Numerical Aspects of Data Reconciliation in Industrial Applications

Abstract

:1. Introduction

2. Overview of Data Reconciliation in Industrial Applications

2.1. Problem Formulation

2.2. Solution Methods

2.3. Solution Strategies

2.4. Optimization Algorithms for Nonlinear Programming

Solution Approach

3. Numerical Assessment of Different Settings for Solving Nonlinear Steady-State Data Reconciliation

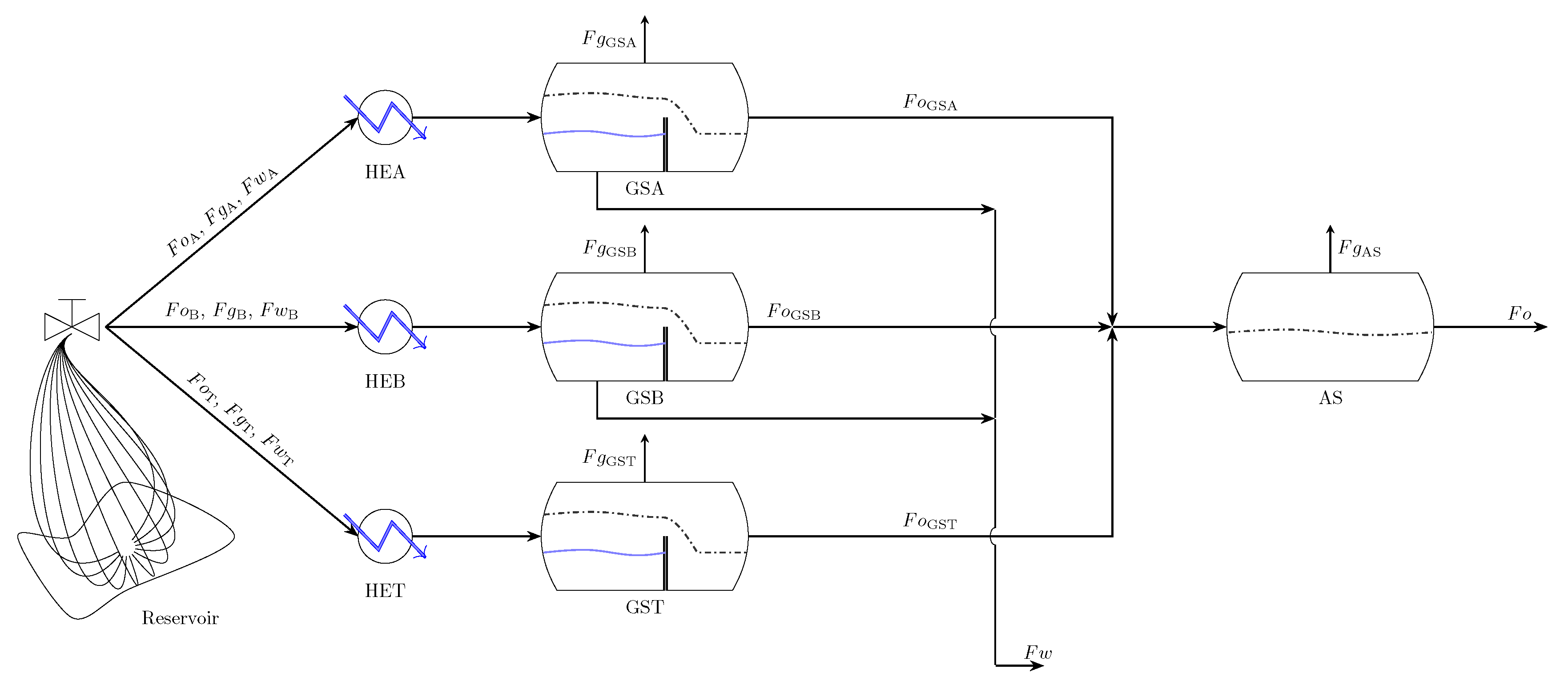

3.1. Process Description

3.2. Case Studies

4. Results

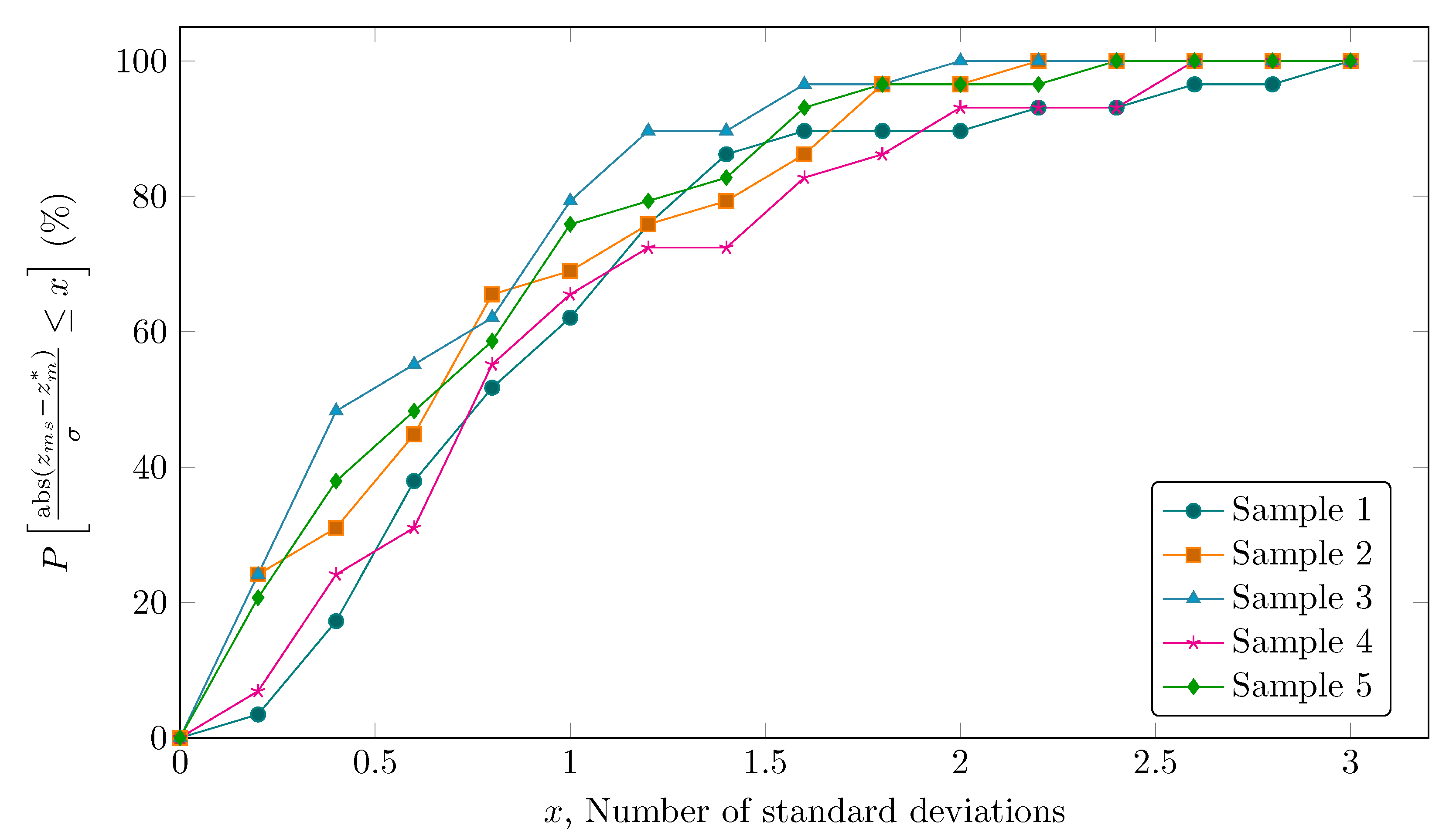

4.1. Solution Approach

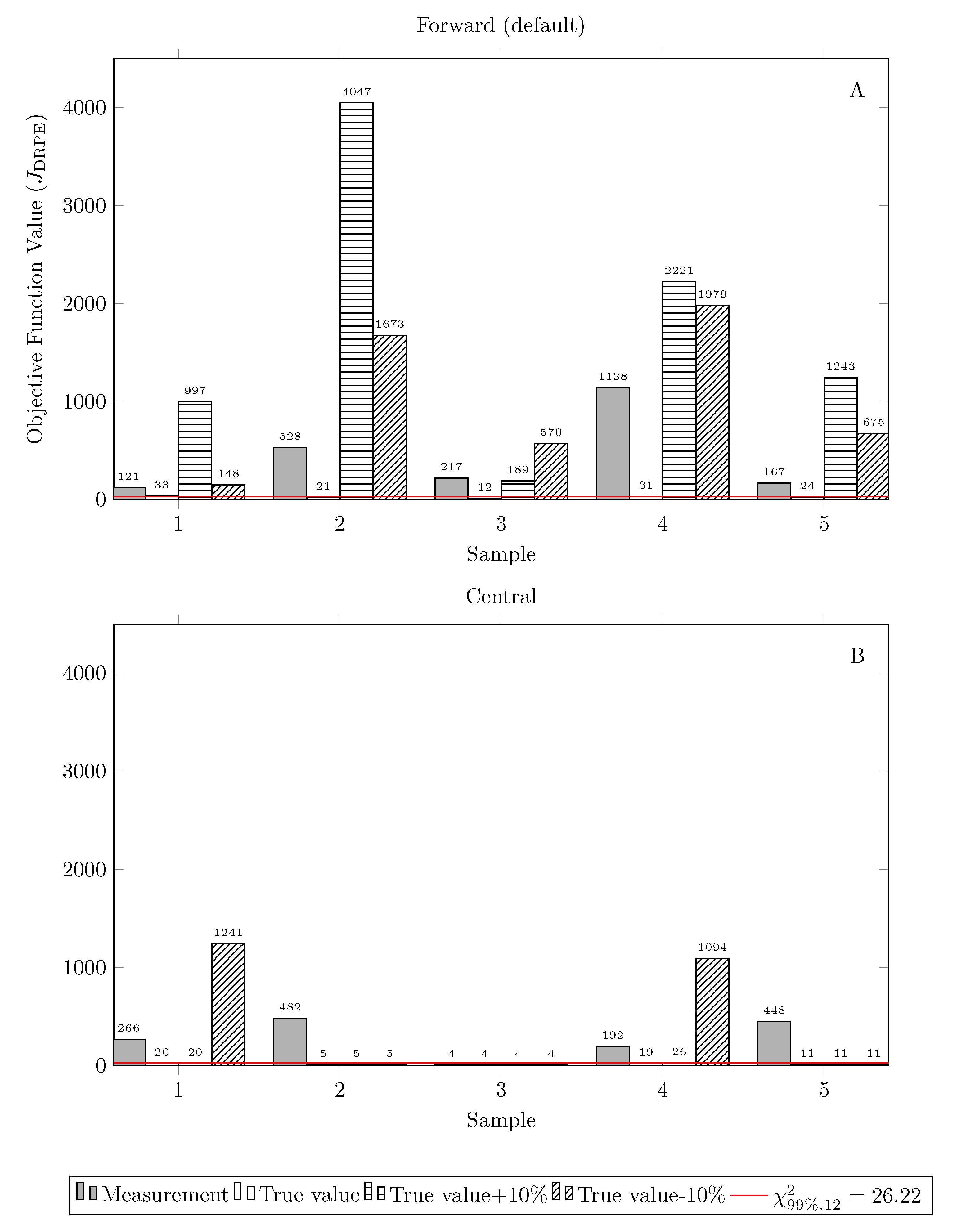

4.2. Initial Guess and Gradient Estimation

4.3. Problem Formulation and Optimization Algorithm

4.4. A Short Note on the Performance Metric

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| CV | Coefficient of variation |

| DF | Degrees of freedom |

| DR | Data reconciliation |

| DRPE | Data reconciliation with simultaneous parameter estimation |

| EVM | Error-in-variables method |

| GL | Gaussian likelihood |

| GN | Gauss-Newton algorithm |

| GRG | Generalized reduced gradient |

| IP | Interior-point algorithm |

| LM | Levenberg-Marquardt algorithm |

| NB | Newton based algorithm |

| NLP | Nonlinear programming |

| PCA | Principal component analysis |

| PSO | Particle swarm optimization |

| QP | Quadratic programming |

| SQP | Successive quadratic programming |

| WLS | Weighted least squares |

References

- Hodouin, D.; Everell, M. A hierarchical procedure for adjustment and material balancing of mineral processes data. Int. J. Miner. Process. 1980, 7, 91–116. [Google Scholar] [CrossRef]

- Taylor, J.H.; del Pilar Moreno, R. Nonlinear dynamic data reconciliation: In-depth case study. In Proceedings of the 2013 IEEE International Conference on Control Applications (CCA), Hyderabad, India, 28–30 August 2013; pp. 746–753. [Google Scholar]

- Morad, K.; Young, B.R.; Svrcek, W.Y. Rectification of plant measurements using a statistical framework. Comput. Chem. Eng. 2005, 29, 919–940. [Google Scholar] [CrossRef]

- Johnston, L.P.M.; Kramer, M.A. Maximum likelihood data rectification: Steady-state systems. AIChE J. 1995, 41, 2415–2426. [Google Scholar] [CrossRef]

- Narasimhan, S.; Jordache, C. Data Reconciliation and Gross Error Detection: An Intelligent Use of Process Data; Gulf Professional Publishing: Houston, TX, USA, 1999. [Google Scholar]

- Nounou, M.N.; Bakshi, B.R. On-line multiscale filtering of random and gross errors without process models. AIChE J. 1999, 45, 1041–1058. [Google Scholar] [CrossRef]

- Martini, A.; Sorce, A.; Traverso, A.; Massardo, A. Data Reconciliation for power systems monitoring: Application to a microturbine-based test rig. Appl. Energy 2013, 111, 1152–1161. [Google Scholar] [CrossRef]

- Naysmith, M.R.; Douglas, P.L. Review of Real Time Optimization in the Chemical Process Industries. Dev. Chem. Eng. Miner. Process. 1995, 3, 67–87. [Google Scholar] [CrossRef]

- Marlin, T.E.; Hrymak, A.N. Real-time operations optimization of continuous processes. In AIChE Symposium Series; American Institute of Chemical Engineers: New York, NY, USA, 1997; Volume 93, pp. 156–164. [Google Scholar]

- Zhang, Z.; Pike, R.W.; Hertwig, T.A. Source reduction from chemical plants using on-line optimization. Waste Manag. 1995, 15, 183–191. [Google Scholar] [CrossRef]

- Hlaváček, V. Analysis of a complex plant-steady state and transient behavior. Comput. Chem. Eng. 1977, 1, 75–100. [Google Scholar] [CrossRef]

