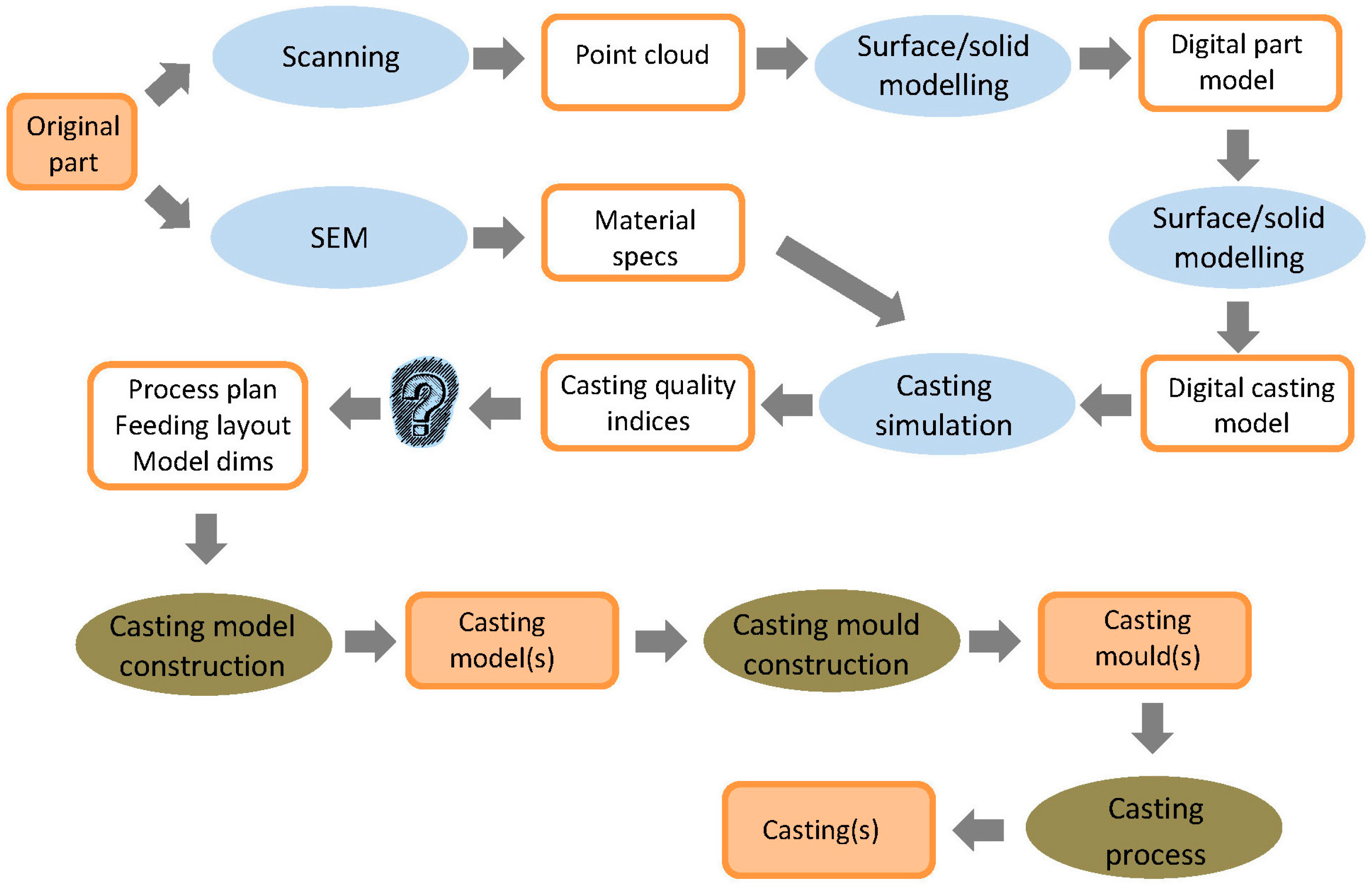

Digital Manufacturing Process Chain for One-Off Replacement Parts: A Precision Casting Case Study

Abstract

:1. Introduction

- The desired thickness of the layer used to build up the full tool may not be achieved by available machines and their positioning may not be accurate enough, leading to a gross approximation of the desired shape [5]. In addition, even if the layer thickness is small enough, the resulting fabrication time may be prohibitively large, especially for large parts [7].

- The material processed by AM machines may not always by appropriate for casting patterns. Initially this was some kind of wax, thereafter some resin with appropriate melting point, developments in this field being significant in optimizing casting quality [8].

- Initially contact scanners and then laser scanners were available but they were tedious in planning the different setups to use and also too slow when scanning usually along line patterns. White light and image based approaches followed and were orders of magnitude faster, but they were less accurate than the former. In addition, for intricate shapes several viewing angles should be tried in order to fully cover the part and their determination was a matter of trial and error [13,14], since blind areas and occlusions are inherent pitfalls of all optical methods [15].

- Accuracy of fitting surfaces to points has always been a pitfall of the pertinent CAD software, although this is usually not admitted in applications reported in literature [16]. Typically, increased desired accuracy results in discontinuities in the surfaces with associated dimensional tolerance issues. This is especially the case when just one sample is available, but even if there were enough samples, time and cost are restrictive. In addition, various techniques have been used to suppress noise present in optical scanning to varying degrees of success [17].

- The material and microstructure of the part would need to be determined by suitable techniques, totally different to shape digitizing. Thus, low expertise would usually keep the relevant activities to a minimum resulting in manufacturing to incomplete or wrong specifications [18].

- Shrinkage allowance for the casting would normally be universally applied although this is known to not hold true, leading to accuracy issues in large parts. Thus, dimensional discrepancies between the scanned sample and the casting would be encountered unless compensated [17].

- Constructing a correct finite element mesh for the casting to be studied is often time-consuming, requiring manual correction at several locations and intricate knit-picking work [20].

