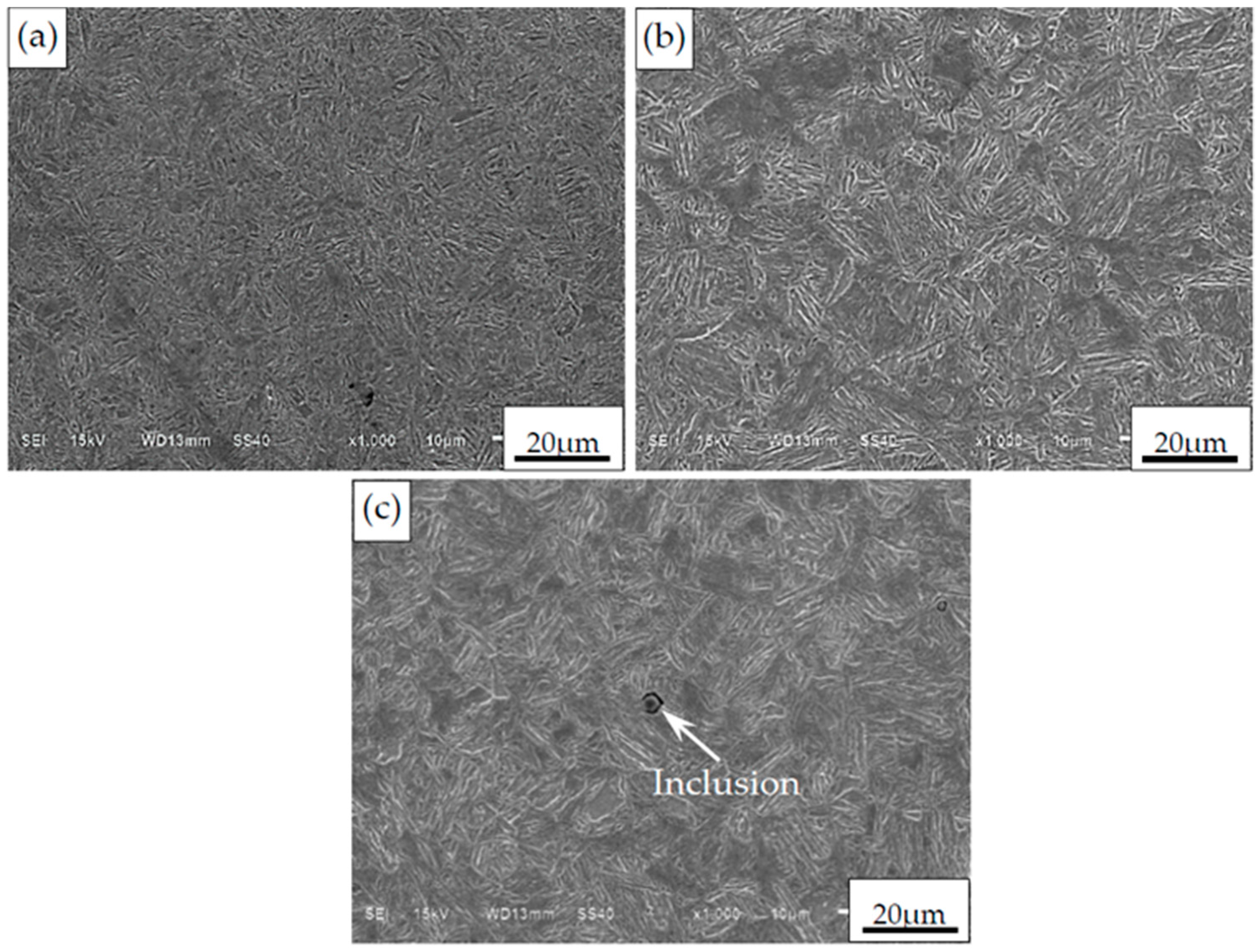

2.2. Carburizing and Microstructure

2.3. Experimental Method

3. Results and Discussion

