1. Introduction

With the development of modern industry, more and more thin plate structures are used in manufacturing/production due to their light-weight and energy saving nature. However, there many difficulties associated with the application of sheet metal components in manufacturing, especially welding. In some cases, the welding of thin plate structure is even more difficult than that of the plate structure because it involves a different welding technique to ensure not to blowing through the metal. At present, it has become a typical welding technology problem because the thin plate is very sensitive to heat input during welding. It is therefore easy to produce deformation, warping, and penetration through the thermal effect, which seriously affects the manufacturing precision of thin plate and reduces the service life. There are many deformation factors that affect the welding structure, such as the structure and stiffness of the weldment, the constraint conditions of the workpiece, the welding sequence, and the welding specification parameters. Welding deformation of thin plate is inevitable, however, measures can be taken to reduce the deformation after welding through the manufacturing process, material selection, and other aspects.

The most widely used arc welding method for thin sheet are gas metal arc welding and gas tungsten arc welding (GMAW and GTAW), more popularly known metal inert gas (MIG) and tungsten inert gas (TIG) [

1,

2]. TIG and MIG welding machines are less costly, easy to handle and operate, capable of a wide range of current levels, have a high adaptability to various welding positions for easier full penetration, and improved welding arc quality. The weld surface is smooth and has excellent corrosion and fatigue resistance. The main drawback of these welding methods is that the welding speed is fairly low with a single electrode torch, affecting the production efficiency and it is not easy for production line automation. Tseng and Lin [

3] compared the effects of micro and nano oxide particles on the welding of stainless steel using TIG welding. The results show that, when compared with the micro SiO

2 particles, the TIG welding with nano SiO

2 particles has better penetration and smaller angular deformation in the weldment. However, TIG welding with nano Al

2O

3 particles does not lead to substantial increase in penetration or deformation reduction. The influence of active flux and welding parameters on penetration and depth-to-width ratio (DWR) on Inconel 718 alloy using the TIG welding process was investigated by Lin and Wu [

3]. Both the single and mixed component fluxes of the TIG welding such as SiO

2, NiO, MoS

2, MoO

3, 50% SiO

2 + 50% MoO

3, and 50% SiO

2 + 50% NiO significantly increased the penetration and depth-to-width ratio (DWR) of the Inconel 718 alloy welds.

Plasma Arc Welding (PAW) is an urbanized arc welding method of joining thin sheet metals by heating them with a constricted nozzle arc between non consumable tungsten electrode and thin sheet metals [

4,

5,

6]. PAW’s main advantage is that it can reach a higher production rate due to a high concentration of heat input. The heat input distribution is even, which leads to a smaller weld heat affected zone with more accurate weld beads, which is beneficial to the properties of base metal. Moreover, the electrode in PAW is not directly in contacted with the molten pool, so the possibility of tungsten inclusion is reduced to the minimum and the life of the electrode is also increased [

7]. In addition, due to its advantages of large energy density, narrow penetration depth, deep penetration depth, and good arc stability, it is superior to other conventional processes. It has been widely used in aerospace, chemical, naval, nuclear industries, and other fields [

8]. Rao et al. [

9] discussed the welding of Inconel 625 by pulsed micro plasma arc welding. The welding quality characteristics, such as weld pool geometry parameters, microstructure, grain size, hardness, and tensile properties at different welding speeds were investigated. The results show that better welding quality characteristics can be obtained under the welding speed of 260 mm/min. The welding quality characteristics of austenitic stainless steel by pulsed current plasma arc welding were studied by Prasada et al. [

10]. The welding quality characteristics, including weld pool geometry, microstructure, grain size, hardness, and tensile properties were taken into account. It was established that SS 304L achieves better welding quality characteristics as compared with SS 316L, SS 316Ti, and SS 321 at the same welding conditions.

Laser Beam Welding (LBW) is an advanced welding process that is capable of joining multiple pieces of metallic and non-metallic materials together using a laser beam. Laser welding is based on the interaction of laser light with material, and the processes consist of the following four major steps: (i) absorption of focused laser on the material surface; (ii) transfer of absorbed laser energy into the bulk material by conduction; (iii) heating and melting of the material; and (iv) instant solidification of the melt material to form a weld pool [

11]. Laser beam welding has high-potential advantage in welding of heat sensitive components with precision control of heat input, minimal thermal distortion, small HAZ, good mechanical properties, and excellent repeatability [

12,

13]. Furthermore, laser welding is well known for its deep penetration capability, although it can be successfully used in conduction mode for thin sheet metal welding [

14]. As a consequence of these advantages, laser welding offers a higher welding speed when compared to conventional arc welding. Marashi et al. [