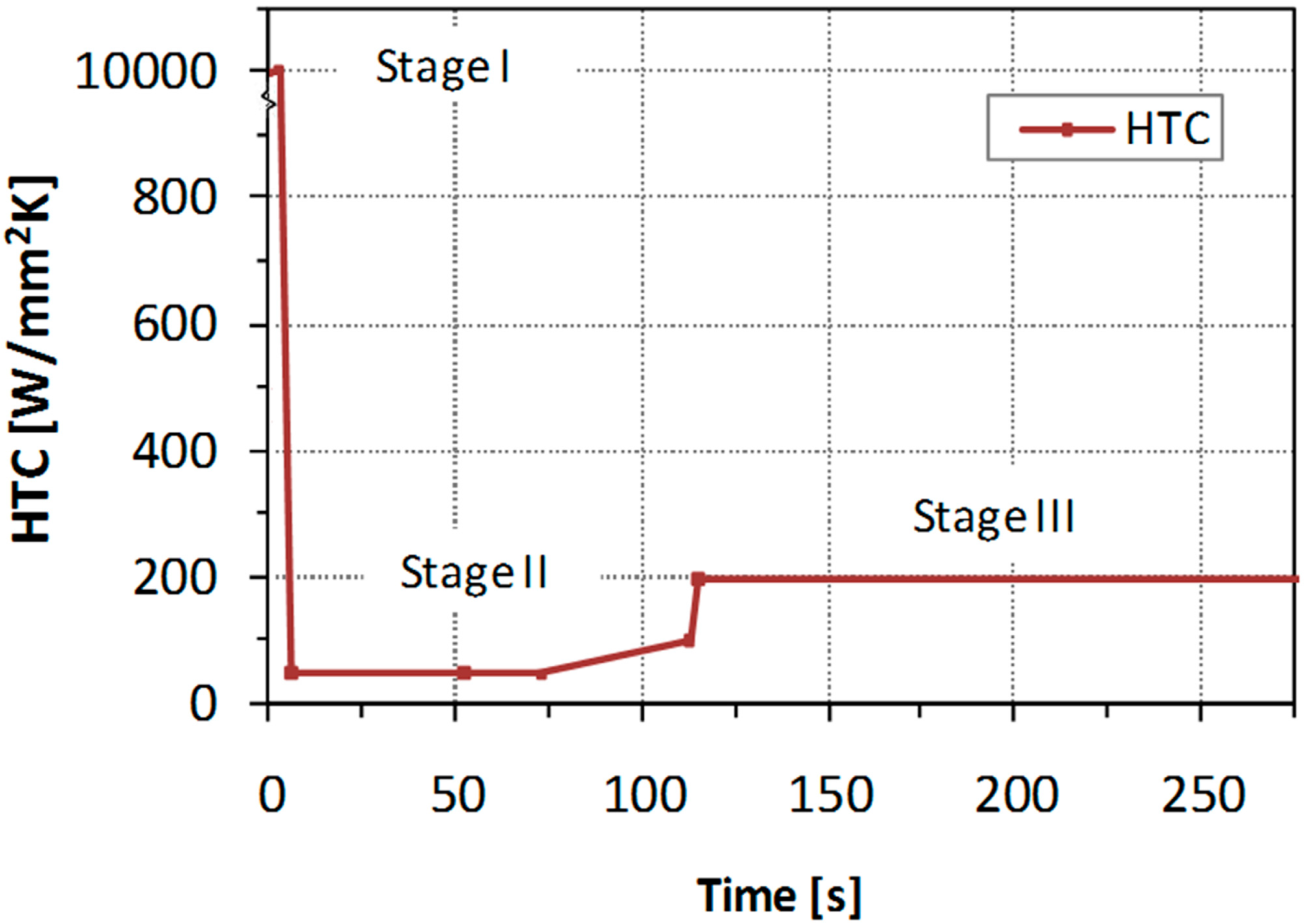

- The so-called heat transfer coefficient (HTC) for the particular casting and mold materials used, as well as for the particular geometry viz. combination of casting moduli characterizing the different sections of the casting, is generally not known, but may be determined by emerging sophisticated software [23].

