Using Exergy to Correlate Energy Research Investments and Efficiencies: Concept and Case Studies

Abstract

:1. Introduction

2. Background

2.1. Exergy

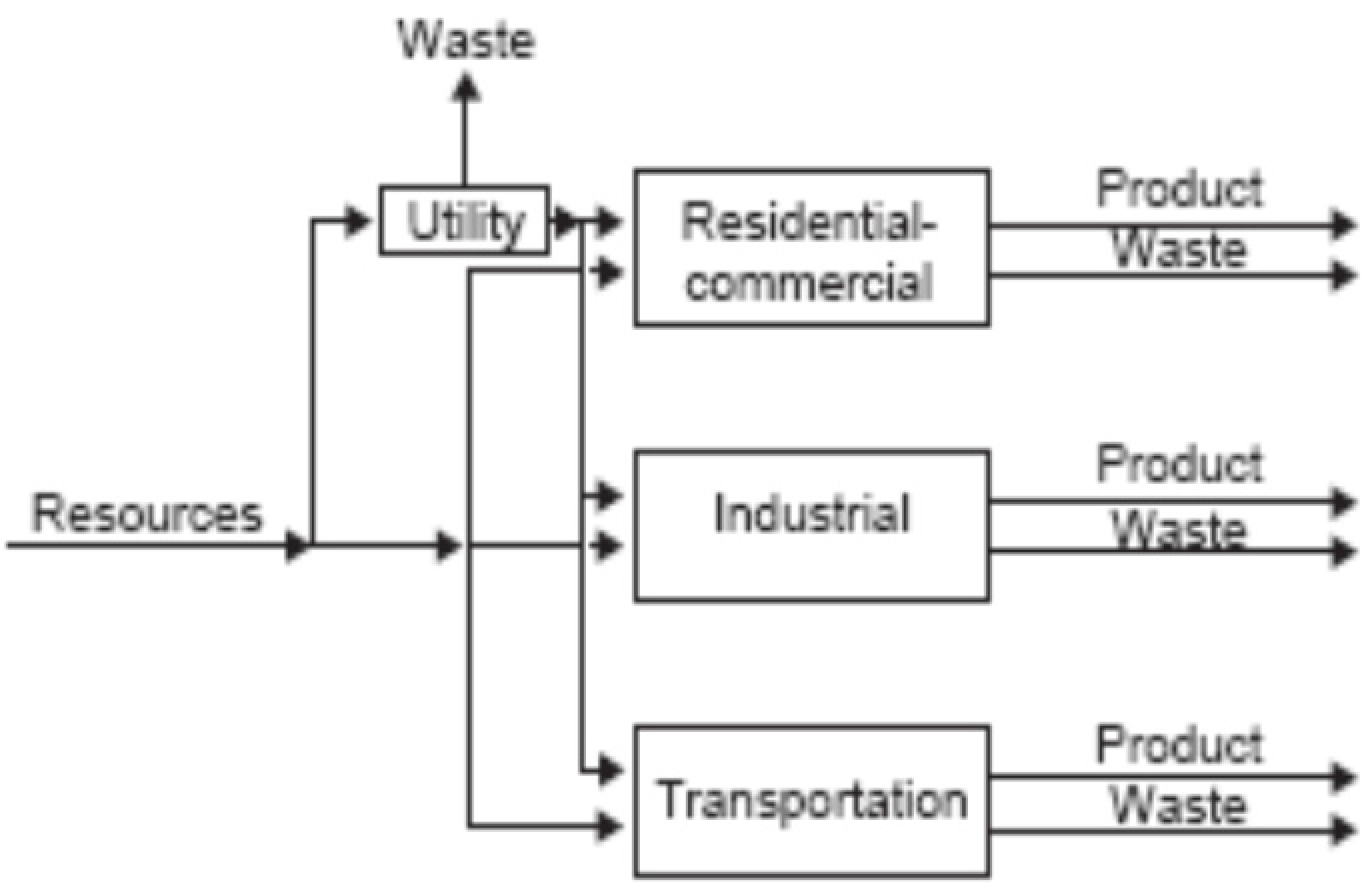

2.2. Exergy Analysis of Regions and Countries

2.2.1. Regional and National Applications of Exergy Analysis

- Industrial: Exergy was utilized to assess energy and materials processing in industry and to compare industries [46]. Assessments have been undertaken of exergy use in industrial processes using artificial intelligence [47] and the effect of reference-state temperatures on exergy assessments of industrial sectors [48]. Wall [49] has examined energy and exergy flows in industrial processes. The industrial sectors of several countries have been investigated using exergy, including Turkey [50,51] and South Africa [52]. The global industrial sector has also been examined with exergy methods [43].

- Agricultural: Energy and exergy utilization in the agricultural sector of Saudi Arabia has been investigated [53].

- Residential and commercial: Genetic algorithms for estimating exergy inputs and outputs have been reported [54], as have investigations of the effect of the reference state on efficiencies for the residential and commercial sectors [55]. Residential sectors have been investigated using exergy for several countries, including Jordan [56], Turkey [57,58,59,60], with the latter investigation including a thermoeconomic analysis, and Malaysia [61,62], with the latter including an assessment of the commercial sector.

- Public and private: Energy and exergy use in the public and private sector of Saudi Arabia has been assessed [72].

- Exergy analysis indicates a less efficient picture of energy flow through the country's economy than does energy analysis.

