A Macroporous TiO2 Oxygen Sensor Fabricated Using Anodic Aluminium Oxide as an Etching Mask

Abstract

:1. Introduction

2. Experimental

2.1. Preparation of the AAO Process

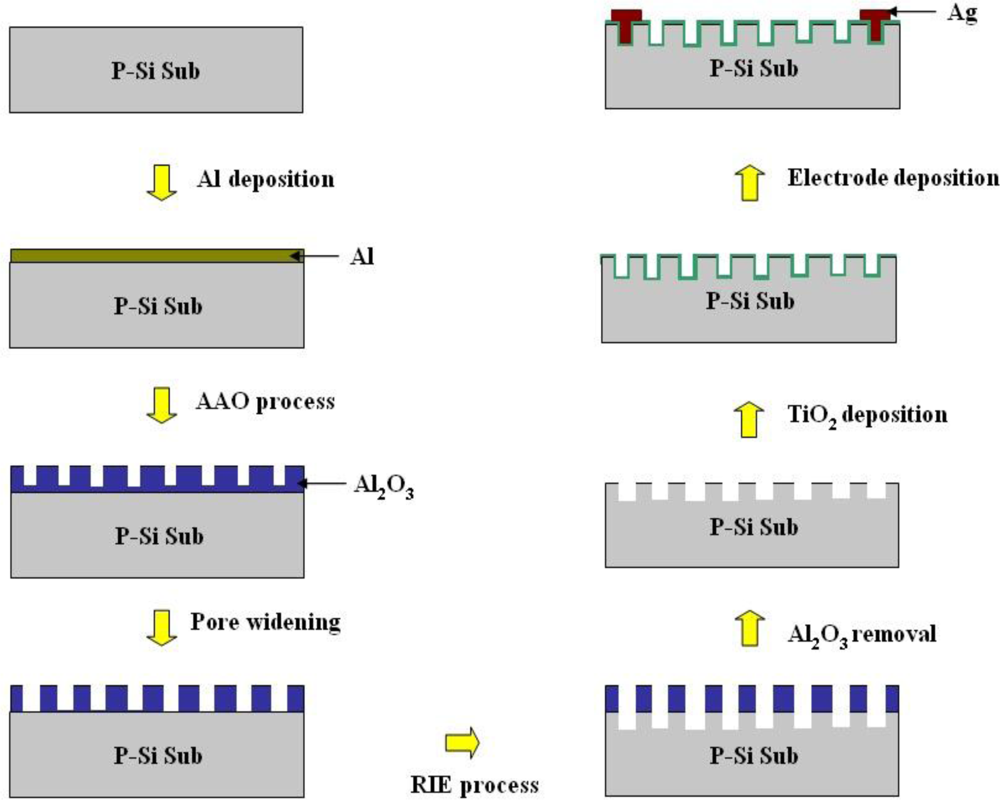

2.2. Manufacture of Macroporous Silicon

