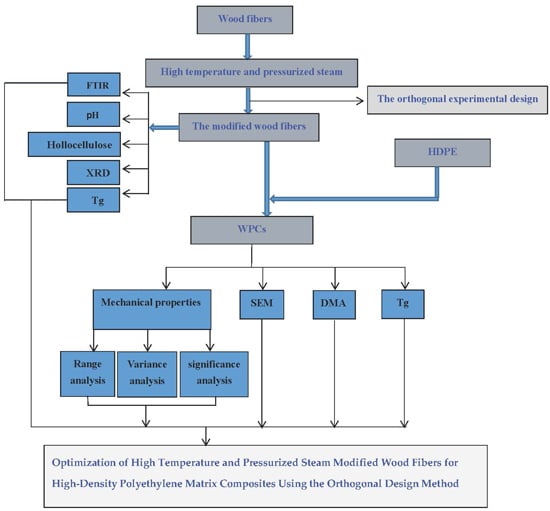

Figure 1.

Range analysis of the effect of the process parameters on the impact, tensile, and flexural strengths of the wood fiber/high-density polyethylene (HDPE) composites. (a) Range analysis of wood plastic composite (WPC) impact; (b) Range analysis of WPC tensile; (c) Range analysis of WPC flexural.

Figure 1.

Range analysis of the effect of the process parameters on the impact, tensile, and flexural strengths of the wood fiber/high-density polyethylene (HDPE) composites. (a) Range analysis of wood plastic composite (WPC) impact; (b) Range analysis of WPC tensile; (c) Range analysis of WPC flexural.

Figure 2.

Effect of high temperature and pressurized steam on the hollocellulose content of wood fibers.

Figure 2.

Effect of high temperature and pressurized steam on the hollocellulose content of wood fibers.