- Weiss, G.; Romagnoli, J.; Islam, K. Data reconciliation—An industrial case study. Comput. Chem. Eng. 1996, 20, 1441–1449. [Google Scholar] [CrossRef]

- Piccolo, M.; Douglas, P.L.; Lee, P.L. Data Reconciliation Using AspenPlus. Dev. Chem. Eng. Miner. Process. 1996, 4, 157–182. [Google Scholar] [CrossRef]

- MacDonald, R.J.; Howat, C.S. Data reconciliation and parameter estimation in plant performance analysis. AIChE J. 1988, 34, 1–8. [Google Scholar] [CrossRef]

- McBrayer, K.F.; Soderstrom, T.A.; Edgar, T.F.; Young, R.E. The application of nonlinear dynamic data reconciliation to plant data. Comput. Chem. Eng. 1998, 22, 1907–1911. [Google Scholar] [CrossRef]

- Kim, I.W.; Liebman, M.J.; Edgar, T.F. Robust error-in-variables estimation using nonlinear programming techniques. AIChE J. 1990, 36, 985–993. [Google Scholar] [CrossRef]

- Kazemi, N.; Duever, T.A.; Penlidis, A. A powerful estimation scheme with the error-in-variables-model for nonlinear cases: Reactivity ratio estimation examples. Comput. Chem. Eng. 2013, 48, 200–208. [Google Scholar] [CrossRef]

- Prata, D.M.; Schwaab, M.; Lima, E.L.; Pinto, J.C. Simultaneous robust data reconciliation and gross error detection through particle swarm optimization for an industrial polypropylene reactor. Chem. Eng. Sci. 2010, 65, 4943–4954. [Google Scholar] [CrossRef]

- Tjoa, I.; Biegler, L. Simultaneous strategies for data reconciliation and gross error detection of nonlinear systems. Comput. Chem. Eng. 1991, 15, 679–690. [Google Scholar] [CrossRef]

- Arora, N.; Biegler, L.T. Redescending estimators for data reconciliation and parameter estimation. Comput. Chem. Eng. 2001, 25, 1585–1599. [Google Scholar] [CrossRef]

- Prata, D.M.; Pinto, J.C.; Lima, E.L. Comparative analysis of robust estimators on nonlinear dynamic data reconciliation. In 18th European Symposium on Computer Aided Process Engineering; Braunschweig, B., Joulia, X., Eds.; Elsevier: Amsterdam, The Netherlands, 2008; Volume 25, pp. 501–506. [Google Scholar]

- Zhang, Z.; Shao, Z.; Chen, X.; Wang, K.; Qian, J. Quasi-weighted least squares estimator for data reconciliation. Comput. Chem. Eng. 2010, 34, 154–162. [Google Scholar] [CrossRef]

- Faber, R.; Arellano-Garcia, H.; Li, P.; Wozny, G. An optimization framework for parameter estimation of large-scale systems. Chem. Eng. Process. Process Intensif. 2007, 46, 1085–1095. [Google Scholar] [CrossRef]

- Tong, H.; Crowe, C.M. Detection of gross erros in data reconciliation by principal component analysis. AIChE J. 1995, 41, 1712–1722. [Google Scholar] [CrossRef]

- Narasimhan, S.; Bhatt, N. Deconstructing principal component analysis using a data reconciliation perspective. Comput. Chem. Eng. 2015, 77, 74–84. [Google Scholar] [CrossRef]

- Chen, J.; Romagnoli, J. A strategy for simultaneous dynamic data reconciliation and outlier detection. Comput. Chem. Eng. 1998, 22, 559–562. [Google Scholar] [CrossRef]

- Vachhani, P.; Rengaswamy, R.; Venkatasubramanian, V. A framework for integrating diagnostic knowledge with nonlinear optimization for data reconciliation and parameter estimation in dynamic systems. Chem. Eng. Sci. 2001, 56, 2133–2148. [Google Scholar] [CrossRef]

- Özyurt, D.B.; Pike, R.W. Theory and practice of simultaneous data reconciliation and gross error detection for chemical processes. Comput. Chem. Eng. 2004, 28, 381–402. [Google Scholar] [CrossRef]

- Chen, J.; Peng, Y.; Munoz, J.C. Correntropy estimator for data reconciliation. Chem. Eng. Sci. 2013, 104, 1019–1027. [Google Scholar] [CrossRef]

