A Noise Reduction Method for Dual-Mass Micro-Electromechanical Gyroscopes Based on Sample Entropy Empirical Mode Decomposition and Time-Frequency Peak Filtering

Abstract

:1. Introduction

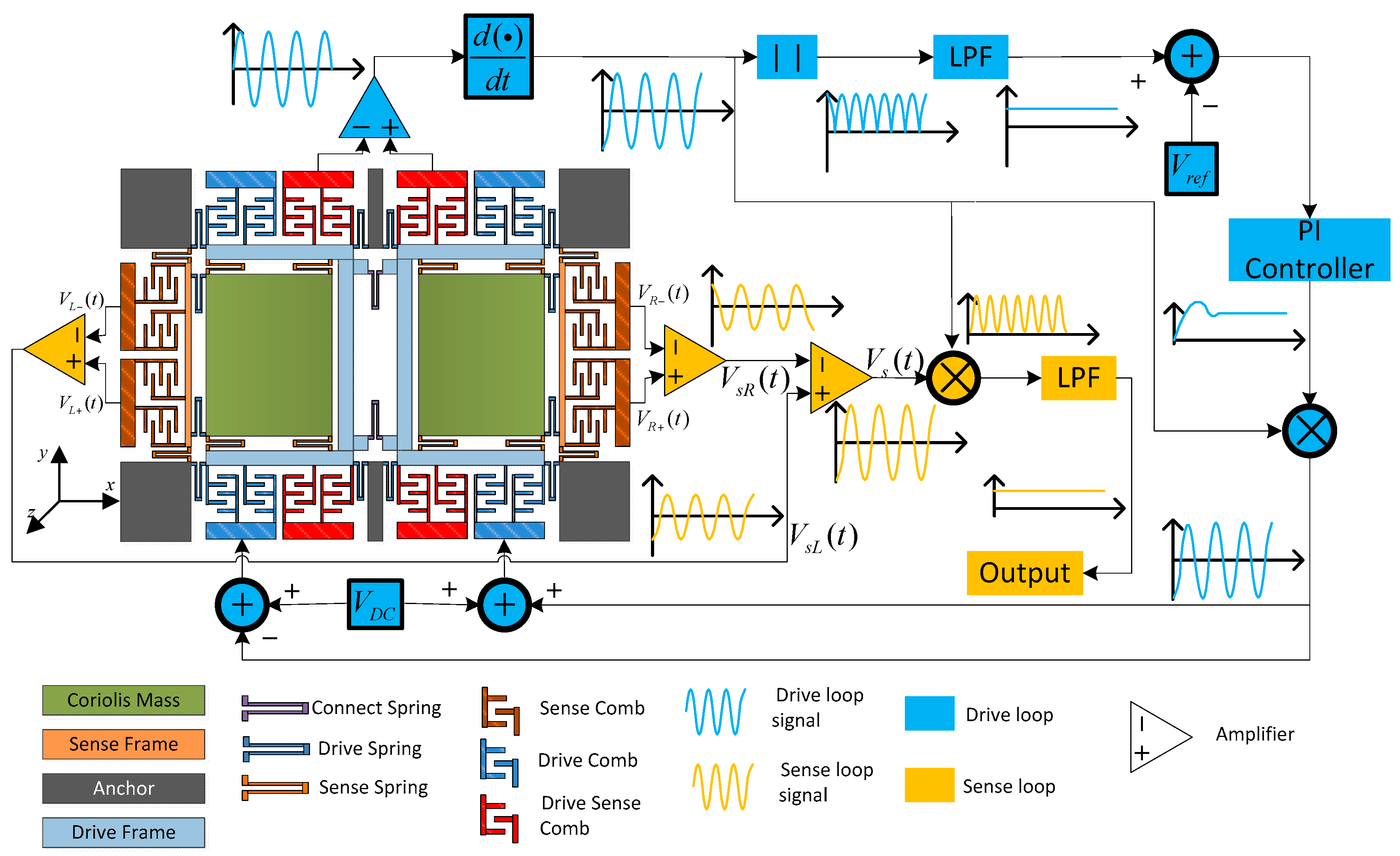

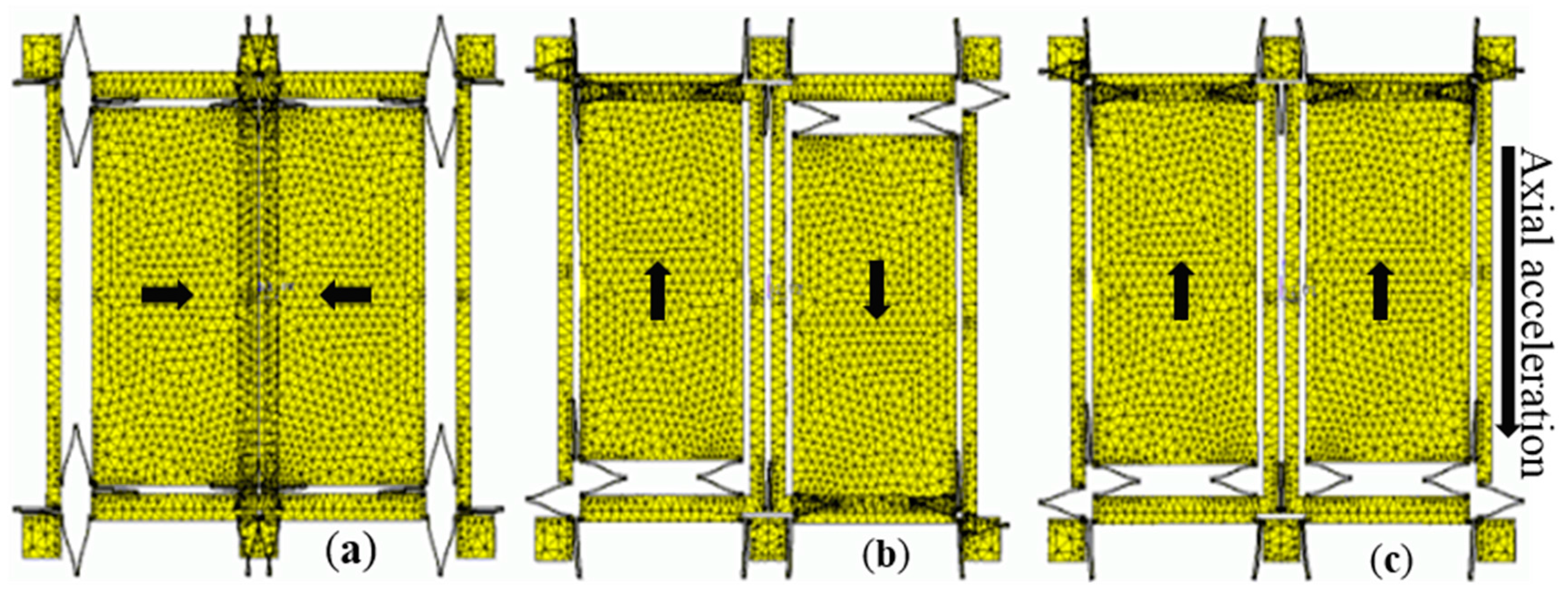

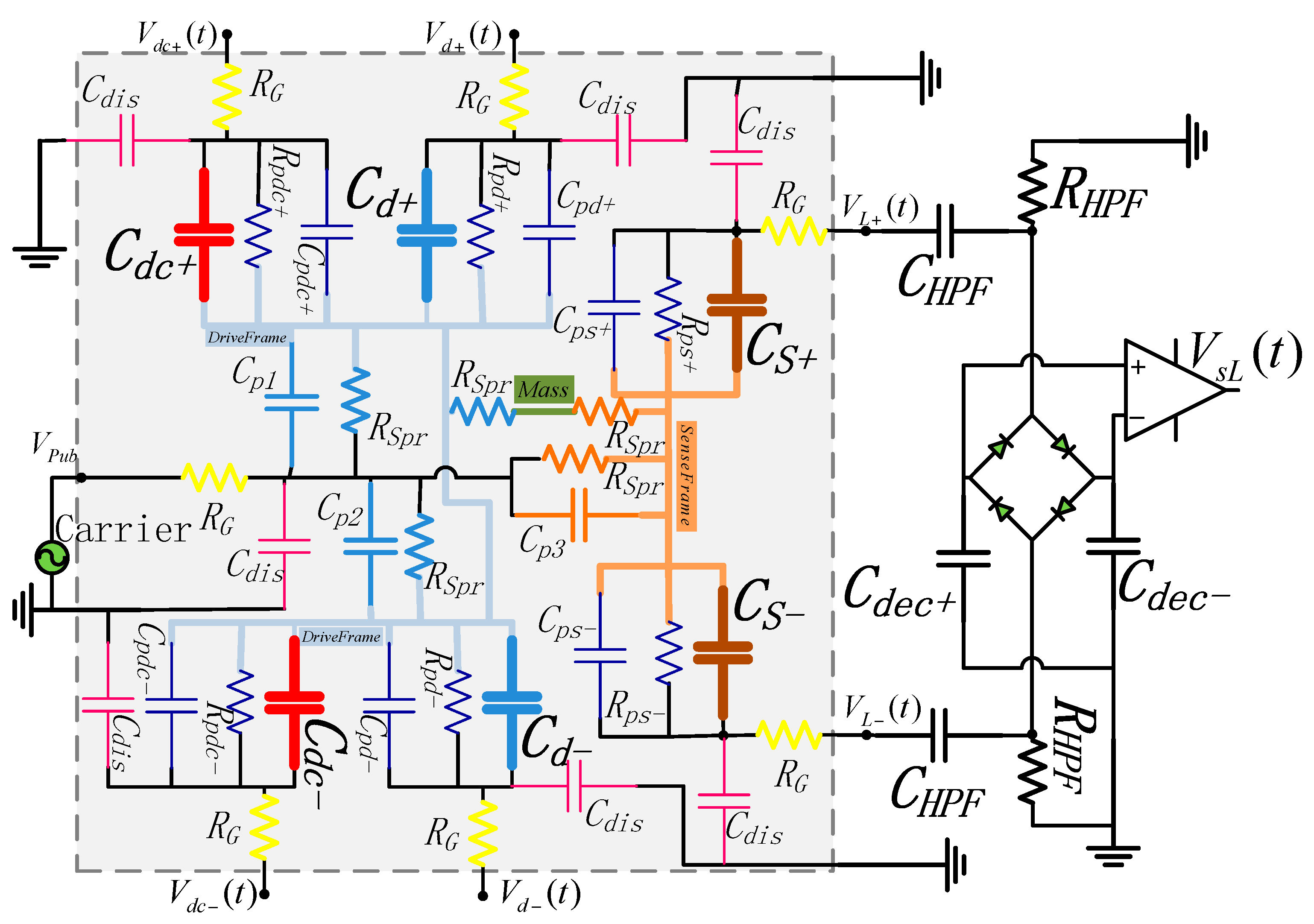

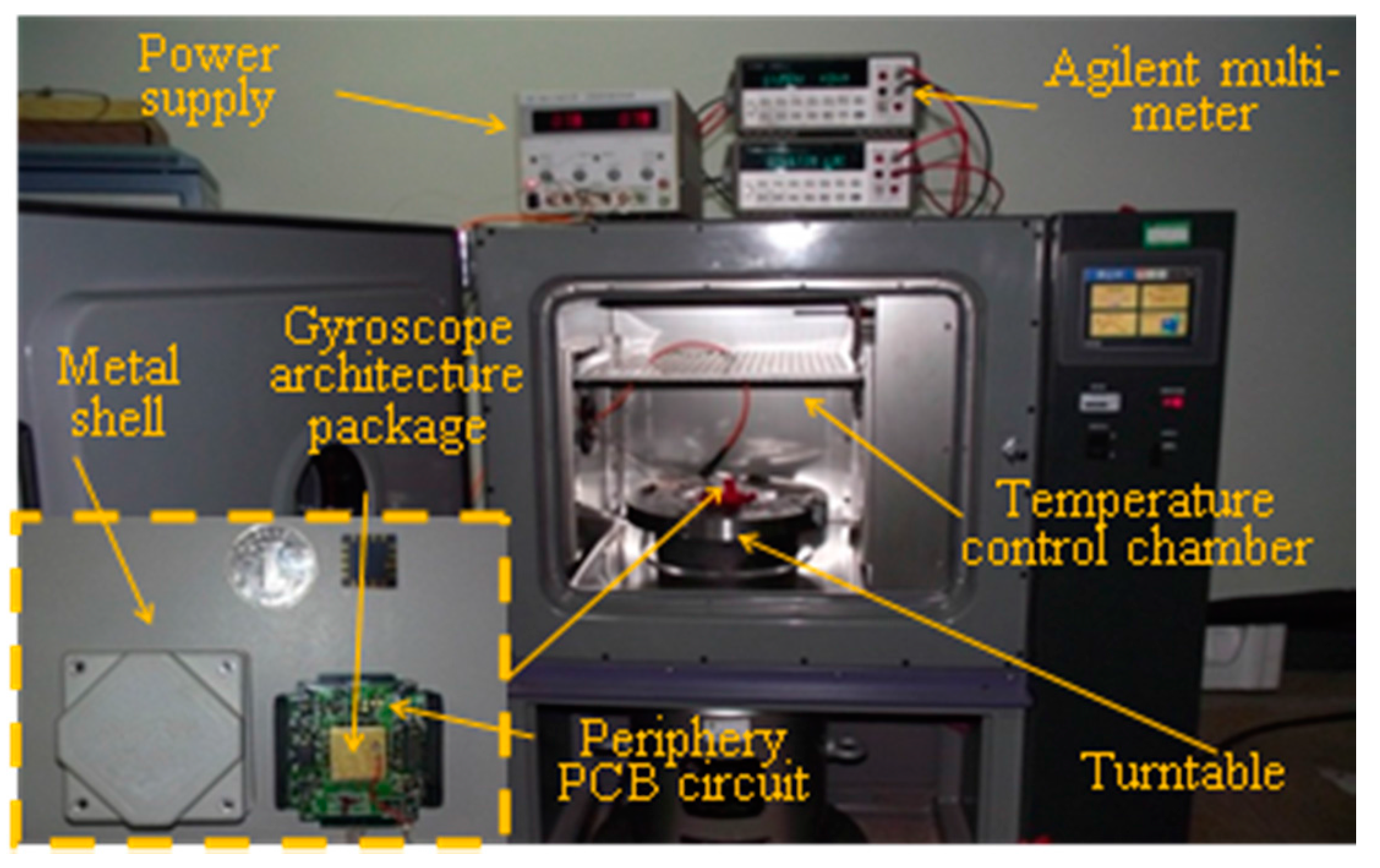

2. Dual-Mass MEMS Gyroscope and Noise Analysis

2.1. Dual-Mass MEMS Gyroscope

2.2. Noise Analysis

- (1)

- Mechanical-Thermal Noise (MTN). This noise exists widely in MEMS gyro structures, and is caused by molecular agitation inside the silicon structure; it is commonly considered as the mechanical sensitivity limitation. The essence of MTN is white Gaussian noise and can be equal to adding a noise force generator together with damper, which can be expressed as:where kB is the Boltzman constant, T is the absolute temperature, c is the gyro mode damping, and B is the noise bandwidth.

- (2)