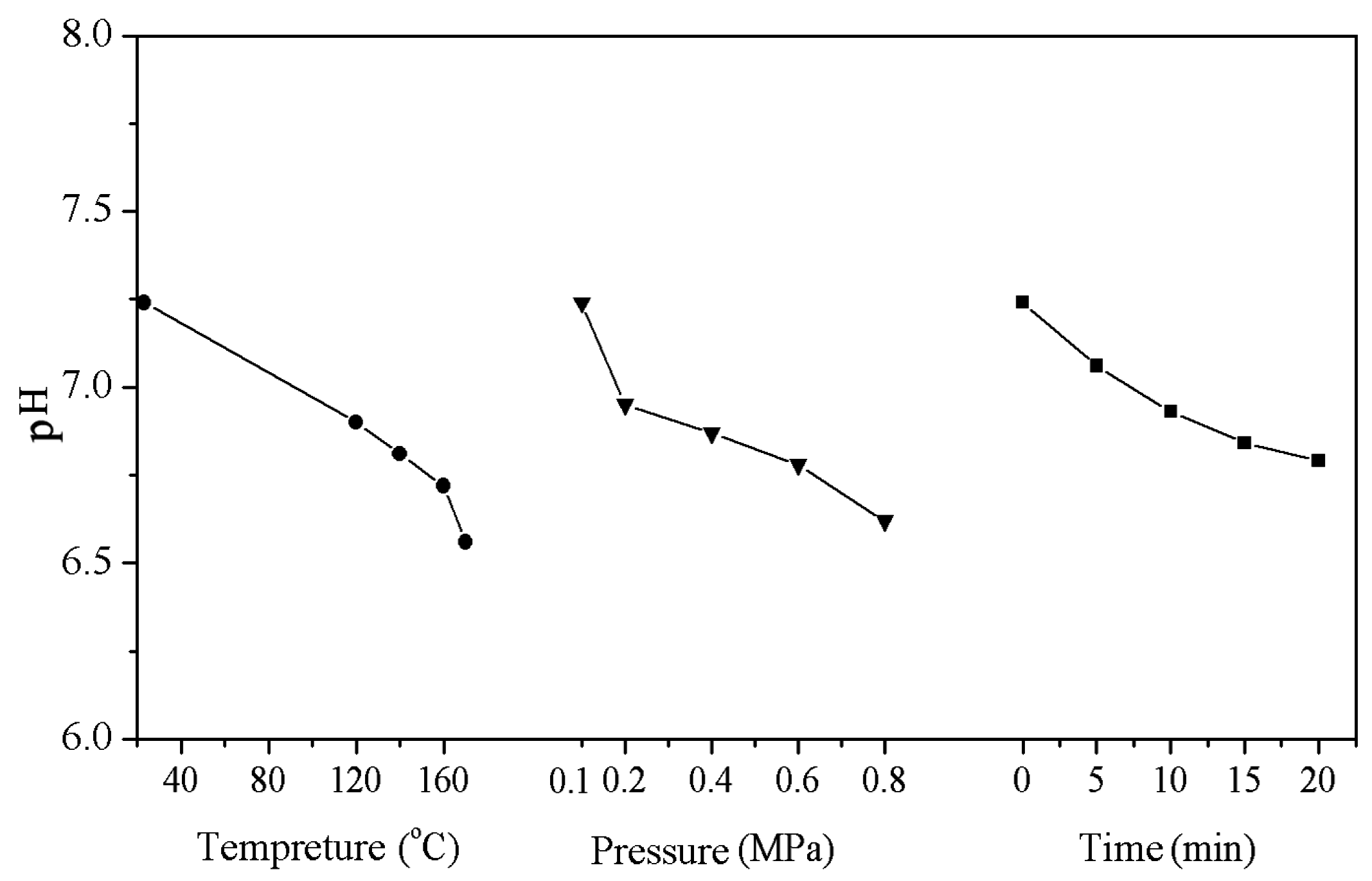

Figure 3.

Effect of the high temperature and pressurized steam on the pH of the wood fibers.

Figure 3.

Effect of the high temperature and pressurized steam on the pH of the wood fibers.