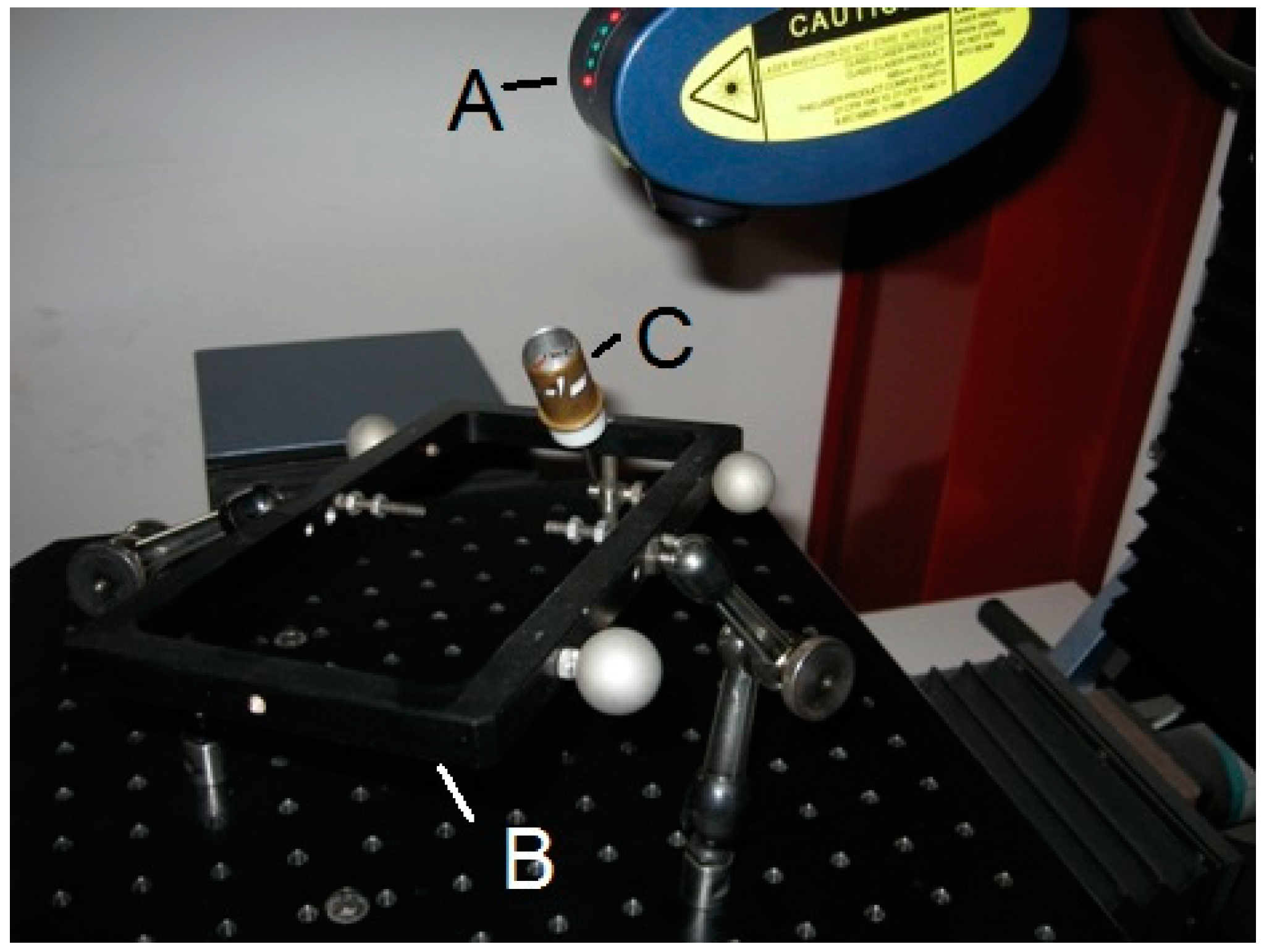

2. Scanning

2.1. The Part

2.2. The Process

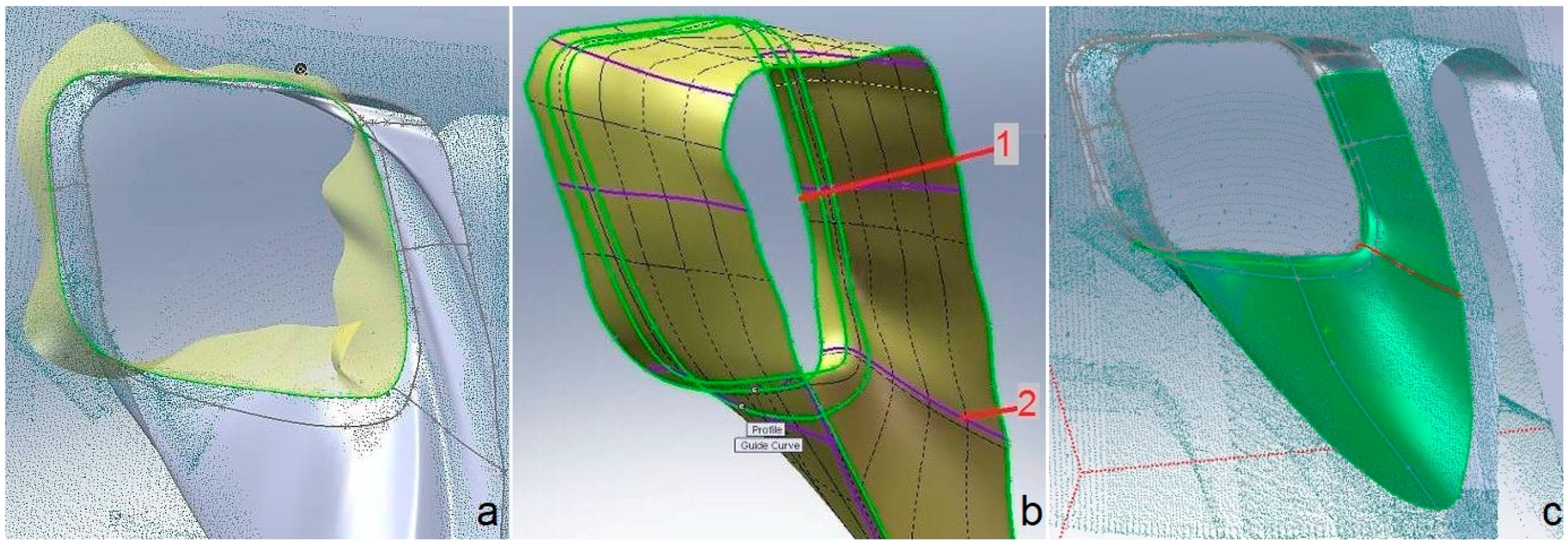

3. Digital Part Model

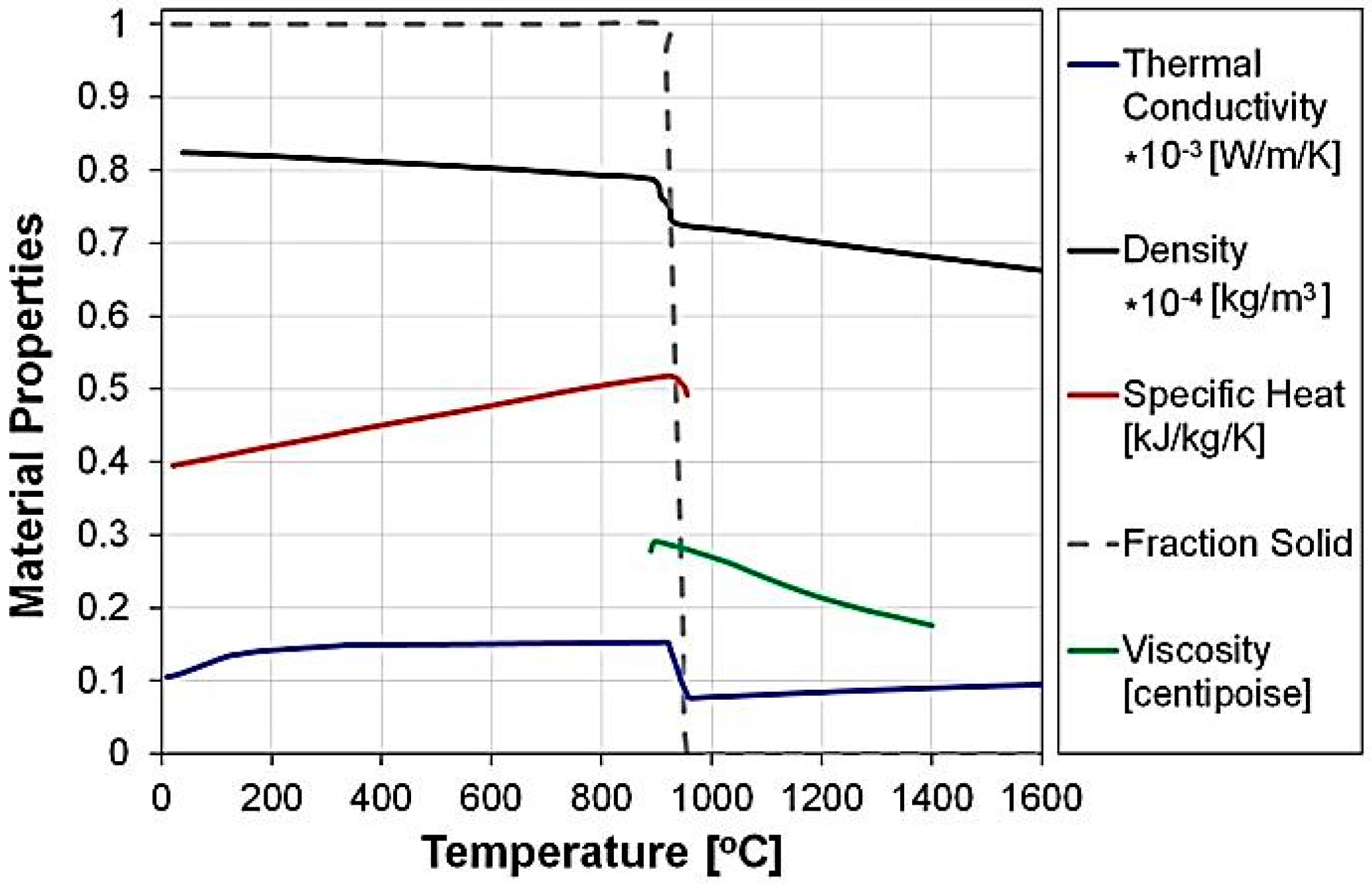

4. Material Investigation

5. Casting Simulation

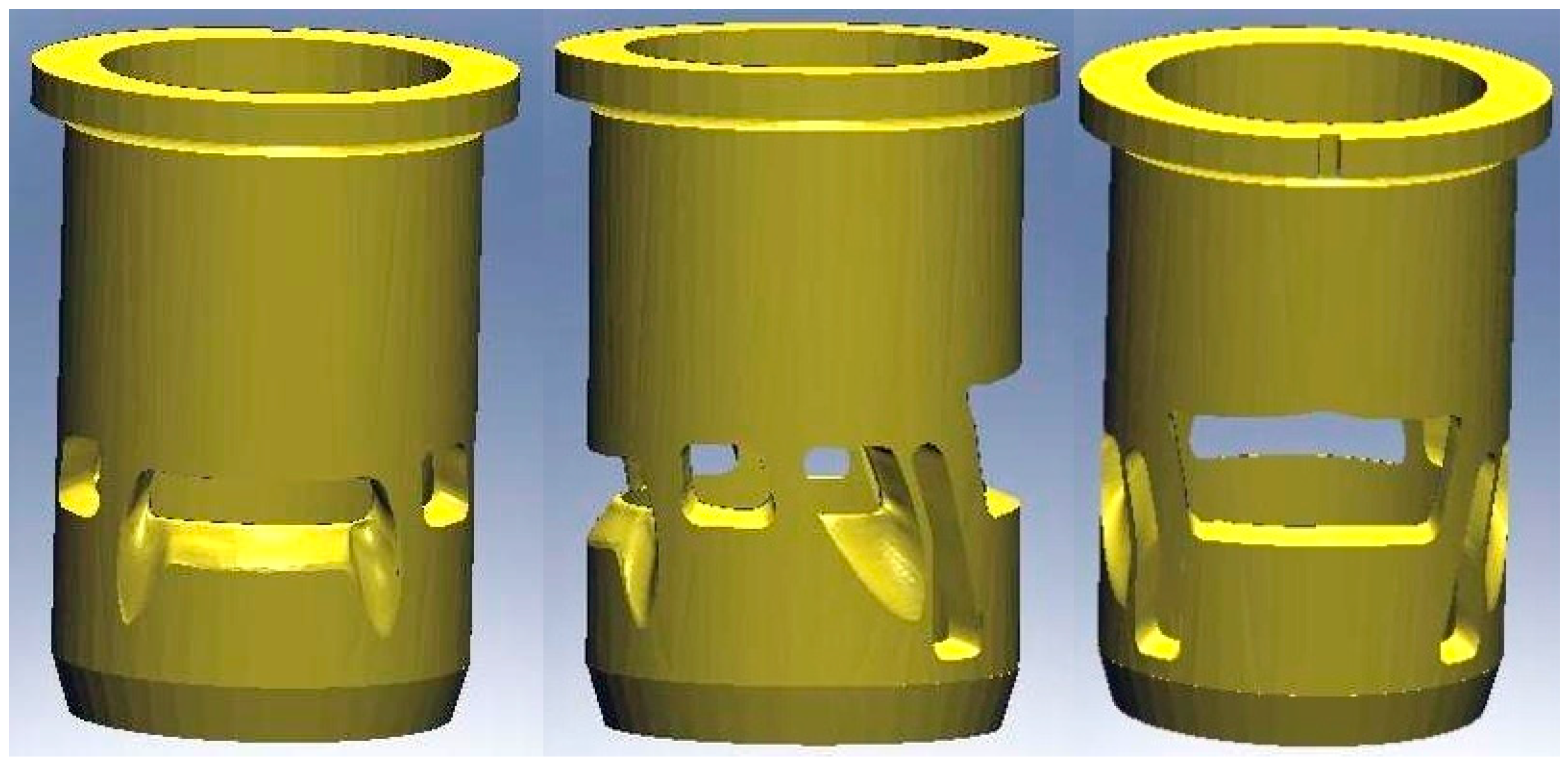