- Zhang, Z.; Chuang, Y.Y.; Chen, J. Methodology of data reconciliation and parameter estimation for process systems with multi-operating conditions. Chemom. Intell. Lab. Syst. 2014, 137, 110–119. [Google Scholar] [CrossRef]

- Tamhane, A.C.; Mah, R.S.H. Data Reconciliation and Gross Error Detection in Chemical Process Networks. Technometrics 1985, 27, 409–422. [Google Scholar] [CrossRef]

- Crowe, C.M. Data reconciliation—Progress and challenges. J. Process Control 1996, 6, 89–98. [Google Scholar] [CrossRef]

- Mah, R.S. Chemical Process Structures and Information Flows; Butterworth-Heinemann: Oxford, UK, 1990. [Google Scholar]

- Madron, F. Process Plant Performance: Measurement and Data Processing for Optimization and Retrofits; Ellis Horwood: New York, NY, USA, 1992. [Google Scholar]

- Veverka, V.V.; Madron, F. Material and Energy Balancing in the Process Industries: From Microscopic Balances to Large Plants; Elsevier: Amsterdam, The Netherlands, 1997; Volume 7. [Google Scholar]

- Romagnoli, J.A.; Sánchez, M.C. Data Processing and Reconciliation for Chemical Process Operations; Academic Press: Cambridge, MA, USA, 2000. [Google Scholar]

- Kuehn, D.; Davidson, H. Computer control II. Mathematics of control. Chem. Eng. Progress 1961, 57, 44–47. [Google Scholar]

- Kim, I.W.; Kang, M.S.; Park, S.; Edgar, T.F. Robust data reconciliation and gross error detection: The modified MIMT using NLP. Comput. Chem. Eng. 1997, 21, 775–782. [Google Scholar] [CrossRef]

- Du, Y.G.; Hodouin, D.; Thibault, J. Use of a novel autoassociative neural network for nonlinear steady-state data reconciliation. AIChE J. 1997, 43, 1785–1796. [Google Scholar] [CrossRef]

- Pages, A.; Pingaud, H.; Meyer, M.; Joulia, X. A strategy for simultaneous data reconciliation and parameter estimation on process flowsheets. Comput. Chem. Eng. 1994, 18, S223–S227. [Google Scholar] [CrossRef]

- Takiyama, H.; Naka, Y.; O’shima, E.; Adriani, A. Sensor-Based Data Reconciliation Method and Application to the Pilot Plant. J. Chem. Eng. Jpn. 1991, 24, 339–346. [Google Scholar] [CrossRef]

- Fillon, M.; Meyer, M.; Pingaud, H.; Enjalbert, M. An Efficient Formulation for Batch Reactor Data Reconciliation. Ind. Eng. Chem. Res. 1996, 35, 2288–2298. [Google Scholar] [CrossRef]

- Fillon, M.; Meyer, M.; Pingaud, H.; Joulia, X. Data reconciliation based on elemental balances applied to batch experiments. Comput. Chem. Eng. 1995, 19, 293–298. [Google Scholar] [CrossRef]

- Darouach, M.; Zasadzinski, M. Data reconciliation in generalized linear dynamic systems. AIChE J. 1991, 37, 193–201. [Google Scholar] [CrossRef]

- Liebman, M.; Edgar, T.; Lasdon, L. Efficient data reconciliation and estimation for dynamic processes using nonlinear programming techniques. Comput. Chem. Eng. 1992, 16, 963–986. [Google Scholar] [CrossRef]

- Albuquerque, J.S.; Biegler, L.T. Data reconciliation and gross-error detection for dynamic systems. AIChE J. 1996, 42, 2841–2856. [Google Scholar] [CrossRef]

- Prata, D.M.; Lima, E.L.; Pinto, J.C. Simultaneous Data Reconciliation and Parameter Estimation in Bulk Polypropylene Polymerizations in Real Time. Macromol. Symp. 2006, 243, 91–103. [Google Scholar] [CrossRef]

- Bagajewicz, M.J.; Rollins, S.D.K. Data Reconciliation and Software Methods for Bias Detection. In Instrument Engineers’ Handbook, Process Software and Digital Networks, 4th ed.; Lipták, B.G., Eren, H., Eds.; CRC Press: Boca Raton, FL, USA, 2011; Chapter 22; Volume 3, pp. 364–381. [Google Scholar]

- Ham, P.; Cleaves, G.; Lawlor, J. PD 23 (3) Operation Data Reconciliation: An Aid to Improved Plant Performance. In Proceedings of the 10th World Petroleum Congress, Bucharest, Romania, 9–14 September 1979. [Google Scholar]

- Chiari, M.; Bussani, G.; Grottoli, M.; Pierucci, S. On-line data reconciliation and optimisation: Refinery applications. Comput. Chem. Eng. 1997, 21, S1185–S1190. [Google Scholar] [CrossRef]

- Chen, X.; Pike, R.W.; Hertwig, T.A.; Hopper, J.R. Optimal implementation of on-line optimization. Comput. Chem. Eng. 1998, 22, S435–S442. [Google Scholar] [CrossRef]

- Reimers, C.; Werther, J.; Gruhn, G. Flowsheet simulation of solids processes: Data reconciliation and adjustment of model parameters. Chem. Eng. Process. Process Intensif. 2008, 47, 138–158. [Google Scholar] [CrossRef]

- Kyriakopoulou, D.; Kalitventzeff, B. Validation of measurement data using an interior point SQP. Comput. Chem. Eng. 1996, 20, S563–S568. [Google Scholar] [CrossRef]

- Sarabia, D.; de Prada, C.; Gómez, E.; Gutierrez, G.; Cristea, S.; Sola, J.; Gonzalez, R. Data reconciliation and optimal management of hydrogen networks in a petrol refinery. Control Eng. Pract. 2012, 20, 343–354. [Google Scholar] [CrossRef]

- Sanchez, M.; Bandoni, A.; Romagnoli, J. Pladat: A package for process variable classification and plant data reconciliation. Comput. Chem. Eng. 1992, 16, S499–S506. [Google Scholar] [CrossRef]

- Bhat, S.A.; Saraf, D.N. Steady-State Identification, Gross Error Detection, and Data Reconciliation for Industrial Process Units. Ind. Eng. Chem. Res. 2004, 43, 4323–4336. [Google Scholar] [CrossRef]

- Trierweiler, J.O. Real-Time Optimization of Industrial Processes. In Encyclopedia of Systems and Control; Baillieul, J., Samad, T., Eds.; Springer: London, UK, 2014; pp. 1–11. [Google Scholar]

- Islam, K.; Weiss, G.; Romagnoli, J. Non-linear data reconciliation for an industrial pyrolysis reactor. Comput. Chem. Eng. 1994, 18, S217–S221. [Google Scholar] [CrossRef]

- Hu, M.; Shao, H. Theory Analysis of Nonlinear Data Reconciliation and Application to a Coking Plant. Ind. Eng. Chem. Res. 2006, 45, 8973–8984. [Google Scholar] [CrossRef]

- Krist, J.; Lapère, M.; Wassink, S.G.; Neyts, R.; Koolen, J. Generic System for On-Line Optimization & the Implementation in a Benzene plant. Comput. Chem. Eng. 1994, 18, S517–S524. [Google Scholar]

- Pierucci, S.; Brandani, P.; Ranzi, E.; Sogaro, A. An industrial application of an on-line data reconciliation and optimization problem. Comput. Chem. Eng. 1996, 20, S1539–S1544. [Google Scholar] [CrossRef]

- Kelly, J.D. Techniques for solving industrial nonlinear data reconciliation problems. Comput. Chem. Eng. 2004, 28, 2837–2843. [Google Scholar] [CrossRef]

- Poku, M.Y.B.; Biegler, L.T.; Kelly, J.D. Nonlinear Optimization with Many Degrees of Freedom in Process Engineering. Ind. Eng. Chem. Res. 2004, 43, 6803–6812. [Google Scholar] [CrossRef]

- Prata, D.M.; Schwaab, M.; Lima, E.L.; Pinto, J.C. Nonlinear dynamic data reconciliation and parameter estimation through particle swarm optimization: Application for an industrial polypropylene reactor. Chem. Eng. Sci. 2009, 64, 3953–3967. [Google Scholar] [CrossRef]

- Poulin, Éric; Hodouin, D.; Lachance, L. Impact of plant dynamics on the performance of steady-state data reconciliation. Comput. Chem. Eng. 2010, 34, 354–360. [Google Scholar]

- Quelhas, A.D.; de Jesus, N.J.C.; Pinto, J.C. Common vulnerabilities of RTO implementations in real chemical processes. Can. J. Chem. Eng. 2013, 91, 652–668. [Google Scholar] [CrossRef]

- Câmara, M.M.; Quelhas, A.D.; Pinto, J.C. Performance Evaluation of Real Industrial RTO Systems. Processes 2016, 4, 44. [Google Scholar] [CrossRef]

- Serth, R.; Valero, C.; Heenan, W. Detection Of Gross Errors In Nonlinearly Constrained Data: A Case Study. Chem. Eng. Commun. 1987, 51, 89–104. [Google Scholar] [CrossRef]

- Holly, W.; Cook, R.; Crowe, C.M. Reconciliation of mass flow rate measurements in a chemical extraction plant. Can. J. Chem. Eng. 1989, 67, 595–601. [Google Scholar] [CrossRef]

- Meyer, M.; Koehret, B.; Enjalbert, M. Data reconciliation on multicomponent network process. Comput. Chem. Eng. 1993, 17, 807–817. [Google Scholar] [CrossRef]