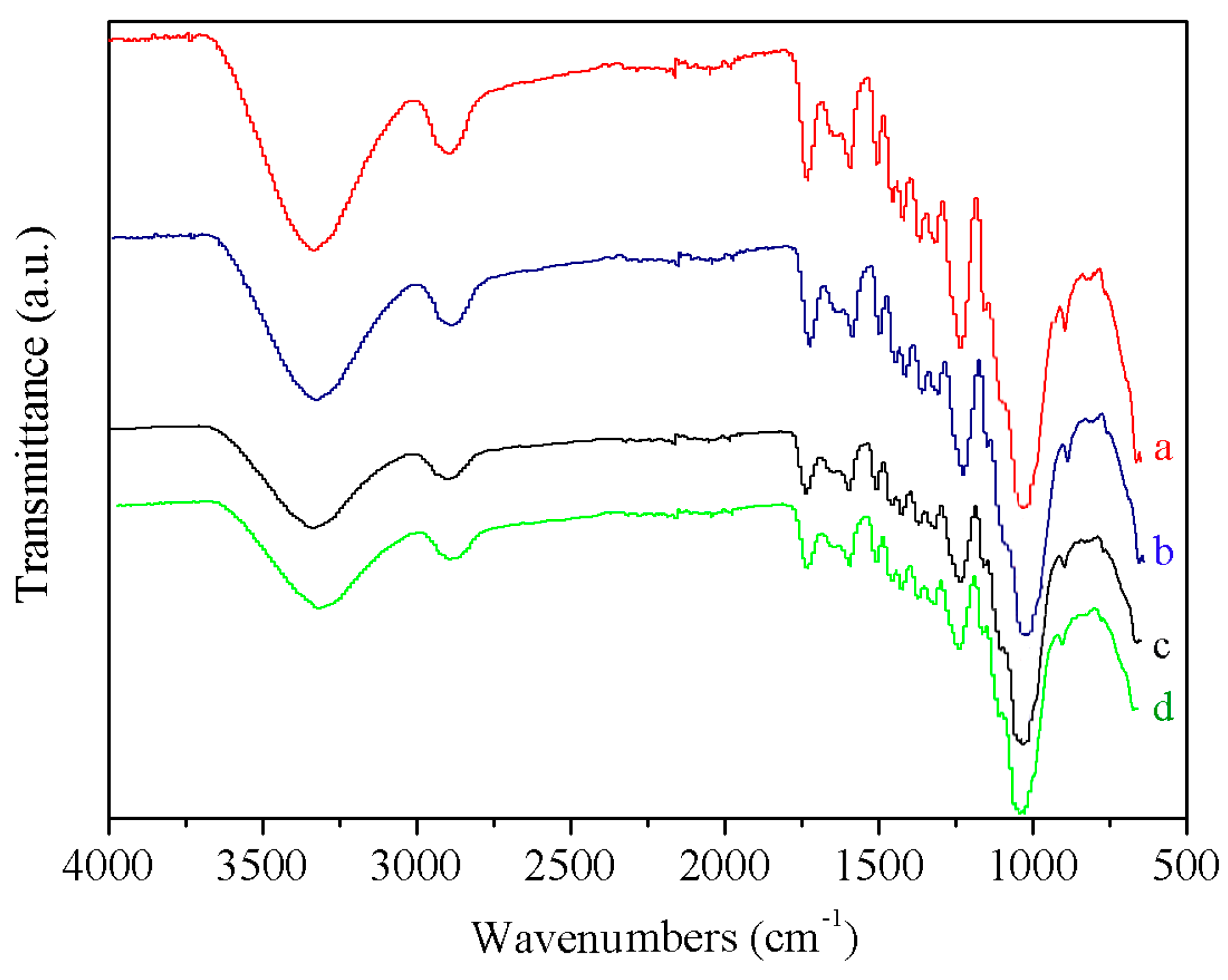

Figure 4.

Comparison of the fourier transform infrared (FTIR) spectra obtained for untreated wood fibers and wood fibers modified through a high temperature and pressurized steam treatment under different conditions:

a: untreated fibers; b: T = 120 °C, p = 0.2 MPa, t = 5 min; c: T = 160 °C, p = 0.6 MPa, t = 15 min; and d: T = 170 °C, p = 0.8 MPa, t = 5 min.

Figure 4.

Comparison of the fourier transform infrared (FTIR) spectra obtained for untreated wood fibers and wood fibers modified through a high temperature and pressurized steam treatment under different conditions:

a: untreated fibers; b: T = 120 °C, p = 0.2 MPa, t = 5 min; c: T = 160 °C, p = 0.6 MPa, t = 15 min; and d: T = 170 °C, p = 0.8 MPa, t = 5 min.

Figure 5.

X-ray diffraction (XRD) patterns obtained for the untreated wood fibers and the wood fibers modified through a high temperature and pressurized steam treatment under different conditions: a: untreated fibers;

b: T = 120 °C, p = 0.2 MPa, t = 5 min; c: T = 160 °C, p = 0.6 MPa, t = 5 min; d: T = 140 °C, p = 0.6 MPa, t = 15 min; and e: T = 170 °C, p = 0.8 MPa, t = 5 min.

Figure 5.

X-ray diffraction (XRD) patterns obtained for the untreated wood fibers and the wood fibers modified through a high temperature and pressurized steam treatment under different conditions: a: untreated fibers;

b: T = 120 °C, p = 0.2 MPa, t = 5 min; c: T = 160 °C, p = 0.6 MPa, t = 5 min; d: T = 140 °C, p = 0.6 MPa, t = 15 min; and e: T = 170 °C, p = 0.8 MPa, t = 5 min.

