Role of Morphological Structure, Doping, and Coating of Different Materials in the Sensing Characteristics of Humidity Sensors

Abstract

: The humidity sensing characteristics of different sensing materials are important properties in order to monitor different products or events in a wide range of industrial sectors, research and development laboratories as well as daily life. The primary aim of this study is to compare the sensing characteristics, including impedance or resistance, capacitance, hysteresis, recovery and response times, and stability with respect to relative humidity, frequency, and temperature, of different materials. Various materials, including ceramics, semiconductors, and polymers, used for sensing relative humidity have been reviewed. Correlations of the different electrical characteristics of different doped sensor materials as the most unique feature of a material have been noted. The electrical properties of different sensor materials are found to change significantly with the morphological changes, doping concentration of different materials and film thickness of the substrate. Various applications and scopes are pointed out in the review article. We extensively reviewed almost all main kinds of relative humidity sensors and how their electrical characteristics vary with different doping concentrations, film thickness and basic sensing materials. Based on statistical tests, the zinc oxide-based sensing material is best for humidity sensor design since it shows extremely low hysteresis loss, minimum response and recovery times and excellent stability.1. Introduction

Humidity, which is amount of water vapor present in air or atmosphere, is highly variable and changes according to seasons, land, sea, temperature and so on, and has an important role in the quality of industrial products, advanced instruments and human life. The regulation of humidity is important for human comfort, storage of various goods, industrial process control, high-tech instruments, and plenty of advanced sectors [1]. In industry, optimum humidity conditions should be provided on production lines for obtaining high quality products. For example, in textile processing, generation of electrostatic charges during the fabrication may cause the materials to cling. This is prevented by keeping the environment in damp conditions. On the other hand, dry conditions are required during processing of silicon wafers in a clean room, assembling electrical products on the assembly line and so on. In the automobile industry, humidity sensors are used in rear window defoggers and motor assembly lines. In the agriculture sector, since adequate environmental humidity conditions are needed to grow fruits and vegetables, similar conditions are needed in the preservation of different types of foods and cottons. There are many domestic applications, such as cooking control for microwave ovens, intelligent control of laundry and the living environment in buildings, and intelligent control and so on. In the medical field, humidity sensors are used in respiratory equipment, sterilizers, and incubators, pharmaceutical processing, and biological products. Thus, the measurement and control of humidity have significant importance in many areas for different purposes.

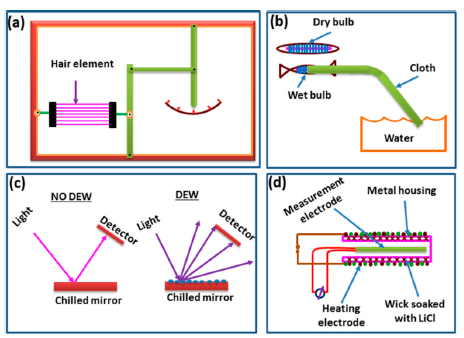

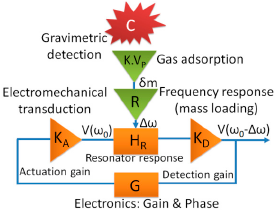

In 1450, Nicolas Cryfts invented a hygrometer which is the first humidity measurement instrument on record. This hygrometer used wool to determine the changes of humidity in air [2,3]. Over the past 550 years, many other kinds of hygrometer have been invented. A century later, in 1550, the device was improved by substituting a sponge for the wool and various versions of the hygrometer were devised. Subsequently, the sponge was replaced by paper, hair, nylon, and acetate. During the seventeenth and eighteenth centuries, there were several opinions about how water dissolves in air. It was also established that a relationship exists between humidity and frequency or temperature. Currently, miniaturized humidity sensors have shown many advantages, including integration, small size, low power consumption, high performance, low cost, and ease of mass fabrication, compared to the classical measurement used in different hygrometers such as lithium chloride (LiCl), dew point, and chilled mirror type sensors [4]. The different types of humidity sensors are classified according to the working technology and sensing principle and illustrated in Figure 1a,b.

Humidity is evaluated by different functions such as vapor pressure, saturation vapor pressure, dew/frost point temperature, and relative humidity [5]. Vapor pressure (hPa) is a partial pressure of water vapor in the air. Saturation vapor pressure is measured on a surface of water or ice at thermodynamic equilibrium condition. Dew point is a temperature, above 0 °C, at which the air will be cooled down to reach saturation at constant pressure condition and it is generally equal to or lower than the actual air temperature. Frost point is a temperature, below 0 °C, at which moist air saturates with respect to ice.

Relative humidity (RH, %) is a ratio of the vapor pressure (VP) of moist air to its saturation vapor pressure (SVP) at a given temperature, which is expressed by Equation (1):

Humidity can also be expressed in other ways like absolute humidity (g/m3), defined as the amount of water vapor contained in a unit volume of dry air, i.e., mixing ratio mr (parts per million by volume, ppmv) and the ratio with respect to saturation is defined as saturation deficit psd (mbar).

Development of an ideal humidity sensor depends on some key criteria, such as accuracy, power consumption, precision, repeatability, long-term stability, response time, size, packaging, and cost. In recent advances, cost effective miniaturization with ultra-high precise performance has received much attention for advanced application fields. To know the effect of different doping elements or materials in the sensor materials is most vital part of humidity sensor development for the different applications.

In this review, we aim to present extensive researches and developments of humidity sensing materials and characteristics for a wide variety of applications. Particularly changes in impedance or resistance, capacitance, hysteresis, recovery and response times, and stability with respect to relative humidity, frequency, and temperature are the primary interest of this present review article. Applications of humidity sensors in each field require different operating conditions, and various types of humidity sensing mechanisms based on a variety of sensing materials will be described. A typical comparative study of the above particular characteristics changes with different materials is critically reviewed in the following sections. Due to heavy population growth and their daily activities, environmental pollution is a great problem for a healthy atmosphere. Hence different types of gas sensors have an important role to detect or analyze the different contaminants present in the atmosphere. Importantly, the detection of humidity is one of the most important tasks owing to its versatile application in the fields of industrial control, agriculture, material analysis and biomedical instruments. A potential versatile humidity sensor must have good reproducibility, low hysteresis, low cost, be resistant against contaminants, good sensitivity, good durability and long life time, a very short response time, and low dependency on temperature.

This review paper is organized as follows: the general notion and definitions of humidity are presented at the beginning of the Introduction section. Section 2 highlights the miniaturization of humidity sensors with their potential advantages and disadvantages. This section mainly discusses the distinct transduction principles of different types of humidity sensors such as resistive, capacitive, hygrometric, gravimetric, and optical sensors. The essential physical or morphological properties and typical electrical characteristics of relative humidity sensors based on different key materials such as carbon, polymer, silicon, vanadium, iron, tin, titanium, zinc, zirconia, and sodium are highlighted in Section 3. This section also focuses the changes in the physical, chemical, electrical as well as structural characteristics of the base material due to different coatings or dopants. Section 4 follows with a brief review where a number of key applications of humidity and moisture measurement are highlighted in areas such as structural health monitoring (SHM), food processing and storage, medicine, ecology, agriculture, mineral processing, fuel quality control, and aerospace. Finally the concluding remarks are provided in Section 5.

2. Miniaturized Humidity Sensors

For many sophisticated applications, there has been a keen attempt to reduce the size of the sensors using the most advanced technologies collectively called miniaturization. Miniaturized humidity sensors mainly depend on five different transduction principles: hygrometry, capacity, resistance, gravimetry and optical properties.

2.1. Hygrometric Sensors

For many decades hygrometric sensors have been using in old devices that are classified into four basic types—mechanical, dry bulb-wet bulb, chilled mirror, LiCl dew point—for the measurement of the humidity of air, which is converted into mechanical energy [6–10]. These are illustrated in Figure 2a–d.

Generally, hygrometric sensors have two different materials with different thermal expansions coefficients, such as a polysilicon membrane and a hygroscopic material such as polyimide. The polyimide as a hygroscopic coating expands due to the absorption of water. Due to the unequal expansion that occurs between the polyimide and polysilicon, a change in the bending structure of the membranes is observed. The change in bending is converted into an electrical signal via a piezoresistor. The hygrometric sensor has some advantages as well as some disadvantages which are listed below:

Advantages:

Low cost;

No power supply is required;

It provides a primary rather than a secondary measurement of dew point;

High accuracy;

High repeatability;

Traceable to N.I.S.T. or other national standards labs;

Wide dew point range;

Wide temperature range;

Low hysteresis;

No drift.

Disadvantages:

More complex, may be more expensive;

Narrow flow rate range;

Periodic cleaning may be required;

High uncertainty (±2% to 5%).

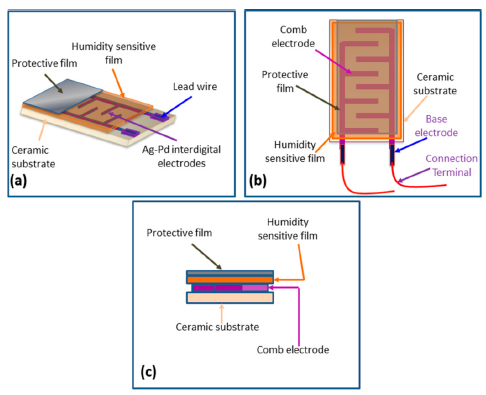

2.2. Resistive Sensors

The most common resistive sensors are based on electrical resistance. The electrical resistance of a material is the opposition to the passage of an electric current through that conducting material. Since the humidity can change the electrical resistance or impedance of a material noticeably, resistive humidity sensors have been developed using this principle. Generally the all resistive sensors have four layers: substrate, interdigital electrode, humidity sensitive film and protective layer which are shown in Figure 3a–c. In resistive or impedance humidity sensors, air humidity changes with the variation of resistance and follows Equation (2) [11]. Measurement of resistance is very simple and straight-forward in comparison to capacitance measurement. Ceramics, polymers and electrolytes are commonly used material for resistive type sensor:

The sensing response (SR) can be measured using an expression given in Equation (3) [12]:

A CA-NH4BF4-PEG600 thin film resistive type humidity sensor is based on cellulose acetate (CA), ammonium tetrafluoroborate (NH4BF4) and polyethylene glycol (PEG600) [13]. This sensor shows a very good response towards humidity, good linearity and good stability. The size of the resistive humidity sensor can be reduced by using excellent electrically sensitive multiwall carbon nanotube (MWCNT)-reinforced polyimide NC films [14]. The flexibility of a resistive micro-electrode (1.4 mm × 1.4 mm in size) has been improved by using a polyimide substrate and a commercial alumina-based electrode [15]. The interpenetrating polymer network (IPN) of polyimide enhance the polyelectrolyte and water molecule interactions, which provide high sensitivity, water durability, and stability under high humidity and humidity condition to the micro sensors. Resistive sensors have some advantages as well as disadvantages which are listed below:

Advantages:

Small and cheap;

Mass production possible;

Interchangeable/field replaceable.

Disadvantages:

Limited range (typically 15% to 95% RH);

High temperature dependency;

Poor stability;

Sensitive to contamination, condensation;

Reading altered by all substances that affect resistance; salts, hydrogen, oxidizing agents, other chemicals;

Resistive type sensors find difficulty in measuring low values (below 5% RH);

The change in impedance is too high and hence it is difficult to control the dynamics and temperature effects significantly.

