Metals 2023, 13(4), 688; https://doi.org/10.3390/met13040688 - 30 Mar 2023

Cited by 1 | Viewed by 2024

Abstract

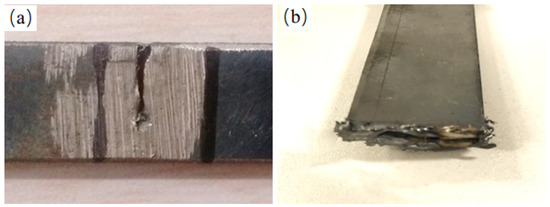

This study reports the welded joint of a novel 590 MPa V-N microalloyed wheel steel on microstructure and mechanical properties after flash butt welding. The welding parameters were flash current 48°/582.0 A, upsetting current 44°/516.6 A, and workpiece clearance 1.5 mm. The evolution

[...] Read more.

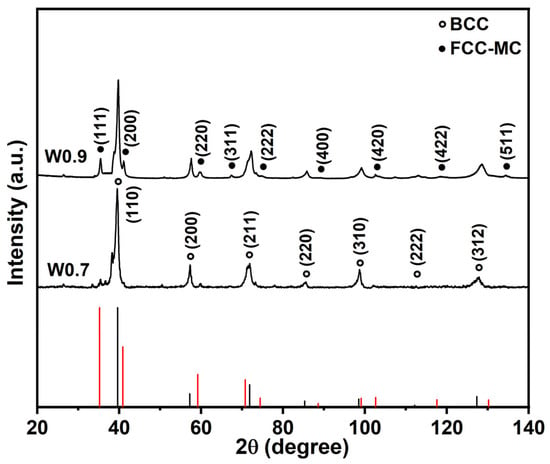

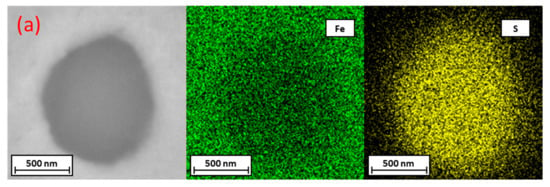

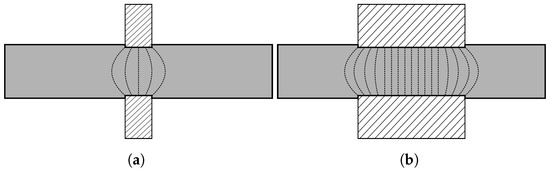

This study reports the welded joint of a novel 590 MPa V-N microalloyed wheel steel on microstructure and mechanical properties after flash butt welding. The welding parameters were flash current 48°/582.0 A, upsetting current 44°/516.6 A, and workpiece clearance 1.5 mm. The evolution of microstructure in the welded joint occurred as follows: welding seam (ferrite side plate + acicular ferrite +martensite)→coarse-grained zone (acicular ferrite + granular bainite)→fine-grained zone (fine-grained ferrite + M/A island)→base metal (equiaxed ferrite + pearlite). The standard impact energy value of welding seam, coarse grain zone, fine grain zone, and base metal at −40 °C was 116, 128, 144, and 88 J, respectively. The mechanical property of the joint was excellent. The microstructure, the number of grain boundaries, and the dislocation density directly affected the strength and hardness of the joint. The increase of large angle grain boundaries and the decrease of effective grain size were beneficial to the improvement of toughness. The hot-rolled 590 MPa V-N microalloyed wheel steel had superior weldability.

Full article

(This article belongs to the Special Issue Metal Catalysts for Heterogeneous Catalytic Reactions)

►

Show Figures