- The residential-commercial sector shows the most variation of all the sectors, depending on whether an energy or exergy analysis is considered. This is due to the extent to which high-grade energy sources are utilized for low-grade energy demands.

- The most significant efficiency differences between energy and exergy analyses are caused by thermal processes (heating and cooling).

- Several aspects of this research could yield important industrial and socio-economic benefits. Specifically, using the results of the present research rather than the results of the energy balances conventionally used today, the author feels that the efficiency of national and regional energy utilization is more clearly illuminated, and more rational assessments are obtained of how R&D effort related to energy systems is presently allocated and could be made in the future. Consequently, the results could provide important guidelines and insights, to both energy industries and governments, for developing the most appropriate energy systems and making energy R&D investments.

| Sector | Energy Efficiency, η (%) | Exergy Efficiency, ψ (%) | ||||||

| Ontario | Canada | Turkey | Saudi Arabia | Ontario | Canada | Turkey | Saudi Arabia | |

| Residential-commercial | 70 | 72 | 69 | 81 | 21 | 14 | 12 | 10 |

| Transportation | 18 | 19 | 22 | 22 | 18 | 19 | 22 | 22 |

| Industrial | 65 | 73 | 68 | 63 | 45 | 42 | 42 | 40 |

| Utility | 39 | 53 | 45 | 32 | 39 | 53 | 45 | 32 |

| Overall | 43 | 51 | 42 | 60 | 24 | 24 | 26 | 39 |

2.2.2. Details on Methodology for Exergy Analysis of Regions and Countries

2.2.2.1 Efficiencies for Processes in Regions and Countries

- Work production: Electric and fossil-fuel work production processes produce shaft work W. The energy and exergy efficiencies for shaft work production from electricity We are both η = ψ = W/We, while the energy and exergy efficiencies for shaft work production from fuel are both η = ψ = W/mfHf. Here, mf denotes the mass of fuel and Hf the energy content of fuel in terms of its heating value (usually higher).

- Electricity generation: The efficiencies for the generation of electricity We from fuel are both η = ψ = W/mfHf.

- Heating: Electric and fossil fuel heating processes are taken to generate product heat Qp at a constant temperature Tp, either from electrical energy We or fuel mass mf. The energy efficiency for electrical heating is η = Qp/We and the exergy efficiency is ψ = Qp(1 – To/Tp)/We, where To denotes the reference-environment temperature. For fuel heating, the energy efficiency is η = Qp/mfHf and the exergy efficiency is ψ = Qp(1 – To /Tp)/mfHf.

- Cooling: Electric cooling removes heat Qp at a constant temperature Tp using electrical energy We. The energy efficiency for electric cooling is η = We/Qp and the exergy efficiency is ψ = Qp(1 – To/Tp)/We. Analogous efficiencies can be determined for thermally driven cooling using absorption chillers.

- Kinetic energy production: The efficiencies for the fossil fuel-driven kinetic energy production processes, which occur in mainly in the transportation sector and which produce a change in kinetic energy Δke in a stream of matter ms, are both η = ψ = msΔke/mfHf.

2.2.2.2. Energy and Exergy Values for Commodities in Regions and Countries

| Energy Commodity | Exergy-Energy Ratio |

|---|---|

| Shaft work | 1 |

| Electricity | 1 |

| Steam at 600°C | 0.6 |

| Water at 90°C | 0.2 |

| Heat at the reference-environment temperature, To | 0 |

| Chemical energy for most hydrocarbon fuels | 0.85-1.1 |

2.2.2.3. Reference Environment for Regions and Countries

2.3. Assessment of Links between Exergy and Research Funding in Countries and Regions

3. Methodology

- determination of energy and exergy losses for the country or region and for each of its sectors;

- acquisition of up-to-date data on sector and overall allocations of energy R&D in the country or region (i.e., the quantity of money allocated and the types of projects related to energy R&D); and

- comparison of energy and exergy loss values to R&D allocations for each energy sector, along with interpretation of the results and development of appropriate conclusions.

- acquisition of data on energy utilization in the country or region (i.e., the quantities and types of energy flowing into and out of the various sectors of the country or region);

- evaluation of the exergy values associated with each of the energy flows, so that an understanding of exergy utilization in country or region can be obtained; and

- determination of energy and exergy efficiencies for each of the sectors as well as the overall country or region.

4. Case Studies

4.1. Case Study for Ontario, Canada

4.1.1. R&D Funding Data

- The requirements for Enersearch funding for a project are broad enough to encompass energy-related projects in all sectors. The Ontario Ministry of Energy [78] stipulated that Enersearch projects are required to be directed toward such goals as:

- ○

- Reducing energy demand through the application of innovative technology to achieve efficient utilization of existing energy sources.

- ○

- Developing innovative technology to gain additional supplies from alternative and renewable sources.

- ○

- Developing the equipment and capabilities required to utilize these new energy forms.

- ○

- Encouraging replication and use of new energy processes and innovative technologies among potential users.

- The range of activities to which Enersearch applies is broad, and include [78]:

- ○

- Research and laboratory testing (proving scientific concepts).

- ○

- Equipment development and testing (proving engineering processes and equipment).

- ○

- Pilot plant equipment.

- ○

- Full-scale field trials and technical demonstrations of innovative technologies to determine system performance, reliability and economics.

- ○

- Initial demonstrations of existing technologies used outside Canada to determine their suitability for application in Ontario.

- ○

- Technology and information transfer of results obtained during research, development and demonstration activities.