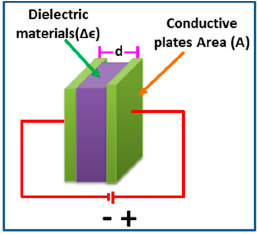

2.3. Capacitive Sensors

The capacitance of a sensor indicates the ability of a body to store an electrical charge. It can change significantly with humidity. Using this principle, capacitive type humidity sensors have been developed. Fundamentally, the operation of capacitive type humidity sensors is a function of the dielectric changes of thin films due to the absorption of water vapor. Their characteristics mainly depend on the hygroscopic nature of the material and the geometry of the electrode. In this regards, capacitance (C) of all the parallel plate capacitive sensors (see Figure 4) follows a relation given by Equation (4):

A capacitive type humidity sensor based on gold-poly(vinyl alcohol) (PVA) encapsulated gold (Au) nanoparticle nanocomposites (NCs) was analyzed by Yao et al. [16]. Here, Au-PVA core-shell NCs were used as dielectric material in between the electrodes. In most capacitive sensors, different types of polymers or elastomer-based materials are used as dielectric materials. The variation of capacitance can be measured as a function of the change in dielectric constant of the polymeric materials, which changes with the absorption of moisture or humidity. On the other hand, silicon (Si) chips and microscopic glass slides are generally used as electrode substrates, while two electrodes are typically coated with conducting metal such as silver (Ag) on the surface of substrate by using advanced nanotechnology. An ultra-thin flexible capacitive humidity sensor was designed by Pantalei et al. [17]. This capacitive sensor consists of two parallel metal plates separated by a thin film layer of bis(benzocyclobutene), which behaves as a dielectric material. The two metallic plate electrodes are arranged properly, so that the dielectric material can easily absorb atmospheric moisture or chemical compounds. Wei et al. [18] developed a femto-farad capacitive sensor for picoliter liquid monitoring. The sensor consisted of vertical silicon electrodes integrated into a through-wafer channel for the measurement of the liquid level variations inside a channel. Currently, detection of high-resolution capacitance is a big challenge. In this context, Carminati et al. [19] have developed a highly accurate and precise calculation of capacitance using a complementary metal oxide semiconductor (CMOS)-based nanosensor. This sensor circuit consists of a CMOS ultra-low-noise and wide-bandwidth current sensing circuit, coupled to a lock-in amplifier for the measurement of capacitance and conductance in a frequency range from DC to 1 MHz. Matko et al. [20] highlighted a highly sensitive capacitive humidity sensor for high air humidity measurements. This sensor consists of an analog-to-digital (A/D) to digital-to-analog (D/A) converter and crystal oscillators. Their device showed as a highly sensitivity but the stability of crystal oscillator is still a big challenge. A stability analysis of a crystal oscillator was reviewed by Wall et al. [21]. After long time operation of the oscillator, it is normally affected by aging effects [22]. Matko [23] developed a quartz sensor for water absorption measurements in glass-fiber resins (GFRs). The GFRs-based capacitive sensor is not highly precise due to its nonlinear frequency-temperature characteristics, however, this problem was solved by using an AT-cut quartz crystal sensing device [24]. There are several high quality capacitive methods for absorption of water vapour (including without thin films) in humidity measurements which use simple open capacitors (with good electronic circuits and quartz oscillators) in a form of a comb or two plates, and have many advantages and disadvantages such as [18–24]:

Advantages:

Wide measurement range 0%–100% RH;

Wide temperature range (up to 200 °C);

Low temperature dependence (temperature compensation);

Low hysteresis (below 1%);

Low drift;

Have no problems with high humidity measurement or saturation and response time;

Have no absorbing material;

Excellent stability & linearity;

Fast response;

Full recovery from condensation;

Highly resistant to contaminants;

Small in size;

Low cost;

Require very little maintenance.

Disadvantages:

Can be limited by distance from electronics to sensor;

Loss of relative accuracy at low end (<5%);

Requires electronics to convert capacitance to relative humidity;

Significant drift.

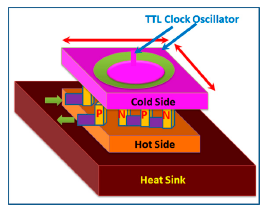

2.4. Gravimetric Sensors

The quartz crystal microbalance (QCM) [25] is the main source of inspiration for gravimetric sensors. This sensor consists of a piezoelectric quartz plate, which is coated with a hygroscopic material having resonance frequency in the MHz range, and it measures humidity due to the change of frequency as shown in Figure 5. The change of frequency (Δf) can be calculated by the Sauerbrey Equation (6) [26]:

In this case, a resonance frequency shift occurs due to the absorption of mass in the chemical layer which is recorded by the resonator. The gravimetric sensor has some advantages as well as some disadvantages which are listed below:

Advantages:

Relatively low response time;

Good accuracy;

Low drift.

Disadvantages:

Nonlinear characteristics;

High temperature dependence;

Require complicated systems for signal processing of sensor outputs.

2.5. Optical Sensors

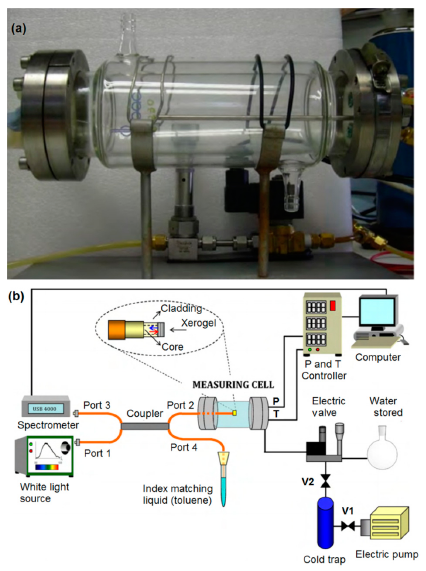

All the above discussed humidity sensors have their own transduction principles to measure the humidity with some advantages and disadvantages. Normally electronic devices related to the above sensors cannot work under electromagnetic interference or in remote monitoring systems and hazardous or explosive environments. However, optical sensor-based humidity sensors are ideal devices to work under the above severe conditions, thus they sees significant use in many advanced applications where they show enhanced efficiency. The detection limit of this optical humidity sensor is less than 4% RH.

Hence, based on the versatile applications and numerous advantages of optical fiber technology, researchers have been focusing on fiber optic-based techniques for the measurement of humidity for the last few years. A fiber optic humidity sensor proposed by de Vicente et al. is depicted in Figure 7a [29]. A schematic of an optical humidity sensor is depicted in Figure 7b. The main sensing principle of an optical humidity sensor is based on the change in reflected optical power due to the water molecules adsorbed on a porous sensing element such as a silica xerogel film, which is embedded on the optical fibers. The relative reflected power at an interface between the two media changes with the refractive index of the media, incidence angle and polarization of the incident wave.

The reflected optical power (I) due to the perpendicular light impingement from the interface depends on the refractive indices n1 and n2 of the two media and follows Equation (7) [29]:

A porous sensing film of silica xerogel on the tip of an optical fiber provides an optical cavity where the fiber-xerogel interface gives the first refection and the xerogel-vapour interface gives the second reflection. The reflectance of this sensing element can be expressed by Equation (8) [30]:

According to Equations (7) and (8), it is obvious that the variation in refractive index of the sensing film (xerogel) and the external medium leads to change in the reflectance at the fiber-film interface and, therefore, in the sensor output signal. The changes in the reflectance at the fiber-film and film-external medium interfaces also vary with film thickness. Optical fiber humidity sensors have many advantages compared with conventional measuring methods, but also some disadvantages, which are given below:

Advantages:

Low cost;

High sensitivity;

Small size;

Robustness;

Flexibility;

Ability for remote monitoring as well as multiplexing;

Used even in the presence of unfavorable environmental conditions such as noise, strong electromagnetic fields, high voltages, nuclear radiation, in explosive or chemically corrosive media, at high temperatures;

Good reproducibility;

Low hysteresis.

Disadvantages:

Inherent losses;

Dispersion;

Nonlinearity;

Birefringence.

There are various types of fiber optic humidity sensors to fulfill the desired advanced needs, such as fiber grating sensors, evanescent wave sensors, interferometric sensors, hybrid sensors (i.e., grating integrated with interferometric), absorbance sensors, direct spectroscopic-based sensors and fluorescence-based sensors etc. and listed in Table 1, which covers all types of optical humidity sensors together to highlight the potential results of some reported works chronologically.

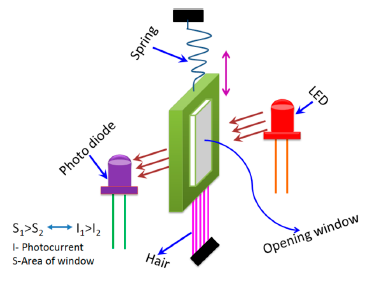

2.6. Mechanical-Optoelectronic Humidity Sensors

In addition to the abovementioned five main types of humidity sensors, they can also be categorized by principle, which is the mechanical-optoelectronic principle, as shown in Figure 8 [72]. This device consists of a light emitting diode (LED), a very sensitive photodiode, and a mechanical system. The sensor has a bunch of human hair at one end and other end has a thin metal sheet with a fittable window with respect to the LED and photodiode. Human hair acts as a capacitor in this humidity sensor. A spiral spring is connected with the metal sheet. When the humidity concentration changes the contraction and expansion occurs in the hair, this hair pulls the metal sheet up or down. Thus, the window opening area changes and this varies the light intensity reaching the photo detector from the LED, resulting in a photocurrent change with respect to humidity on the output side. This sensor has a very good linearity, long life time, small hysteresis, stable operation, and less temperature dependency.

3. Different Key Sensing Materials and Their Characteristics in Humidity Sensors

During the last five decades, plenty of sensing materials have been developed for different types of humidity sensors in a wide range of applications. The most common commercial sensors are mostly based on metal oxides, porous silicon and polymers [12]. In a humidity sensor, fundamentally, the humidity signals obtained via two-electrode techniques are affected by polarization effects. This happens due to the migration of electrons from the metal probe into the conductive specimen. Polarization effects may be caused by the migration of H+ ions into the metallic probe as H+ ions are found in the physisorbed absorbed water [12,73]. Thus, positive charges in the specimen migrate towards the metallic probe and create a cation layer between the metallic probe and the specimen. In this context, plenty of electrode structures have been proposed for various sensing systems. Hence, this review article is mainly focused on the key sensing materials and their typical characteristic properties for the application in humidity sensors.

Addition of different coatings or dopants to a base material changes its physical, chemical, electrical as well as structural characteristics and these characteristics are also changed with different base materials. In this section, different electrical characteristics (i.e., impedance or resistance, capacitance, response and recovery time, hysteresis, and stability with the variation of relative humidity, frequency, and temperature) of various sensor materials based on carbon, vanadium, iron, silicon, polymer, tin, titanium, zinc, zirconia and sodium are compared. Both similarities and dissimilarities in the electrical characteristics for different sensor materials are observed, which vary strongly with the doping concentration of different materials, film thickness of the substrates and the morphological changes.

