Intermittent and Continuous Rotary Ultrasonic Machining of K9 Glass: An Experimental Investigation

Abstract

:1. Introduction

1.1. K9 Glass

1.2. Rotary Ultrasonic Machining and Its Application to K9 Glass Machining

2. Material, Experimental Set-Up and Measurement Procedures

2.1. Material

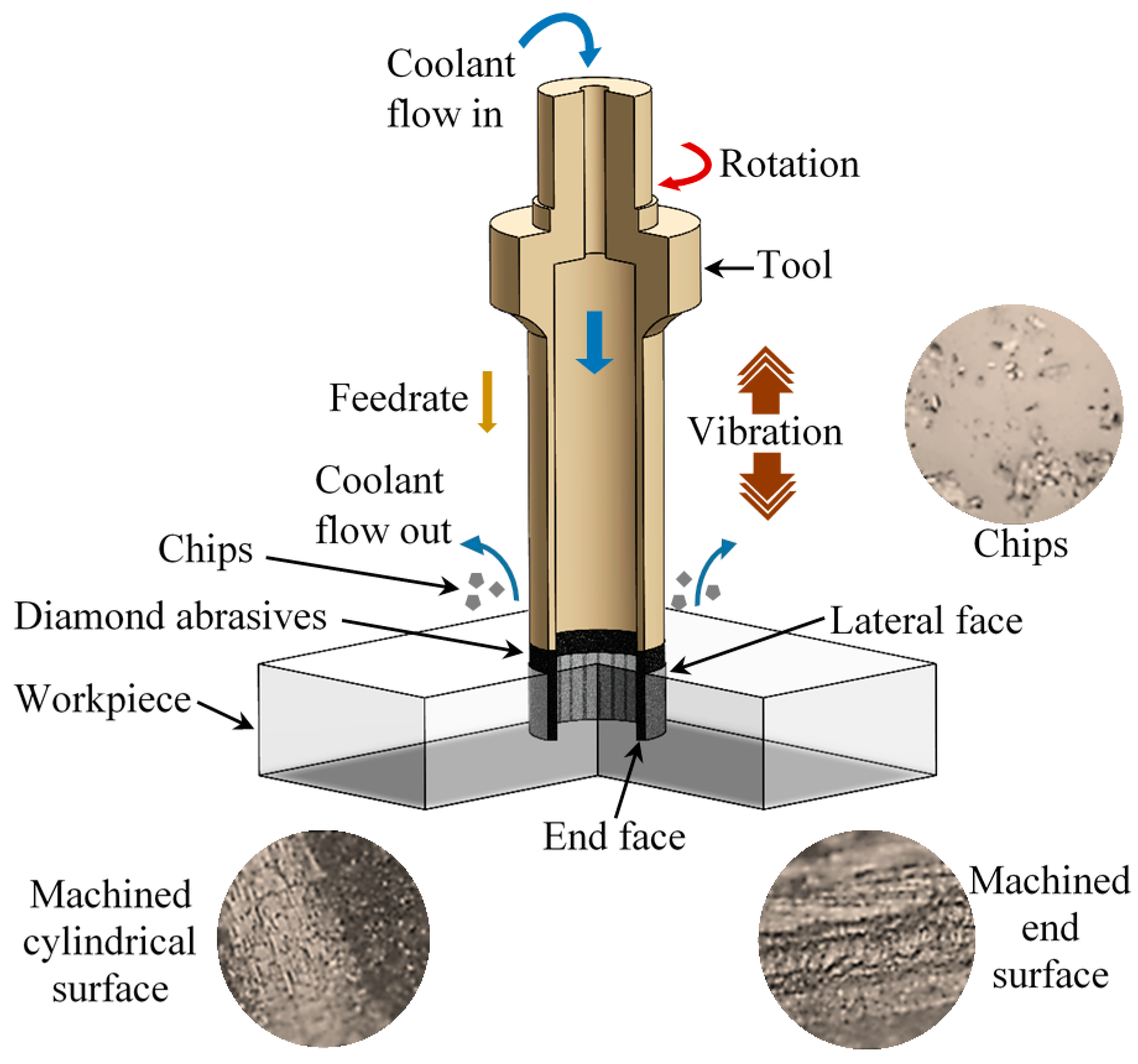

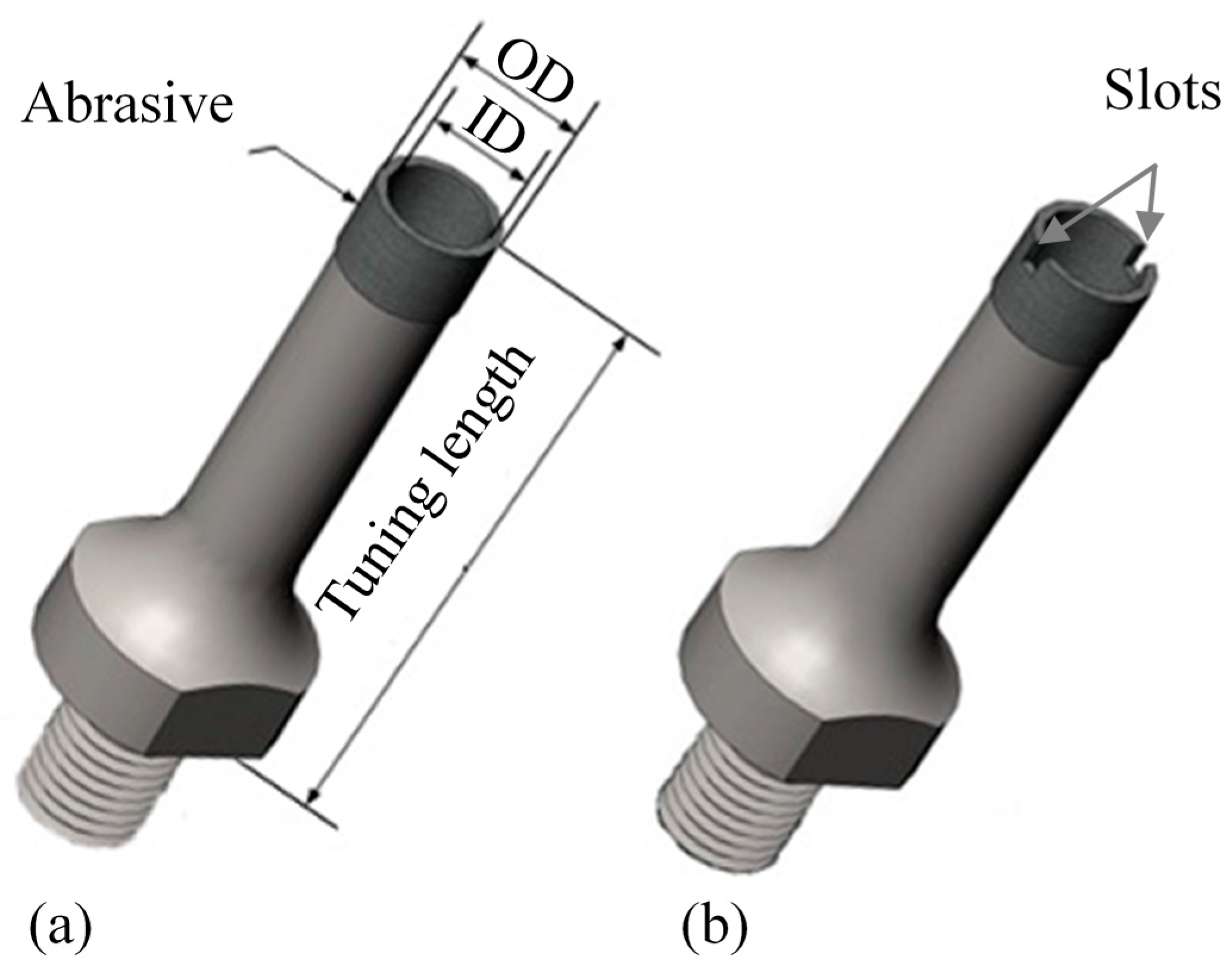

2.2. Experimental Set-Up

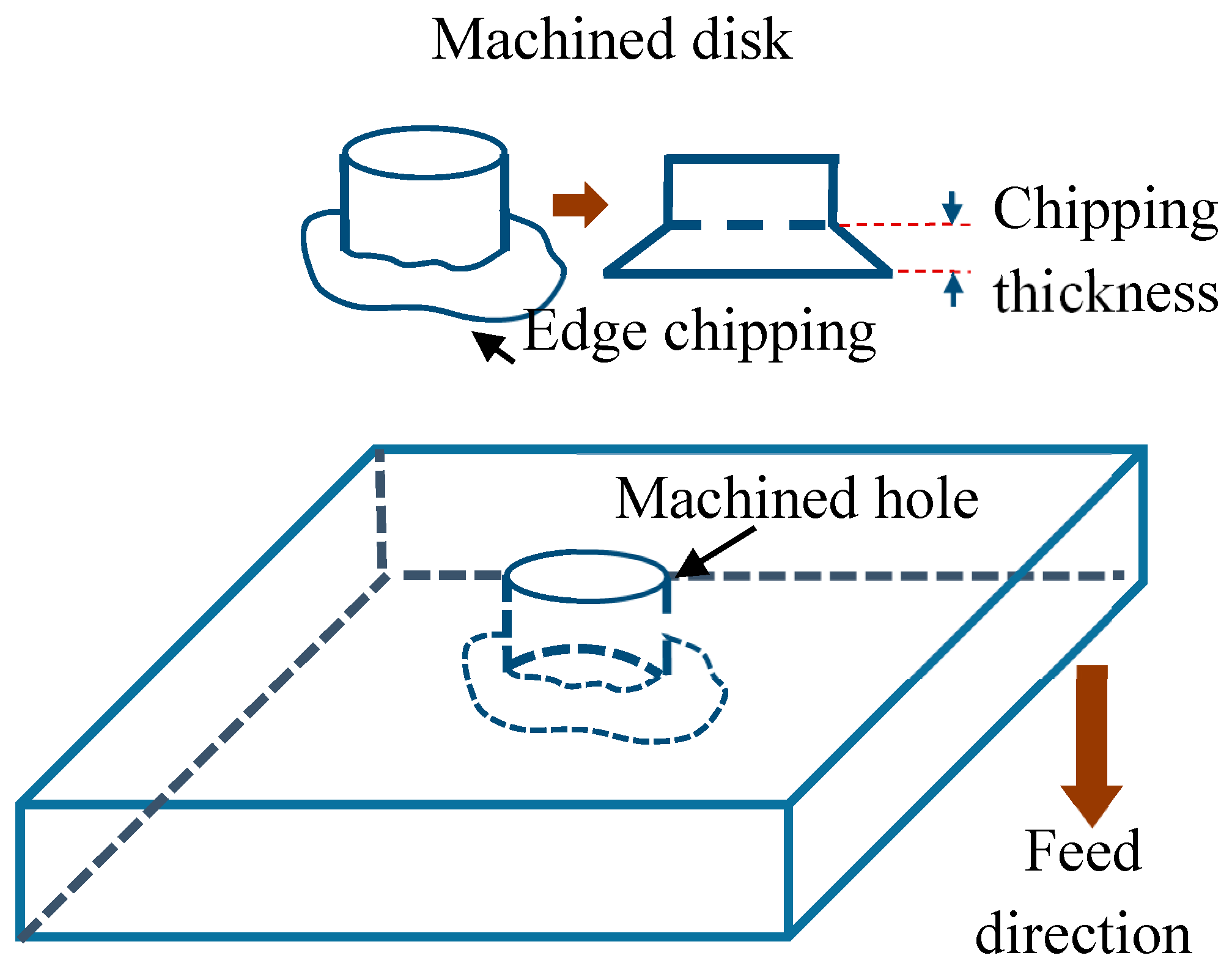

