Figure 1.

Experimentally observed gas–liquid flow regimes in millichannel (1.0 × 1.0 mm) upstream of the micronozzle. Arrows indicate direction of flow. Gaseous phase is marked with “g”, liquid phase with “l”. (a) Bubbly flow at = 15%, = 40 mL/min; (b) slug flow at = 25%, = 40 mL/min; (c) parallel flow at = 40%, = 60 mL/min.

Figure 1.

Experimentally observed gas–liquid flow regimes in millichannel (1.0 × 1.0 mm) upstream of the micronozzle. Arrows indicate direction of flow. Gaseous phase is marked with “g”, liquid phase with “l”. (a) Bubbly flow at = 15%, = 40 mL/min; (b) slug flow at = 25%, = 40 mL/min; (c) parallel flow at = 40%, = 60 mL/min.

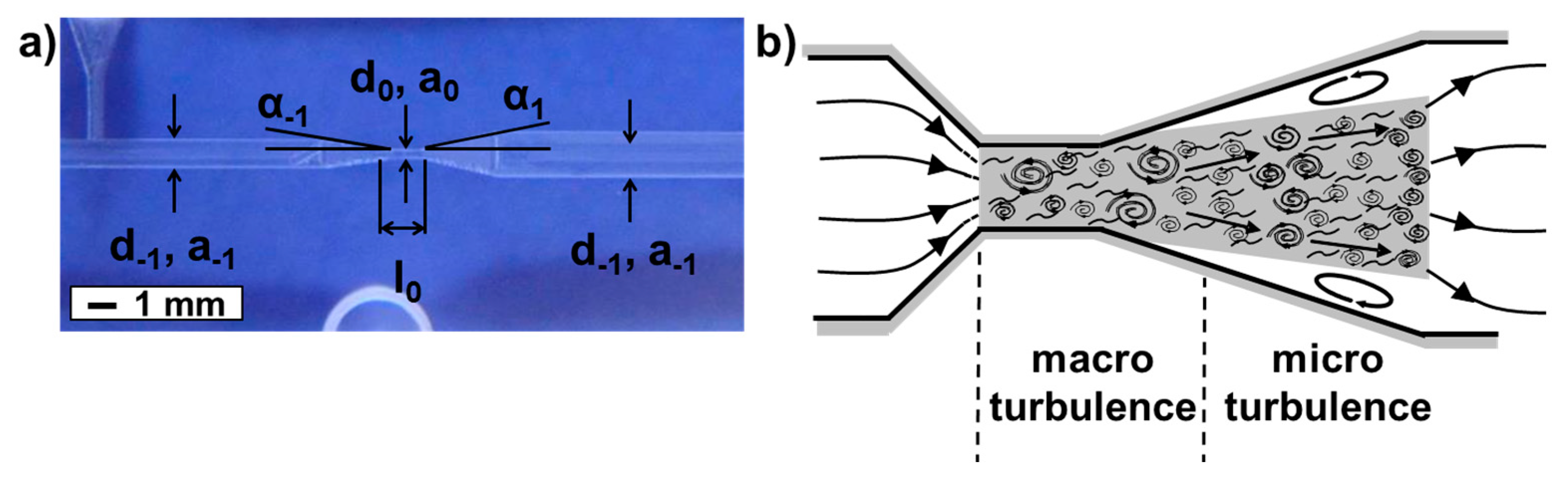

Figure 2.

(a) Characteristic geometrical parameters of the micronozzle; (b) turbulent field in diverging nozzle section. Dissipation volume is marked grey and regions of macro and micro turbulence are given.

Figure 2.

(a) Characteristic geometrical parameters of the micronozzle; (b) turbulent field in diverging nozzle section. Dissipation volume is marked grey and regions of macro and micro turbulence are given.

Figure 3.

Bubble generation in T-junction (left) and turbulent dispersion downstream of the nozzle with = 3732 and = 1846.

Figure 3.

Bubble generation in T-junction (left) and turbulent dispersion downstream of the nozzle with = 3732 and = 1846.

Figure 4.

Process inputs and outputs in Design of Experiments set-up for turbulent bubble breakup in microchannel nozzle.

Figure 4.

Process inputs and outputs in Design of Experiments set-up for turbulent bubble breakup in microchannel nozzle.

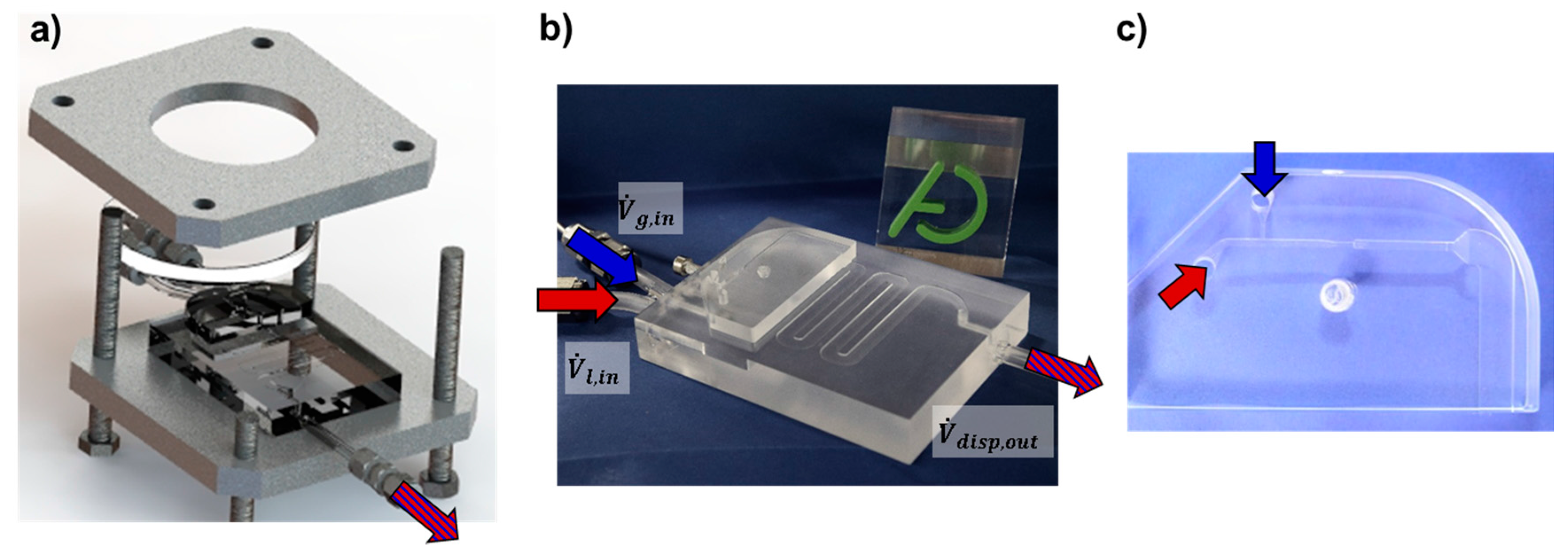

Figure 5.