Although humidity sensors based on different materials have been used for more than six decades, the key factors to improve sensing characteristics in different applications are still not well defined. This is extremely important in the miniaturization of sensors in nanotechnology for many advanced applications. Therefore, in ordered to determine the best humidity sensor based on different materials, the plots of the important electrical characteristics of various morphological structures, coatings or doping agents are recognized and typically compared.

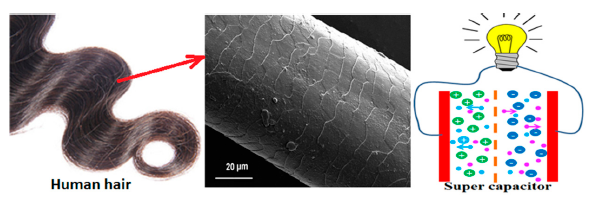

3.1. Carbon

Carbon is highest abundance material present on Earth. Different allotropic forms of carbon have been widely used in broad application fields. Carbon materials are available in different forms like carbonized porous form [74], graphite [75], diamond or diamond like carbon [76], fullerenes [77,78], graphene [79], amorphous carbon [79–81], carbon nanotubes (CNTs) [82], carbon nanofibers (CNFs) [83] and nanostructured carbon films (carbon nanosheets and nanohoneycombs) [12]. A small amount of carbon present as an inclusion or dopant may also be able to change the properties of materials exponentially. Interestingly, human hair-derived carbon flakes have recently shown excellent capacitance behaviour and thus have been used as a supercapacitor (Figure 9) [84].

Carbon nanostructured materials have shown the most attractive sensing properties in various applications. A large sensing area, high chemical inertness, and large porosity nature of carbon make it popular in the humidity sensor field. Different techniques such as physical vapor deposition, thermal carbonization, magnetron sputtering, thin film deposition and so on have been used to fabricate carbon-based nanostructured humidity sensors. The doping of different materials in carbon changes its physical, electrical and humidity sensing characteristics as explained below. The electrical characteristics (resistance, capacitance, sensitivity, response time, hysteresis, stability) changes with the variation of frequency, temperature and relative humidity of carbon-based sensor materials are explained in the following subsections.

3.1.1. Effect of Temperature and Frequency on Resistance-RH Characteristics

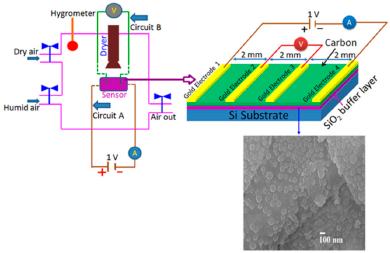

For carbon-based resistance humidity sensors, in most cases it has been found that the resistance increases as the RH value increases. The change in resistance is greater in the high humidity region. Nanostructured carbon films (i.e., carbon nanosheets and nanohoneycombs) coated on Si(100) substrate have been used in a humidity sensor device, which is depicted in Figure 10 [12].

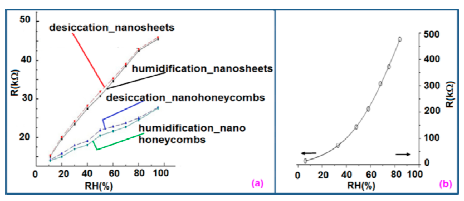

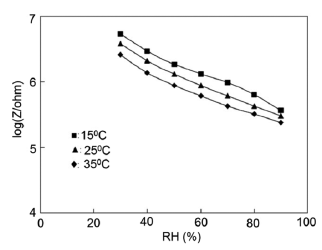

It shows a linear variation of resistance with relative humidity in the range of 11%–95% as illustrated in Figure 11a [12]. The resistive sensing response of the carbon nanosheet- and nanohoneycomb-based sensors increases up to 225% and 110%, respectively, at 95% relative humidity (RH). It has also been found that nanocarbon films, including carbon nanosheet- and carbon nanohoneycomb-based sensors give excellent linearity (see Figure 11a) under any humidity condition between 11% and 95%. Unlike nanocarbon films, thermally carbonized porous silicon (TC-PS)-based humidity sensors show nonlinear behavior in their resistance vs. RH characteristics with a significantly higher resistance value (see Figure 11b). The non-linearity of the TC-PS based humidity sensor is related to the dielectric changes of a porous layer upon water vapor uptake while the condensed vapor replaces the air in the pores as the relative humidity increases [74]. It is to be noted that linearity in this characteristic is more desirable to improve the efficiency of sensors. The resistance of the carbon-based sensors also strongly depends on the temperature as well as structural morphology. The resistance value decreases with increasing temperature owing to the increased amount of free electrons. Chu et al. showed that the resistance of nanohoneycomb carbon is significantly lower than that of nanosheet carbon when all other conditions are the same [12]. This may be due to more transportation freedom for the migrating ions or free charges available in the nanohoneycomb structure compared to nanosheets. In this context, a quantitative analysis showed that a charge transfer of 0.03 e− from a single water molecule to a carbon nanofilm can occur [12,85]. It has also been reported that the variation of frequency may affect the resistance value. In a multiwall carbon nanotubes (MWCNTs)-based humidity sensor, the resistance decreases with increasing frequency [86].

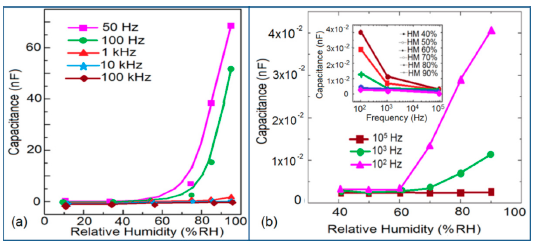

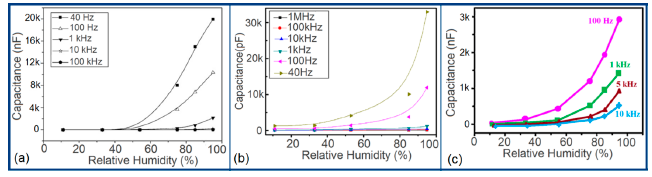

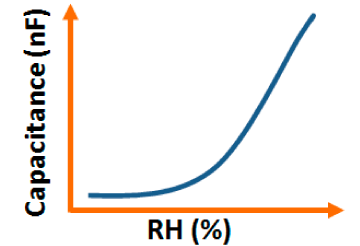

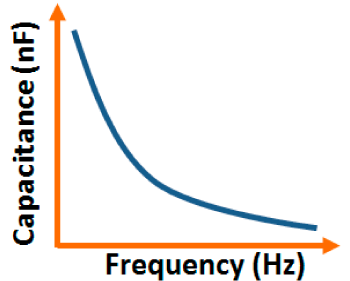

3.1.2. Effect of Frequency on Capacitance-RH Characteristics

The capacitance value of a humidity sensor generally increases nonlinearly with increasing relative humidity. This has been clearly observed over a wide range of RH values from 11% to 95% for a capacitive humidity sensor in which amorphous carbon (a-C) films are deposited on nanosilicon (n-Si) [87]. Here, the a-C and Si form a heterojunction layer. The capacitance of the heterojunctions increases with decreasing frequency at high RH values and this is depicted in Figure 12a.

a-C/n-Si sensors have shown excellent linearity in comparison to TC-PS-based humidity sensors. The range of capacitance values in a-C/n-Si based sensor is several times higher than in TC-PS-based humidity sensors, however, it has also been found that the capacitance decreases with increasing RH for TC-PS material [74]. This is related to the dielectric changes of a porous layer upon water vapor uptake when the air in the voids is replaced by condensed vapor as the relative humidity increases. The capacitance variations with different RH values for both the sensors are shown in Figure 12b,c. For practical applications, a-C/n-Si based sensors give optimized results at 1 kHz frequency since there they show the best linearity as compare to other frequencies [87].

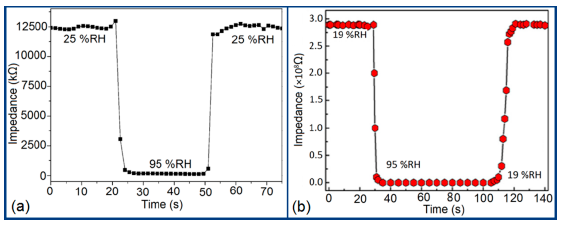

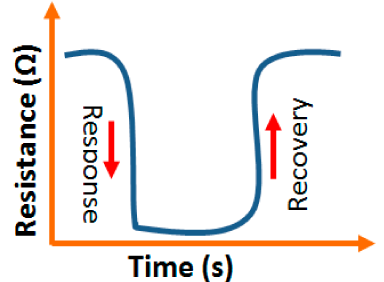

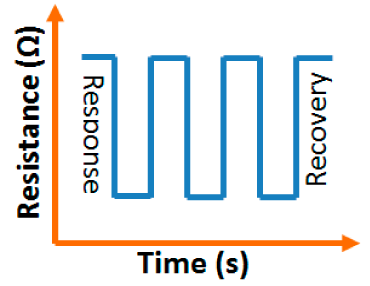

3.1.3. Response and Recovery Time

For the estimation of the performance of humidity sensors, response and recovery behavior are some of the most significant features. Response time is defined as the time taken by the sensor to achieve 90% of the total resistance or capacitance change in case of adsorption and the recovery time in case of desorption of the water vapors. The response and recovery time are very structure sensitive. The values are different for different carbon material morphological structures in humidity sensors. The response time of a TC-PS-based capacitive humidity sensor was 90 s in a low humidity range (<70% RH), but at higher RH (>90%) the response time was 120 s [74], whereas, the response time of a MWCNTs-based humidity sensor was 16 s and the recovery time was 8 s [86]. The response and recovery time of a-C/n-Si based sensor were 3 min and 4 min, respectively [87]. The response and recovery times of a carbon nanosheet-based sensor were 30 s and 90 s, respectively, at 40% RH, which are even better than that obtained with a carbon nanohoneycomb-based sensor [12]. This has been observed because the nanoparticles on the surface of the carbon nanosheets make water molecules adsorb more easily compared to carbon nanohoneycombs. The hydroxyl groups in the water molecules act as adsorption sites for water molecules to connect between the nanoparticles on surface of the carbon nanostructured materials. For a practical application, the response and recovery time of a sensor must be as short as possible. For comparison, it is concluded that the MWCNTs-based humidity sensor has the smallest response and recovery time and the a-C/n-Si based sensor has the highest response and recovery time. The a-C/n-Si based humidity sensor may give excellent linearity but it has very slow response for humidity sensing, therefore, a MWCNTs-based humidity sensor would be a first choice as best humidity sensor.

3.1.4. Sensitivity Response

The humidity sensitivity is determined from the slope of a capacitance vs. RH curve. The sensitivity of capacitive and resistive type humidity sensors can be calculated using Equations (3) and (5), respectively. The sensitivity of a humidity sensor can also be evaluated at different frequencies. It has been reported that the sensitivity of a TC-PS sensor at 55 Hz, 120 Hz and at 1 kHz is 900%, 800% and 450%, respectively [74]. The sensitivities of a-C/n-Si sensor at 100 Hz, 1 kHz, 10 kHz, and 100 kHz are reportedly 0.9887, 0.9470, 0.8484, and 0.7881, respectively [87]. It has been noticed that the sensitivity decreases with increasing frequency and the sensors give maximum sensitivity at the low frequency range. Like the capacitance sensitivities, conductance sensitivity can also be calculated to evaluate a sensor using Equation (12) at minimum and maximum RH vales [86]:

It has been reported that the conductance sensitivity of a MWCNTs-based sensor is −0.02 ms at 50 Hz and at 1 MHz the sensitivity (S) reaches its maximum value (1.906 ms) [86]. This indicates that the conductance sensitivity increases as the frequency increases but the capacitance sensitivity decreases with increasing sensitivity.