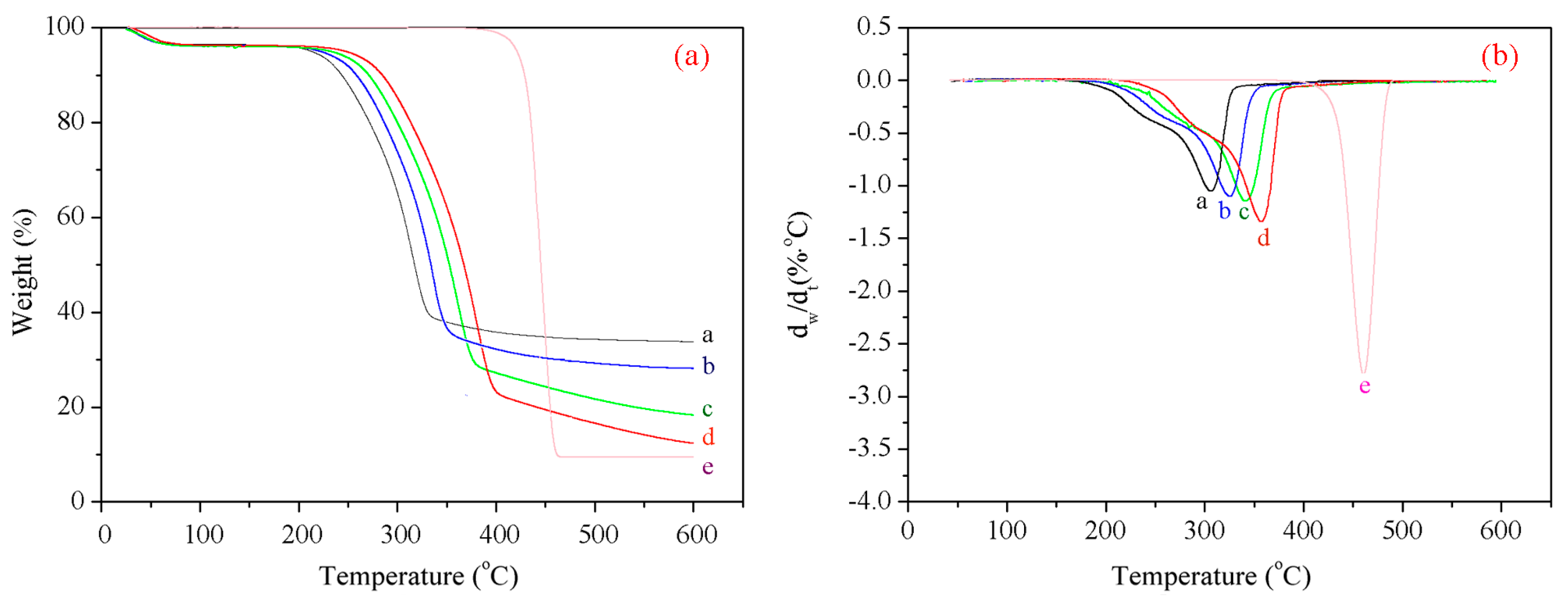

Figure 6.

(a) TG and (b) DTG curves obtained for the unmodified and modified wood fibers; a: untreated fibers; b: T = 120 °C, p = 0.2 MPa, t = 5 min; c: T = 170 °C, p = 0.8 MPa, t = 5 min; d: T = 170 °C, p = 0.8 MPa, t = 15 min;

and e: HDPE.

Figure 6.

(a) TG and (b) DTG curves obtained for the unmodified and modified wood fibers; a: untreated fibers; b: T = 120 °C, p = 0.2 MPa, t = 5 min; c: T = 170 °C, p = 0.8 MPa, t = 5 min; d: T = 170 °C, p = 0.8 MPa, t = 15 min;

and e: HDPE.

Figure 7.

Variation of (a) the storage modulus and (b) the loss modulus and the loss factor with the steam temperature: a: untreated fibers; b: T = 120 °C, p = 0.2 MPa, t = 5 min; c: T = 160 °C, p = 0.6 MPa, t = 5 min; d: T = 160 °C, p = 0.6 MPa, t = 15 min; and e: T = 170 °C, p = 0.8 MPa, t = 5 min.

Figure 7.

Variation of (a) the storage modulus and (b) the loss modulus and the loss factor with the steam temperature: a: untreated fibers; b: T = 120 °C, p = 0.2 MPa, t = 5 min; c: T = 160 °C, p = 0.6 MPa, t = 5 min; d: T = 160 °C, p = 0.6 MPa, t = 15 min; and e: T = 170 °C, p = 0.8 MPa, t = 5 min.

