A Real-Time Smooth Weighted Data Fusion Algorithm for Greenhouse Sensing Based on Wireless Sensor Networks

Abstract

:1. Introduction

2. Data Fusion and Self-Learning

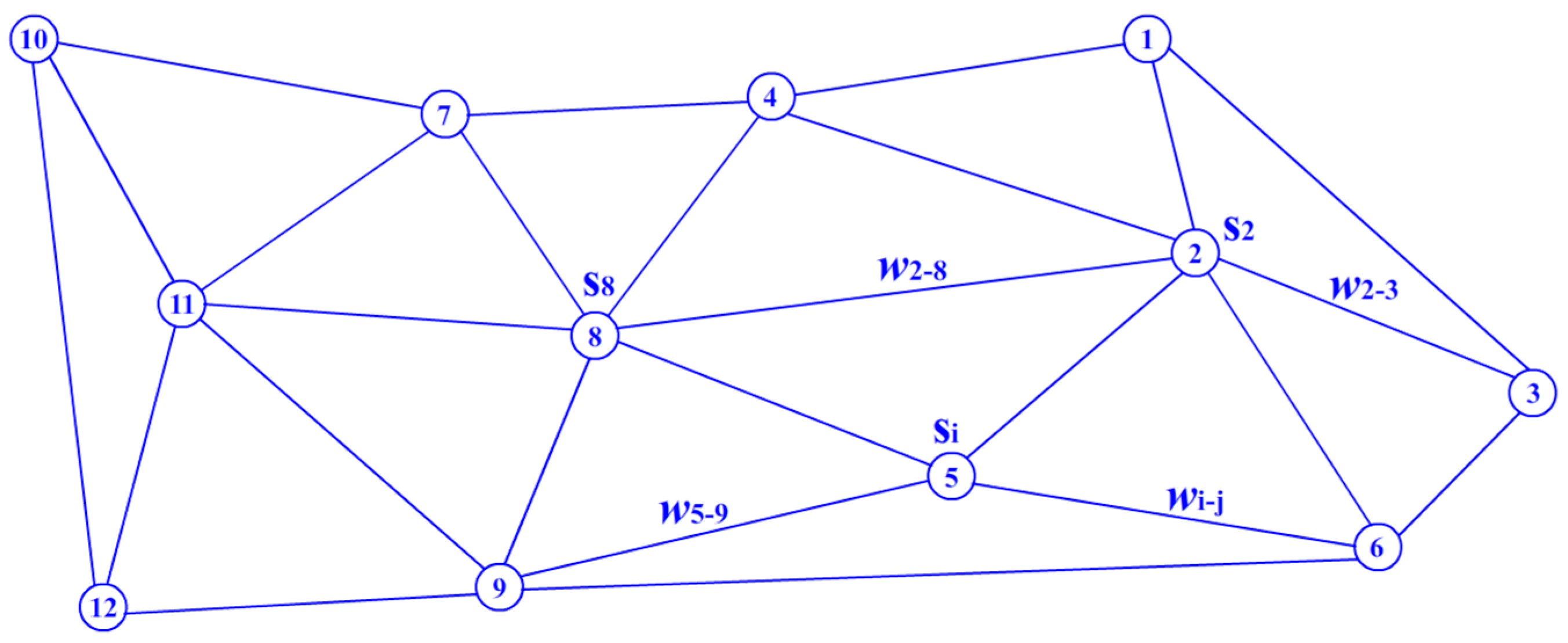

2.1. Adjacent Graph and Stable Area

| Algorithm 1. Procedure to find a stable area via a search algorithm | |

| Input: | The adjacent graph ({V, S, E, W}), in which V = {u0, u1, u2, …} is the set of nodes with corresponding S = {s0, s1, s2, …} as their smoothing values and E is the set of arcs with W as their weights. |

| Output: a set of nodes U in the stable area | |

| Start: | |

| Sort the set V from small to large by their smoothing value S to make V’ | |

| Initialize U = {u0}, O = {} and TE = {}, in which u0 is the first vertex in V’, O is a set for storing obsolete vertexes during operation and TE is a set for storing valid arcs during operation. | |

