Use of a Ceramic Membrane to Improve the Performance of Two-Separate-Phase Biocatalytic Membrane Reactor

Abstract

:1. Introduction

2. Results and Discussion

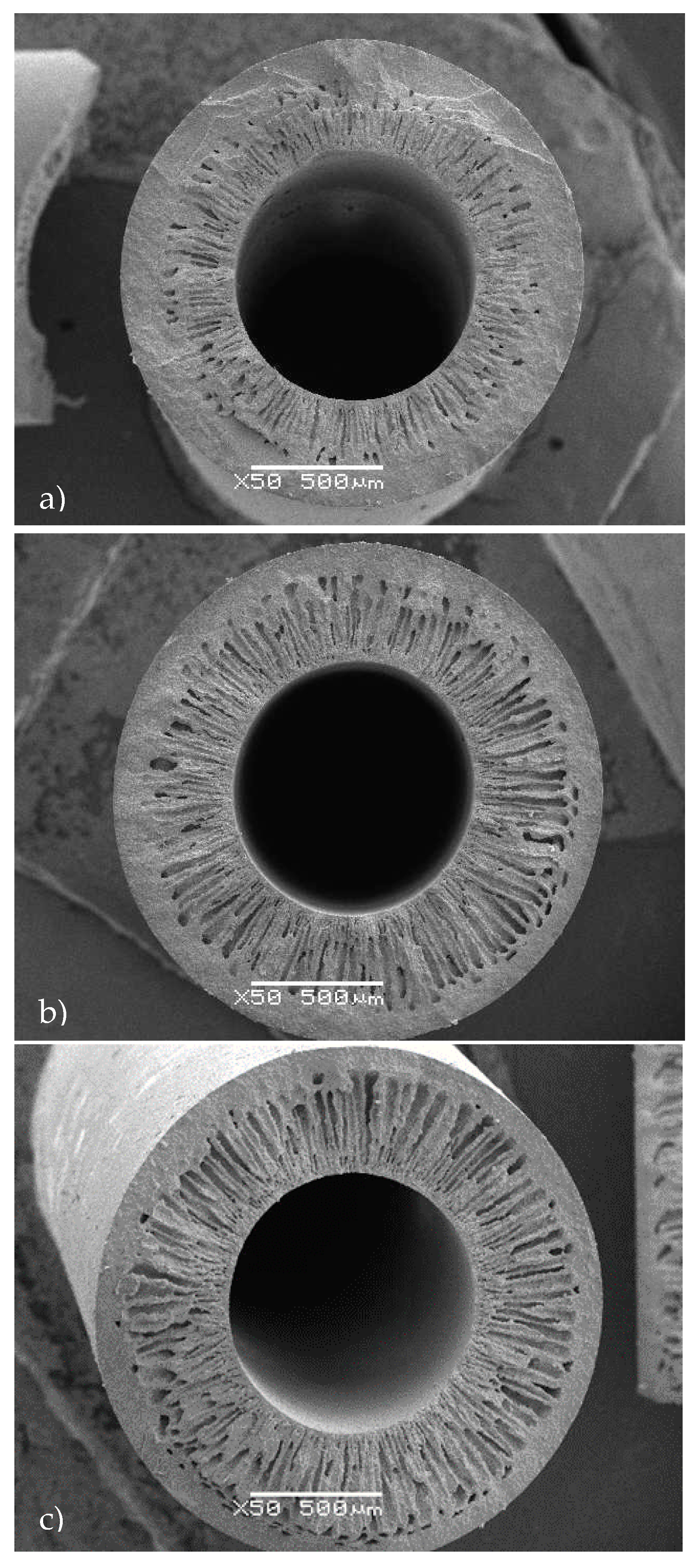

2.1. Alumina Hollow Fiber Membrane Preparation

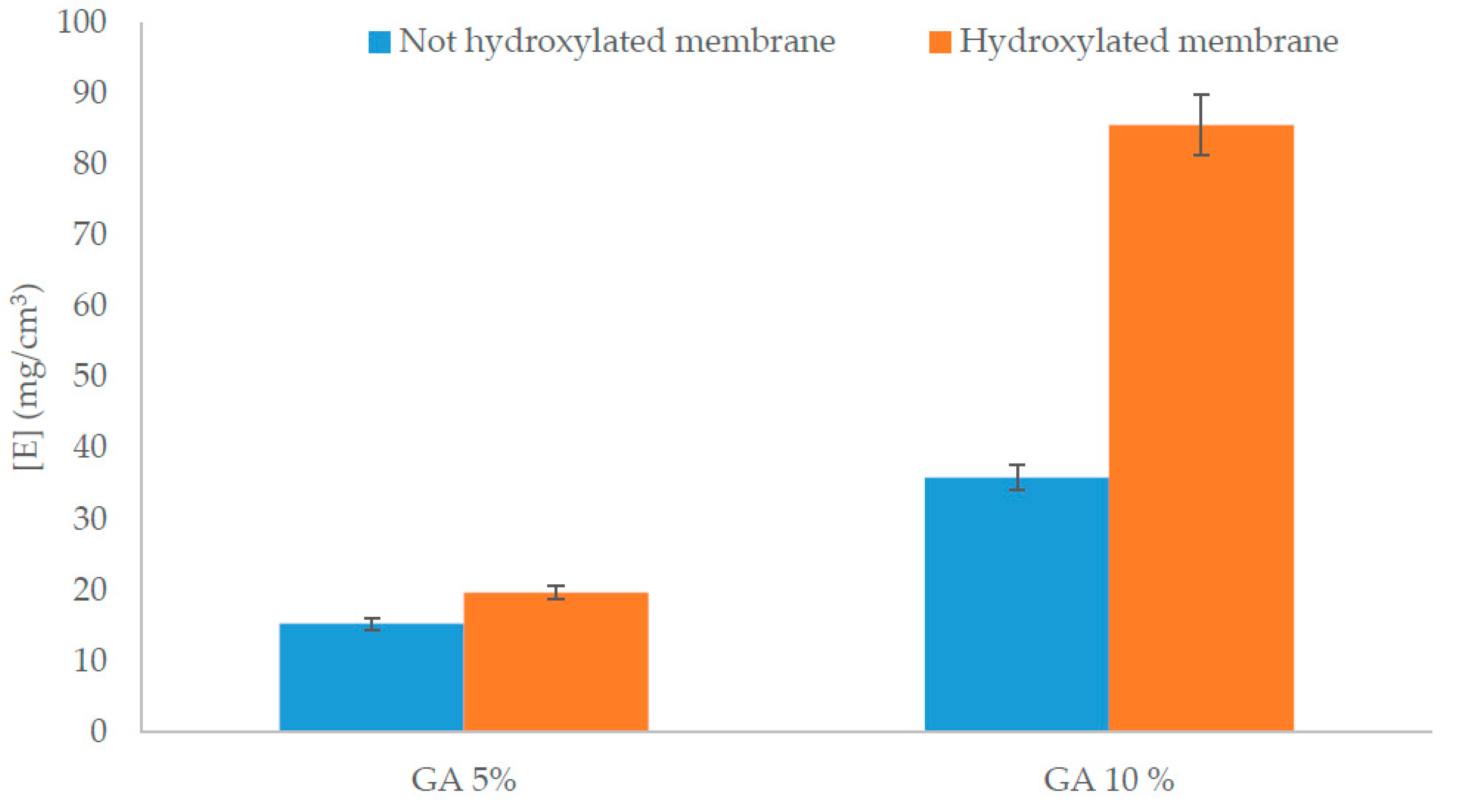