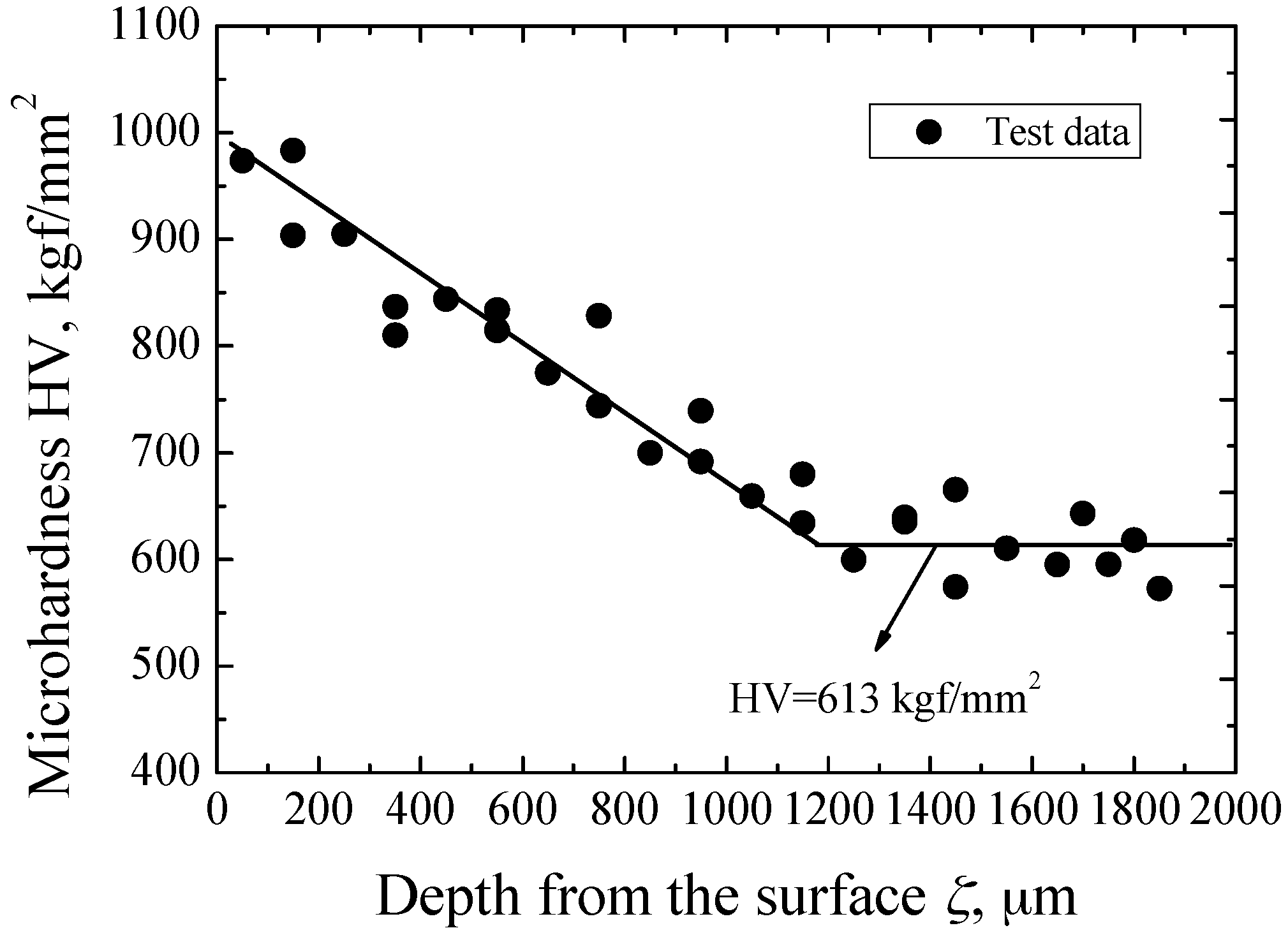

3.1. Micro-Hardness and Residual Stress

3.2. S-N Characteristics

3.3. Fatigue Fracture Mechanism

