Tool Condition Monitoring and Remaining Useful Life Prognostic Based on a Wireless Sensor in Dry Milling Operations

Abstract

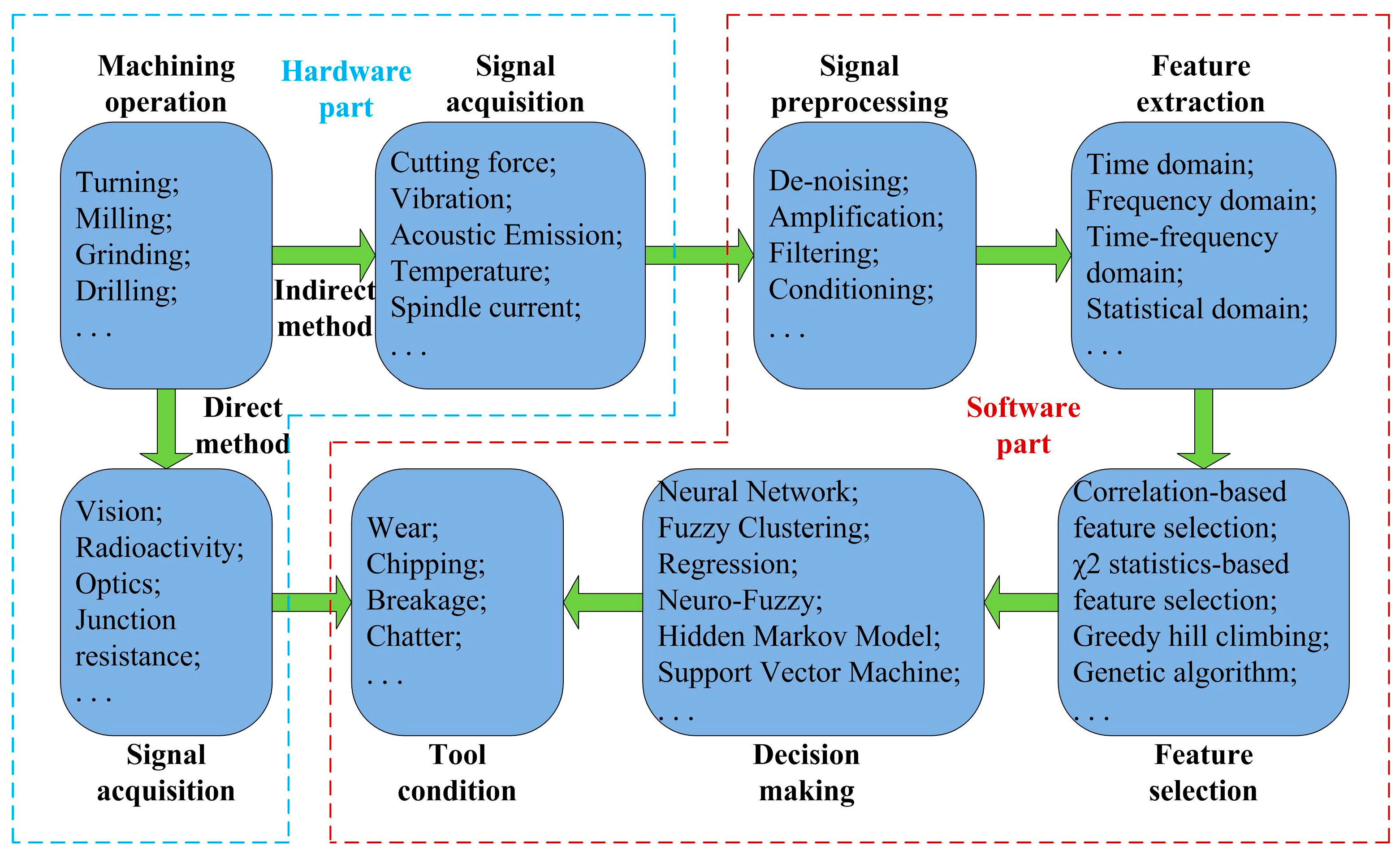

:1. Introduction

2. Literature Review

2.1. Cutting Force and Torque

2.2. Vibration

2.3. Acoustic Emission

2.4. Other Sensors and Multi-Sensors Fusion

2.5. Advantages and Challenges of Wireless Sensors in Equipment Monitoring

2.6. Problem Statements

3. Theoretical Framework

