A Photocatalytic Rotating Disc Reactor with TiO2 Nanowire Arrays Deposited for Industrial Wastewater Treatment

Abstract

:1. Introduction

2. Results

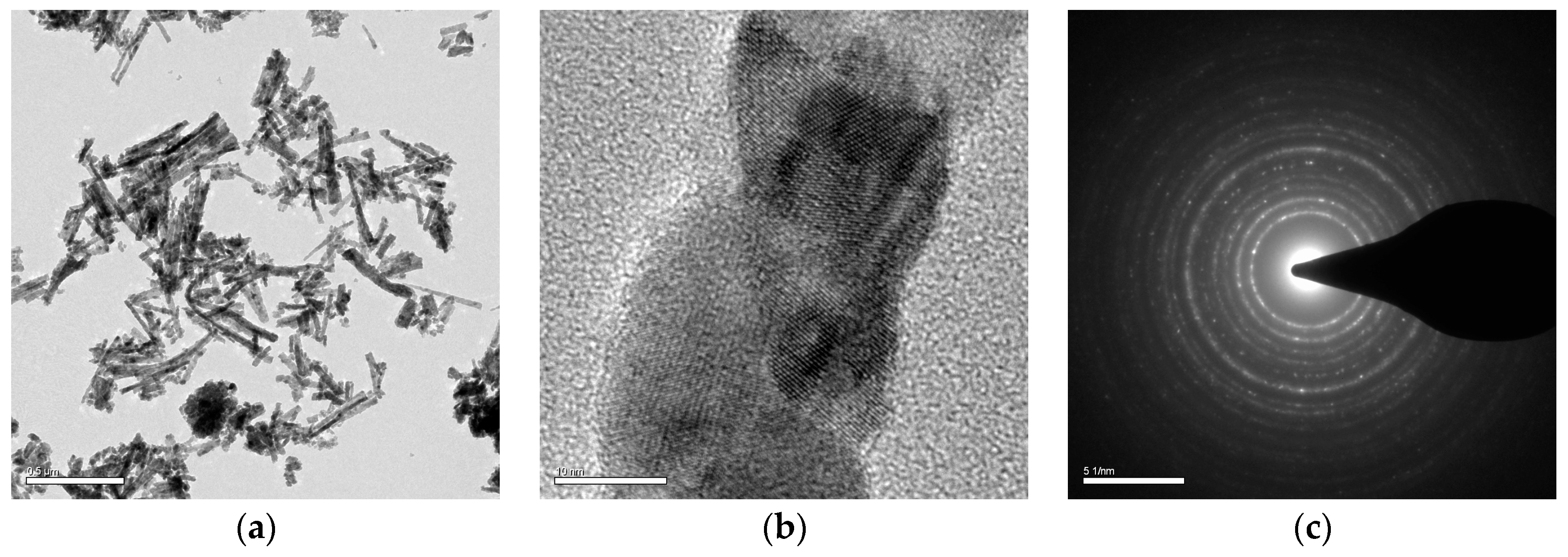

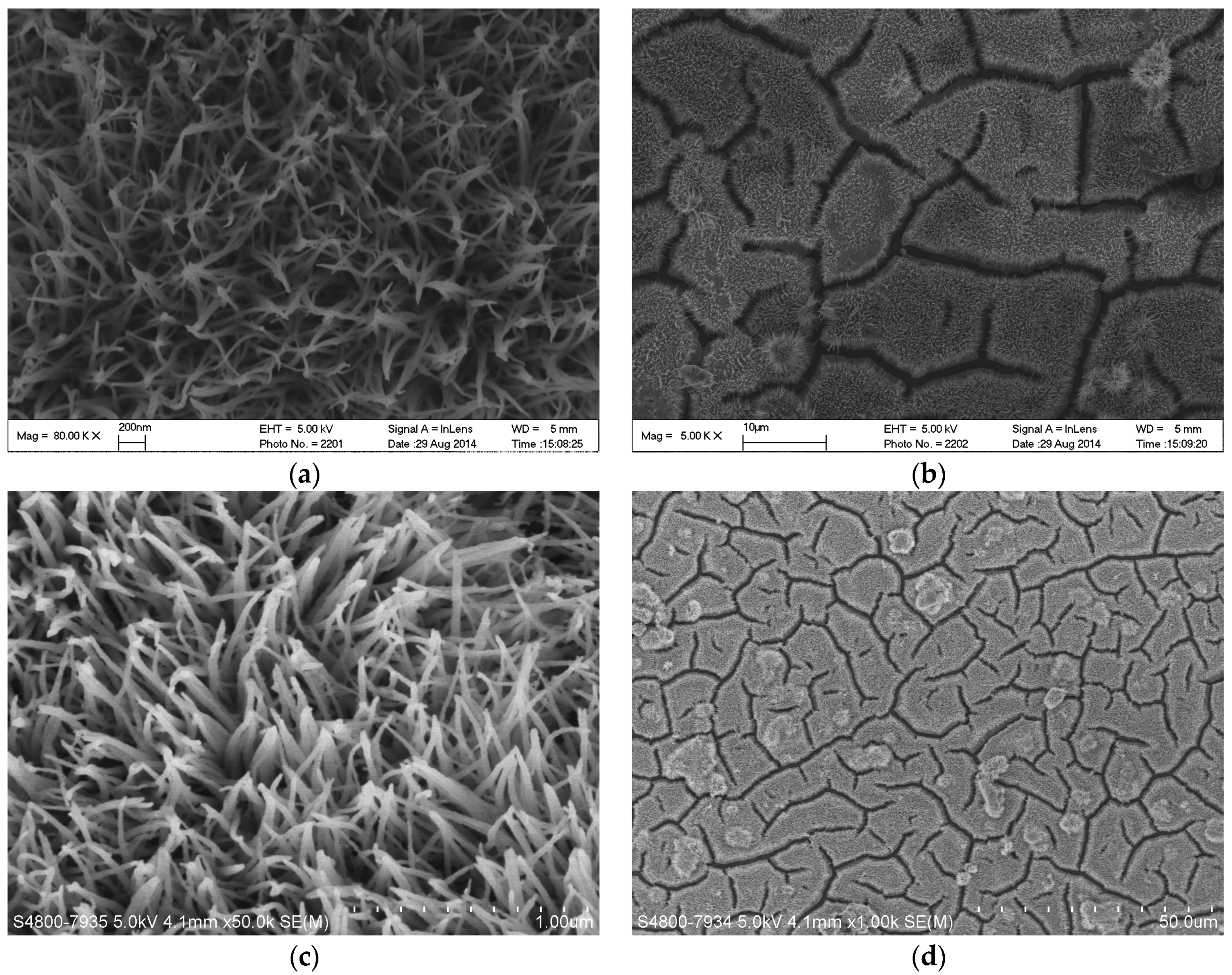

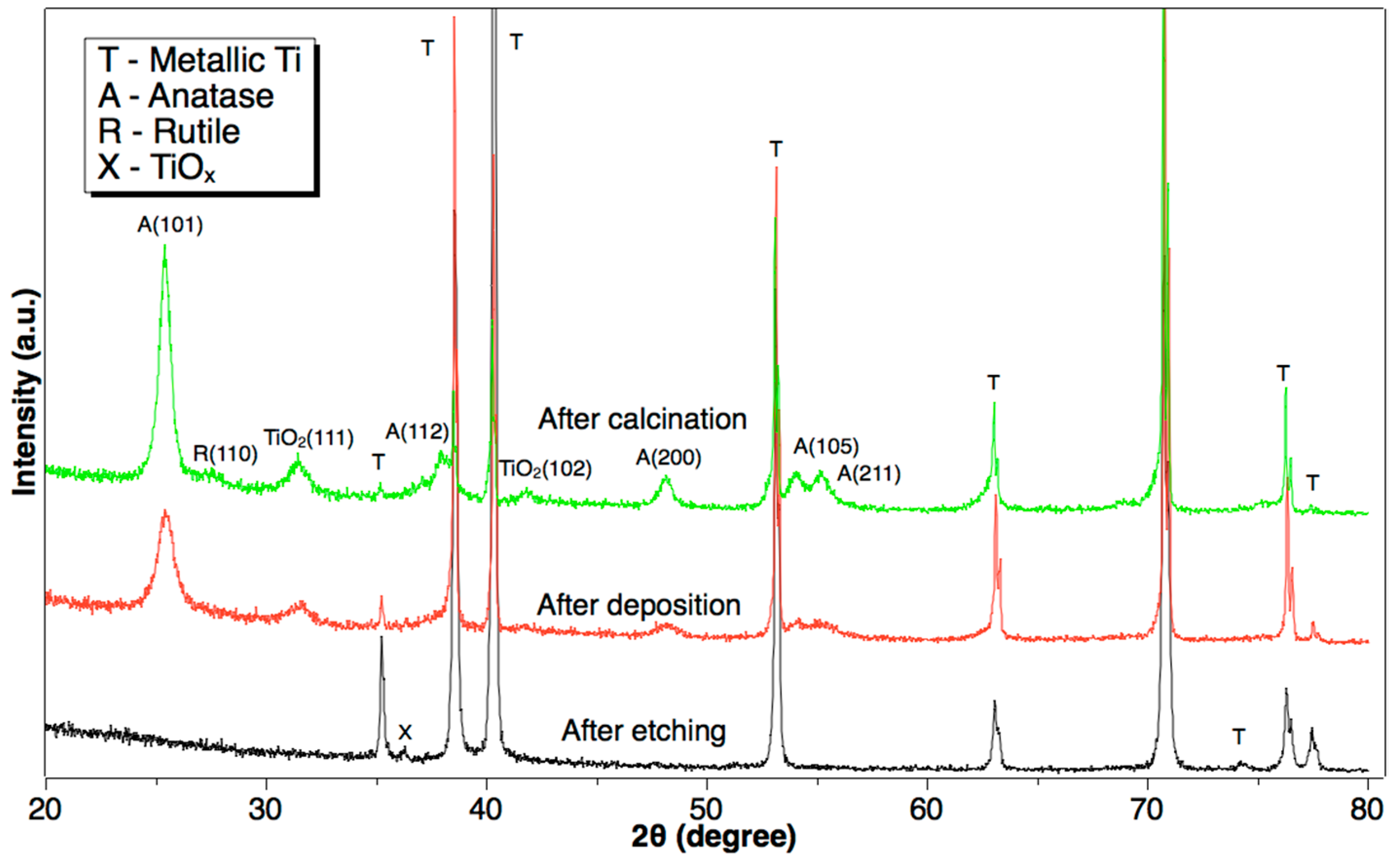

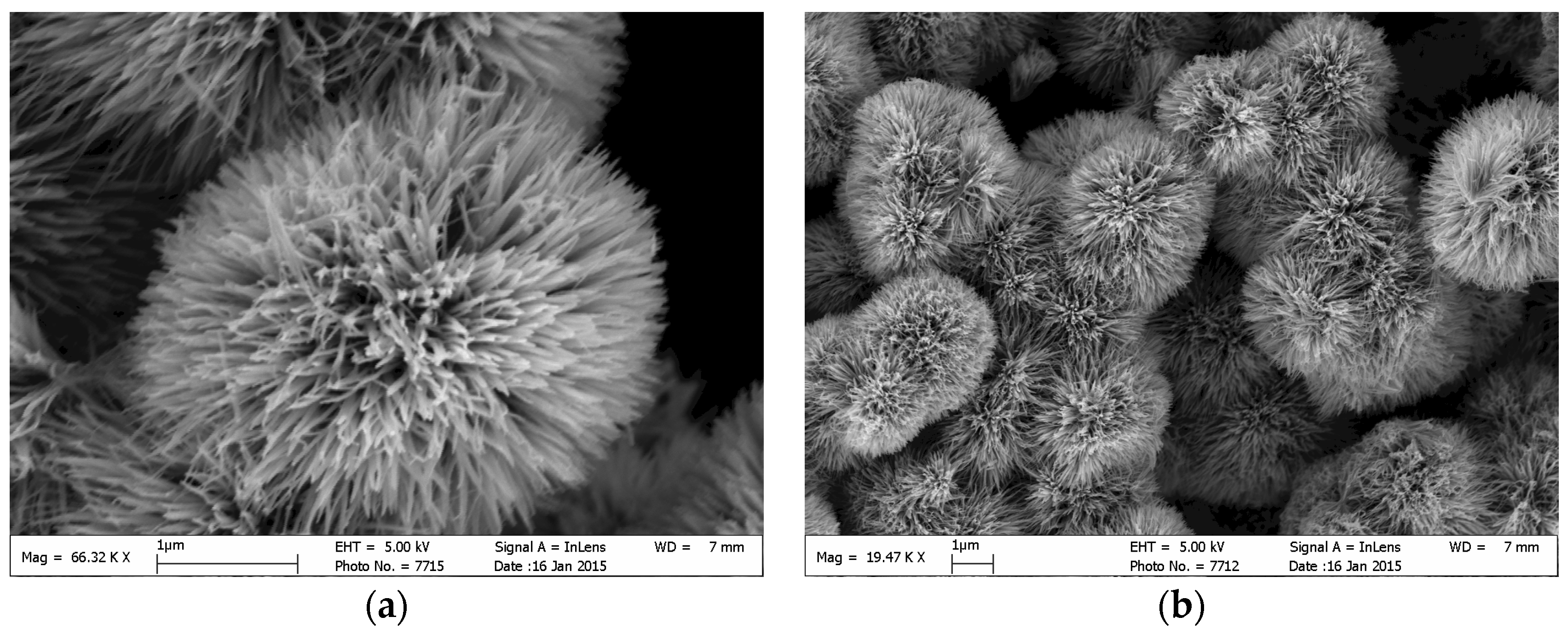

2.1. Morphologies and Microstructure

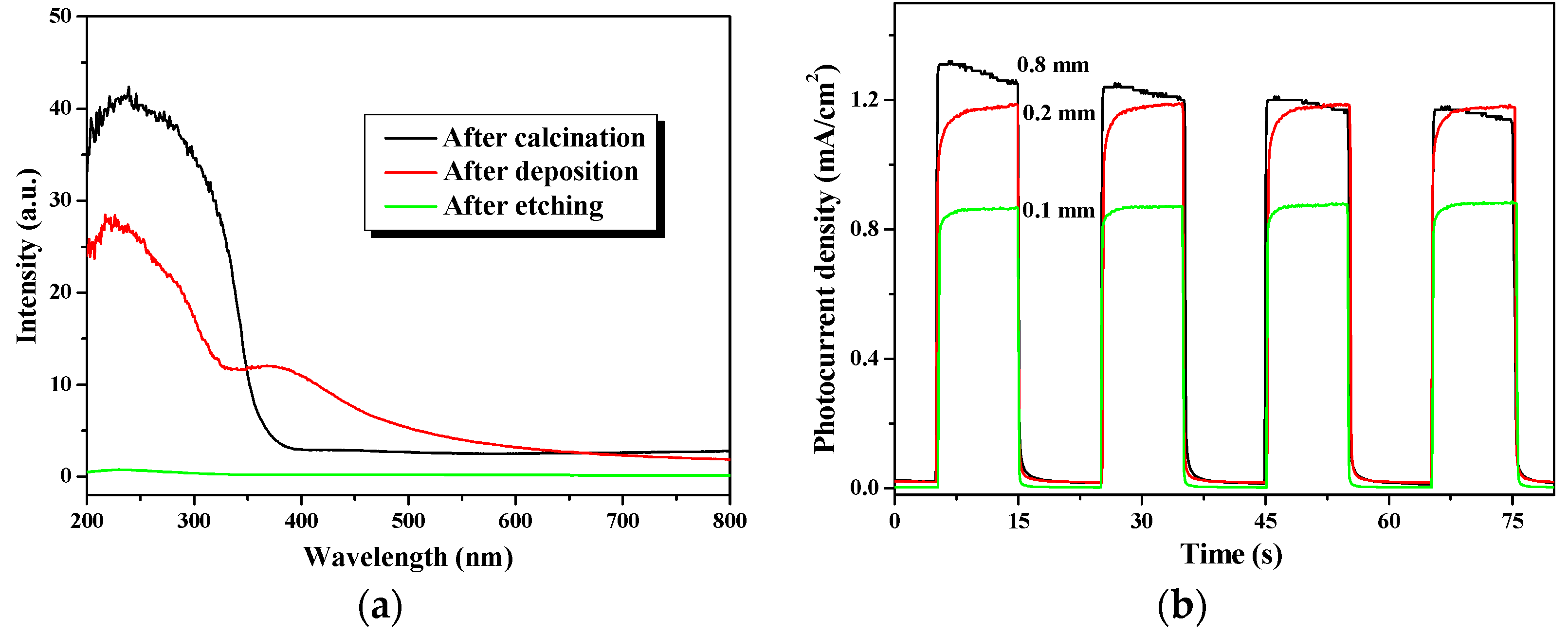

2.2. Photoelectrochemical Performance

2.3. Photocatalytic Activity Test

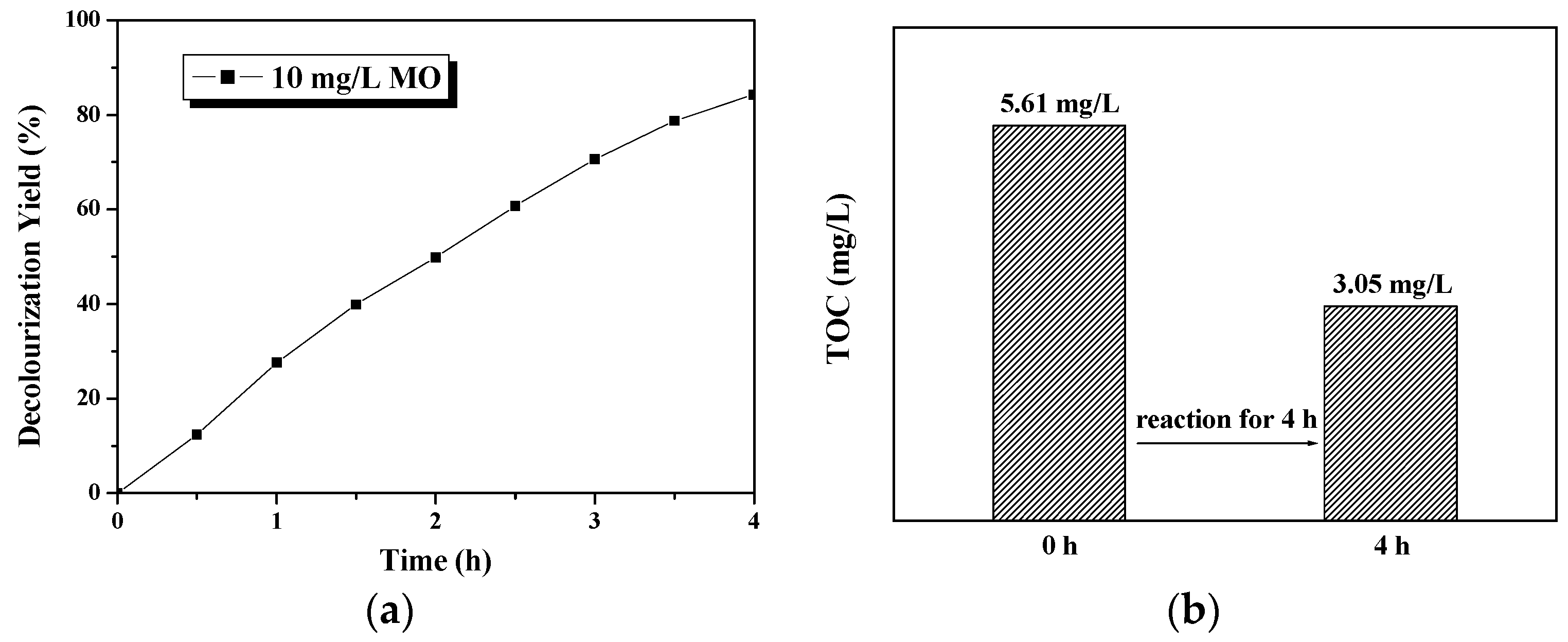