5.1. Simulation Setup

5.2. Results

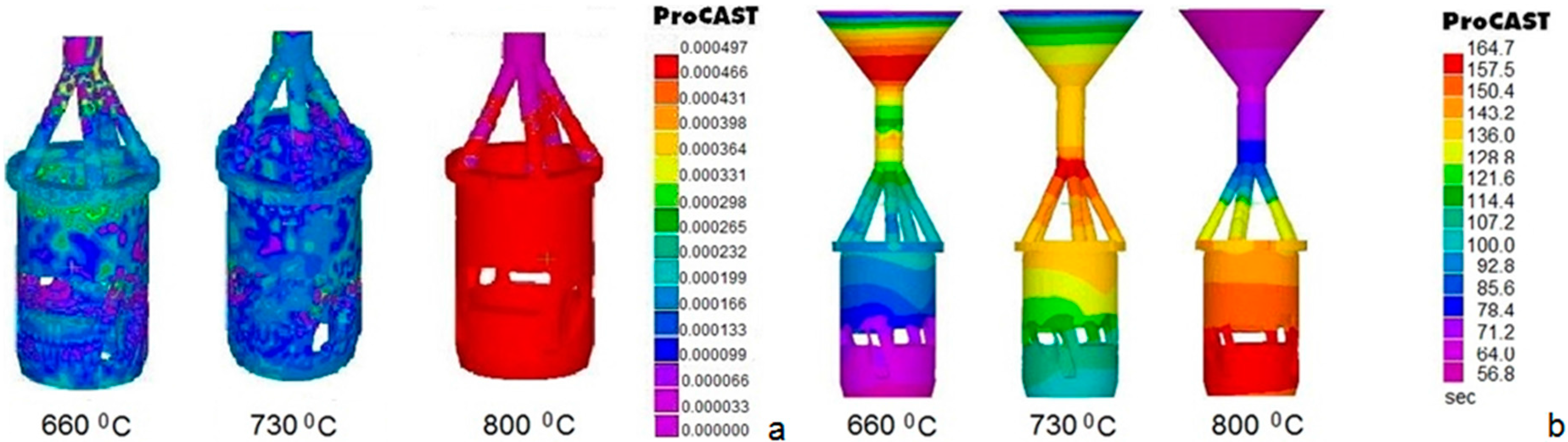

5.2.1. Different Feeding System and Melt Temperatures

5.2.2. Different Mold Temperatures

- The porosity levels to be within an “acceptable” limit, which in this case, was set to 0.01 in line with the simulation software user guide, in order to avoid macroporosity [30]),

- Uniformity of porosity levels within the cast part (excluding the feeding system),

- Uniformity of solidification time throughout the cast part volume,

- Avoidance of gaps (voids), especially in the regions around the “ports”.