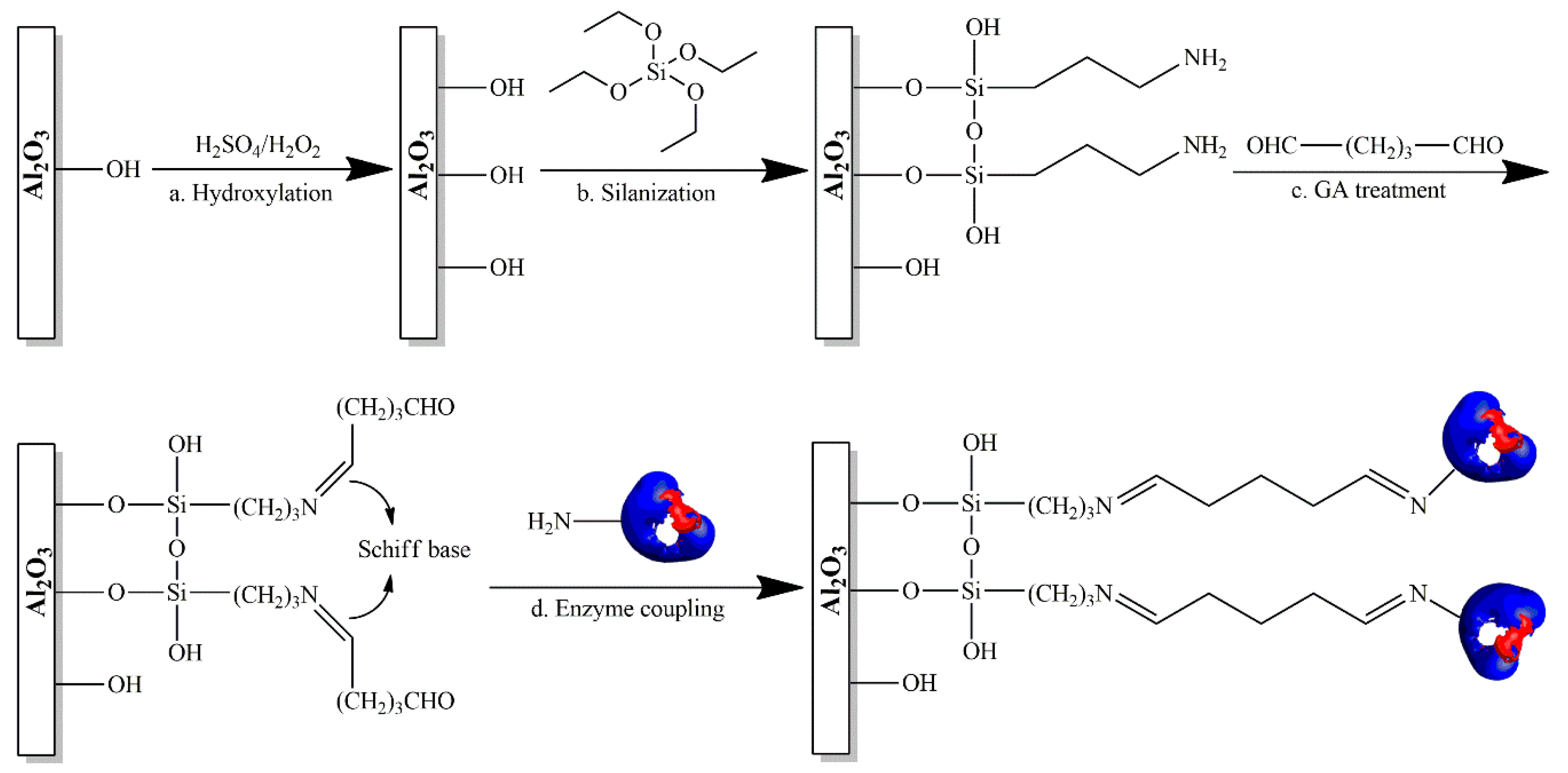

2.2. Membrane Functionalization and Enzyme Immobilization

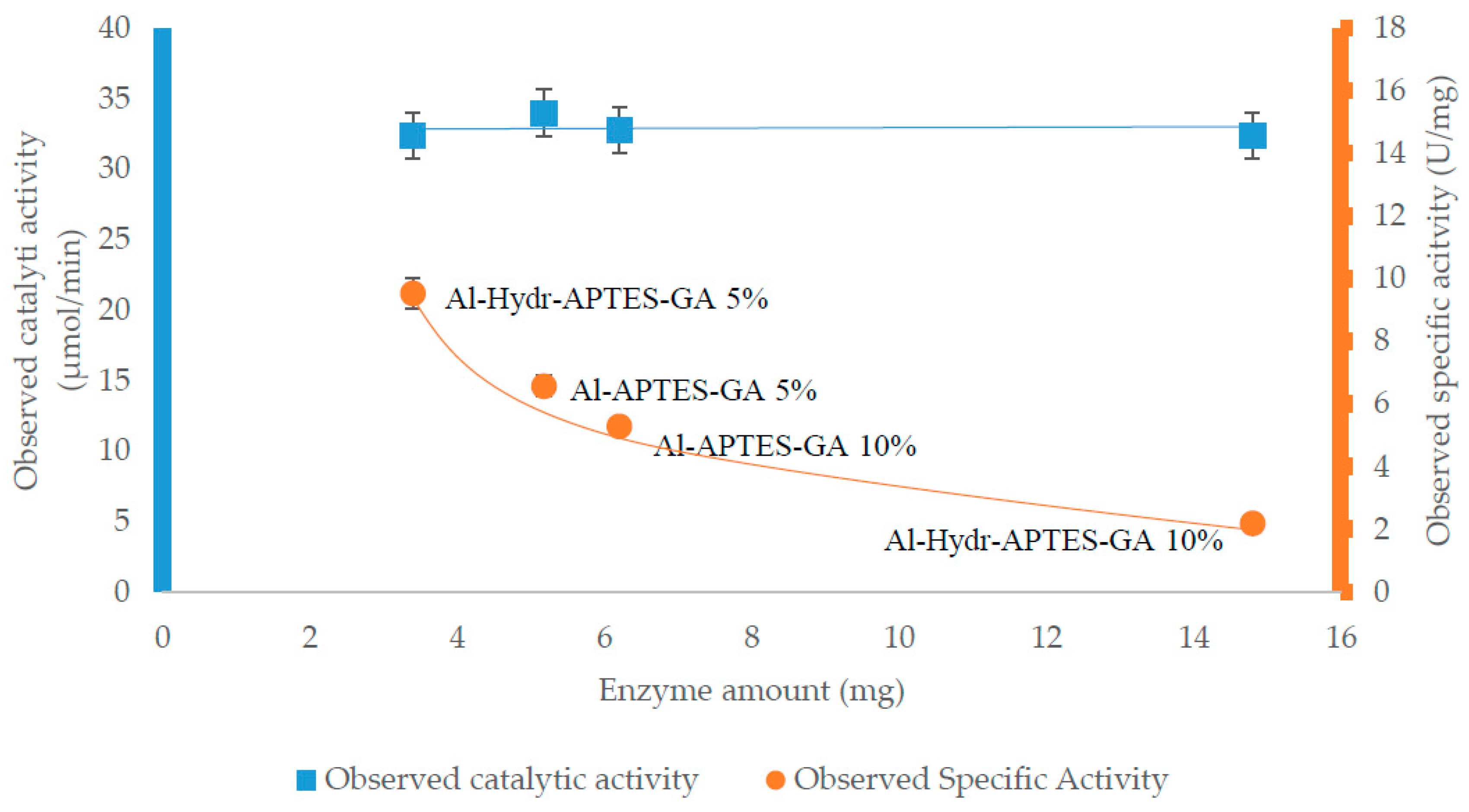

2.3. Lipase Activity Measurements

3. Materials and Methods

3.1. Materials and Chemicals

3.2. Equipment

3.2.1. Alumina Hollow Fiber Membranes Preparation

3.2.2. Surface Activation and Enzymatic Covalent Immobilization

3.2.3. Stirred Tank Reactor (STR) Setup

3.2.4. Two-Separate-Phase Biocatalytic Membrane Reactor (TSP-BMR)

3.3. Operation Mode

3.3.1. Preparation of Alumina Hollow Fiber Membranes

3.3.2. Membrane Functionalization and Enzyme Immobilization

3.3.3. Two-separate-phase Biocatalytic Membrane Reactor (TSP-BMR)

3.3.4. Membrane Cleaning Procedure

3.4. Characterizations

3.4.1. Characterization of Prepared Membranes

3.4.2. Characterization of Grafted Alumina Membranes Surface

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| APTES | (3-Aminopropyl) triethoxysilane |