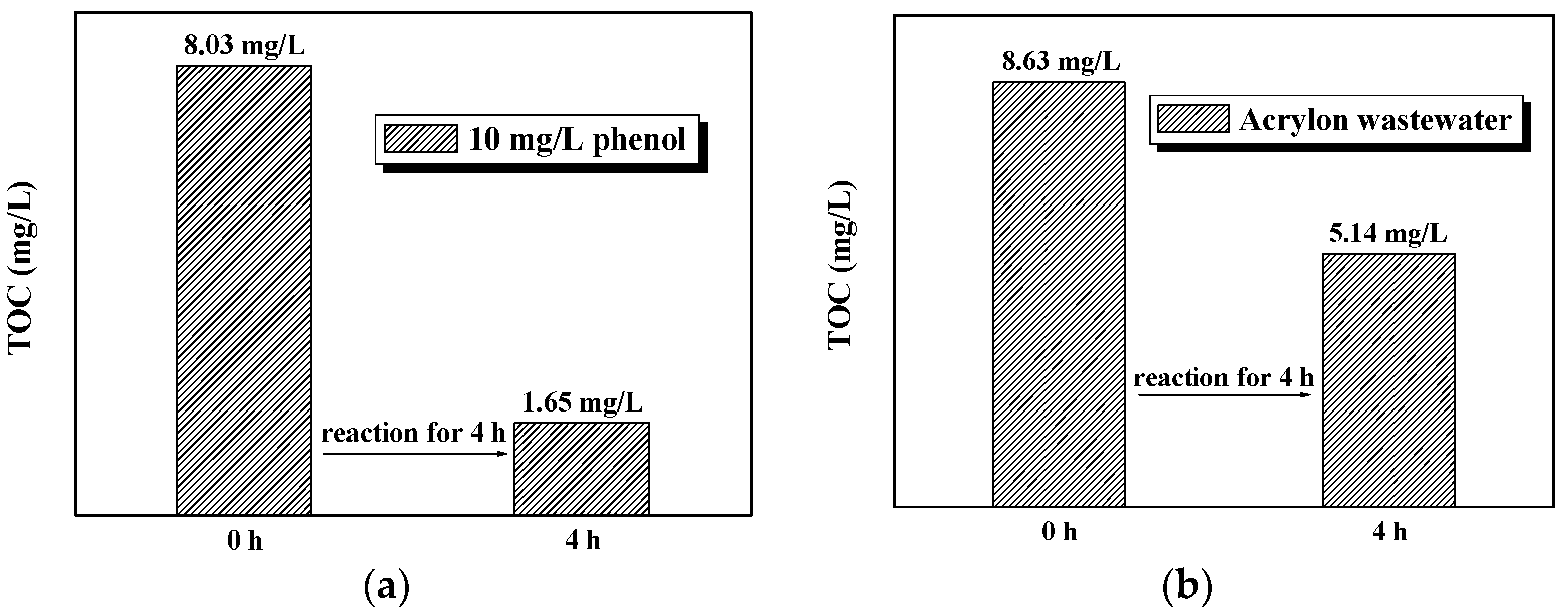

2.3.1. Stagnant Test

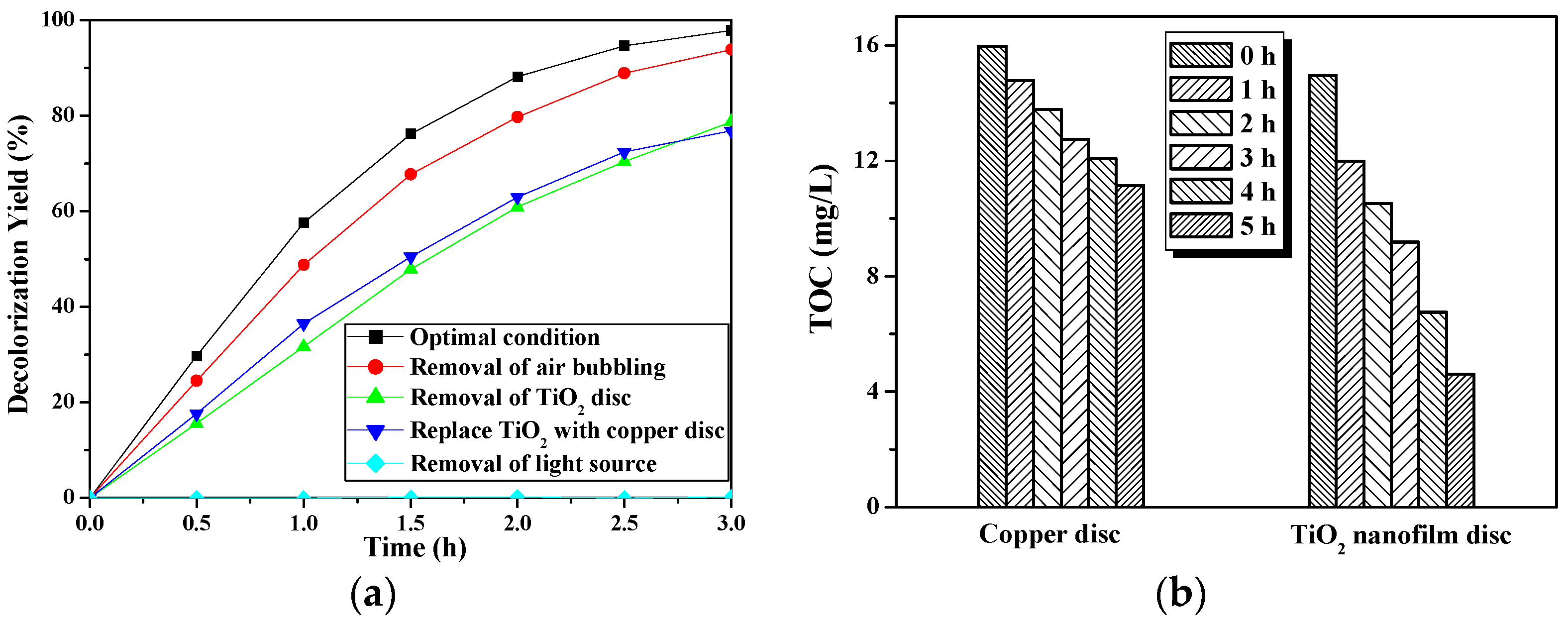

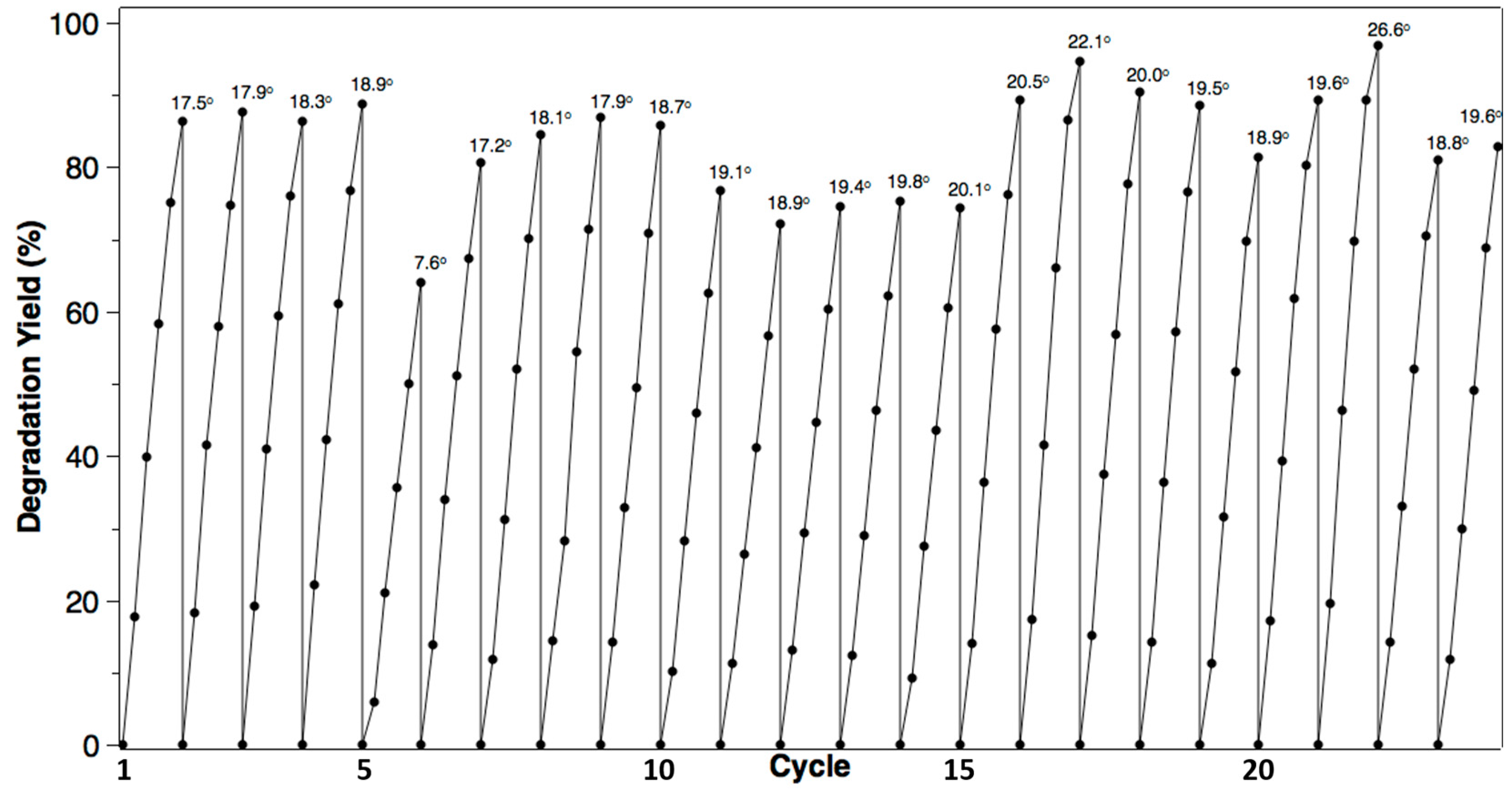

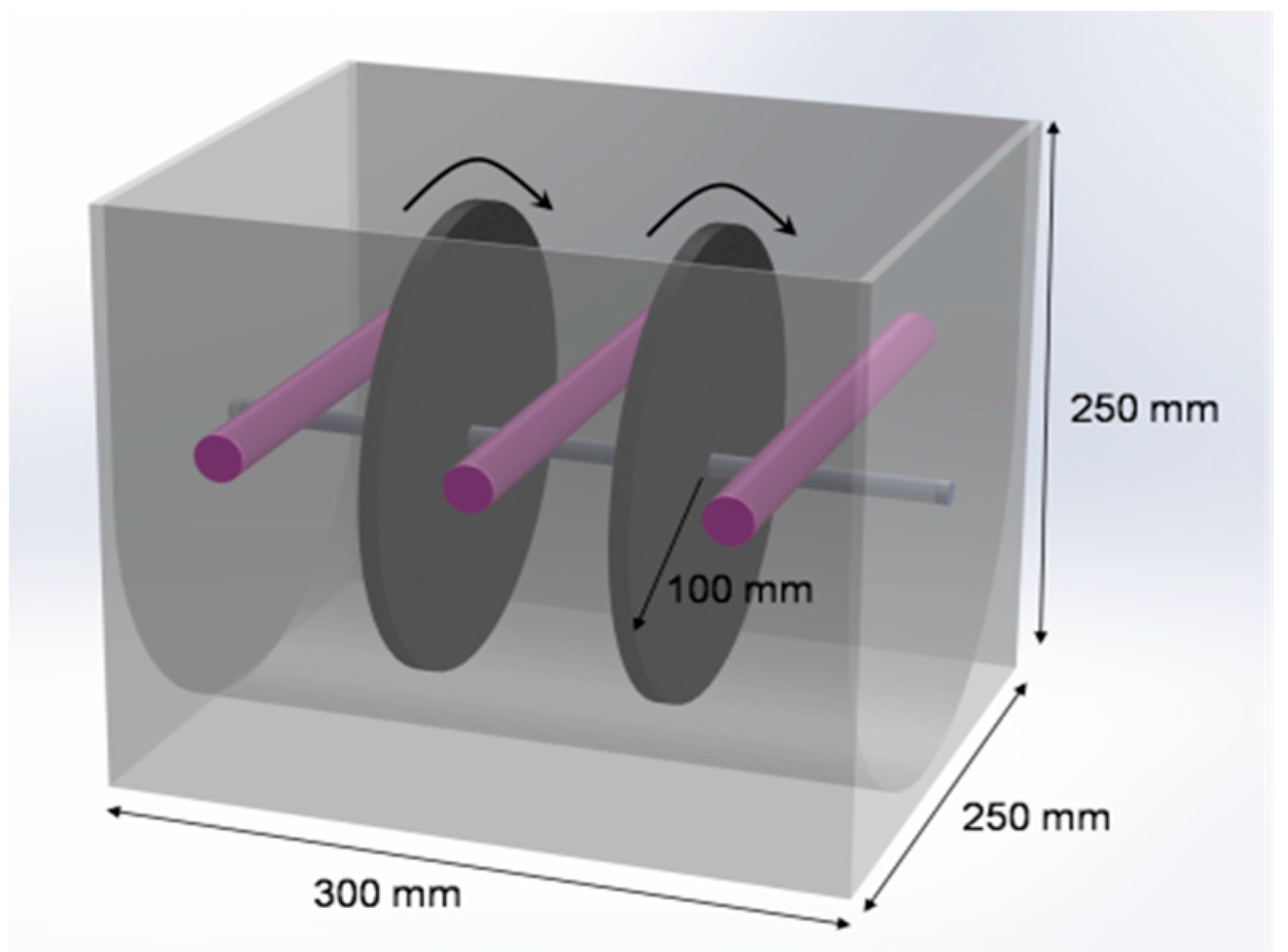

2.3.2. PRD-Reactor Experiment

3. Discussion

4. Materials and Methods

4.1. Materials

4.2. Preparation of TiO2 Nanowire Arrays

4.3. Characterization

4.4. Major Design Parameters of the PRD-Reactor

5. Conclusions

- Our PRD-reactor can be up-scaled for application in industrial wastewater treatment.

