Nondestructive Technique for Identifying Adulteration and Additives in Lemon Juice Based on Analyzing Volatile Organic Compounds (VOCs)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

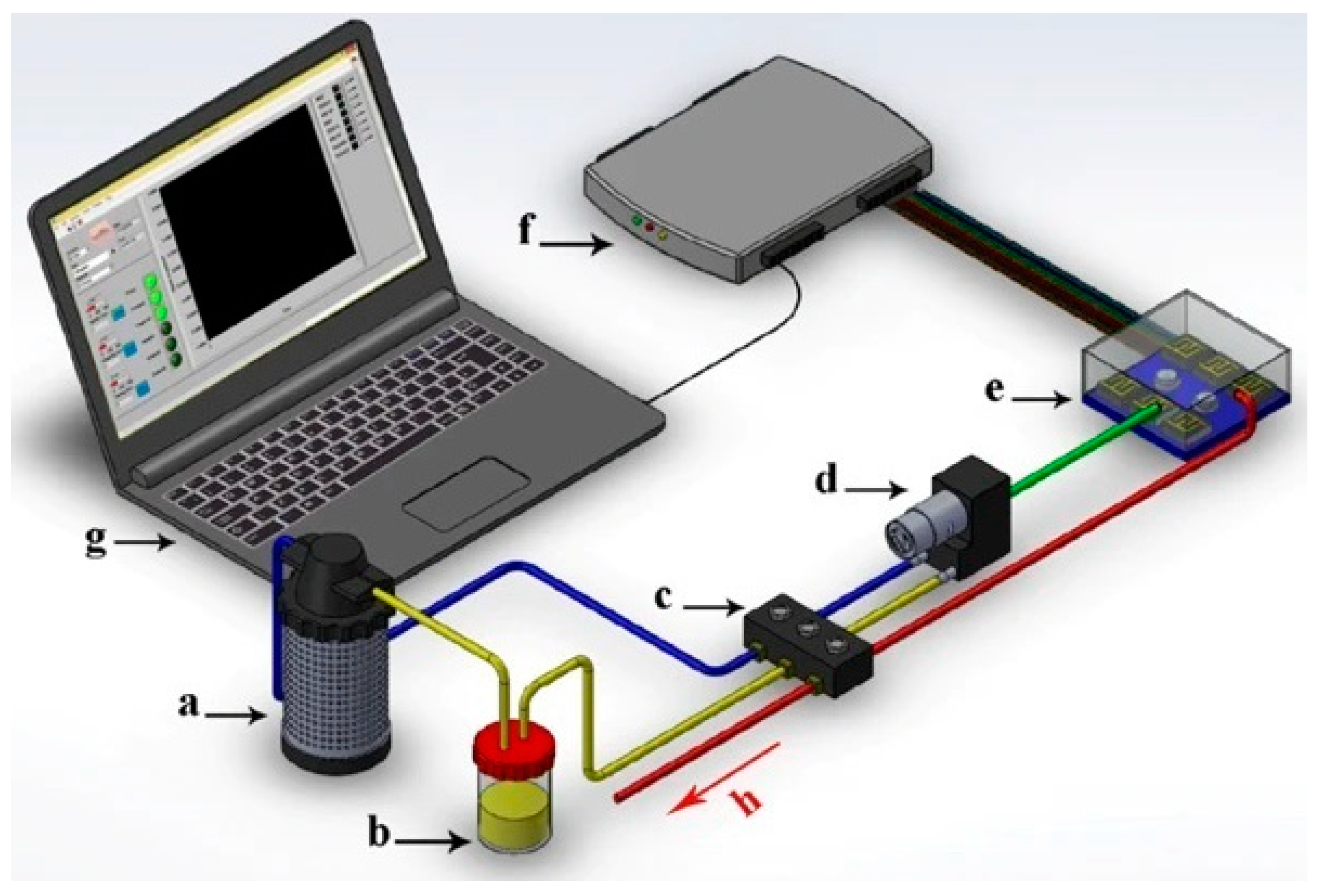

2.2. The Electronic Nose System