| GA | Glutaraldehyde |

| TSP-BMR | Two-separate-phase biocatalityc membrane reactor |

| Al-APTES-GA 5% | Non-hydroxylated alumina fibers functionalized with APTES and GA 5% |

| Al-APTES-GA 10% | Non-hydroxylated alumina fibers functionalized with APTES and GA 10% |

| Al-Hydr-APTES-GA 5% | Hydroxylated alumina fibers functionalized with APTES and GA 5% |

| Al-Hydr-APTES-GA 10% | Hydroxylated alumina fibers functionalized with APTES and GA 10% |

| STR | Stirred tank reactor |

References

- Lu, G.Q.; Diniz da Costa, J.C.; Duke, M.; Giessler, S.; Socolow, R.; Williams, R.H.; Kreutz, T. Inorganic membranes for hydrogen production and purification: A critical review and perspective. J. Colloid Interface Sci. 2007, 314, 589–603. [Google Scholar] [CrossRef] [PubMed]

- Armor, J.N. Applications of catalytic inorganic membrane reactors to refinery products. J. Membr. Sci. 1998, 147, 217–233. [Google Scholar] [CrossRef]

- Gbenedio, E.; Wu, Z.; Hatim, I.; Kingsbury, B.F.K.; Li, K. A multifunctional Pd/alumina hollow fibre membrane reactor for propane dehydrogenation. Catal. Today 2010, 156, 93–99. [Google Scholar] [CrossRef]

- Weber, R.; Chmiel, H.; Mavrov, V. Characteristics and application of new ceramic nanofiltration membranes. Desalination 2003, 157, 113–125. [Google Scholar] [CrossRef]

- Neomagus, H.W.J.; Saracco, G.; Wessel, H.F.; Versteeg, G. The catalytic combustion of natural gas in a membrane reactor with separate feed of reactants. Chem. Eng. J. 2000, 77, 165–177. [Google Scholar] [CrossRef]

- Koonaphapdeelert, S.; Li, K. The development of ceramic hollow fibre membranes for a membrane contactor. Desalination 2006, 200, 581–583. [Google Scholar] [CrossRef]

- Wang, Z.-H.; Jin, G. Covalent immobilization of proteins for the biosensor based on imaging ellipsometry. J. Immunol. Methods 2004, 285, 237–243. [Google Scholar] [CrossRef] [PubMed]

- Magnan, E. Immobilization of lipase on a ceramic membrane: Activity and stability. J. Membr. Sci. 2004, 241, 161–166. [Google Scholar] [CrossRef]

- Lozano, P. Active membranes coated with immobilized Candida antarctica lipase B: Preparation and application for continuous butyl butyrate synthesis in organic media. J. Membr. Sci. 2002, 201, 55–64. [Google Scholar] [CrossRef]

- Van Gestel, T. Corrosion properties of alumina and titania NF membranes. J. Membr. Sci. 2003, 214, 21–29. [Google Scholar] [CrossRef]

- Wessely, L.; Samhaber, W.M. Separation Performance of Polymer Membranes for Organic Solvent Mixtures. Chem. Eng. Trans. 2013, 32, 1815–1890. [Google Scholar] [CrossRef]

- Penha, F.M.; Razzadori, K.; Proner, M.C.; Zanatta, V.; Zin, G.; Tondo, D.W.; de Oliveira, J.V.; Petrus, J.C.C.; di Luccio, M. Influence of different solvent and time of pre-treatment on commercial polymeric ultrafiltration membranes applied to non-aqueous solvent permeation. Eur. Polym. J. 2015, 66, 492–501. [Google Scholar] [CrossRef]

- Kingsbury, B.F.K.; Li, K. A morphological study of ceramic hollow fibre membranes. J. Membr. Sci. 2009, 328, 134–140. [Google Scholar] [CrossRef]