- Capability of advanced treatment of biodegraded wastewater with a high efficiency.

Author Contributions

Conflicts of Interest

References

- Fujishima, A.; Honda, K. Electrochemical photolysis of water at a semiconductor electrode. Nature 1972, 238, 37–38. [Google Scholar] [CrossRef] [PubMed]

- Zangeneh, H.; Zinatizadeh, A.A.L.; Habibi, M.; Akia, M.; Hasnain Isa, M. Photocatalytic oxidation of organic dyes and pollutants in wastewater using different modified titanium dioxides: A comparative review. J. Ind. Eng. Chem. 2015, 26, 1–36. [Google Scholar] [CrossRef]

- Pettit, S.L.; McCane, C.H.; Wolan, J.T.; Kuhn, J.N. Synthesis, Characterization, and Photocatalytic Degradation Performances of Composite Photocatalytic Semiconductors (InVO4–TiO2) Using Pure and Mixed Phase Titania Powders. Catal. Lett. 2013, 143, 772–776. [Google Scholar] [CrossRef]

- Aslam, M.; Ismail, I.M.I.; Chandrasekaran, S.; Hameed, A. Morphology controlled bulk synthesis of disc-shaped WO3 powder and evaluation of its photocatalytic activity for the degradation of phenols. J. Hazard. Mater. 