- Bussani, G.; Chiari, M.; Grottoli, M.; Pierucci, S.; Faravelli, T.; Ricci, G.; Gioventù, G. Application of data-reconciliation and optimisation procedure to hydrogen plant. Comput. Chem. Eng. 1995, 19, 299–304. [Google Scholar] [CrossRef]

- Zhang, Z.; Pike, R.W.; Hertwig, T.A. An approach to on-line optimization of chemical plants. Comput. Chem. Eng. 1995, 19, 305–310. [Google Scholar] [CrossRef]

- Sánchez, M.; Sentoni, G.; Schbib, S.; Tonelli, S.; Romagnoli, J. Gross measurements error detection/identification for an industrial ethylene reactor. Comput. Chem. Eng. 1996, 20, S1559–S1564. [Google Scholar] [CrossRef]

- Sánchez, M.; Romagnoli, J. Use of orthogonal transformations in data classification-reconciliation. Comput. Chem. Eng. 1996, 20, 483–493. [Google Scholar] [CrossRef]

- Heyen, G.; Maréchal, E.; Kalitventzeff, B. Sensitivity calculations and variance analysis in plant measurement reconciliation. Comput. Chem. Eng. 1996, 20, S539–S544. [Google Scholar] [CrossRef]

- Christiansen, L.J.; Bruniche-Olsen, N.; Carstensen, J.H.; Schrøder, M. Performance evaluation of catalytic processes. Comput. Chem. Eng. 1997, 21, S1179–S1184. [Google Scholar] [CrossRef]

- Heyen, G.; Kalitventzeff, B. Methodology for optimization of operation to reduce site-scale energy use in production plants. Appl. Therm. Eng. 1997, 17, 1005–1014. [Google Scholar] [CrossRef]

- Dempf, D.; List, T. On-line data reconciliation in chemical plants. Comput. Chem. Eng. 1998, 22, S1023–S1025. [Google Scholar] [CrossRef]

- Plácido, J.; Loureiro, L. Industrial application of data reconciliation. Comput. Chem. Eng. 1998, 22, S1035–S1038. [Google Scholar] [CrossRef]

- Bourouis, M.; Pibouleau, L.; Floquet, P.; Domenech, S.; Al-Gobaisi, D.M. Simulation and data validation in multistage flash desalination plants. Desalination 1998, 115, 1–14. [Google Scholar] [CrossRef]

- Lee, M.H.; Lee, S.J.; Han, C.; Chang, K.S.; Kim, S.H.; You, S.H. Hierarchical on-line data reconciliation and optimization for an industrial utility plant. Comput. Chem. Eng. 1998, 22, S247–S254. [Google Scholar] [CrossRef]

- Bazin, C.; Hodouin, D.; Duchesne, C.; Thibault, J.; Trusiak, A.R. Reconciliation of Mass and Energy Data Measurements: Application to a Rotary Dryer. Can. Metall. Q. 1998, 37, 333–342. [Google Scholar] [CrossRef]

- Soderstrom, T.A.; Edgar, T.F.; Russo, L.P.; Young, R.E. Industrial Application of a Large-Scale Dynamic Data Reconciliation Strategy. Ind. Eng. Chem. Res. 2000, 39, 1683–1693. [Google Scholar] [CrossRef]

- Li, B.; Chen, B.; Wang, J.; Cong, S. Steady-state online data reconciliation in a crude oil distillation unit. Hydrocarb. Process. 2001, 80, 61–64. [Google Scholar]

- Zhang, P.; Rong, G.; Wang, Y. A new method of redundancy analysis in data reconciliation and its application. Comput. Chem. Eng. 2001, 25, 941–949. [Google Scholar] [CrossRef]

- Eksteen, J.; Frank, S.; Reuter, M. Dynamic structures in variance based data reconciliation adjustments for a chromite smelting furnace. Miner. Eng. 2002, 15, 931–943. [Google Scholar] [CrossRef]

- Sunde, S.; Berg, Öivind. Data reconciliation and fault detection by means of plant-wide mass and energy balances. Progress Nucl. Energy 2003, 43, 97–104. [Google Scholar] [CrossRef]

- Bagajewicz, M.J.; Cabrera, E. Data Reconciliation in Gas Pipeline Systems. Ind. Eng. Chem. Res. 2003, 42, 5596–5606. [Google Scholar] [CrossRef]

- Vieira, R.; Embiruçu, M.; Sayer, C.; Pinto, J.; Lima, E. Control strategies for complex chemical processes. Applications in polymerization processes. Comput. Chem. Eng. 2003, 27, 1307–1327. [Google Scholar] [CrossRef]

- Chatterjee, T.; Saraf, D.N. On-line estimation of product properties for crude distillation units. J. Process Control 2004, 14, 61–77. [Google Scholar] [CrossRef]

- Yi, H.S.; Han, C. Industrial Application of MILP-Based Simultaneous Compensation to a Large-Scale Byproduct Gases Network in an Iron- and Steel-Making Plant. Ind. Eng. Chem. Res. 2004, 43, 119–126. [Google Scholar] [CrossRef]

- Chen, P.-C.; Andersen, H. The Implementation of the Data Validation Process in a Gas Turbine Performance Monitoring System. In Proceedings of the Turbo Expo 2005: Power for Land, Sea, and Air, Reno-Tahoe, NV, USA, 6–9 June 2005; American Society of Mechanical Engineers: New York, NY, USA; pp. 609–616. [Google Scholar]

- De Andrade Lima, L. Nonlinear data reconciliation in gold processing plants. Miner. Eng. 2006, 19, 938–951. [Google Scholar] [CrossRef]

- Al-Arfaj, M.A. Shortcut data reconciliation technique: Development and industrial application. AIChE J. 2006, 52, 414–417. [Google Scholar] [CrossRef]

- Faber, R.; Li, B.; Li, P.; Wozny, G. Data reconciliation for real-time optimization of an industrial coke-oven-gas purification process. Simul. Model. Pract. Theory 2006, 14, 1121–1134. [Google Scholar] [CrossRef]

- Li, B.; Chen, B.; Duan, D.; Kong, M. Correction coefficient method for gross error detection based on temporal redundancy. J. Tsinghua Univ. (Sci. Technol.) 2000, 40, 65–69. [Google Scholar]

- Schladt, M.; Hu, B. Soft sensors based on nonlinear steady-state data reconciliation in the process industry. Chem. Eng. Process. Process Intensif. 2007, 46, 1107–1115. [Google Scholar] [CrossRef]

- Bellec, S.; Jiang, T.; Kerr, B.; Diamond, M.; Stuart, P. On-line processing and steady-state reconciliation of pulp and paper mill process data. Pulp Pap. Can. 2007, 108, 36–40. [Google Scholar]

- Lid, T.; Skogestad, S. Data reconciliation and optimal operation of a catalytic naphtha reformer. J. Process Control 2008, 18, 320–331. [Google Scholar] [CrossRef]

- Embiruçu, M.; Prata, D.M.; Lima, E.L.; Pinto, J.C. Continuous Soluble Ziegler-Natta Ethylene Polymerizations in Reactor Trains, 2–Estimation of Kinetic Parameters from Industrial Data. Macromol. React. Eng. 2008, 2, 142–160. [Google Scholar] [CrossRef]

- Prata, D.M.; Lima, E.L.; Pinto, J.C. In-Line Monitoring of Bulk Polypropylene Reactors Based on Data Reconciliation Procedures. Macromol. Symp. 2008, 271, 26–37. [Google Scholar] [CrossRef]

- Puig, S.; van Loosdrecht, M.; Colprim, J.; Meijer, S. Data evaluation of full-scale wastewater treatment plants by mass balance. Water Res. 2008, 42, 4645–4655. [Google Scholar] [CrossRef] [PubMed]

- Cicciotti, M.; Xenos, D.P.; Bouaswaig, A.E.; Martinez-Botas, R.F.; Manenti, F.; Thornhill, N.F. Simultaneous Nonlinear Reconciliation and Update of Parameters for Online Use of First-Principles Models: An Industrial Case-Study on Compressors. In 24th European Symposium on Computer Aided Process Engineering; Jivrí Jaromír Klemevs, P.S.V., Liew, P.Y., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; Volume 33, pp. 457–462. [Google Scholar]

- Jiang, X.; Liu, P.; Li, Z. Data reconciliation for steam turbine on-line performance monitoring. Appl. Therm. Eng. 2014, 70, 122–130. [Google Scholar] [CrossRef]

- Eghbal Ahmadi̇, M.H. Data reconciliation and gross error detection: Application in chemical processes. Cumhur. Sci. J. 2015, 36, 1905–1913. [Google Scholar]

- Guo, S.; Liu, P.; Li, Z. Estimation of exhaust steam enthalpy and steam wetness fraction for steam turbines based on data reconciliation with characteristic constraints. Comput. Chem. Eng. 2016, 93, 25–35. [Google Scholar] [CrossRef]

- Guo, S.; Liu, P.; Li, Z. Inequality constrained nonlinear data reconciliation of a steam turbine power plant for enhanced parameter estimation. Energy 2016, 103, 215–230. [Google Scholar] [CrossRef]

- Behnami, A.; Shakerkhatibi, M.; Dehghanzadeh, R.; Benis, K.Z.; Derafshi, S.; Fatehifar, E. The implementation of data reconciliation for evaluating a full-scale petrochemical wastewater treatment plant. Environ. Sci. Pollut. Res. 2016, 23, 22586–22595. [Google Scholar] [CrossRef] [PubMed]

- Rafiee, A.; Behrouzshad, F. Data reconciliation with application to a natural gas processing plant. J. Nat. Gas Sci. Eng. 2016, 31, 538–545. [Google Scholar] [CrossRef]