- Jochems, P.; Satyawali, Y.; Diels, L.; Dejonghe, W. Enzyme immobilization on/in polymeric membranes: Status, challenges and perspectives in biocatalytic membrane reactors (BMRs). Green Chem. 2011, 13, 1609. [Google Scholar] [CrossRef]

- Tanvir, S.; Morandat, S.; Frederic, N.; Adenier, H.; Pulvin, S. Activity of immobilised rat hepatic microsomal CYP2E1 using alumina membrane as a support. New Biotechnol. 2009, 26, 222–228. [Google Scholar] [CrossRef] [PubMed]

- Milka, P.; Krest, I.; Keusgen, M. Immobilization of alliinase on porous aluminum oxide. Biotechnol. Bioeng. 2000, 69, 344–348. [Google Scholar] [CrossRef]

- Tanvir, S.; Pantigny, J.; Boulnois, P.; Pulvin, S. Covalent immobilization of recombinant human cytochrome CYP2E1 and glucose-6-phosphate dehydrogenase in alumina membrane for drug screening applications. J. Membr. Sci. 2009, 329, 85–90. [Google Scholar] [CrossRef]

- Aissaoui, N.; Landoulsi, J.; Bergaoui, L.; Boujday, S.; Lambert, J.-F. Catalytic activity and thermostability of enzymes immobilized on silanized surface: Influence of the crosslinking agent. Enzym. Microb. Technol. 2013, 52, 336–343. [Google Scholar] [CrossRef] [PubMed]

- Hou, J.; Dong, G.; Ye, Y.; Chen, V. Laccase immobilization on titania nanoparticles and titania-functionalized membranes. J. Membr. Sci. 2014, 452, 229–240. [Google Scholar] [CrossRef]

- Yang, Z.; Si, S.; Dai, H.; Zhang, C. Piezoelectric urea biosensor based on immobilization of urease onto nanoporous alumina membranes. Biosens. Bioelectron. 2007, 22, 3283–3287. [Google Scholar] [CrossRef] [PubMed]

- Kjellander, M.; Mazari, A.M.A.; Boman, M.; Mannervik, B.; Johansson, G. Glutathione transferases immobilized on nanoporous alumina: Flow system kinetics, screening, and stability. Anal. Biochem. 2014, 446, 59–63. [Google Scholar] [CrossRef] [PubMed]

- Giorno, L.; Molinari, R.; Natoli, M.; Drioli, E. Hydrolysis and regioselective transesterification catalyzed by immobilized lipases in membrane bioreactors. J. Membr. Sci. 1997, 125, 177–187. [Google Scholar] [CrossRef]

- Prazeres, D.M.F.; Cabral, J.M.S. Enzymatic membrane bioreactors and their applications. Enzym. Microb. Technol. 1994, 16, 738–750. [Google Scholar] [CrossRef]

- Miletić, N.; Fahriansyah; Nguyen, L.-T.T.; Loos, K. Formation, topography and reactivity of Candida antarctica lipase B immobilized on silicon surface. Biocatal. Biotransform. 2010, 28, 357–369. [Google Scholar] [CrossRef]

- Monsan, P. Optimization of glutaraldehyde activation of a support for enzyme immobilization. J. Mol. Catal. 1978, 3, 371–384. [Google Scholar] [CrossRef]

- Migneault, I.; Dartiguenave, C.; Bertrand, M.J.; Waldron, K.C. Glutaraldehyde: Behavior in aqueous solution, reaction with proteins, and application to enzyme crosslinking. Biotechniques 2004, 37, 790–802. [Google Scholar] [PubMed]

- Barbosa, O.; Ortiz, C.; Berenguer-Murcia, Á.; Torres, R.; Rodrigues, R.C.; Fernandez-Lafuente, R. Glutaraldehyde in bio-catalysts design: A useful crosslinker and a versatile tool in enzyme immobilization. RSC Adv. 2014, 4. [Google Scholar] [CrossRef]

- Giorno, L.; Drioli, E. Catalytic behaviour of lipase free and immobilized in biphasic membrane reactor with different low water-soluble substrates. J. Chem. Technol. Biotechnol. 1997, 69, 11–14. [Google Scholar] [CrossRef]