| while U∪O ≠ V’ | |

| Find the arc (ui, vj) with minimum weight that satisfies ui∈U, vj∈V’-U-O | |

| if sj < λ (sj is the smoothing value for vertex vj) | |

| U = U∪{vj}; TE = TE∪{(ui, vj)} | |

| else | |

| O = O∪{vj} | |

| end if | |

| end while | |

| end | |

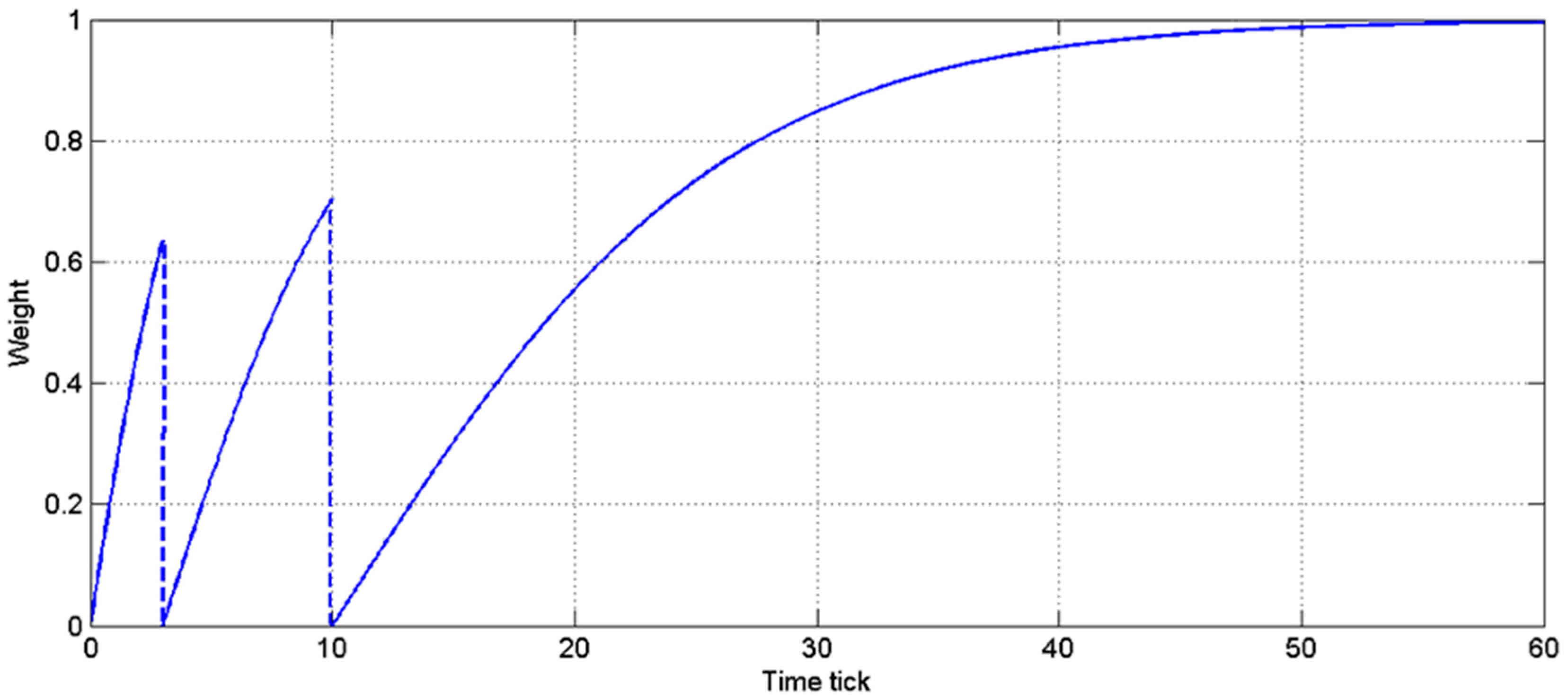

2.2. Data Fusion Based on Dynamic Weight

3. Acceleration Mechanism with an Adaptive Threshold

3.1. Procedure of the Acceleration Mechanism

3.2. Prediction Algorithm

| Algorithm 2. Kalman filter procedure |

| Initialization: |

| Calculation: when k ≥ 0, |

4. Simulation and Experiments

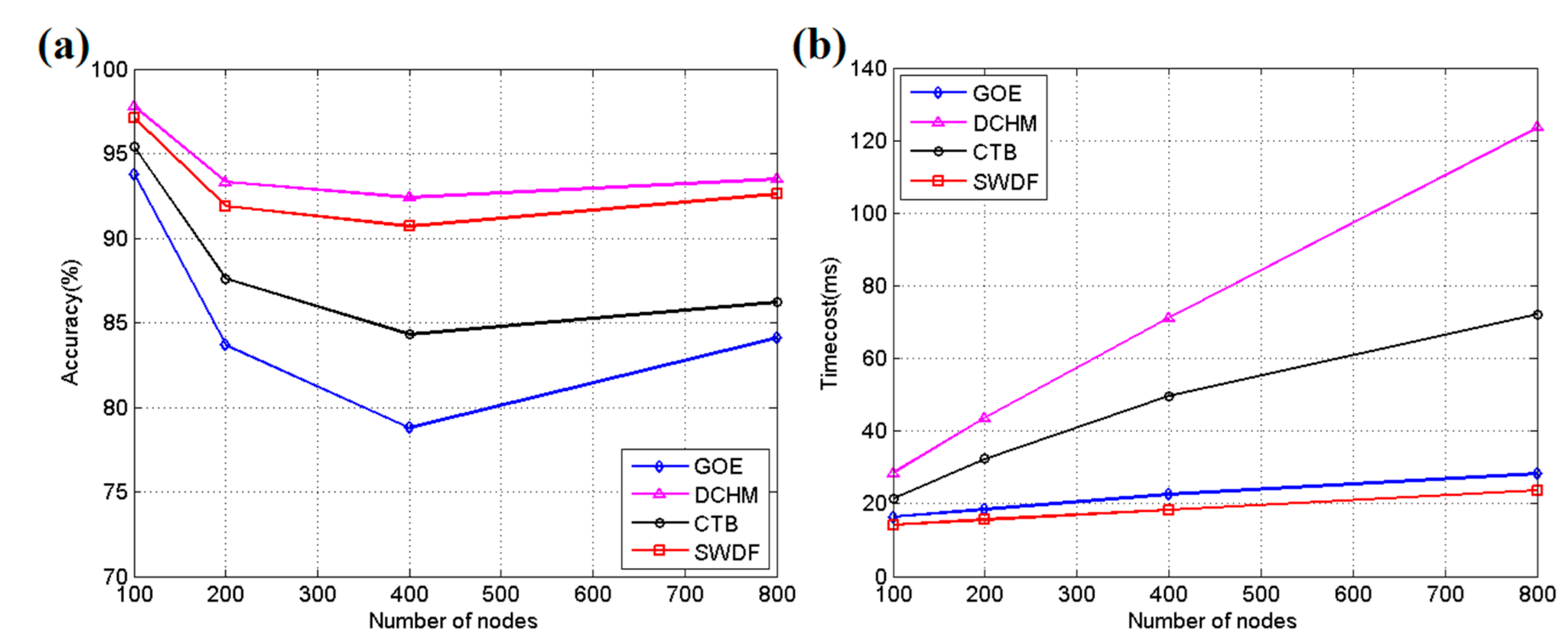

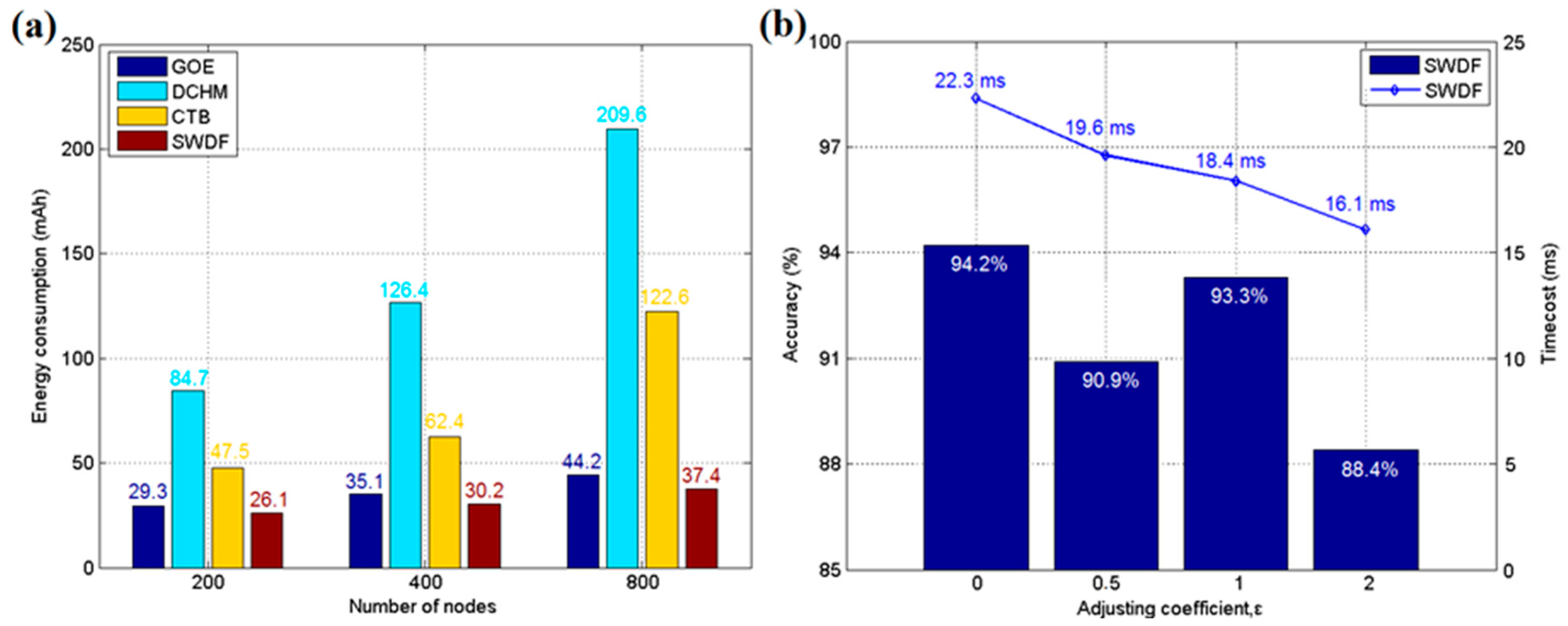

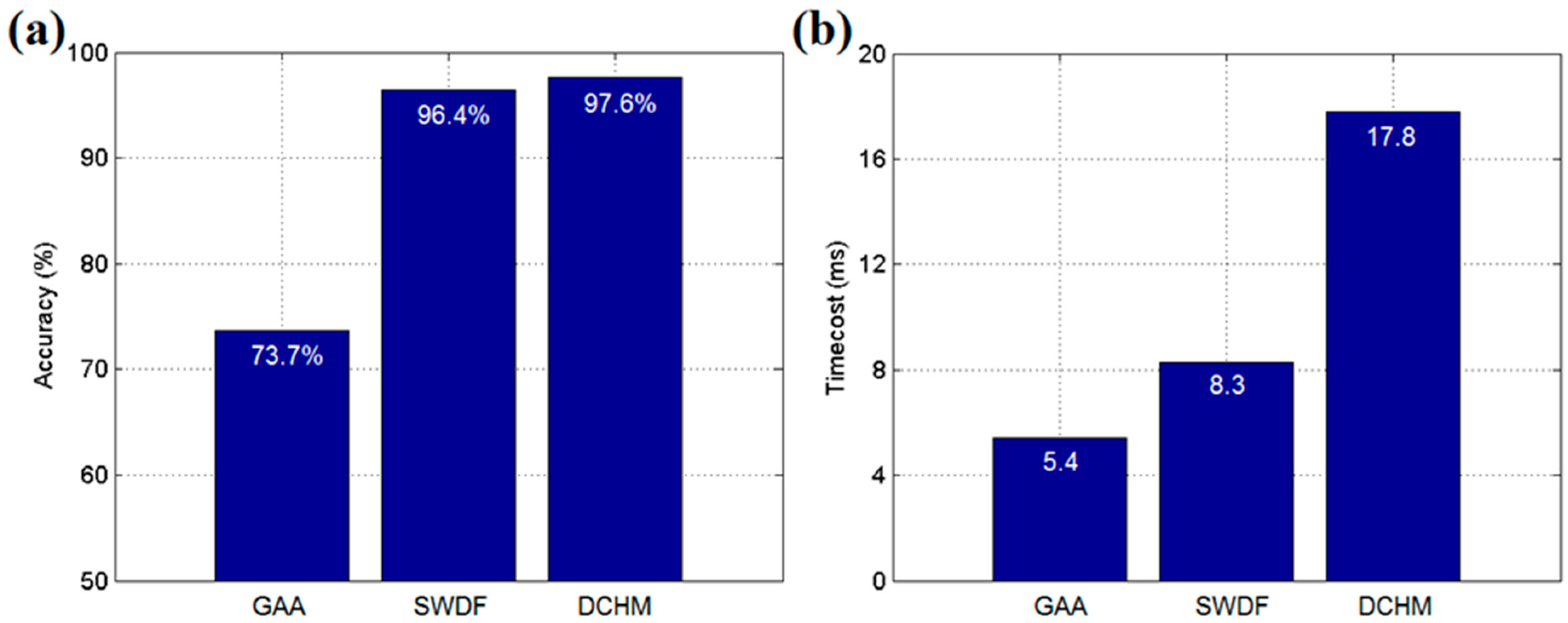

4.1. Simulation Results and Discussion

4.2. Implementation and Experiments

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kampianakis, E.; Kimionis, J.; Tountas, K.; Konstantopoulos, C.; Koutroulis, E.; Bletsas, A. Wireless