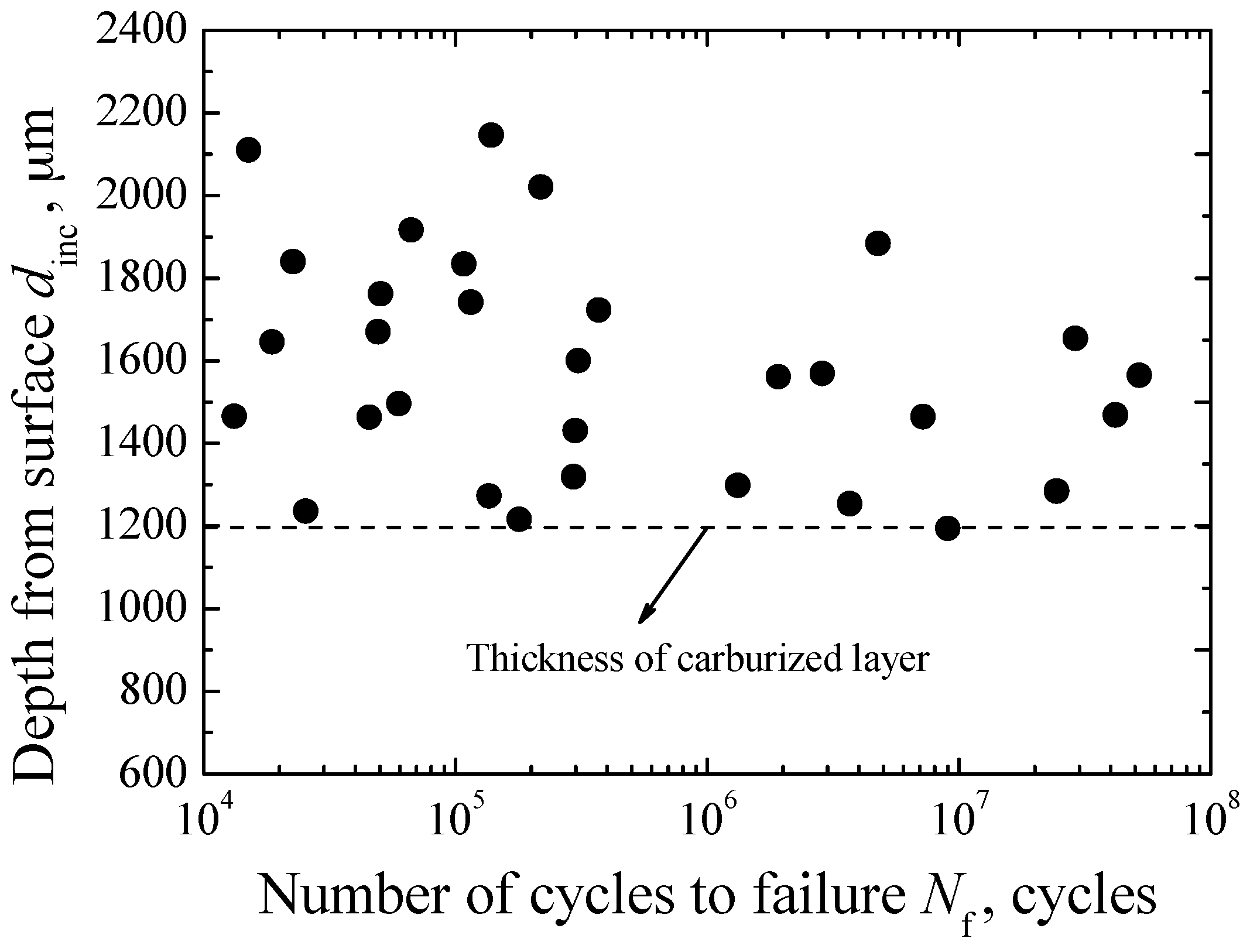

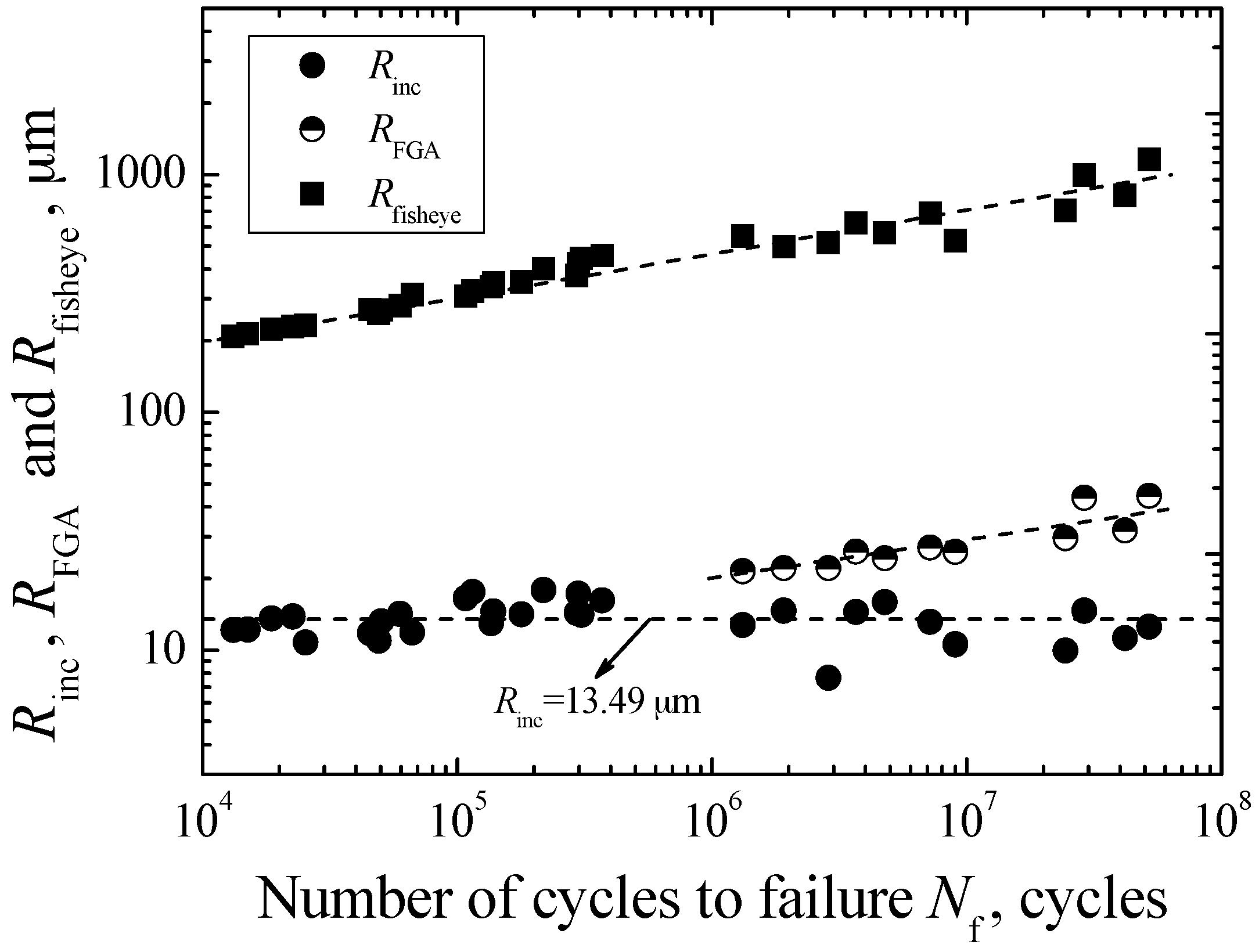

3.4. Crack Size Characteristics

- For fisheye:

- For FGA:

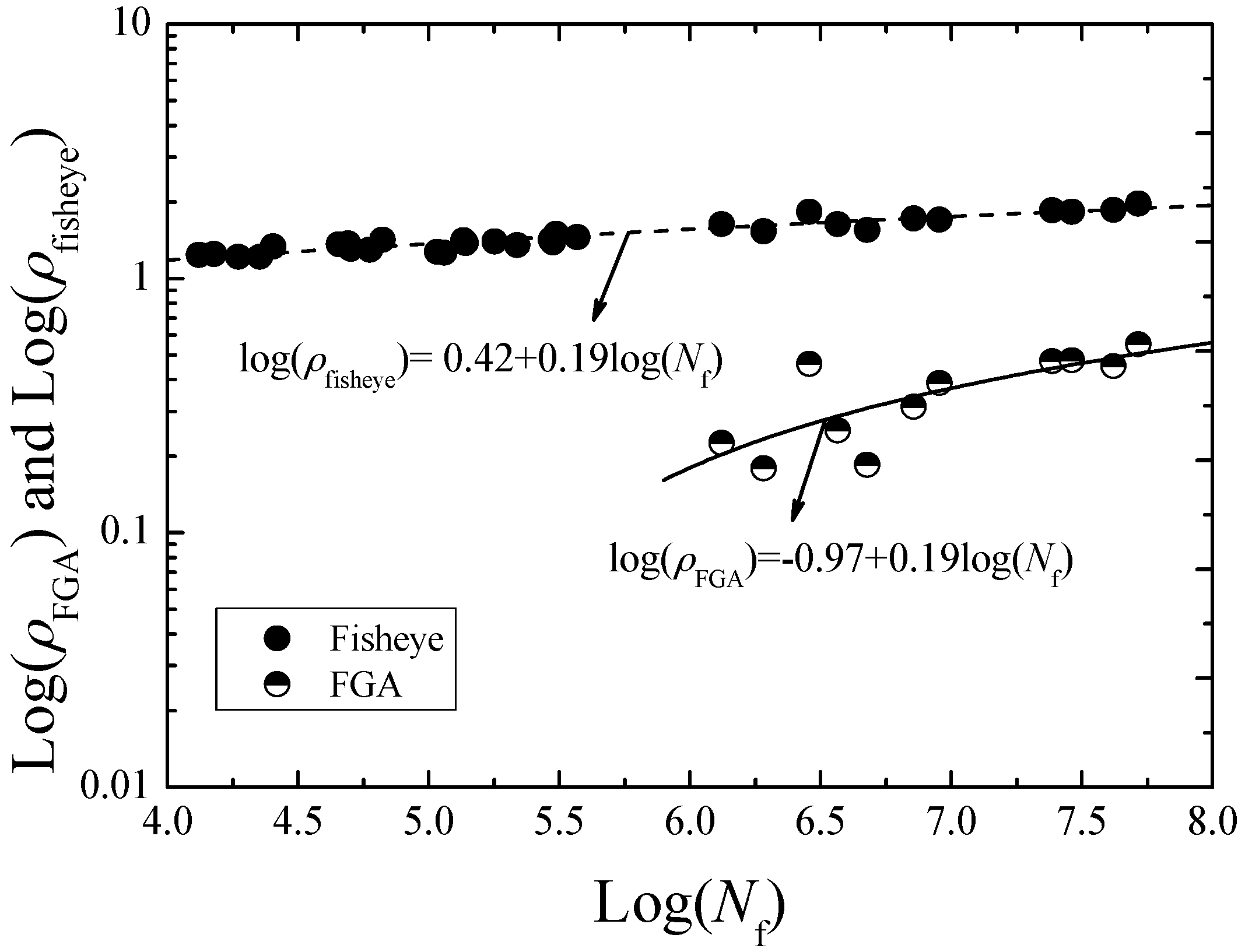

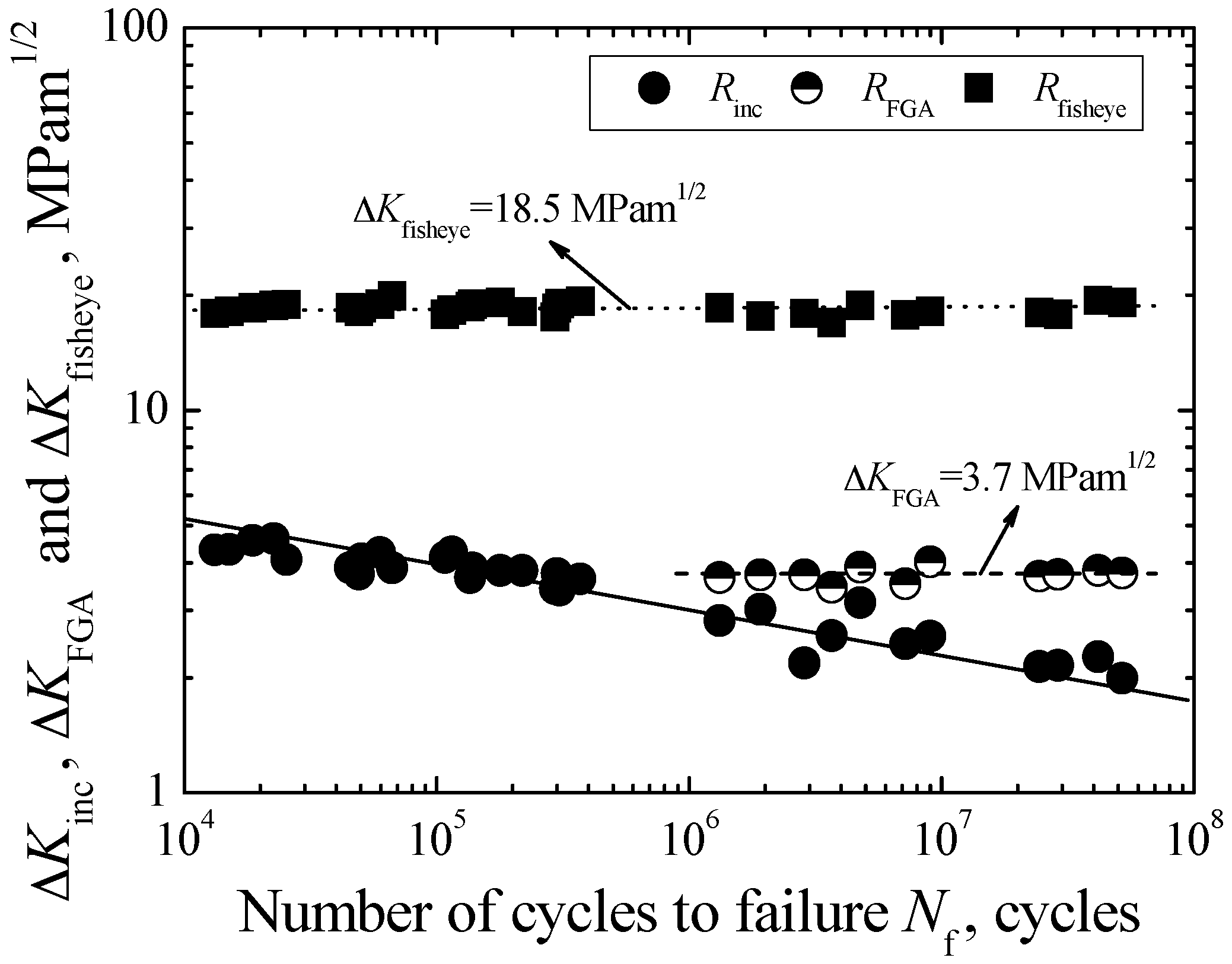