(a) 3D model of the microreactor set-up with reaction plate, exchangeable nozzle element, view glass, and outer flanges; (b) reaction plate and nozzle insert made from PMMA; (c) exchangeable inlet element with micronozzle.

Figure 5.

(a) 3D model of the microreactor set-up with reaction plate, exchangeable nozzle element, view glass, and outer flanges; (b) reaction plate and nozzle insert made from PMMA; (c) exchangeable inlet element with micronozzle.

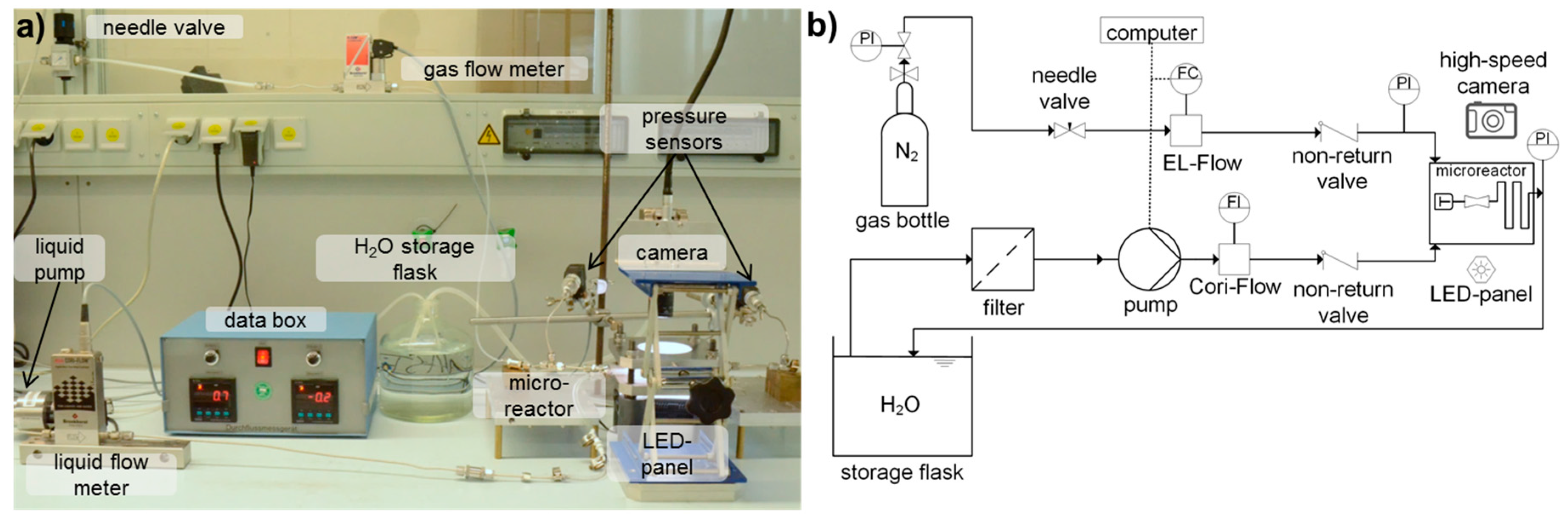

Figure 6.

(a) Experimental set-up for energy-efficient turbulent bubble breakup investigations; (b) accompanying flow chart.

Figure 6.

(a) Experimental set-up for energy-efficient turbulent bubble breakup investigations; (b) accompanying flow chart.

Figure 7.

Flow maps for varying total volumetric flow rates and void fraction. (a) Void fraction plotted over total volumetric flow rate with observed flow regimes; (b) void fraction plotted over capillary number Ca with observed flow regimes. Legends are included in the diagram.

Figure 7.

Flow maps for varying total volumetric flow rates and void fraction. (a) Void fraction plotted over total volumetric flow rate with observed flow regimes; (b) void fraction plotted over capillary number Ca with observed flow regimes. Legends are included in the diagram.

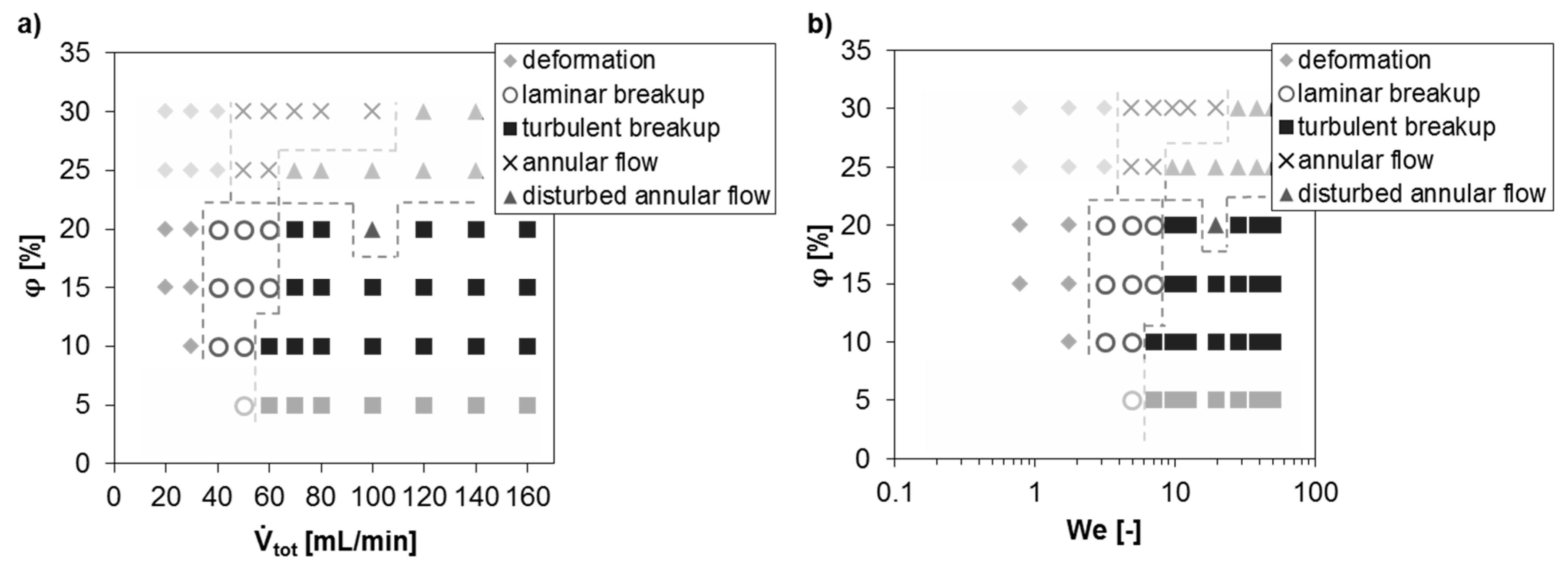

Figure 8.

