An Online MFL Sensing Method for Steel Pipe Based on the Magnetic Guiding Effect

Abstract

:1. Introduction

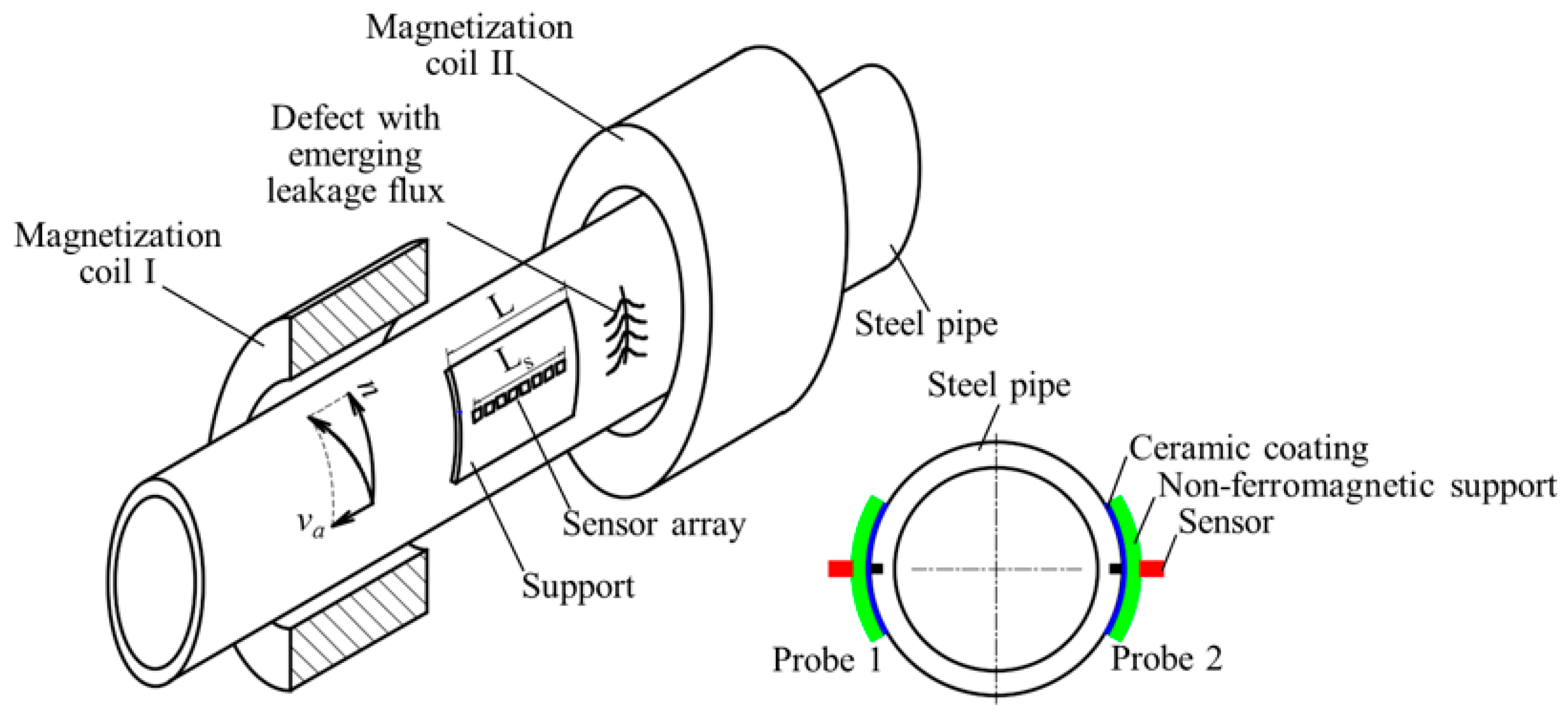

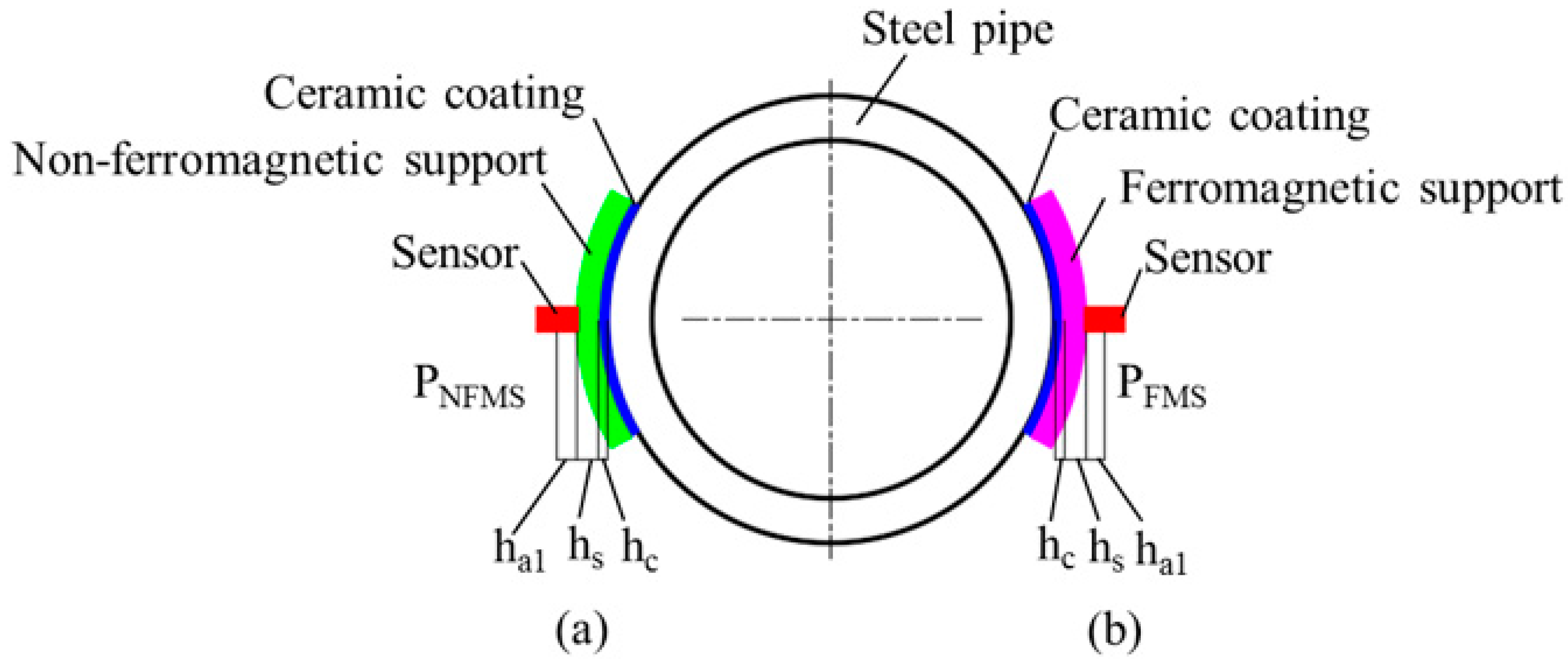

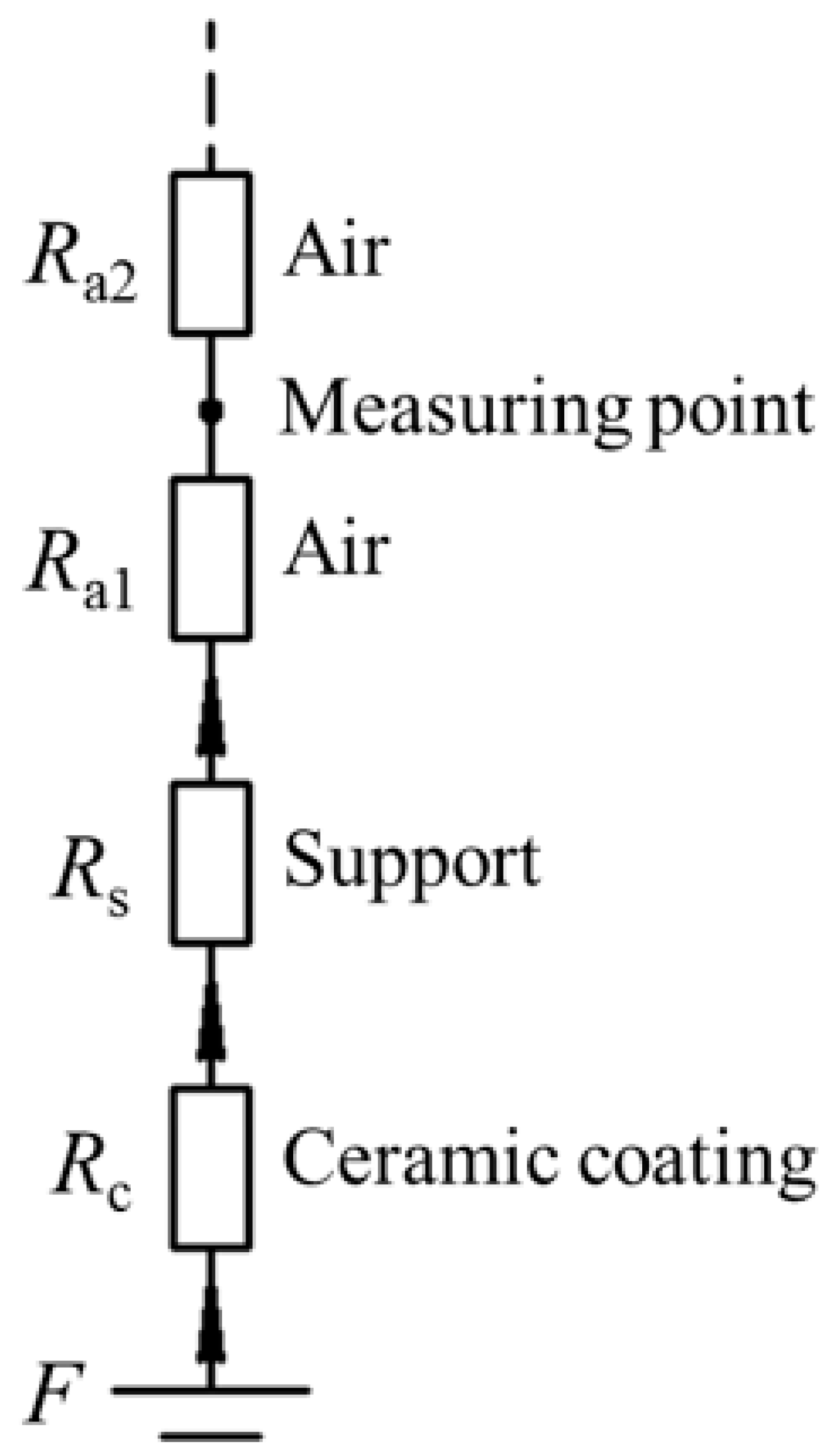

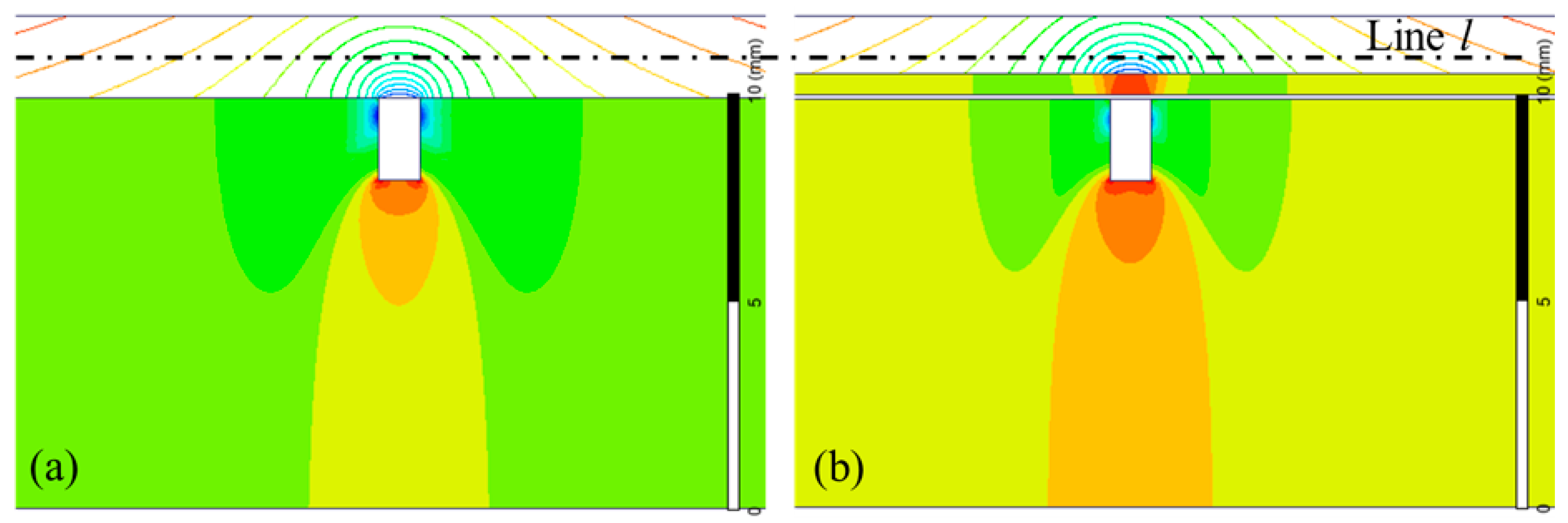

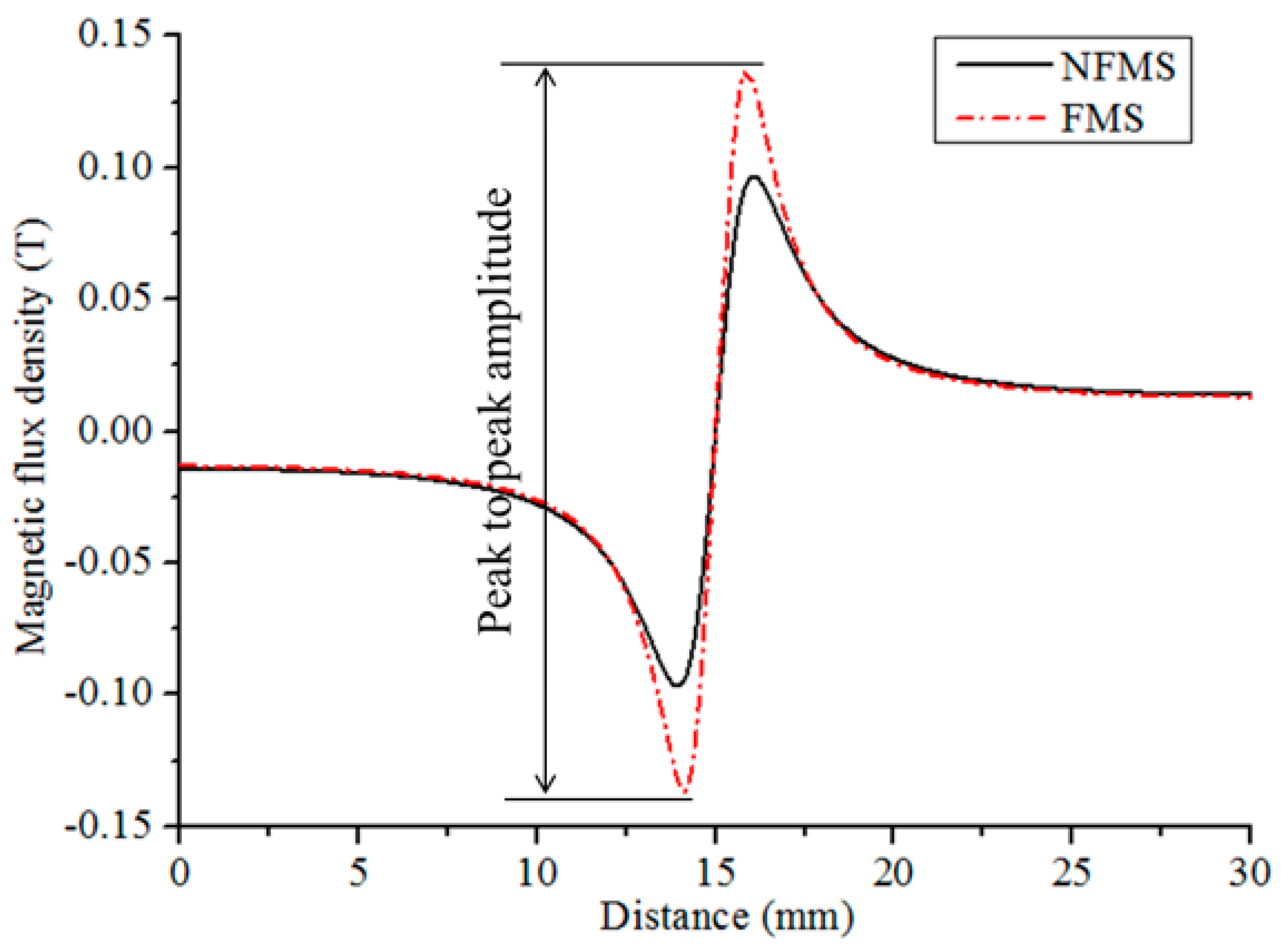

