Photocatalytic Activities of Copper Doped Cadmium Sulfide Microspheres Prepared by a Facile Ultrasonic Spray-Pyrolysis Method

Abstract

:1. Introduction

2. Results and Discussion

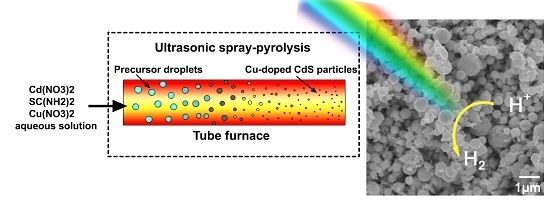

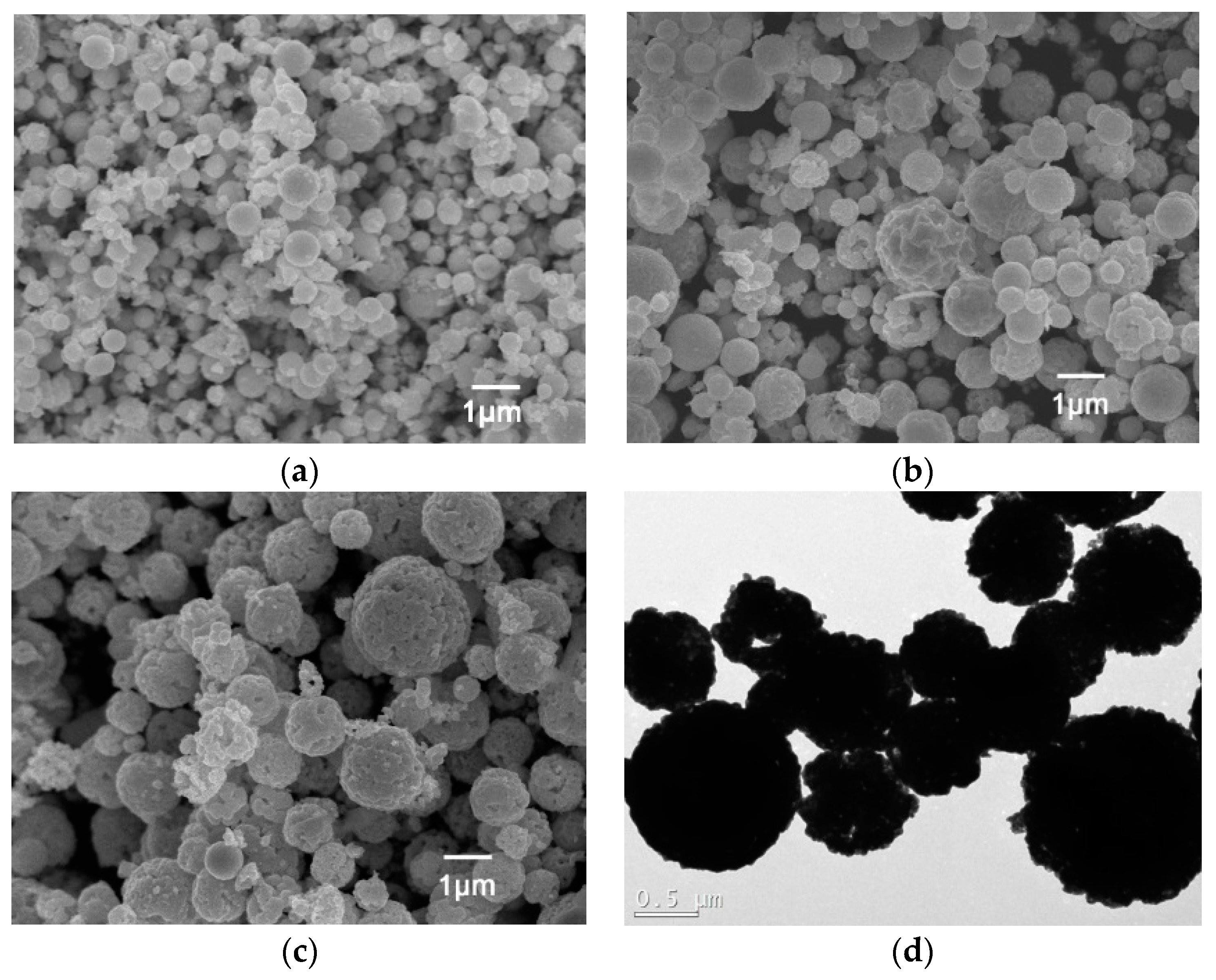

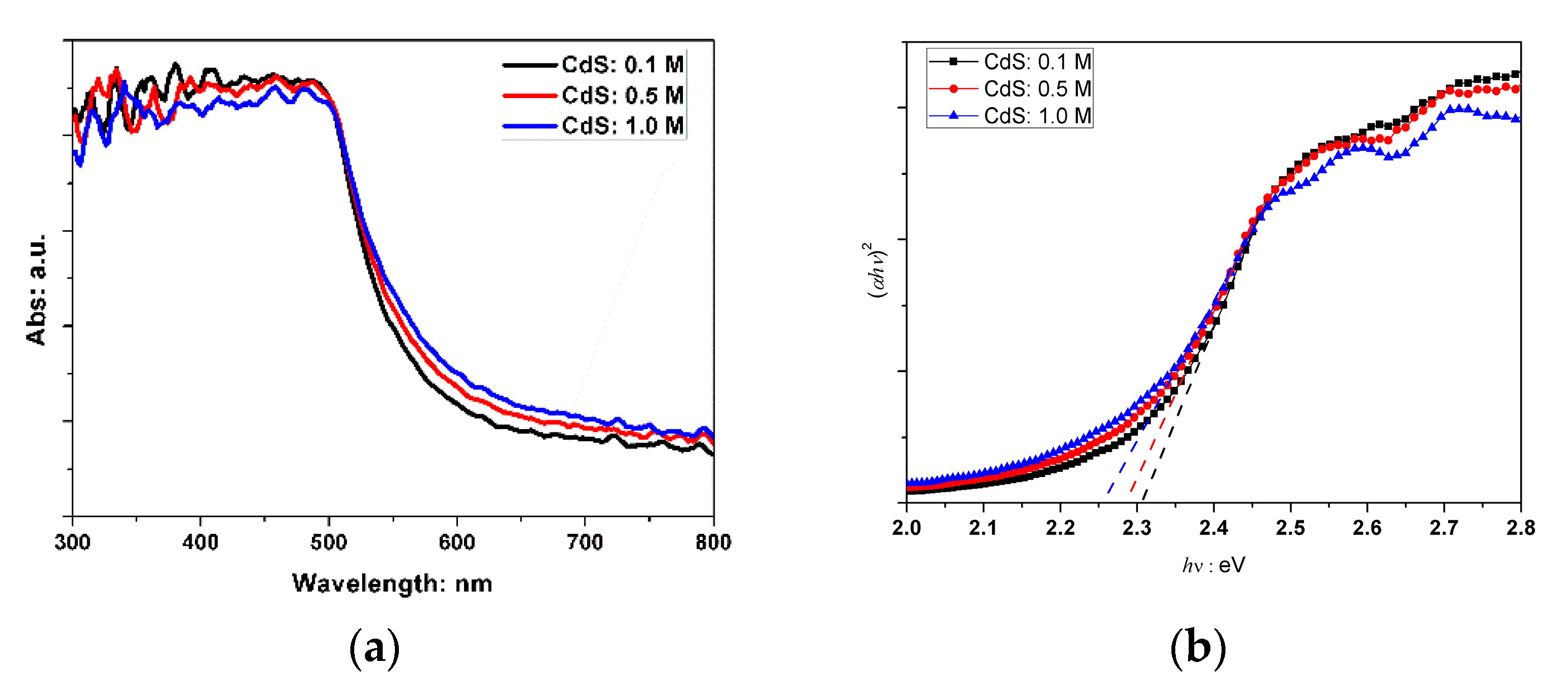

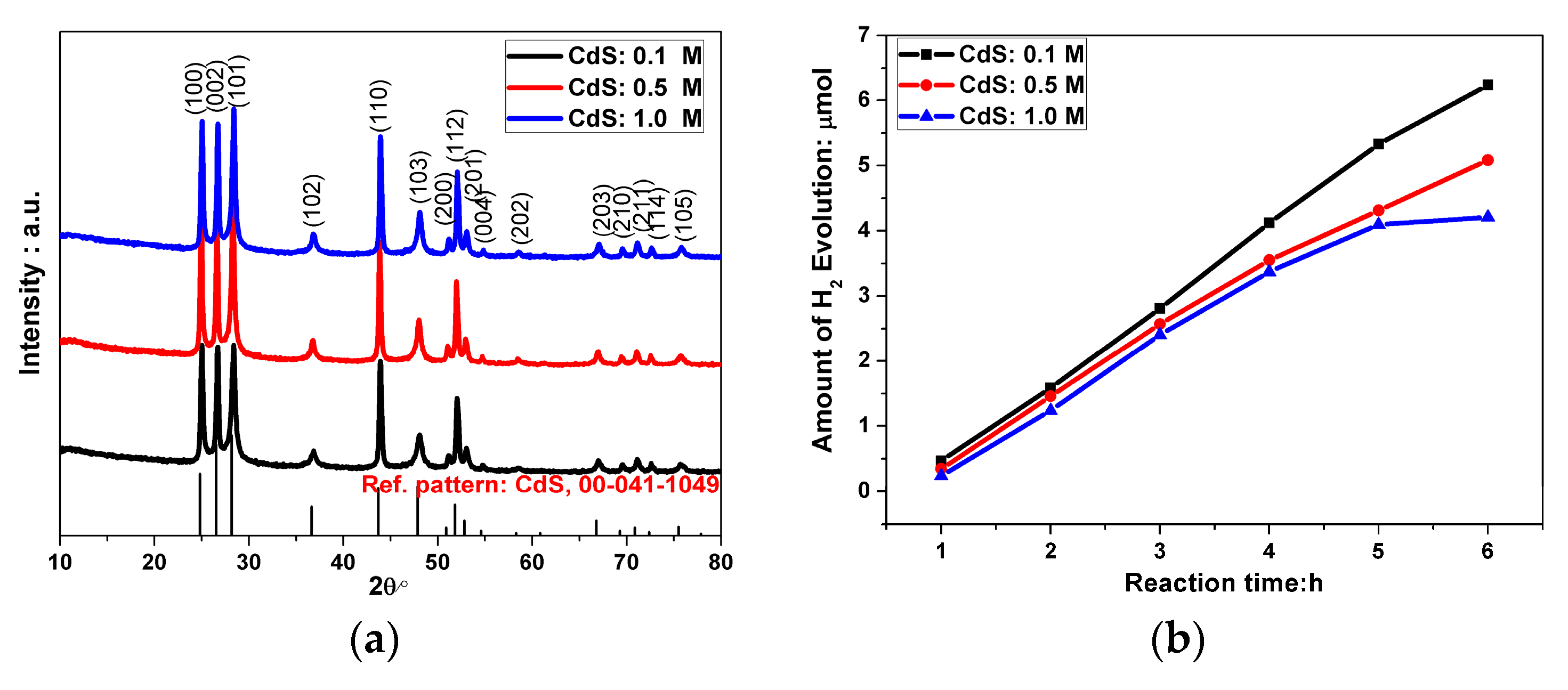

2.1. Morphological, Optical and Structural Properties of Undoped CdS Particles