- White, D. Online optimization: What, where and estimating ROI: Process optimization: Process control and instrumentation. Hydrocarb. Process. 1997, 76, 43–51. [Google Scholar]

- Bard, Y. Nonlinear Parameter Estimation; Academic Press: New York, NY, USA, 1974; Volume 513. [Google Scholar]

- Britt, H.I.; Luecke, R.H. The Estimation of Parameters in Nonlinear, Implicit Models. Technometrics 1973, 15, 233–247. [Google Scholar] [CrossRef]

- Anderson, T.F.; Abrams, D.S.; Grens, E.A. Evaluation of parameters for nonlinear thermodynamic models. AIChE J. 1978, 24, 20–29. [Google Scholar] [CrossRef]

- Wang, D.; Romagnoli, J.A. A Framework for Robust Data Reconciliation Based on a Generalized Objective Function. Ind. Eng. Chem. Res. 2003, 42, 3075–3084. [Google Scholar] [CrossRef]

- Liebman, M.; Edgar, T. Data reconciliation for nonlinear processes. In Proceedings of the AIChE Annual Meeting, Washington, DC, USA, 27 November–2 December 1988. [Google Scholar]

- Barbosa, V., Jr.; Wolf, M.; Maciel Fo, R. Development of data reconciliation for dynamic nonlinear system: Application the polymerization reactor. Comput. Chem. Eng. 2000, 24, 501–506. [Google Scholar] [CrossRef]

- Lucia, A.; Xu, J. Chemical process optimization using Newton-like methods. Comput. Chem. Eng. 1990, 14, 119–138. [Google Scholar] [CrossRef]

- Lucia, A.; Xu, J.; D’Couto, G.C. Sparse quadratic programming in chemical process optimization. Ann. Oper. Res. 1993, 42, 55–83. [Google Scholar] [CrossRef]

- Rod, V.; Hančil, V. Iterative estimation of model parameters when measurements of all variables are subject to error. Comput. Chem. Eng. 1980, 4, 33–38. [Google Scholar] [CrossRef]

- Reilly, P.M.; Patino-Leal, H. A Bayesian Study of the Error-in-Variables Model. Technometrics 1981, 23, 221–231. [Google Scholar] [CrossRef]

- Doví, V.; Paladino, O. Fitting of experimental data to implicit models using a constrained variation algorithm. Comput. Chem. Eng. 1989, 13, 731–735. [Google Scholar] [CrossRef]

- Valkó, P.; Vajda, S. An extended Marquardt-type procedure for fitting error-in-variables models. Comput. Chem. Eng. 1987, 11, 37–43. [Google Scholar] [CrossRef]

- Faber, R.; Li, P.; Wozny, G. Sequential Parameter Estimation for Large-Scale Systems with Multiple Data Sets. 1. Computational Framework. Ind. Eng. Chem. Res. 2003, 42, 5850–5860. [Google Scholar] [CrossRef]

- Faber, R.; Li, P.; Wozny, G. Sequential Parameter Estimation for Large-Scale Systems with Multiple Data Sets. 2. Application to an Industrial Coke-Oven-Gas Purification Process. Ind. Eng. Chem. Res. 2004, 43, 4350–4362. [Google Scholar] [CrossRef]

- Moré, J.J.; Wright, S.J. Software Classification. In Optimization Software Guide; Society for Industrial and Applied Mathematics: Philadelphia, PA, USA, 1993; Chapter 12; pp. 67–149. [Google Scholar]

- Chen, X.; Rao, K.; Yu, J.; Pike, R. Comparison of GAMS, AMPL, and MINOS for optimization. Chem. Eng. Educ. 1996, 30, 220–227. [Google Scholar]

- Leyffer, S.; Mahajan, A. Software For Nonlinearly Constrained Optimization. In Wiley Encyclopedia of Operations Research and Management Science; Cochran, J.J., Cox, L.A., Keskinocak, P., Kharoufeh, J.P., Smith, J.C., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010. [Google Scholar]

- Conn, A.R.; Gould, G.I.M.; Toint, P.L. LANCELOT: A Fortran Package for Large-Scale Nonlinear Optimization (Release A); Springer: Berlin, Germany, 1992; Volume 17. [Google Scholar]

- Murtagh, B.; Saunders, M. MINOS 5.5 User’s Guide; Technical Report SOL 83-20R, Revised July 1998; Systems Optimization Laboratory, Department of Operations Research, Stanford University: Stanford, CA, USA, 1998; pp. 94022–94305. [Google Scholar]

- Drud, A.S. CONOPT–A Large-Scale GRG Code. ORSA J. Comput. 1994, 6, 207–216. [Google Scholar] [CrossRef]

- Gill, P.E.; Murray, W.; Saunders, M.A. SNOPT: An SQP Algorithm for Large-Scale Constrained Optimization. SIAM Rev. 2005, 47, 99–131. [Google Scholar] [CrossRef]

- Alkaya, D.; Vasantharajan, S.; Biegler, L. Successive Quadratic Programming: Applications in the Process Industry. In Encyclopedia of Optimization; Floudas, C.A., Pardalos, P.M., Eds.; Springer: New York, NY, USA, 2001; pp. 2574–2587. [Google Scholar]

- Tjoa, I.B.; Biegler, L. Reduced successive quadratic programming strategy for errors-in-variables estimation. Comput. Chem. Eng. 1992, 16, 523–533. [Google Scholar] [CrossRef]

- Betts, J.T.; Frank, P.D. A sparse nonlinear optimization algorithm. J. Optim. Theory Appl. 1994, 82, 519–541. [Google Scholar] [CrossRef]

- Sargent, R.W.H.; Ding, M. A New SQP Algorithm for Large-Scale Nonlinear Programming. SIAM J. Optim. 2001, 11, 716–747. [Google Scholar] [CrossRef]

- Forsgren, A.; Gill, P.E.; Wright, M.H. Interior Methods for Nonlinear Optimization. SIAM Rev. 2002, 44, 525–597. [Google Scholar] [CrossRef]

- Esposito, W.R.; Floudas, C.A. Global Optimization in Parameter Estimation of Nonlinear Algebraic Models via the Error-in-Variables Approach. Ind. Eng. Chem. Res. 1998, 37, 1841–1858. [Google Scholar] [CrossRef]

- Gau, C.Y.; Stadtherr, M.A. Deterministic global optimization for error-in-variables parameter estimation. AIChE J. 2002, 48, 1192–1197. [Google Scholar] [CrossRef]

- Biegler, L.; Cuthrell, J. Improved infeasible path optimization for sequential modular simulators-II: The optimization algorithm. Comput. Chem. Eng. 1985, 9, 257–267. [Google Scholar] [CrossRef]

- Bailey, J.; Hrymak, A.; Treiber, S.; Hawkins, R. Nonlinear optimization of a hydrocracker fractionation plant. Comput. Chem. Eng. 1993, 17, 123–138. [Google Scholar] [CrossRef]

- Wolpert, D.; Macready, W. No free lunch theorems for optimization. IEEE Trans. Evolut. Comput. 1997, 1, 67–82. [Google Scholar] [CrossRef]

- Köppen, M. No-Free-Lunch theorems and the diversity of algorithms. In Proceedings of the Congress on Evolutionary Computation, CEC2004, Portland, OR, USA, 19–23 June 2004; Volume 1, pp. 235–241. [Google Scholar]

- Lid, T.; Skogestad, S. Scaled steady state models for effective on-line applications. Comput. Chem. Eng. 2008, 32, 990–999. [Google Scholar] [CrossRef]

- Biegler, L. Recent Advances in Chemical Process Optimization. Chem. Ing. Tech. 2014, 86, 943–952. [Google Scholar] [CrossRef]

- Conn, A.R.; Scheinberg, K.; Vicente, L.N. Introduction to Derivative-Free Optimization; MPS-SIAM Series on Optimization; Society for Industrial and Applied Mathematics: Philadelphia, PA, USA, 2009. [Google Scholar]

- Schwaab, M.; Biscaia, E.C., Jr.; Monteiro, J.L.; Pinto, J.C. Nonlinear parameter estimation through particle swarm optimization. Chem. Eng. Sci. 2008, 63, 1542–1552. [Google Scholar] [CrossRef]

- Biegler, L.T. Solution of dynamic optimization problems by successive quadratic programming and orthogonal collocation. Comput. Chem. Eng. 1984, 8, 243–247. [Google Scholar] [CrossRef]

- Safdarnejad, S.M.; Hedengren, J.D.; Lewis, N.R.; Haseltine, E.L. Initialization strategies for optimization of dynamic systems. Comput. Chem. Eng. 2015, 78, 39–50. [Google Scholar] [CrossRef]

- Hedengren, J.; Mojica, J.; Cole, W.; Edgar, T. APOPT: MINLP solver for differential and algebraic systems with benchmark testing. In Proceedings of the INFORMS National Meeting, Phoenix, AZ, USA, 14–17 October 2012; Volume 1417. [Google Scholar]

- Safdarnejad, S.M.; Gallacher, J.R.; Hedengren, J.D. Dynamic parameter estimation and optimization for batch distillation. Comput. Chem. Eng. 2016, 86, 18–32. [Google Scholar] [CrossRef]

- Biegler, L.T.; Cervantes, A.M.; Wächter, A. Advances in simultaneous strategies for dynamic process optimization. Chem. Eng. Sci. 2002, 57, 575–593. [Google Scholar] [CrossRef]

- Biegler, L.T.; Grossmann, I.E. Retrospective on optimization. Comput. Chem. Eng. 2004, 28, 1169–1192. [Google Scholar] [CrossRef]

- Biegler, L. Advanced Optimization Strategies For Integrated dynamic Process Operations. In Proceedings of the Foundations of Computer-Aided Process Operations (FOCAPO) and Chemical Process Control (CPC) 2017, Tucson, Arizona, 8–12 January 2017. [Google Scholar]

- Martínez-Maradiaga, D.; Bruno, J.C.; Coronas, A. Steady-state data reconciliation for absorption refrigeration systems. Appl. Therm. Eng. 2013, 51, 1170–1180. [Google Scholar] [CrossRef]

- MATLAB; MATLAB and Optimization Toolbox Release 2010a; The MathWorks Inc.: Natick, MA, USA, 2010.