2. The Principle of the MFL Sensing Method Based on the Magnetic Guiding Effect

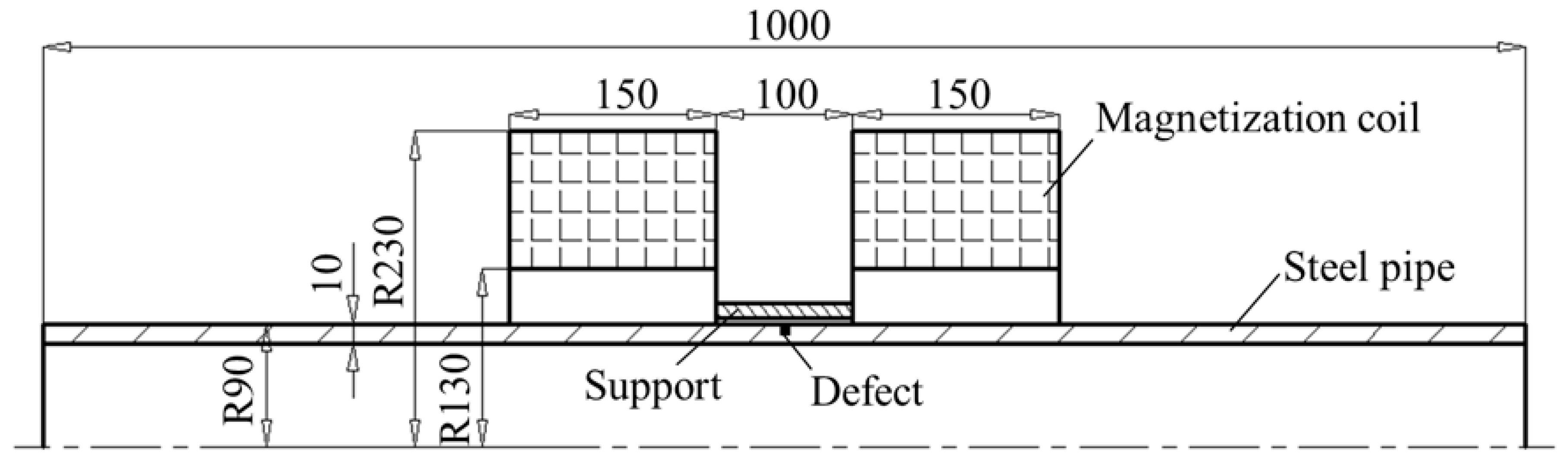

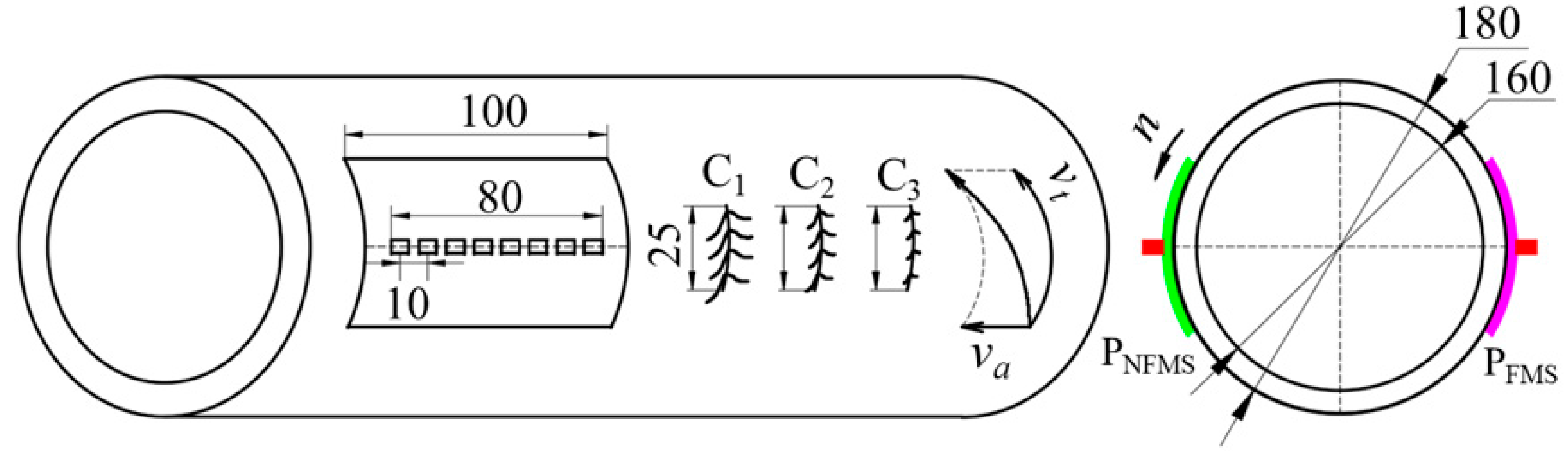

3. Numerical Simulation of the MFL Sensing Method Based on the Magnetic Guiding Effect

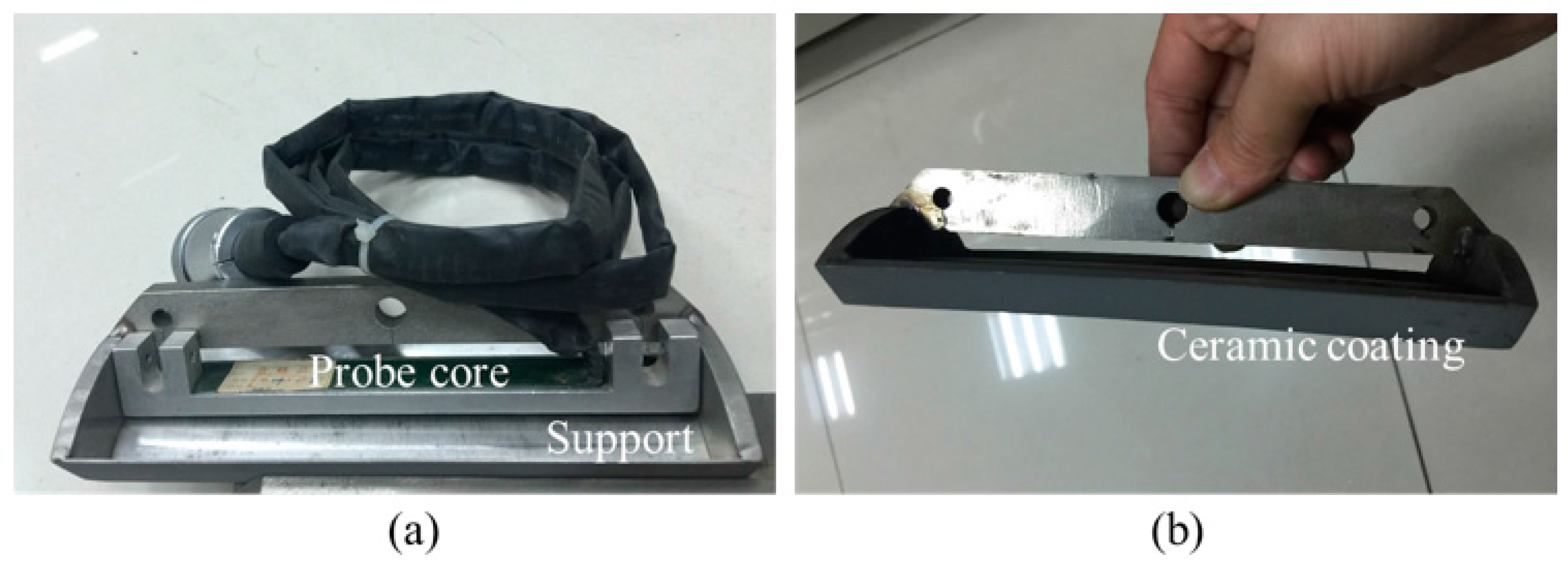

4. Experimental Study of the MFL Sensing Method Based on the Magnetic Guiding Effect

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- American Petroleum Institute (API). API Spec 5D-Specification for Drill Pipe, 5th ed.; API: Washington, DC, USA, 2002. [Google Scholar]

- Leslie, T.E. Ultrasonic Pipe Testing System. U.S. Patent 3921,440, 25 November 1975. [Google Scholar]

- Tu, J.; Kang, Y.; Wu, J.; Sun, Y. A calibration method based on the reconstruction for automatic ultrasonic flaw detection of the upset region of the drill pipe. Int. J. Appl. Electromagn. Mech. 2014, 45, 131–135. [Google Scholar]

- Jiles, D.C. Review of magnetic methods for nondestructive evaluation. NDT Int. 1990, 23, 83–92. [Google Scholar]

- Chen, Z.; Yusa, N.; Miya, K. Enhancements of eddy current testing techniques for quantitative nondestructive testing of key structural components of nuclear power plants. Nuclear Eng. Des. 2008, 238, 1651–1656. [Google Scholar] [CrossRef]