- The program applies to a broad range of energy technologies, including [78]:

- ○

- Fuel research and evaluation.

- ○

- Transportation equipment.

- ○

- Bio-energy conversion.

- ○

- Electro-technologies.

- ○

- Energy production from waste and biomass.

- ○

- Residential, industrial and commercial building technologies.

- ○

- Energy-efficient industrial processes.

- ○

- Heat recovery and recuperation.

- ○

- Hydrogen technology.

- ○

- Renewable energy systems.

- A wide variety of organizations can apply for funding under this program, including [78]:

- ○

- Energy equipment manufacturers and suppliers.

- ○

- Industrial and commercial energy users and producer.

- ○

- Consulting firms.

- ○

- Industrial and research organizations (but excluding electric utilities and publicly funded institutions except when they are in support of private sector proponents).

- Enersearch participated in over sixty projects totalling $27 million between 1986 and 1989, making it the largest government energy R&D program for Ontario.

- The projects undertaken in this program by the participants received an average total government contribution of 33% of their projected eligible net cost. With this substantial yet limited government contribution to the project, the participants incur a large portion of the R&D costs thus projects are typically well planned and thought out. Further, the projects thus directly account for private-sector R&D expenditures as well as those by government.

4.1.2. Energy and Exergy Data

4.1.3. Analysis

4.1.4. Results and Discussion

4.1.4.1. Energy Research and Development Budget Allocations

| Sector | Total project costs ($) | Breakdown of budget allocation (%) |

|---|---|---|

| Residential | 3,278,524 | 7 |

| Commercial | 1,133,101 | 2 |

| Industrial | 24,793,117 | 54 |

| Transportation | 6,806,834 | 15 |

| Utility | 10,008,471 | 22 |

| Overall | 46,020,047 | 100 |

4.1.4.2. Sector Inefficiencies

| Sector | Breakdown of Overall Inefficiencies | Breakdown of Total Energy R&D Budget Allocations (%) | |

| Portion of perceived inefficiency attributable to sector (%) | Portion of actual inefficiency attributable to sector (%) | ||

| Residential-commercial | 12 | 24 | 9 |

| Industrial | 21 | 25 | 54 |

| Transportation | 27 | 20 | 15 |

| Utility | 40 | 31 | 22 |

| Overall | 100 | 100 | 100 |

4.1.4.3. Relation between Energy Sector R&D Funding and Inefficiencies

- Actual inefficiencies are higher than the perceived inefficiencies in the residential-commercial sector and the industrial sector. For the transportation and utility sectors, the actual inefficiencies are lower than the perceived inefficiencies.

- A relationship is observed between perceived inefficiency and R&D allocations, in that energy R&D budget allocation increases as sector perceived inefficiency increases for all sectors in Ontario (except the industrial sector).