- Electronic Thermal Noise (ETN). This noise is also named Johnson noise, which is caused by charge thermal agitation in resistors. The voltage generated by ETN can be described as:where R is the resistance. Although ETN exists in both the structure electronic model and the periphery circuit, ETN (mainly produced by the parasitic resistors) considered in this paper causes more negative influences because the weak signal produced by sense capacitors is more vulnerable to ETN. From Figure 1, it can be found that the distributed resistances Rpdc+, Rpdc−, Rps+ and Rps− are high-value ones (their values are several hundred MΩ), therefore, the sense loop output signals will be easily influenced by their ETN.

- (3)

- Flicker Noise (FN). This noise is well known as 1/f noise and generated by the result of conductivity fluctuations in a semiconductor device, This paper expresses its equivalent voltage as:where K is a constant that depends on the type of material and its geometry, R is the resistor value, I is the average value of direct current, f is the frequency of the passing signal. From the equation above, we can find that FN doesn’t depend on the temperature, and it is inversely proportional to f, so increasing carrier frequency fc is an effective way to restrain FN in a silicon structure.

- (4)

- In Phase Noise (IPN). This kind of noise has the same frequency and phase characteristics as the Coriolis signal in the sense loop. Normally it contains the cross-coupling of the drive signal (through drive and sense capacitance) and the sense mode motion directly stimulated by drive signals (caused by the non-idealities in the structure element), so different gyroscopes have different IPN. The IPN in this paper can be described as:where AIPN is the amplitude of IPN equivalent voltage. Usually, its equivalent input angular rate is several deg/s and it cannot be eliminated.

- (5)

- Other Noise (OTN). The above four noises sources form the principal parts of structure noise, besides which, there are also several noises existing in MEMS gyroscope, such as diode noise, demodulation phase noise, residual stress noise and so on.