2.3. Design and Fabrication of Macroporous TiO2 Gas Sensors

2.4. Gas Characterization of the Macroporous TiO2 Sensor

3. Results and Discussion

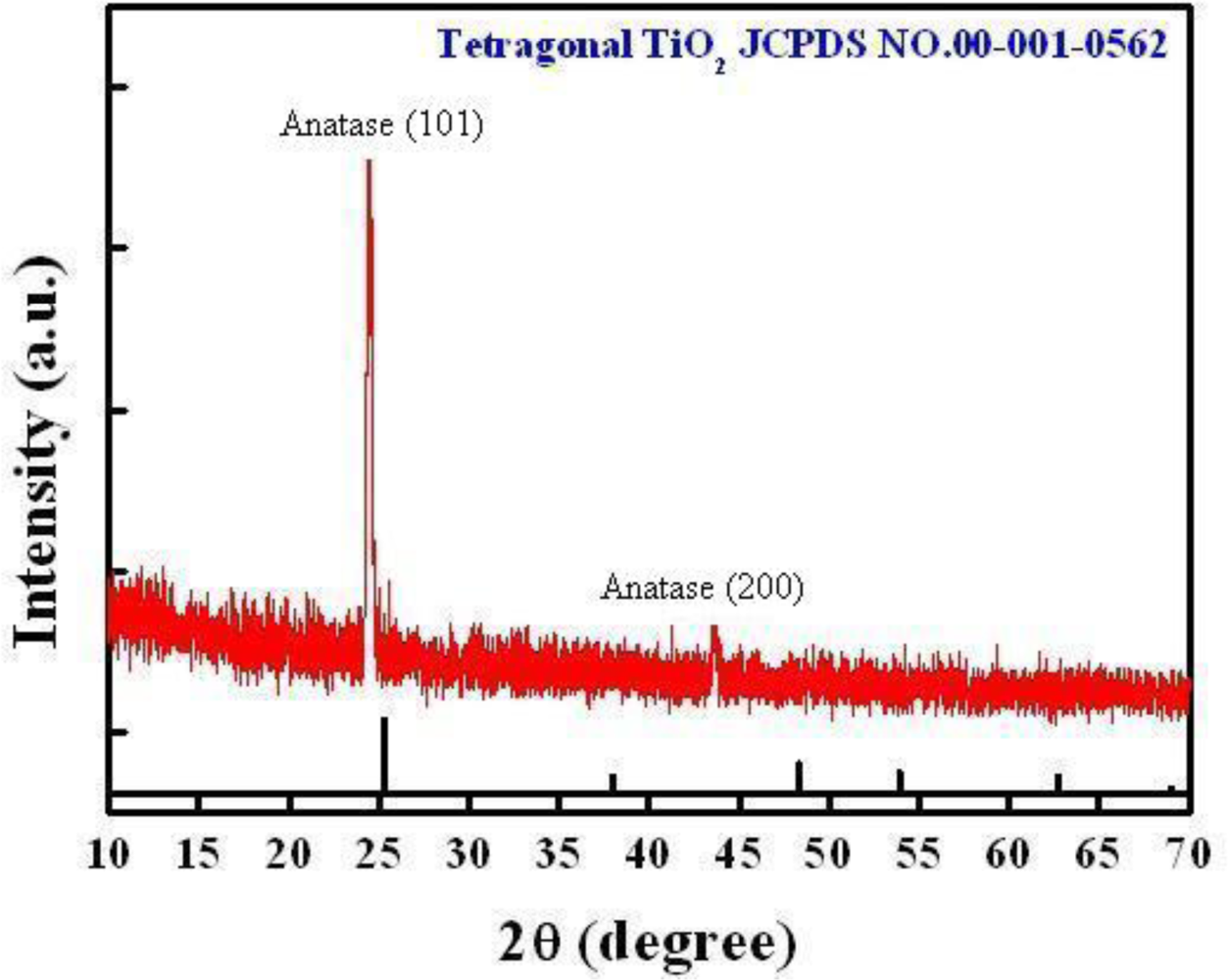

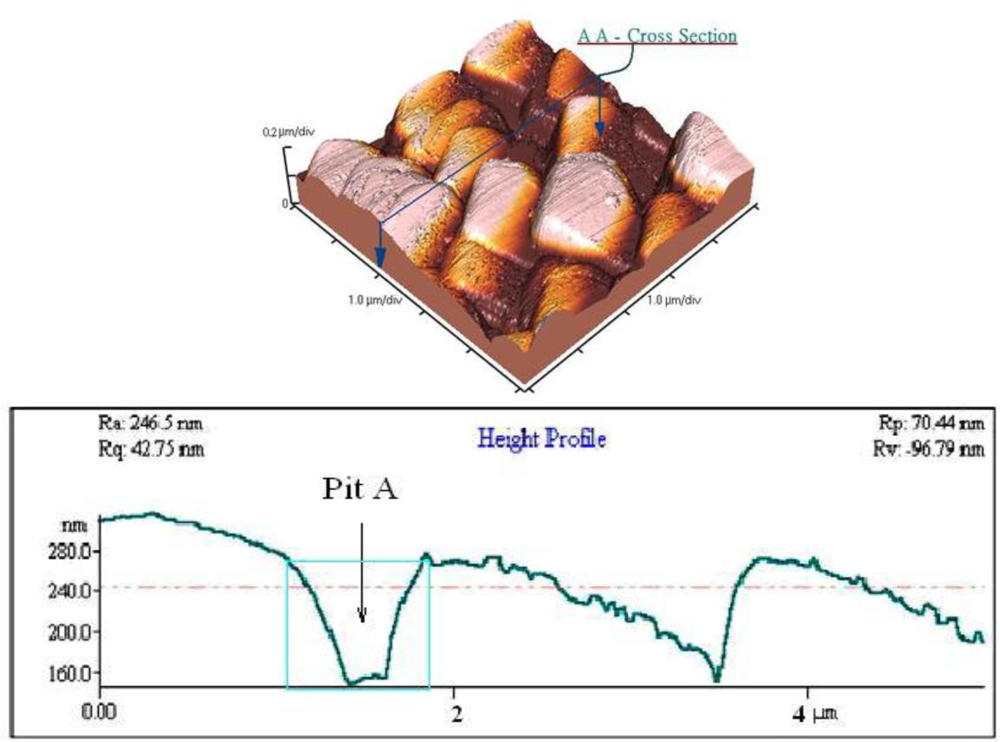

3.1. Characterization of the Porous TiO2 Thin Film