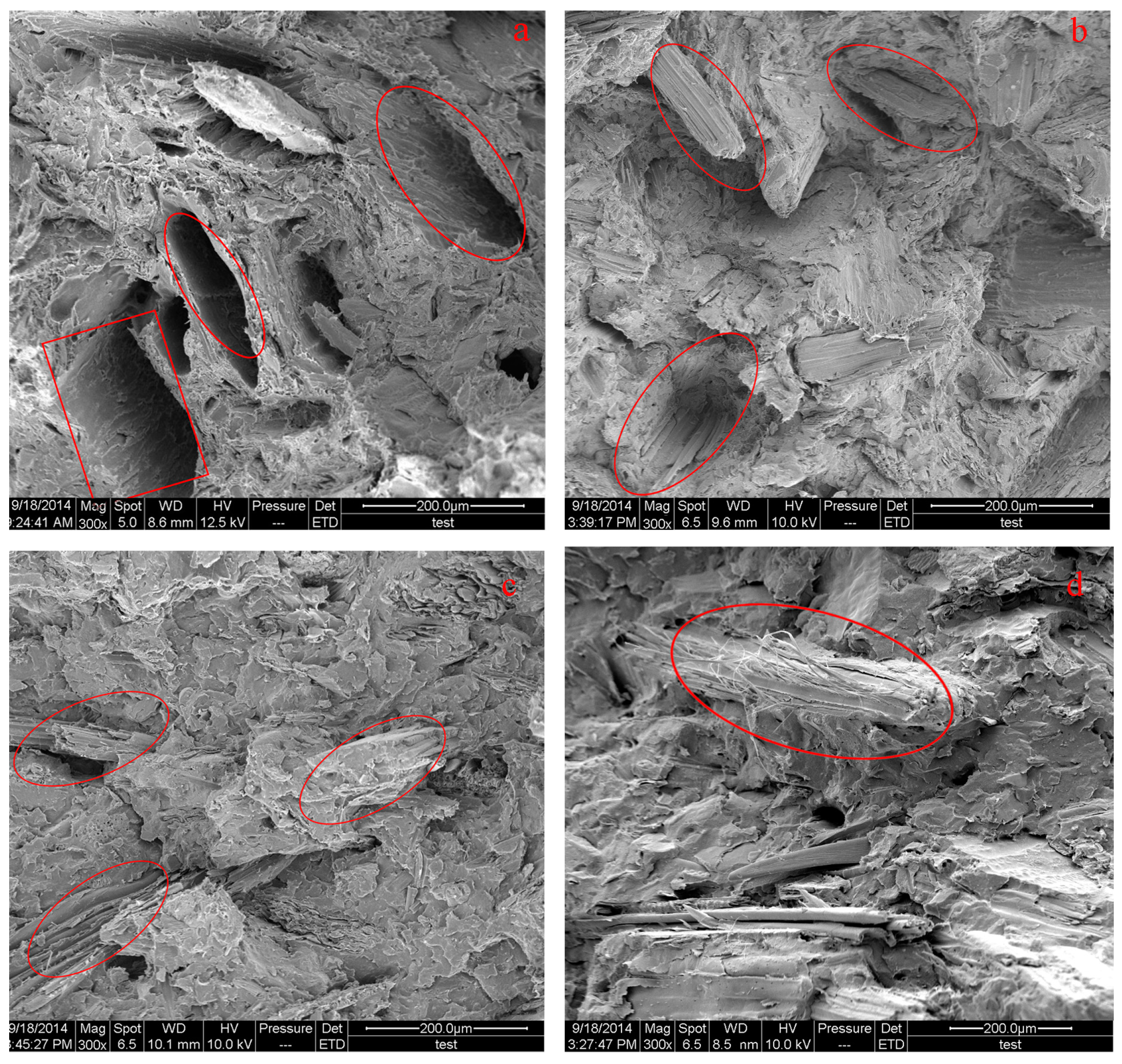

Figure 8.

Scanning electron microscopy (SEM) micrographs of WPC prepared from untreated wood fibers and fibers modified through high-temperature high-pressure steam under different conditions: (a) untreated fibers; (b) T = 120 °C, p = 0.2 MPa, t = 5 min; (c) T = 170 °C, p = 0.8 MPa, t = 5 min; and (d) T = 170 °C, p = 0.8 MPa, t = 15 min.

Figure 8.

Scanning electron microscopy (SEM) micrographs of WPC prepared from untreated wood fibers and fibers modified through high-temperature high-pressure steam under different conditions: (a) untreated fibers; (b) T = 120 °C, p = 0.2 MPa, t = 5 min; (c) T = 170 °C, p = 0.8 MPa, t = 5 min; and (d) T = 170 °C, p = 0.8 MPa, t = 15 min.

Table 1.

Factors and levels of the orthogonal array.

Table 1.