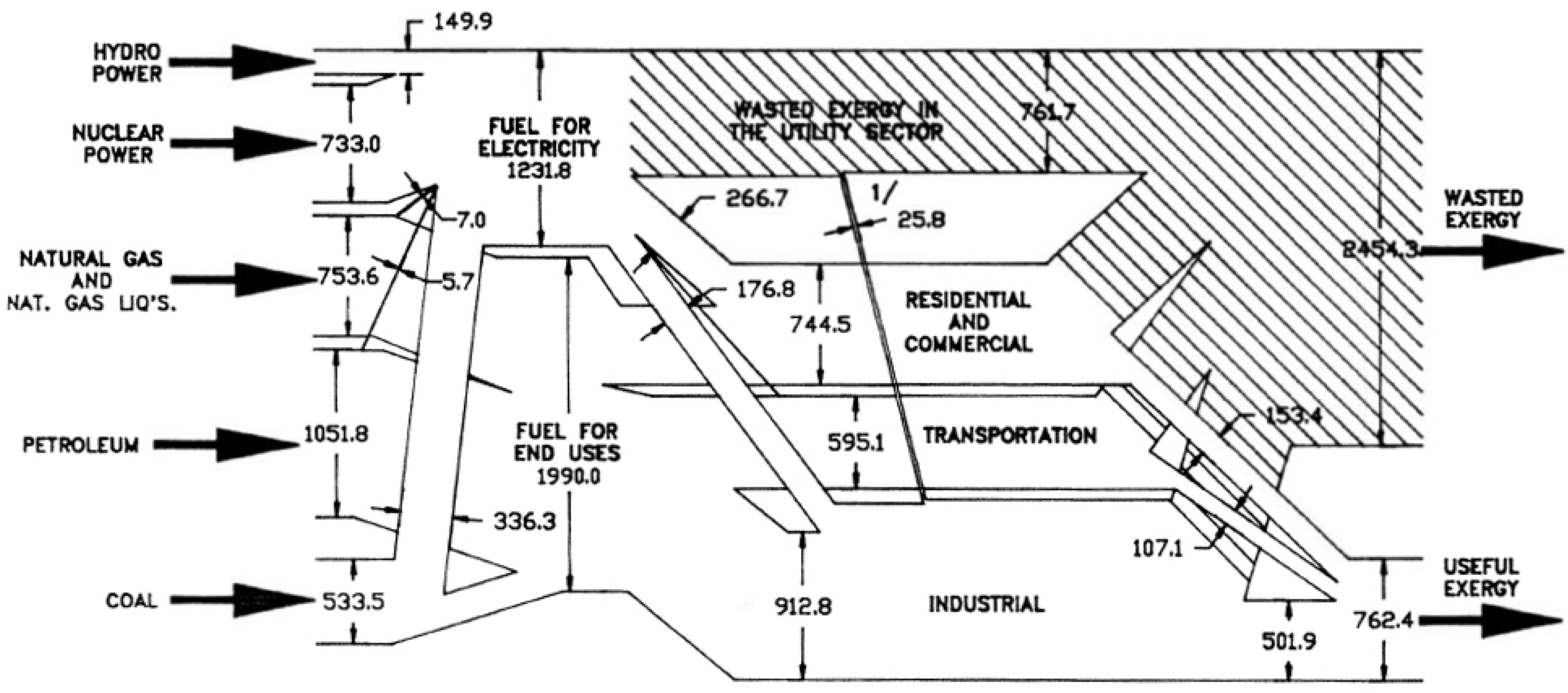

4.2. Case Study for the United States

4.2.1. Data and Analysis

4.2.2. Results and Discussion

- The utility sector receives the second largest budget allocation of any sector and yet has the least losses on an exergy basis while, on an energy basis, it is second only to the transportation sector as having the most losses.

| Sector | Breakdown of Overall Inefficiencies | Breakdown of Total Energy R&D Budget Allocations (%) | ||

|---|---|---|---|---|

| Portion of actual inefficiency attributable to sector (%) | Portion of perceived inefficiency attributable to sector (%) | |||

| Residential-commercial | 30 | 20 | 20 | |

| Industrial | 32 | 15 | 18 | |

| Transportation | 24 | 40 | 34 | |

| Utility | 14 | 25 | 28 | |

| Overall | 100 | 100 | 100 | |

4.3. Comparison of Case Studies and Generalizations

- The fact that the Enersearch program operates on a two-thirds, one-third funding policy (i.e., 2/3 of the cost of a project is incurred by the participant and 1/3 by the Ministry of Energy) results in participants primarily from industry, and thus may skew energy R&D budget allocations. Approximately 46 of the 55 projects are directly related to specific industrial processes, 19 of which are completely disassociated with any other sector (see Appendix C of [76]).

- Electric utilities and publicly funded institutions (e.g., universities, electrical utilities) are not eligible for funding, except in support of private sector proponents. This restriction significantly reduces the number of publicly funded organizations in the program. For instance, only 2 of the 55 projects involve universities. If universities participated more, one would likely see different energy R&D budget allocations to the sectors, and, in particular, less funding to the industrial sector.

- The documentation on the Enersearch program provided by the Ontario Ministry of Energy does not indicate funding amounts on a sector basis. Thus, since the authors had to subjectively estimate the separation of projects into sectors, inaccuracies may have been introduced.

- The large variation in project costs in comparison to the overall budget may also skew the results. For example, it can be seen in Appendix C of Ref. Lemieux that the actual total project costs in the Enersearch program for the period considered are $28,678,131 and the individual project costs range from $23,300 to $6,085,100. This large variation in individual project costs in relation to the total budget results in large variations between energy sector funding and may suppress the trend between perceived inefficiencies and R&D budget allocations.

- The fact that other Ontario government ministries also allocate funding to energy R&D for specific sectors (e.g., the Ministry of Transportation likely allocates money for R&D to the transportation sector) may also skew the results. This skewing may be amplified because the Enersearch program may tend not to fund R&D in a sector if a particular ministry is funding it significantly. Therefore, a sector may in reality be receiving considerably more funding than indicated in Table 3.

- The subset or sample group used in this report to assess R&D funding trends is relatively small. To realize more meaningful statistics, it is important to include as many sources of R&D funding as possible when analysing a system. In particular, confidence in the results would increase if a larger sample size were used, preferably by attaining data on the entire R&D spending in the province.

4.4. Implications for the Present and Future

5. Extensions and Generalizations

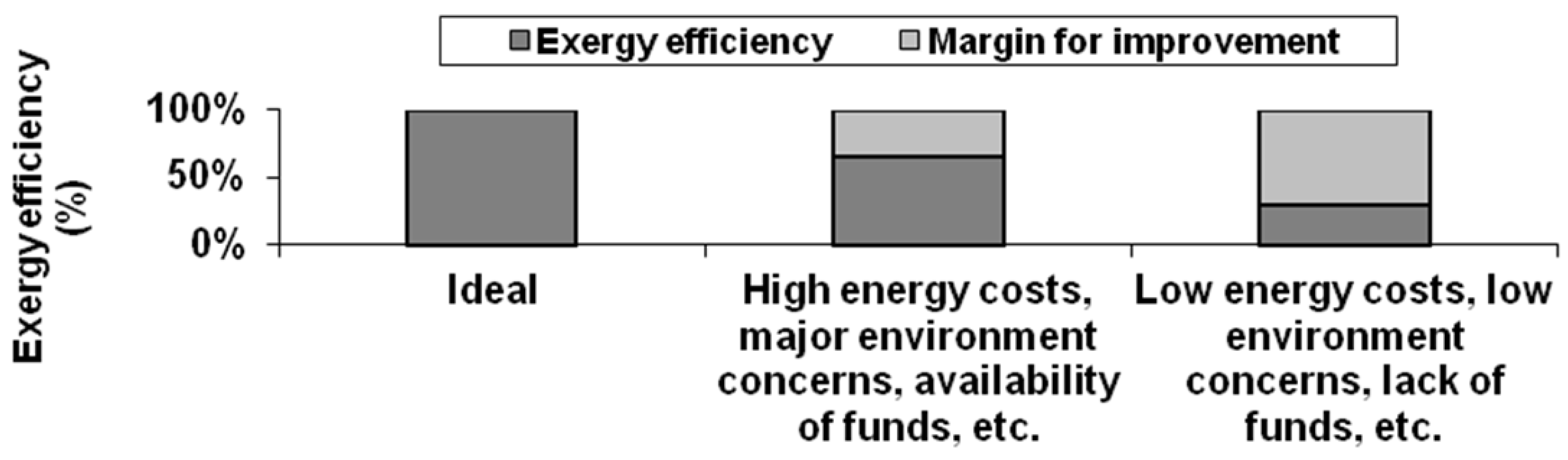

- Countries and regions with lower rather than higher exergy efficiencies have greater margins for efficiency improvement, which are characterized by actual inefficiencies.