3.5. Evaluation of Interior Crack Growth

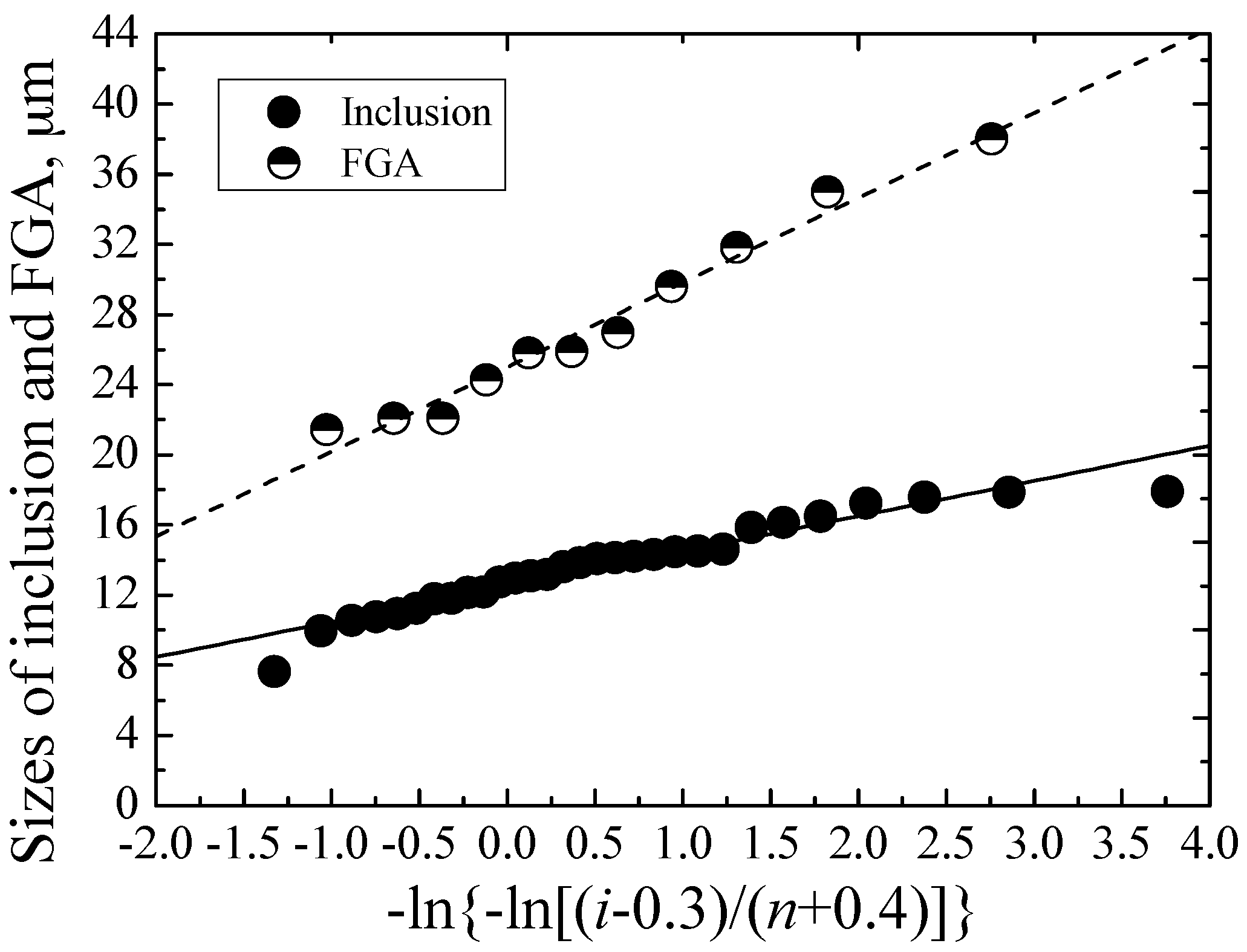

3.6. Evaluation of Maximum Inclusion and FGA Sizes

3.7. Prediction of Fatigue Life

4. Conclusions

- (1)