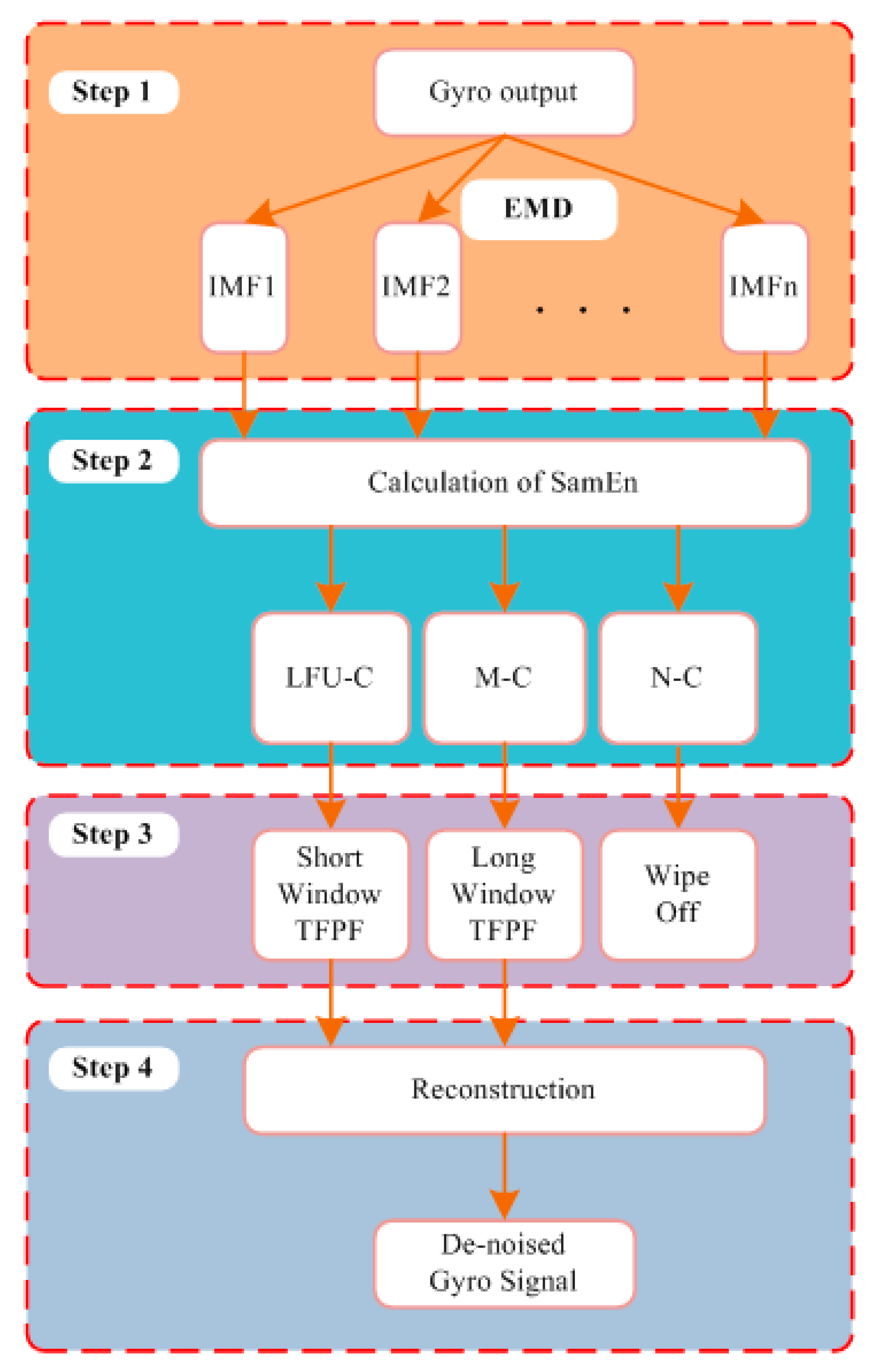

3. Noise Reduction Algorithm

3.1. Sample Entropy Based Empirical Mode Decomposition

- (1)

- The number of extrema and the number of zero crossings should be equal or maintain a difference of no more than one;

- (2)

- The local average defined by the average of the maximum and minimum envelops is zero, i.e., both envelopes are locally symmetric around the envelope mean.

3.2. Time-Frequency Peak Filtering

3.3. Steps of SEEMD-TFPF Algorithm

- Step 1:

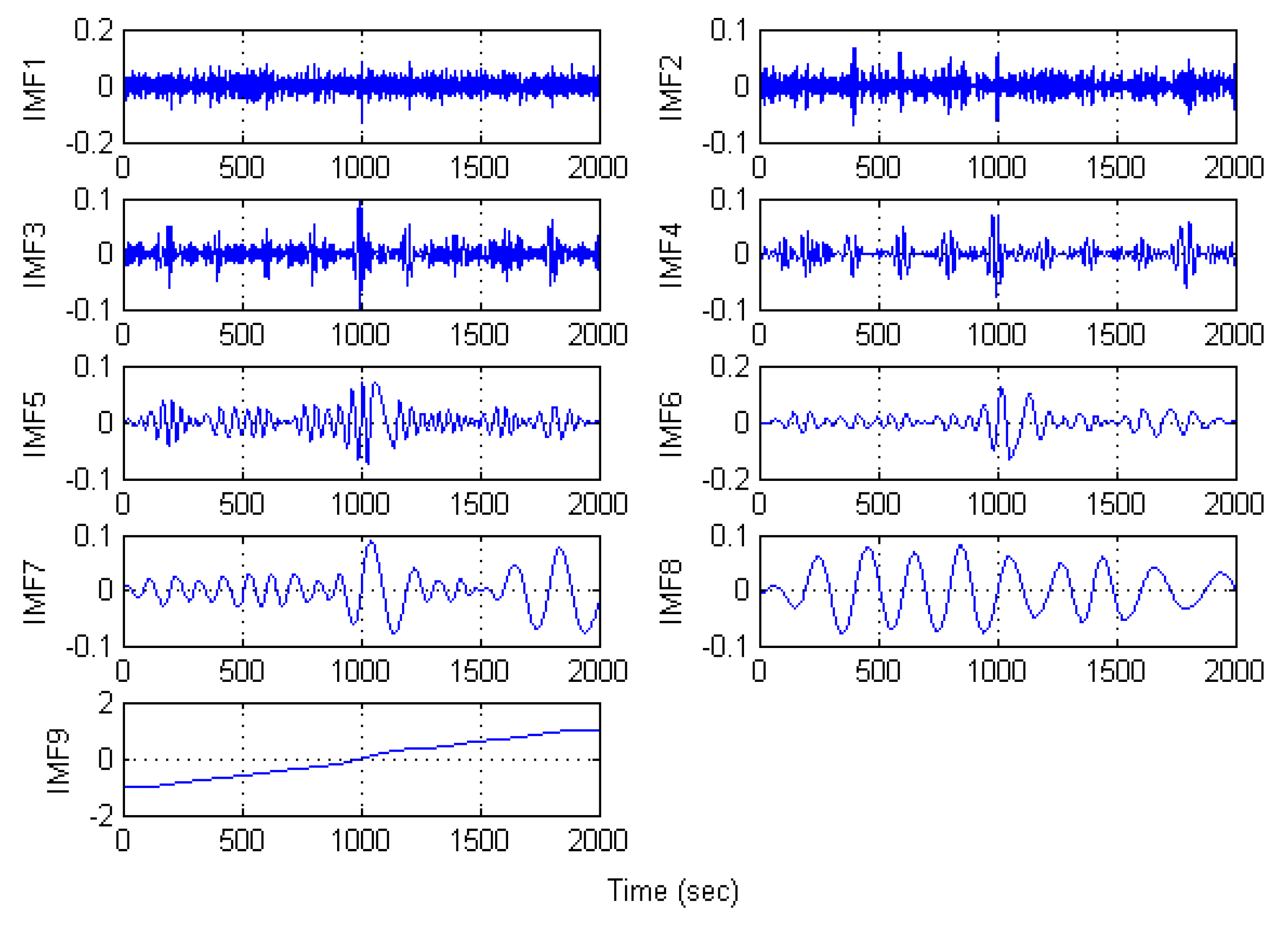

- Decomposition. The original signal is decomposed into IMFs by EMD;

- Step 2:

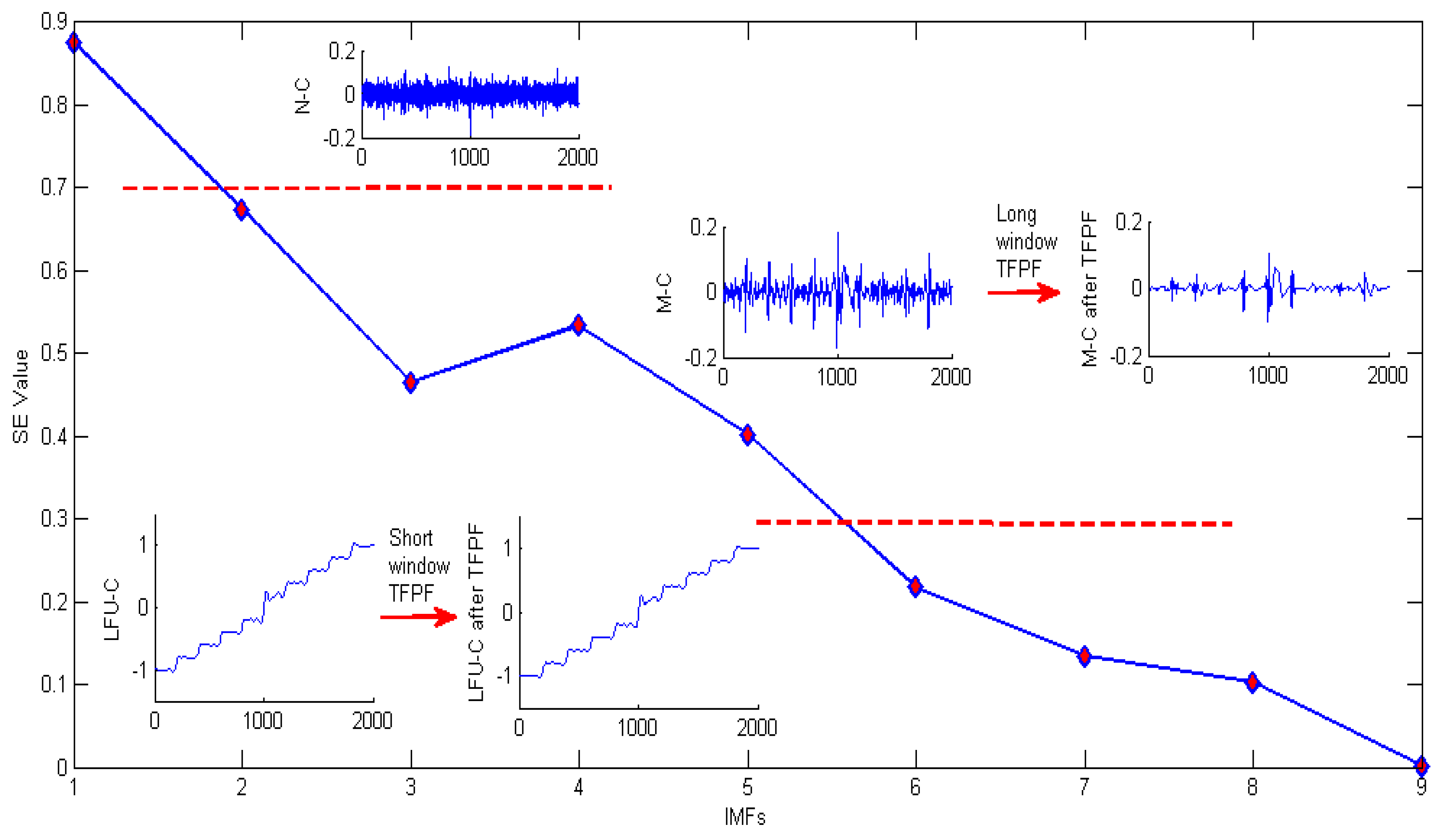

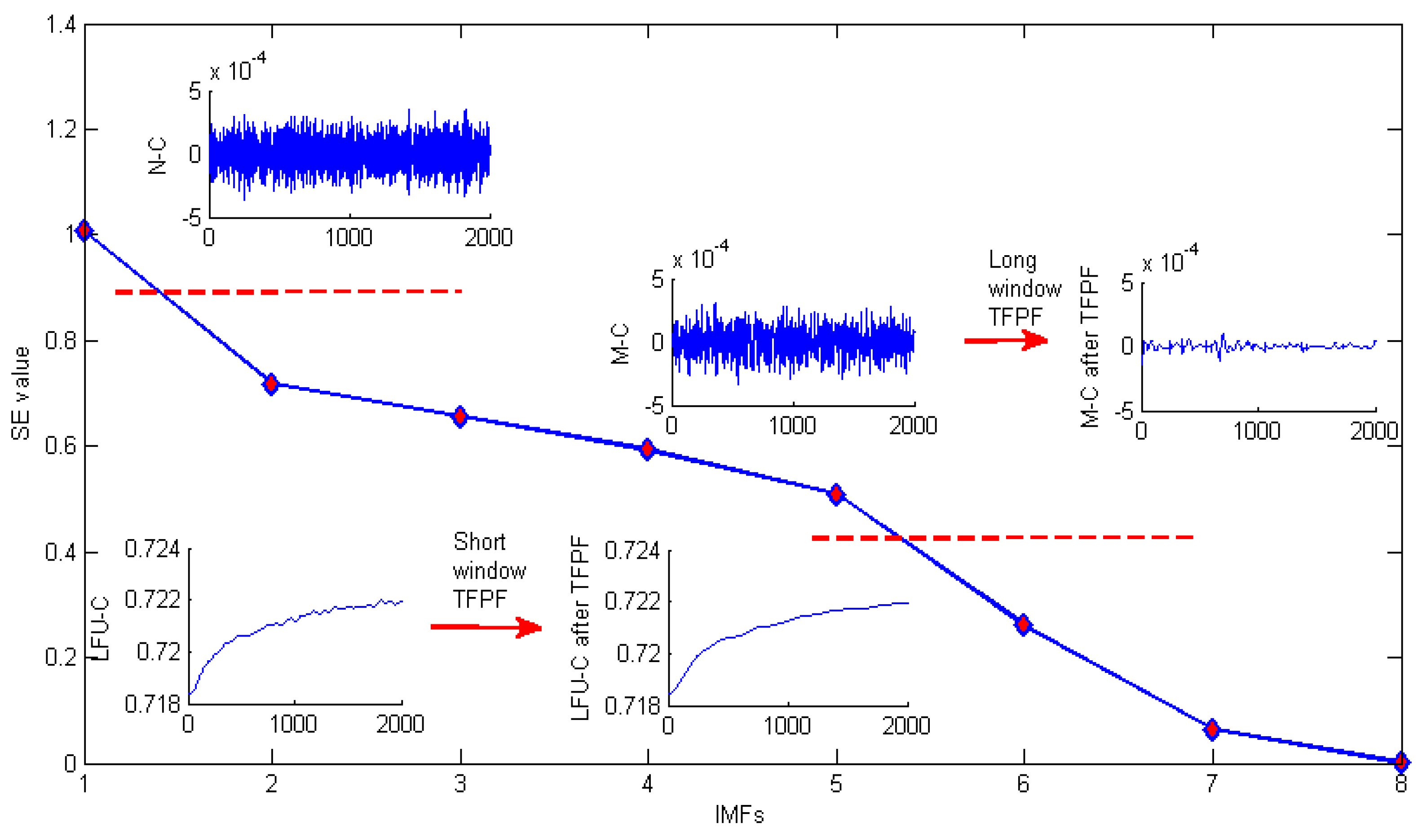

- Classification. The SE of each IMF is calculated, and then the IMFs with similar SE value are classified into one component. By analyzing the gyroscope data, normally three components can be obtained according to the similarity of SE, which are named as low frequency useful component (LFU-C), mixed component (M-C) and noise component (N-C), respectively.