environmental sensor networking with analog scatter radio and timer principles. IEEE Sens. J. 2014, 14, 3365–3376. [Google Scholar] [CrossRef]

- Iqbal, M.; Naeem, M.; Anpalagan, A.; Ahmed, A.; Azam, M. Wireless sensor network optimization: Multi-objective paradigm. Sensors 2015, 15, 17572–17620. [Google Scholar] [CrossRef] [PubMed]

- Zou, T.; Lin, S.; Feng, Q.; Chen, Y. Energy-Efficient Control with Harvesting Predictions for Solar-Powered Wireless Sensor Networks. Sensors 2016, 16, 53. [Google Scholar] [CrossRef] [PubMed]

- Polo, J.; Hornero, G.; Duijneveld, C.; García, A.; Casas, O. Design of a low-cost Wireless Sensor Network with UAV mobile node for agricultural applications. Comp. Electron. Agric. 2015, 119, 19–32. [Google Scholar] [CrossRef]

- Jiang, J.A.; Wang, C.H.; Liao, M.S.; Zheng, X.Y.; Liu, J.H.; Chuang, C.L.; Hung, C.L.; Chen, C.P. A wireless sensor network-based monitoring system with dynamic convergecast tree algorithm for precision cultivation management in orchid greenhouses. Precis. Agric. 2016, 17, 766–785. [Google Scholar] [CrossRef]