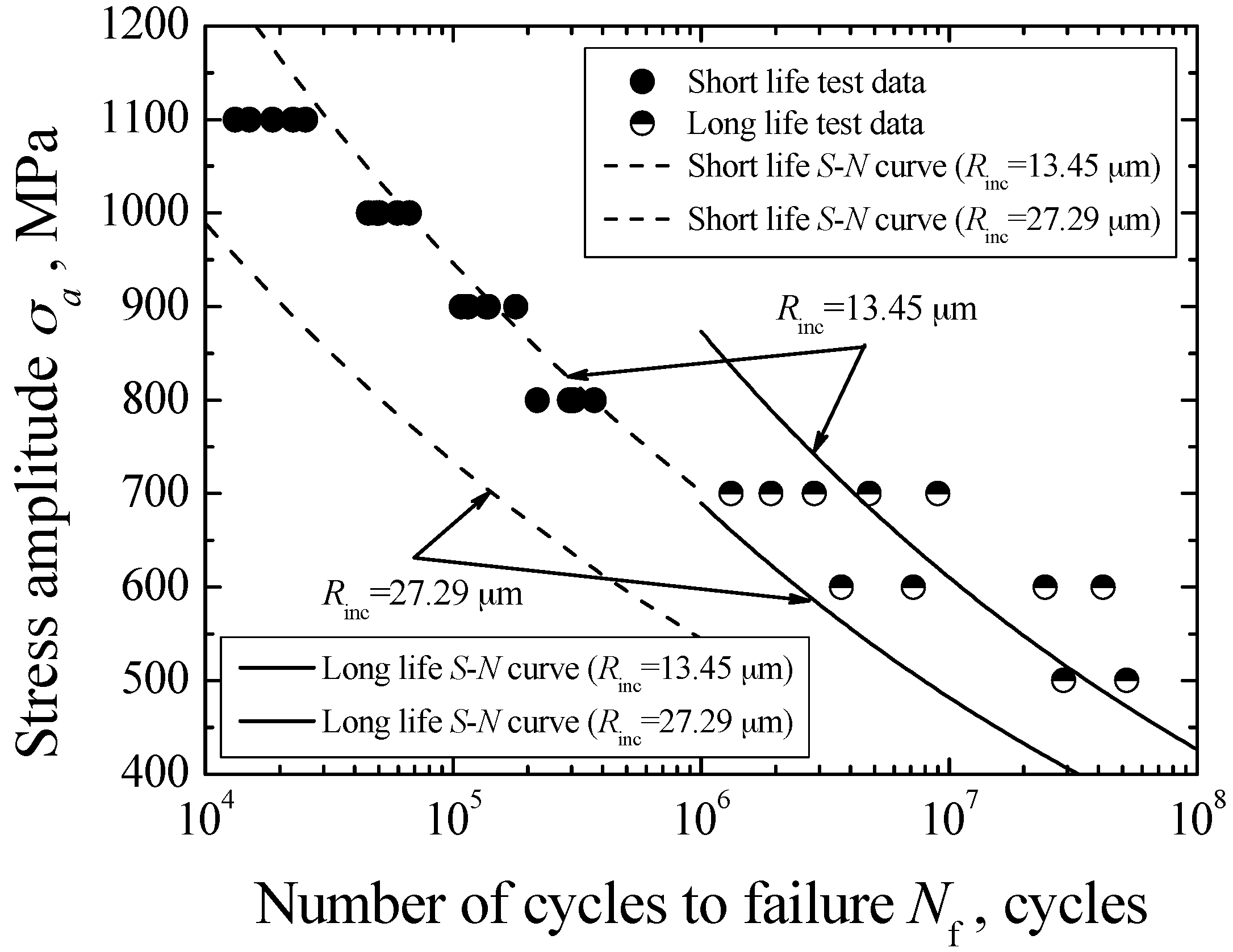

- The carburized Cr-Ni gear steel exhibits the constantly decreasing duplex S-N property without the traditional fatigue limit related to 107 cycles.

- (2)

- Fatigue cracks are all originated from the inclusions limited in the matrix region due to the inhabitation effect of the carburized layer.

- (3)

- The inclusion-fisheye induced fracture is the main fracture mechanism in the short timeframe, whereas the inclusion-FGA-fisheye induced fracture is the main fracture mechanism in the long timeframe.

- (4)

- ΔKFGA can be viewed as the threshold value controlling stable long crack growth, and ∆Kfisheye can be regarded as the threshold value for controlling unstable long crack growth.

- (5)

- The evaluated maximum sizes of inclusion and FGA in the effective damage volume of specimen are 27.29 μm and 57.15 μm, respectively.

- (6)

- The proposed life prediction method involving crack growth can be acceptable based on the good agreement between predicted and experimental results.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Akita, M.; Tokaji, K. Effect of carburizing on notch fatigue behavior in AJSI 316 austenitic stainless steel. Surf. Coat. Technol. 2006, 200, 6073–6078. [Google Scholar] [CrossRef]

- Shiozawa, K.; Lu, L. Very high-cycle fatigue behavior of shot-peened high-carbon-chromium bearing steel. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 813–822. [Google Scholar] [CrossRef]

- Shiozawa, K.; Murai, M.; Shimatani, Y.; Yoshimoto, T. Transition of fatigue failure mode of Ni-Cr-Mo low-alloy steel in very high cycle regime. Int. J. Fatigue 2010, 32, 541–550. [Google Scholar] [CrossRef]

- Naito, T.; Ueda, H.; Kikuchui, M. Fatigue behavior of carburized steel with internal oxides and nonmartensitic microstructure near the surface. Metall. Trans. 1984, 15, 1431–1436. [Google Scholar] [CrossRef]

- Sakai, T.; Sato, Y.; Oguma, N. Characteristic S-N properties of high-carbon-chromium-bearing steel under axial loading in long-life fatigue. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 765–773. [Google Scholar] [CrossRef]