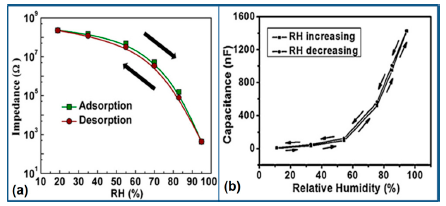

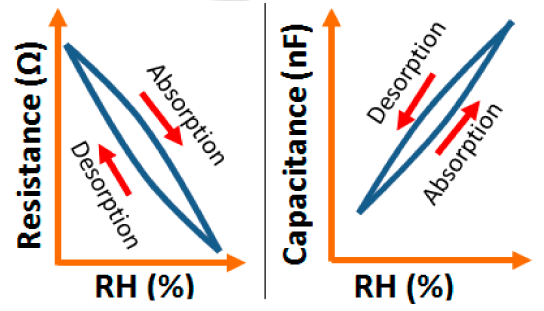

3.1.5. Hysteresis Characteristics

Hysteresis is defined as the non-coincidence between the loading and unloading behavior of a particular plot. The loading and unloading curves of a perfect sensor normally follow the same path, which is different for different morphologies. For example, the maximum humidity hysteresis for nanostructured carbon sensors such as carbon nanosheet- and nanohoneycomb-based sensors is 3.57% and 6.83%, respectively, at 50% RH [12]. Although nanohoneycomb morphology carbon films show better properties in resistive and capacitive humidity sensors, from a hysteresis point of view carbon nanosheet humidity sensors are more suitable for humidity sensing applications than carbon nanohoneycomb-based sensors since a lower hysteresis value is more desirable for stabilization of an electronic instrument. On the other hand, TC-PS-based humidity sensors show poor hysteresis, even at different frequencies [74], although increasing the porosity may improve the hysteresis by widening the porosity in the material structure. However, while this technique may help to reduce the hysteresis the sensitivity and response time of the TC-PS sensor may suffer significantly.

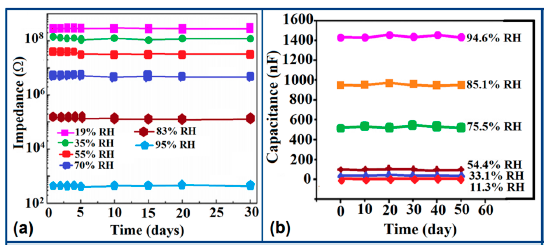

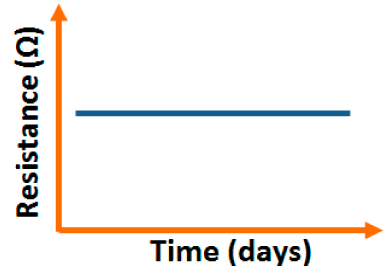

3.1.6. Stability and Repeatability Analysis

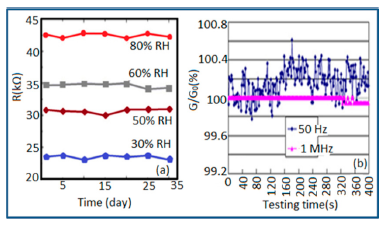

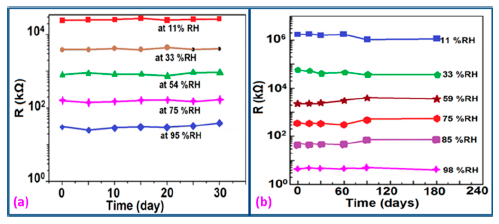

Carbon nanofilm-based sensors showed good stability and durability in a repeatability study when tested for a month at 5-day intervals, as shown in Figure 13a [12]. It has also been noticed that at high frequency range, nearly 1 MHz, MWCNTs-based humidity sensors show greater stability compared to a lower frequency such as 50 Hz, as depicted in Figure 13b [86].

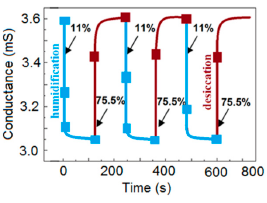

Furthermore, TC-PS-based sensors have shown less stability compared to carbon nanosheet- and MWCNTs-based sensors. On the other hand, for MWCNTs sensors, an excellent reversibility or repeatability in conductance with RH through adsorption-desorption dynamic cycles at 1 MHz has been repeatedly shown between 11% and 75.5% RH, as illustrated in Figure 14 [86]. Similar comparisons in repeatability of capacitance-time plots between two different materials such as a-C/n-Si (at 1 kHz, between 33% and 95% RH) [87] and TC-PS (at 120 Hz, between 6% and 58% RH) [74] have also been reported. This comparison indicates that the TC-PS based sensor shows repeatability at low humidity range at low frequency, which is also lower than that of MWCNTs-based humidity sensors (which showed repeatability at 1 MHz).

3.2. Vanadium-Based Materials for Humidity Sensors

The abrupt change in electric properties and a sharp change in optical transmittance or reflectance make vanadium (V) a “smart material” [88,89]. Vanadium has a tremendous application in the fields of thermochromic coatings, temperature sensing devices, optical switching devices and Mott field-effect transistors [90,91]. Ceramic materials have potential applications in the field of humidity sensors. Recently rutile phase vanadium dioxide (VO2) (R/M1) has also been used in humidity sensors [91] since it undergoes a first-order reversible metal-insulator transition (MIT) near room temperature (68 °C) [92] among over ten crystalline phases of VO2 [93]. Nanostructured VO2 has received great attention owing to its physical and chemical properties that differ greatly from those of the bulk counterpart [91]. Vanadium-based humidity sensor materials such as nanostructured VO2(B) or VO2(M1) can be synthesized by several methods such as thermolysis [94], solution-based methods [95], hydrothermal methods [91], and hydrothermal methods followed by heat-transformation [91], sol-gel [96], chemical vapor deposition [97], pulsed laser ablation [98], magnetron sputtering [99], and so on. The morphology of VO2 can be changed by using different synthesis techniques. It has been found that different concentrations of reductant also can change the morphology of VO2. Recently, Yin et al. [91], have shown that with variation of a vanadium salt concentration (i.e., NH4VO3 as a source) in a reductant (i.e., oxalic acid) the morphology of nanostructured VO2(M1) could be changed to nanospheres integrated with nanowires (synthesized with 0.125 mol/L oxalic acid at 180 °C for 24 h), nanoflowers (synthesized with 0.1 mol/L oxalic acid at 180 °C for 24 h) and nanorods with some nanoflakes (synthesized with 0.065 mol/L oxalic acid at 180 °C for 24 h). The all the basic properties, including field emission (FE) current density (J, mA/cm−2) and sensitivity of the nanostructured VO2(M1) based humidity sensors changed significantly with the different structures. The variations of the electrical characteristics (resistance, capacitance, sensitivity, response time, hysteresis, stability) of vanadium-based sensor materials with the variation of frequency, temperature and relative humidity are explained in the following subsections.

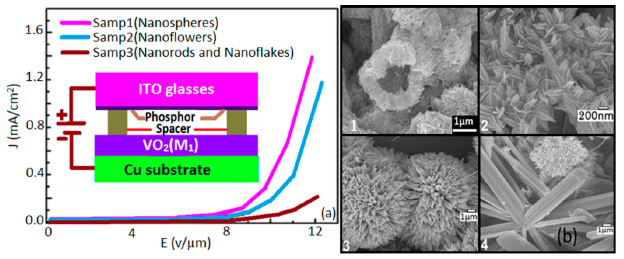

3.2.1. Field Emission Characteristics

The field emission current density J increases exponentially with the applied field (E, V/μm) and the nanosphere structure. As depicted in Figure 15a, a Sample1-based sensor showed the highest FE current with the best turn-on field (around 4 V/μm) when the threshold field is the lowest (around 11 V/μm). The turn-on (around 5.3 V/μm) and threshold (may be more than 13 V/μm) fields are the poorest for the nanorods with some nanoflakes-based sensors (Sample 3).

Emitter geometry (such as aspect ratios), crystal structure, and the spatial distribution of emitting centers are the main cause for this field emission effect. Each nanosphere Sample1 sensor has many VO2(M1) nanowires or belts (nearly 100 nm wide) with a large aspect (i.e., length-to-diameter) ratio which easily enhances the electron emission from these nanowires (see Figure 15b). On the other hand, Sample 3 has large diameter nanoroads without having any sharp tip, which is the main reason of the electron emission. The blunt edged larger diameter structures in Sample 3 causes its less electron emission. Furthermore, VO2(M1) nanoflowers and hollow nanospheres both are more sensitive to humidity since both have high surface to volume ratio.

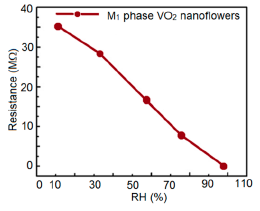

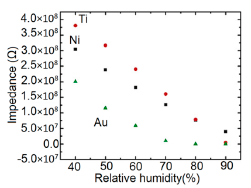

3.2.2. Effect on Resistance of the Variation of RH

In general vanadium-based humidity sensor materials show linear resistance characteristics. The resistance decreases with increasing RH, as shown in Figure 16. In contrast, water coverage on the surface of VO2(M1) nanoflower structured sensors is not continuous under low humidity conditions, which causes a very weak electrolytic conduction. Thus, the resistance value becomes high since the sensor surface absorbs very few water particles discontinuously. On the other hand, under high humidity conditions, a number of continuous water layers are formed on the VO2(M1) porous structure, which causes a very good electrolytic conduction by accelerating H+ ions and thus, the value of resistance decreases.

3.2.3. Sensitivity Analysis

Sensitivity is measured from the slope of the linear fit resistance vs. RH curve. The sensitivity factor (Sf) is the ratio of minimum RH to maximum RH. The VO2(M1) nanoflower-based humidity sensors show extremely high sensitivity, i.e., 118.

3.2.4. Response and Recovery Characteristics

Response and recovery times are the most important dynamic characteristics of all sensors. VO2(M1) nanoflower-based humidity sensors show a response time of 13 s at 1 V AC signal and frequency of 100 Hz and the recovery time is 5 s. The VO2(M1) nanoflower-based humidity sensors have better response compared to the ZnO- [100], SnO2- [101], and TiO2-based [102] resistive sensors.

3.2.5. Stability and Reproducibility Analysis

Stability and reproducibility are also very important dynamic characteristics of a sensor. Yin et al. [91] have done a stability analysis of VO2(M1) nanoflower-based humidity sensors by repeatedly measuring the resistance once a week for five weeks by exposing the sensor to air. The resistance fluctuations showed by this sensor was less than ±10% over the five weeks, which shows excellent stability (Figure 17a) and good reproducibility (see Figure 17b) with seven consecutive cycles with narrow fluctuation. This narrow fluctuation occurred due to the fluctuation of RH in the laboratory atmosphere and the moist air which was formed in an aqueous solution of K2SO4.