Bubble breakup regime maps using nozzle inlay A. Regions outside of 10% < < 20% and 20 mL/min < < 160 mL/min are faded due to earlier exclusion. (a) Bubble breakup map for void fraction plotted over total volumetric flow rate; (b) bubble breakup map for void fraction plotted over characteristic Weber number.

Figure 8.

Bubble breakup regime maps using nozzle inlay A. Regions outside of 10% < < 20% and 20 mL/min < < 160 mL/min are faded due to earlier exclusion. (a) Bubble breakup map for void fraction plotted over total volumetric flow rate; (b) bubble breakup map for void fraction plotted over characteristic Weber number.

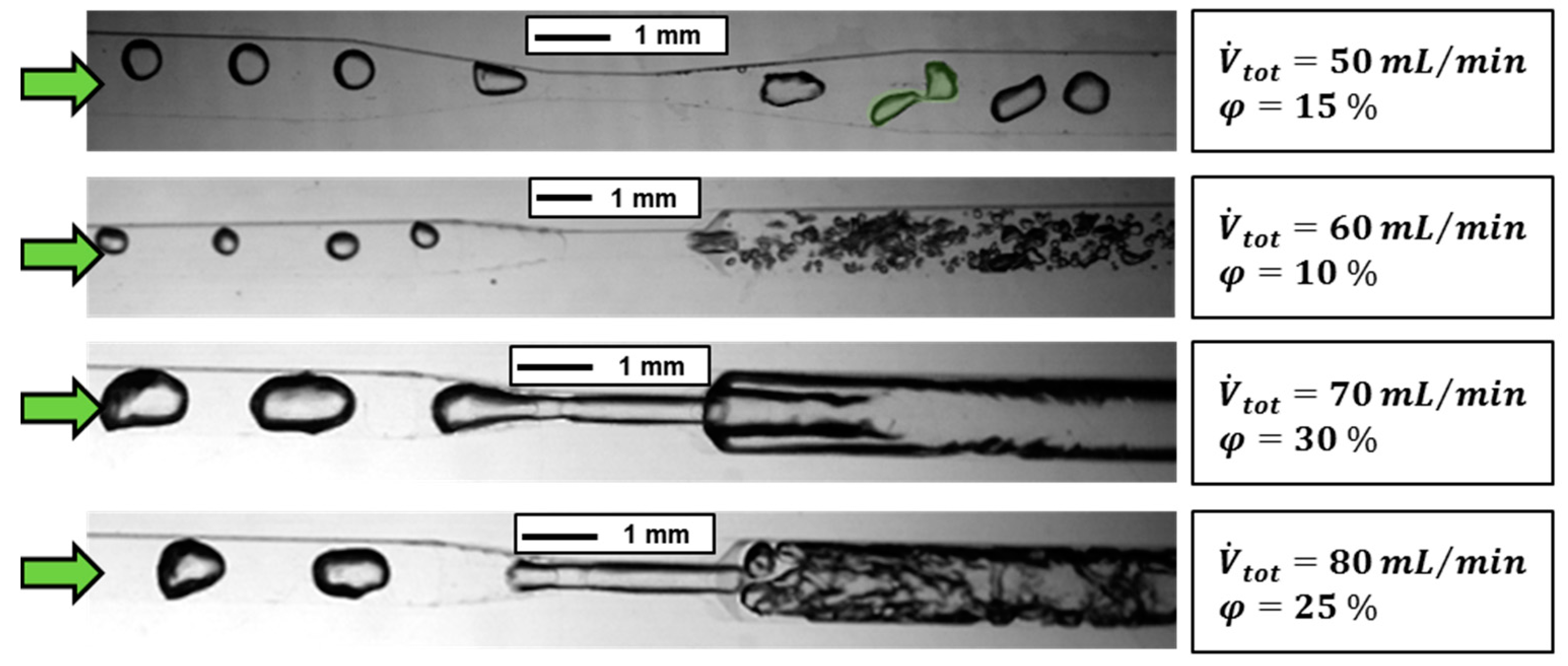

Figure 9.

Observed bubble breakup and flow regimes behind the micronozzle. The arrow marks the direction of flow. Process parameters are given next to the respective picture. From top to bottom: Laminar bubble breakup with ≈ 5 and ≈ 1660, turbulent breakup with ≈ 7 and ≈ 2300, annular flow with ≈ 10 and ≈ 2330, disturbed annular flow with ≈ 10 and ≈ 2660.

Figure 9.

Observed bubble breakup and flow regimes behind the micronozzle. The arrow marks the direction of flow. Process parameters are given next to the respective picture. From top to bottom: Laminar bubble breakup with ≈ 5 and ≈ 1660, turbulent breakup with ≈ 7 and ≈ 2300, annular flow with ≈ 10 and ≈ 2330, disturbed annular flow with ≈ 10 and ≈ 2660.

Figure 10.

Influence of mother bubble size on daughter bubble size. The top row diagrams (a,b) show results for constant void fraction = 10% and varied total volumetric flow rate. The bottom row diagrams; (c,d) show same diagrams for constant liquid flow rate = 100 mL/min and varied gas flow rate.

Figure 10.

Influence of mother bubble size on daughter bubble size. The top row diagrams (a,b) show results for constant void fraction = 10% and varied total volumetric flow rate. The bottom row diagrams; (c,d) show same diagrams for constant liquid flow rate = 100 mL/min and varied gas flow rate.