- Dave, D.J.; Dabhiya, M.Z.; Satyadev, S.; Ganguly, S.; Saraf, D.N. Online tuning of a steady state crude distillation unit model for real time applications. J. Process Control 2003, 13, 267–282. [Google Scholar] [CrossRef]

- Feital, T.; Prata, D.M.; Pinto, J.C. Comparison of methods for estimation of the covariance matrix of measurement errors. Can. J. Chem. Eng. 2014, 92, 2228–2245. [Google Scholar] [CrossRef]

- Feital, T.; Pinto, J.C. Use of variance spectra for in-line validation of process measurements in continuous processes. Can. J. Chem. Eng. 2015, 93, 1426–1437. [Google Scholar] [CrossRef]

- Jiang, X.; Liu, P.; Li, Z. Data reconciliation and gross error detection for operational data in power plants. Energy 2014, 75, 14–23. [Google Scholar] [CrossRef]

- Parsopoulos, K.; Vrahatis, M. Recent approaches to global optimization problems through Particle Swarm Optimization. Nat. Comput. 2002, 1, 235–306. [Google Scholar] [CrossRef]

- Flores-Tlacuahuac, A.; Moreno, S.T.; Biegler, L.T. Global Optimization of Highly Nonlinear Dynamic Systems. Ind. Eng. Chem. Res. 2008, 47, 2643–2655. [Google Scholar] [CrossRef]

- Thangaraj, R.; Pant, M.; Abraham, A.; Bouvry, P. Particle swarm optimization: Hybridization perspectives and experimental illustrations. Appl. Math. Comput. 2011, 217, 5208–5226. [Google Scholar] [CrossRef]

| Reference | Math. Nature | Estimator | Solution Method | Algorithm-Package/Simulator | Industrial Process |

|---|---|---|---|---|---|

| Hodouin and Everell [1] | static nonlinear | GL | Lagrange multipliers | Conjugate gradient method | Sections of mineral processing plant |

| Serth et al. [68] | static nonlinear | GL | Lagrange multipliers, Suc. Lin. | BSOLVE | Metallurgical grinding circuit |

| Holly et al. [69] | static linear | GL | Lagrange multipliers | analytical | Chemical extraction plant |

| Sanchez et al. [55] | static nonlinear | WLS | NLP solver | SQP/PLADAT | Ethylene plant |

| Meyer et al. [70] | static nonlinear | GL | Lagrange multipliers | Newton-Raphson | Beverage alcohol distillation plant |

| Islam et al. [58] | static nonlinear | GL | Linear solution, Suc. Lin., NLP solver | SQP | Industrial pyrolisis reactor |

| Krist et al. [60] | on-line static nonlinear | LS | Lagrange multipliers | Speedup/Aspenplus | Benzene plant |

| Bussani et al. [71] | on-line static nonlinear | WLS of relative errors | NLP solver | SQP/ORO | Hydrogen plant |

| Zhang et al. [10] | on-line static nonlinear | DR: contaminated gaussian, PE: LS | NLP solver | MINOS-GAMS/Aspen Plus | Monsanto sulfuric acid plant |

| Zhang et al. [72] | on-line static nonlinear | Contaminated gaussian | NLP solver | MINOS-GAMS/Aspen | Monsanto sulfuric acid plant |

| Weiss et al. [12] | static nonlinear | GL | Linear solution, Suc. Lin., NLP solver | Gauss-Marquardt, SQP | Industrial pyrolisis reactor |

| Sánchez et al. [73] | static nonlinear | GL | Linear solution, Suc. Lin., NLP solver | SQP | Industrial pyrolisis reactor |

| Sánchez and Romagnoli [74] | static (bi)linear | GL | Lagrange multipliers | Matrix Projection Method, QR decomposition | Industrial ethylene plant and simplified ammonia plant |

| Pierucci et al. [61] | on-line static nonlinear | WLS | NLP solver | SQP, Levenberg Marquardt, LNSI/ORO | Industrial furnace |

| Piccolo et al. [13] | static nonlinear | WLS | NLP solver | SQP/Apen Plus, MINOS5-GAMS | Refinery, gas separation system located downstream from a fluidized catalytic cracking unit |

| Heyen et al. [75] | static nonlinear | GL | Lagrange multipliers | NA | power plant |

| Kyriakopoulou and Kalitventzeff [53] | static nonlinear | GL | NLP solver | SQPIP, SOLDOG-BELSIM, SQPHP/VALI-BELSIM | Steam production network |

| Chiari et al. [50] | on-line static nonlinear | WLS of relative errors | NLP solver | SQP/ORO | Industrial hydrogen and sulfur plants |

| Christiansen et al. [76] | static nonlinear | GL | Suc. Lin., NLP solver | SQP | Industrial synthesis gas for production of ammonia |

| Heyen and Kalitventzeff [77] | static nonlinear | GL | NLP, MINLP | SQPIP, MINLP | Energy supply and utility distribution networks |

| McBrayer et al. [15] | dynamic nonlinear | WLS | NLP solver | SQP | Exxon chemical process |

| Dempf and List [78] | on-line static nonlinear | GL | NA | NA/VALI | Vinyl acetate and ketene plants |

| Plácido and Loureiro [79] | static nonlinear | GL | Lagrange multipliers | Matrix Projection Method | Ammonia plant |

| Bourouis et al. [80] | static nonlinear | Contaminated gaussian | NLP solver | NA | Multistage flash desalination plant |

| Chen et al. [51] | on-line static nonlinear | Contaminated gaussian, Lorentzian (GED-DR),WLS (DRPE) | NLP solver | CONOPT-GAMS | Sulfuric acid plant |

| Lee et al. [81] | on-line static (non)linear | GL | NLP solver | SQP | Industrial utility plant |

| Bazin et al. [82] | static nonlinear | GL | NLP solver | Conjugate gradient method | Rotary drier |

| Soderstrom et al. [83] | dynamic nonlinear | WLS | NLP solver | SQP-NOVA | Exxon chemical process |

| Li et al. [84] | on-line static nonlinear | WLS | Suc. Lin. | NA | Industrial crude oil distillation unit |

| Zhang et al. [85] | static linear | GL | Lagrange multipliers | NA | Refinery |

| Eksteen et al. [86] | static bilinear | 1. GL, 2. Closure residual | 1. NLP solver, 2. Lagrange multipliers | 1. GRG, 2. NA | Furnace from a pyrometallurgical industry |

| Sunde and Öivind Berg [87] | static nonlinear | GL | NA | NA/TEMPO system | Turbine cycle of a boiling water reactor (3300 MW) |

| Bagajewicz and Cabrera [88] | static nonlinear | GL | NLP solver | GAMS/SIMSCI | Gas pipeline systems |

| Vieira et al. [89] | dynamic nonlinear | GL | Lagrange multipliers | Gauss-Newton | Industrial polymerization reactor |

| Bhat and Saraf [56] | static linear | GL | Lagrange multipliers | analytical | Crude distillation unit |

| Chatterjee and Saraf [90] | static nonlinear | LS | NLP solver | SQP-NPSOL | Crude distillation unit refineries |

| Özyurt and Pike [28] | static nonlinear | Contaminated normal, Cauchy, Fair, Hampel, Logistic, and Lorentzian | NLP solver | Conopt2, Minos5 | Sulfuric acid plant |

| Yi and Han [91] | static MILP | GL | MILP | MILP | Gases network in an iron and steel making plant |

| Chen and Andersen [92] | static nonlinear | GL on closure residual | Lagrange multipliers | NA | Gas turbine |

| de Andrade Lima [93] | static nonlinear | GL | NLP solver | SQP-NPSOL | Industrial hydrometallurgical plants for gold extraction |

| AI-Arfaj [94] | static linear | GL | Lagrange multipliers | QR approach | Methyl-terc-butyl-ether plant |

| Faber et al. [95] | on-line static linear and nonlinear | Robust estimator of [96], Fair function | NLP solver | SQP - IMSL | Coke-oven-gas purification pilot plant |

| Hu and Shao [59] | static nonlinear | GL | Lagrange multipliers, Suc. Lin. | NA | Industrial coking plant |

| Prata et al. [47] | dynamic nonlinear | GL | NLP solver | Gauss-Newton | Industrial polymerization reactor |

| Faber et al. [23] | on-line static linear and nonlinear | Robust estimator of [96], Fair function | NLP solver | SQP - IMSL | Coke-oven-gas purification pilot plant |

| Schladt and Hu [97] | static nonlinear | Contaminated normal | NLP solver | SQP-SNOPT | Industrial distillation column |

| Bellec et al. [98] | online static bilinear | WLS | Kalman filter | Sigmafine (OSIsoft) | Paper machine stock approach system at an integrated newsprint paper mill |

| Lid and Skogestad [99] | static nonlinear | Contaminated normal | NLP solver | Fmincon-MATLAB | Refinery naphtha reformer |