- Xu, L. Design of a RSSI location system for greenhouse environment. Int. J. Distrib. Sens. Netw. 2015, 11. [Google Scholar] [CrossRef]

- Li, T.; Zhang, M.; Ji, Y.; Sha, S.; Jiang, Y.; Li, M. Management of CO2 in a tomato greenhouse using WSN and BPNN techniques. Int. J. Agric. Biol. Eng. 2015, 8, 43. [Google Scholar]

- Lai, Y.; Xie, J.; Lin, Z.; Wang, T.; Liao, M. Adaptive data gathering in mobile sensor networks using speedy mobile elements. Sensors 2015, 15, 23218–23248. [Google Scholar] [CrossRef] [PubMed]

- Cayirpunar, O.; Kadioglu-Urtis, E.; Tavli, B. Optimal base station mobility patterns for wireless sensor network lifetime maximization. IEEE Sens. J. 2015, 15, 6592–6603. [Google Scholar] [CrossRef]

- Yin, X.; Fang, D.; Wang, W.; Chen, X. EETC: To transmit or not to transmit in mobile wireless sensor networks. Wirel. Netw. 2016, 22, 635–646. [Google Scholar] [CrossRef]

- Moshou, D.; Pantazi, X.E.; Kateris, D.; Gravalos, I. Water stress detection based on optical multisensor fusion with a least squares support vector machine classifier. Biosyst. Eng. 2014, 117, 15–22. [Google Scholar] [CrossRef]

- Moshou, D.; Gravalos, I.; Bravo, D.K.C.; Oberti, R.; West, J.S.; Ramon, H. Multisensor fusion of remote sensing data for crop disease detection. In Geospatial Techniques for Managing Environmental Resources; Springer: Dordrecht, The Netherlands, 2011; pp. 201–219. [Google Scholar]

- Felisberto, F.; Fdez-Riverola, F.; Pereira, A. A ubiquitous and low-cost solution for movement monitoring and accident detection based on sensor fusion. Sensors 2014, 14, 8961–8983. [Google Scholar] [CrossRef] [PubMed]

- Fu, J.S.; Liu, Y. Double cluster heads model for secure and accurate data fusion in wireless sensor networks. Sensors 2015, 15, 2021–2040. [Google Scholar] [CrossRef] [PubMed]

