Fault Detection in Wastewater Treatment Systems Using Multiparametric Programming

Abstract

:1. Introduction

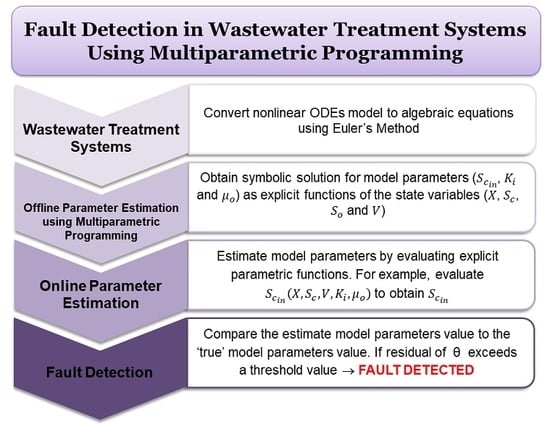

2. Problem Statement and Solution Approach

Problem Definition

- (i)

- The nonlinear ODEs model in Equation (2) was discretized using Euler’s method to algebraic equations on the interval, . The Euler’s method provideswhere the step size is given by .

- (ii)

- Fault detection problem was formulated as a nonlinear programming (NLP) problem as follows:Problem 2.subject to:where is the set of nonlinear algebraic equations obtained by discretizing the ODEs given by Equation (5), and is considered in this work.

- (iii)

- For Problem 2, the Lagrangian function is given bywhereand represents the Lagrange multipliers. The first-order Karush-Kuhn-Tucker (KKT) conditions are given by the equality constrains as follows

- (iv)

- The equality constraints corresponding to the KKT conditions given by Equations (12) and (13) were solved symbolically to obtain Lagrange multipliers and model parameters, , as an explicit function of measurements, .

- (v)

- The solutions obtained in the previous step were examined and solutions with imaginary parts were ignored.

- (vi)

- The estimated model parameters, , were calculated using the measurements, , by simple evaluation of .

- (vii)

- Faults were diagnosed by monitoring residual changes in model parameters. Any significant difference between estimated and observed model parameters may be attributed to occurrence of a fault.

3. Wastewater Treatment System

Fault Detection Problem for the Wastewater Treatment Process

- (i)

- The nonlinear ODE model in Equations (16)–(19) is discretized using explicit Euler’s method and reformulated as the following algebraic equations:

- (ii)

- The discrete-time fault detection problem is formulated as the following NLP:Problem 4.subject to:

- (iii)

- Equations (27)–(30) are substituted into Equation (26) to obtain:

- (iv)

- The equality constraints in Equations (36)–(38) are solved analytically in Mathematica, and the symbolic solution for model parameters is given by

- (v)

- Equations (39)–(41) represent the symbolic solution for model parameters, , , and , obtained as explicit functions of the state variables, , , , and . In this case study, single fault was assumed to occur at any time. Hence, as an example in Equation (39), the solution of was obtained in terms of model parameters, and , and state variables, , , and . In Equation (40), the solution of was obtained in terms of model parameters, and , and state variables, , , , and . The solution of was obtained in terms of model parameters and , and state variables, , , , and , as shown in Equation (41). Simple function evaluation was performed to evaluate the model parameters without the need for solving the online optimization problem. Then, the fault detection was performed by monitoring the residuals of model parameters. Any substantial discrepancy between estimated and observed model parameters indicates changes in the process and may be attributed to a fault.