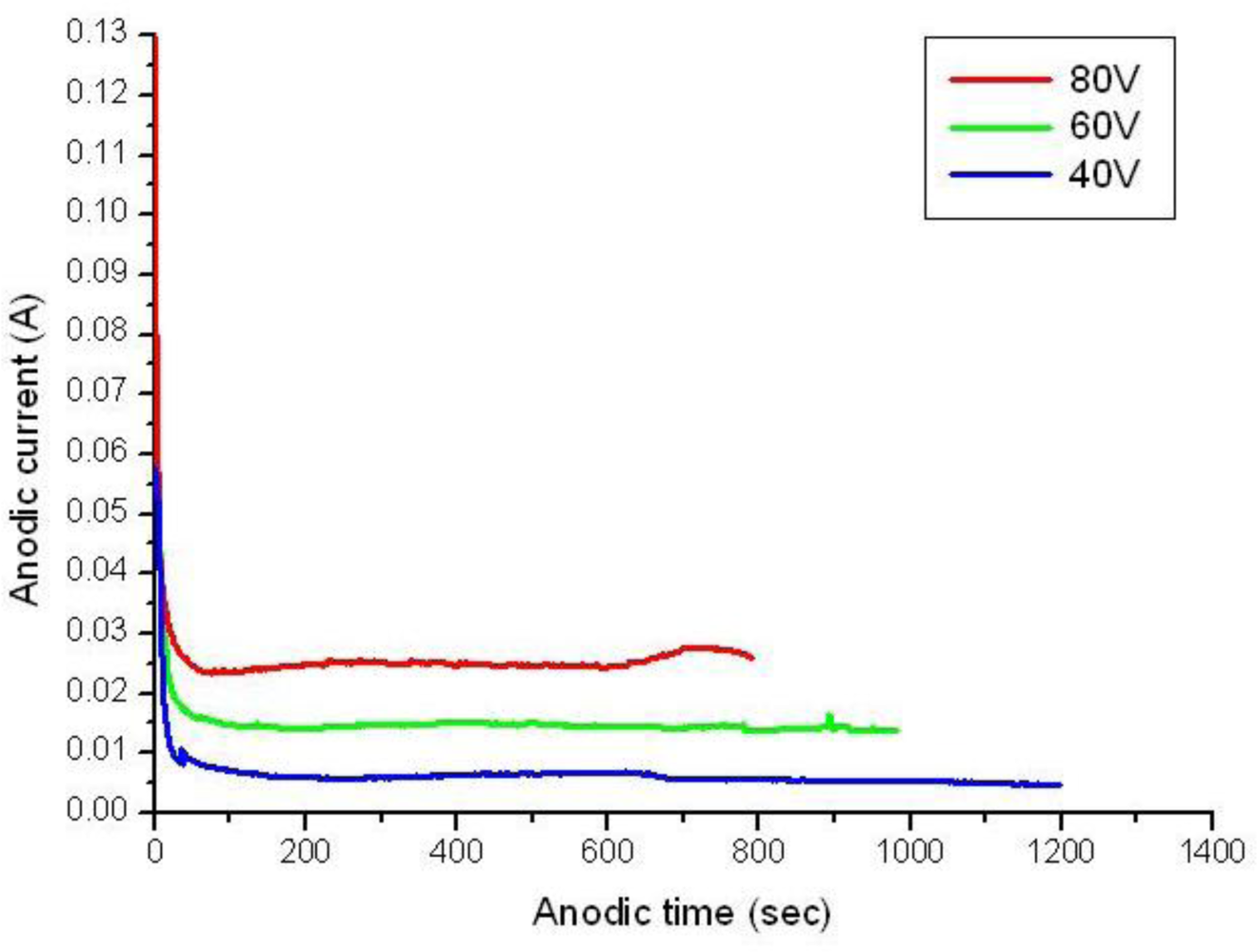

3.2. Modulation and Analysis of AAO Porosity

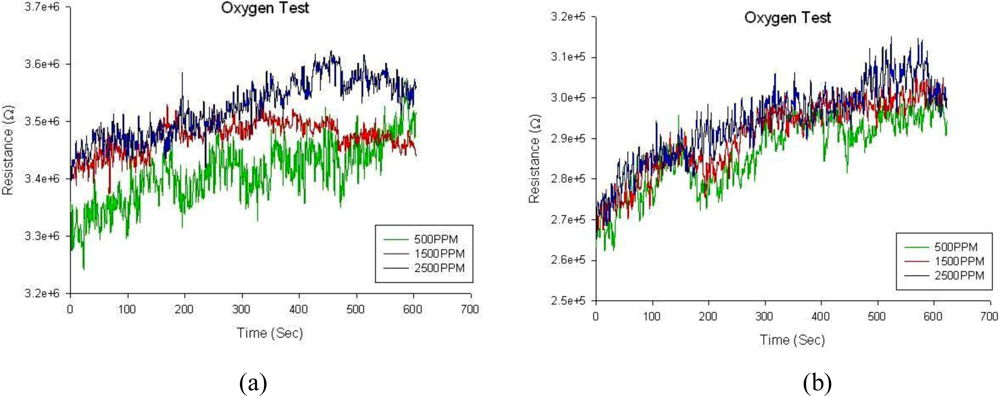

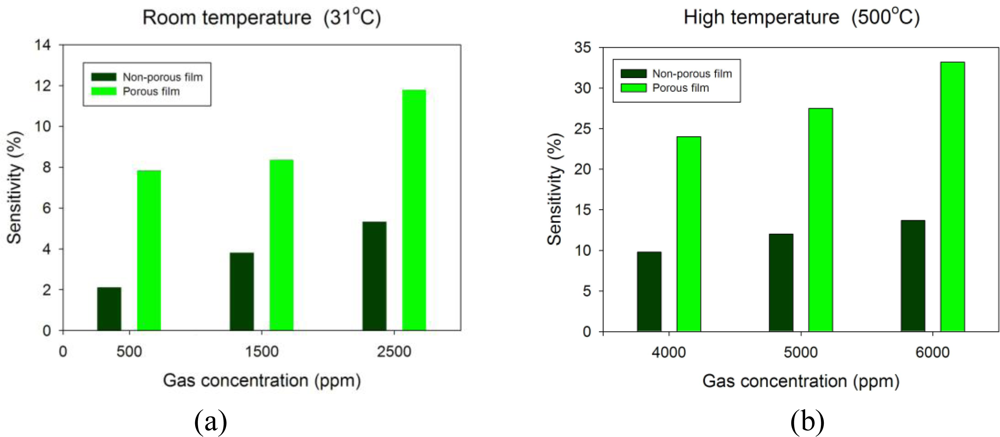

3.3. Oxygen Response at Room Temperature (31°C)

3.4. Oxygen Response at High Temperature (500 °C)

4. Conclusions

Acknowledgments

References

- Suehle, J.S.; Cavicchi, R.E.; Gaitan, M.; Semancik, S. Tin oxide gas sensor fabricated using CMOS micro-hotplates and in-situ processing. IEEE Electron Dev. Lett 1993, 14, 118–120. [Google Scholar]