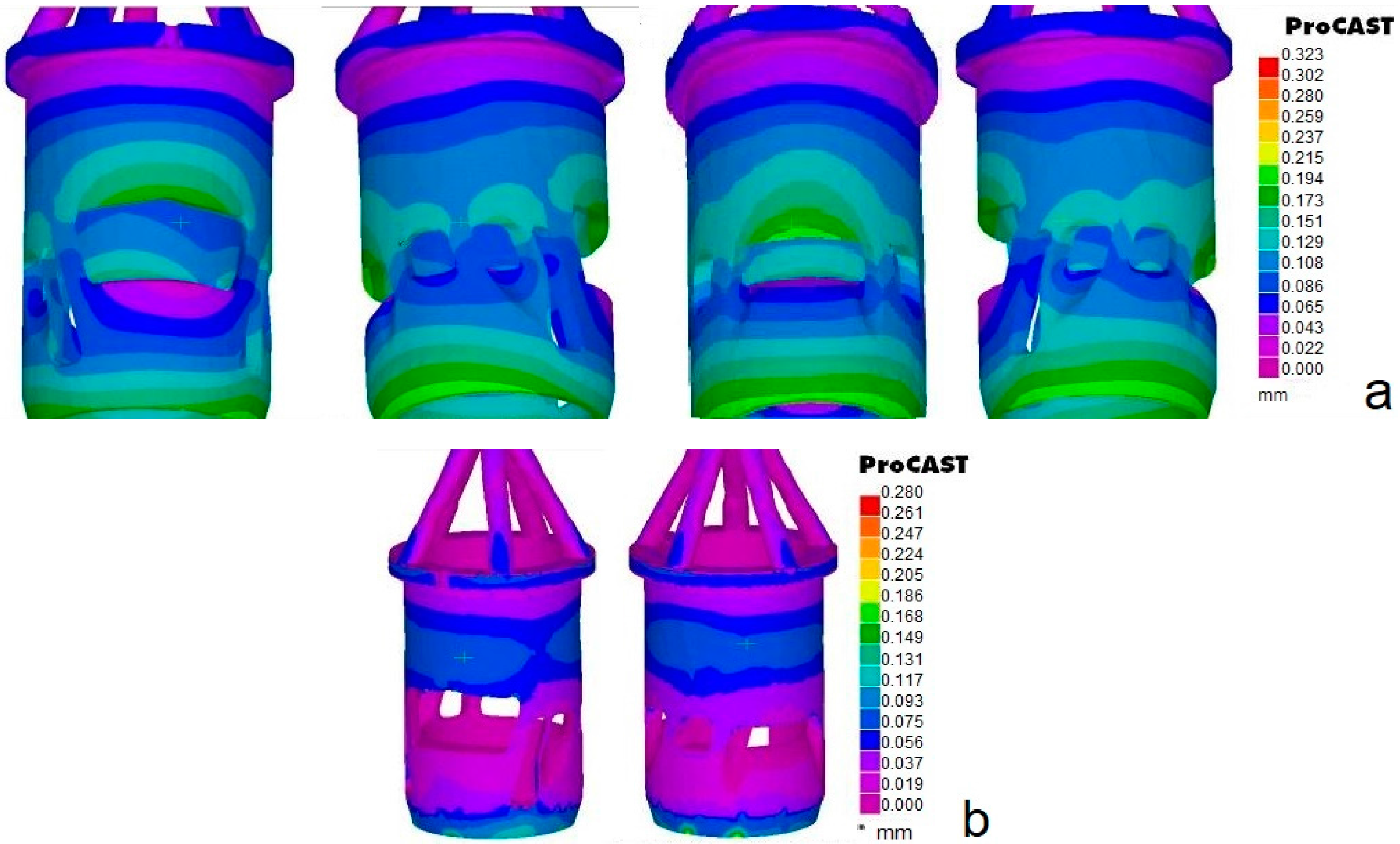

5.2.3. Stress and Distortion for the Best Casting Case

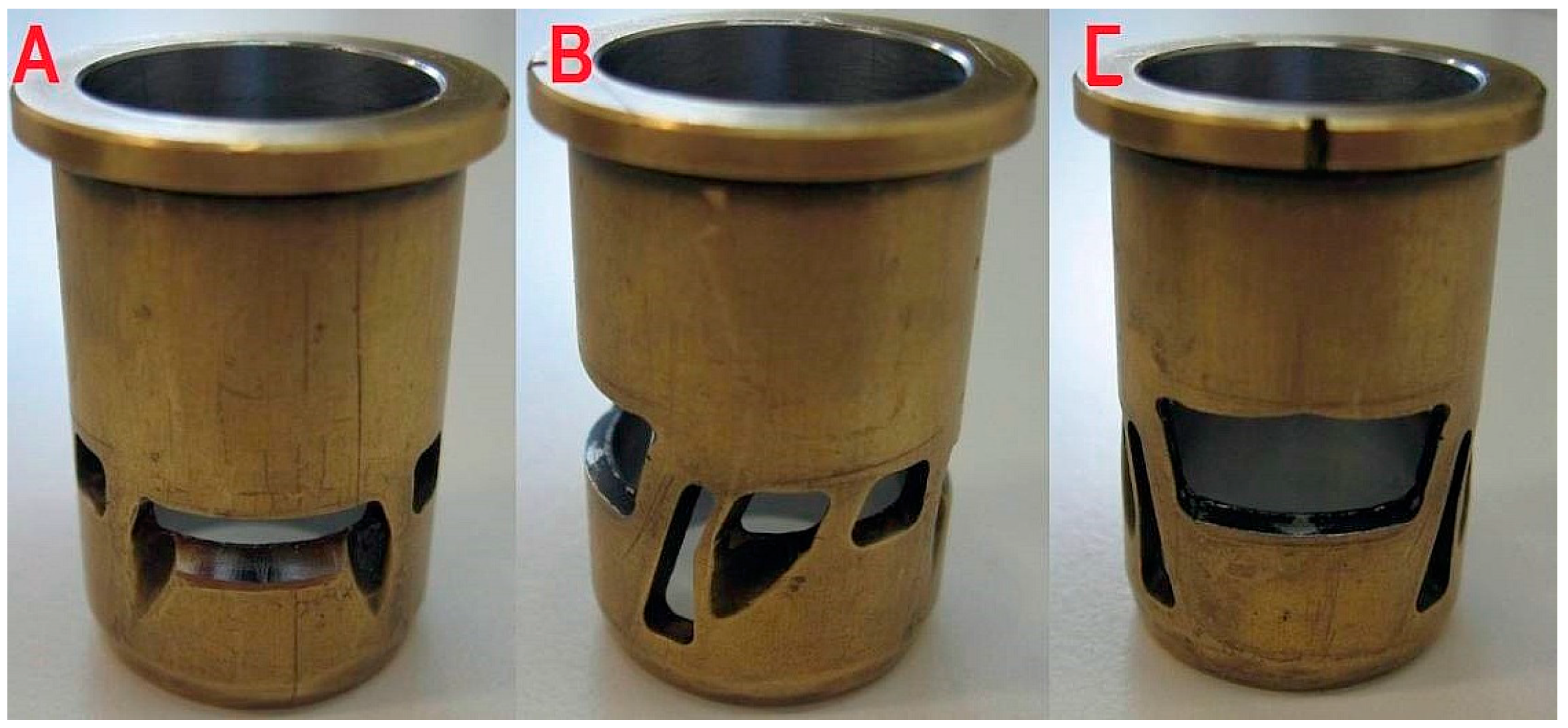

6. Casting Implementation

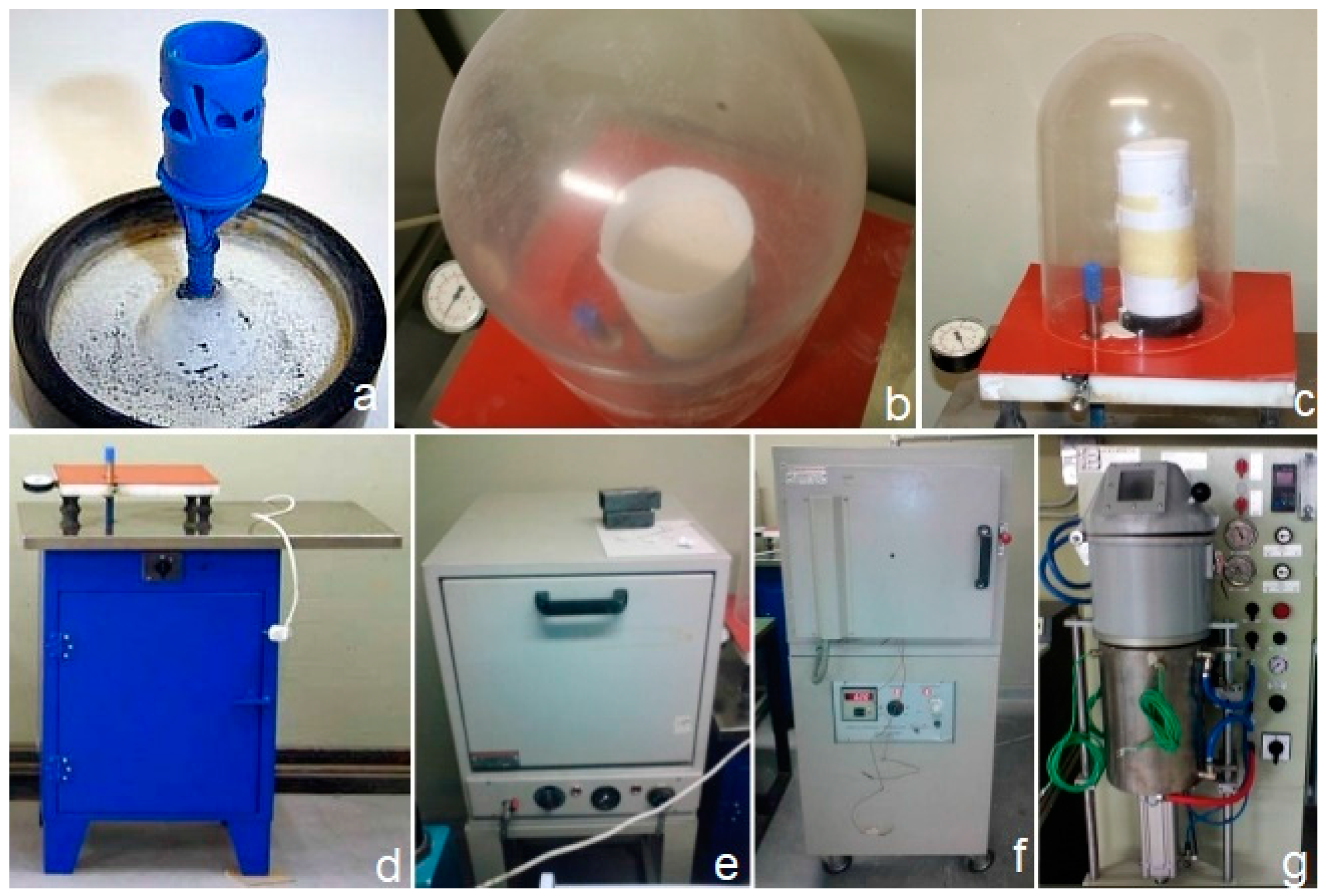

6.1. Procedure

6.2. Casting Quality

7. Discussion

7.1. Part Digitising

7.2. Part Modelling

7.3. Material Identification

7.4. Virtual Casting

7.5. Casting Tool Construction

8. Conclusions

Author Contributions

Conflicts of Interest

References

- Karunakaran, K.P.; Bernard, A.; Suryakumar, S.; Dembinski, L.; Taillandier, G. Rapid manufacturing of metallic objects. Rapid Prototyp. J. 2012, 18, 264–280. [Google Scholar] [CrossRef]

- Ramos, A.M.; Simões, J.A. CAD-CAM-RTV–lost-wax casting technology for medical implants. Rapid Prototyp. J. 2009, 15, 211–215. [Google Scholar] [CrossRef]

- Cheah, C.M.; Chua, C.K.; Lee, C.W.; Feng, C.; Totong, K. Rapid prototyping and tooling techniques: A review of applications for rapid investment casting. Int. J. Adv. Manuf. Technol. 2004, 25, 308–320. [Google Scholar] [CrossRef]

- Chhabra, M.; Singh, R. Rapid casting solutions: A review. Rapid Prototyp. J. 2011, 17, 328–350. [Google Scholar] [CrossRef]

- Bassoli, E.; Gatto, A.; Iuliano, L.; Violante, M.G. 3D printing technique applied to rapid casting. Rapid Prototyp. J. 2007, 13, 148–155. [Google Scholar] [CrossRef]