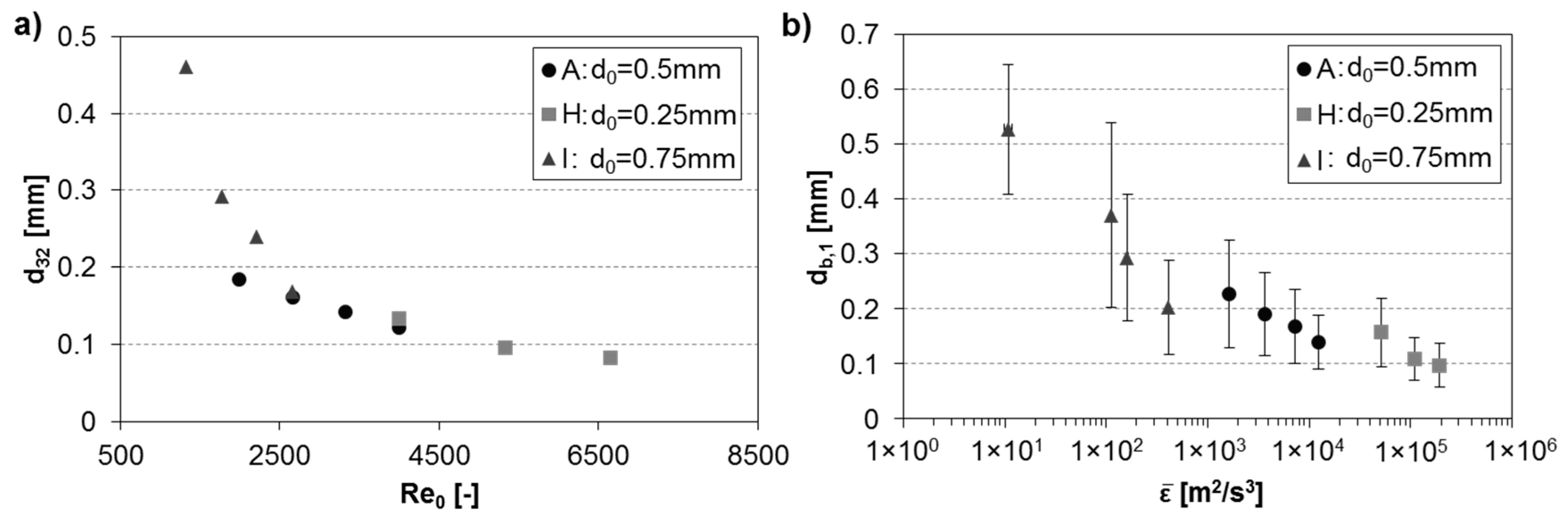

Figure 11.

Influence of hydraulic diameter on bubble breakup behind micronozzles. Constant geometrical nozzle parameter for all displayed inlay elements: = 1 mm, = 8°, = 2.5 mm, = 47.5°, = 1.25 mm. Nozzle inlay A: = 0.5 mm, nozzle inlay H: = 0.25 mm, and nozzle inlay I: = 0.75 mm. Volumetric flow rates are = 60, 80, 100, and 120 mL/min. (a) Sauter diameter plotted over Reynolds number in smallest cross section for varied ; (b) mean daughter bubble diameter over mean energy dissipation rate for varied .

Figure 11.

Influence of hydraulic diameter on bubble breakup behind micronozzles. Constant geometrical nozzle parameter for all displayed inlay elements: = 1 mm, = 8°, = 2.5 mm, = 47.5°, = 1.25 mm. Nozzle inlay A: = 0.5 mm, nozzle inlay H: = 0.25 mm, and nozzle inlay I: = 0.75 mm. Volumetric flow rates are = 60, 80, 100, and 120 mL/min. (a) Sauter diameter plotted over Reynolds number in smallest cross section for varied ; (b) mean daughter bubble diameter over mean energy dissipation rate for varied .

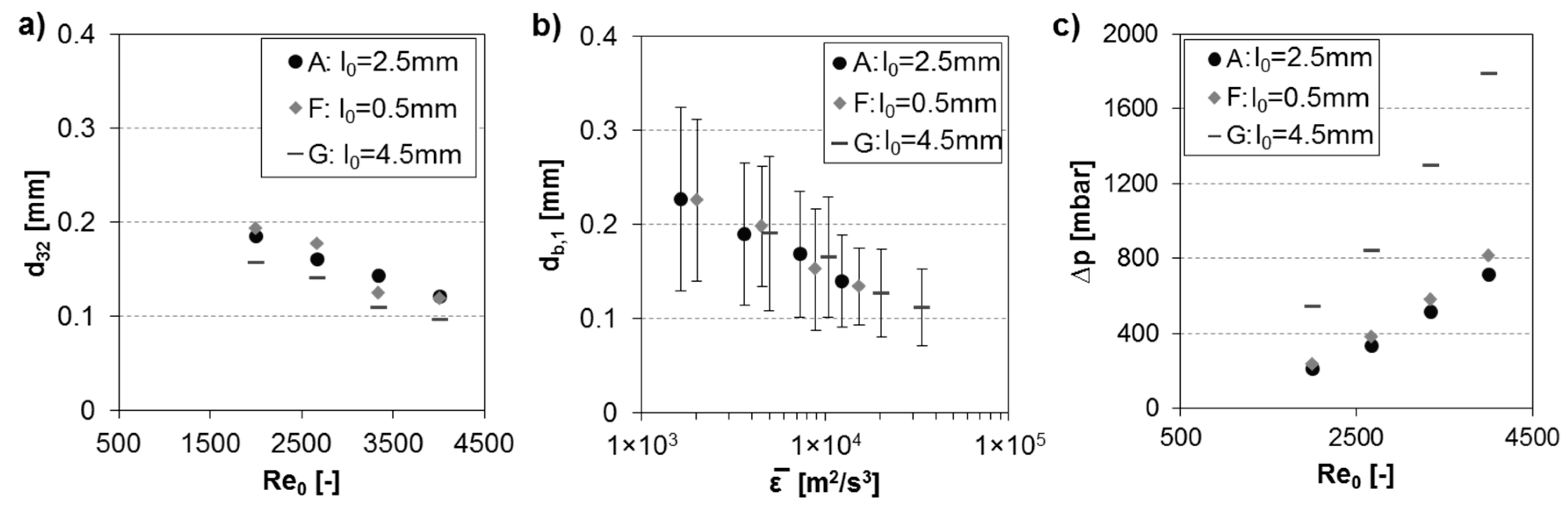

Figure 12.

Figure 12. Influence of length of smallest cross section on size of refined bubbles behind micronozzles. Constant geometrical nozzle parameter for all displayed inlay elements: = 1 mm, = 8°, = 0.5 mm, = 47.5°, = 1.25 mm. Length of nozzle’s smallest cross section exhibited different values, i.e., for nozzle F: = 0.5 mm, for nozzle A: = 2.5 mm, and for nozzle G: = 4.5 mm. Volumetric flow rates of = 60, 80, 100, and 120 mL/min are employed for each nozzle inlay. (a) Sauter bubble diameter plotted over Reynolds number in smallest cross section for varied ; (b) mean bubble diameter of refined dispersed phase plotted over mean energy dissipation rate for varied ; (c) pressure drop for tested nozzle inlays A, F, and G.