- Low exergy efficiencies are usually observed in countries and regions with low energy costs, lack of funding for efficient technologies, lax environmental constraints, lack of awareness of efficient technologies and processes, and lack of a sufficiently educated and skilled workforce. High exergy efficiencies are usually observed in countries and regions with circumstances that foster high efficiency, such as high energy costs, funding availability for efficient technologies, readily available export markets for energy commodities, strict environmental constraints or emissions limitations, etc.

- The ultimate margin for efficiency improvement is seen to be the difference between the ideal exergy efficiency of 100%, which applies to ideal processes or devices, and the actual exergy efficiency. An awareness of this limit helps in establishing realistic targets for efficiency improvement.

- When energy-related factors change, countries and regions tend to respond (or should respond as it is usually in their best interests to do so). For instance, countries and regions tend to introduce measures that lead to increased exergy efficiency when energy costs increase or environmental regulations become stricter.

- An important observation for any region or country related to the above point is that exergy efficiency increases when circumstances warrant improved efficiency, but energy efficiencies do not necessarily increase. Appropriate efficiency targets and energy research efforts and support should be established based on exergy, as confusion and waste can result if efforts to determine appropriate efficiency research and targets are based on energy.

- Although the characteristics of countries with developing economies vary greatly, many less developed countries fall into rightmost category in Figure 4 because for them energy resources are often less affordable (i.e., energy costs are high as a proportion of gross domestic product or average income per capita), obtaining funding for efficient technologies is difficult, and environmental laws are less strict. This behaviour is partly related to the focus of such countries on developing economically and in other ways and/or meeting basic needs.

- Developed or industrialized countries tend to fall into the middle category in Figure 4, since they usually have high energy costs and readily available mechanisms for exporting energy resources, strict environmental restrictions and laws, and funding for efficient energy conversion and utilization technologies. The wealth of such countries often makes them require or expect energy resources to be used efficiently and cleanly.

- In our globalized economy, it is unlikely that a country would have an extremely low exergy efficiency based on market forces, which exist in a similar form for developed or developing regions, because globalization makes it relatively easy to buy and sell energy commodities.

6. Conclusions

Acknowledgments

Nomenclature

| H | heating value |

| ke | specific kinetic energy |

| m | mass |

| P | pressure |

| Q | heat |

| T | temperature |

| W | work |

| We | electrical energy |

Greek Symbols

| η | energy efficiency |

| ψ | exergy efficiency |

Subscripts

| e | electrical |

| f | fuel |

| o | reference-environment state |

| p | product |

| s | stream of matter |

References and Notes

- Energy Balances of Non-OECD Countries, 2004–2005, 2007 Edition ed; International Energy Agency: Paris, France, 2007.

- Energy Balances of OECD Countries, 2004–2005, 2007 Edition ed; International Energy Agency: Paris, France, 2007.

- Rosen, M.A. Evaluation of energy utilization efficiency in Canada using energy and exergy analyses. Energy 1992, 17, 339–350. [Google Scholar] [CrossRef]

- Rosen, M.A. Energy utilization efficiency in a macrosystem (Ontario): Evaluation and improvement through cogeneration. In Proceedings of the International Symposium on CO2 Fixation and Efficient Utilization of Energy, Tokyo, Japan; 1993; pp. 17–26. [Google Scholar]

- Dincer, I.; Rosen, M.A. Exergy.: Energy, Environment and Sustainable Development, 2nd ed.; Elsevier: Oxford, UK, 2013. [Google Scholar]

- Moran, M.J.; Shapiro, H.N.; Boettner, D.D.; Bailey, M.B. Fundamentals of Engineering Thermodynamics, 7th ed.; Wiley: New York, NY, USA, 2011. [Google Scholar]

- Bryant, J. A thermodynamic theory of economics. Int.J. Exergy. 2007, 4, 302–337. [Google Scholar] [CrossRef]

- Gogus, Y.A. Thermoeconomic optimization. Int.J. Exergy Res. 2005, 29, 559–580. [Google Scholar] [CrossRef]

- Tsatsaronis, G. A review of exergoeconomic methodologies. In Second Law Analysis of Thermal Systems; American Society of Mechanical Engineers: New York, NY, USA, 1987; pp. 81–87. [Google Scholar]

- Kotas, T.J. The Exergy. Method of Thermal Plant. Analysis, reprint ed.; Krieger: Malabar, FL, USA, 1995. [Google Scholar]

- Yantovskii, E.I. Energy and Exergy. In Currents: An Introduction to Exergonomics; Nova Science Publishers: New York, NY, USA, 1994. [Google Scholar]