| Reimers et al. [52] | static linear | GL | Lagrange multipliers | Gauss-Jordan/SolidSim | Dressing of brown coal |

| Embiruçu et al. [100] | dynamic nonlinear | GL | Lagrange multipliers | Gauss-Newton | Ethylene polymerization |

| Prata et al. [101] | dynamic nonlinear | GL | Lagrange multipliers | Gauss-Newton | Industrial polymerization reactor |

| Puig et al. [102] | static linear | GL | NA | Macrobal | Wastewater treatment plants (WWTPs) |

| Prata et al. [64] | dynamic nonlinear | GL | 1. Lagrange multipliers, 2. NLP solver | 1. Gauss-Newton, 2. PSO | Industrial polymerization reactor |

| Prata et al. [18] | dynamic nonlinear | GL, Welsch estimator | NLP solver | PSO | Industrial polypropylene reactor |

| Sarabia et al. [54] | on-line static nonlinear | GL | NLP solver | SQP-NAG/EcosimPro, IPOPT-GAMS | Hydrogen networks in oil refinery Petronor |

| Quelhas et al. [66] | on-line static nonlinear | GL | NLP solver | Gauss-Newton | Ethylene production |

| Zhang et al. [30] | static nonlinear | GL, Correntropy estimator | NA | NA | Air separation process |

| Cicciotti et al. [103] | static nonlinear | GL | NLP solver | NA | Multi-stage centrifugal compressor |

| Jiang et al. [104] | on-line static nonlinear | GL | Suc. Lin. | NA | Coal-fired steam turbine power plant (1000 MW) |

| Eghbal Ahmadi [105] | static nonlinear | GL | NLP solver | SQP/Aspen HySys | Part of a sulfur recovery unit |

| Guo et al. [106] | static nonlinear | GL | NLP solver | NA-MATLAB | Coal-fired steam turbine power plant (1000 MW) |

| Guo et al. [107] | static nonlinear | GL | NLP solver | SQP-fmincon/MATLAB | Coal-fired steam turbine power plant (1000 MW) |

| Behnami et al. [108] | static linear | WLS | Lagrange multipliers | MATLAB | Full-scale petrochemical wastewater treatment plant (WWTP) |

| Rafiee and Behrouzshad [109] | static nonlinear | GL | NLP solver | Fmincon-MATLAB | Natural gas processing plant |

| Câmara et al. [67] | on-line static nonlinear | WLS | NLP solver | SQP | Crude oil distillation |

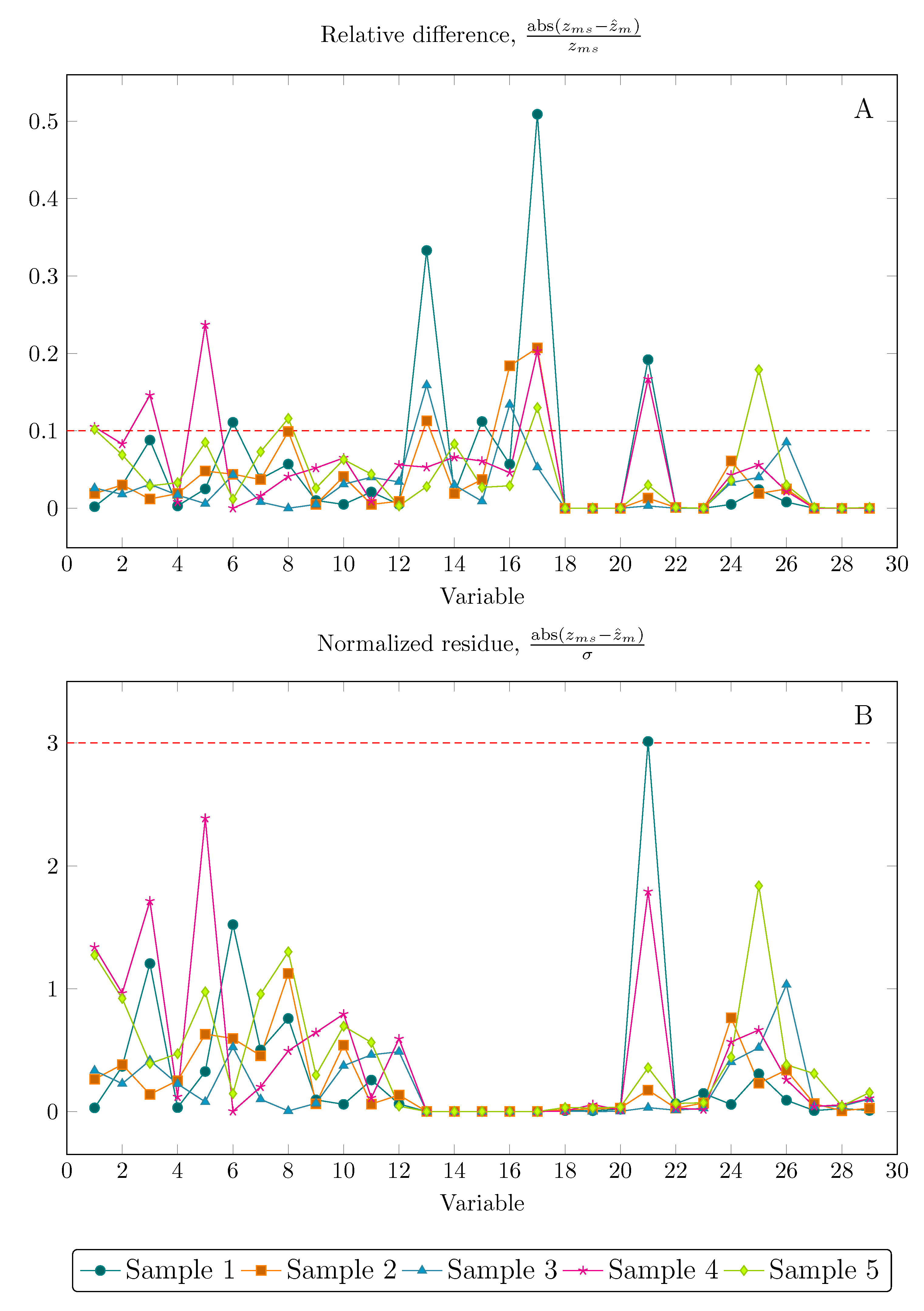

| Variable | Type | Unit | CV (%) |

|---|---|---|---|

| Inlet oil stream of HEA | 1 | m/day | 8 |

| Inlet gas stream of HEA | 1 | m/day | 8 |

| Inlet water stream of HEA | 1 | m/day | 8 |

| Inlet oil stream of HEB | 1 | m/day | 8 |

| Inlet gas stream of HEB | 1 | m/day | 8 |

| Inlet water stream of HEB | 1 | m/day | 8 |

| Inlet oil stream of HET | 1 | m/day | 8 |

| Inlet gas stream of HET | 1 | m/day | 8 |

| Inlet water stream of HET | 1 | m/day | 8 |

| Water feed stream of HEA | 1 | m/day | 8 |

| Water feed stream of HEB | 1 | m/day | 8 |

| Water feed stream of HET | 1 | m/day | 8 |

| Overall heat transfer coefficient of HEA | 2 | kcal m h C | 8 |

| Overall heat transfer coefficient of HEB | 2 | kcal m h C | 8 |

| Overall heat transfer coefficient of HET | 2 | kcal m h C | 8 |

| Split coefficient of SGA | 2 | % | 8 |

| Split coefficient of SGB | 2 | % | 8 |

| Outlet gas stream of SGA | 3 | m/day | 0.2 |

| Outlet gas stream of SGB | 3 | m/day | 0.2 |

| Outlet gas stream of SGT | 3 | m/day | 0.2 |

| Outlet gas stream of AS | 3 | m/day | 8 |

| Discharged water stream | 3 | m/day | 2 |

| Exported oil stream | 3 | m/day | 0.2 |

| Temperature of outlet water stream of HEA | 3 | C | 8 |

| Temperature of outlet water stream of HEB | 3 | C | 8 |

| Temperature of outlet water stream of HET | 3 | C | 8 |

| Temperature of outlet oil stream of HEA | 3 | C | 0.4 |

| Temperature of outlet oil stream of HEB | 3 | C | 0.4 |

| Temperature of outlet oil stream of HET | 3 | C | 0.4 |

| Setting | Solution Approach | Finite Difference | Initial guess | Degrees of Freedom | Optimization Algorithm | |

|---|---|---|---|---|---|---|

| 1 | simultaneous | central | measurement | yes | 12 | IP |

| 2a | sequential | central | measurement | yes | 12 | IP |

| 2b | sequential | central | true value | yes | 12 | IP |

| 2c | sequential | central | true value + 10% | yes | 12 | IP |

| 2d | sequential | central | true value − 10% | yes | 12 | IP |

| 2e | sequential | forward | measurement | yes | 12 | IP |

| 2f | sequential | forward | true value | yes | 12 | IP |

| 2g | sequential | forward | true value + 10% | yes | 12 | IP |

| 2h | sequential | forward | true value − 10% | yes | 12 | IP |

| 3 | sequential | central | measurement | no | 7 | IP |

| 4 | sequential | central | measurement | no | 7 | PSO/IP |

| Parameter | Description | Value |

|---|---|---|

| TolFun | Termination tolerance on the function value | 1 × 10 |

| TolX | Termination tolerance on decision variables | 1 × 10 |

| MaxIter | Maximum number of iterations allowed | 5000 |

| MaxFunEvals | Maximum number of function evaluations allowed | 10,000 |

| Description | Value |

|---|---|

| Number of generations | 60 |

| Number of particles | 5 |

| Local search parameter | 1 |

| Global search parameter | 1 |

| Sample | Time (min) | |||||

|---|---|---|---|---|---|---|

| Simultaneous (Setting 1) | Sequential (Setting 2a) | Relative Difference (%) | Simultaneous (Setting 1) | Sequential (Setting 2a) | Relative Difference (%) | |