15] investigated on the influence of laser spot welding parameters on the joint quality of low carbon steel sheets by the Taguchi design of the experiment method. The optimum process parameters in the studied range were found, which ensured desirable pull-out failure mode and thus maximum failure energy. Yilbas et al. [

16] carried out Laser welding of mild steel sheets under ambient nitrogen assisting gas and computed the temperature and stress fields in the welding region through the finite element method for comparison with XRD technique. The results showed that the von Mises stress attains high values in the cooling cycle after the solidification of the molten regions and the predicted residual stress agreed well with the XRD results. The temperature decay rate in the molten zone was lower than in the solid due to absorption and dissipation of the laser energy in the molten zone, which was generated in the surface region.

The formation of residual stresses during manufacturing can also cause unwanted and awkward deformations, which may be too expensive to correct. During the welding process, there are a large number of non-uniform heat inputs resulting in the distribution of residual stress, which often produce adverse mechanical effects. This leads to the frequent cause of tensile residual stresses problem in welding engineering practice [

17]. Alternatively, the deliberate introduction of compressive stress sometimes by shot peening mechanical treatment is used to improve some benefits [

18,

19]. The development of residual stress is closely related to the welding process. Therefore, it is very important to understand the nature and size of the residual stress at the end of the welding because it can directly affect the service life of parts. Dias [

20] et al. analyze the residual stresses resulting from laser beam welding and plasma arc welding processes by X-ray diffraction technique, with sin2ψ method in Interstitial free (IF) steel butt joints. The result indicated that the residual stresses at the top and root of the welded joint are very similar in magnitude for both of the welding processes. The longitudinal tensile residual stresses in the welding heat affected zone (~170 MPa) and fusion zone (~300 MPa) were verified in the upper part for the two welding processes. The effects of welding speed on microstructure and mechanical characterization of welded joint of AISI316L austenitic stainless steel and EH36 ship steels using fiber laser welding were investigated by Cao et al. [