3.3. Iron-Based Materials for Humidity Sensors

Ceramic materials have tremendous applications in the field of humidity sensors. The most commonly used ceramic materials for humidity sensors are TiO2, ZnO, ferrite, silica, perovskite oxides BaTiO3, and (Ba,Sr)TiO3. Copper-zinc spinel ferrite has a very high electrical resistance, due to which it can't be used as a good sensitive material for humidity sensors. To bring this ferrite material into a measurable zone and to increase its conductivity, tungsten and iron have been added to this composite [103] to develop a copper-zinc-tungsten Cu0.5Zn0.5W0.3Fe1.7O4 spinel ferrite by the sol-gel technique. On the other hand, maghemite γ-Fe2O3 is an n-type semiconductor and many researchers have used it as a humidity sensor material. γ-Fe2O3 based sensor has significantly high sensitivity, simple design, and low cost, but this sensor material lacks selectivity. This problem can be overcome by different doping techniques using different ions such as lithium (Li+) [104], tin (Sn4+) [105], molybdenum (Mo6+) [105] in iron based humidity sensors. In contrast, lithium has been doped in γ-Fe2O3 based humidity sensors by a chemical synthesis technique [104] and Sn4+ and Mo6+ have been doped by substituting Mg and/or Fe in MgFe2O4 to produce a potential humidity sensor composite material (i.e., Mg1−xSnxFe2−yMoyO4) using the sol-gel technique [105]. Many other humidity sensor materials have also been developed using different synthesis techniques. Li-doped iron oxide thin film-based humidity sensors have been developed using a liquid phase decomposition technique [106]. A potassium (K+)-doped LaCo0.3Fe0.7O3 thick film humidity sensor was developed by using a screen printing technique [107]. It has been found that K-substitution at La-sites in the La1−xKxCo0.3Fe0.7O3−δ perovskite structure has a significant effect on humidity detection [108]. The perovskite structured composite developed by the sol-gel technique has shown better homogeneity results and more significant properties compared that prepared by a simple mechanical mixing method. Furthermore, a mesoporous LaFeO3 humidity sensor has been developed through a nanocasting method by using mesoporous SBA-15 as a hard template [109]. The high surface area, high pore volume and crystalline wall are the major characteristics of an iron-based humidity sensor. The electrical characteristics (resistance, capacitance, sensitivity, response time, hysteresis, stability) variation with the variation of frequency, temperature and relative humidity of iron-based sensor materials are explained in the following subsections.

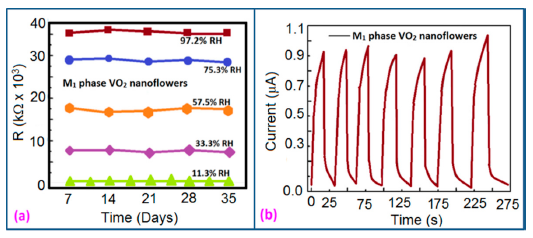

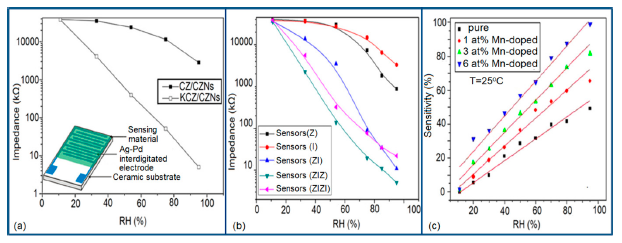

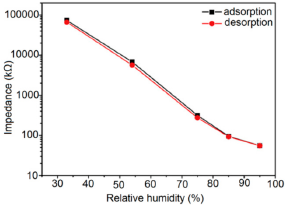

3.3.1. Resistance or Impedance Variation with Relative Humidity (RH)

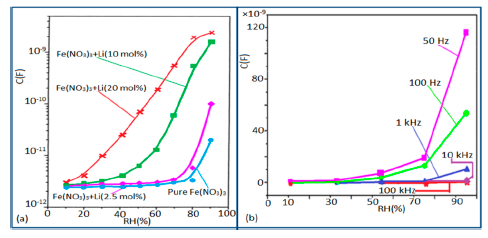

It has been found that a small size and highly local charge content Li-ions significantly enhance the water absorbing property in a sensor, which leads to more chemisorbed water molecules on the material surface and lesser resistance in the sensor. Thus, an undoped sensor (FF80) shows extremely high resistance values in comparison to a Li-doped iron oxide sensor. With increasing Li-content in the iron oxide-based humidity sensor the resistance values decrease significantly and at higher RH (>60% RH), the rate of resistance fall is sharp in comparison to low RH range (see Figure 18a) [106]. Like Li+ ion, in K+-doped LaCo0.3Fe0.7O3 thick film sensors, the resistivity decreases with increasing humidity over the whole range of RH values, as shown in Figure 18b [107]. It is to be noticed that in undoped conditions, in a γ-Fe2O3-based humidity sensor, the resistance decreases immediately with increasing RH value, but a LaCo0.3Fe0.7O3 thick film sensor is only sensitive to the moisture above 54% RH. Only 2 wt % of K+ addition to a LaCo0.3Fe0.7O3 thick film sensor can give excellent resistance linearity with increase of RH. On the other hand, a Li-doped iron oxide sensor does not show any linearity at all. Due to the addition of Li-ions to iron oxide no microstructural changes occur but due to the addition of K+ ion in LaCo0.3Fe0.7O3 its pore diameter changes, which in turn changes its resistance characteristics. In both cases, the resistance measured at RH 10% is much lower (up to four orders of magnitude) than that of the undoped films. It has also been reported that the resistance value may increase above a critical amount of doping agent in iron oxide-based sensors.

In contrast, Kadam et al., had shown that 0.45 mol % of Li-doping in a γ-Fe2O3-based humidity senor is critical, since it showed maximum linearity [104]. Below that level (e.g., 0.15 and 0.30 mol %) this critical doping value showed nonlinear resistance-RH characteristics and above it (i.e., 0.75 mol %), it showed increased resistance values, which were also higher than that of an undoped γ-Fe2O3-based humidity sensor (see Figure 18c) [104].

Therefore, excess doping, above an optimal or critical value, is not at all suitable for humidity sensor design. Another noteworthy point is that the resistance of Li-doped γ-Fe2O3 sensors does not decrease continuously over the whole range of RH values like other sensors. It has been reported that tin (Sn)-substituted MgFe2O4 based ferrite (i.e., Mg0.9Sn0.01Fe2O4 sample) showed a higher value of resistivity (109 Ω·cm at 11% to 85% RH) compared to Mo-substituted ferrite (i.e., a MgFe2Mo0.02O4 sample) that exhibits the smallest resistivity (106 Ωcm at 11% to 85% RH (see Figure 18d) [105]. Material composition, crystallite size, surface area and porosity are responsible for humidity sensitivity enhancement in this sensor material. High surface area and large porosity materials absorb more water vapors, which cause a decrease of the resistance value. Sn-substituted ferrite material is the most sensitive material to humidity changes and its resistance deceases with increased humidity, because of its very large surface area (23.8 m2/g).

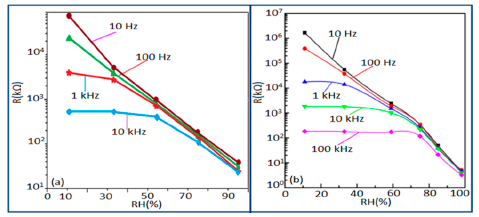

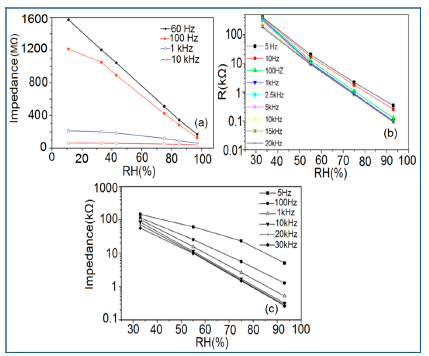

3.3.2. Effect of Frequency on Resistance-RH Characteristics

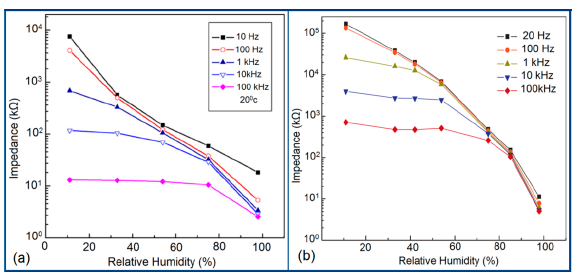

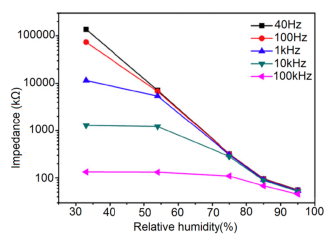

Normally in the low frequency region (10 and 100 Hz), iron-based sensors show high sensitivity and good linearity of their resistance-RH or impedance-RH characteristics but at higher frequency, the sensor shows less sensitivity at a low RH range. This effect is observed because at high frequency the absorbed water cannot be polarized, and the dielectric phenomena disappear. Therefore, to get high sensitivity and good linearity a low working frequency is always applicable. For example, with 2 wt % of K+ addition in a LaCo0.3Fe0.7O3 thick film sensor, the resistance decreases effectively as the frequency increases at a low RH range and the difference in resistance value between two working frequencies becomes smaller at a high RH range [107]. Similarly, Wang et al. [108] observed almost same effect for the impedance with variation of frequency over the whole humidity range by substituting K-ions at La-sites of La1−xKxCo0.3Fe0.7O3−δ perovskite for humidity detection as shown in Figure 19a as in another study performed in 2007 [107]. The value of impedance decreases with increasing frequency the low humidity region and in the high relative humidity region the impedance becomes independent of frequency. Good linearity and high sensitivity are observed in the 10–100 Hz frequency range. It has also been noticed that in the low relative humidity region, the frequency has a strong effect on impedance. For example, in the 11% to 98% RH range and at 10 Hz frequency, the impedance of a mesoporous LaFeO3 sensor decreases greatly, by more than five orders in magnitude (1.7 × 106 to 4.5 kΩ) with good linearity (see Figure 19b) [109]. The highest humidity response and the best linearity are observed at 10 Hz frequency in the entire humidity range but in the previous two sensors 100 Hz is the best optimized frequency for practical applications. It has also been observed that the impedance of the bulk LaFeO3 sensor changes by up to three orders in magnitude at 10 Hz frequency in comparison to mesoporous materials [109]. The mesoporous LaFeO3 sensor has much higher response than that of the bulk LaFeO3 sensor, probably due to the increased specific pore surface area provided by the mesoporous structure.