| 1 | 347 | 266 | −23 | 54 | 9 | −83 |

| 2 | * 633 | 482 | −24 | 14 | 9 | −34 |

| 3 | * 62 | 4 | −93 | 63 | 29 | −54 |

| 4 | * 3352 | 192 | −94 | 77 | 8 | −89 |

| 5 | 990 | 448 | −55 | 50 | 9 | −81 |

| Setting | 2e | 2a | 2f | 2b | 2g | 2c | 2h | 2d |

|---|---|---|---|---|---|---|---|---|

| Initial Guess | Measurement | True Value | (True Value) × 1.1 | (True Value) × 0.9 | ||||

| Sample\Finite Difference | Forward | Central | Forward | Central | Forward | Central | Forward | Central |

| 1 | 121 | 266 | 33 | 20 | 997 | 20 | 148 | 1241 |

| 2 | 528 | 482 | 21 | 5 | 4047 | 5 | 1673 | 5 |

| 3 | 217 | 4 | 12 | 4 | 189 | 4 | 570 | 4 |

| 4 | 1138 | 192 | 31 | 19 | 2221 | 26 | 1979 | 1094 |

| 5 | 167 | 448 | 24 | 11 | 1243 | 11 | 675 | 11 |

| Average | 434 | 279 | 24 | 12 | 1739 | 13 | 1009 | 471 |

| Relative difference (%) | −36 | −50 | −99 | −53 | ||||

| Setting | 2e | 2a | 2f | 2b | 2g | 2c | 2h | 2d |

|---|---|---|---|---|---|---|---|---|

| Initial Guess | Measurement | True Value | (True Value) × 1.1 | (True Value) × 0.9 | ||||

| Sample\Finite Difference | Forward | Central | Forward | Central | Forward | Central | Forward | Central |

| 1 | 33 | 9 | 6 | 22 | 13 | 24 | 29 | 8 |

| 2 | 70 | 9 | 18 | 21 | 3 | 29 | 5 | 24 |

| 3 | 25 | 29 | 31 | 20 | 26 | 31 | 5 | 23 |

| 4 | 6 | 8 | 3 | 14 | 27 | 24 | 22 | 14 |

| 5 | 60 | 9 | 2 | 25 | 12 | 27 | 33 | 26 |

| Average | 39 | 13 | 12 | 21 | 16 | 27 | 19 | 19 |

| Relative difference (%) | −67 | 72 | 65 | 0 | ||||

| Sample | Time (min) | |||||

|---|---|---|---|---|---|---|

| Forward | Central | Relative Difference (%) | Forward | Central | Relative Difference (%) | |

| 1 | 325 | 387 | 19 | 20 | 16 | −22 |

| 2 | 1567 | 125 | −92 | 24 | 21 | −15 |

| 3 | 247 | 4 | −98 | 22 | 26 | 19 |

| 4 | 1342 | 333 | −75 | 14 | 15 | 6 |

| 5 | 527 | 120 | −77 | 27 | 22 | −18 |

| Sample | Time (min) | |||||

|---|---|---|---|---|---|---|

| (Setting 2a) | (Setting 3) | Relative Difference (%) | (Setting 2a) | (Setting 3) | Relative Difference (%) | |

| 1 | 266 | 485 | 82 | 9 | 6 | −32 |

| 2 | 482 | 1042 | 116 | 9 | 4 | −52 |

| 3 | 4 | 3 | −38 | 29 | 24 | −17 |

| 4 | 192 | 171 | −11 | 8 | 9 | 8 |

| 5 | 448 | 528 | 18 | 9 | 5 | −41 |

| Sample | (Setting 2a) | (Setting 3) |

|---|---|---|

| 1 | 6 | 5 |

| 2 | 5 | 5 |

| 3 | 0 | 0 |

| 4 | 6 | 3 |

| 5 | 6 | 8 |

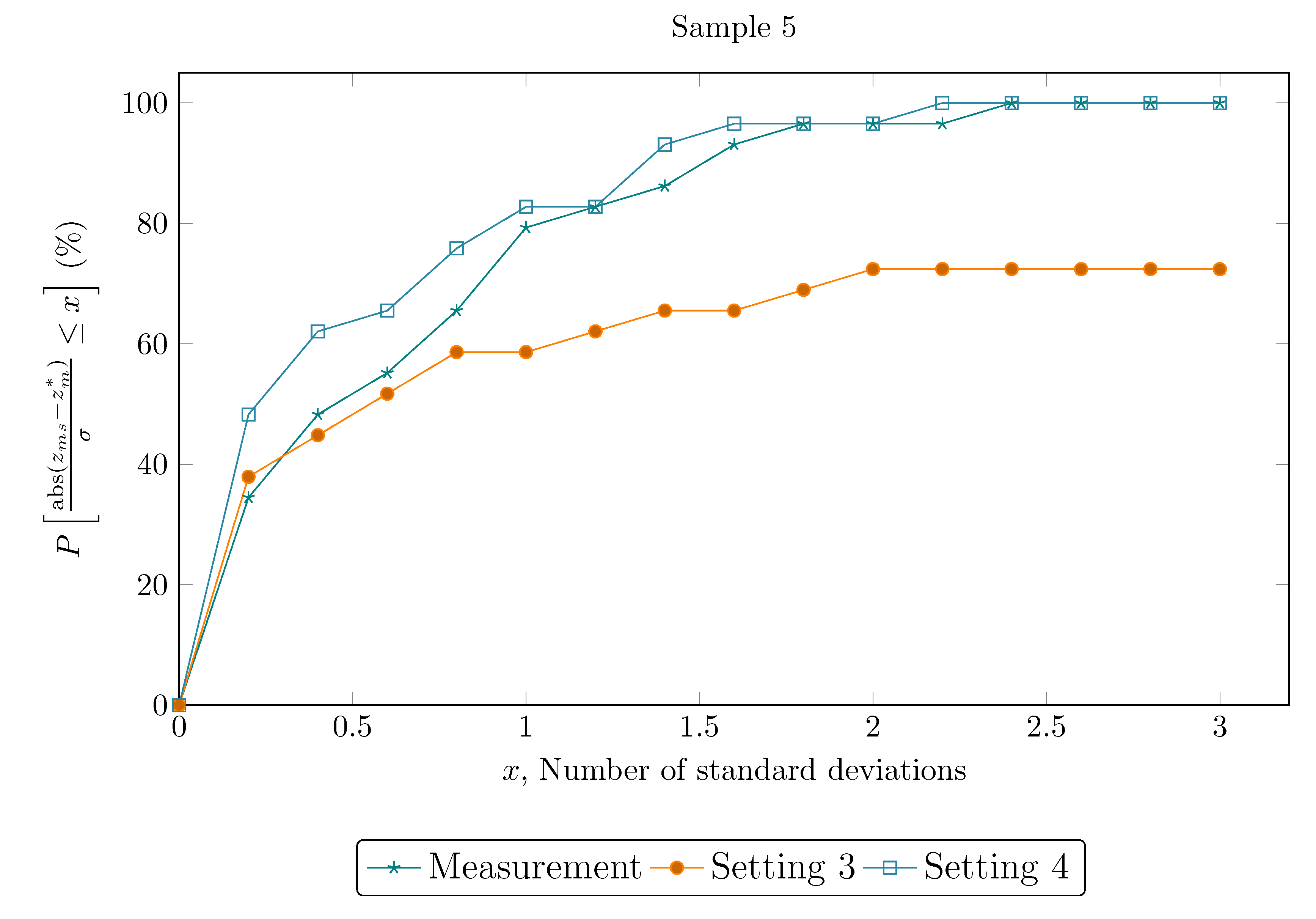

| Sample | Time (min) | |||||

|---|---|---|---|---|---|---|

| IP (Setting 3) | PSO + IP (Setting 4) | Relative Difference (%) | IP (Setting 3) | PSO + IP (Setting 4) | Relative Difference (%) | |

| 1 | 485 | 748/14 | −97 | 6 | 7 + 21 = 28 | 354 |

| 2 | 1042 | 89/4 | −99.7 | 4 | 6 + 11 = 17 | 309 |

| 3 | 3 | 578/3 | 0 | 24 | 6 + 22 = 28 | 16 |

| 4 | 171 | 291/17 | −90 | 9 | 6 + 11 = 17 | 91 |

| 5 | 528 | 686/11 | −98 | 5 | 6 + 13 = 19 | 242 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Câmara, M.M.; Soares, R.M.; Feital, T.; Anzai, T.K.; Diehl, F.C.; Thompson, P.H.; Pinto, J.C. Numerical Aspects of Data Reconciliation in Industrial Applications. Processes 2017, 5, 56. https://doi.org/10.3390/pr5040056

Câmara MM, Soares RM, Feital T, Anzai TK, Diehl FC, Thompson PH, Pinto JC. Numerical Aspects of Data Reconciliation in Industrial Applications. Processes. 2017; 5(4):56. https://doi.org/10.3390/pr5040056

Chicago/Turabian StyleCâmara, Maurício M., Rafael M. Soares, Thiago Feital, Thiago K. Anzai, Fabio C. Diehl, Pedro H. Thompson, and José Carlos Pinto. 2017. "Numerical Aspects of Data Reconciliation in Industrial Applications" Processes 5, no. 4: 56. https://doi.org/10.3390/pr5040056