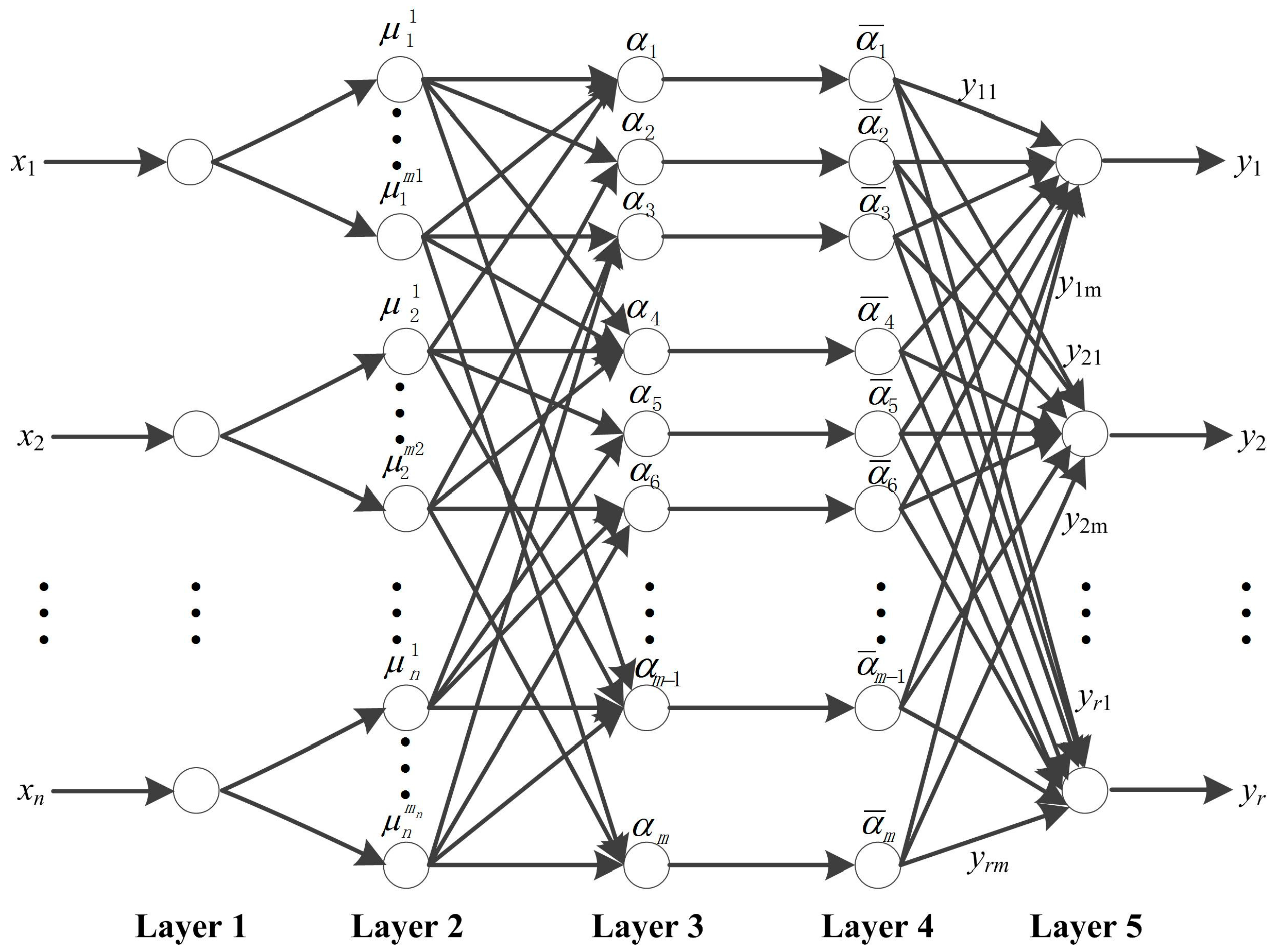

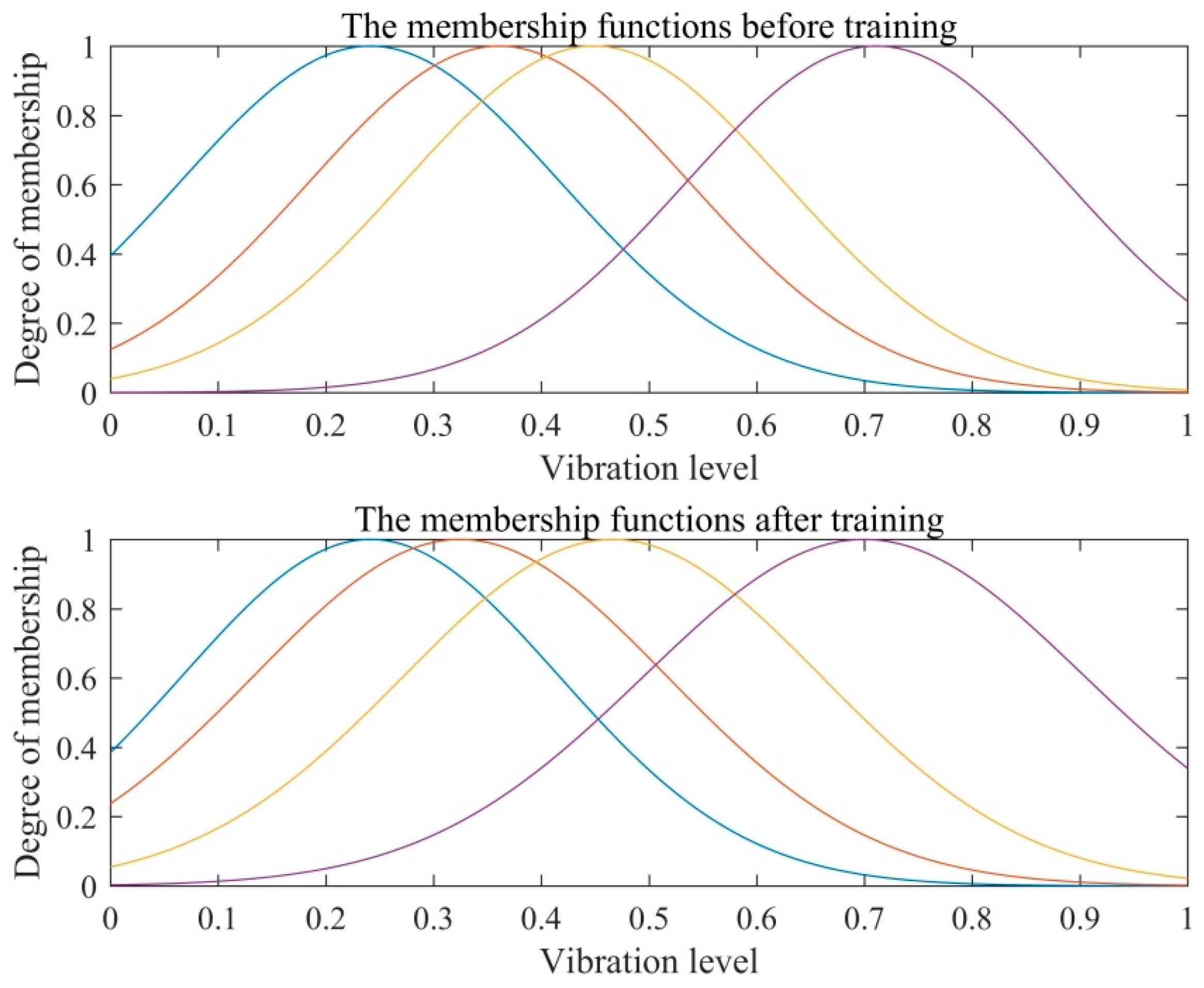

3.1. The NFN Architecture

3.2. NFN Learning Algorithm

4. Experimental Results and Discussion

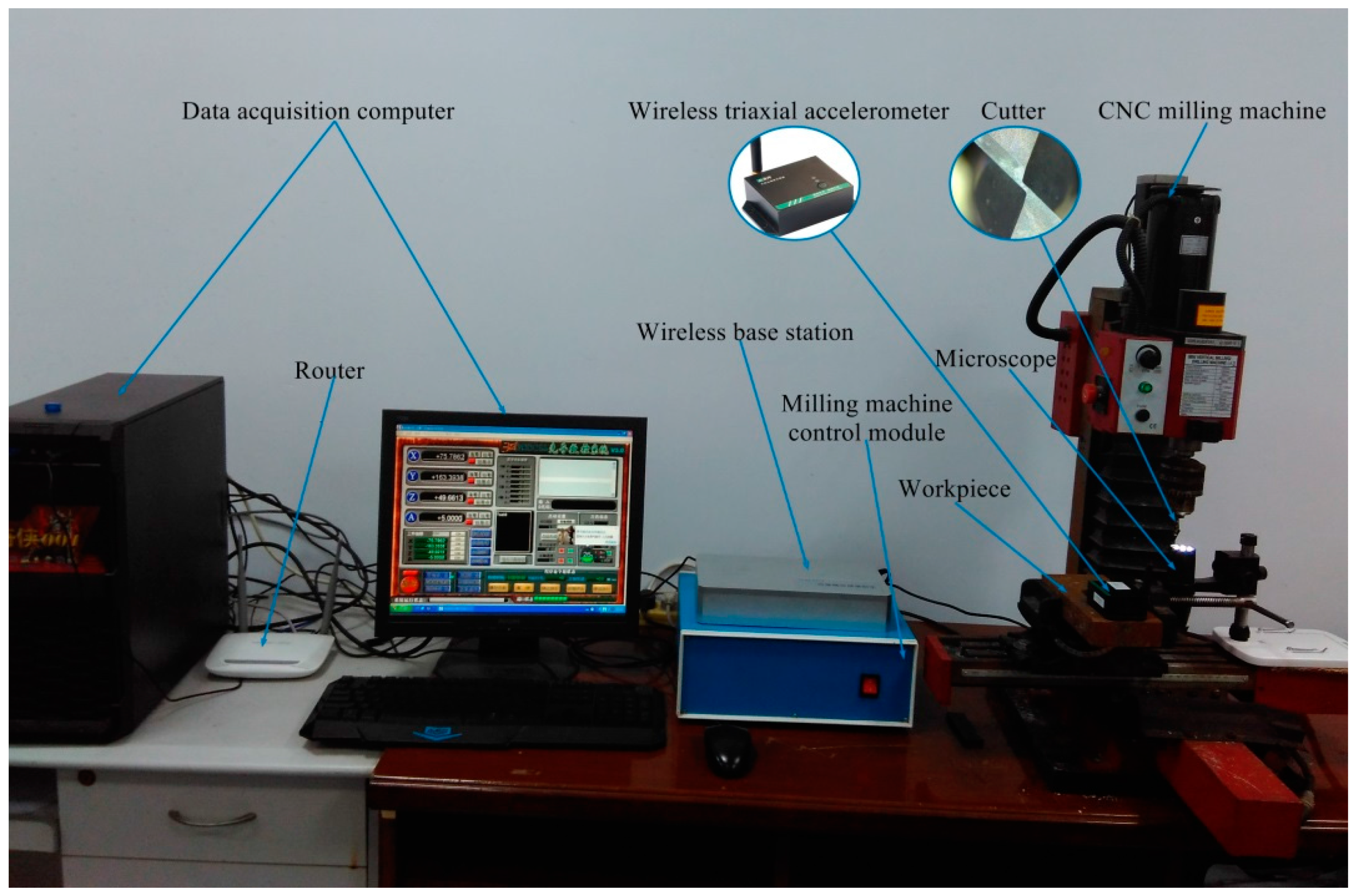

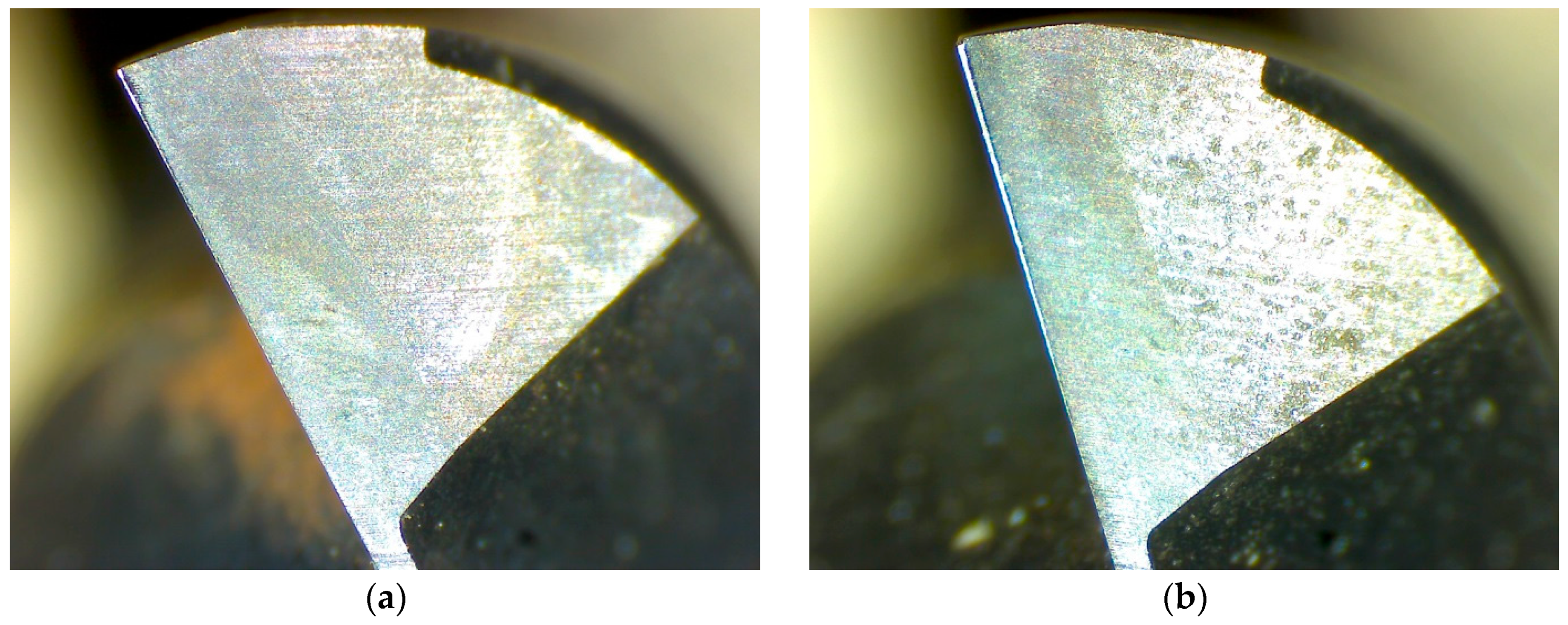

4.1. Experimental Setup and Data Acquisition

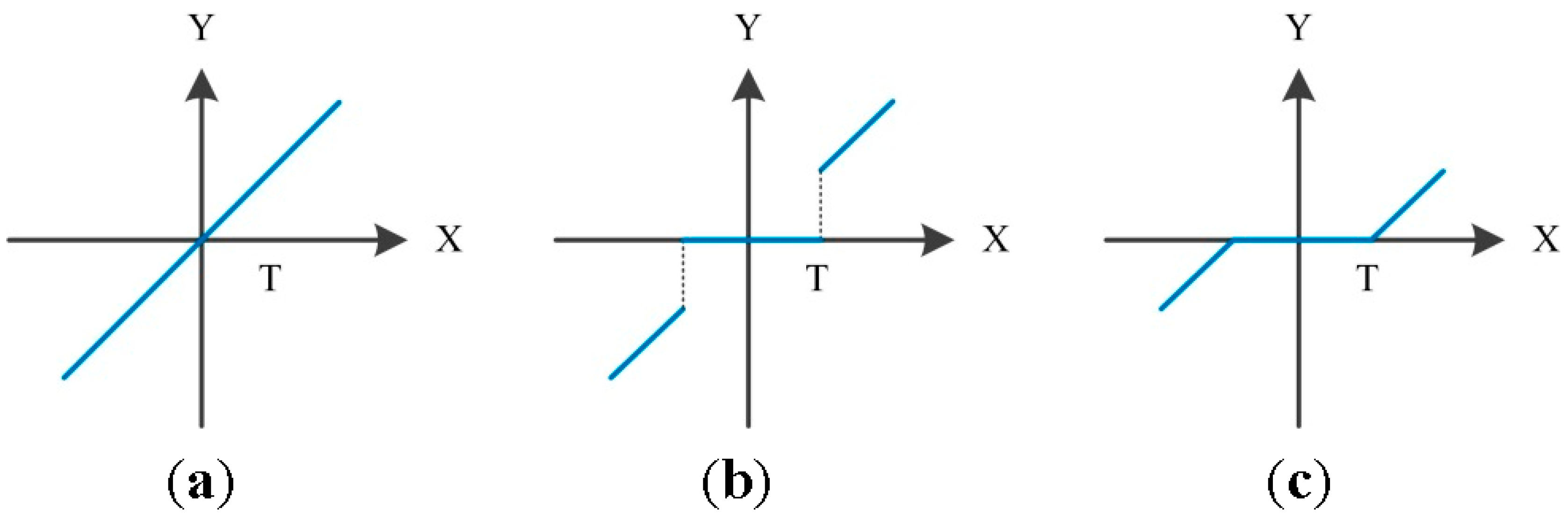

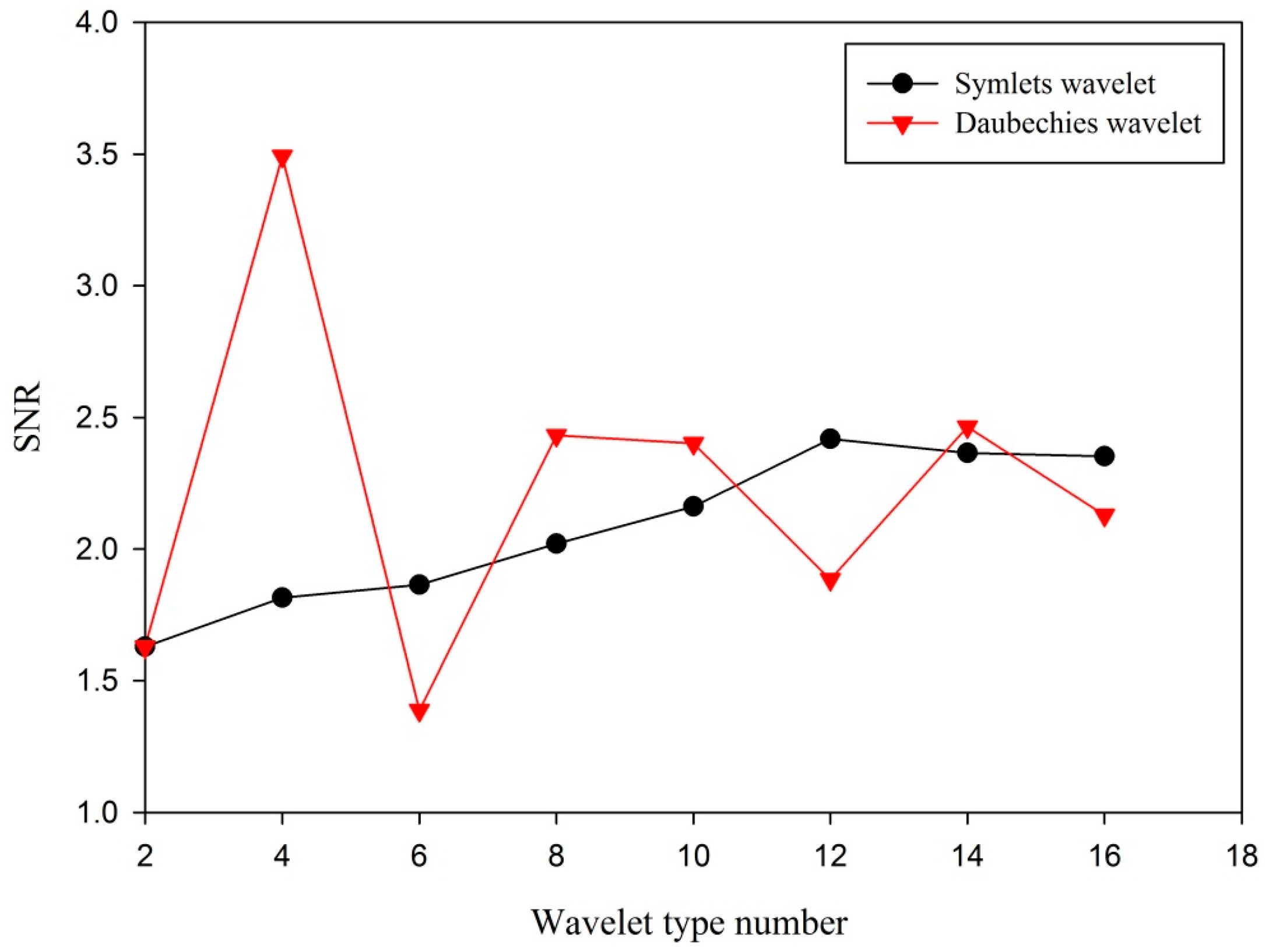

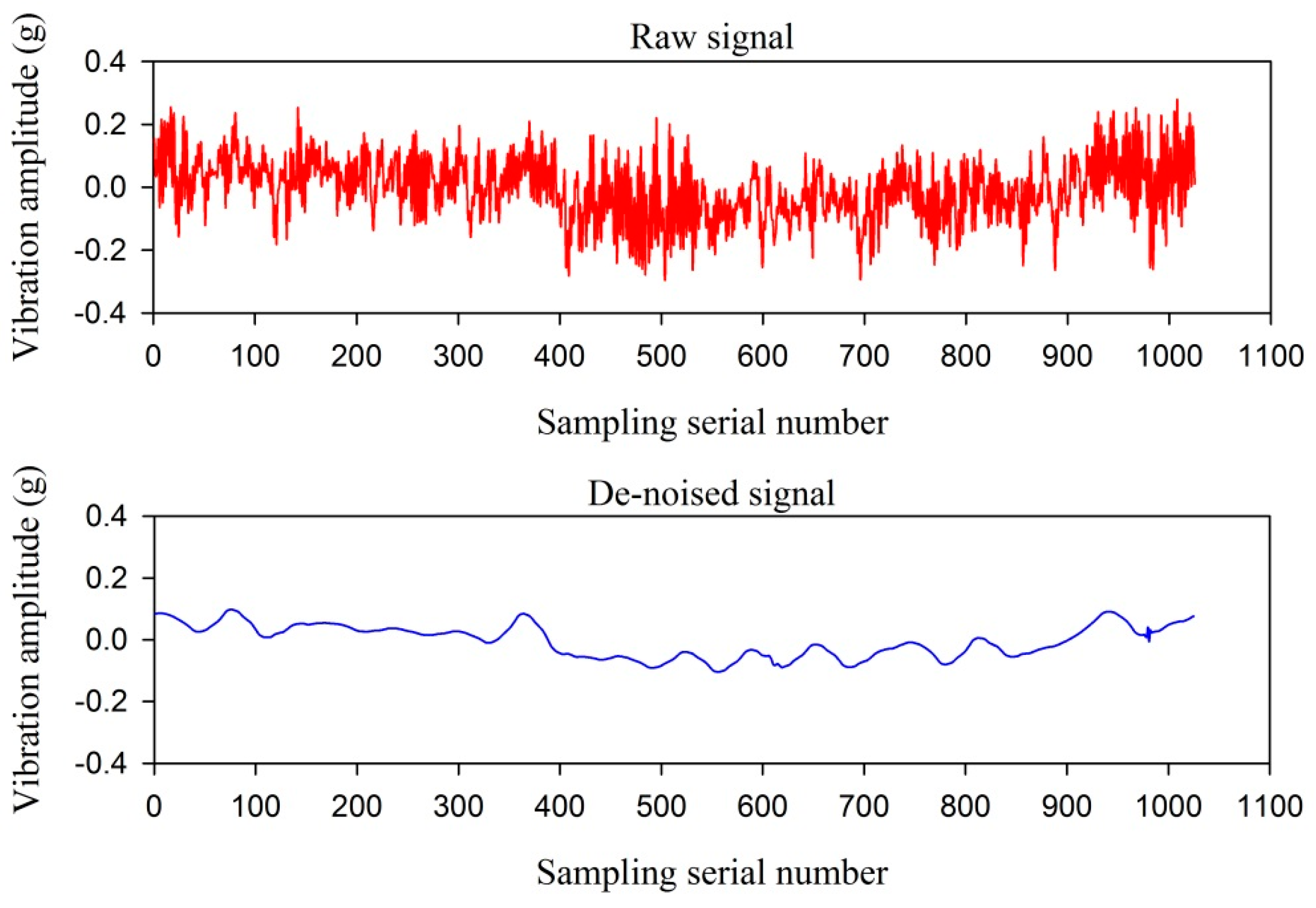

4.2. Signal Preprocessing

4.3. Feature Extraction