- Shiozawa, K.; Lu, L.; Ishihara, S. S-N curve characteristics and subsurface crack initiation behaviour in ultra-long life fatigue of a high carbon-chromium bearing steel. Fatigue Fract. Eng. Mater. Struct. 2001, 24, 781–790. [Google Scholar] [CrossRef]

- Murakami, Y.; Yokoyama, N.N.; Nagata, J. Mechanism of fatigue failure in ultralong life regime. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 735–746. [Google Scholar] [CrossRef]

- Grad, P.; Reuscher, B.; Brodvanski, A.; Kopnarski, M.; Kerscher, E. Mechanism of fatigue crack initiation and propagation in the very high cycle fatigue regime of high-strength steels. Scr. Mater. 2012, 67, 838–841. [Google Scholar] [CrossRef]

- Nakamura, T.; Oguma, H.; Shinohara, Y. The effect of vacuum-like environment inside sub-surface fatigue crack on the formation of ODA fracture surface in high strength steel. Procedia Eng. 2010, 2, 2121–2129. [Google Scholar] [CrossRef]

- Hong, Y.; Liu, X.; Lei, Z.; Sun, C. The formation mechanism of characteristic region at crack initiation for very-high-cycle fatigue of high-strength steels. Int. J. Fatigue 2016, 89, 108–118. [Google Scholar] [CrossRef]

- Wang, Q.Y.; Bathias, C.; Kawagoishi, N.; Chen, Q. Effect of inclusion on subsurface crack initiation and gigacycle fatigue strength. Int. J. Fatigue 2002, 24, 1269–1274. [Google Scholar] [CrossRef]

- Stanzl-Tschegg, S. Fracture mechanisms and fracture mechanics at ultrasonic frequencies. Fatigue Fract. Eng. Mater. Struct. 1999, 22, 567–579. [Google Scholar] [CrossRef]

- Stanzl-Tschegg, S.; Schönbauer, B. Near-threshold fatigue crack propagation and internal cracks in steel. Procedia Eng. 2010, 2, 1547–1555. [Google Scholar] [CrossRef]

- Murakami, Y.; Miller, K. What is damage? A view point from the observation of low cycle fatigue process. Int. J. Fatigue 2010, 32, 155–168. [Google Scholar] [CrossRef]

- Tanaka, K.; Akiniwa, Y. Fatigue crack propagation behavior derived from S-N data in very high cycle regime. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 775–784. [Google Scholar] [CrossRef]

- Akiniwa, Y.; Miyamoto, N.; Tsuru, H.; Tanaka, K. Notch effect on fatigue strength reduction of bearing steel in the very high cycle regime. Int. J. Fatigue 2006, 28, 1555–1565. [Google Scholar] [CrossRef]

- Peterson, R.E. Stress Concentration Factors; John Wiley: New York, NY, USA, 1974. [Google Scholar]

- Murakami, Y.; Beretta, S. Small defects and inhomgenities in fatigue strength: Experiments, models and statistical implications. Extremes 1999, 2, 123–147. [Google Scholar] [CrossRef]

- Pippan, R.; Tabernig, B.; Gach, E.; Riemelmoser, F. Non-propagation conditions for fatigue cracks and fatigue in the very high-cycle regime. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 805–811. [Google Scholar] [CrossRef]

- Hertzberg, R.W.; Pecorini, T.J. An examination of load shedding during fatigue fracture. Int. J. Fatigue 1993, 15, 509–551. [Google Scholar] [CrossRef]

- Li, W.; Deng, H.L.; Sun, Z.D.; Zhang, Z.Y.; Lu, L.T.; Sakai, T. Subsurface inclusion-induced crack nucleation and growth behaviors of high strength steels under very High cycle fatigue: Characterization and microstructure-based modeling. Mater. Sci. Eng. A 2015, 641, 10–20. [Google Scholar] [CrossRef]

- Murakami, Y. Metal Fatigue: Effects of Small Defects and Nonmetallic Inclusions; Elsevier Science: Boston, MA, USA, 2002. [Google Scholar]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Deng, H.; Liu, P. Interior Fracture Mechanism Analysis and Fatigue Life Prediction of Surface-Hardened Gear Steel under Axial Loading. Materials 2016, 9, 843. https://doi.org/10.3390/ma9100843

Li W, Deng H, Liu P. Interior Fracture Mechanism Analysis and Fatigue Life Prediction of Surface-Hardened Gear Steel under Axial Loading. Materials. 2016; 9(10):843. https://doi.org/10.3390/ma9100843

Chicago/Turabian StyleLi, Wei, Hailong Deng, and Pengfei Liu. 2016. "Interior Fracture Mechanism Analysis and Fatigue Life Prediction of Surface-Hardened Gear Steel under Axial Loading" Materials 9, no. 10: 843. https://doi.org/10.3390/ma9100843