- Step 3:

- De-noising. From Step 2 we can see that the LFU-C might consisted of the true signal and drift, the M-C might consisted of true signal, drift and noise, and the N-C consists of noise. It is necessary to choose different de-noising methods for the three different components. Therefore, considering the features of TFPF, short window TFPF is selected to process LFU-C in order to preserve the valid signal as much as possible, and long window TFPF is selected to process M-C in order to reduce the random noise as much as possible, at last the N-C would be wipe off directly.

- Step 4:

- Reconstruction. After de-noising, the LFU-C and M-C are reconstructed, and the final signals are obtained.

4. Experimental and Results

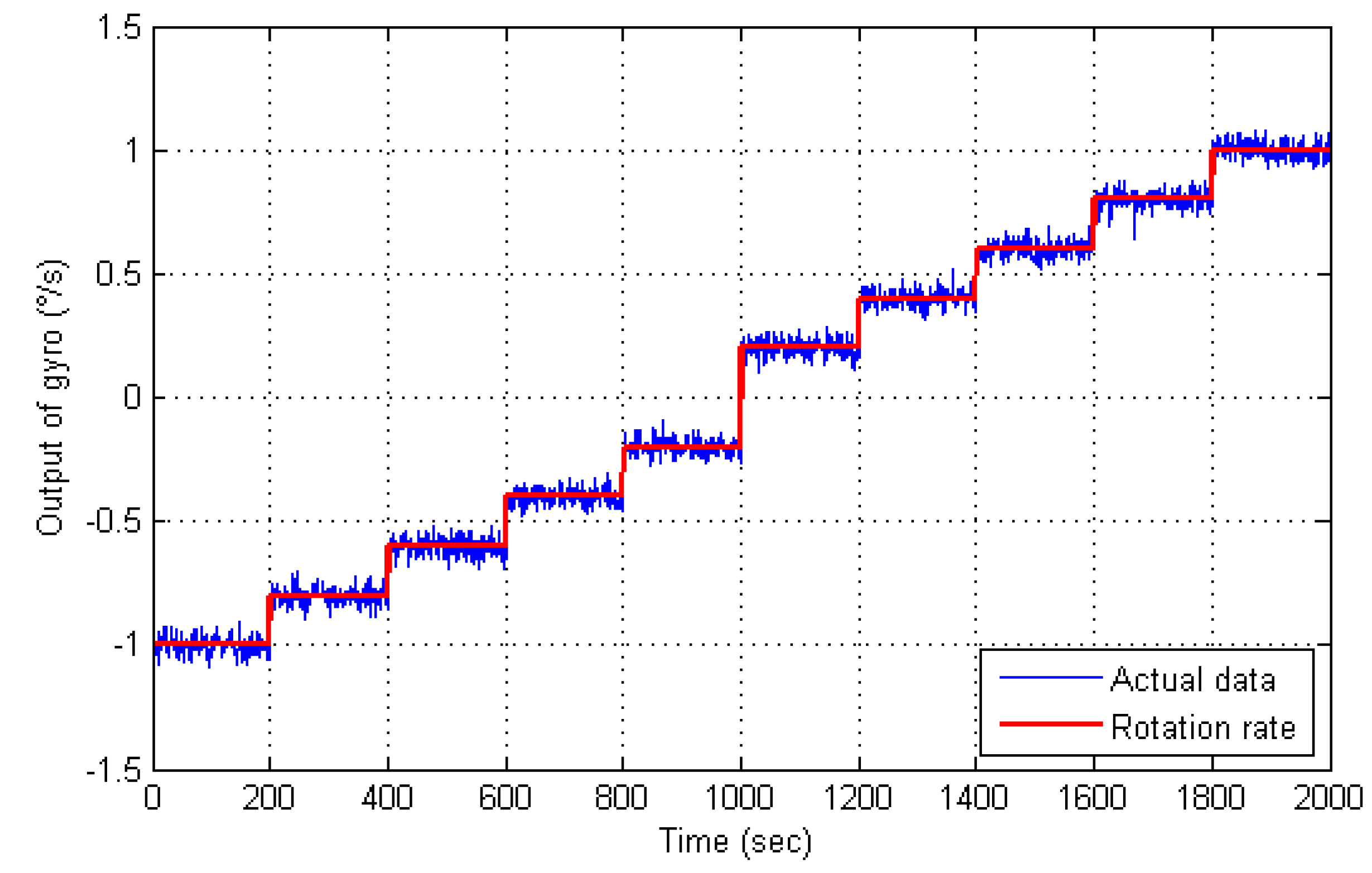

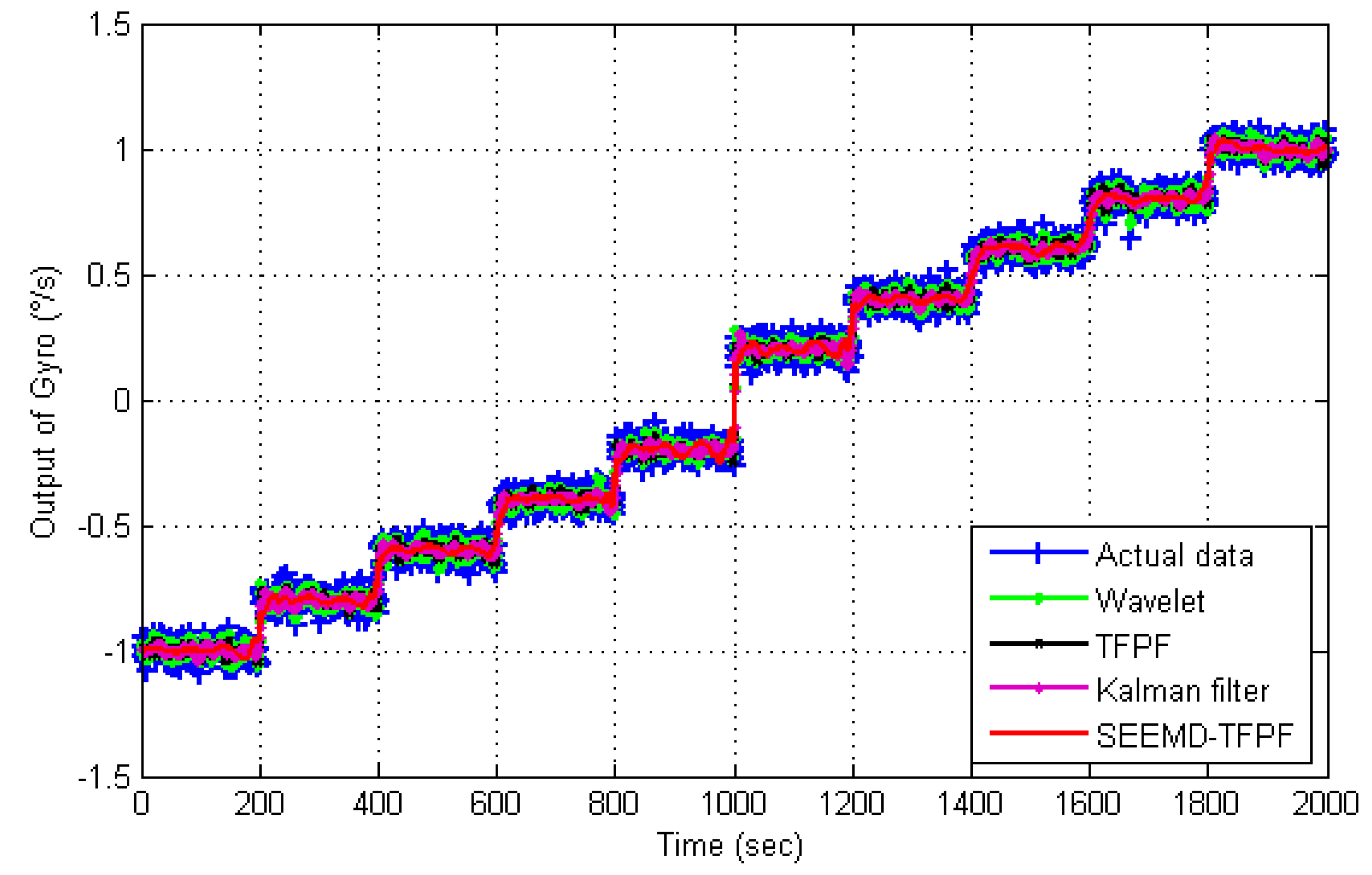

4.1. Rotation Experimental and Comparison

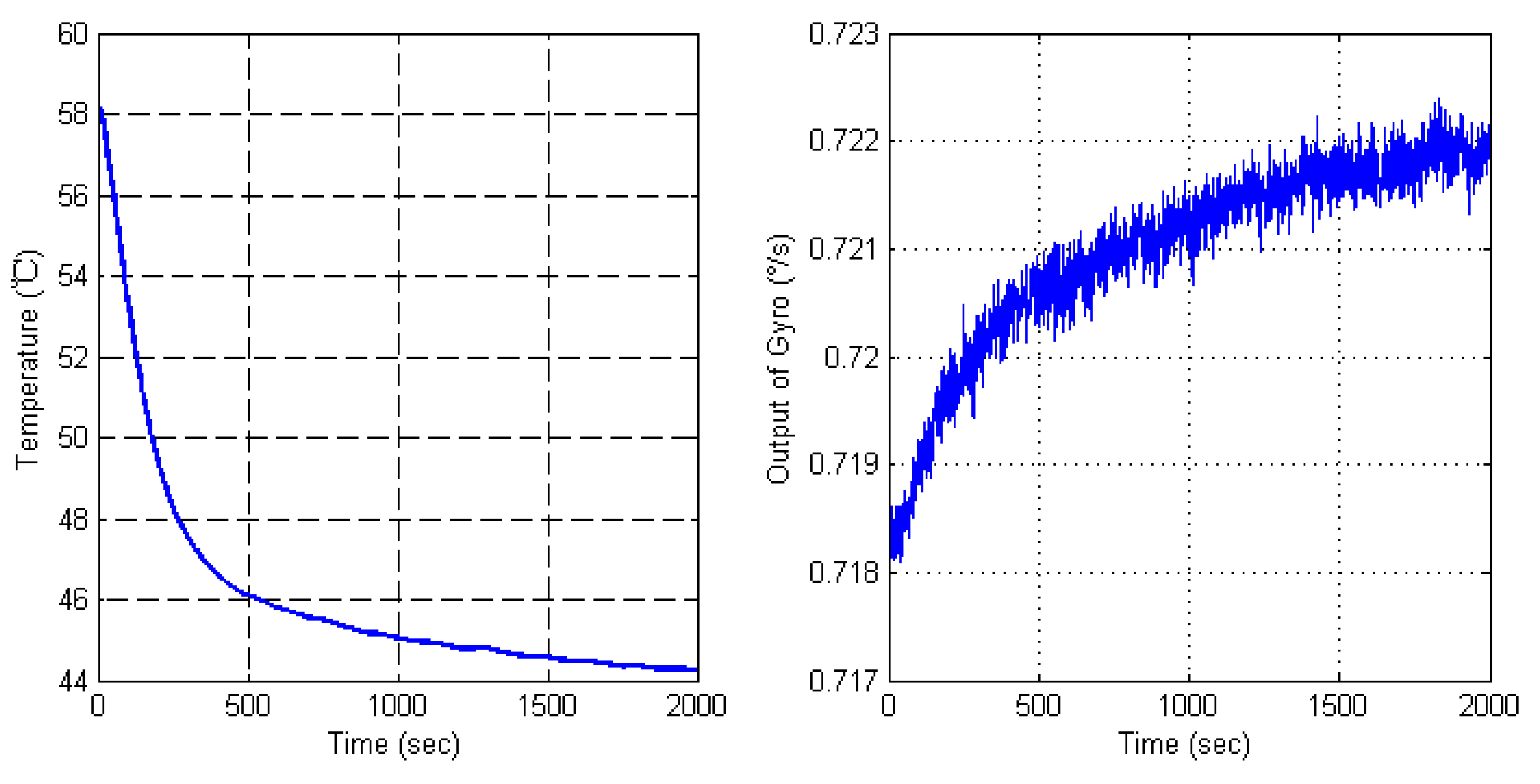

4.2. Temperature Experimental and Comparison

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Huang, H.Q.; Chen, X.Y.; Zhou, Z.K.; Xu, Y.; Lv, C.P. Study of the algorithm of backtracking decoupling and adaptive extended Kalman filter based on the quaternion expanded to the state variable for under glider navigation. Sensors 2014, 14, 23041–23066. [Google Scholar] [CrossRef] [PubMed]

- Zhuang, Y.; EI-Sheimy, N. Tightly-coupled integration of WiFi and MEMS sensors on handheld devices for indoor pedestrian navigation. IEEE Sens. J. 2016, 16, 224–234. [Google Scholar] [CrossRef]

- Cao, H.L.; Li, H.S.; Kou, Z.W.; Shi, Y.B.; Tang, J.; Ma, Z.M.; Shen, C.; Liu, J. Optimization and experimentation of dual-mass MEMS gyroscope Quadrature error correction methods. Sensors 2016, 16, 71. [Google Scholar] [CrossRef] [PubMed]

- Li, H.S.; Cao, H.L.; Ni, Y.F. Electrostatic stiffness correction for quadrature error in decoupled dual-mass MEMS gyroscope. J. Micro Nanolithogr. MEMS MOEMS 2014, 13, 033003. [Google Scholar] [CrossRef]