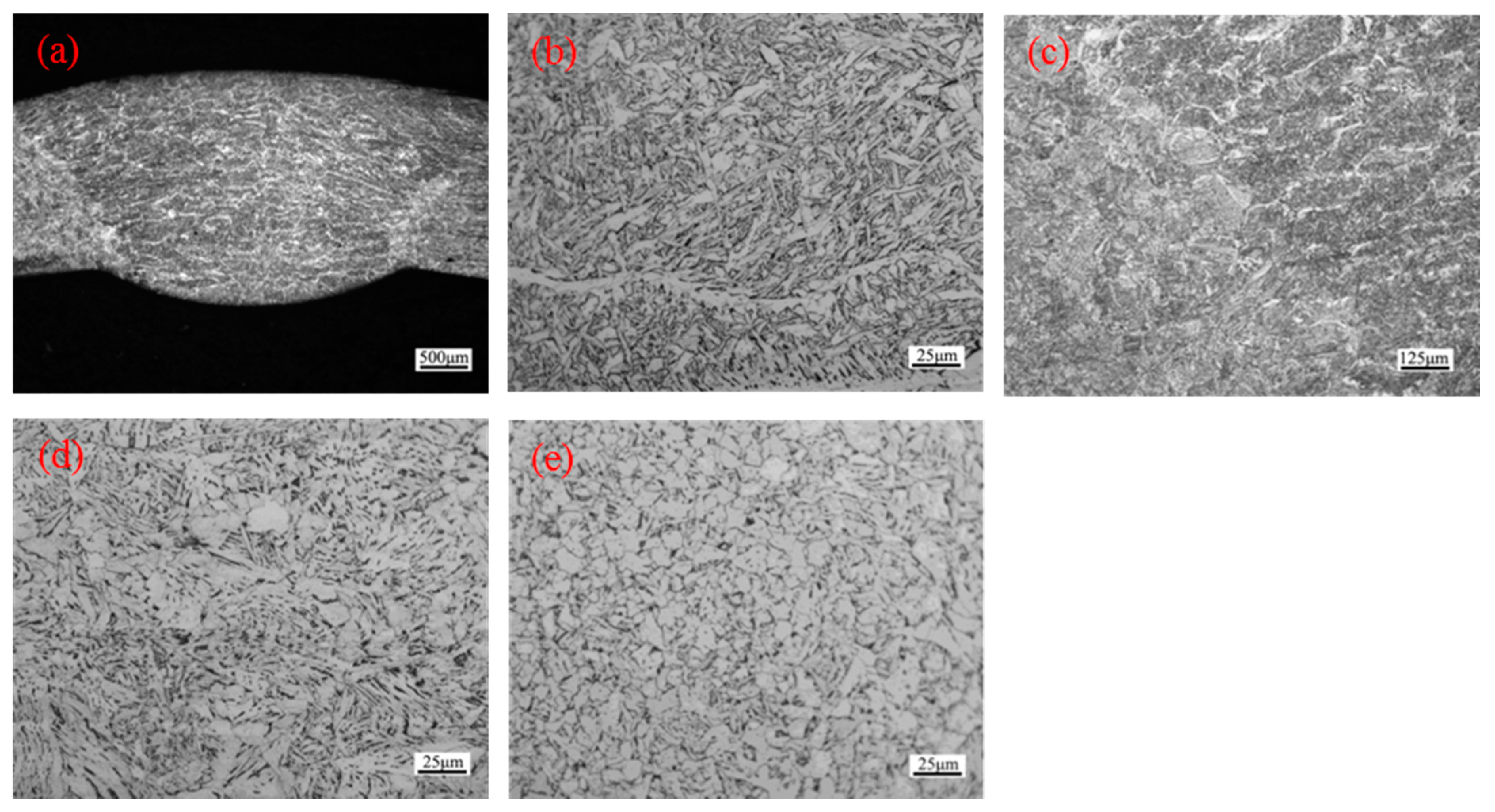

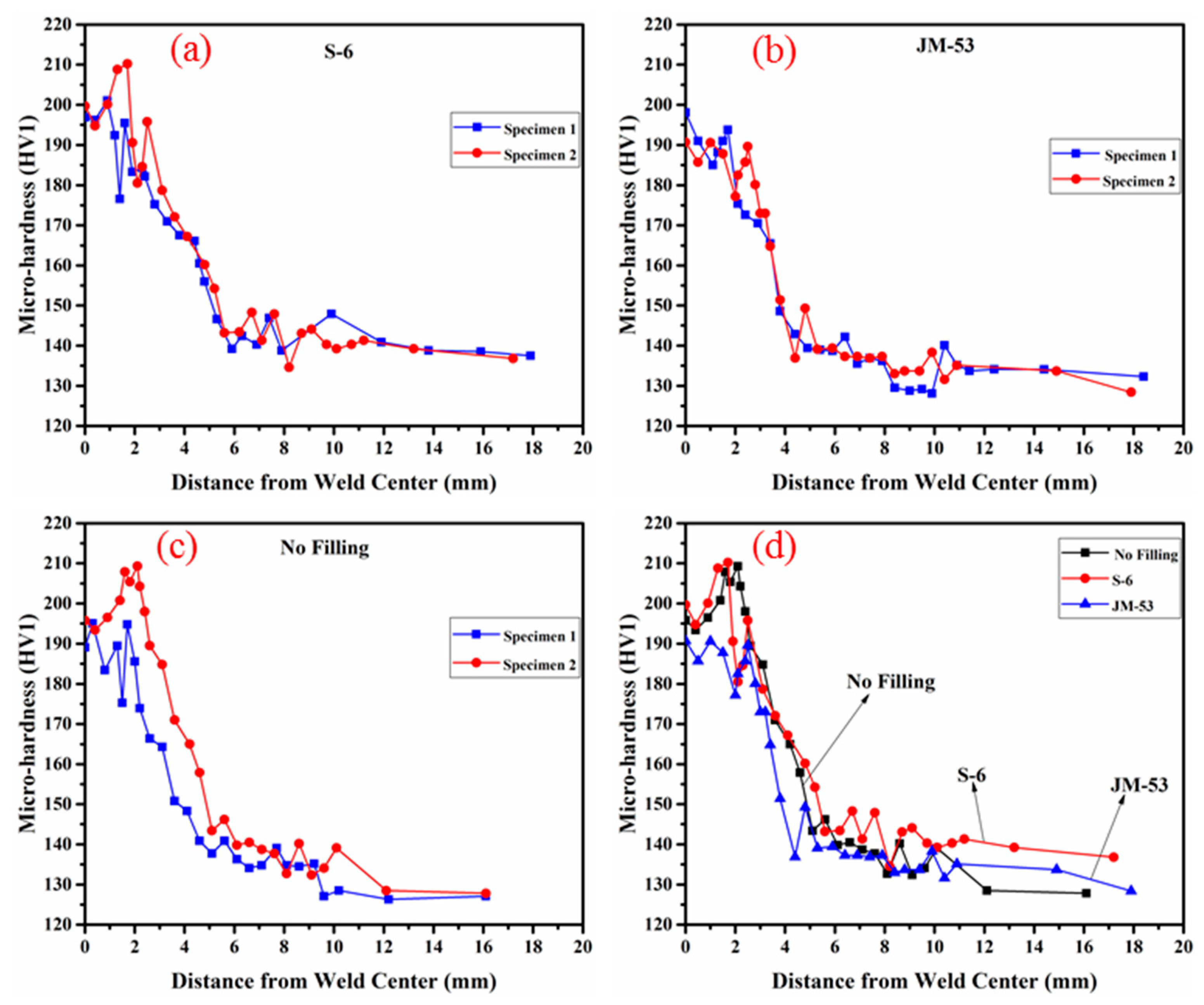

21]. It was found that the micro-hardness of the joint is about 350 HV1 and fluctuates slightly along the weld across section, which is two times higher than that of base materials (it is about 180 HV1) that are caused by the formation of lath martensite. The tensile strength of the joint with full penetration is better than the dissimilar metals.