- El-Sayed, Y. The Thermoeconomics of Energy Conversion; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Sciubba, E. Exergo-economics: Thermodynamic foundation for a more rational resource use. Int. J. Energy Res. 2005, 29, 613–636. [Google Scholar] [CrossRef]

- Valero, A. Exergy accounting: Capabilities and drawbacks. Energy 2006, 31, 164–180. [Google Scholar] [CrossRef]

- Valero, A.; Serra, L.; Uche, J. Fundamentals of exergy cost accounting and thermoeconomics. Part I: Theory. Trans. ASME: J. Energy Resour. Technol. 2006, 128, 1–8. [Google Scholar] [CrossRef]

- Valero, A.; Serra, L.; Uche, J. Fundamentals of exergy cost accounting and thermoeconomics. Part II: Applications. Trans. ASME: J. Energy Resour. Technol 2006, 128, 9–15. [Google Scholar] [CrossRef]

- Lazzaretto, A.; Tsatsaronis, G. SPECO: A systematic and general methodology for calculating efficiencies and costs in thermal systems. Energy 2006, 31, 1257–1289. [Google Scholar] [CrossRef]

- Reistad, G.M. Available energy conversion and utilization in the United States. J. Eng. Power 1975, 97, 429–434. [Google Scholar] [CrossRef]

- Wall, G. Exergy conversion in the Japanese Society. Energy 1990, 15, 435–444. [Google Scholar] [CrossRef]

- Utlu, Z.; Hepbasli, A. A review on analyzing and evaluating the energy utilization efficiency of countries. Renew. Sust. Energy Rev. 2007, 11, 1–29. [Google Scholar] [CrossRef]

- Ertesvag, I.S. Society exergy analysis: A comparison of different societies. Energy 2001, 26, 253–270. [Google Scholar] [CrossRef]

- Ayres, R.U.; Ayres, L.W.; Warr, B. Exergy, power and work in the US economy, 1900–1998. Energy 2003, 28, 219–273. [Google Scholar] [CrossRef]

- Wall, G. Exergy conversions in the Finnish, Japanese and Swedish societies. In Report EE; Turku School of Economics: Turku, Finland, 1991. [Google Scholar]

- Chen, G.Q.; Qi, Z.H. Systems account of societal exergy utilization: China 2003. Ecol. Modell. 2007, 208, 102–118. [Google Scholar] [CrossRef]

- Chen, B.; Chen, G.Q. Exergy analysis for resource conversion of the Chinese Society 1993 under the material product system. Energy 2006, 31, 1115–1150. [Google Scholar] [CrossRef]

- Chen, B.; Chen, G.Q.; Yang, Z.F. Exergy-based resource accounting for China. Ecol. Modell. 2006, 196, 313–328. [Google Scholar] [CrossRef]

- Hammond, G.P.; Stapleton, A.J. Exergy analysis of the United Kingdom energy system. Proc. Instn. Mech. Engrs. 2001, 215, 141–162. [Google Scholar] [CrossRef]

- Gasparatos, A.; El-Haram, M.; Horner, M. Assessing the sustainability of the UK society using thermodynamic concepts: Part 1. Renew. Sust. Energy Rev. 2009, 13, 1074–1081. [Google Scholar] [CrossRef]

- Gasparatos, A.; El-Haram, M.; Horner, M. Assessing the sustainability of the UK society using thermodynamic concepts: Part 2. Renew. Sust. Energy Rev. 2009, 13, 956–970. [Google Scholar] [CrossRef]

- Warr, B.; Schandl, H.; Ayres, R.U. Long term trends in resource exergy consumption and useful work supplies in the UK, 1900 to 2000. Ecol. Econ. 2008, 68, 126–140. [Google Scholar] [CrossRef]

- Wall, G. Exergy conversion in the Swedish society. Resour. Energy 1987, 9, 55–73. [Google Scholar] [CrossRef]

- Wall, G. Exergy use in the Swedish society 1994. In Proceedings of the International Conference on Thermodynamic Analysis and Improvement of Energy Systems, Beijing, China, 10–13 June 1997; pp. 403–413.

- Ertesvag, I.S.; Mielnik, M. Exergy analysis of the Norwegian society. Energy 2000, 25, 957–973. [Google Scholar] [CrossRef]

- Ertesvag, I.S. Energy, exergy, and extended-exergy analysis of the Norwegian society 2000. Energy 2005, 30, 649–675. [Google Scholar] [CrossRef]

- Ptasinski, K.J.; Koymans, M.N.; Verspagen, H.H.G. Performance of the Dutch energy sector based on energy, exergy and extended exergy accounting. Energy 2006, 31, 3135–3144. [Google Scholar] [CrossRef]

- Wall, G.; Sciubba, E.; Naso, V. Exergy use in the Italian society. Energy 1994, 19, 1267–1274. [Google Scholar] [CrossRef]

- Stepanov, V.S. A method for estimating the energy efficiency of the economy. Energy 1995, 20, 577–583. [Google Scholar] [CrossRef]

- Ozdogan, O.; Arikol, M. Energy and exergy analyses of selected Turkish industries. Energy 1995, 20, 73–80. [Google Scholar] [CrossRef]

- Ileri, A.; Gurer, T. Energy and exergy utilization in Turkey during 1995. Energy 1998, 23, 1099–1106. [Google Scholar] [CrossRef]

- Schaeffer, R.; Wirtshafter, R.M. An exergy analysis of the Brazilian economy: From energy production to final energy use. Energy 1992, 17, 841–855. [Google Scholar] [CrossRef]