- Kaiser, E.; Colescott, R.L.; Bossinger, C.D.; Cook, P.I. Color test for detection of free terminal amino groups in the solid-phase synthesis of peptides. Anal. Biochem. 1970, 34, 595–598. [Google Scholar] [CrossRef]

- Sarin, V.K.; Kent, S.B.H.; Tam, J.P.; Merrifield, R.B. Quantitative monitoring of solid-phase peptide synthesis by the ninhydrin reaction. Anal. Biochem. 1981, 117, 147–157. [Google Scholar] [CrossRef]

- Poli, E.; Chaleix, V.; Damia, C.; Hjezi, Z.; Champion, E.; Sol, V. Efficient quantification of primary amine functions grafted onto apatite ceramics by using two UV-Vis spectrophotometric methods. Anal. Methods 2014, 6, 9622–9627. [Google Scholar] [CrossRef]

- Sample Availability: Not available.

| Immobilized Protein | Catalyzed Reaction | Inorganic Material Support | Ref. |

|---|---|---|---|

| Candida antarctica lipase B | Hydrolysis of p-nitrophenyl palmitate | Alumina | [9] |

| Rat hepatic microsomal CYP2E1 | Para-nitrophenol hydroxylation | Alumina | [15] |

| Alliinase | Conversion of alliin in alliicin | Alumina | [16] |

| Glucose-6-phosphate dehydrogenase | Oxidation of Glucose-6 phosphate (G6P) | Alumina | [17] |

| Silica | [18] | ||

| Laccase | Oxidation of 2,2′-azino-bis-(3 ethylbenzothiazoline-6-sulfonic acid) | Titania | [19] |

| Urease | Urea hydroxylation | Alumina | [20] |

| Glutathione transferase | Glutathione conjugation to 1-chloro-2,4-dinitrobenzene | Alumina | [21] |

| Biocatalytic Membrane Reactor | Membrane Void Volume (cm3) |

|---|---|

| Al-APTES-GA 5% | 0.34 (±0.06) |

| Al-APTES-GA 10% | 0.17 (±0.03) |

| Al-Hydr-APTES-GA 5% | 0.19 (±0.03) |

| Al-Hydr-APTES-GA 10% | 0.16 (±0.02) |

| Biocatalytic Membrane Reactors | Volumetric Reaction Rate (mmol/dm3h) | |

|---|---|---|

| Free Lipase | Immobilized Lipase | |

| In a previous work with Polyamide membranes [28] | 6.95 (±0.61) | 0.044 (±0.008) |

| In the present work with Alumina membranes | 12.4 (±0.62) | 7.2 (±0.36) |

| Sample No | Internal Coagulant Flow Rate | Polymer:Powder Ratio | Air Gap | Spinning Suspension Flow Rate | Sintering Temperature |

|---|---|---|---|---|---|

| 1 | 5 mL·min−1 | 1:10 | 150 mm | 7 mL·min−1 | 1350 °C |

| 2 | 10 mL·min−1 | ||||

| 3 | 20 mL·min−1 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ranieri, G.; Mazzei, R.; Wu, Z.; Li, K.; Giorno, L. Use of a Ceramic Membrane to Improve the Performance of Two-Separate-Phase Biocatalytic Membrane Reactor. Molecules 2016, 21, 345. https://doi.org/10.3390/molecules21030345

Ranieri G, Mazzei R, Wu Z, Li K, Giorno L. Use of a Ceramic Membrane to Improve the Performance of Two-Separate-Phase Biocatalytic Membrane Reactor. Molecules. 2016; 21(3):345. https://doi.org/10.3390/molecules21030345

Chicago/Turabian StyleRanieri, Giuseppe, Rosalinda Mazzei, Zhentao Wu, Kang Li, and Lidietta Giorno. 2016. "Use of a Ceramic Membrane to Improve the Performance of Two-Separate-Phase Biocatalytic Membrane Reactor" Molecules 21, no. 3: 345. https://doi.org/10.3390/molecules21030345