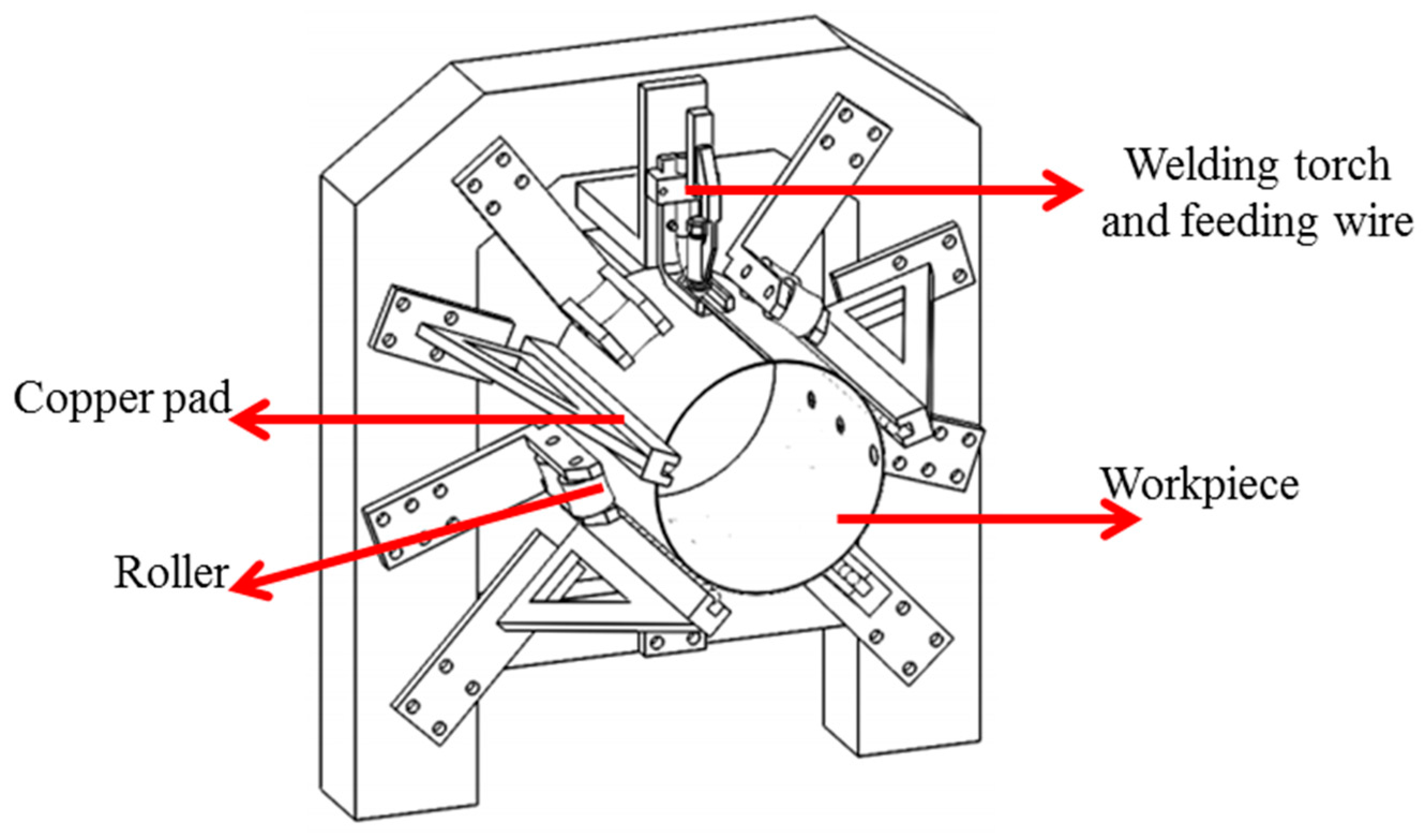

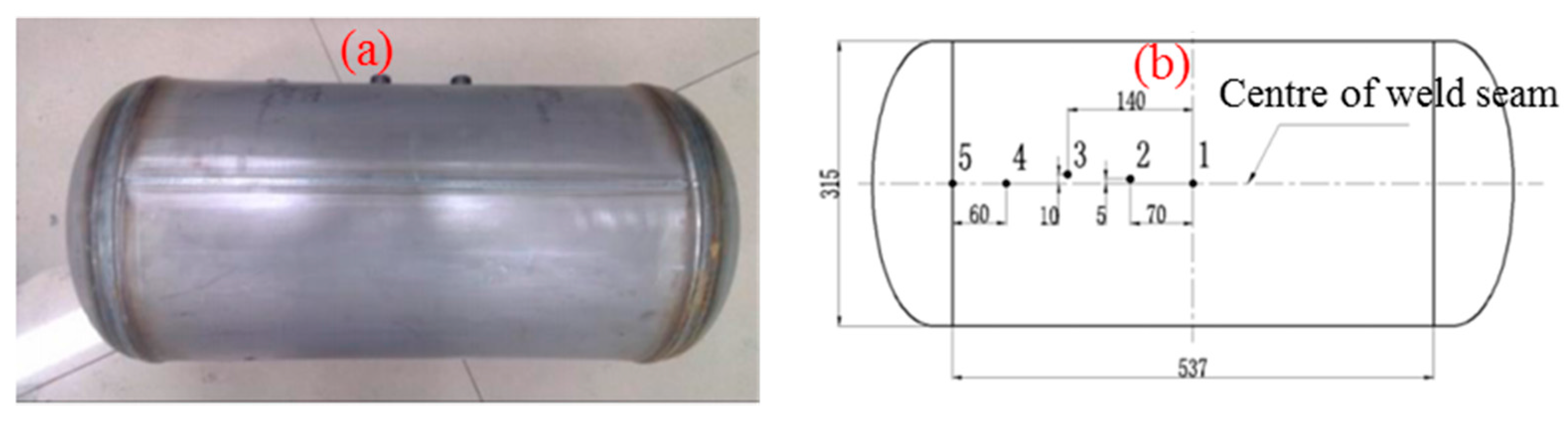

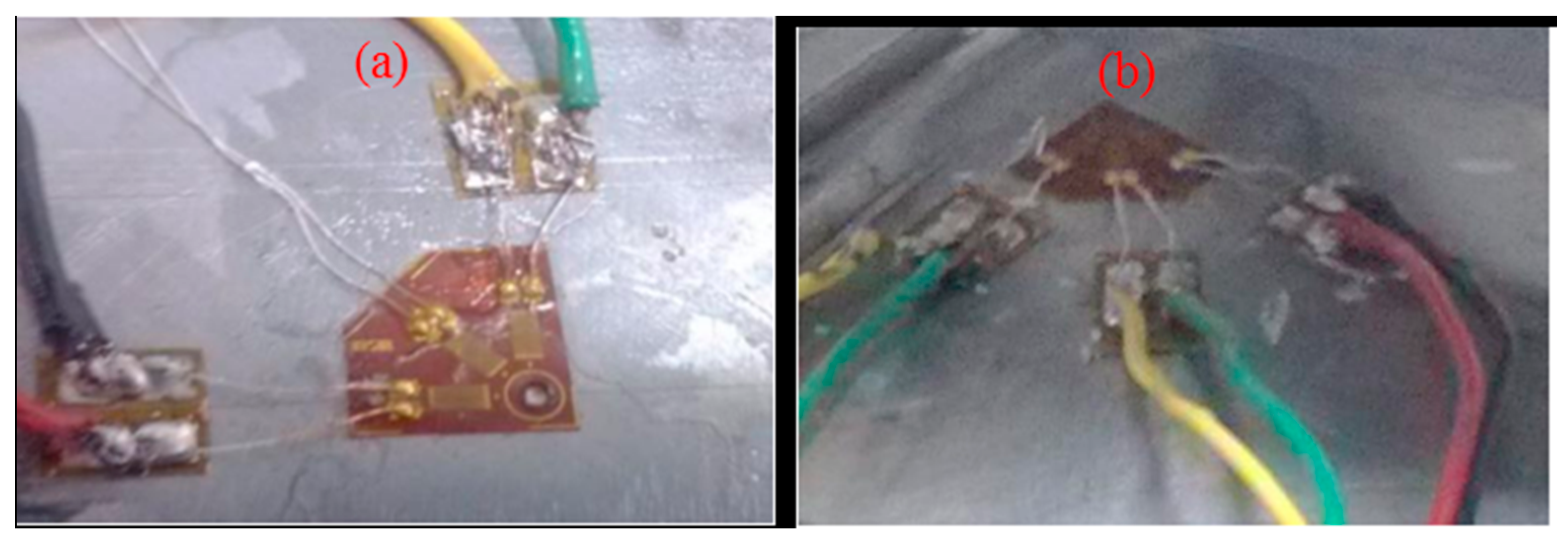

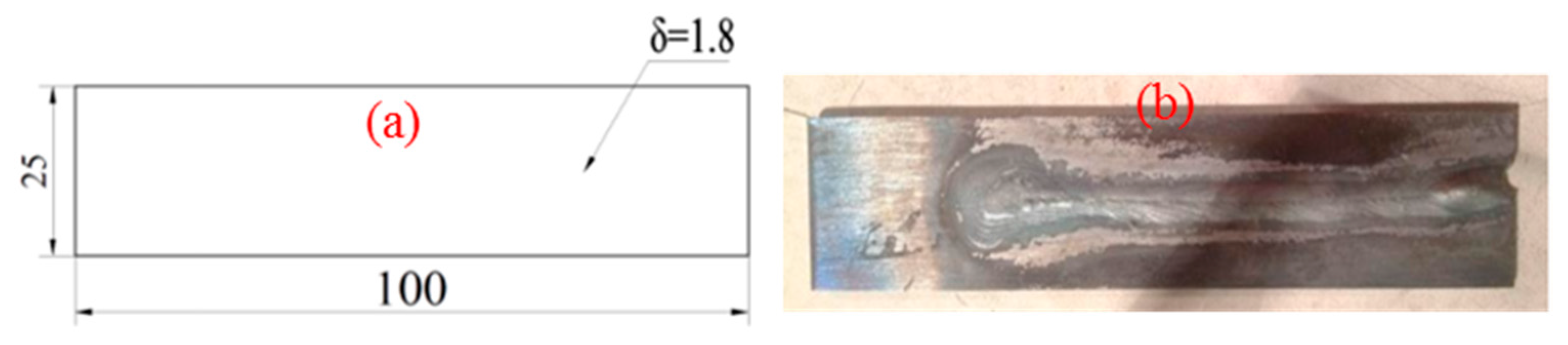

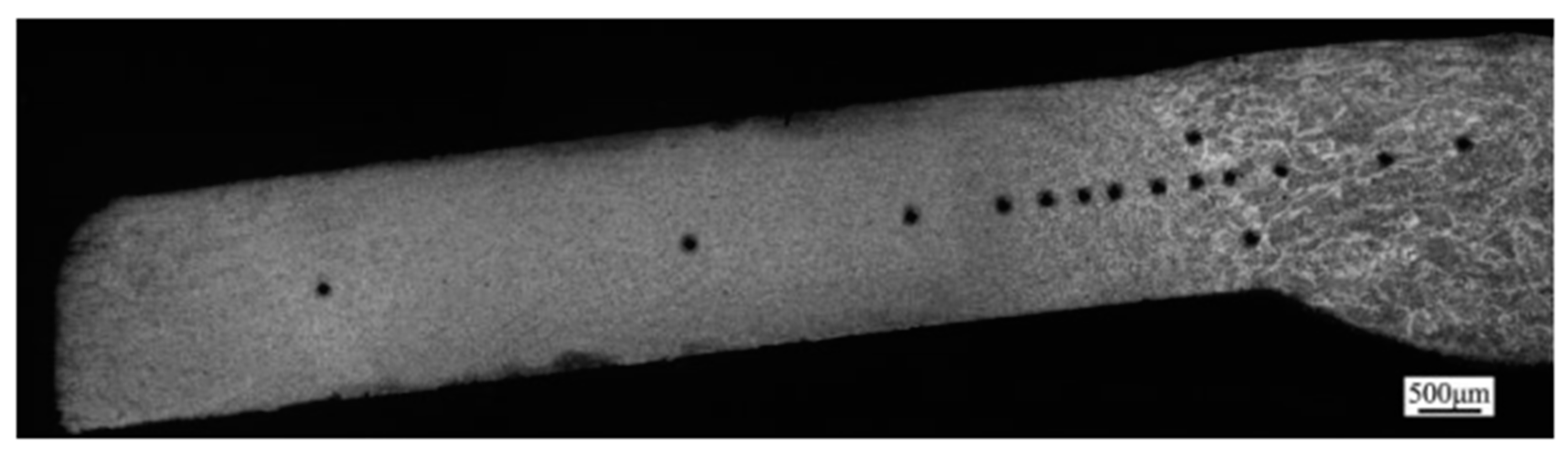

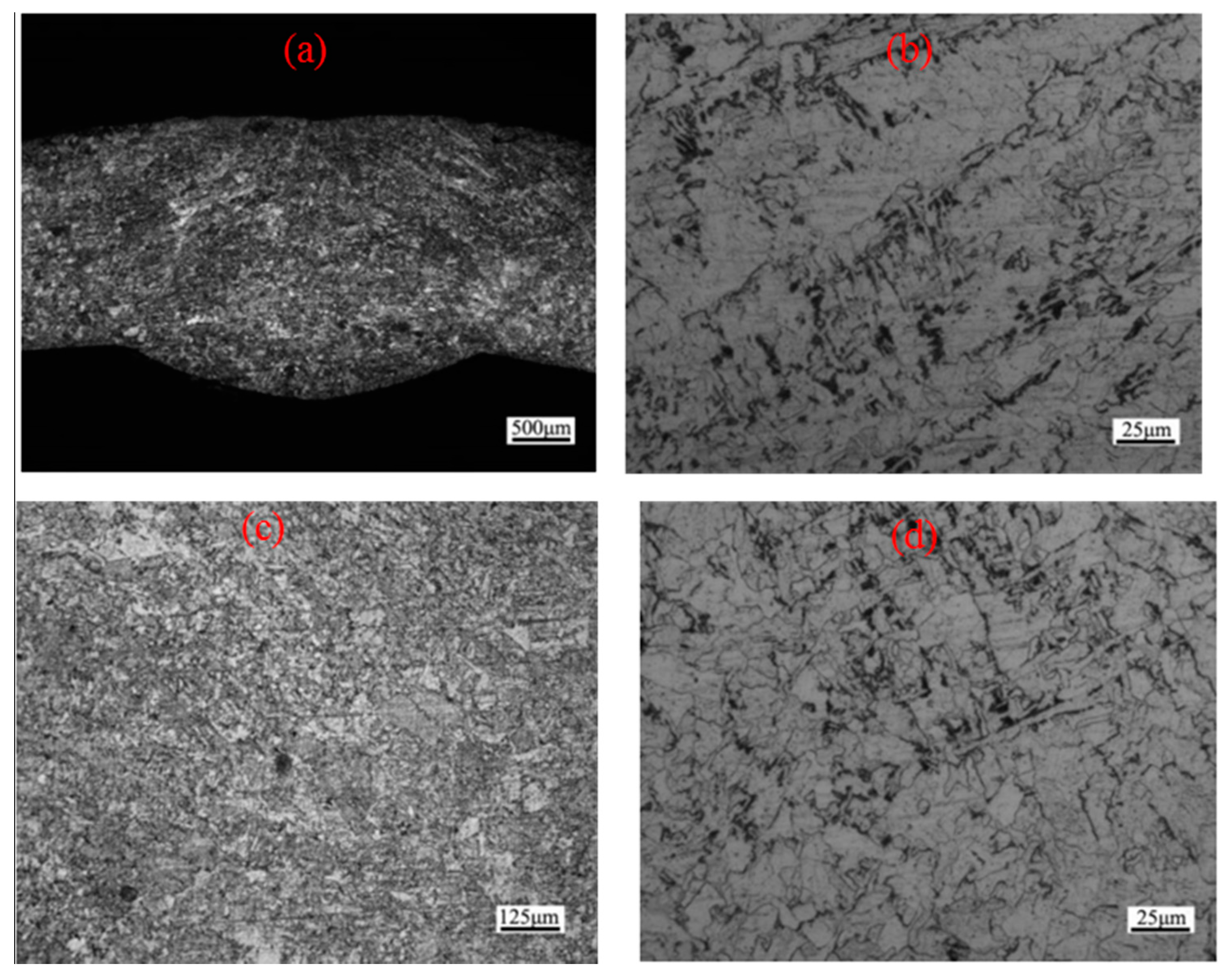

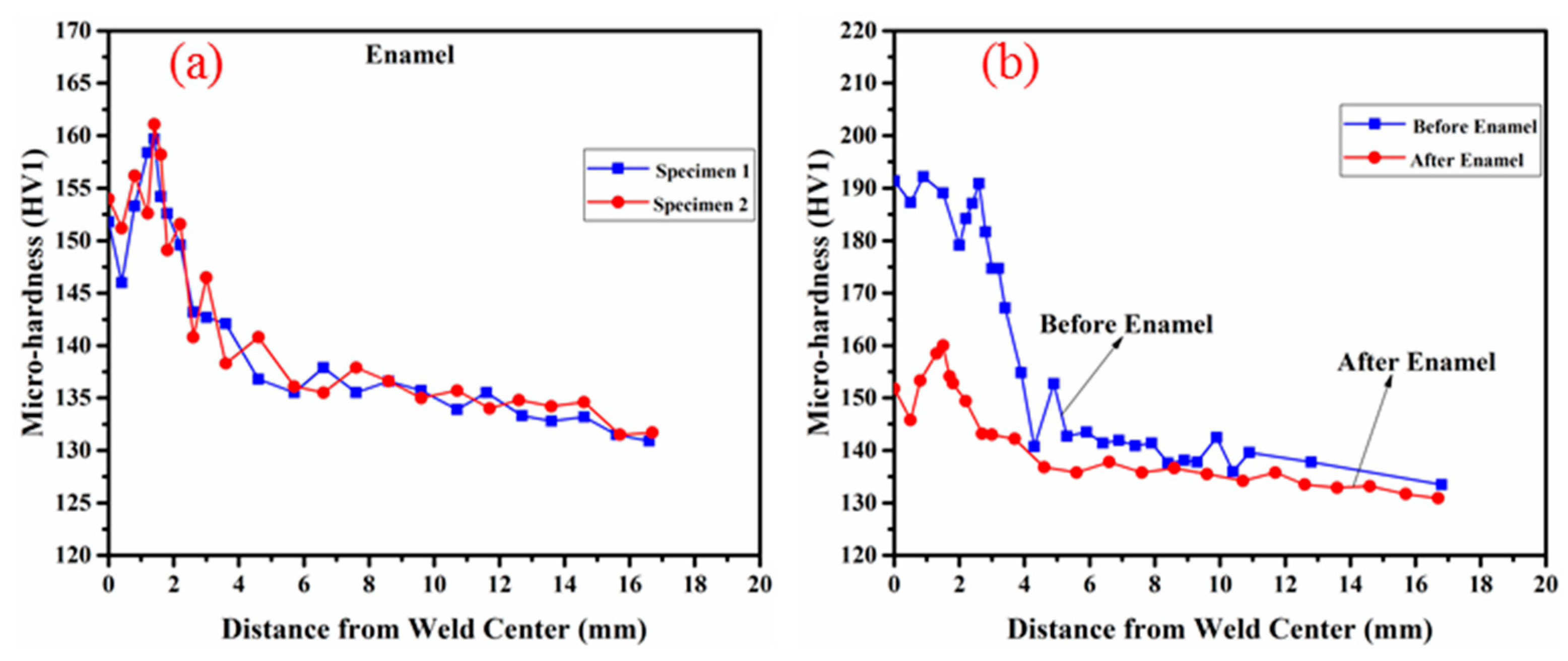

Generally, the electric water heater consists of five parts: shell, liner, insulation layer, heating, and temperature control system. The manufacturing technology of the inner tank is the