Figure 12.

Figure 12. Influence of length of smallest cross section on size of refined bubbles behind micronozzles. Constant geometrical nozzle parameter for all displayed inlay elements: = 1 mm, = 8°, = 0.5 mm, = 47.5°, = 1.25 mm. Length of nozzle’s smallest cross section exhibited different values, i.e., for nozzle F: = 0.5 mm, for nozzle A: = 2.5 mm, and for nozzle G: = 4.5 mm. Volumetric flow rates of = 60, 80, 100, and 120 mL/min are employed for each nozzle inlay. (a) Sauter bubble diameter plotted over Reynolds number in smallest cross section for varied ; (b) mean bubble diameter of refined dispersed phase plotted over mean energy dissipation rate for varied ; (c) pressure drop for tested nozzle inlays A, F, and G.

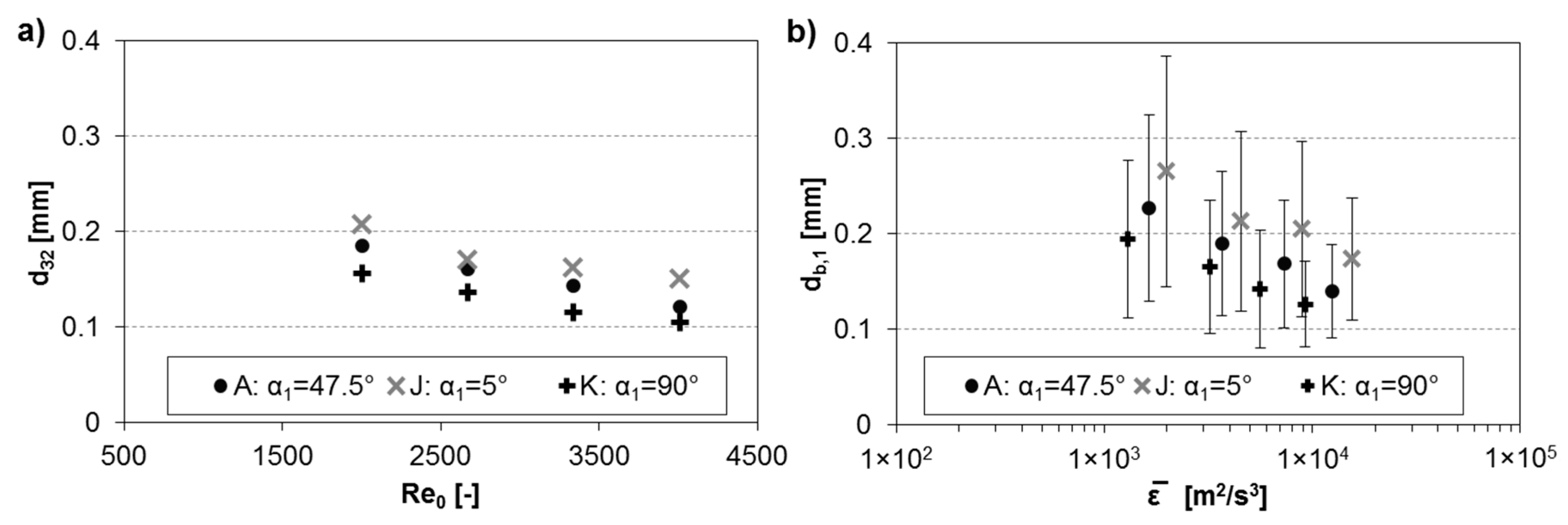

Figure 13.

Influence of diffusor angle on bubble breakup behind micronozzles. Geometrical nozzle parameter besides are held constant for investigated inlay elements: = 1 mm, = 8°, = 0.5 mm, = 2.5 mm, = 1.25 mm. Diffusor angle possessed varied values, i.e., nozzle inlay J: = 5°, nozzle inlay A: = 47.5°, and nozzle inlay K: = 90°. Volumetric flow rates of = 60, 80, 100, and 120 mL/min are employed for each nozzle inlay. (a) Obtained Sauter diameter of broken up bubbles plotted over Renumber in smallest cross section for different ; (b) mean bubble diameter of refined dispersed phase plotted over mean energy dissipation rate for various .

Figure 13.

Influence of diffusor angle on bubble breakup behind micronozzles. Geometrical nozzle parameter besides are held constant for investigated inlay elements: = 1 mm, = 8°, = 0.5 mm, = 2.5 mm, = 1.25 mm. Diffusor angle possessed varied values, i.e., nozzle inlay J: = 5°, nozzle inlay A: = 47.5°, and nozzle inlay K: = 90°. Volumetric flow rates of = 60, 80, 100, and 120 mL/min are employed for each nozzle inlay. (a) Obtained Sauter diameter of broken up bubbles plotted over Renumber in smallest cross section for different ; (b) mean bubble diameter of refined dispersed phase plotted over mean energy dissipation rate for various .