3.3.3. Effect of Frequency on Capacitance-RH Characteristics

In a wide range of RH values, the capacitance values of undoped iron oxide sensors remains constant (i.e., in the range of 10−11–10−12 F). The capacitance value increases with increased Li doping concentration in iron oxide film over the full RH range at 1 kHz frequency and at high RH (90%), the capacitance value increased by about one order in magnitude (see Figure 20a) [106]. On the other hand, due to the addition of K+-ion, the capacitance value of a La0.93K0.07Co0.3Fe0.7O3−δ-based humidity sensor increases with increasing RH (especially at RH > 54%) in the low frequency range (i.e., ≤100 Hz) and in the high frequency region (i.e., ≥10 kHz), the capacitance becomes almost independent of RH (see Figure 20b) [107].

Due to the addition of K+-ion, in the low frequency range (50–100 Hz), the value of capacitance increases with the increasing value of RH (especially at RH > 54%) and in the high frequency region (10–100 kHz), the capacitance becomes almost independent of RH, is illustrated in Figure 20b. In the low frequency region, absorbed water molecules are polarized rapidly and more water particles are absorbed on the surface of the sensor. However, on the other hand, in the high frequency range, the electric field changes its direction rapidly and thus it can't synchronize with the water molecule polarization. As a result, the capacitance value becomes small and independent of RH.

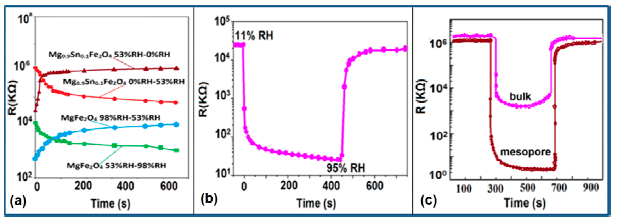

3.3.4. Response and Recovery Time Analysis

Response and recovery characteristics are some of the most significant parameters for estimating humidity sensor performance. It has been found that the addition of Sn+ ion may improve the response time of an iron-based humidity sensor. The response times of MgFe2O4 (in the 53%–98% RH range) and Mg0.9Sn0.1Fe2O4 (in the 0%–53% RH range) sensors, which are 5 min and 3 min, respectively, is shown in Figure 21a [105]. For K+ doping in an iron-based humidity sensor, the response and recovery times in a humidity range of 33%–95% RH are 100 s and 120 s, respectively [107]. Recently, the response and recovery time resulting from the substitution of K+-ion at La-sites of a La1−xKxCo0.3Fe0.7O3−δ perovskite humidity sensor have been observed to be 32 s and 50 s, respectively, in the 11%–95% RH humidity range (see Figure 21b) [108].

This comparison result clearly indicates that the K+-ion doped perovskite structure [109] of an iron-based humidity sensor has a better response and recovery time compared to a K+-ion doped perovskite nanocrystal structure [107] and a Sn-doped [105] sensor. Recently, a response and recovery time comparison for the mesoporous and bulk LaFeO3 humidity sensors has been reported by Zhao et al., in which the response times of both sensors was the same, i.e., 1 s, but the recovery time of the mesoporous sensor (i.e., 148 s) is higher than that of the bulk sensor (i.e., 36 s) (see Figure 21c) [109]. In another Li+-ion doped γ-Fe2O3 humidity sensor, the response and recovery time of the sensor were 150 s and 180 s, respectively, in the 20%–90% RH humidity range [104].

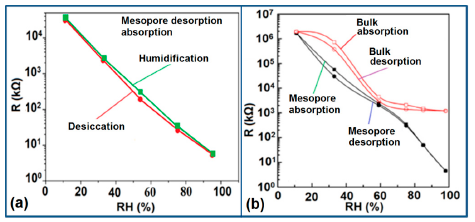

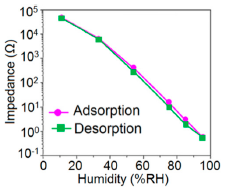

3.3.5. Hysteresis Response Characteristics

K+-ion-doped iron oxide perovskite type nanocrystals show narrow hysteresis loops during cyclic humidity operation. The hysteresis of a 2 wt % K2CO3-doped sample between humidification and desiccation processes over the whole humidity range with 1 V, 100 Hz and at room temperature is shown in Figure 22a [107]. A maximum difference in impedance between the adsorption and desorption curves of the La1−xKxCo0.3Fe0.7O3−δ perovskite humidity sensor is observed [108]. This sensor exhibits a narrow hysteresis loop with the maximum hysteresis around 4% RH during cyclic humidity operation. For LaFeO3 sensors, the largest humidity hysteresis for the sensors using the mesoporous and bulk LaFeO3 were observed as 4% and 16%, respectively (see Figure 22b) [109].

Interestingly, in a 0.45 mol % Li doped humidity sensor [104], there is an absence of hysteresis loop during cyclic operation from 20% to 60% RH, but a very narrow hysteresis loop is observed in the humidity range from 65% to 90% RH. After analyzing the above comparison it is confirmed that the bulk LaFeO3 sensor has the highest hysteresis.

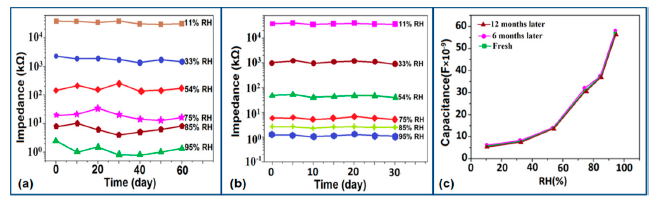

3.3.6. Stability Analysis

The stability of iron-based humidity sensors is observed from their resistance or impedance vs. time characteristics under different humidity conditions. In this instance, a K+-doped perovskite type iron-based humidity sensor (La1−xKxCo0.3Fe0.7O3−δ) showed very good stability for one month as shown in Figure 23a [108]. A very low change in impedance observed over time indicates the good long-time stability for practical use. In another work, the resistance variation with time for a mesoporous LaFeO3 sensor under different humidity conditions was observed for 6 months to analyze the long term stability as shown in Figure 23b [104] It has been observed that the impedance varies very slightly over the entire humidity region with time, which indicates that the mesoporous LaFeO3 humidity sensor has excellent long-term stability.

The stability of iron-based humidity sensors also can be examined from their humidity-resistivity characteristics. In contrast, Sn4+-doped MgFe2O4 humidity sensors shows very good stability at 20 °C, between 11% and 98% RH for up to 25 days as no significant changes were observed [105].

3.4. Silicon-Based Materials for Humidity Sensors

In order to achieve good performance, different materials such as ceramics, semiconductor oxides, carbon nanotubes, porous silicon, and organic polymers have been used for the development of humidity sensors. Among these materials silicon-based sensor materials have shown good responses for humidity measurement. Flexible surface properties, high temperature stability, resistance to aging and chemical assault have made silicon materials more robust and popular in the humidity sensor application field. To enhance the humidity sensing characteristics of silicon many researchers have developed different doping and coating techniques. Silicon-based humidity sensors can be fabricated with different silicon forms and/or dopants such as silica nanoparticle aerogels [110], mesoporous silica with different concentrations of Li+-ion doping [111], Li+-doped 3D periodic mesoporous silica [112], K+-doped 3D periodic mesoporous silica [113,114], mesoporous ZnO–SiO2 composites with various Si/Zn molar ratios [115], SiC nanowires grown on silicon nanoporous pillar arrays (Si-NPA) [116], and Zn2SiO4 thin film grown on silicon nanoporous pillar arrays (Zn2SiO4/Si-NPA) [117]. The most important materials and methods for silicon-based humidity sensors are listed in Table 2.

The electrical characteristics (resistance, capacitance, sensitivity, response time, hysteresis, stability) changes with the variation of frequency, temperature and relative humidity of silicon-based sensor materials are explained in the following subsections.

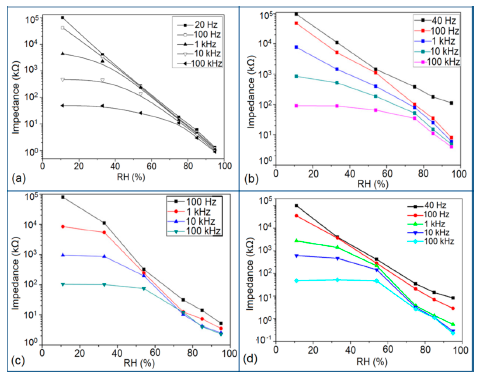

3.4.1. Resistance/Impedance Variation with Relative Humidity

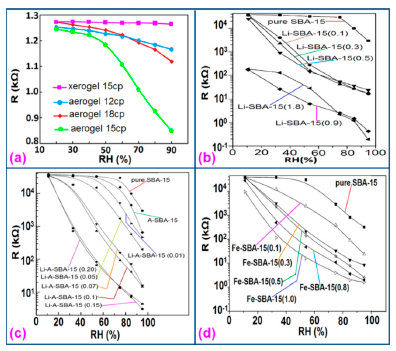

Silica aerogels and xerogels are attractive sensor materials and have been used as different coating materials in humidity sensors [110]. These authors have taken one xerogel sensor film coated at 15 cp, and three aerogel sensors film coated at 12, 15 and 18 cp for humidity sensing. The xerogel sensor showed poor sensitivity towards humidity and its impedance value remained independent at any RH value. On the other hand, the aerogel sensors showed better sensitivity than the xerogel sensor. The resistance value of the coating materials decreases more as the viscosity of the aerogel increases. To get the best results, the coating silica layer must have good uniformity as well as high porosity. At low viscosity the formation of a thin film of silica on the highly rough surface of the alumina substrate will not be perfect. However, at high viscosity the silica coating will be very thick and thus the impedance will be very high. It has also been noticed that layers of highly viscous solutions of silica on alumina substrates crack easily after supercritical drying, thus the electrical field conduction fails. Therefore, the silica aerogel sensor made at optimized viscosity, i.e., 15 cp, shows the best linear sensing performance compared to the viscosities of 12 cp and 18 cp, as illustrated in Figure 24a [110].

In Figure 24a for an aerogel coating made at a viscosity of 15 cp, a dual response occurs due mainly to two consecutive water adsorption steps onto the silica surface [121]. In range of 20%–40% RH, the sluggish impedance change rate is related to the first adsorption stage, i.e., surface interaction of hydrogen-bonded water molecules with isolated oxygen ions (≡Si−O−) in large silica mesopores under an electrostatic field [122]. Therefore, electrically activated protons are released from hydroxyl groups to form stable hydronium (H3O+) ions by interacting with adsorbing water (i.e., H+ + H2O → H3O+). These stable charge carriers take part in the electrical conduction along with the water sub-monolayer during sensor operation [123]. In the second regime between 50% and 70% RH, the linear characteristic of impedance-RH curve is associated with the physisorption of bulk water on the silica aerogel film. The water layer formed by hydrogen bonding between water molecules acts as a continuous protonic conductor due to a greater conductivity of liquid water than that of air. Thus, a significant fast transport of charged H3O+ protons across the water band significantly improves the current density in the short path. The sensitivity of this aerogel is 900 Ω/% RH (R2 = 0.94) in the 20%–40% RH region and 9700 Ω/% RH (R2 = 0.99) in the 50%–70% RH region. At very high RH, the linear sensitivity may be lowered due to the bulk water that has physically filled up microporous voids of the silica film by capillary condensation in the presence of abundant moisture.