- Yusa, N.; Chen, Z.; Miya, K. Quantitative profile evaluation of natural cracks in a steam generator tube from eddy current signals. Int. J. Appl. Electromagn. Mech. 2000, 12, 139–150. [Google Scholar]

- Forster, F. New findings in the field of non-destructive magnetic leakage field inspection. NDT Int. 1986, 19, 3–14. [Google Scholar] [CrossRef]

- Forster, F. On the way from the «Know-haw» to the «Know-why» in the magnetic leakage field method of nondestructive testing. Mater. Eval. 1985, 43, 1154–1162. [Google Scholar]

- Sperry, E.A. Fissure Detector for Magnetic Materials. U.S. Patent 1867685, 19 July 1932. [Google Scholar]

- Ramuhalli, P.; Udpa, L.; Udpa, S. Neural network-based inversion algorithms in magnetic flux leakage nondestructive evaluation. J. Appl. Phys. 2003, 93, 8274–8276. [Google Scholar] [CrossRef]

- Kang, Y.; Wu, J.; Sun, Y. The use of magnetic flux leakage testing method and apparatus for steel pipe. Mater. Eval. 2012, 70, 821–827. [Google Scholar]

- Liu, B.; He, L.; Zhang, H.; Cao, Y.; Fernandes, H. The axial crack testing model for long distance oil-gas pipeline based on magnetic flux leakage internal inspection method. Measurement 2017, 103, 275–282. [Google Scholar] [CrossRef]

- Li, Z.; Jarvis, R.; Nagy, P.B.; Dixon, S.; Cawley, P. Experimental and simulation methods to study the Magnetic Tomography Method (MTM) for pipe defect detection. NDT E Int. 2017, 92, 59–66. [Google Scholar] [CrossRef]

- Usarek, Z.; Warnke, K. Inspection of Gas Pipelines Using Magnetic Flux Leakage Technology. Adv. Mater. Sci. 2017, 17, 37–45. [Google Scholar] [CrossRef]

- Kim, Y.G.; Moon, H.S.; Kim, J.; Kim, J.H. Development of Health Monitoring System Using Self Magnetization Magnetostrictive Sensor. J. Korean Inst. Intell. Syst. 2012, 22, 481–486. [Google Scholar] [CrossRef]

- Yusa, N. Magnetic flux leakage testing for defect characterization. Electromagn. Nondestruct. Eval. (XIX) 2016, 41, 126. [Google Scholar]

- Deng, Z.; Sun, Y.; Yang, Y.; Kang, Y. Effects of surface roughness on magnetic flux leakage testing of micro-cracks. Meas. Sci. Technol. 2017, 28, 045003. [Google Scholar] [CrossRef]

- Chang, Y.; Jiao, J.; Li, G.; Liu, X.; He, C.; Wu, B. Effects of excitation system on the performance of magnetic-flux-leakage-type non-destructive testing. Sens. Actuators A Phys. 2017, 268, 201–212. [Google Scholar] [CrossRef]

- Dutta, S.M. Magnetic Flux Leakage SENSING: The Forward and Inverse Problem. Ph.D. Thesis, Rice University, Houston, TX, USA, 2008. [Google Scholar]

- Wang, P.; Gao, Y.; Tian, G.Y.; Wang, H. Velocity effect analysis of dynamic magnetization in high speed magnetic flux leakage inspection. NDT E Int. 2014, 64, 7–12. [Google Scholar] [CrossRef]

- Li, Y.; Wilson, J.; Tian, G.Y. Experiment and simulation study of 3D magnetic field sensing for magnetic flux leakage defect characterisation. NDT E Int. 2007, 40, 179–184. [Google Scholar] [CrossRef]

- Weischedel, H.R. The inspection of wire ropes in service: A critical review. Mater. Eval. 1985, 43, 1592–1594. [Google Scholar]

- Weischedel, H.R.; Ramsey, R. Electromagnetic testing, a reliable method for the inspection of wire ropes in service. NDT E Int. 1989, 22, 155–161. [Google Scholar] [CrossRef]

- Kashyap, S.; Laxminarayna, G.; Tewathri, S.; Sinha, A. In Non-Destructive Testing of Steel Wire Ropes and Their Discard Criteria. In Proceedings of the 8th International Conference on Non-Destructive Testing in Engineering, Portoroz, Slovenia, 1–3 September 2005; pp. 229–235. [Google Scholar]

- Cui, W.; Xing, H.; Jiang, M.; Leng, J.C. Using a New Magnetic Flux Leakage Method to Detect Tank Bottom Weld Defects. Open Pet. Eng. J. 2017, 10, 73–81. [Google Scholar] [CrossRef]

- Tu, J.; Qiu, G.; Chen, H.; Song, X. An automatic navigation magnetic flux leakage testing robot for tank floor inspection. Int. J. Appl. Electromagn. Mech. 2016, 52, 399–405. [Google Scholar] [CrossRef]

- Xu, J.; Wu, X.; Cheng, C.; Ben, A. A magnetic flux leakage and magnetostrictive guided wave hybrid transducer for detecting bridge cables. Sensors 2012, 12, 518–533. [Google Scholar] [CrossRef] [PubMed]

- Rogers, J.P. Magnetic Flux Leakage System and Method. U.S. Patent 11591712, 8 May 2008. [Google Scholar]