4.3.1. Feature Extraction in Time Domain

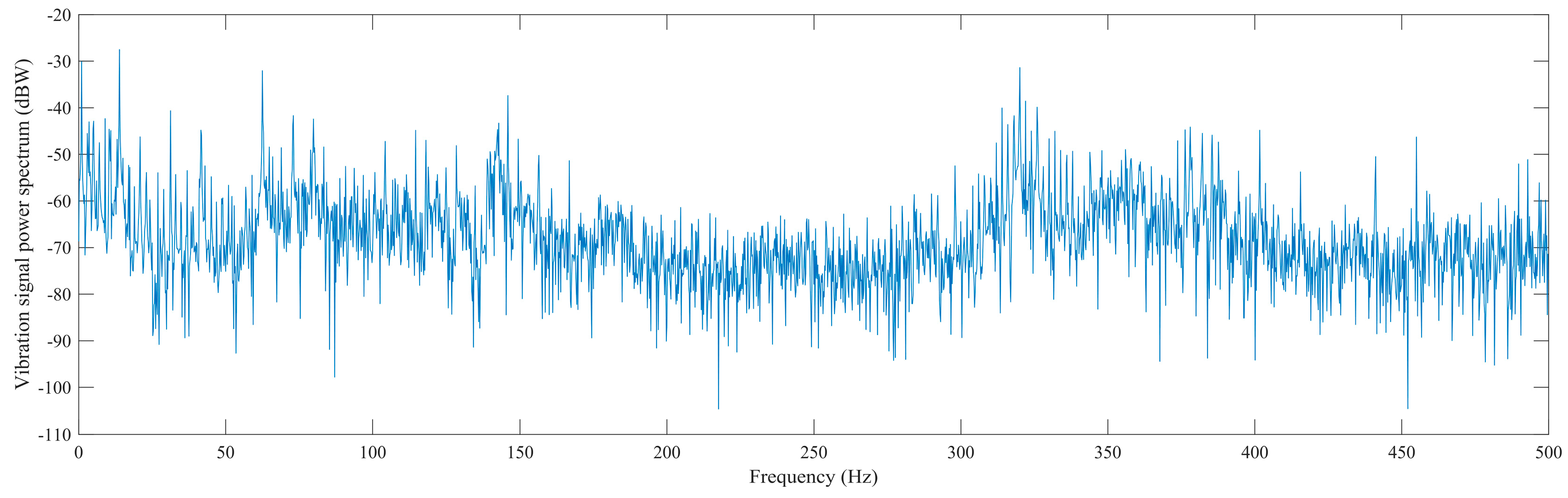

4.3.2. Feature Extraction in Frequency Domain

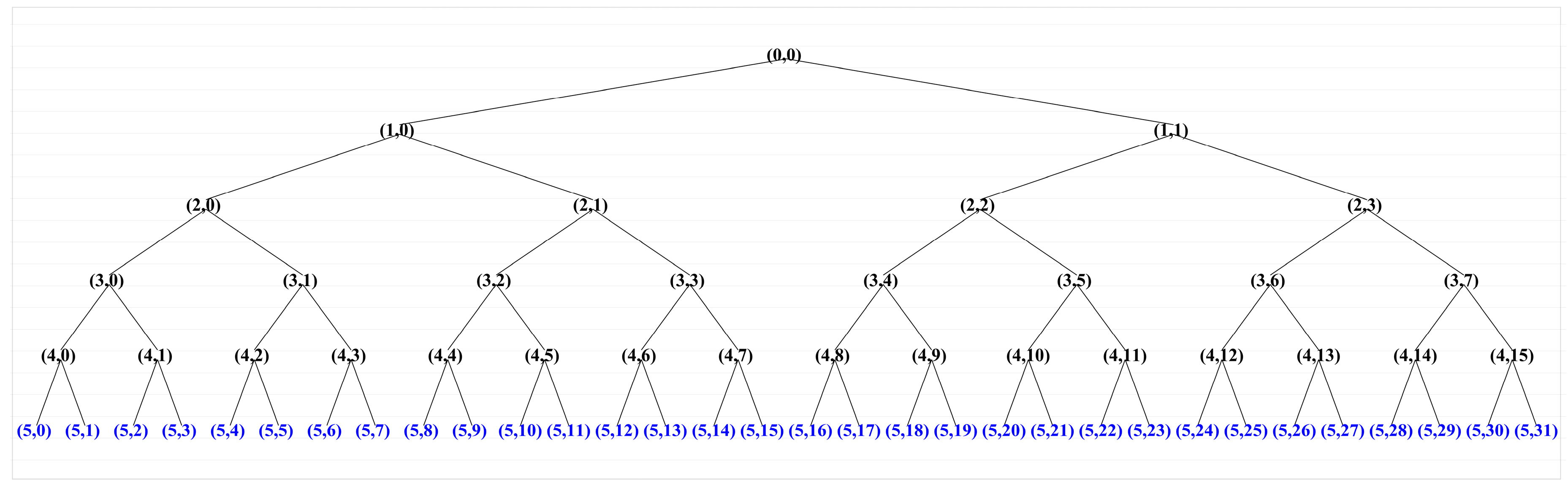

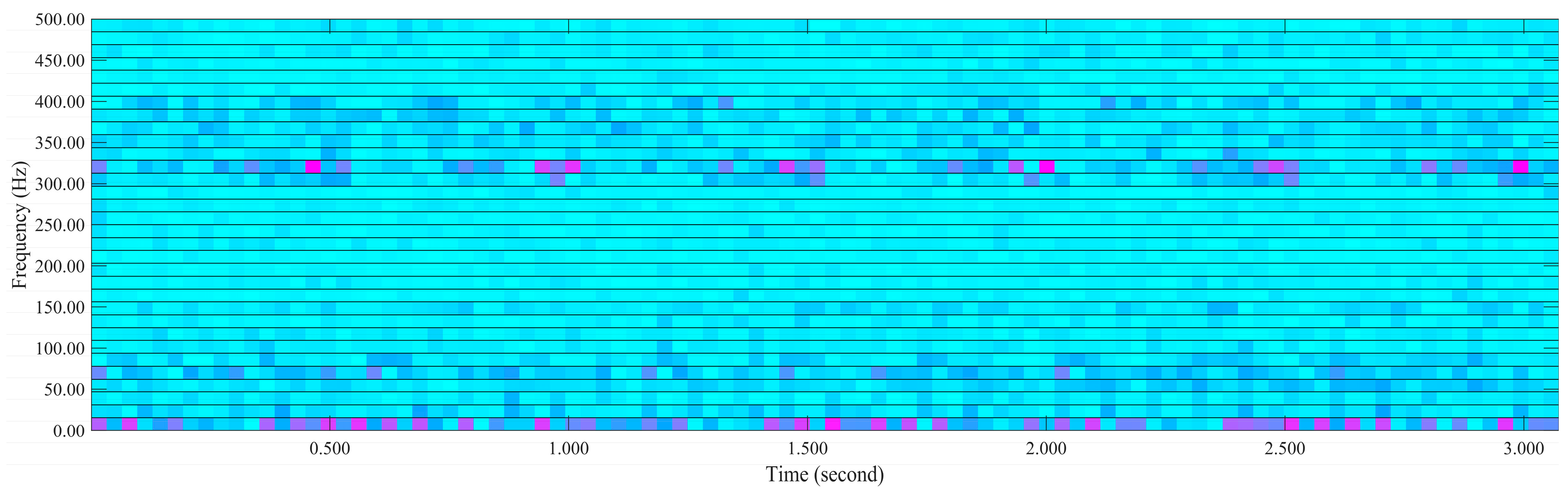

4.3.3. Feature Extraction in Time–Frequency Domain

4.4. Feature Selection

4.5. Modeling for Cutting Tool

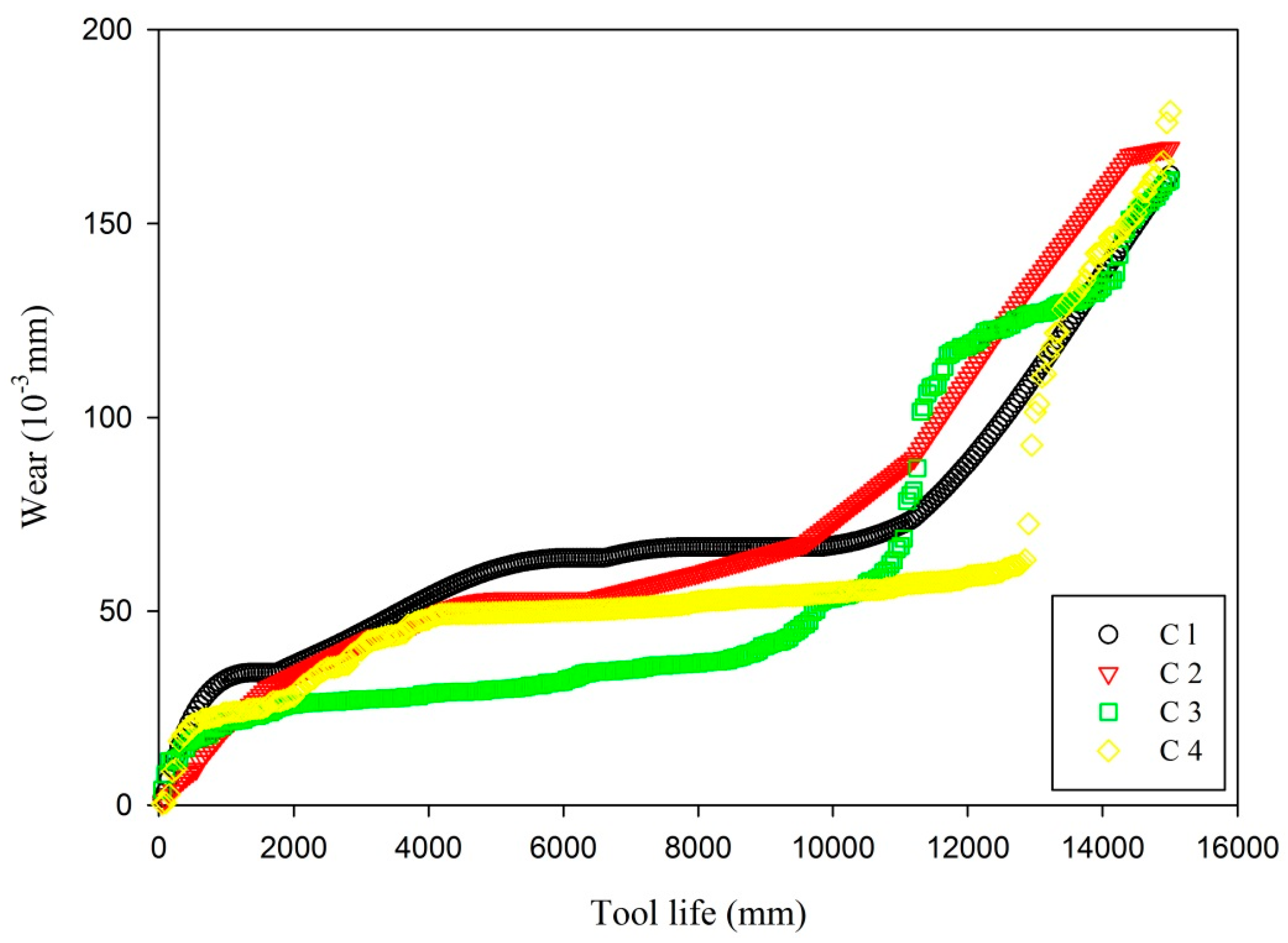

4.6. Prediction of Tool Wear and RUL

4.6.1. Prediction of Tool Wear and RUL Based NFN