2014, 276, 120–128. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Sun, H.; Suvorova, A.; Wang, S. One-pot hydrothermal synthesis of ZnO-reduced graphene oxide composites using Zn powders for enhanced photocatalysis. Chem. Eng. J. 2013, 229, 533–539. [Google Scholar] [CrossRef]

- Hoshiyama, N.; Dabwan, A.H.A.; Katsumata, H.; Suzuki, T.; Furukawa, M.; Kaneco, S. Enhanced Photocatalytic Degradation of Bisphenol A in Aqueous Solution by Ag-Doping ZnO. Open J. Inorg. Non-Met. Mater. 2016, 6, 13–17. [Google Scholar]

- Zwilling, V.; Aucouturier, M.; Darque-Ceretti, E. Anodic oxidation of titanium and TA6V alloy in chromic media. An electrochemical approach. Electrochim. Acta 1999, 45, 921–929. [Google Scholar] [CrossRef]

- Shankar, K.; Mor, G.K.; Prakasam, H.E.; Yoriya, S.; Paulose, M.; Varghese, O.K.; Grimes, C.A. Highly-ordered TiO2 nanotube arrays up to 220 µm in length: Use in water photoelectrolysis and dye-sensitized solar cells. Nanotechnology 2007, 18, 65707. [Google Scholar] [CrossRef]

- Ye, M.; Gong, J.; Lai, Y.; Lin, C.; Lin, Z. High-efficiency photoelectrocatalytic hydrogen generation enabled by palladium quantum dots-sensitized TiO2 nanotube arrays. J. Am. Chem. Soc. 2012, 134, 15720–15723. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.N.; Liu, M.N.; Wang, M.C.; Oloyede, A.; Bell, J.M.; Yan, C. Nanoindentation study of the mechanical behavior of TiO2 nanotube arrays. J. Appl. Phys. 2015, 118, 145301. [Google Scholar] [CrossRef]