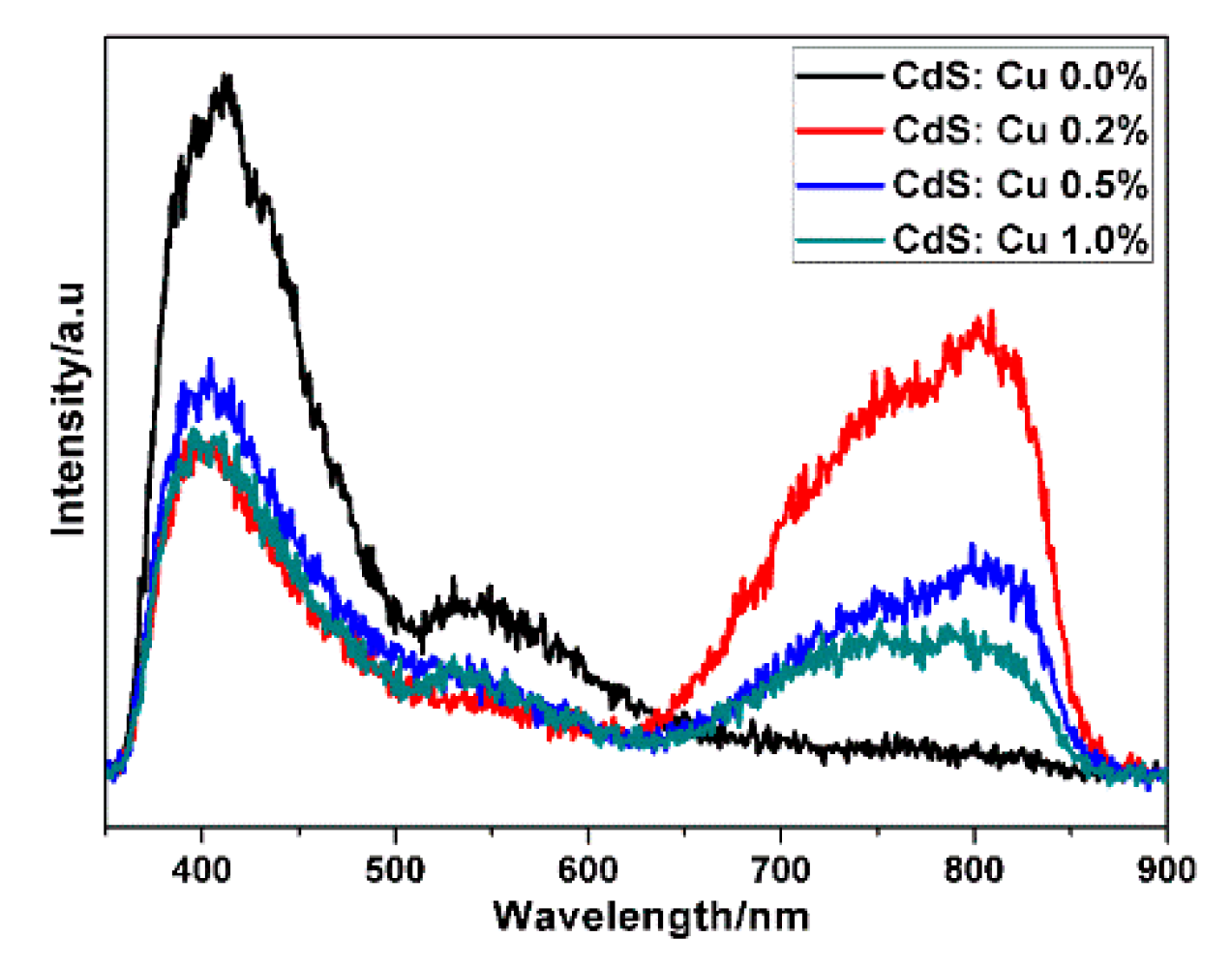

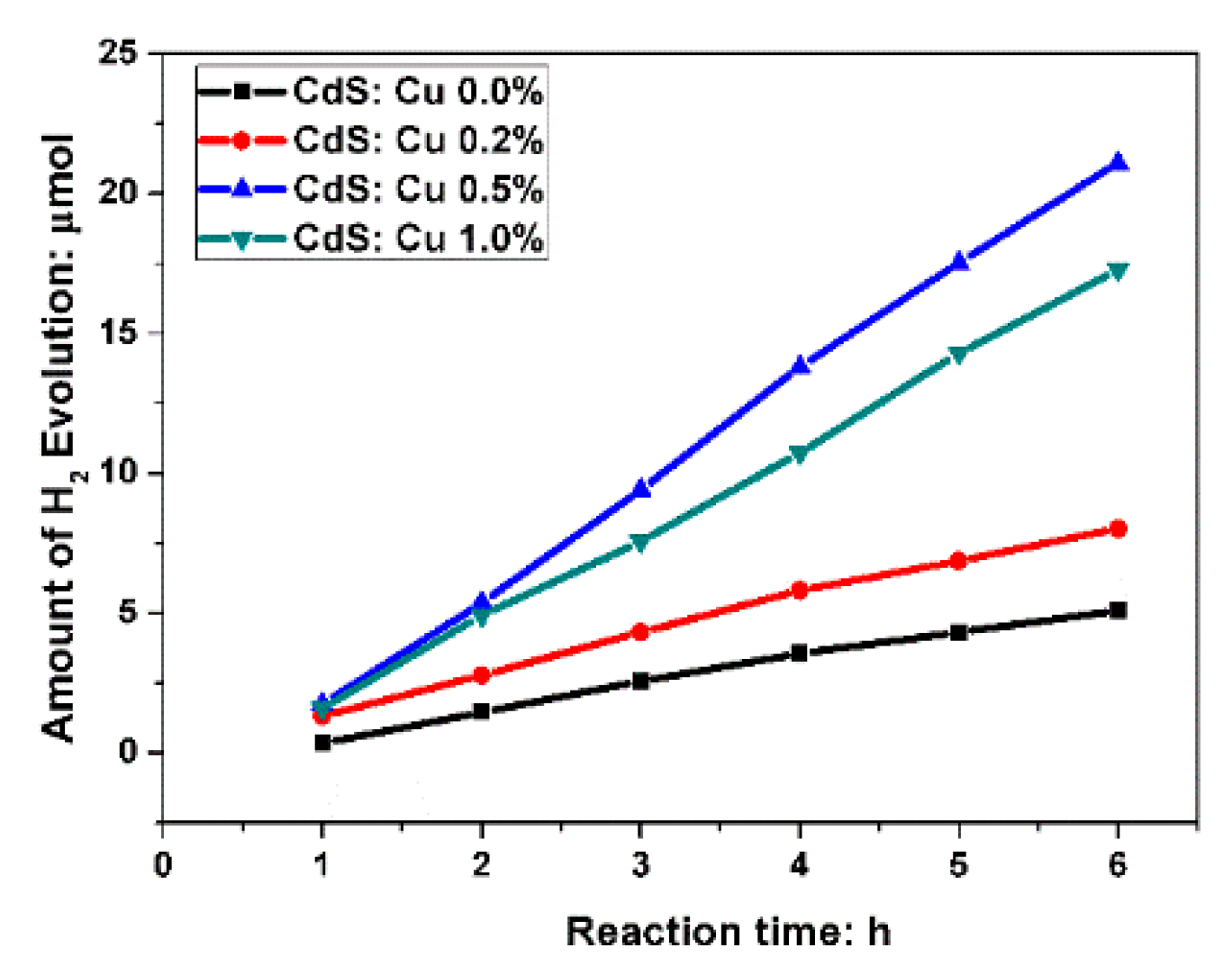

2.2. Morphological, Optical and Structural Properties of Cu Doped CdS Particles

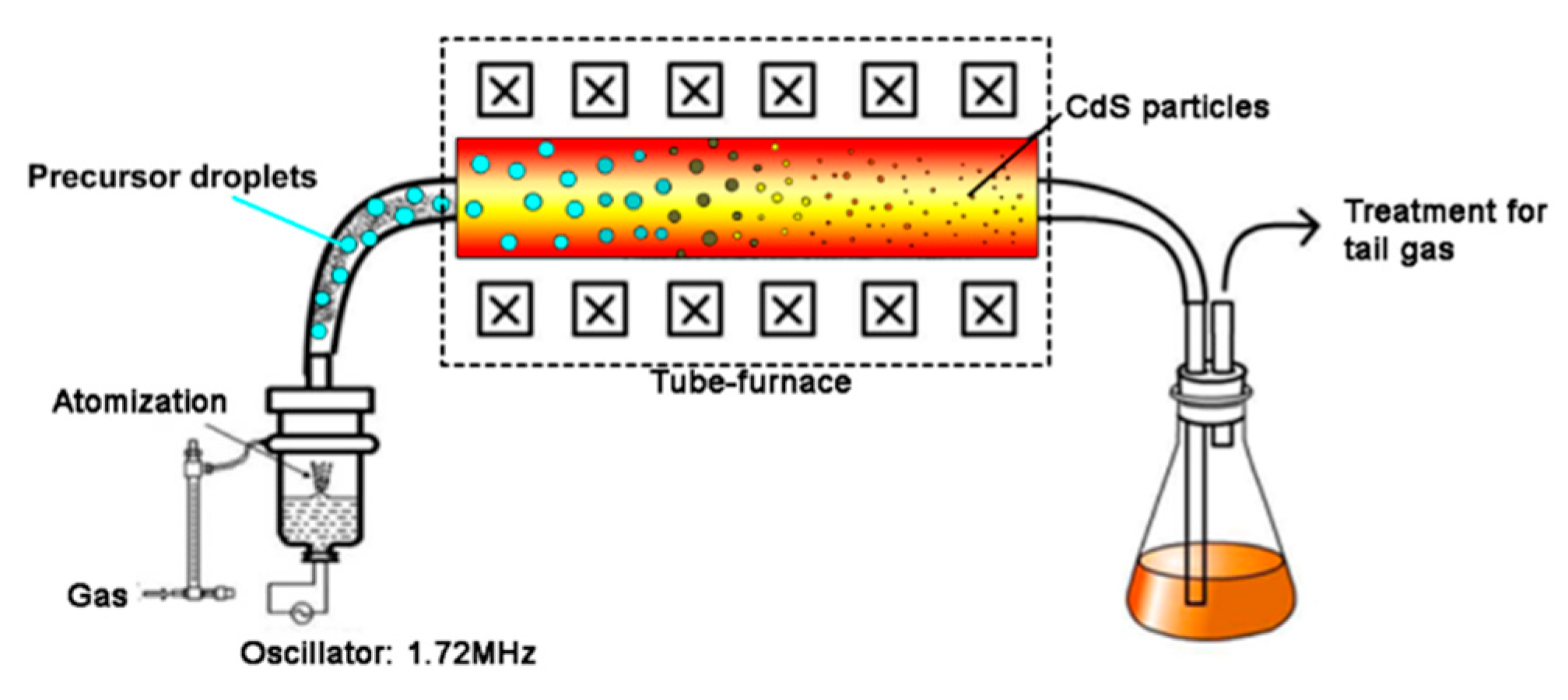

3. Materials and Methods

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Fujishima, A.; Honda, K. Electrochemical Photolysis of Water at a semiconductor Electrode. Nature 1972, 238, 37–38. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Guo, L. Metal sulphide semiconductors for photocatalytic hydrogen production. Catal. Sci. Technol. 2013, 3, 1672–1690. [Google Scholar] [CrossRef]