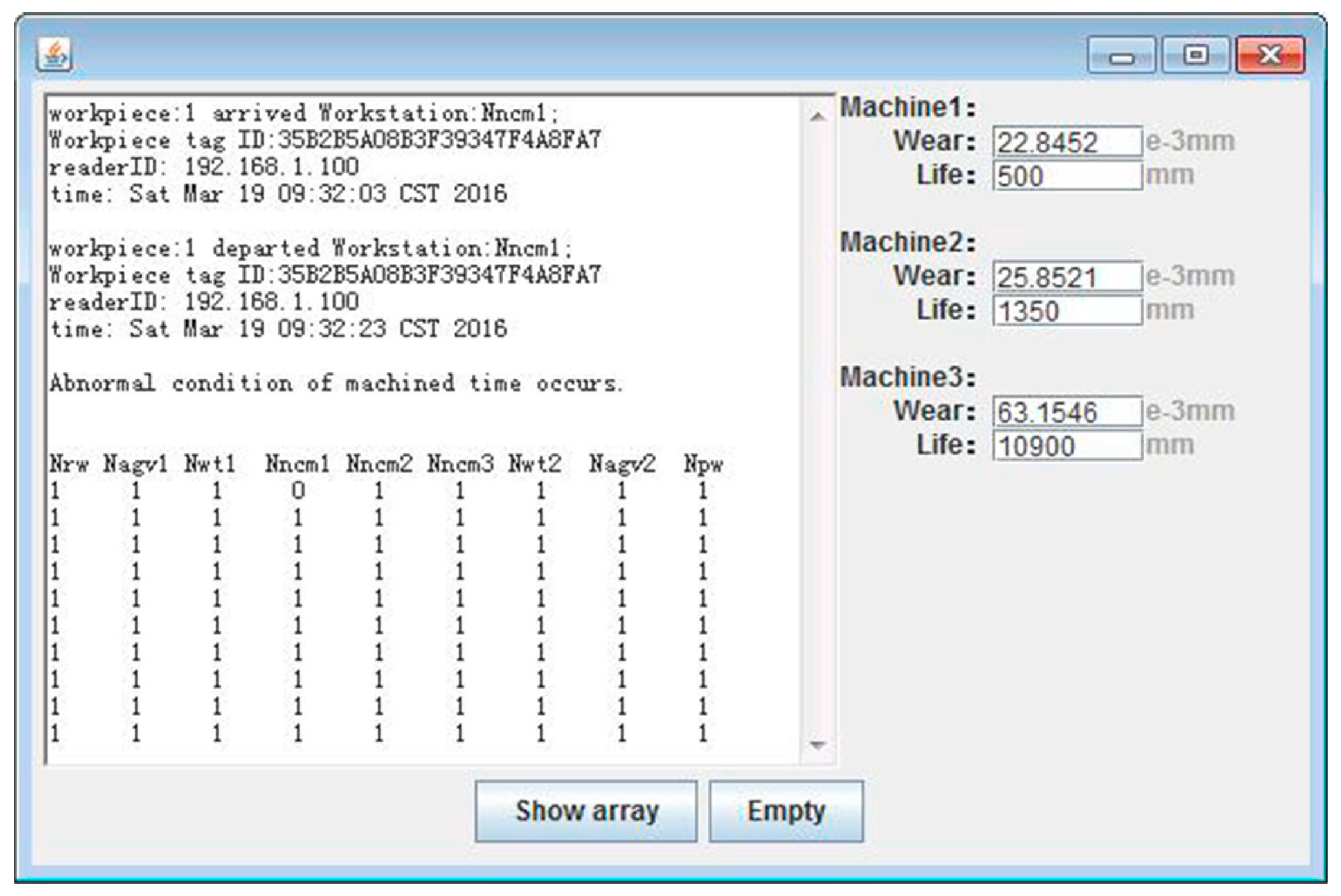

4.6.2. User Interface of Tool Wear and RUL

4.7. Comparison with BPNN, RBFN and NFN

5. Conclusions and Future Work

Supplementary Materials

Supplementary File 1Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rehorn, A.G.; Jiang, J.; Orban, P.E. State-of-the-art methods and results in tool condition monitoring: A review. Int. J. Adv. Manuf. Technol. 2005, 26, 693–710. [Google Scholar] [CrossRef]

- Zhu, K.; San Wong, Y.; Hong, G.S. Wavelet analysis of sensor signals for tool condition monitoring: A review and some new results. Int. J. Mach. Tools Manuf. 2009, 49, 537–553. [Google Scholar] [CrossRef]

- Kurada, S.; Bradley, C. A review of machine vision sensors for tool condition monitoring. Comput. Ind. 1997, 34, 55–72. [Google Scholar] [CrossRef]

- Cho, S.; Binsaeid, S.; Asfour, S. Design of multisensor fusion-based tool condition monitoring system in end milling. Int. J. Adv. Manuf. Technol. 2010, 46, 681–694. [Google Scholar] [CrossRef]

- Siddhpura, A.; Paurobally, R. A review of flank wear prediction methods for tool condition monitoring in a turning process. Int. J. Adv. Manuf. Technol. 2013, 65, 371–393. [Google Scholar] [CrossRef]

- Wu, Y.; Du, R. Feature extraction and assessment using wavelet packets for monitoring of machining processes. Mech. Syst. Signal Proc. 1996, 10, 29–53. [Google Scholar] [CrossRef]