- Hafizah, N.; Sopyan, I. Nanosized TiO2 Photocatalyst Powder via Sol-Gel Method: Effect of Hydrolysis Degree on Powder Properties. Int. J. Photoenergy 2009, 2009, 1–8. [Google Scholar] [CrossRef]

- Qin, D.D.; Bi, Y.P.; Feng, X.J.; Wang, W.; Barber, G.D.; Wang, T.; Mallouk, T.E. Hydrothermal Growth and Photoelectrochemistry of Highly Oriented, Crystalline Anatase TiO2 Nanorods on Transparent Conducting Electrodes. Chem. Mater. 2015, 27, 4180–4183. [Google Scholar] [CrossRef]

- Li, B.; Wu, J.M.; Guo, T.T.; Tang, M.Z.; Wen, W. A facile solution route to deposit TiO2 nanowire arrays on arbitrary substrates. Nanoscale 2014, 6, 3046–3050. [Google Scholar] [CrossRef] [PubMed]

- Qu, X.; Alvarez, P.J.J.; Li, Q. Applications of nanotechnology in water and wastewater treatment. Water Res. 2013, 47, 3931–3946. [Google Scholar] [CrossRef] [PubMed]

- Akhavan, O.; Ghderi, E. Capping antibacterial Ag nanorods aligned on Ti interlayer by mesoporous TiO2 layer. Surf. Coat. Technol. 2009, 203, 3123–3128. [Google Scholar] [CrossRef]

- Malato, S.; Fernández-Ibáñez, P.; Maldonado, M.I.; Blanco, J.; Gernjak, W. Decontamination and disinfection of water by solar photocatalysis: Recent overview and trends. Catal. Today 2009, 147, 1–59. [Google Scholar] [CrossRef]

- Han, F.; Kambala, V.S.R.; Srinivasan, M.; Rajarathnam, D.; Naidu, R. Tailored titanium dioxide photocatalysts for the degradation of organic dyes in wastewater treatment: A review. Appl. Catal. A Gen. 2009, 359, 25–40. [Google Scholar] [CrossRef]

- Xu, Y.; He, Y.; Cao, X.; Zhong, D.; Jia, J. TiO2/Ti Rotating Disk Photoelectrocatalytic (PEC) Reactor: A Combination of Highly Effective Thin-Film PEC and Conventional PEC Processes on a Single Electrode. Environ. Sci. Technol. 2008, 42, 2612–2617. [Google Scholar] [CrossRef] [PubMed]

- Xiao, L.; Green, A.N.M.; Haque, S.A.; Mills, A.; Durrant, J.R. Light-driven oxygen scavenging by titania/polymer nanocomposite films. J. Photochem. Photobiol. A Chem. 2004, 162, 253–259. [Google Scholar] [CrossRef]

- Fernández, J.; Kiwi, J.; Baeza, J.; Freer, J.; Lizama, C.; Mansilla, H.D. Orange II photocatalysis on immobilised TiO2: Effect of the pH and H2O2. Appl. Catal. B Environ. 2004, 48, 205–211. [Google Scholar] [CrossRef]

- Akhavan, O.; Azimirad, R. Photocatalytic property of Fe2O3 nanograin chains coated by TiO2 nanolayer in visible light irradiation. Appl. Catal. A Gen. 2009, 369, 77–82. [Google Scholar] [CrossRef]

- Akhavan, O. Thickness dependent activity of nanostructured TiO2/α-Fe2O3 photocatalyst thin films. Appl. Surf. Sci. 2010, 257, 1724–1728. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, Q.; Feng, Z.; Li, M.; Li, C. Importance of the Relationship between Surface Phases and Photocatalytic Activity of TiO2. Angew. Chem. Int. Ed. 2008, 47, 1766–1769. [Google Scholar] [CrossRef] [PubMed]

- Ju, M.; Sun, G.; Wang, J.; Meng, Q.; Liang, W. Origin of High Photocatalytic Properties in the Mixed-Phase TiO2: A First-Principles Theoretical Study. ACS Appl. Mater. Interfaces 2014, 6, 12885–12892. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.M.; Xue, H.X. Photocatalytic Active Titania Nanowire Arrays on Ti Substrates. J. Am. Ceram. Soc. 2009, 92, 2139–2143. [Google Scholar] [CrossRef]

- Hiromoto, S. Composition of surface oxide film of titanium with culturing murine fibroblasts L929. Biomaterials 2004, 25, 979–986. [Google Scholar] [CrossRef]

- Sample Availability: Samples of the compounds including TiO2 nanowire arrays deposited on the Ti plate and TiO2 nanoflower powder are available from the authors for two years after the publication of the manuscript.

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, F.; Szeto, W.; Huang, H.; Li, J.; Leung, D.Y.C. A Photocatalytic Rotating Disc Reactor with TiO2 Nanowire Arrays Deposited for Industrial Wastewater Treatment. Molecules 2017, 22, 337. https://doi.org/10.3390/molecules22020337

Li F, Szeto W, Huang H, Li J, Leung DYC. A Photocatalytic Rotating Disc Reactor with TiO2 Nanowire Arrays Deposited for Industrial Wastewater Treatment. Molecules. 2017; 22(2):337. https://doi.org/10.3390/molecules22020337

Chicago/Turabian StyleLi, Fang, Wai Szeto, Haibao Huang, Jiantao Li, and Dennis Y. C. Leung. 2017. "A Photocatalytic Rotating Disc Reactor with TiO2 Nanowire Arrays Deposited for Industrial Wastewater Treatment" Molecules 22, no. 2: 337. https://doi.org/10.3390/molecules22020337