- Chen, Y.; Feng, X.; Liu, M.; Su, J.; Shen, S. Towards efficient solar-to-hydrogen conversion: Fundamentals and recent progress in copper-based chalcogenide photocathodes. Nanophotonics 2016. [Google Scholar] [CrossRef]

- Chen, J.; Wu, X.; Yin, L.; Li, B.; Hong, X.; Fan, Z.; Chen, B.; Xue, C.; Zhang, H. One-pot Synthesis of CdS Nanocrystals Hybridized with Single-Layer Transition-Metal Dichalcogenide Nanosheets for Efficient Photocatalytic Hydrogen Evolution. Angew. Chem. Int. Ed. 2015, 54, 1210–1214. [Google Scholar] [CrossRef] [PubMed]

- Vaquero, F.; Fierro, J.L.G.; Navarro Yerga, R.M. From Nanorods to Nanowires of CdS Synthesized by a Solvothermal Method: Influence of the Morphology on the Photoactivity for Hydrogen Evolution from Water. Molecules 2016, 21, 401. [Google Scholar] [CrossRef] [PubMed]

- Sakimoto, K.K.; Wong, A.B.; Yang, P. Self-photosensitization of nonphotosynthetic bacteria for solar-to-chemical production. Science 2016, 351, 74–77. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Yu, Y.; Zhou, P.; Xiao, W.; Cheng, B. Morphology-dependent photocatalytic H2-production activity of CdS. Appl. Catal. B Environ. 2014, 156, 184–191. [Google Scholar] [CrossRef]

- Xiang, Q.; Cheng, B.; Yu, J. Hierarchical porous CdS nanosheet-assembled flowers with enhanced visible-light photocatalytic H2-production performance. Appl. Catal. B Environ. 2013, 138, 299–303. [Google Scholar] [CrossRef]

- Jin, J.; Yu, J.; Liu, G.; Wong, P.K. Single crystal CdS nanowires with high visible-light photocatalytic H2-production performance. J. Mater. Chem. A 2013, 1, 10927–10934. [Google Scholar] [CrossRef]

- Zhang, N.; Yang, M.; Tang, Z.; Xu, Y. CdS-graphene nanocomposites as visible light photocatalyst for redox reactions in water: A green route for selective transformation and environmental remediation. J. Catal. 2013, 303, 60–69. [Google Scholar] [CrossRef]

- Long, L.; Yu, X.; Wu, L.; Li, J.; Li, X. Nano-CdS confined within titanate nanotubes for efficient photocatalytic hydrogen production under visible light illumination. Nanotechnology 2014, 25, 035603. [Google Scholar] [CrossRef] [PubMed]

- Fu, J.; Chang, B.; Tian, Y.; Xi, F.; Dong, X. Novel C3N4-CdS composite photocatalysts with organic-inorganic heterojunctions: In situ synthesis, exceptional activity, high stability and photocatalytic mechanism. J. Mater. Chem. A 2013, 1, 3083–3090. [Google Scholar] [CrossRef]

- Moriya, M.; Minegishi, T.; Kumagai, H.; Katayama, M.; Kubota, J.; Domen, K. Stable Hydrogen Evolution from CdS-Modified CuGaSe2 Photoelectrode under Visible-Light Irradiation. J. Am. Chem. Soc. 2013, 135, 3733–3735. [Google Scholar] [CrossRef] [PubMed]

- Lingampalli, S.R.; Gautam, U.K.; Rao, C.N.R. Highly efficient photocatalytic hydrogen generation by solution-processed ZnO/Pt/CdS, ZnO/Pt/Cd1−xZnxS and ZnO/Pt/CdS1−xSex hybrid nanostructures. Energy Environ. Sci. 2013, 6, 3589–3594. [Google Scholar] [CrossRef]

- Zhang, K.; Jing, D.; Xing, C.; Guo, L. Significantly improved photocatalytic hydrogen production activity over Cd1−xZnxS photocatalysts prepared by a novel thermal sulfuration method. Int. J. Hydrog. Energy 2007, 32, 4685–4691. [Google Scholar] [CrossRef]

- Liu, M.; Jing, D.; Zhou, Z.; Guo, L. Twin-induced one-dimensional homojunctions yield high quantum efficiency for solar hydrogen generation. Nat. Commun. 2013, 4. [Google Scholar] [CrossRef] [PubMed]