- Pal, D.; Ravi, B. Rapid tooling route selection and evaluation for sand and investment casting. Virtual Phys. Prototyp. 2007, 2, 197–207. [Google Scholar] [CrossRef]

- Chua, C.K.; Feng, C.; Lee, C.W.; Ang, G.Q. Rapid investment casting: Direct and indirect approaches via model maker II. Int. J. Adv. Manuf. Technol. 2004, 25, 26–32. [Google Scholar] [CrossRef]

- Pattnaik, S.; Karunakar, D.B.; Jha, P.K. Developments in investment casting process—A review. J. Mater. Process. Technol. 2012, 212, 2332–2348. [Google Scholar] [CrossRef]

- Yarlagadda, P.K.D.V.; Hock, T.S. Statistical analysis on accuracy of wax patterns used in investment casting process. J. Mater. Process. Technol. 2003, 138, 75–81. [Google Scholar] [CrossRef]

- Sabau, A.S.; Viswanathan, S. Material properties for predicting wax pattern dimensions in investment casting. Mater. Sci. Eng. A 2003, 362, 125–134. [Google Scholar] [CrossRef]

- Ferreira, J.C.; Alves, N.F. Integration of reverse engineering and rapid tooling in foundry technology. J. Mater. Process. Technol. 2003, 142, 374–382. [Google Scholar] [CrossRef]

- Liu, G.H.; Wong, Y.S.; Zhang, Y.F.; Loh, H.T. Modelling cloud data for prototype manufacturing. J. Mater. Process. Technol. 2003, 138, 53–57. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, L.; Zhu, Z.; Zhang, D. Geometric analysis of investment casting turbine blades based on digital measurement data. China Foundry 2014, 11, 20–27. [Google Scholar]