- Nakicenovic, N.; Gilli, P.V.; Kurz, R. Regional and global exergy and energy efficiencies. Energy 1996, 21, 223–237. [Google Scholar] [CrossRef]

- Hermann, W.A. Quantifying global exergy resources. Energy 2006, 31, 1685–1702. [Google Scholar] [CrossRef]

- Banerjee, R.; Cong, Y.; Gielen, D.; Jannuzzi, G.; Maréchal, F.; McKane, A.T.; Rosen, M.A.; van Es, D.; Worrell, E. Chapter 8, End-Use Efficiency: Industry. In Global Energy Assessment: Toward a Sustainable Future; Gomez-Echeverri, L., Johansson, T.B., Nakicenovic, N., Patwardhan, A., Eds.; International Institute for Applied Systems Analysis, Vienna, Austria and Cambridge University Press: Cambridge, UK, 2012; pp. 513–573. [Google Scholar]

- Chen, G.Q. Exergy consumption of the earth. Ecol. Modell. 2005, 184, 363–380. [Google Scholar] [CrossRef]

- Rosen, M.A.; Scott, D.S. Entropy production and exergy destruction—Part I: Hierarchy of Earth's major constituencies. Int. J. Hydrogen Energy 2003, 28, 1307–1313. [Google Scholar] [CrossRef]

- Brodyanski, V.M.; Sorin, M.V.; Le Goff, P. The efficiency of industrial processes. In Exergy Analysis and Optimization; Elsevier: London, UK, 1994. [Google Scholar]

- De Jong, E.D.; Keuken, H.; van der Pol, E.; den Dekker, E.; Kerckhoffs, E.J.H. Exergy analysis of industrial processes using AI techniques. Comput. Chem. Engng. 1996, 20 (Suppl.), S1631–S1636. [Google Scholar] [CrossRef]

- Utlu, Z.; Hepbasli, A. Energetic and exergetic assessment of the industrial sector at varying dead (reference) state temperatures: A review with an illustrative example. Renewable Sustainable Energy Rev. 2008, 12, 1277–1301. [Google Scholar] [CrossRef]

- Wall, G. Exergy flows through industrial processes. Energy 1988, 13, 197–208. [Google Scholar] [CrossRef]

- Utlu, Z.; Hepbasli, A. A review and assessment of the energy utilization efficiency in the Turkish industrial sector using energy and exergy analysis method. Renewable Sustainable Energy Rev. 2007, 11, 1438–1459. [Google Scholar] [CrossRef]

- Hepbasli, A.; Ozalp, N. Development of energy efficiency and management implementation in the Turkish industrial sector. Energy Convers. Manage. 2003, 44, 231–249. [Google Scholar] [CrossRef]

- Oladiran, M.T.; Meyer, J.P. Energy and exergy analyses of energy consumptions in the industrial sector in South Africa. Appl. Energy 2007, 84, 1056–1067. [Google Scholar] [CrossRef]

- Dincer, I.; Hussain, M.M.; Al-Zaharnah, I. Energy and exergy utilization in agricultural sector of Saudi Arabia. Energy Policy 2005, 33, 1461–1467. [Google Scholar] [CrossRef]

- Ozturk, H.K.; Canyurt, O.E.; Hepbasli, A.; Utlu, Z. Three different genetic algorithm approaches to the estimation of residential exergy input/output values. Build. Environ. 2004, 39, 807–816. [Google Scholar] [CrossRef]

- Utlu, Z.; Hepbasli, A. Parametrical investigation of the effect of dead (reference) state on energy and exergy utilization efficiencies of residential-commercial sectors: A review and an application. Renewable Sustainable Energy Rev. 2007, 11, 603–634. [Google Scholar] [CrossRef]

- Al-Ghandoor, A.; Al-Hinti, I.; Akash, B.; Abu-Nada, E. Analysis of energy and exergy use in the Jordanian urban residential sector. Int. J. Exergy 2008, 5, 413–428. [Google Scholar] [CrossRef]

- Utlu, Z.; Hepbasli, A. A study on the evaluation of energy utilization efficiency in the Turkish residential-commercial sector using energy and exergy analyses. Energy Build. 2003, 35, 1145–1153. [Google Scholar] [CrossRef]

- Utlu, Z.; Hepbasli, A. Analysis of energy and exergy use of the Turkish residential-commercial sector. Build. Environ. 2005, 40, 641–655. [Google Scholar] [CrossRef]

- Utlu, Z.; Hepbasli, A. Estimating the energy and exergy utilization efficiencies for the residential-commercial sector: An application. Energy Policy 2006, 34, 1097–1105. [Google Scholar] [CrossRef]

- Utlu, Z.; Hepbasli, A. Thermoeconomic analysis of energy utilization in the residential-commercial sector: An application. Build. Environ. 2008, 43, 896–904. [Google Scholar] [CrossRef]

- Saidur, R.; Masjuki, H.H.; Jamaluddin, M.Y. An application of energy and exergy analysis in residential sector of Malaysia. Energy Policy 2007, 35, 1050–1063. [Google Scholar] [CrossRef]

- Saidur, R.; Sattar, M.A.; Masjuki, H.H.; Abdessalam, H.; Shahruan, B.S. Energy and exergy analysis at the utility and commercial sectors of Malaysia. Energy Policy 2007, 35, 1956–1966. [Google Scholar] [CrossRef]