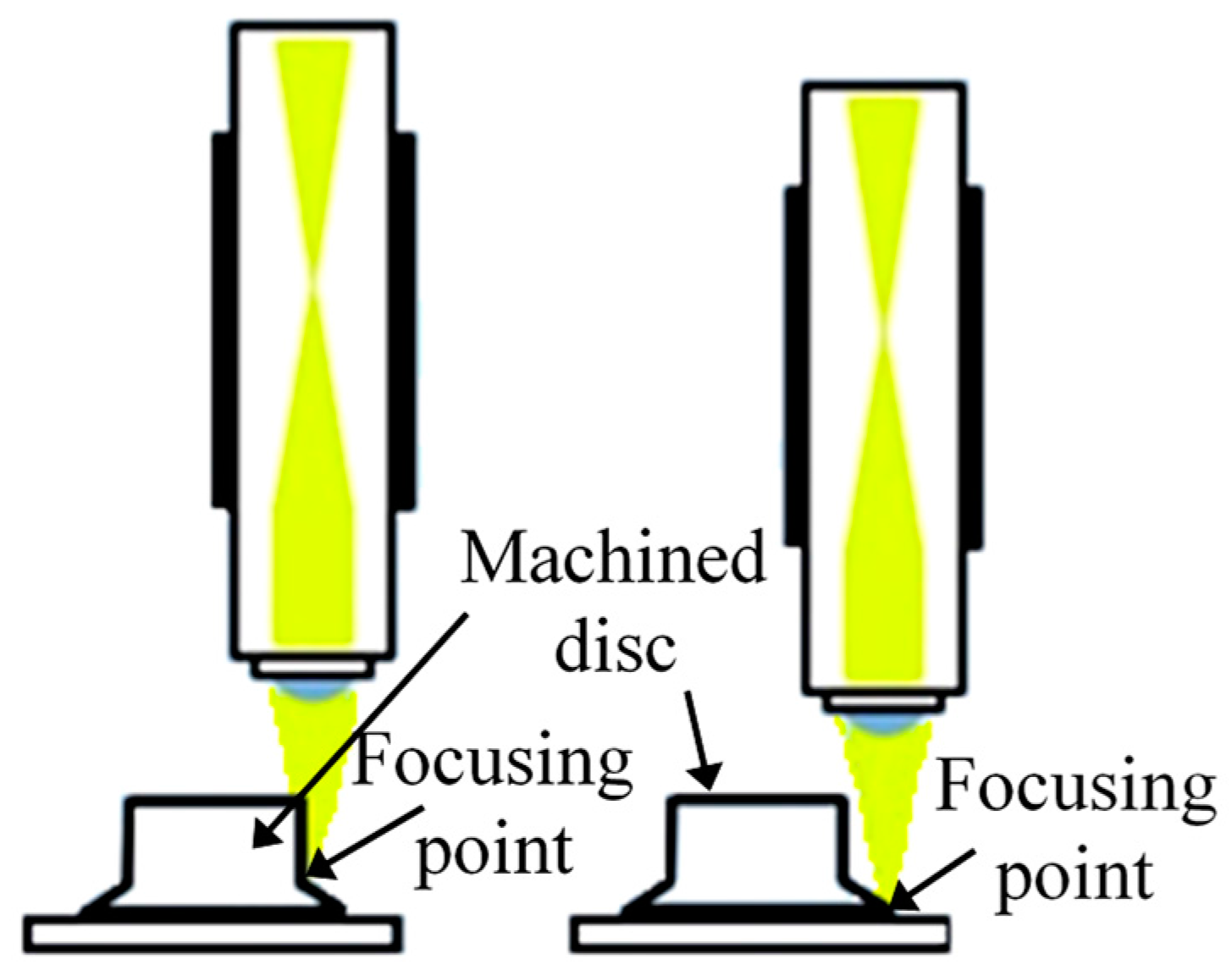

2.3. Measurement Procedures

3. Experimental Results

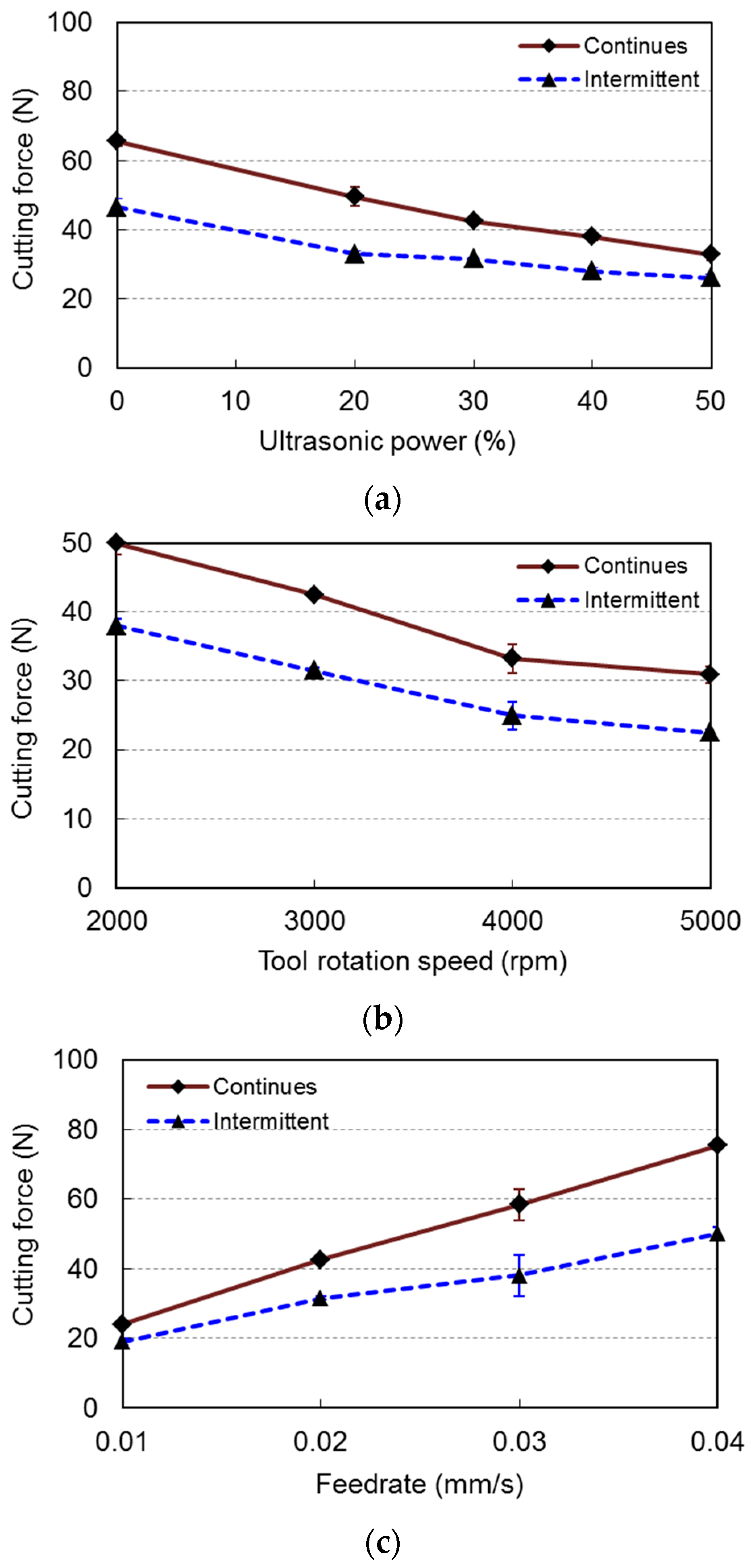

3.1. Effects on Cutting Force

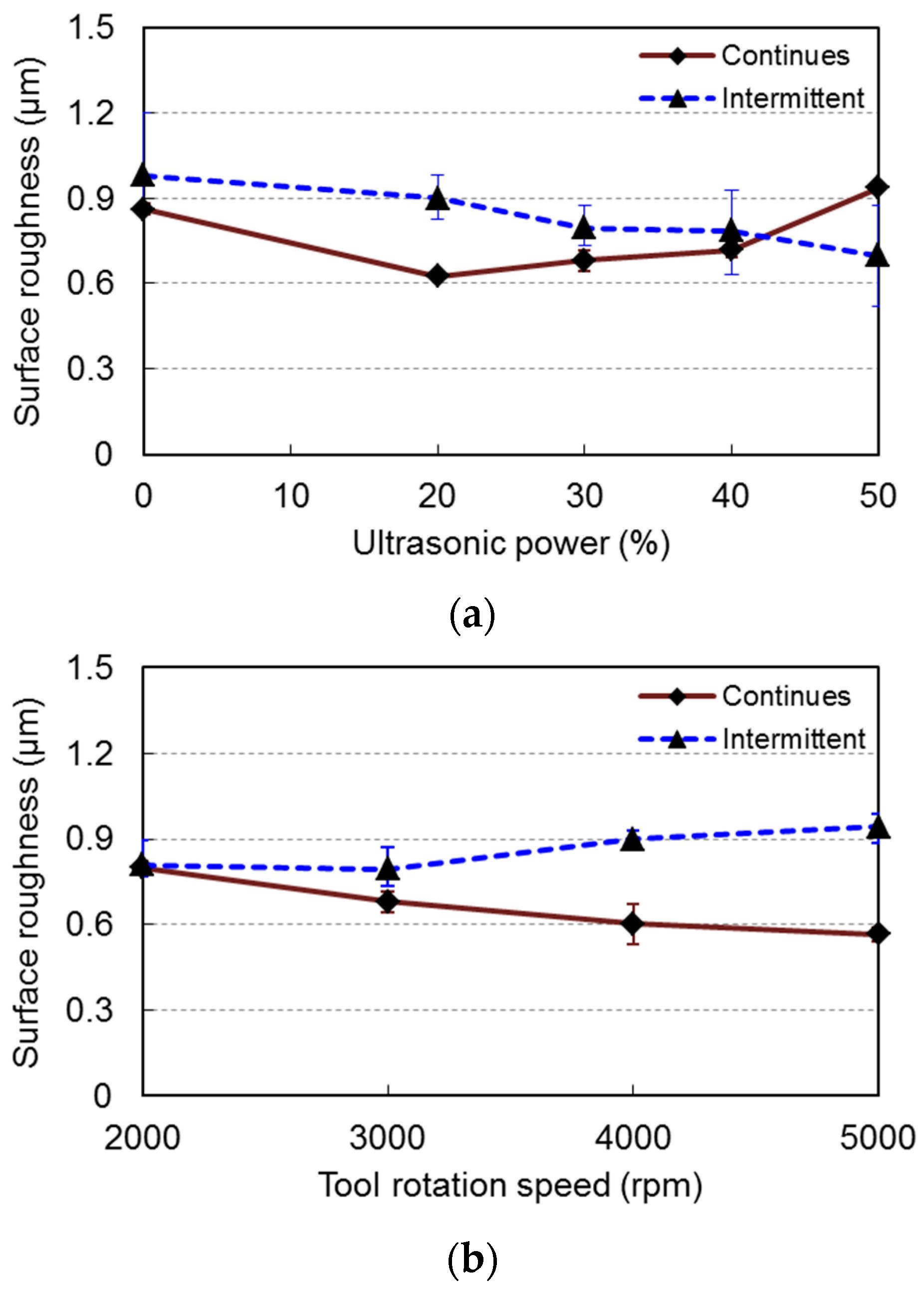

3.2. Effects on Surface Roughness

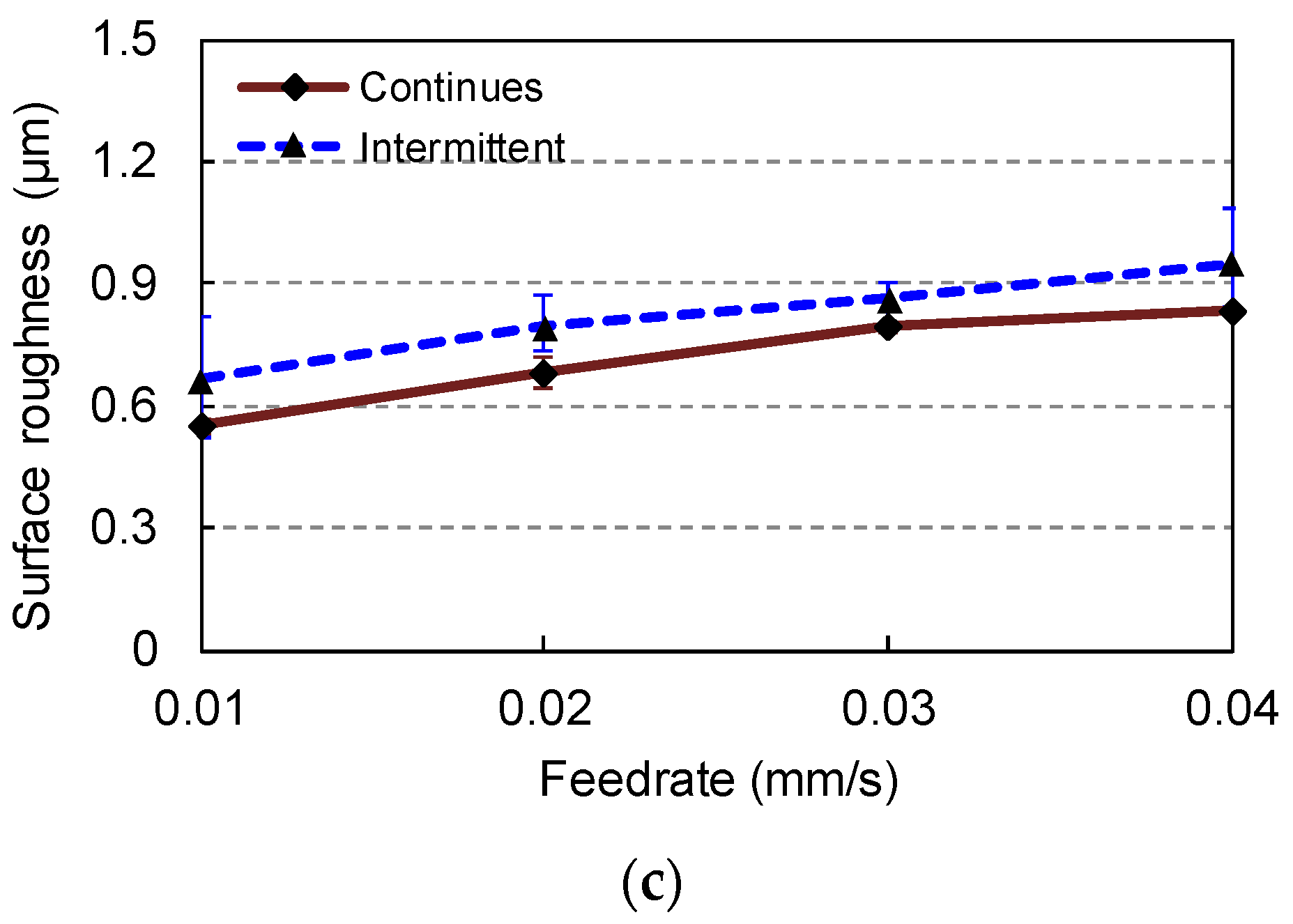

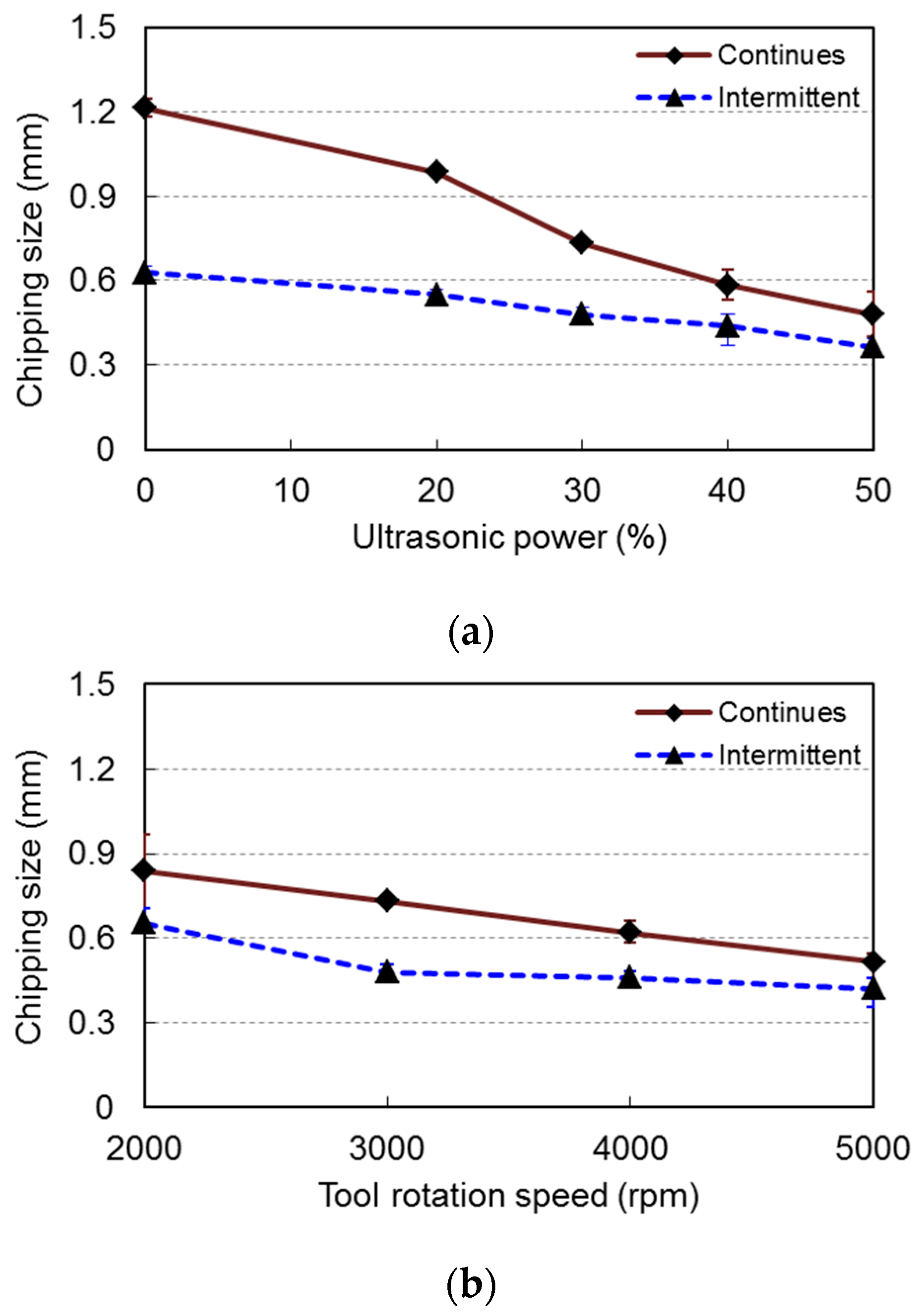

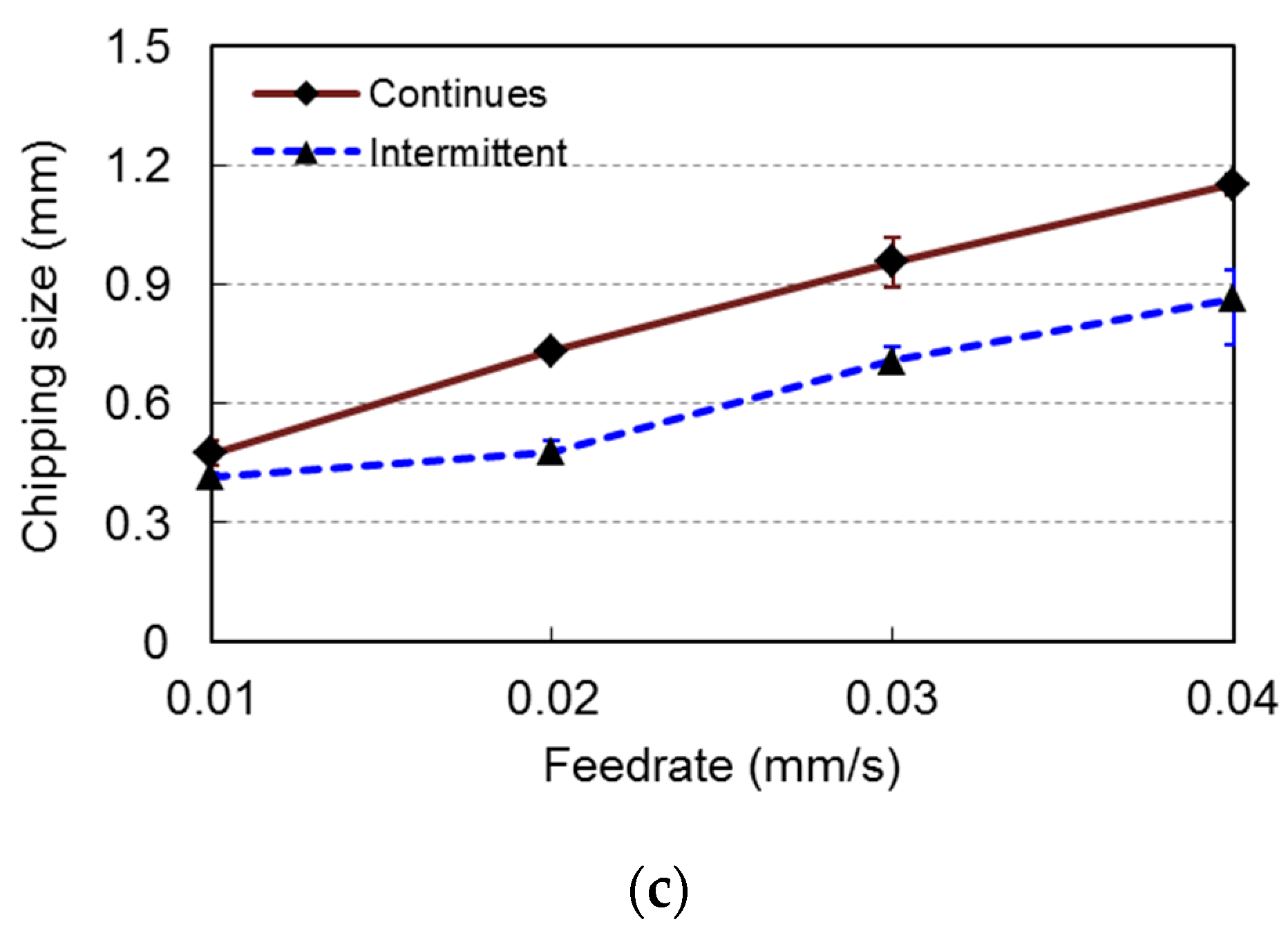

3.3. Effects on Edge Chipping