- Bao, N.; Shen, L.; Takata, T.; Domen, K. Self-Templanted Synthesis of Nanoporous CdS Nanostructures for Highly Efficienct Photocatalytic Hydrogen Production under Visible Light. Chem. Mater. 2008, 20, 110–117. [Google Scholar] [CrossRef]

- Zang, J.; Zhao, G.; Han, G. Preparation of CdS Nanopaticles by Hydrothemal Method in Microemulsion. Front. Chem. China 2007, 2, 98–101. [Google Scholar] [CrossRef]

- Murali, G.; Reddy, D.A.; Sambasivam, S.; Vijayalakshmi, R.P.; Reddy, V.R. CdS microflowers and interpenetrated nanorods grown on Si substrate: Structural, optical properties and growth mechanism. Mater. Chem. Phys. 2014, 146, 399–405. [Google Scholar] [CrossRef]

- Tripathi, R.M.; Bhadwal, A.S.; Singh, P.; Shrivastav, A.; Singh, M.P.; Shrivastav, B.R. Mechanistic aspects of biogenic synthesisof CdS nanoparticles using Bacillus licheniformis. Adv. Nat. Sci. Nanosci. Nanotechnol. 2014, 5, 025006. [Google Scholar] [CrossRef]

- Zhou, L.; Hu, X.; Wu, S. Effects of deposition temperature on the performance of CdS films with chemical bath deposition. Surf. Coat. Tech. 2013, 228, S171–S174. [Google Scholar] [CrossRef]

- Okuyama, K.; Lenggoro, I.W.; Tagami, N.; Tamaki, S.; Tohge, N. Preparation of ZnS and CdS fine particles with different particle sizes by a spray-pyrolysis method. J. Mater. Sci. 1997, 32, 1229–1237. [Google Scholar] [CrossRef]

- Huang, J.; Cheuk, W.; Wu, Y.; Lee, F.S.; Ho, W. Template-free synthesis of ternary sulfides submicrospheres as visible light photocatalysts by ultrasonic spray pyrolysis. Catal. Sci. Technol. 2012, 2, 1825–1827. [Google Scholar] [CrossRef]

- Sunil, M.A.; Deepa, K.G.; Nagaraju, J. Growth of AgInS2 thin films by ultrasonic spray pyrolysis technique. Thin Solid Films 2014, 550, 71–75. [Google Scholar] [CrossRef]

- Korake, P.V.; Achary, S.N.; Gupta, N.M. Role of aliovalent cation doping in the activity of nanocrystalline CdS for visible-light-driven H2 production from water. Int. J. Hydrog. Energy 2015, 40, 8695–8705. [Google Scholar] [CrossRef]

- Chen, X.; Burda, C. The electronic origin of the visible-light absorption properties of C-, N- and S-doped TiO2 nanomaterials. J. Am. Chem. Soc. 2008, 130, 5018–5019. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.; Lin, Y.; Yang, J.; Li, X.; Zhang, J.; Yu, J.; Shi, H.; Wang, W.; Yu, Y. Enhanced photocatalytic activity and stability of semiconductor by Ag doping and simultaneous deposition: The case of CdS. RSC Adv. 2013, 3, 20782–20792. [Google Scholar] [CrossRef]

- Xie, R.; Su, J.; Li, M.; Guo, L. Structural and Photoelectrochemical Properties of Cu-Doped CdS Thin Films Prepared by Ultrasonic Spray Pyrolysis. Int. J. Photoenergy 2013. [Google Scholar] [CrossRef]

- Rmili, A.; Ouachtari, F.; Bouaoud, A.; Louardi, A.; Chtouki, T.; Elidrissi, B.; Erguig, H. Structural, optical and electrical properties of Ni-doped CdS thin films prepared by spray pyrolysis. J. Alloy. Compd. 2013, 557, 53–59. [Google Scholar] [CrossRef]

- Tauc, J. Amorphous And Liquid Semiconductors; Plenum Press: London, UK, 1974. [Google Scholar]

- Cortes, A.; Gomez, H.; Marotti, R.E.; Riveros, G.; Dalchiele, E.A. Grain size dependence of the bandgap in chemical bath deposited CdS thin films. Sol. Energy Mater. Sol. Cells 2004, 82, 21–34. [Google Scholar] [CrossRef]

- Wei, S.; Zhang, S.; Zunger, A. First-principles calculation of band offsets, optical bowings, and defects in CdS, CdSe, CdTe, and their alloys. J. Appl. Phys. 2000, 87, 1304. [Google Scholar] [CrossRef]