core technology of the electric water heater. In order to prolong the life of the electric water heater, it is necessary to make the inner tank with higher manufacturing quality and better service performance. To achieve these capabilities, the key lies in the selection of bladder material and the manufacturing process of the bladder. The inner liner of the electric water heater belongs to a thin-wall pressure vessel and the main production process thereof is welding. The welding process comprises of longitudinal seam welding of the cylinder body, welding of the two ring welds of the barrel and the two heads end, and the welding of the three micro saddle shaped welds of the magnesium bar seat, the water pipe seat and the inner cylinder body of the inner container. After-sales service feedback report from clients of an electric water heater tank manufacturing company indicates a high rate of water leakage from the tank. Field tests conducted by the researchers on the manufacturing site showed that the longitudinal seam of the inner liner is more prone to fatigue delayed crack than the ring joint. This is because the longitudinal joint of the liner is more difficult to weld than the ring joint. In addition, many other defects, such as burn-through, incomplete fusion, and deformation were also easily discovered in the welds of the tanks. These imperfections had a negative effect on production quality of the water heater. It is therefore very significance to ensure quality welding of the inner tank during production. This research paper mainly focuses on how to improve the longitudinal seam weld quality of the inner liner of the electric water heater tank. The residual stress and diffusible hydrogen in the longitudinal joint fatigue crack are investigated. The tensile strength and micro-hardness of the longitudinal joint are also tested and the influence of enamel on the welding seam is analyzed.