- Li, L.; Schemenauer, N.; Peng, X.; Zeng, Y.; Gu, P. A reverse engineering system for rapid manufacturing of complex objects. Robot. Comput. Integr. Manuf. 2002, 18, 53–67. [Google Scholar] [CrossRef]

- Salvi, J.; Matabosch, C.; Fofi, D.; Forest, J. A review of recent range image registration methods with accuracy evaluation. Image Vis. Comput. 2007, 25, 578–596. [Google Scholar] [CrossRef]

- Ferreira, J.C.; Mateus, A.S.; Alves, N.F. Rapid tooling aided by reverse engineering to manufacture EDM electrodes. Int. J. Adv. Manuf. Technol. 2006, 34, 1133–1143. [Google Scholar] [CrossRef]

- Zhang, D.H.; Jiang, R.S.; Li, J.L.; Wang, W.H.; Bu, K. Cavity optimization for investment casting die of turbine blade based on reverse engineering. Int. J. Adv. Manuf. Technol. 2009, 48, 839–846. [Google Scholar] [CrossRef]

- McEvily, A.J. Reverse engineering gone wrong: A case study. Eng. Fail. Anal. 2005, 12, 834–838. [Google Scholar] [CrossRef]

- Bernard, A.; Delplace, J.; Perry, N.; Gabriel, S. Integration of CAD and rapid manufacturing for sand casting optimisation. Rapid Prototyp. J. 2003, 9, 327–333. [Google Scholar] [CrossRef] [Green Version]

- Vassiliou, A.N.; Pantelis, D.I.; Vosniakos, G. Investigation of centrifugal casting conditions influence on part quality. In Proceedings of the International Conference on Manufacturing Engineering, Halkidiki, Greece, 1–3 October 2008; pp. 347–356. [Google Scholar]

- Gramegna, N.; della Corte, E.; Poles, S. Manufacturing process simulation for product design chain optimization. Mater. Manuf. Process. 2011, 26, 527–533. [Google Scholar] [CrossRef]

- Iqbal, H.; Sheikh, A.K.; Al-Yousef, A.; Younas, M. Mold design optimization for sand casting of complex geometries using advance simulation tools. Mater. Manuf. Process. 2012, 27, 775–785. [Google Scholar] [CrossRef]

- Vasileiou, A.; Vosniakos, G.; Pantelis, D. Determination of local heat transfer coefficients in precision castings by genetic optimisation aided by numerical simulation. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2014, 16. [Google Scholar] [CrossRef]

- Singh, J.P.; Singh, R. Investigations for a statistically controlled rapid casting solution of lead alloys using three-dimensional printing. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2009, 223, 2125–2134. [Google Scholar] [CrossRef]

- He, J.; Li, D.; Lu, B.; Wang, Z.; Zhang, T. Custom fabrication of a composite hemi-knee joint based on rapid prototyping. Rapid Prototyp. J. 2006, 12, 198–205. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, H. Application of rapid prototyping technology in die making of diesel engine. Tsinghua Sci. Technol. 2009, 14, 127–131. [Google Scholar] [CrossRef]

- Wang, L.; Li, H.; Gui, Y.; Zhao, G. A rapid design and manufacturing system for product development applications. Rapid Prototyp. J. 2004, 10, 200–206. [Google Scholar]

- Sokovic, M.; Kopac, J. RE (reverse engineering) as necessary phase by rapid product development. J. Mater. Process. Technol. 2006, 175, 398–403. [Google Scholar] [CrossRef]

- Pal, D.; Ravi, B.; Bhargava, L.; Chandrasekhar, U. Rapid casting development using reverse engineering, rapid prototyping and process simulation. Indian Foundry J. 2005, 51, 23–34. [Google Scholar]

- ESI Group. PROCAST v2004.1; ESI Group: Paris, France, 2004. [Google Scholar]

- Campbell, J. Castings-The New Metallurgy of Cast Metals; Butterworth Heinemann: Oxford, UK, 2003. [Google Scholar]

| Main Body | Coating | ||||||

|---|---|---|---|---|---|---|---|

| Element | C | Cu | Zn | C | O | Si | Cr |

| Weight % | 4.49 | 61.40 | 34.11 | 13.82 | 16.59 | 0.86 | 68.73 |

| Atomic % | 20.06 | 51.91 | 28.03 | 32.50 | 29.29 | 0.86 | 37.34 |

| Digital Experiment—Set | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | ||||||||

| Number of runners | 3 | 3 | 4 | 4 | 5 | 5 | 5 | 5 | 5 | 5 |

| Melt temperature (°C) | 970 | 1000 | 970 | 1000 | 970 | 1000 | 1000 | 1000 | 1000 | 970 |

| Mold temperature (°C) | 730 | 730 | 730 | 730 | 730 | 730 | 660 | 730 | 800 | 730 |

| Part | Height (mm) | External Diameter (mm) | Max Internal Diameter (mm) |

|---|---|---|---|

| Original | 30.400 | 9.750 | 8.204 |

| Wax | 30.862 | 9.898 | 8.328 |

| Cast copy | 30.440 | 9.668 | 8.161 |

| Absolute error (μm) | 40 | −82 | −43 |

| Relative error (%) | 0.13 | −0.84 | −0.52 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vosniakos, G.-C.; Michael, S.; Vasileiou, A. Digital Manufacturing Process Chain for One-Off Replacement Parts: A Precision Casting Case Study. J. Manuf. Mater. Process. 2017, 1, 17. https://doi.org/10.3390/jmmp1020017

Vosniakos G-C, Michael S, Vasileiou A. Digital Manufacturing Process Chain for One-Off Replacement Parts: A Precision Casting Case Study. Journal of Manufacturing and Materials Processing. 2017; 1(2):17. https://doi.org/10.3390/jmmp1020017

Chicago/Turabian StyleVosniakos, George-Christopher, Stefanos Michael, and Anastasia Vasileiou. 2017. "Digital Manufacturing Process Chain for One-Off Replacement Parts: A Precision Casting Case Study" Journal of Manufacturing and Materials Processing 1, no. 2: 17. https://doi.org/10.3390/jmmp1020017