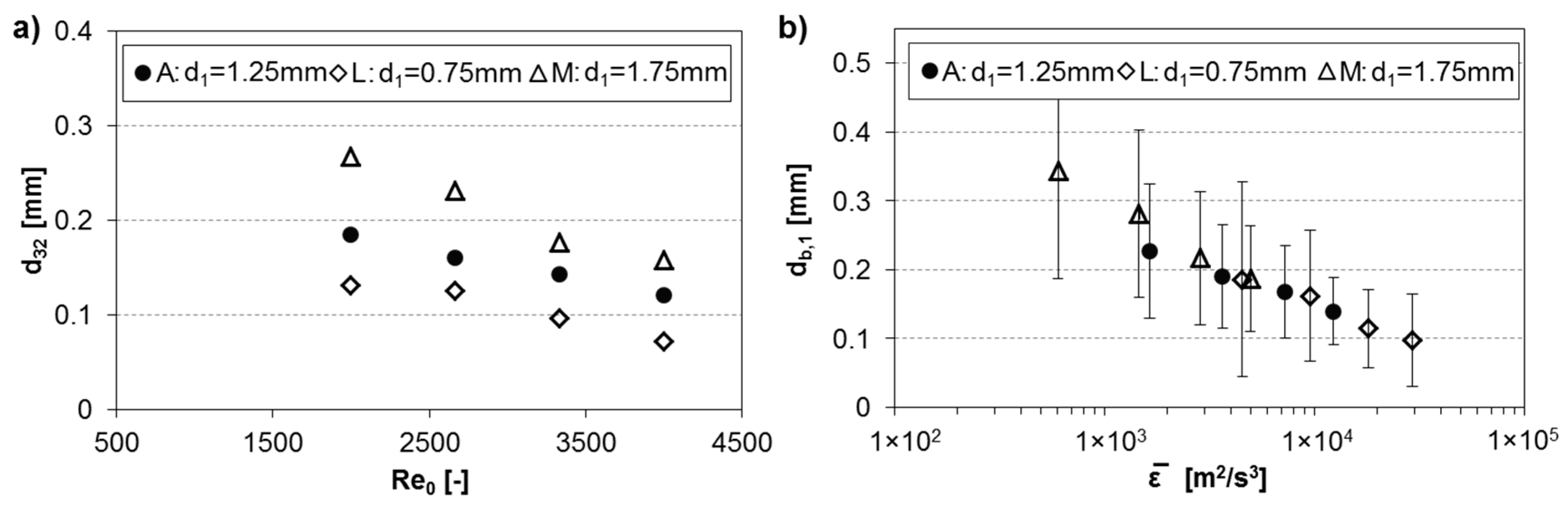

Figure 14.

Impact of downstream channel hydraulic diameter on micronozzle induced turbulent bubble breakup. Geometrical nozzle parameter besides are held constant for investigated inlay elements: = 1 mm, = 8°, = 0.5 mm, = 2.5 mm, = 47.5°. Hydraulic diameter exhibited following values, i.e., nozzle inlay L: = 0.75 mm, nozzle inlay A: = 1.25 mm, nozzle inlay M: = 1.75 mm. Volumetric flow rates of = 60, 80, 100, and 120 mL/min are employed for each nozzle inlay. (a) Obtained Sauter diameter of broken up bubbles plotted over Reynolds number in smallest cross section for different ; (b) mean bubble diameter of refined dispersed phase plotted over mean energy dissipation rate for various .

Figure 14.

Impact of downstream channel hydraulic diameter on micronozzle induced turbulent bubble breakup. Geometrical nozzle parameter besides are held constant for investigated inlay elements: = 1 mm, = 8°, = 0.5 mm, = 2.5 mm, = 47.5°. Hydraulic diameter exhibited following values, i.e., nozzle inlay L: = 0.75 mm, nozzle inlay A: = 1.25 mm, nozzle inlay M: = 1.75 mm. Volumetric flow rates of = 60, 80, 100, and 120 mL/min are employed for each nozzle inlay. (a) Obtained Sauter diameter of broken up bubbles plotted over Reynolds number in smallest cross section for different ; (b) mean bubble diameter of refined dispersed phase plotted over mean energy dissipation rate for various .

Figure 15.

Impact of total volumetric flow rate on bubble breakup for varied nozzle geometries, see

Table 4. Volumetric flow rates of

= 60, 80, 100, and 120 mL/min are used at void fraction of 0.1 for each nozzle inlay. (

a) Obtained pressure drop plotted over total volumetric flow rate for nozzle inlays A, G, and I; (

b) mean energy dissipation rates plotted over total volumetric flow rate for nozzle inlays A, G, and I; (

c) obtained Sauter diameter of dispersed bubbles plotted over total volumetric flow rate for nozzle inlays A, G, and I; (

d) bubble density distribution for nozzle inlay A at various total volumetric flow rates.

Figure 15.

Impact of total volumetric flow rate on bubble breakup for varied nozzle geometries, see

Table 4. Volumetric flow rates of

= 60, 80, 100, and 120 mL/min are used at void fraction of 0.1 for each nozzle inlay. (

a) Obtained pressure drop plotted over total volumetric flow rate for nozzle inlays A, G, and I; (

b) mean energy dissipation rates plotted over total volumetric flow rate for nozzle inlays A, G, and I; (

c) obtained Sauter diameter of dispersed bubbles plotted over total volumetric flow rate for nozzle inlays A, G, and I; (

d) bubble density distribution for nozzle inlay A at various total volumetric flow rates.