4. Results

4.1. Fault-Free Scenario

4.2. Faulty Scenario

5. Concluding Remarks

Author Contributions

Funding

Conflicts of Interest

References

- Mo, W.; Zhang, Q. Energy–nutrients–water nexus: Integrated resource recovery in municipal wastewater treatment plants. J. Environ. Manag. 2013, 127, 255–267. [Google Scholar] [CrossRef] [PubMed]

- Tyagi, V.K.; Lo, S.-L. Sludge: A waste or renewable source for energy and resources recovery? Renew. Sustain. Energy Rev. 2013, 25, 708–728. [Google Scholar] [CrossRef]

- Batstone, D.J.; Hülsen, T.; Mehta, C.M.; Keller, J. Platforms for energy and nutrient recovery from domestic wastewater: A review. Chemosphere 2015, 140, 2–11. [Google Scholar] [CrossRef] [PubMed]

- Rosen, C.; Röttorp, J.; Jeppsson, U. Multivariate on-line monitoring: Challenges and solutions for modern wastewater treatment operation. Water Sci. Technol. 2003, 47, 171–179. [Google Scholar] [CrossRef] [PubMed]

- Mhaskar, P.; Gani, A.; El-farra, N.H.; Mcfall, C.; Christofides, P.D.; Davis, J.F. Integrated fault-detection and fault-tolerant control of process systems. AIChE J. 2006, 52, 2129–2148. [Google Scholar] [CrossRef]

- Mhaskar, P.; McFall, C.; Gani, A.; Christofides, P.D.; Davis, J.F. Isolation and handling of actuator faults in nonlinear systems. Automatica 2008, 44, 53–62. [Google Scholar] [CrossRef]

- Du, M.; Mhaskar, P. Isolation and handling of sensor faults in nonlinear systems. Automatica 2014, 50, 1066–1074. [Google Scholar] [CrossRef]

- Maier, H.R.; Dandy, G.C. Neural networks for the prediction and forecasting of water resources variables: A review of modelling issues and applications. Environ. Model. Softw. 2000, 15, 101–124. [Google Scholar] [CrossRef]

- Caccavale, F.; Digiulio, P.; Iamarino, M.; Masi, S.; Pierri, F. A neural network approach for on-line fault detection of nitrogen sensors in alternated active sludge treatment plants. Water Sci. Technol. 2010, 62, 2760–2768. [Google Scholar] [CrossRef] [PubMed]

- Honggui, H.; Ying, L.; Junfei, Q. A fuzzy neural network approach for online fault detection in waste water treatment process. Comput. Electr. Eng. 2014, 40, 2216–2226. [Google Scholar] [CrossRef]

- Lee, J.-M.; Yoo, C.; Choi, S.W.; Vanrolleghem, P.A.; Lee, I.-B. Nonlinear process monitoring using kernel principal component analysis. Chem. Eng. Sci. 2004, 59, 223–234. [Google Scholar] [CrossRef]

- Baggiani, F.; Marsili-Libelli, S. Real-time fault detection and isolation in biological wastewater treatment plants. Water Sci. Technol. 2009, 60, 2949–2961. [Google Scholar] [CrossRef] [PubMed]

- Sanchez-Fernández, A.; Fuente, M.J.; Sainz-Palmero, G.I. Fault detection in wastewater treatment plants using distributed pca methods. In Proceedings of the 2015 IEEE 20th Conference on Emerging Technologies & Factory Automation (ETFA), Luxembourg, Germany, 8–11 September 2015; pp. 1–7. [Google Scholar]

- Garcia-Alvarez, D.; Fuente, M.J.; Vega, P.; Sainz, G. Fault detection and diagnosis using multivariate statistical techniques in a wastewater treatment plant. In Proceedings of the 7th IFAC International Symposium on Advanced Control of Chemical Processes, Istanbul, Turkey, 12–15 July 2009; Volume 42, pp. 952–957. [Google Scholar]

- Chen, A.; Zhou, H.; An, Y.; Sun, W. Pca and pls monitoring approaches for fault detection of wastewater treatment process. In Proceedings of the 2016 IEEE 25th International Symposium on Industrial Electronics (ISIE), Santa Clara, CA, USA, 8–10 June 2016; pp. 1022–1027. [Google Scholar]

- Carlsson, B.; Zambrano, J. Fault detection and isolation of sensors in aeration control systems. Water Sci. Technol. 2016, 73, 648–653. [Google Scholar] [CrossRef] [PubMed]