- Palafox-Albarran, J.; Jedermann, R.; Hong, B.; Lang, W. Cokriging for cross-attribute fusion in sensor networks. Inf. Fusion 2015, 24, 137–146. [Google Scholar] [CrossRef]

- Soganli, A.; Ercetin, O.; Cetin, M. On the Quality and Timeliness of Fusion in a Random Access Sensor Network. IEEE Signal Process. Lett. 2015, 22, 1259–1263. [Google Scholar] [CrossRef]

- Luo, X.; Chang, X. A novel data fusion scheme using grey model and extreme learning machine in wireless sensor networks. Int. J. Control Autom. Syst. 2015, 13, 539–546. [Google Scholar] [CrossRef]

- Mostefaoui, A.; Boukerche, A.; Merzoug, M.A.; Melkemi, M. A scalable approach for serial data fusion in Wireless Sensor Networks. Comp. Netw. 2015, 79, 103–119. [Google Scholar] [CrossRef]

- Lu, Z.; Tan, S.L.; Biswas, J. Fusion function placement for Active Networks paradigm in wireless sensor networks. Wirel. Netw. 2013, 19, 1525–1536. [Google Scholar] [CrossRef]

- Yan, L.; Jiang, L.; Xia, Y.; Fu, M. State estimation and data fusion for multirate sensor networks. Int. J. Adapt. Control Signal Process. 2016, 30, 3–15. [Google Scholar] [CrossRef]

- Saska, D.; Blum, R.S.; Kaplan, L. Fusion of Quantized and Unquantized Sensor Data for Estimation. IEEE Signal Process. Lett. 2015, 22, 1927–1930. [Google Scholar] [CrossRef]

- He, H.; Zhu, Z.; Mäkinen, E. Task-oriented distributed data fusion in autonomous wireless sensor networks. Soft Comp. 2015, 19, 2305–2319. [Google Scholar] [CrossRef]

- Rawat, S.; Rawat, S. Multi-sensor data fusion by a hybrid methodology-A comparative study. Comp. Ind. 2016, 75, 27–34. [Google Scholar] [CrossRef]

- Ferrari, G.; Martalò, M.; Abrardo, A. Information fusion in wireless sensor networks with source correlation. Inf. Fusion 2014, 15, 80–89. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, T.; Chen, D.; Zhang, W. Novel algorithm for identifying and fusing conflicting data in wireless sensor networks. Sensors 2014, 14, 9562–9581. [Google Scholar] [CrossRef] [PubMed]

- Jing, L.; Wang, T.; Zhao, M.; Wang, P. An Adaptive Multi-Sensor Data Fusion Method Based on Deep Convolutional Neural Networks for Fault Diagnosis of Planetary Gearbox. Sensors 2017, 17, 414. [Google Scholar] [CrossRef] [PubMed]

- Si, L.; Wang, Z.; Liu, X.; Tan, C.; Xu, J.; Zheng, K. Multi-sensor data fusion identification for shearer cutting conditions based on parallel quasi-newton neural networks and the Dempster-Shafer theory. Sensors 2015, 15, 28772–28795. [Google Scholar] [CrossRef] [PubMed]

- Chuang, P.J.; Jiang, Y.J. Effective neural network-based node localization scheme for wireless sensor networks. IET Wirel. Sens. Syst. 2014, 4, 97–103. [Google Scholar] [CrossRef]

- Tian, G.Y.; Gledhill, D. Visualisation based feedback control for multiple sensor fusion. In Proceedings of the Tenth International Conference on Information Visualisation (IV’06), London, UK, 5–7 July 2006. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, T.; Wang, Y.; Wang, M.; Lin, S. A Real-Time Smooth Weighted Data Fusion Algorithm for Greenhouse Sensing Based on Wireless Sensor Networks. Sensors 2017, 17, 2555. https://doi.org/10.3390/s17112555

Zou T, Wang Y, Wang M, Lin S. A Real-Time Smooth Weighted Data Fusion Algorithm for Greenhouse Sensing Based on Wireless Sensor Networks. Sensors. 2017; 17(11):2555. https://doi.org/10.3390/s17112555

Chicago/Turabian StyleZou, Tengyue, Yuanxia Wang, Mengyi Wang, and Shouying Lin. 2017. "A Real-Time Smooth Weighted Data Fusion Algorithm for Greenhouse Sensing Based on Wireless Sensor Networks" Sensors 17, no. 11: 2555. https://doi.org/10.3390/s17112555