Factors and levels of the orthogonal array.

| Number | Factors | Levels |

|---|

| 1 | 2 | 3 | 4 |

|---|

| 1 | Temperature (°C) | 120 | 140 | 160 | 170 |

| 2 | Steam pressure (MPa) | 0.2 | 0.4 | 0.6 | 0.8 |

| 3 | Time (min) | 5 | 10 | 15 | 20 |

Table 2.

Orthogonal experimental design for the L16 (45) orthogonal array.

Table 2.

Orthogonal experimental design for the L16 (45) orthogonal array.

| Piece Number | Temperature (°C) | Steam Pressure (MPa) | Time (min) | Test Battery |

|---|

| A | B | C |

|---|

| 1 | 120 | 0.2 | 5 | A1B1C1 |

| 2 | 120 | 0.4 | 10 | A1B2C2 |

| 3 | 120 | 0.6 | 15 | A1B3C3 |

| 4 | 120 | 0.8 | 20 | A1B4C4 |

| 5 | 140 | 0.2 | 10 | A2B1C2 |

| 6 | 140 | 0.4 | 5 | A2B2C1 |

| 7 | 140 | 0.6 | 20 | A2B3C4 |

| 8 | 140 | 0.8 | 15 | A2B4C3 |

| 9 | 160 | 0.2 | 15 | A3B1C3 |

| 10 | 160 | 0.4 | 20 | A3B2C4 |

| 11 | 160 | 0.6 | 5 | A3B3C1 |

| 12 | 160 | 0.8 | 10 | A3B4C2 |

| 13 | 170 | 0.2 | 20 | A4B1C4 |

| 14 | 170 | 0.4 | 15 | A4B2C3 |

| 15 | 170 | 0.6 | 10 | A4B3C2 |

| 16 | 170 | 0.8 | 5 | A4B4C1 |

Table 3.

Results of the range analysis of the effect of the processing parameters on the mechanical properties of the prepared wood plastic composites (WPCs).

Table 3.

Results of the range analysis of the effect of the processing parameters on the mechanical properties of the prepared wood plastic composites (WPCs).

| Impact Strength (kJ·m−2) | Tensile (MPa) | Flexural (MPa) |

|---|

| Temperature | Pressure | Time | Temperature | Pressure | Time | Temperature | Pressure | Time |

|---|

| δj1 | 38.04 | 41.02 | 43.87 | 80.04 | 80.70 | 83.64 | 187.59 | 190.71 | 193.58 |

| δj2 | 42.68 | 44.41 | 44.77 | 83.36 | 83.80 | 83.63 | 192.49 | 195.23 | 195.81 |

| δj3 | 46.10 | 45.65 | 45.49 | 85.59 | 85.65 | 84.93 | 198.47 | 197.87 | 197.39 |

| δj4 | 54.35 | 50.09 | 47.04 | 89.72 | 88.56 | 86.51 | 208.28 | 203.02 | 200.05 |

| 9.51 | 10.26 | 10.97 | 20.01 | 20.18 | 20.91 | 46.90 | 47.68 | 48.40 |

| 10.67 | 11.10 | 11.19 | 20.84 | 20.95 | 20.91 | 48.12 | 48.81 | 48.95 |

| 11.53 | 11.41 | 11.37 | 21.40 | 21.41 | 21.23 | 49.62 | 49.47 | 49.35 |

| 13.59 | 12.52 | 11.76 | 22.43 | 22.14 | 21.63 | 52.07 | 50.76 | 50.01 |

| R | 4.08 | 1.42 | 0.18 | 2.42 | 1.19 | 0.33 | 5.17 | 1.95 | 0.40 |

| Flexural | A > B > C | A > B > C | A > B > C |

Table 4.

Variance analysis of the impact, tensile, and flexural strengths of the wood fiber/HDPE composites.

Table 4.