- Mohd-Yasin, F.; Nagel, D.J.; Ong, D.S.; Korman, C.E.; Chuah, H.T. Low frequency noise measurement and analysis of capacitive micro-accelerometers. Microelectron. Eng. 2007, 84, 1788–1791. [Google Scholar] [CrossRef]

- Mohd-Yasin, F.; Korman, C.E.; Nagel, D.J. Measurement of noise characteristics of MEMS accelerometers. Solid State Electron. 2003, 47, 357–360. [Google Scholar] [CrossRef]

- Mohd-Yasin, F.; Zaiyadi, N.; Nagel, D.J.; Ong, D.S.; Korman, C.E.; Faidz, A.R. Noise and reliability measurement of a three-axis micro-accelerometer. Microelectron. Eng. 2009, 86, 991–995. [Google Scholar] [CrossRef]

- Cao, H.L.; Li, H.S.; Liu, J.; Shi, Y.B.; Tang, J.; Shen, C. An improved interface and noise analysis of a turning fork microgyroscope structure. Mech. Syst. Signal Process. 2016, 70–71, 1209–1220. [Google Scholar] [CrossRef]

- Xue, L.; Jiang, C.Y.; Wang, L.X.; Liu, J.Y.; Yuan, W.Z. Noise reduction of MEMS gyroscope based on direct modeling for an angular rate signal. Micromachines 2015, 6, 266–280. [Google Scholar] [CrossRef]

- Yuan, J.G.; Yuan, Y.T.; Liu, F.L.; Pang, Y.; Lin, J.Z. An improved noise reduction algorithm based on wavelet transformation for MEMS gyroscope. Front. Optoelectron. 2015, 8, 413–418. [Google Scholar] [CrossRef]

- Zhao, L.Y.; Li, H.S.; Wang, S.R. The silicon micro-gyroscope signal processing method based on morphological wavelet filter. Inf. Int. Interdiscip. J. 2012, 15, 4633–4640. [Google Scholar]

- Liu, D.C.; He, C.H.; Zhao, Q.C.; Yang, Z.C.; Hao, Y.L.; Yan, G.Z. Digital signal processing for a micromachined vibratory gyroscope based on a three dimensional adaptive filter demodulator. Measurement 2014, 50, 198–202. [Google Scholar] [CrossRef]

- Xiong, M.J.; Li, Y.; Wu, N. Random-noise attenuation for seismic data by local parallel radial-trace TFPF. IEEE Trans. Geosci. Remote Sens. 2014, 52, 4025–4031. [Google Scholar] [CrossRef]

- Tian, Y.A.; Li, Y.; Yang, B.J. Variable-eccentricity hyperbolic-trace TFPF for seismic random noise attenuation. IEEE Trans. Geosci. Remote Sens. 2014, 52, 6449–6458. [Google Scholar] [CrossRef]

- Wu, N.; Li, Y.; Yang, B.J. Noise attenuation for 2-D seismic data by radial-trace time frequency peak filtering. IEEE Geosci. Remote Sens. Lett. 2011, 8, 847–878. [Google Scholar] [CrossRef]

- Zhang, C.; Li, Y.; Lin, H.B.; Yang, B.J. Signal preserving and seismic random noise attenuation by Hurst exponent based time-frequency peak filter. Geophys. J. Int. 2015, 203, 901–909. [Google Scholar] [CrossRef]

- Lin, H.B.; Ma, H.T.; Li, Y.; Shao, D.Y. Elimination of seismic random noise based on the SW statistic adaptive TFPF. Chin. J. Geophys. 2015, 58, 4559–4567. [Google Scholar]

- Zhuang, G.H.; Li, Y.; Wu, N.; Tian, Y.N. Curvature-varying Hyperbolic trace TFPF for seismic random noise attenuation. IEEE Geosci. Remote Sens. Lett. 2015, 12, 2252–2256. [Google Scholar] [CrossRef]

- Cao, H.L.; Li, H.S. Investigation of a vacuum packaged MEMS gyroscope architecture’s temperature robustness. Int. J. Appl. Electromagn. Mech. 2013, 41, 495–506. [Google Scholar]

- Ahn, J.H.; Kwak, D.H.; Koh, B.H. Fault detection of a roller-bearing system through the EMD of a wavelet denoised signal. Sensors 2014, 14, 15022–15038. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.L.; Wang, K.Q.; Sun, L.J.; Zhen, J.J. Applying empirical mode decomposition (EMD) and entropy to diagnose circuit breaker faults. Optik 2015, 126, 2338–2342. [Google Scholar]

- Xu, M.J.; Shang, P.J.; Huang, J.J. Modified generalized sample entropy and surrogate data analysis for stock markets. Commun. Nonlinear Sci. Numer. Simul. 2016, 35, 17–24. [Google Scholar] [CrossRef]

- Cui, B.B.; Chen, X.Y. Improved hybrid filter for fiber optic gyroscope signal denoising based on EMD and forward linear prediction. Sens. Actuators A Phys. 2015, 230, 150–155. [Google Scholar] [CrossRef]

| De-Noising Methods | Actual Data | Wavelet | TFPF | Kalman | SEEMD-TFPF |

|---|---|---|---|---|---|

| Standard deviation (°/s) | 0.7129 | 0.6637 | 0.6018 | 0.4539 | 0.2634 |

| De-Noising Methods | Actual Data | Wavelet | TFPF | Kalman | SEEMD-TFPF |

|---|---|---|---|---|---|

| Standard deviation (°/s) | 9.74E−4 | 9.03E−4 | 8.89E−4 | 7.18E−4 | 4.54E−4 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, C.; Li, J.; Zhang, X.; Shi, Y.; Tang, J.; Cao, H.; Liu, J. A Noise Reduction Method for Dual-Mass Micro-Electromechanical Gyroscopes Based on Sample Entropy Empirical Mode Decomposition and Time-Frequency Peak Filtering. Sensors 2016, 16, 796. https://doi.org/10.3390/s16060796

Shen C, Li J, Zhang X, Shi Y, Tang J, Cao H, Liu J. A Noise Reduction Method for Dual-Mass Micro-Electromechanical Gyroscopes Based on Sample Entropy Empirical Mode Decomposition and Time-Frequency Peak Filtering. Sensors. 2016; 16(6):796. https://doi.org/10.3390/s16060796

Chicago/Turabian StyleShen, Chong, Jie Li, Xiaoming Zhang, Yunbo Shi, Jun Tang, Huiliang Cao, and Jun Liu. 2016. "A Noise Reduction Method for Dual-Mass Micro-Electromechanical Gyroscopes Based on Sample Entropy Empirical Mode Decomposition and Time-Frequency Peak Filtering" Sensors 16, no. 6: 796. https://doi.org/10.3390/s16060796