- Lu, C.C.; Liao, K.H.; Udrea, F.; Covington, J.A.; Gardner, J.W. A CMOS-MEMS smart sensory platform using SOI technology for high temperature gas detection. J. Micromech. Microeng 2008, 18. No. 075010.. [Google Scholar]

- Barrettino, D.; Graf, M.; Song, W.H.; Kirstein, K.U. Hotplate-based monolithic CMOS microsystems for gas detection and material characterization for operating temperatures up to 500 °C. IEEE J. Solid-State Circ 2004, 39, 1202–1207. [Google Scholar]

- Rothschild, A.; Komem, Y. The effect of grain size on the sensitivity of nanocrystalline metal-oxide gas sensors. J. Appl. Phys 2004, 95, 6374–6380. [Google Scholar]

- Mardare, D.; Iftimie, N.; Luca, D. TiO2 thin films as sensing gas materials. J. Non-Crystal. Solids 2008, 354, 4396–4400. [Google Scholar]

- Devi, G.S.; Hyodo, T.; Shimizu, Y.; Egashira, M. Synthesis of mesoporous TiO2-based powders and their gas-sensing properties. Sens. Actuat. B: Chem 2002, 87, 122–129. [Google Scholar]

- Carney, C.M.; Yoo, S.H.; Akbar, S.A. TiO2-SnO2 nanostructures and their H2 sensing behavior. Sens. Actuat. B: Chem 2005, 108, 29–33. [Google Scholar]

- Meng, D.; Toshinari, Y.; Yanbai, S.; Liu, Z.; Toshio, K. Preparation of WO3 nanoparticles and application to NO2 sensor. Appl. Surf. Sci 2009, 256, 1050–1053. [Google Scholar]

- Ali, M.; Wang, C.Y.; Rohlig, C.; Stauden, C.C.; Ambacher, V.O. NOx sensing properties of In2O3 thin films grown by MOCVD. Sens. Actuat. B: Chem 2008, 129, 467–472. [Google Scholar]

- Ryu, H.W.; Park, B.S.; Akbar, S.A.; Lee, W.S.; Lee, K.J.; Seo, Y.J.; Shin, D.C.; Park, J.S.; Choi, G.P. ZnO sol-gel derived porous film for CO gas sensing. Sens. Actuat. B: Chem 2003, 96, 717–722. [Google Scholar]

- Lu, C.C.; Liao, K.H. Microfabrication and chemoresistive characteristics of SBA-15-templated mesoporous carbon gas sensors with CMOS compatibility. Sens. Actuat. B: Chem 2009. [Google Scholar] [CrossRef]

- Calvert, J.M. Lithographic patterning of self-assembled films. J. Vac. Sci. Technol. B 1993, 11, 2155–2158. [Google Scholar]

- Marrian, C.R.K.; Colton, R.J. Low-voltage electron beam lithography with a scanning tunneling microscope. Appl. Phys. Lett 1990, 56, 755–757. [Google Scholar]

- Connolly, E.J.; Timmer, B.; Pham, T.M.; Groeneweg, J.; Sarro, P.M. A porous SiC ammonia sensor. Sens. Actuat. B: Chem 2005, 109, 44–46. [Google Scholar]

- Keller, F.; Hunter, M.S.; Robinson, D.L. Structural features of oxide coating on aluminium. Electrochem. Soc 1953, 100, 411–419. [Google Scholar]

- Masuda, H.; Fukuda, K. Ordered metal nanohole arrays made by a 2-step replication of honeycomb structure of anodic alumina. Science 1995, 268, 1466–1468. [Google Scholar]