- Utlu, Z.; Hepbasli, A. Assessment of the Turkish utility sector through energy and exergy analyses. Energy Policy 2007, 35, 5012–5020. [Google Scholar] [CrossRef]

- Dincer, I.; Hussain, M.M.; Al-Zaharnah, I. Energy and exergy use in the utility sector of Saudi Arabia. Desalination 2004, 169, 245–255. [Google Scholar] [CrossRef]

- Utlu, Z.; Hepbasli, A. Assessment of the energy utilization efficiency in the Turkish transportation sector between 2000 and 2020 using energy and exergy analysis method. Energy Policy 2006, 34, 1611–1618. [Google Scholar] [CrossRef]

- Ediger, V.S.; Camdali, U.O. Energy and exergy efficiencies in Turkish transportation sector, 1988–2004. Energy Policy 2007, 35, 1238–1244. [Google Scholar] [CrossRef]

- Koroneos, C.J.; Nanaki, E.A. Energy and exergy utilization assessment of the Greek transport sector. Resour. Conserv. Recycl. 2008, 52, 700–706. [Google Scholar] [CrossRef]

- Jaber, J.O.; Al-Ghandoor, A.; Sawalha, S.A. Energy analysis and exergy utilization in the transportation sector of Jordan. Energy Policy 2008, 36, 2995–3000. [Google Scholar] [CrossRef]

- Ji, X.; Chen, G.Q. Exergy analysis of energy utilization in the transportation sector in China. Energy Policy 2006, 34, 1709–1719. [Google Scholar] [CrossRef]

- Saidur, R.; Sattar, M.A.; Masjuki, H.H.; Ahmed, S.; Hashim, U. An estimation of the energy and exergy efficiencies for the energy resources consumption in the transportation sector in Malaysia. Energy Policy 2007, 35, 4018–4026. [Google Scholar] [CrossRef]

- Federici, M.; Ulgiati, S.; Basosi, R. A thermodynamic, environmental and material flow analysis of the Italian highway and railway transport systems. Energy 2008, 33, 760–775. [Google Scholar] [CrossRef]

- Dincer, I.; Hussain, M.M.; Al-Zaharnah, I. Energy and exergy use in public and private sector of Saudi Arabia. Energy Policy 2004, 32, 1615–1624. [Google Scholar] [CrossRef]

- Gaggioli, R.A.; Petit, P.J. Use the second law first. Chemtech 1977, 7, 496–506. [Google Scholar]

- Gaggioli, R.A. Personal communication Presentation to Technical Staff at the Institute for Hydrogen Systems. Mississauga, Ontario, USA, 1985. [Google Scholar]

- Gaggioli, R.A. Second law analysis for process and energy engineering. In Efficiency and Costing: Second Law Analysis of Processes; American Chemical Society: Washington DC, USA, 1983; ACS Symposium Series 235; pp. 7–50. [Google Scholar]

- Lemieux, M.A.; Rosen, M.A. Energy and Exergy Analyses of Energy Utilization in Ontario. Report for Imperial Oil Ltd.; Ryerson Polytechnical Institute: Toronto, ON, Canada, 1989. [Google Scholar]

- Brown, H.L.; Hamel, B.B.; Hedman, B.A.; Koluch, M.; Gajanana, B.C.; Troy, P. Analysis of 108 Industrial Processes; Fairmount Press: Liburn, GA, USA, 1985. [Google Scholar]

- Proposal Criteria and Application Form; Energy Programs and Technology Division, Ontario Ministry of Energy: Toronto, ON, Canada, 1989.

- Brooks, D.; Torrie, R. Electricity Conservation Supply Curves for Ontario; Marbek Resource Consultants: Ottawa, ON, Canada, 1987. [Google Scholar]

- Appliance Efficiency Information Base; Marbek Resource Consultants Limited: Ottawa, ON, Canada, 1987.

- Commercial/Institutional Buildings, Electrical Energy Technology Study; Engineering Interface Limited and Marbek Resource Consultants Limited: ON, Canada, 1988.

- Quarterly Report on Energy Supply and Demand, 1987-IV; Ministry of Supply and Services Canada: Ottawa, ON, Canada, 1987; Volume 12.

- An Energy Efficient Ontario toward the Year 2000; Series: Energy Policy Paper; Ontario Ministry of Energy: Toronto, ON, Canada, 1986.

- Ontario's Future Electricity Demand; Ontario Ministry of Energy: Toronto, ON, Canada, 1987.

- Reistad, G.M. Available energy utilization in the United States. In Thermodynamics: Second Law Analysis; American Chemical Society: Washington, DC, USA, 1980; ACS Symposium Series 122; pp. 93–110. [Google Scholar]

- Rosen, M.A. Economics and Exergy: An. Enhanced Approach to Energy Economics; Nova Science Publishers: Hauppauge, NY, USA, 2011. [Google Scholar]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Rosen, M.A. Using Exergy to Correlate Energy Research Investments and Efficiencies: Concept and Case Studies. Entropy 2013, 15, 262-286. https://doi.org/10.3390/e15010262

Rosen MA. Using Exergy to Correlate Energy Research Investments and Efficiencies: Concept and Case Studies. Entropy. 2013; 15(1):262-286. https://doi.org/10.3390/e15010262

Chicago/Turabian StyleRosen, Marc A. 2013. "Using Exergy to Correlate Energy Research Investments and Efficiencies: Concept and Case Studies" Entropy 15, no. 1: 262-286. https://doi.org/10.3390/e15010262