- Gontarski, C.A.; Rodrigues, P.R.; Mori, M.; Prenem, L.F. Simulation of an industrial wastewater treatment plant using artificial neural networks. Comput. Chem. Eng. 2000, 24, 1719–1723. [Google Scholar] [CrossRef]

- Fragkoulis, D.; Roux, G.; Dahhou, B. Detection, isolation and identification of multiple actuator and sensor faults in nonlinear dynamic systems: Application to a waste water treatment process. Appl. Math. Model. 2011, 35, 522–543. [Google Scholar] [CrossRef]

- Wimberger, D.; Verde, C. Fault diagnosticability for an aerobic batch wastewater treatment process. Control Eng. Pract. 2008, 16, 1344–1353. [Google Scholar] [CrossRef]

- Brouwer, H.; Klapwijk, A.; Keesman, K.J. Modelling and control of activated sludge plants on the basis of respirometry. Water Sci. Technol. 1994, 30, 265–274. [Google Scholar] [CrossRef]

- Carlsson, B.; Lindberg, C.; Hasselblad, S.; Xu, S. On-line estimation of the respiration rate and the oxygen transfer rate at kungsangen wastewater treatment plant in uppsala. Water Sci. Technol. 1994, 30, 255–263. [Google Scholar] [CrossRef]

- Carlsson, B. On-line estimation of the respiration rate in an activated sludge process. Water Sci. Technol. 1993, 28, 427–434. [Google Scholar] [CrossRef]

- Lindberg, C.-F.; Carlsson, B. Estimation of the respiration rate and oxygen transfer function utilizing a slow do sensor. Water Sci. Technol. 1996, 33, 325–333. [Google Scholar] [CrossRef]

- Jiang, T.; Khorasani, K.; Tafazoli, S. Parameter estimation-based fault detection, isolation and recovery for nonlinear satellite models. IEEE Trans. Control Syst. Technol. 2008, 16, 799–808. [Google Scholar] [CrossRef]

- Isermann, R. Fault diagnosis of machines via parameter estimation and knowledge processing—Tutorial paper. Automatica 1993, 29, 815–835. [Google Scholar] [CrossRef]

- Huang, B. Detection of abrupt changes of total least squares models and application in fault detection. IEEE Trans. Control Syst. Technol. 2001, 9, 357–367. [Google Scholar] [CrossRef]

- Garatti, S.; Bittanti, S. A new paradigm for parameter estimation in system modeling. Int. J. Adapt. Control Signal Process. 2012, 27, 667–687. [Google Scholar] [CrossRef]

- Park, S.; Himmelblau, D.M. Fault detection and diagnosis via parameter estimation in lumped dynamic systems. Ind. Eng. Chem. Process Des. Dev. 1983, 482–487. [Google Scholar] [CrossRef]

- Pouliezos, A.; Stavrakakis, G.; Lefas, C. Fault detection using parameter estimation. Qual. Reliab. Eng. Int. 1989, 5, 283–290. [Google Scholar] [CrossRef]

- Venkatasubramanian, V.; Rengaswamy, R.; Yin, K.; Kavuri, S.N. A review of process fault detection and diagnosis part i: Quantitative model-based methods. Comput. Chem. Eng. 2003, 27, 293–311. [Google Scholar] [CrossRef]

- Hwang, I.; Kim, S.; Kim, Y.; Seah, C.E. A survey of fault detection, isolation, and reconfiguration methods. IEEE Trans. Control Syst. Technol. 2010, 18, 636–653. [Google Scholar] [CrossRef]

- Che Mid, E.; Dua, V. Model-based parameter estimation for fault detection using multiparametric programming. Ind. Eng. Chem. Res. 2017, 56, 8000–8015. [Google Scholar] [CrossRef]

- Dua, V.; Pistikopoulos, E.N. Algorithms for the solution of multiparametric mixed-integer nonlinear optimization problems. Ind. Eng. Chem. Res. 1999, 38, 3976–3987. [Google Scholar] [CrossRef]