- Wang, Y.D.; Chua, S.J.; Sander, M.S.; Chen, P.; Tripathy, S.; Fonstad, C.G. Fabrication and properties of nanoporous GaN films. Appl. Phys. Lett 2004, 85, 816–818. [Google Scholar]

- Hidetaka, A.; Mamoru, M.; Megumi, Y.; Sachiko, O. Transfer of nanoporous pattern of anodic porous alumina into Si substrate. Appl. Phys. Lett 2003, 83, 4408–4410. [Google Scholar]

- Masuda, H.; Satoh, M. Fabrication of gold nanodot array using anodic porous alumina as an evaporation mask. J. Appl. Phys 1996, 35, 126–129. [Google Scholar]

- Sander, M.S.; Tan, L.S. Nanoparticle arrays on surfaces fabricated using anodic alumina films as templates. Adv. Funct. Master 2003, 13, 393–397. [Google Scholar]

- Almawlawi, D.; Bosnick, K.A.; Osika, A.; Moskovits, M. Fabrication of nanometer-scale patterns by ion-milling with porous anodic alumina masks. Adv. Mater 2000, 12, 1252–1256. [Google Scholar]

- Hu, M.; Yu, R.; MacManus-Driscoll, J.L.; Robinson, A.P. Large-area silica nanotubes with controllable geometry on silicon substrates. Appl. Surf. Sci 2009, 255, 3563–3566. [Google Scholar]

- Nasirpouri, F.M.; Abdollahzadeh, M.J.; Almasi, N. A comparison between self-ordering of nanopores in aluminium oxide films achieved by two- and three-step anodic oxidation. Curr. Appl. Phys 2009, 9, 91–94. [Google Scholar]

- Lee, W.; Ji, R.; Ulrich, G.; Kornelius, N. Fast fabrication of long-range ordered porous alumina membranes by hard anodization. Nat. Mater 2006, 5, 741–743. [Google Scholar]

- Hatice, U.; Tae, B.H.; Kimb, H.K. Thin alumina nanoporous membranes for similar size biomolecule separation. J. Membr. Sci 2009, 343, 1–6. [Google Scholar]

- Lu, C.; Chen, Z. High-temperature resistive hydrogen sensor based on thin macroporous rutile TiO2 film on anodic aluminium oxide. Sens. Actuat. B: Chem 2009, 140, 109–115. [Google Scholar]

- Tang, H.; Prasad, K.; Sanjines, R.; Levy, F. TiO2 anatase thin films as gas sensors. Sens. Actuat. B: Chem 1995, 26, 71–75. [Google Scholar]

- Morrison, S.R. Mechanism of semiconductor gas sensor operation. Sens. Actuat 1987, 11, 283–287. [Google Scholar]

- Buso, D.; Post, M.; Cantalini, C.; Mulvaney, P.; Martucci, A. Gold nanoparticle-doped TiO2 semiconductor thin films:gas sensing properties. Adv. Funct. Mater 2008, 18, 3843–3849. [Google Scholar]

©2010 by the authors; licensee Molecular Diversity Preservation International, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/)

Share and Cite

Lu, C.-C.; Huang, Y.-S.; Huang, J.-W.; Chang, C.-K.; Wu, S.-P. A Macroporous TiO2 Oxygen Sensor Fabricated Using Anodic Aluminium Oxide as an Etching Mask. Sensors 2010, 10, 670-683. https://doi.org/10.3390/s100100670

Lu C-C, Huang Y-S, Huang J-W, Chang C-K, Wu S-P. A Macroporous TiO2 Oxygen Sensor Fabricated Using Anodic Aluminium Oxide as an Etching Mask. Sensors. 2010; 10(1):670-683. https://doi.org/10.3390/s100100670

Chicago/Turabian StyleLu, Chih-Cheng, Yong-Sheng Huang, Jun-Wei Huang, Chien-Kuo Chang, and Sheng-Po Wu. 2010. "A Macroporous TiO2 Oxygen Sensor Fabricated Using Anodic Aluminium Oxide as an Etching Mask" Sensors 10, no. 1: 670-683. https://doi.org/10.3390/s100100670