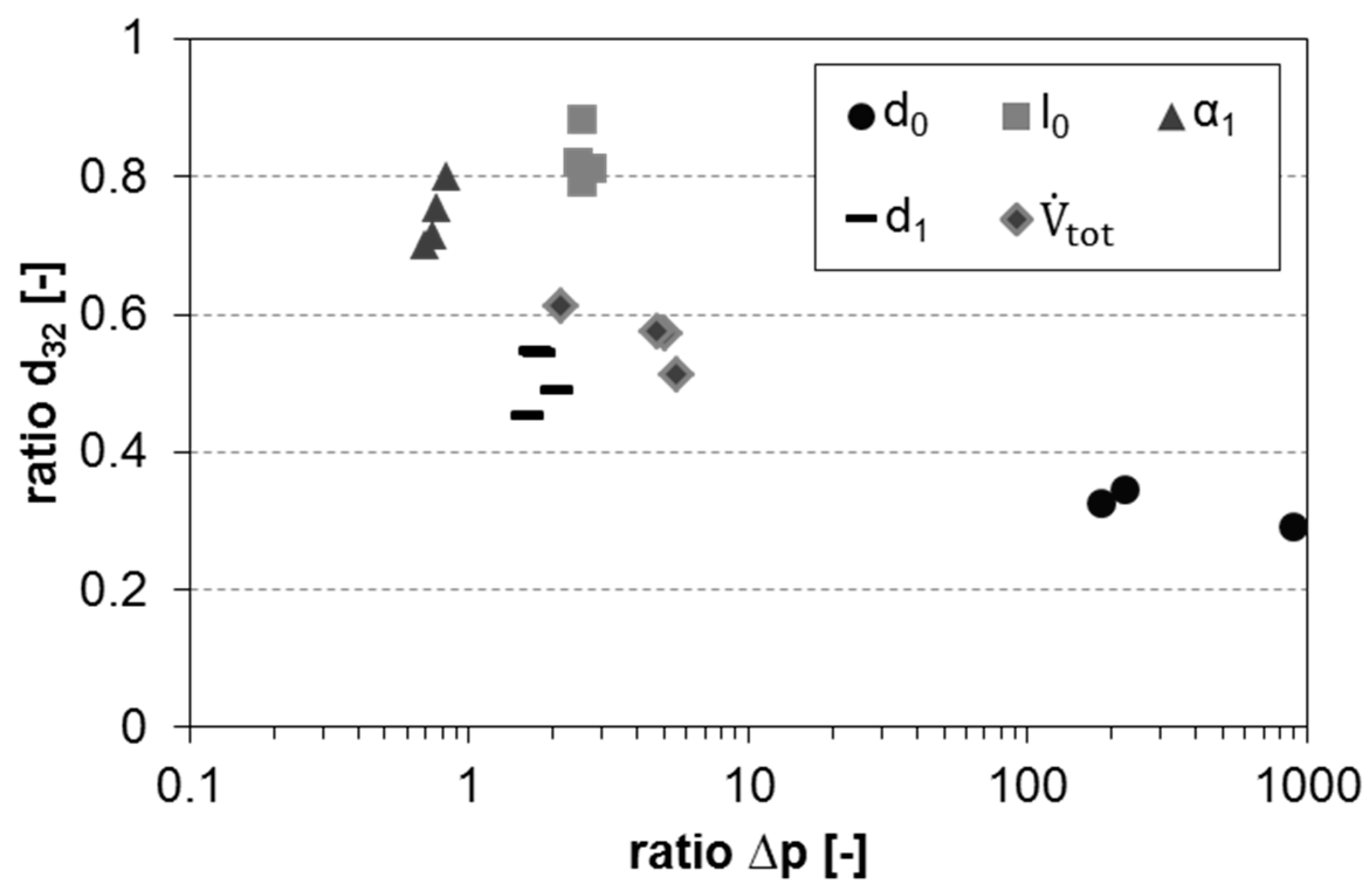

Figure 16.

Diameter ratio for different pressure drop ratios indicating bubble breakup efficacy.

Figure 16.

Diameter ratio for different pressure drop ratios indicating bubble breakup efficacy.

Figure 17.

All obtained mean bubble diameters plotted over corresponding pressure drops within the DoE.

Figure 17.

All obtained mean bubble diameters plotted over corresponding pressure drops within the DoE.

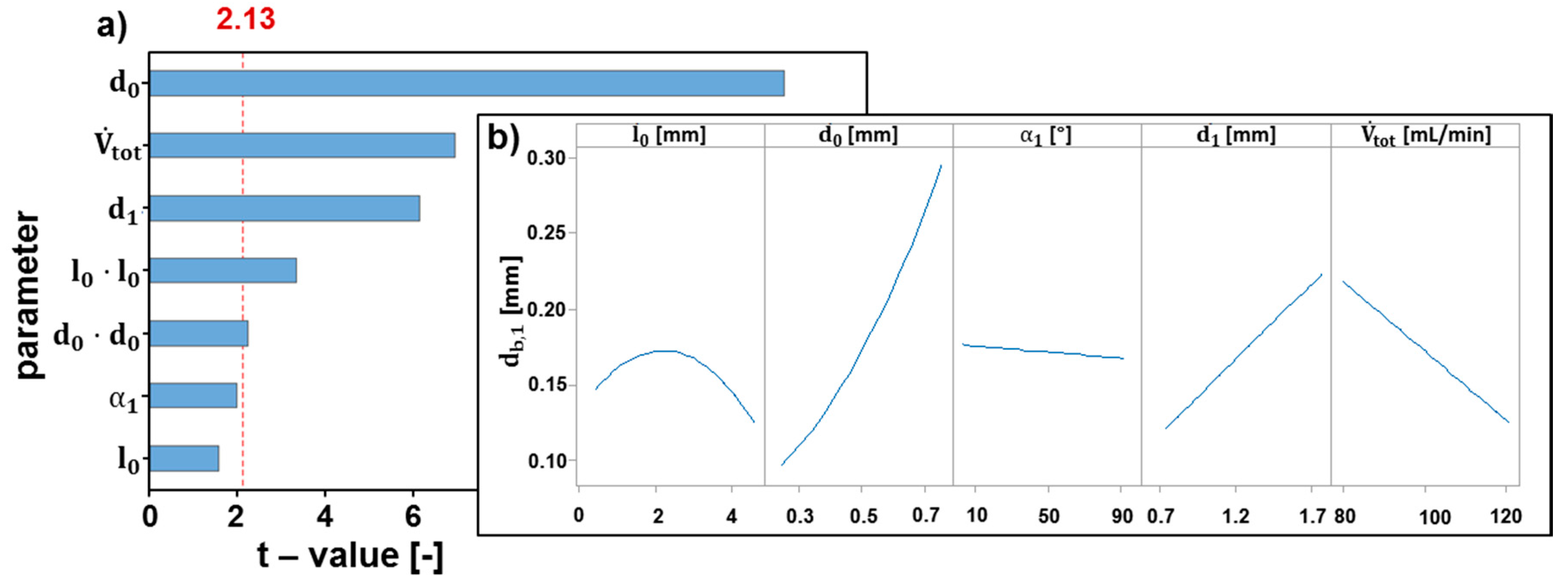

Figure 18.

Final Pareto chart of effects (a) for mean daughter bubble size after exclusion of non-significant parameters and corresponding main effect diagram (b).

Figure 18.

Final Pareto chart of effects (a) for mean daughter bubble size after exclusion of non-significant parameters and corresponding main effect diagram (b).

Figure 19.

Final Pareto chart of effects (a) for pressure drop after exclusion of non-significant parameters and corresponding main effects diagram (b).

Figure 19.

Final Pareto chart of effects (a) for pressure drop after exclusion of non-significant parameters and corresponding main effects diagram (b).

Figure 20.

Factor optimization tool in Minitab® 17 for daughter bubble size and pressure drop.

Figure 20.

Factor optimization tool in Minitab® 17 for daughter bubble size and pressure drop.

Figure 21.

Manufactured micronozzle with optimal parameter settings.

Figure 21.

Manufactured micronozzle with optimal parameter settings.