- Siebert, M.; Sutherland, J. Application of the Circumferential Component of Magnetic Flux Leakage Measurement for In-line Inspection of Pipelines. Corrosion 1999, 99, 25–30. [Google Scholar]

- Smith, J.W.K.; Hay, B.R. Magnetic Flux Leakage Inspection Tool for Pipelines. U.S. Patent 6,023,986, 15 February 2000. [Google Scholar]

- Sun, Y.; Kang, Y. High-speed magnetic flux leakage technique and apparatus based on orthogonal magnetization for steel pipe. Mater. Eval. 2010, 68, 452–458. [Google Scholar]

- Sun, Y.; Kang, Y. The feasibility of MFL inspection for omni-directional defects under a unidirectional magnetization. Int. J. Appl. Electromagn. Mech. 2010, 33, 919–925. [Google Scholar]

- Wu, J.; Sun, Y.; Feng, B.; Kang, Y. The effect of motion-induced eddy current on circumferential magnetization in MFL testing for a steel pipe. IEEE Trans. Magn. 2017, 53, 6201506. [Google Scholar] [CrossRef]

- Li, Y.; Tian, G.Y.; Ward, S. Numerical simulation on magnetic flux leakage evaluation at high speed. NDT E Int. 2006, 39, 367–373. [Google Scholar] [CrossRef]

- Yang, S.; Sun, Y.; Udpa, L.; Udpa, S.S.; Lord, W. 3D simulation of velocity induced fields for non-destructive evaluation application. IEEE Trans. Magn. 1999, 35, 1754–1756. [Google Scholar] [CrossRef]

- Zhiye, D.; Jiangjun, R.; Ying, P.; Shifeng, Y.; Yu, Z.; Yan, G.; Tianwei, L. 3-D FEM simulation of velocity effects on magnetic flux leakage testing signals. IEEE Trans. Magn. 2008, 44, 1642–1645. [Google Scholar] [CrossRef]

- Shin, Y.K.; Lord, W. Numerical modeling of moving probe effects for electromagnetic nondestructive evaluation. IEEE Trans. Magn. 1993, 29, 1865–1868. [Google Scholar] [CrossRef]

- Lu, S.; Feng, J.; Li, F.; Liu, J. Precise Inversion for the Reconstruction of Arbitrary Defect Profiles Considering Velocity Effect in Magnetic Flux Leakage Testing. IEEE Trans. Magn. 2017, 53, 1–12. [Google Scholar] [CrossRef]

- Wu, J.; Fang, H.; Wang, J.; Kang, Y. Sensitivity difference caused by eddy-current magnetic field in Hi-speed MFL testing and its elimination method. Int. J. Appl. Electromagn. Mech. 2016, 52, 1007–1014. [Google Scholar] [CrossRef]

- Sophian, A.; Tian, G.Y.; Zairi, S. Pulsed magnetic flux leakage techniques for crack detection and characterisation. Sens. Actuators A Phys. 2006, 125, 186–191. [Google Scholar] [CrossRef]

- Tian, G.Y.; Wilson, J.; Morozov, M.; Thompson, D.O.; Chimenti, D.E. Complementary electromagnetic non-destructive evaluation. AIP Conf. Proc. 2011, 1335, 1256–1263. [Google Scholar]

- Katragadda, G.; Lord, W.; Sun, Y.S.; Udpa, S.; Udpa, L. Alternative magnetic flux leakage modalities for pipeline inspection. IEEE Trans. Magn. 1996, 32, 1581–1584. [Google Scholar] [CrossRef]

- Ma, Y.; He, R.; Chen, J. A method for improving SNR of drill pipe leakage flux testing signals by means of magnetic concentrating effect. IEEE Trans. Magn. 2015, 51, 1–7. [Google Scholar] [CrossRef]

- Wu, J.; Hui, F.; Long, L.; Yihua, K. The signal characteristics of rectangular induction coil affected by sensor arrangement and scanning direction in MFL application. Int. J. Appl. Electromagn. Mech. 2016, 52, 1257–1265. [Google Scholar] [CrossRef]

- Wu, J.; Fang, H.; Li, L.; Wang, J. A Lift-Off-Tolerant Magnetic Flux Leakage Testing Method for Drill Pipes at Wellhead. Sensors 2017, 17, 201. [Google Scholar] [CrossRef] [PubMed]

- Jianbo, W.; Hui, F.; Jie, W.; Yihua, K. The influence of non-uniform wall thickness on MFL testing for a steel pipe. Insight-Non-Destruct. Test. Cond. Monit. 2015, 57, 703–708. [Google Scholar] [CrossRef]

- Tsukada, K.; Majima, Y.; Nakamura, Y.; Yasugi, T.; Song, N.; Sakai, K.; Kiwa, T. Detection of Inner Cracks in Thick Steel Plates Using Unsaturated AC Magnetic Flux Leakage Testing with a Magnetic Resistance Gradiometer. IEEE Trans. Magn. 2017, 53. [Google Scholar] [CrossRef]

- Chen, L.; Que, P.W.; Jin, T. A giant-magnetoresistance sensor for magnetic-flux-leakage nondestructive testing of a pipeline. Russ. J. Nondestruct. Test. 2005, 41, 462–465. [Google Scholar] [CrossRef]