- Scherrer, P. Estimation of the size and internal structure of colloidal particles by means of röntgen. Nachr. Ges. Wiss. Göttingen 1918, 2, 96–100. [Google Scholar]

- Mandal, P.; Talwar, S.S.; Major, S.S.; Srinivasa, R.S. Orange-red luminescence from Cu doped CdS nanophosphor prepared using mixed Langmuir-Blodgett multilayers. J. Chem. Phys. 2008, 128, 114703. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Huang, S.; Sun, Y. Low-temperature synthesis of hexagonal transition metal ion doped ZnS nanoparticles by a simple colloidal method. Appl. Surf. Sci. 2013, 270, 178–183. [Google Scholar] [CrossRef]

- Nakanishi, T.; Ohtani, B.; Uosaki, K. Fabrication and char-acterization of CdS-nanoparticle mono- and multilayers on a self-assembled monolayer of alkanedithiols on gold. J. Phys. Chem. B 1998, 102, 1571–1577. [Google Scholar] [CrossRef]

- Wang, Y.; Suna, A.; Mahler, W.; Kosowski, R. PbS in polymers. From molecules to bulk solids. J. Chem. Phys. 1987, 87, 7315–7322. [Google Scholar] [CrossRef]

- Chen, H.; Huang, X.; Xu, L.; Xu, J.; Chen, K.; Feng, D. Self-assembly and photoluminescence of CdS-mercaphtoacetic clusters with internal structures. Superlattice Microst. 2000, 27, 1–5. [Google Scholar] [CrossRef]

- Chen, W.; Xu, Y.; Lin, Z.; Wang, Z.; Lin, L. Formation, structure and fluorescence of CdS clusters in a mesoporous zeolite. Solid State Commun. 1998, 105, 129–134. [Google Scholar] [CrossRef]

- Costa, V.C.; Shen, Y.; Bray, K.L. Luminescence properties of nanocrystalline CdS and CdS: Mn2+ doped silica-type glasses. J. Non-Cryst. Solids 2002, 304, 217–223. [Google Scholar] [CrossRef]

- Panda, R.; Rathore, V.; Rathore, M.; Shelke, V.; Badera, N.; Sharath Chandra, L.S.; Jain, D.; Gangrade, M.; Shripati, T.; Ganesan, V. Carrier recombination in Cu doped CdS thin films: Photocurrent and optical studies. Appl. Surf. Sci. 2012, 258, 5086–5093. [Google Scholar] [CrossRef]

- Abe, T.; Kashiwaba, Y.; Baba, M.; Imai, J.; Sasaki, H. XPS analysis of p-type Cu-doped CdS thin films. Appl. Surf. Sci. 2001, 175, 549–554. [Google Scholar] [CrossRef]

- Kashiwaba, Y.; Kanno, I.; Ikeda, T. p-Type characteristics of Cu-doped CdS thin films. Jpn. J. Appl. Phys. 1992, 31, 1170–1175. [Google Scholar] [CrossRef]

- Sample Availability: All samples are available from the authors.

| Title | Cu | Cd | S | O |

|---|---|---|---|---|

| Intensity (KCps) | 11.0 | 346.3 | 223.3 | 0.1 |

| wt % | 0.385 | 66.7 | 27.5 | 5.46 |

| mol % | 0.335 | 32.965 | 47.74 | 18.957 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, J.; Zhang, T.; Li, Y.; Chen, Y.; Liu, M. Photocatalytic Activities of Copper Doped Cadmium Sulfide Microspheres Prepared by a Facile Ultrasonic Spray-Pyrolysis Method. Molecules 2016, 21, 735. https://doi.org/10.3390/molecules21060735

Su J, Zhang T, Li Y, Chen Y, Liu M. Photocatalytic Activities of Copper Doped Cadmium Sulfide Microspheres Prepared by a Facile Ultrasonic Spray-Pyrolysis Method. Molecules. 2016; 21(6):735. https://doi.org/10.3390/molecules21060735

Chicago/Turabian StyleSu, Jinzhan, Tao Zhang, Yufeng Li, Yubin Chen, and Maochang Liu. 2016. "Photocatalytic Activities of Copper Doped Cadmium Sulfide Microspheres Prepared by a Facile Ultrasonic Spray-Pyrolysis Method" Molecules 21, no. 6: 735. https://doi.org/10.3390/molecules21060735

APA StyleSu, J., Zhang, T., Li, Y., Chen, Y., & Liu, M. (2016). Photocatalytic Activities of Copper Doped Cadmium Sulfide Microspheres Prepared by a Facile Ultrasonic Spray-Pyrolysis Method. Molecules, 21(6), 735. https://doi.org/10.3390/molecules21060735