1

Key Laboratory of Special Purpose Equipment and Advanced Manufacturing Technology, Ministry of Education & Zhejiang Province, Zhejiang University of Technology, Hangzhou 310023, China

2

School of Automobile, Zhejiang Institute of Communication, Hangzhou 311112, China

3

School of Transportation, Zhejiang Industry Polytechnic College, Shaoxing 312000, China

Machines 2022, 10(10), 860; https://doi.org/10.3390/machines10100860 - 26 Sep 2022

Cited by 2 | Viewed by 2338

Abstract

Highly enhanced pump power density inevitably results in a profound rise in pump temperature, which seriously influences both power loss and service performance. Heat loss analysis is an important part of analyzing the mechanical and cooling efficiency of a 2D piston pump. This

[...] Read more.

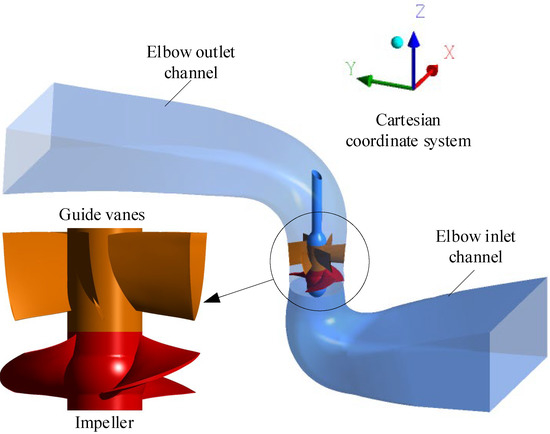

Highly enhanced pump power density inevitably results in a profound rise in pump temperature, which seriously influences both power loss and service performance. Heat loss analysis is an important part of analyzing the mechanical and cooling efficiency of a 2D piston pump. This paper focuses on heat loss analysis of this pump’s transmission. Firstly, theoretical and experimental studies are carried out on the thermal–hydraulic model to investigate the heat loss of the pump’s transmission. A pump test rig is developed and thermal experiments are conducted, from 1000 rpm to 6000 rpm. Furthermore, its transient thermal simulation model is implemented with Ansys software to capture the pump’s thermal status. The test convective heat transfer coefficients and temperature data are set in the model, and the simulation results are mutually validated with the experimental ones. Finally, the transmission’s heat loss is compared with its reference churning loss formula. The distribution of the transient heat loss is 49.66% into the end cap, 27.74% into the cylinder head, 13.30% into the inner cylinder, and 9.30% into the oil. The heat loss simulation results agree with the churning loss below 4000 rpm; therefore, the transmission thermal model is accurate and efficient.

Full article

(This article belongs to the Section Electromechanical Energy Conversion Systems)

▼

Show Figures