- Philip, J.; Rao, C.B.; Jayakumar, T.; Raj, B. A new optical technique for detection of defects in ferromagnetic materials and components. NDT E Int. 2000, 33, 289–295. [Google Scholar] [CrossRef]

- Parra-Raad, J.A.; Roa-Prada, S. Multi-Objective Optimization of a Magnetic Circuit for Magnetic Flux Leakage-Type Non-destructive Testing. J. Nondestruct. Eval. 2016, 35, 14. [Google Scholar] [CrossRef]

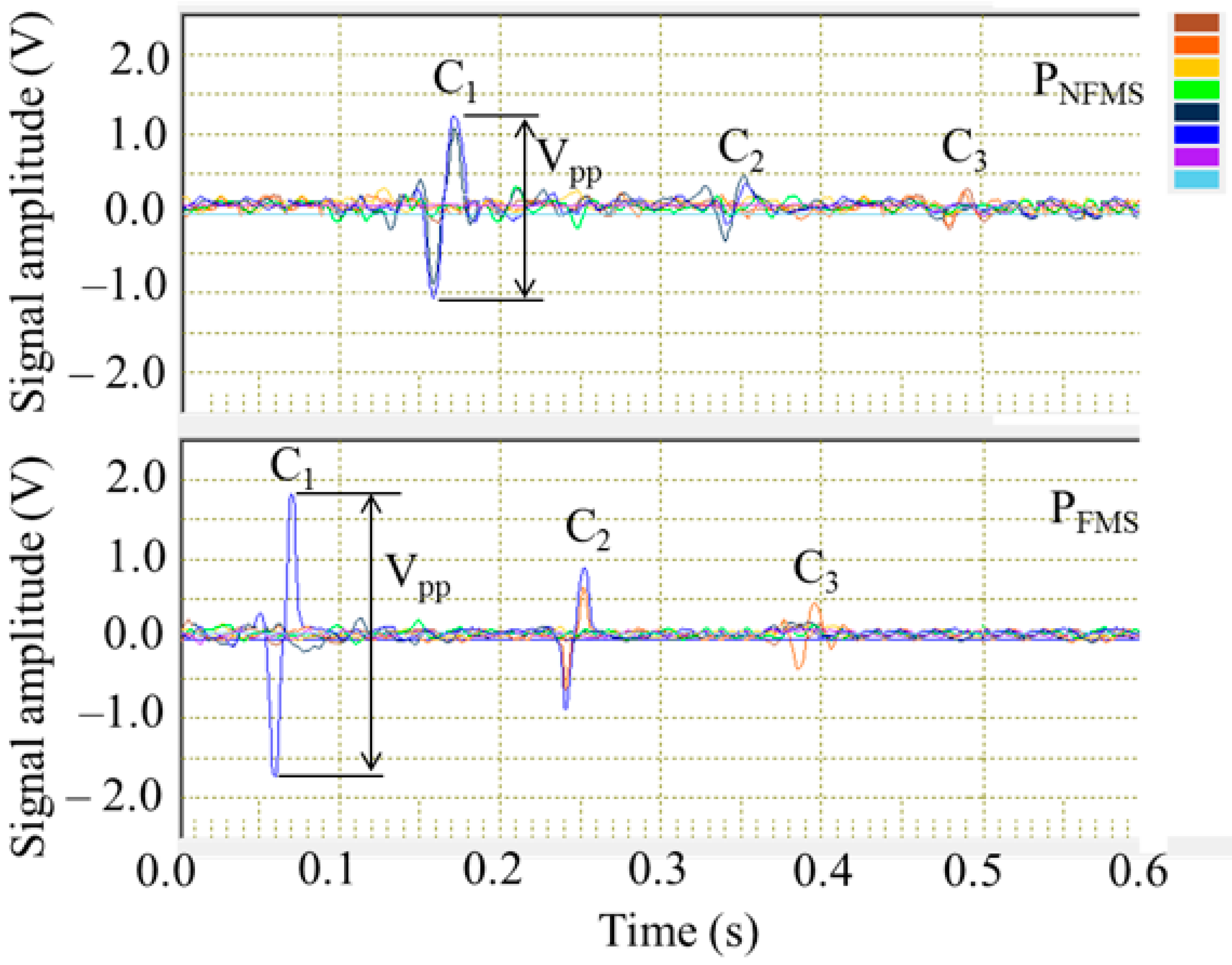

| Probe | C1 | C2 | C3 |

|---|---|---|---|

| PNFMS | 16.5 dB | 8.3 dB | / |

| PFMS | 19.3 dB | 13.4 dB | 6.3 dB |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Fang, H.; Huang, X.; Xia, H.; Kang, Y.; Tang, C. An Online MFL Sensing Method for Steel Pipe Based on the Magnetic Guiding Effect. Sensors 2017, 17, 2911. https://doi.org/10.3390/s17122911

Wu J, Fang H, Huang X, Xia H, Kang Y, Tang C. An Online MFL Sensing Method for Steel Pipe Based on the Magnetic Guiding Effect. Sensors. 2017; 17(12):2911. https://doi.org/10.3390/s17122911

Chicago/Turabian StyleWu, Jianbo, Hui Fang, Xiaoming Huang, Hui Xia, Yihua Kang, and Chaoqing Tang. 2017. "An Online MFL Sensing Method for Steel Pipe Based on the Magnetic Guiding Effect" Sensors 17, no. 12: 2911. https://doi.org/10.3390/s17122911