4. Conclusions

- (a)

- Using intermittent RUM led to a lower cutting force than using continuous RUM in K9 glass machining.

- (b)

- Compared to the continuous RUM, intermittent RUM didn’t improve the surface roughness of drilled holes.

- (c)

- Chipping size in intermittent RUM was smaller than that in continuous RUM when other input variables stayed constant.

- (d)

- It was observed that higher cutting force resulted in a larger chipping size, and this relationship was close to linear.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gu, W.; Yao, Z. Evaluation of surface cracking in micron and sub-micron scale scratch tests for optical glass BK7. J. Mech. Sci. Technol. 2011, 25, 1167–1174. [Google Scholar] [CrossRef]

- Choi, J.; Jeon, B.; Kim, B. Chemical-assisted ultrasonic machining of glass. J. Mater. Process. Technol. 2007, 191, 153–156. [Google Scholar] [CrossRef]

- Zhang, C.; Cong, W.; Feng, P.; Pei, Z. Rotary ultrasonic machining of optical K9 glass using compressed air as coolant: A feasibility study. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2014, 228, 504–514. [Google Scholar] [CrossRef]

- Gu, W.; Yao, Z.; Li, H. Investigation of grinding modes in horizontal surface grinding of optical glass BK7. J. Mater. Process. Technol. 2011, 211, 1629–1636. [Google Scholar] [CrossRef]

- Park, D.; Cho, M.; Lee, H.; Cho, W. Micro-grooving of glass using micro-abrasive jet machining. J. Mater. Process. Technol. 2004, 146, 234–240. [Google Scholar] [CrossRef]

- Matsumura, T.; Muramatsu, T.; Fueki, S. Abrasive water jet machining of glass with stagnation effect. CIRP Ann. 2011, 60, 355–358. [Google Scholar] [CrossRef]

- Lv, D.; Huang, Y.; Wang, H.; Tang, Y.; Wu, X. Improvement effects of vibration on cutting force in rotary ultrasonic machining of BK7 glass. J. Mater. Process. Technol. 2013, 213, 1548–1557. [Google Scholar] [CrossRef]

- Lv, D.; Huang, Y.; Tang, Y.; Wang, H. Relationship between subsurface damage and surface roughness of glass BK7 in rotary ultrasonic machining and conventional grinding processes. Int. J. Adv. Manuf. Technol. 2012, 67, 613–622. [Google Scholar] [CrossRef]