- Lei, Y.; Zuo, M.J.; He, Z.; Zi, Y. A multidimensional hybrid intelligent method for gear fault diagnosis. Expert Syst. Appl. 2010, 37, 1419–1430. [Google Scholar] [CrossRef]

- Zhu, K.; Hong, G.S.; Wong, Y.S.; Wang, W. Cutting force denoising in micro-milling tool condition monitoring. Int. J. Prod. Res. 2008, 46, 4391–4408. [Google Scholar] [CrossRef]

- Wang, G.; Yang, Y.; Guo, Z. Hybrid learning based gaussian artmap network for tool condition monitoring using selected force harmonic features. Sens. Actuator A Phys. 2013, 203, 394–404. [Google Scholar] [CrossRef]

- Saglam, H.; Unuvar, A. Tool condition monitoring in milling based on cutting forces by a neural network. Int. J. Prod. Res. 2003, 41, 1519–1532. [Google Scholar] [CrossRef]

- Bhattacharyya, P.; Sengupta, D.; Mukhopadhyay, S. Cutting force-based real-time estimation of tool wear in face milling using a combination of signal processing techniques. Mech. Syst. Signal Proc. 2007, 21, 2665–2683. [Google Scholar] [CrossRef]

- Jemielniak, K. Laboratory versus industrial cutting force sensor in tool condition monitoring. J. Manuf. Sci. Prod. 2000, 3, 41–47. [Google Scholar] [CrossRef]

- Choudhury, S.K.; Rath, S. In-process tool wear estimation in milling using cutting force model. J. Mater. Process. Technol. 2000, 99, 113–119. [Google Scholar] [CrossRef]

- Gao, D.; Liao, Z.; Lv, Z.; Lu, Y. Multi-scale statistical signal processing of cutting force in cutting tool condition monitoring. Int. J. Adv. Manuf. Technol. 2015, 80, 1843–1853. [Google Scholar] [CrossRef]

- Freyer, B.H.; Heyns, P.S.; Theron, N.J. Comparing orthogonal force and unidirectional strain component processing for tool condition monitoring. J. Intell. Manuf. 2014, 25, 473–487. [Google Scholar] [CrossRef]

- Kaya, B.; Oysu, C.; Ertunc, H.M. Force-torque based on-line tool wear estimation system for CNC milling of inconel 718 using neural networks. Adv. Eng. Softw. 2011, 42, 76–84. [Google Scholar] [CrossRef]

- Garshelis, I.J.; Kari, R.J.; Tollens, S.P.L.; Cuseo, J.M. Monitoring cutting tool operation and condition with a magnetoelastic rate of change of torque sensor. J. Appl. Phys. 2008, 103, 07E908. [Google Scholar] [CrossRef]

- Teti, R.; Jemielniak, K.; O’Donnell, G.; Dornfeld, D. Advanced monitoring of machining operations. CIRP Ann. Manuf. Technol. 2010, 59, 717–739. [Google Scholar] [CrossRef]

- Yen, G.G.; Lin, K.C. Wavelet packet feature extraction for vibration monitoring. IEEE Trans. Ind. Electron. 2000, 47, 650–667. [Google Scholar] [CrossRef]

- Patra, K.; Pal, S.K.; Bhattacharyya, K. Fuzzy Radial Basis Function (FRBF) network based tool condition monitoring system using vibration signals. Mach. Sci. Technol. 2010, 14, 280–300. [Google Scholar] [CrossRef]

- Yesilyurt, I.; Ozturk, H. Tool condition monitoring in milling using vibration analysis. Int. J. Prod. Res. 2007, 45, 1013–1028. [Google Scholar] [CrossRef]

- Xu, C.; Liu, Z.; Luo, W. A frequency band energy analysis of vibration signals for tool condition monitoring. In Proceedings of the International Conference on Measuring Technology and Mechatronics Automation, Zhangjiajie, China, 11–12 April 2009.

- Wang, G.F.; Yang, Y.W.; Zhang, Y.C.; Xie, Q.L. Vibration sensor based tool condition monitoring using v support vector machine and locality preserving projection. Sens. Actuator A Phys. 2014, 209, 24–32. [Google Scholar] [CrossRef]

- Rao, K.V.; Murthy, B.S.N.; Rao, N.M. Cutting tool condition monitoring by analyzing surface roughness, work piece vibration and volume of metal removed for AISI 1040 steel in boring. Measurement 2013, 46, 4075–4084. [Google Scholar]

- Zhang, J.Z.; Chen, J.C. Tool condition monitoring in an end-milling operation based on the vibration signal collected through a microcontroller-based data acquisition system. Int. J. Adv. Manuf. Technol. 2008, 39, 118–128. [Google Scholar] [CrossRef]

- Sun, J.; Hong, G.S.; Rahman, M.; Wong, Y.S. Identification of feature set for effective tool condition monitoring by acoustic emission sensing. Int. J. Prod. Res. 2004, 42, 901–918. [Google Scholar] [CrossRef]

- Ren, Q.; Balazinski, M.; Baron, L.; Jemielniak, K.; Botez, R.; Achiche, S. Type-2 fuzzy tool condition monitoring system based on acoustic emission in micromilling. Inf. Sci. 2014, 255, 121–134. [Google Scholar] [CrossRef]

- Chen, X.; Li, B. Acoustic emission method for tool condition monitoring based on wavelet analysis. Int. J. Adv. Manuf. Technol. 2007, 33, 968–976. [Google Scholar] [CrossRef]

- Tansel, I.; Trujillo, M.; Nedbouyan, A.; Velez, C.; Bao, W.Y.; Arkan, T.T.; Tansel, B. Micro-end-milling-III. Wear estimation and tool breakage detection using acoustic emission signals. Int. J. Mach. Tools Manuf. 1998, 38, 1449–1466. [Google Scholar] [CrossRef]

- Prakash, M.; Kanthababu, M. In-process tool condition monitoring using acoustic emission sensor in microendmilling. Mach. Sci. Technol. 2013, 17, 209–227. [Google Scholar] [CrossRef]

- Pai, S.; Nagabhushana, T.N.; Rao, R.B.K.N. Tool condition monitoring using acoustic emission, surface roughness and growing cell structures neural network. Mach. Sci. Technol. 2012, 16, 653–676. [Google Scholar] [CrossRef]

- Jemielniak, K.; Urbański, T.; Kossakowska, J.; Bombiński, S. Tool condition monitoring based on numerous signal features. Int. J. Adv. Manuf. Technol. 2012, 59, 73–81. [Google Scholar] [CrossRef]

- Bhattacharyya, P.; Sengupta, D.; Mukhopadhyay, S.; Chattopadhyay, A.B. On-line tool condition monitoring in face milling using current and power signals. Int. J. Prod. Res. 2008, 46, 1187–1201. [Google Scholar] [CrossRef]

- Kuo, H.-Y.; Meyer, K.; Lindle, R.; Ni, J. Estimation of milling tool temperature considering coolant and wear. J. Manuf. Sci. 2012, 134, 1–8. [Google Scholar] [CrossRef]

- Li, X.L.; Li, H.X.; Guan, X.P.; Du, R. Fuzzy estimation of feed-cutting force from current measurement—A case study on intelligent tool wear condition monitoring. IEEE Trans. Syst. Man Cybern. C Appl. Rev. 2004, 34, 506–512. [Google Scholar] [CrossRef]

- Martins, C.H.; Aguiar, P.R.; Frech, A.; Bianchi, E.C. Tool condition monitoring of single-point dresser using acoustic emission and neural networks models. IEEE Trans. Instrum. Meas. 2014, 63, 667–679. [Google Scholar] [CrossRef]

- Bhattacharyya, P.; Sengupta, D. Estimation of tool wear based on adaptive sensor fusion of force and power in face milling. Int. J. Prod. Res. 2009, 47, 817–833. [Google Scholar] [CrossRef]