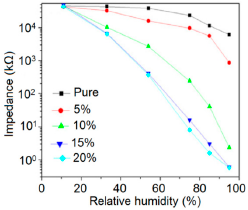

Doping agents in the different silicon particles can also significantly change the resistance, impedance or sensitivity of silicon-based humidity sensors. The doping of Li+ ions in mesoporous silica (e.g., SBA-15) greatly decreases the resistance by more than three orders of magnitude compared to undoped porous silica, SBA-15, and increases the humidity sensitivity with increased RH value in the 11%–95% RH range. The impedance-RH characteristics of undoped SBA-15 and Li-doped SBA-15 with different concentrations humidity sensors are illustrated in Figure 24b [111]. It has been found that the higher doping concentration is not at all suitable for humidity sensing applications. The resistance for pure SBA-15 shows low humidity sensitivity properties with the highest resistance value in the whole range of RH. Geng et al. showed that 10 wt % Li-doped SBA-15 exhibited the maximum humidity sensitive properties and best linearity. However, this same research group again synthesized mesoporous silica (A-SBA-15), which can be doped up to with 15 wt % Li+-ion having maximum sensitivity and best linearity (see Figure 24c) [118].

The addition of different doping materials in SBA-15 also changes its humidity characteristics drastically. Like Li ion, it has also been found that Fe doping decreases the impedance of SBA-15 with increase of RH considerably, compared to undoped SBA-15 (see Figure 24d) [119]. The pure SBA-15 sensor is sensitive to humidity above a RH value of 54%, however, Fe doped SBA-15 (Fe-SBA-15(X), where X is the weight ratio of Fe(NO3)3 to SBA-15, X = 0.1, 0.3, 0.5, 0.8, and 1.0) sensors showed humidity sensitivity in the whole RH range. Unlike Li+ doping, Fe3+-doped SBA-15 shows best performance at higher concentration (i.e., X = 0.5 ≈ 50 wt %) (see Figure 24d). Other silicon based materials such as SBA-16 [112], MCM-41 [120], and SiO2 [115] matrix have been used in humidity sensing applications. Mesoporous silica has also been doped or composited with other materials such as K2CO3 [113], ZnO [115], and MgO [124] to improve the conductivity by reducing the impedance or resistance in humidity sensors.

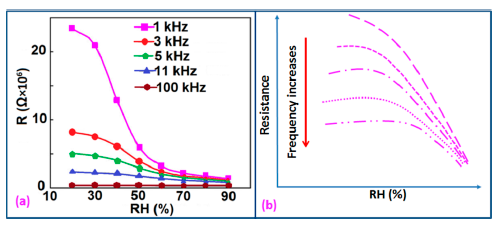

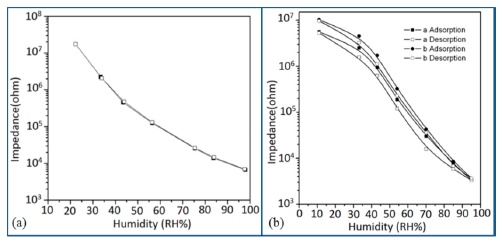

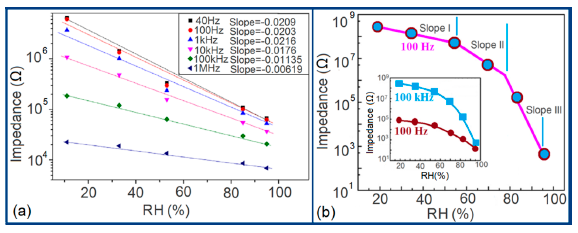

3.4.2. Effect of Frequency on Resistance-RH Characteristics

Frequency has a great impact on the resistance or impedance variation with relative humidity and doping elements in silicon-based sensor materials. It has been found that in a low humidity regime the resistance of silica aerogel film decreases remarkably with increasing frequency. The resistance difference between two working frequencies becomes progressively smaller with increasing RH value. It has also been observed that at higher frequencies, i.e., more than 100 kHz, the resistance becomes independent over the whole RH range. The resistance responses of a silica aerogel-coated sensor (viscosity of 15 cp) at different frequencies as a function of relative humidity at 25 °C are shown in Figure 25a [110].

Like silica coating materials (e.g., xerogels or aerogels), the impedance of doped silica sensors decreases greatly with increasing relative humidity at a lower frequency range, but at higher frequency the rate of impedance change becomes lesser with increasing % RH. For doped silicon-based sensors, the dopants significantly enhance the linearity of the sensors besides decreasing the impedance or resistance value. A schematic representation of impedance vs. RH at different frequencies is illustrated in Figure 25b.

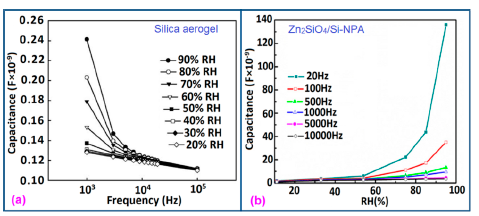

3.4.3. Effect of Frequency on Capacitance-RH Characteristics

The frequency has also significant role in the variation of capacitance of silicon-based sensor materials. At a low frequency range, the capacitance value is generally high and it increases with increased RH value. However at higher frequency (i.e., greater than ≥5 kHz), the change in capacitance with the RH becomes negligible. The capacitance as a function of frequency at different RH values for silica aerogels coated on a 15 cp viscosity sensor material is depicted in Figure 26a [110] and for a Zn2SiO4/Si-NPA humidity sensor as illustrated in Figure 26b [117]. For silica aerogels, the curves become nonlinear at 40% RH and higher. A similar observation was made for SiC nanowires grown on silicon nanoporous pillars (nw-SiC/Si-NPA) [116].

3.4.4. Response and Recovery Time Analysis

For a good sensor, the response and recovery time of humidity sensors must be very small. These may be different for different materials, doping ions, conditions and procedures and thus the RH vs. time plots for different sensors change accordingly. The response and recovery time of some different silicon-based humidity sensor materials are listed in Table 3.

The response and recovery time of some selected silicon-based humidity sensor materials are depicted in Figure 27a–d to compare the response and recovery times shown by the different materials. From these results it is observed that Zn2SiO4/Si-NPA is the only sensor whose recovery time is more than the response time, but all the remaining sensors have greater recovery times than response times. This effect occurs due to the specific surface morphology of Zn2SiO4/Si-NPA. It is observed that all the Zn2SiO4-covered pillars are well separated and form a regular array [117]. The valleys around the pillars connect to each other and form a well-defined channel network. This would provide an effective pathway for the transport of the vapor in and out of the pillar layer, which would surely shorten response time. In addition, the MgO-SBA-15(R = 1) sensor and K+ ion doped K-SBA-15(0.5) sensors have shown lower response times, whereas a Zn2SiO4/Si-NPA sensor has shown the smallest recovery time.

3.4.5. Hysteresis Characteristics Analysis

For a perfect based humidity sensor, the hysteresis value must be very small. The hysteresis values of different silicon-based humidity sensors are listed in Table 3. The hysteresis responses of some selected silicon-based sensors are depicted in Figure 28. Hysteresis in capacitance vs. % RH of Zn2SiO4/Si-NPA is depicted in Figure 28a [117], while the hysteresis of a MgO-SBA-15(R = 1) sample is illustrated in Figure 28b by its impedance vs. % RH plot.

From the above comparison it can be seen that the MgO-SBA-15(R = 1), Zn2SiO4/Si-NPA sensor and ZnO−SiO2(R = 1) sensor materials have the lowest hysteresis and the Li-SBA-15(0.1) sensor has the highest hysteresis.

3.4.6. Stability Analysis

The coating of different silica gels is also suitable for humidity sensors sine it exhibit good stability and reproducibility over time. The iron doped mesoporous silica (i.e., Fe-SBA-15(0.5) or Li-doped SBA-16) sensors has shown acceptable change in the impedances, proving the good stability as shown in schematic Figure 29a,b.

Similarly, the stability of nw-SiC/Si-NPA sensors was evaluated by comparing the capacitance–RH curves measured at 100 Hz and they show excellent stability as the capacitance value after a long time (6-month and 12-month, storage) remained almost unchanged (see Figure 29c).

3.5. Polymer-Based Materials for Humidity Sensors

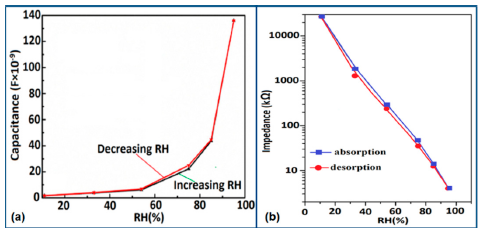

The popularity of polymer-based sensors is increasing day by day due to their high sensitivity, fast response, easy preparation, and low cost. However, instability in humid environments is the main hindrance in their wider application and further development. To overcome this problem, several methods such as introduction of hydrophobic groups by copolymerization and grafting, crosslinking, application of protective films, interpenetration of network structures, or formation of organic/inorganic hybrids have been proposed so far. In contrast, thermoset polymers have shown excellent humidity sensing properties. Cross-linked thermoset polymer network structures are a primary criterion for a humidity sensor. Different copolymers may be coated on different ceramic substrates or can be used directly as bulk the phase. Polymeric sensors have mainly been used in capacitive type and resistive type humidity sensors. Polymer electrolytes or polymer–salt complexes are used for the fabrication of resistive type sensors, whereas hydrophobic polymers are used for capacitive-type sensors. Different types of polymeric humidity sensors are listed chronologically in Table 4. The main advantages of the polymeric sensors are excellent flexibility, outstanding purity and very high condensation resistance. The hysteresis loss of polymeric humidity sensors is very low (nearly 1% RH) in comparison to other ceramic sensors. The key factors and characteristics of the polymeric humidity sensors are also discussed in the following subsections. The variation of the electrical characteristics (resistance, capacitance, sensitivity, response time, hysteresis, stability) with the variation of frequency, temperature and relative humidity of polymer-based sensor materials are explained in the following subsections.