Variance analysis of the impact, tensile, and flexural strengths of the wood fiber/HDPE composites.

| Impact Strength (kJ·m−2) | Tensile Strength (MPa) | Flexural Strength (MPa) |

|---|

| A × 103 | B × 103 | C × 103 | A × 103 | B × 103 | C × 103 | A × 103 | B × 103 | C × 103 |

|---|

| 1.45 | 1.68 | 1.92 | 6.41 | 6.51 | 7 | 35.19 | 36.37 | 37.47 |

| 1.82 | 1.97 | 2.01 | 6.95 | 7.02 | 6.99 | 37.05 | 38.11 | 38.34 |

| 2.23 | 2.08 | 2.07 | 7.33 | 7.34 | 7.21 | 39.39 | 39.15 | 38.92 |

| 2.95 | 2.51 | 2.21 | 8.05 | 7.84 | 7.48 | 43.38 | 41.22 | 40.02 |

| P | 8.35 | 8.25 | 8.21 | 28.73 | 28.71 | 28.69 | 155.01 | 154.85 | 154.79 |

| Q | 2.09 | 2.06 | 2.05 | 7.18 | 7.18 | 7.17 | 38.75 | 38.71 | 38.69 |

| S | 1.17 | 1.15 | 1.14 | 6.27 | 6.26 | 6.25 | 37.84 | 37.8 | 37.78 |

| Impact | A > B > C | A > B > C | A > B > C |

Table 5.

Significance analysis for the factors affecting the impact strength.

Table 5.

Significance analysis for the factors affecting the impact strength.

| Factor | Degree of Freedom | Sum of Deviation Square | Mean Square Error | F | p | Significance |

|---|

| A | 3 | 35.53 | 11.84 | 59.82 | 0.000073 | *** |

| B | 3 | 10.54 | 3.51 | 17.75 | 0.00218 | ** |

| C | 3 | 1.35 | 0.45 | 2.27 | 0.18 | |

| Error | 6 | 0.0003 | 0.00110 | – | – | |

| Model | 15 | 0.0170 | 0.00005 | – | – | |

Table 6.

Significance analysis for the factors affecting the tensile strength.

Table 6.

Significance analysis for the factors affecting the tensile strength.

| Factor | Degree of Freedom | Sum of Deviation Square | Mean Square Error | F | p | Significance |

|---|

| A | 3 | 12.38 | 4.13 | 13.83 | 0.004194 | ** |

| B | 3 | 8.15 | 2.72 | 9.11 | 0.01186 | * |

| C | 3 | 1.40 | 0.47 | 1.56 | 0.01186 | * |

| Error | 6 | 0.0003 | 0.00110 | – | – | |

| Model | 15 | 0.0170 | 0.00005 | – | – | |

Table 7.

Significance analysis for the factors affecting the flexural strength.

Table 7.

Significance analysis for the factors affecting the flexural strength.

| Factor | Degree of Freedom | Sum of Deviation Square | Mean Square Error | F | p | Significance |

|---|

| A | 3 | 59.49 | 19.83 | 57.26 | 0.000083 | *** |

| B | 3 | 19.84 | 6.61 | 19.10 | 0.0018 | ** |

| C | 3 | 5.56 | 1.85 | 5.53 | 0.047 | * |

| Error | 6 | 0.0003 | 0.00110 | – | – | |

| Model | 15 | 0.0170 | 0.00005 | – | – | |

Table 8.

Comparison of the crystal properties and degrees of crystallinity of the unmodified and modified wood fibers.

Table 8.

Comparison of the crystal properties and degrees of crystallinity of the unmodified and modified wood fibers.

| Category | Piece Number | 002 Crystal Plane Angle | Crystallinity |

|---|

| High temperature and pressurized steam treatment | b | 22.62° | 54.02% |

| c | 22.82° | 58.80% |

| d | 22.79° | 52.74% |

| e | 21.67° | 68.94% |

| Control sample | a | 22.88° | 46.68% |

Table 9.

Comparison of the pyrolysis characteristics of the unmodified and modified wood fibers.

Table 9.

Comparison of the pyrolysis characteristics of the unmodified and modified wood fibers.

| Material Code | TGA Analysis |

|---|

| First Stage | Second Stage | Third Stage |

|---|

| Temperature Range | Weight Loss Ratio | Temperature Range | Weight Loss Ratio | Temperature Range | Weight Loss Ratio |

|---|

| a | 30%–205% | 4.4% | 205%–315% | 56% | 315%–600% | 9.3% |

| b | 30%–220% | 4.7% | 220%–340% | 59% | 340%–600% | 6.6% |

| c | 30%–230% | 4.6% | 230%–350% | 64% | 350%–600% | 8.5% |

| d | 30%–250% | 4.6% | 250%–370% | 66% | 370%–600% | 7.3% |

| e | 0% | 0% | 0% | 0% | 375%–475% | 91% |