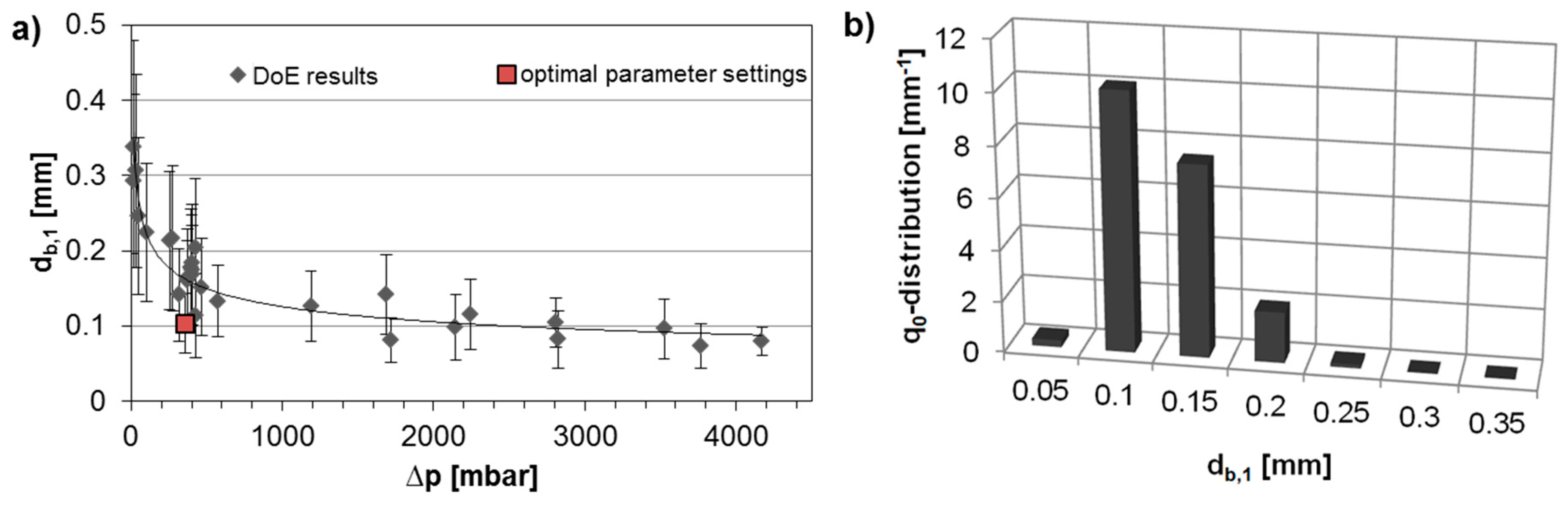

Figure 22.

(a) Mean daughter bubble diameter in dependence of the nozzle induced pressure drop including DoE results and the experimental point for the optimal parameter settings; (b) bubble size density distribution for optimal parameter settings experiment.

Figure 22.

(a) Mean daughter bubble diameter in dependence of the nozzle induced pressure drop including DoE results and the experimental point for the optimal parameter settings; (b) bubble size density distribution for optimal parameter settings experiment.

Table 1.

All adjustable process inputs with potential influence on turbulent bubble breakup.

Table 1.

All adjustable process inputs with potential influence on turbulent bubble breakup.

| Process Parameters | Nozzle Parameters |

|---|

| hydraulic diameter , , aspect ratio , , length of smallest cross section nozzle angle , bend in smallest cross section

|

Table 2.

Parameters included in the DoE with investigated value range.

Table 2.

Parameters included in the DoE with investigated value range.

| Parameters [Unit] | Minimum Value | Maximum Value |

|---|

| [mm] | 0.25 | 0.75 |

| [mm] | 0.5 | 4.5 |

| [°] | 5 | 90 |

| [mm] | 0.75 | 1.75 |

| [mL/min] | 80 | 120 |

Table 3.

Generated DoE using statistical software Minitab® 17 for the investigation of energy optimized turbulent bubble breakup.

Table 3.

Generated DoE using statistical software Minitab® 17 for the investigation of energy optimized turbulent bubble breakup.

| Experiment No. | [mm] | [mm] | [°] | [mm] | [mL/min] | Point Type |

|---|

| 1 | 2.5 | 0.5 | 47.5 | 1.25 | 100 | central point |

| 2 | 0.9 | 0.7 | 81.5 | 1.65 | 84 | corner point |

| 3 | 0.9 | 0.7 | 13.5 | 0.85 | 84 | corner point |

| 4 | 4.1 | 0.7 | 81.5 | 1.65 | 116 | corner point |

| 5 | 4.1 | 0.3 | 13.5 | 1.65 | 116 | corner point |

| 6 | 0.9 | 0.3 | 13.5 | 0.85 | 116 | corner point |

| 7 | 2.5 | 0.5 | 47.5 | 1.25 | 120 | star point |

| 8 | 4.1 | 0.3 | 81.5 | 1.65 | 84 | corner point |

| 9 | 0.5 | 0.5 | 47.5 | 1.25 | 100 | star point |

| 10 | 2.5 | 0.5 | 47.5 | 1.25 | 100 | central point |

| 11 | 2.5 | 0.5 | 90 | 1.25 | 100 | star point |

| 12 | 2.5 | 0.5 | 47.5 | 1.25 | 100 | central point |

| 13 | 2.5 | 0.5 | 47.5 | 0.75 | 100 | star point |

| 14 | 0.9 | 0.3 | 81.5 | 0.85 | 84 | corner point |

| 15 | 4.1 | 0.7 | 13.5 | 0.85 | 116 | corner point |

| 16 | 2.5 | 0.5 | 5 | 1.25 | 100 | star point |

| 17 | 0.9 | 0.3 | 81.5 | 1.65 | 116 | corner point |

| 18 | 2.5 | 0.5 | 47.5 | 1.25 | 100 | central point |

| 19 | 2.5 | 0.5 | 47.5 | 1.25 | 80 | star point |

| 20 | 2.5 | 0.5 | 47.5 | 1.25 | 100 | central point |

| 21 | 2.5 | 0.25 | 47.5 | 1.25 | 100 | star point |

| 22 | 2.5 | 0.5 | 47.5 | 1.75 | 100 | star point |

| 23 | 4.1 | 0.3 | 81.5 | 0.85 | 116 | corner point |

| 24 | 0.9 | 0.7 | 81.5 | 0.85 | 116 | corner point |

| 25 | 4.1 | 0.7 | 13.5 | 1.65 | 84 | corner point |

| 26 | 2.5 | 0.5 | 47.5 | 1.25 | 100 | central point |

| 27 | 4.5 | 0.5 | 47.5 | 1.25 | 100 | star point |

| 28 | 0.9 | 0.7 | 13.5 | 1.65 | 116 | corner point |

| 29 | 4.1 | 0.7 | 81.5 | 0.85 | 84 | corner point |

| 30 | 4.1 | 0.3 | 13.5 | 0.85 | 84 | corner point |

| 31 | 0.9 | 0.3 | 13.5 | 1.65 | 84 | corner point |

| 32 | 2.5 | 0.75 | 47.5 | 1.25 | 100 | star point |

Table 4.

Fabricated micronozzle inlay elements for investigation of turbulent bubble breakup. Nozzle parameters are varied as shown. Close up images of the micronozzles are given. T-mixer geometry, = 8°, and = 1 mm are held constant for all inlay elements.

Table 5.

Optimum factor setting for efficient turbulent bubble breakup.

Table 5.

Optimum factor setting for efficient turbulent bubble breakup.

| Parameter | Value |

|---|

| 2.5 mm |

| 0.9 mm |

| 80° |

| 1.0 mm |

| 115 mL/min |