- Huang, P.; Li, J.; Sun, J.; Ge, M. Milling force vibration analysis in high-speed-milling titanium alloy using variable pitch angle mill. Int. J. Adv. Manuf. Technol. 2012, 58, 153–160. [Google Scholar] [CrossRef]

- Dimla, D.E.; Lister, P.M. On-line metal cutting tool condition monitoring. I: Force and vibration analyses. Int. J. Mach. Tools Manuf. 2000, 40, 739–768. [Google Scholar] [CrossRef]

- Jemielniak, K.; Kossakowska, J.; Urbanski, T. Application of wavelet transform of acoustic emission and cutting force signals for tool condition monitoring in rough turning of Inconel 625. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2011, 225, 123–129. [Google Scholar] [CrossRef]

- Akyildiz, I.F.; Su, W.; Sankarasubramaniam, Y.; Cayirci, E. Wireless sensor networks: a survey. Comput. Netw. 2002, 38, 393–422. [Google Scholar] [CrossRef]

- Low, K.S.; Win, W.N.N.; Er, M.J. Wireless sensor networks for industrial environments. In Proceedings of the International Conference on Computational Intelligence for Modelling, Control and Automation and International Conference on Intelligent Agents, Web Technologies and Internet Commerce (CIMCA-IAWTIC‘06), Vienna, Austria, 28–30 November 2005.

- Åkerberg, J.; Gidlund, M.; Björkman, M. Future research challenges in wireless sensor and actuator networks targeting industrial automation. In Proceedings of the 9th IEEE International Conference on Industrial Informatics, Lisbon, Portugal, 26–29 July 2011.

- Gungor, V.C.; Hancke, G.P. Industrial wireless sensor networks: Challenges, design principles, and technical approaches. IEEE Trans. Ind. Electron. 2009, 56, 4258–4265. [Google Scholar] [CrossRef]

- Rumelhart, D.E.; Hinton, G.E.; Williams, R.J. Learning Internal Representations by Error Propagation. Available online: http://www.dtic.mil/cgi-bin/GetTRDoc?AD=ADA164453 (accessed on 23 March 2016).

- Kruse, R. Fuzzy Neural Network. Available online: http://www.scholarpedia.org/article/Fuzzy_neural_network (accessed on 8 April 2016).

- Guoyong, L. Intelligent Prediction Control and Matlab Realization; Publishing House of Electronics Industry: Beijing, China, 2010. [Google Scholar]

- Zha, X.F. Soft computing in engineering design: A fuzzy neural network for virtual product design. In Applied Soft Computing Technologies: The Challenge of Complexity; Springer: Berlin/Heidelberg, Germany, 2006; Volume 34, pp. 775–784. [Google Scholar]

- Liu, D.; Li, X.; Lu, S.; Ding, D.; Chen, X. Application of fuzzy neural network in burden surface clustering. In Proceedings of the 24th Chinese Control and Decision Conference (CCDC), Taiyuan, China, 23–25 May 2012.

- Zhang, X.Y. A novel greenhouse control system based on fuzzy neural network. In Applied Mechanics and Materials; Trans Tech Publications Inc.: Pfaffikon, Switzerland, 2014; Volume 668–669, pp. 415–418. [Google Scholar]

- AnytySEE-Mac-Manual. Available online: http://www.3r.com.cn/smsxz/&downloadcategoryid=12&isMode=false.html (accessed on 8 April 2016).

- Donoho, D.L. De-noising by soft-thresholding. IEEE Trans. Inf. Theory 1995, 41, 613–627. [Google Scholar] [CrossRef]

- Wavelet Packet Analysis. Available online: http://cn.mathworks.com/help/wavelet/gs/wavelet-packet-analysis.html?searchHighlight=wavelet%20packet (accessed on 8 April 2016).

- Li, X.; Lim, B.; Zhou, J.; Huang, S.; Phua, S.; Shaw, K.; Er, M. Fuzzy Neural Network Modelling for Tool Wear Estimation in Dry Milling Operation. Available online: http://www.phmsociety.org/sites/phmsociety.org/files/phm_submission/2009/phmc_09_68.pdf (accessed on 23 March 2016).

- 2010 PHM Society Conference Data Challenge. Available online: https://www.phmsociety.org/competition/phm/10 (accessed on 23 March 2016).

- Li, X.; Er, M.J.; Lim, B.; Zhou, J.; Gan, O.; Rutkowski, L. Fuzzy regression modeling for tool performance prediction and degradation detection. Int. J. Neural Syst. 2010, 20, 405–419. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Yao, X.; Zhang, J. Abnormal condition monitoring of workpieces based on RFID for wisdom manufacturing workshops. Sensors 2015, 15, 30165–30186. [Google Scholar] [CrossRef] [PubMed]

| Index | Feature | Description |

|---|---|---|

| 1 | Maximum | XMAX = max(xi) |

| 2 | Mean | μ = |

| 3 | Root mean square | XRMS = |

| 4 | Variance | XV = |

| 5 | Standard deviation | σ = |

| 6 | Skewness | XS = |

| 7 | Kurtosis | XK = |

| 8 | Peak-to-peak | XP2P = max(xi)-min(xi) |

| 9 | Crest factor | XCF = |

| Index | Feature | Description |

|---|---|---|

| 1 | Maximum of band power spectrum | SMAX = max() |

| 2 | Sum of band power spectrum | SSBP = |

| 3 | Mean of band power spectrum | Sμ = |

| 4 | Variance of band power spectrum | SV = |

| 5 | Skewness of band power spectrum | SS = |

| 6 | Kurtosis of band power spectrum | SK = |

| 7 | Relative spectral peak per band | SRSPPB = |

| Sensor | Time Domain | Frequency Domain | Time–Frequency Domain | Total | Selected Features |

|---|---|---|---|---|---|

| Vibration | 27 | 21 | 96 | 144 | 13 |

| Parameters | BPNN | RBFN | NFN |

|---|---|---|---|

| Learning rate | 0.1 | 0.1 | 0.1 |

| Training function (Learning algorithm) | Levenberg–Marquardt | - | Back-propagation iterative and gradient optimization |

| Number of layers | 3 | 3 | 5 |

| Number of nodes each layer | 13, 50, 1 | 13, 300, 1 | 13, 52, 128, 128, 1 |

| Number of samples | 7, 800 | 7, 800 | 7, 800 |

| Error | BPNN | RBFN | NFN |

|---|---|---|---|

| MSE | 5.9975 × 10−4 | 1.06 × 10−2 | 3.257 × 10−4 |

| MAPE | 0.0308 | 0.1461 | 0.0224 |

| R2 | 0.9851 | 0.7373 | 0.9919 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Yao, X.; Zhang, J.; Jin, H. Tool Condition Monitoring and Remaining Useful Life Prognostic Based on a Wireless Sensor in Dry Milling Operations. Sensors 2016, 16, 795. https://doi.org/10.3390/s16060795

Zhang C, Yao X, Zhang J, Jin H. Tool Condition Monitoring and Remaining Useful Life Prognostic Based on a Wireless Sensor in Dry Milling Operations. Sensors. 2016; 16(6):795. https://doi.org/10.3390/s16060795

Chicago/Turabian StyleZhang, Cunji, Xifan Yao, Jianming Zhang, and Hong Jin. 2016. "Tool Condition Monitoring and Remaining Useful Life Prognostic Based on a Wireless Sensor in Dry Milling Operations" Sensors 16, no. 6: 795. https://doi.org/10.3390/s16060795

APA StyleZhang, C., Yao, X., Zhang, J., & Jin, H. (2016). Tool Condition Monitoring and Remaining Useful Life Prognostic Based on a Wireless Sensor in Dry Milling Operations. Sensors, 16(6), 795. https://doi.org/10.3390/s16060795