- Pistikopoulos, E.N.; Dua, V.; Bozinis, N.A.; Bemporad, A.; Morari, M. On-line optimization via off-line parametric optimization tools. Comput. Chem. Eng. 2002, 26, 175–185. [Google Scholar] [CrossRef]

- Pistikopoulos, E.N. Perspectives in multiparametric programming and explicit model predictive control. AIChE J. 2009, 55, 1918–1925. [Google Scholar] [CrossRef]

- Oberdieck, R.; Diangelakis, N.A.; Papathanasiou, M.M.; Nascu, I.; Pistikopoulos, E.N. Pop—parametric optimization toolbox. Ind. Eng. Chem. Res. 2016, 55, 8979–8991. [Google Scholar] [CrossRef]

- Pistikopoulos, E.N.; Georgiadis, M.C.; Dua, V. Multi-Parametric Programming: Volume 1: Theory, Algorithms, and Applications; Wiley-VCH: Weinheim, Germany, 2007. [Google Scholar]

- Pistikopoulos, E.N.; Georgiadis, M.C.; Dua, V. Multi-Parametric Model-Based Control: Volume 2: Theory and Applications; Wiley-VCH: Weinheim, Germany, 2007. [Google Scholar]

- Charitopoulos, V.M.; Dua, V. Explicit model predictive control of hybrid systems and multiparametric mixed integer polynomial programming. AIChE J. 2016, 62, 3441–3460. [Google Scholar] [CrossRef] [Green Version]

- Dua, V.; Dua, P. A simultaneous approach for parameter estimation of a system of ordinary differential equations, using artificial neural network approximation. Ind. Eng. Chem. Res. 2011, 51, 1809–1814. [Google Scholar] [CrossRef]

- Irvine, R.L.; Ketchum, L.H., Jr. Sequencing batch reactors for biological wastewater treatment. Crit. Rev. Environ. Control 1988, 18, 225–294. [Google Scholar] [CrossRef]

- Fibrianto, H.; Mazouni, D.; Ignatova, M.; Herveau, M.; Harmand, J.; Dochain, D. Dynamical modelling, identification and software sensors for sbrs. Math. Comput. Model. Dyn. Syst. 2008, 14, 17–26. [Google Scholar] [CrossRef] [Green Version]

| Parameter | Value | Description |

|---|---|---|

| 168 mg/L | the concentration of substrate in the inflow | |

| 0 mg/L | the concentration of dissolved oxygen in the inflow | |

| 14.8 mg/L | the inflow rate | |

| 6 mg/L | the dissolved oxygen mass at saturation | |

| 3.7 | the conversion coefficient of the substrate to biomass | |

| 1.0363 | the conversion coefficient of oxygen to biomass | |

| 0.0059 1/h | the endogenous respiration coefficient | |

| 16.8 1/h | the oxygen mass transfer coefficient | |

| 3.753 mg/L | the inhibition coefficient | |

| 60 mg/L | the half saturation coefficient | |

| 0.1916 1/h | the specific growth rate |

| Fault Kinetic Model Parameter | Fault 1 | Fault 2 | Fault 3 |

|---|---|---|---|

| The concentration of substrate in the inflow, | −30% | - | - |

| The half saturation coefficient, | - | +30% | - |

| Specific growth rate, | - | - | −30% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Che Mid, E.; Dua, V. Fault Detection in Wastewater Treatment Systems Using Multiparametric Programming. Processes 2018, 6, 231. https://doi.org/10.3390/pr6110231

Che Mid E, Dua V. Fault Detection in Wastewater Treatment Systems Using Multiparametric Programming. Processes. 2018; 6(11):231. https://doi.org/10.3390/pr6110231

Chicago/Turabian StyleChe Mid, Ernie, and Vivek Dua. 2018. "Fault Detection in Wastewater Treatment Systems Using Multiparametric Programming" Processes 6, no. 11: 231. https://doi.org/10.3390/pr6110231