- Lv, D.; Wang, H.; Tang, Y.; Huang, Y.; Li, Z. Influences of vibration on surface formation in rotary ultrasonic machining of glass BK7. Precis. Eng. 2013, 37, 839–848. [Google Scholar] [CrossRef]

- Zeng, W.; Li, Z.; Pei, Z.; Treadwell, C. Experimental observation of tool wear in rotary ultrasonic machining of advanced ceramics. Int. J. Mach. Tools Manuf. 2005, 45, 1468–1473. [Google Scholar] [CrossRef]

- Prabhakar, D. Machining Advanced Ceramic Materials Using Rotary Ultrasonic Machining Process. Master’s Thesis, University of Illinois at Urbana-Champaign, Champaign, IL, USA, 1992. [Google Scholar]

- Hu, P.; Zhang, J.; Pei, Z.; Treadwell, C. Modeling of material removal rate in rotary ultrasonic machining: Designed experiments. J. Mater. Process. Technol. 2002, 129, 339–344. [Google Scholar] [CrossRef]

- Zhang, C.; Feng, P.; Zhang, J.; Wu, Z.; Yu, D. Investigation into the rotary ultrasonic face milling of K9 glass with mechanism study of material removal. Int. J. Manuf. Technol. Manag. 2012, 25, 248–266. [Google Scholar] [CrossRef]

- Lv, D.; Tang, Y.; Wang, H.; Huang, Y. Experimental investigations on subsurface damage in rotary ultrasonic machining of glass BK7. Mach. Sci. Technol. 2013, 17, 443–463. [Google Scholar] [CrossRef]

- Lv, D.; Wang, H.; Zhang, W.; Yin, Z. Subsurface damage depth and distribution in rotary ultrasonic machining and conventional grinding of glass BK7. Int. J. Adv. Manuf. Technol. 2016, 86, 2361–2371. [Google Scholar] [CrossRef]

- Lv, D. Influences of high-frequency vibration on tool wear in rotary ultrasonic machining of glass BK7. Int. J. Adv. Manuf. Technol. 2015. [Google Scholar] [CrossRef]

- Cong, W.; Pei, Z.; Deines, T.; Treadwell, C. Rotary ultrasonic machining of CFRP using cold air as coolant: Feasible regions. J. Reinf. Plast. Compos. 2011, 30, 899–906. [Google Scholar] [CrossRef]

- Zeng, W.; Li, Z.; Xu, X.; Pei, Z.; Liu, J.; Pi, J. Experimental Investigation of Intermittent Rotary Ultrasonic Machining. Key Eng. Mater. 2008, 359–360, 425–430. [Google Scholar] [CrossRef]

- Chowdhury, M.; Ullah, A.; Anwar, S. Drilling High Precision Holes in Ti6Al4V Using Rotary Ultrasonic Machining and Uncertainties Underlying Cutting Force, Tool Wear, and Production Inaccuracies. Materials 2017, 10, 1069. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Zhang, C.; Feng, P.; Zhang, J. A model for prediction of subsurface damage in rotary ultrasonic face milling of optical K9 glass. Int. J. Adv. Manuf. Technol. 2015, 83, 347–355. [Google Scholar] [CrossRef]

- Cong, W.; Feng, Q.; Pei, Z.; Deines, T.; Treadwell, C. Rotary ultrasonic machining of carbon fiber-reinforced plastic composites: Using cutting fluid vs. cold air as coolant. J. Compos. Mater. 2011, 46, 1745–1753. [Google Scholar] [CrossRef]

- Cong, W.; Pei, Z.; Sun, X.; Zhang, C. Rotary ultrasonic machining of CFRP: A mechanistic predictive model for cutting force. Ultrasonics 2014, 54, 663–675. [Google Scholar] [CrossRef] [PubMed]

| Property | Unit | Value |

|---|---|---|

| Density | g/cm3 | 2.5 |

| Young’s modulus | GPa | 85.9 |

| Poisson’s ratio | - | 0.28 |

| Vickers hardness | GPa | 7.2 |

| Fracture toughness | MPa·m1/2 | 0.8 |

| Input Variable | Values |

|---|---|

| Ultrasonic power (%) | 0; 10; 20; 30; 40; 50 |

| Tool rotation speed (rpm) | 2000; 3000; 4000; 5000 |

| Feedrate (mm/s) | 0.01; 0.02; 0.03; 0.04 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernando, P.; Zhang, M.; Pei, Z.; Cong, W. Intermittent and Continuous Rotary Ultrasonic Machining of K9 Glass: An Experimental Investigation. J. Manuf. Mater. Process. 2017, 1, 20. https://doi.org/10.3390/jmmp1020020

Fernando P, Zhang M, Pei Z, Cong W. Intermittent and Continuous Rotary Ultrasonic Machining of K9 Glass: An Experimental Investigation. Journal of Manufacturing and Materials Processing. 2017; 1(2):20. https://doi.org/10.3390/jmmp1020020

Chicago/Turabian StyleFernando, Palamandadige, Meng Zhang, Zhijian Pei, and Weilong Cong. 2017. "Intermittent and Continuous Rotary Ultrasonic Machining of K9 Glass: An Experimental Investigation" Journal of Manufacturing and Materials Processing 1, no. 2: 20. https://doi.org/10.3390/jmmp1020020