1

Institut Jean Lamour, UMR 7198, CNRS, Université de Lorraine, Campus ARTEM, 2 allée André Guinier, F-54011 Nancy CEDEX, France

2

LABoratory of EXcellence Design of Alloy Metals for low-mAss Structure (LabEx DAMAS), Université de Lorraine, Nancy 54011, France

3

SIMAP, CNRS, Grenoble INP, University of Grenoble Alpes, F-38000 Grenoble, France

4

UNIROUEN, INSA Rouen, Normandie Université, CNRS, Groupe de Physique des Matériaux F-76000 Rouen, France

5

Institut de Chimie de la matière condensée de Bordeaux, University of Bordeaux, UMR5026, F-33600 Pessac, France

6

Matériaux Ingénierie et Science, UMR CNRS 5510, INSA Lyon, University of Lyon, Bât. Saint-Exupéry, 25 Avenue J. Capelle, F-69621 Villeurbanne CEDEX, France

Materials 2018, 11(8), 1409; https://doi.org/10.3390/ma11081409 - 11 Aug 2018

Cited by 2 | Viewed by 4388

Abstract

Atom Probe Tomography (APT), Transmission Electron Microscopy (TEM), and 3D mechanical calculations in complex geometry and anisotropic strain fields were employed to study the role of minor elements in the precipitation process of silicon and chromium nitrides in nitrided Fe–Si and Fe–Cr alloys,

[...] Read more.

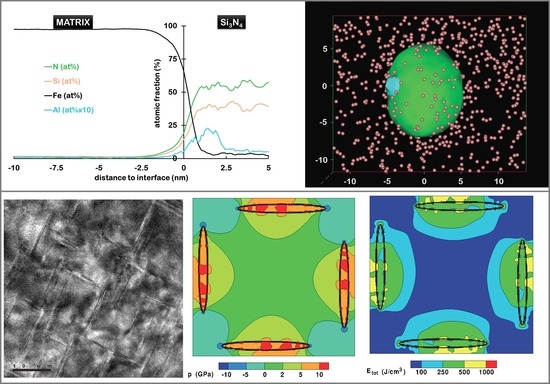

Atom Probe Tomography (APT), Transmission Electron Microscopy (TEM), and 3D mechanical calculations in complex geometry and anisotropic strain fields were employed to study the role of minor elements in the precipitation process of silicon and chromium nitrides in nitrided Fe–Si and Fe–Cr alloys, respectively. In nitrided Fe–Si alloys, an original sequence of Si3N4 precipitation was highlighted. Al–N clusters form first and act as nucleation sites for amorphous Si3N4 nitrides. This novel example of particle-simulated nucleation opens a new way to control Si3N4 precipitation in Fe–Si alloys. In nitrided Fe–Cr alloys, both the presence of iron in chromium nitrides and excess nitrogen in the ferritic matrix are unquestionably proved. Only a certain part of the so-called excess nitrogen is shown to be explained by the elastic accommodation of the misfit between nitride and the ferritic matrix. The presence of immobile excess nitrogen trapped at interfaces can be highly suspected.

Full article

(This article belongs to the Special Issue Design of Alloy Metals for Low-Mass Structures)

▼

Show Figures