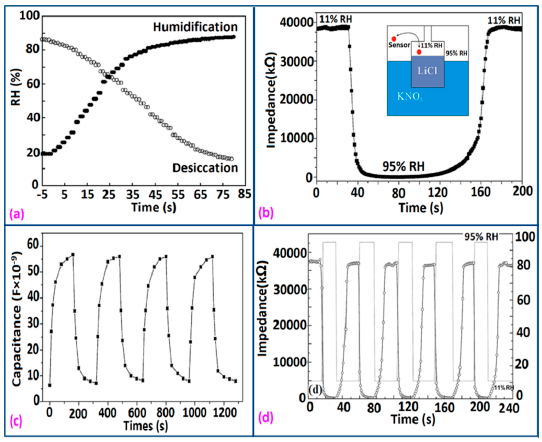

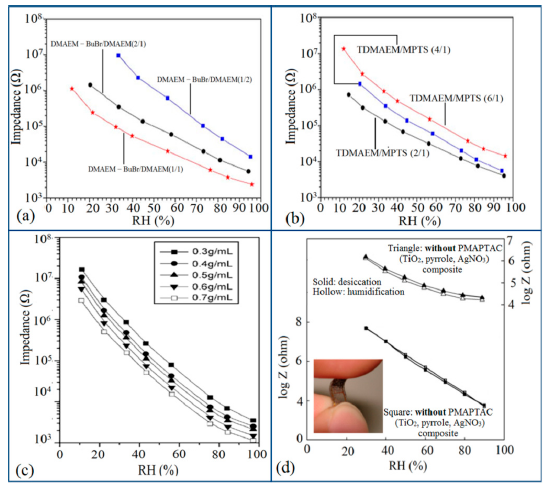

3.5.1. Resistance or Impedance Variation with Relative Humidity

In general, the resistance or impedance level of polymeric humidity sensors is significantly higher than that of ceramic- or silicon-based humidity sensors. For different copolymers and different doping or coating substrate materials, the resistance or impedance value of the humidity sensors changes significantly. It has been seen that the impedance of the polyelectrolyte (PE) copolymer crosslinked with dibromobutane (DBB) does not increase gradually with an increase of dimethylaminoethyl methacrylate (DMAEM) content, which provides crosslinking and quaternizing points in the copolymer (see Figure 30a) [125]. On the other hand, the impedance decreased abnormally as the content of hydrophobic γ-methacryloxypropyltrimethoxysilane (MPTS) co-monomer increased in the polyelectrolytes (see Figure 30b) [125]. An optimized molar ratio between TDMAEM (DMAEM—BuBr + DMAEM) and MPTS of 2 with a mixture of DMAEM—BuBr and DMAEM at molar ratio of 2 has exhibited the best humidity sensitive characteristics. In contrast, MPTS can enhance the flexibility and adhesion of humid membranes to the electrode substrate [126], whereas DMAEM-BuBr contains quaternary nitrogens, which can act as ion moieties in Si-PE molecules, and has potential for enhancing the sensor performance [127].

In another study, it has also been observed that due to using of different ratios of different polymers such as 3-aminopropyltriethoxysilane (APTS) which is quaternized with n-butyl bromide (BB), the impedance decreases slightly and gives very high impedance value at low humidity region (see Figure 30c) [128]. Polymeric nanocomposites have also been used as successful potential candidates for humidity sensors. In a composite of TiO2 nanoparticles, polypyrrole and AgNO3 based humidity sensor, impedance varies significantly with RH with addition of different doping concentration. The impedance decreases with increases of doping concentration in all relative humidity range. The main advantages of the conducting polypyrrole polymers (PPy) are relatively good environmental stability and most importantly its surface charges can easily be modified by different dopants by easy synthesis method [129]. It has also been noticed that the addition of PMAPTAC in a polymer electrolyte enhances the sensitivity characteristics of composite (TiO2, pyrrole, AgNO3) humidity sensor [130]. The basic group, −N+(CH3)3Cl− present in MAPTAC polymer electrolyte is responsible for improving the humidity sensitivity and also makes it flexible to exhibit favorable electrical performance when they were bent as shown in the inset of Figure 30d [130]. The impedance of PMAPTAC induced composite (TiO2 = 0.048 g, pyrrole = 0.125 g, AgNO3 = 0.0314 g, and PMAPTAC = 0.08 g) based sensor decreases greatly in comparison to the best composite (TiO2 = 0.0012 g, pyrrole = 0.125 g, and AgNO3 = 0.0314 g) sensor reported by Su and Huang, 2007 [129]. It has been observed that the composite with PMAPTAC [130] gives far better linearity than that of without PMAPTAC composite [129] sensor.

High impedance at low humidity is a general trend for many copolymer films. The impedance of quaternizedpolypyrrole (PPy) composite film shows a change from 7.8 × 105 to 7.0 × 104 Ω with an increase in RH from 11% to 95% with greater linearity and good sensitivity (0.0370), but copolymer film has poor linearity and less sensitivity (0.0305) [133]. For the doping polymers, it has been noticed that due to addition of dopant (e.g., Fe2+-ion) in polymer (e.g., polypyrrole) its sensitivity increases and impedance decreases sharply with better linearity as increase of RH value [134]. Almost similar trend has been noticed in gold nanoparticles (AuNPs) reinforced generation 1 amine terminated polyamidoamine (PAMAM) dendrimer (G1-NH2) polymer [135]. For G1-NH2 polymer sensor, almost no impedance change occurred from 30% RH up to 70% RH, the impedance falls gradually in the range of 70%–90% RH [135]. The impedance, however, of AUNPs reinforced polymer (G1-NH2-AuNPs) film sensor, was markedly reduced over a wide range of RH, i.e., 30%–90% RH [135]. On the other hand, the impedance of a copolymer also can be tuned by changing of coupling agent. The impedance of a copolymer decreases as the amount of N-(3-dimethylaminopropyl)-N'-ethylcarbodiimide hydrochloride (EDC) increases, because increasing of EDC content increases the degree of anchoring of methyl methacrylate (MMA) and [3-(methacrylamino)propyl] trimethyl ammonium chloride (MAPTAC) copolymer (poly-MMA-MAPTAC) onto the 3-mercaptopropionic acid/gold (MPA/Au) surface by the formation of peptide bonds [136]. The EDC acted as a peptide coupling reagent in this copolymer sensor.

3.5.2. Effect of Frequency on Resistance-RH Characteristics

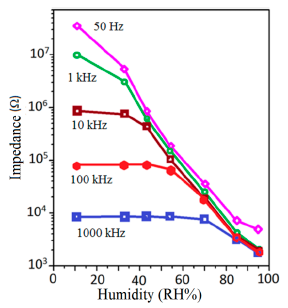

The frequency also significantly affects the impedance of polymeric humidity sensor materials. At low RH, the frequency influences the impedance more significantly than in the case at high RH. The addition of PMAPTAC to a TiO2/polypyrrole sensor enhances its frequency effect on impedance [129]. The similar observation is also shown for polymers based on other polymeric materials such as flexible PMAPTAC/TiO2/polypyrrole [130], TiO2/ polystyrene sulfonic acid sodium (NaPSS) [132], Fe2+ doped polypyrrole [134], G1-NH2-AuNPs film [135], poly-MMA-MAPTAC anchored MPA/Au [136], and so on. The frequency at which the sensors show the best linearity is different for different polymeric materials. The range of RH values is also different for different polymeric humidity sensors at the same frequency. Sun et al. measured the impedance of a TiO2 and polystyrene sulfonic acid sodium (NaPSS) composite sensor over a wide range of frequencies between 50 Hz and 106 Hz, as shown in Figure 31 [132]. They observed that at low RH, the frequency affected the impedance more strongly and linearly than at high RH. When the frequency was high, the electrical field direction was changed so rapidly that the polarization of the adsorbed water cannot keep up with this rapid change, and as a result the dielectric constant remained small and independent of RH (see the curve for 1000 kHz in Figure 31).

3.5.3. Effect of Temperature on Resistance-RH Characteristics

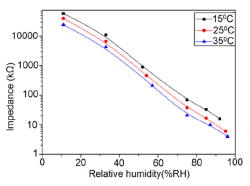

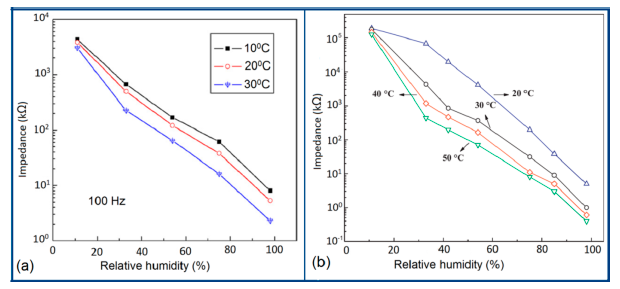

Temperature is another important key parameter which can change the behavior of resistance or impedance vs. relative humidity curves significantly for polymer based sensors. As the temperature increases, the RH characteristic curve shifts toward lower impedance values. For example, a 2-(dimethyl-amino)ethyl methacrylate (DMAEMA), n-butyl bromide (BB)-based composite humidity sensor shows impedance variation with temperature over the whole humidity range and this is clearly illustrated in Figure 32 [131]. The temperature coefficient is estimated to change from −0.36% to −0.42% RH/°C between 15 and 32 °C, and the temperature dependence tendency is found to decrease with increasing humidity. An almost similar trend in the effect of temperature on resistance or impedance vs. significant relative humidity characteristics has been observed for polymer-based sensor materials such as TiO2/pyrrole/AgNO3 composite [129], TiO2/PMAPTAC composite [130], G1-NH2-AuNPs film [135], poly-MMA-MAPTAC anchored onto MPA/Au surface with 200 mM EDC [136], and so on.

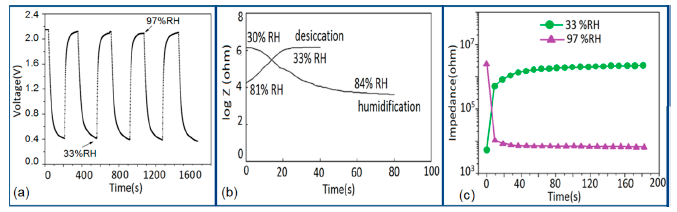

3.5.4. Response and Recovery Time Analysis

Response and recovery times are also significant features for estimation of polymeric humidity sensors. Response and recovery times of different polymeric humidity sensors are listed in Table 5. The response or recovery time of polymeric humidity sensors also can be measured by their voltage vs. RH characteristics as illustrated for APTS and BB one [128] in Figure 33a. A comparison of response or recovery times of three other different types of polymer- or copolymer-based humidity sensor materials, such as TiO2/polypyrrole [129], and DMAEMA and BB [131], measured from impedance vs. % RH plots are shown in Figure 33b,c, respectively.

3.5.5. Hysteresis Characteristics Analysis

Hysteresis properties of different polymeric humidity sensors are listed in Table 5. Polymers containing a hydrophobic monomer (MPTS) show high hysteresis and large reversible responses, but the Si-PE copolymer cross-linked with DBB in a DMAEM-BuBr/DMAEM molar ratio of 4 shows very small hysteresis (∼2% RH) [125]. A very small hysteresis of only ∼1% RH is also shown for the DMAEMA and BB-based humidity sensor as illustrated in Figure 34a [131].

A very small hysteresis loop was observed in a TiO2/NaPSS composite compared to the pure polymer NaPSS humidity sensor as shown in Figure 34b [132]. Another composite quaternized polypyrrole polymer film based humidity sensor shows a relatively wide hysteresis loop, which indicates that the rate of the desorption process of the adsorbed water is slower than that of the water adsorption process [132].

3.5.6. Stability Analysis

The stability of polymer-based humidity sensors materials is excellent in terms of long term applications. In order to analyze the stability of an APTS and BB-based humidity sensor, Lv et al. varied the impedance and observed that the sensor variation was changed little over almost the entire humidity range (11%–97%) after 96 h, showing its excellent stability (Figure 35a) [128].

In this context, Fe2+-doped polypyrrole sensors have shown excellent stability up to 30 days at different RH values as illustrated in Figure 35b [134]. The stability response of other polymer-based humidity sensors, such as TiO2/polypyrrole [129], G1-NH2-AuNPs film [135], and poly-MMA-MAPTAC anchored onto MPA/Au surface with addition of 200 mM EDC [136], have also been measured as very good, with extremely low variation of impedance or resistance for long term applications.

3.6. Tin-Based Materials for Humidity Sensors