2.3. Chemometrics Methods

2.4. Criteria for Model Evaluation

3. Results and Discussion

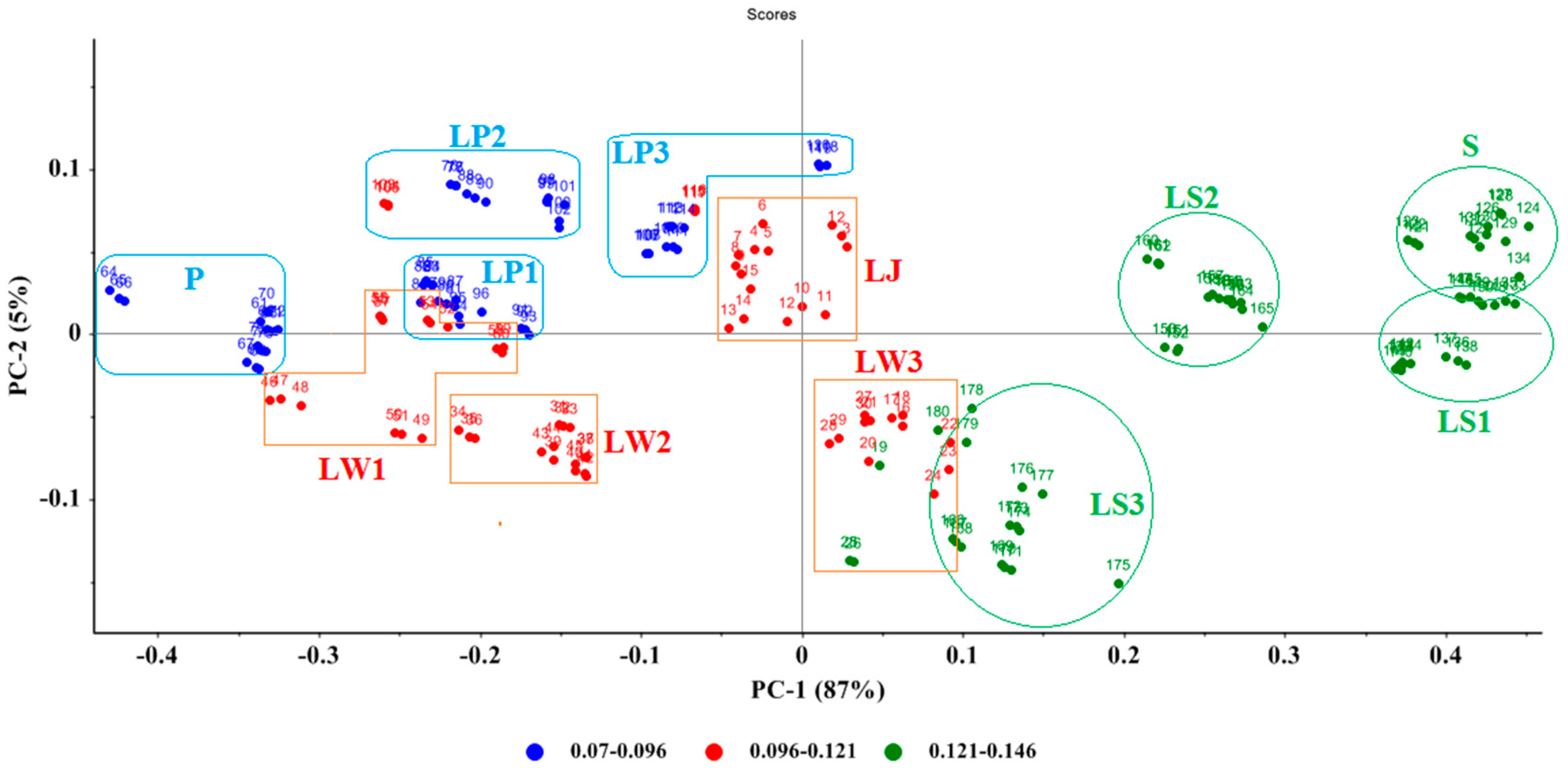

3.1. Principal Component Analysis (PCA)

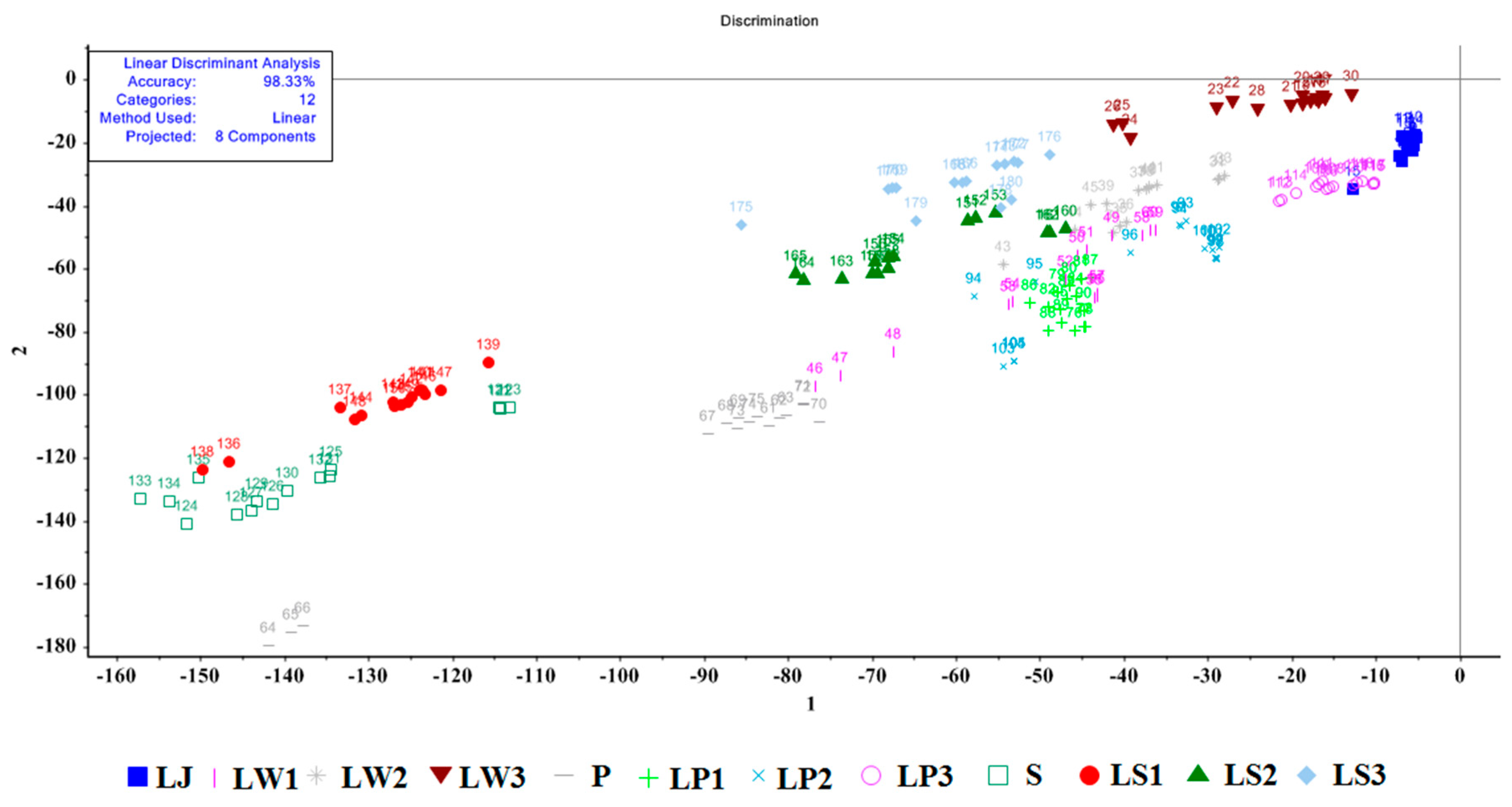

3.2. Linear Discriminant Analysis (LDA)

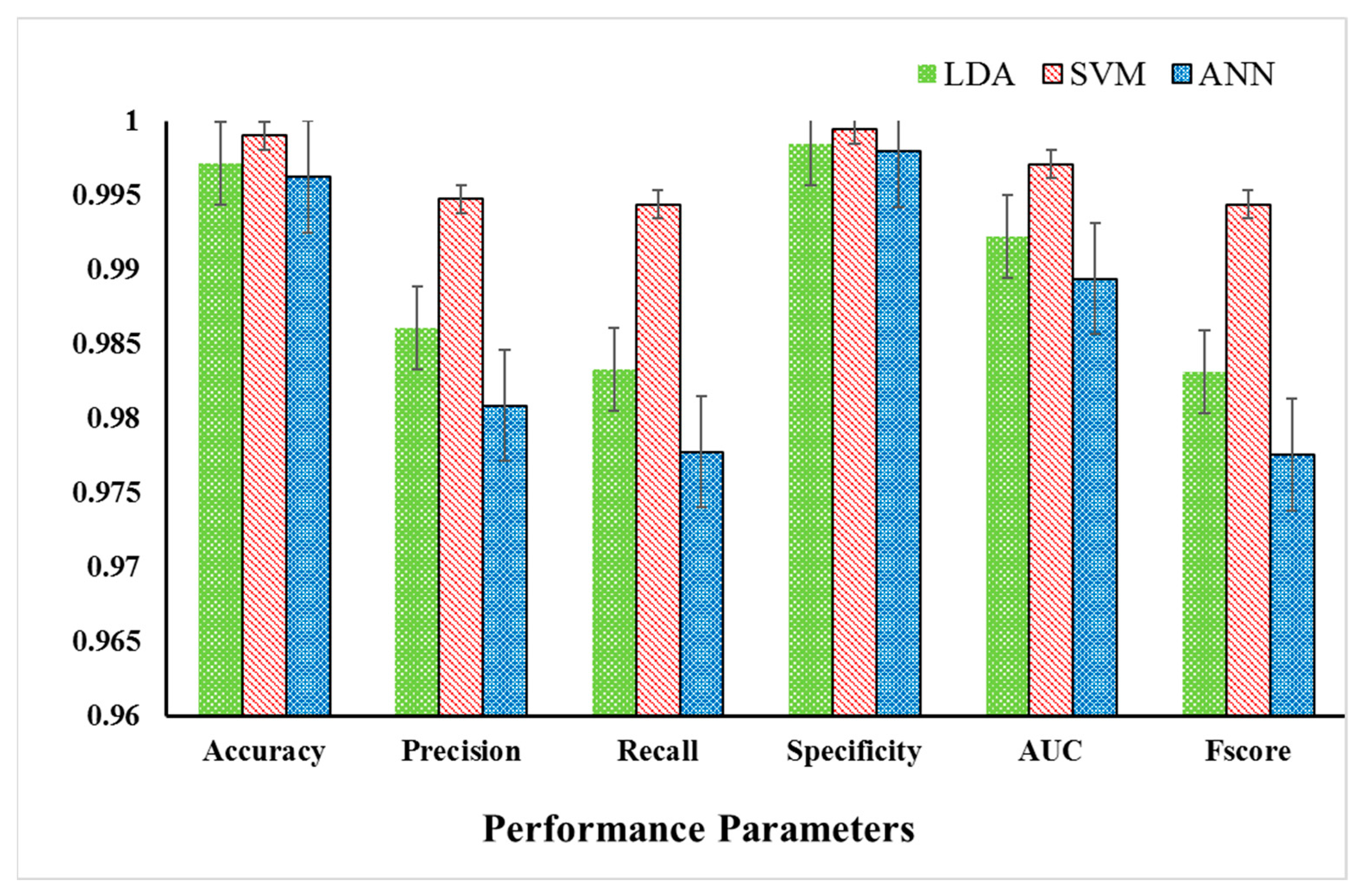

3.3. SVM Results

3.4. ANN Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Karami, H.; Rasekh, M.; Mirzaee-Ghaleh, E. Application of the E-nose machine system to detect adulterations in mixed edible oils using chemometrics methods. J. Food Process. Preserv. 2020, 44, e14696. [Google Scholar] [CrossRef]

- Rasekh, M.; Karami, H. E-nose coupled with an artificial neural network to detection of fraud in pure and industrial fruit juices. Int. J. Food Prop. 2021, 24, 592–602. [Google Scholar] [CrossRef]

- Tibola, C.S.; da Silva, S.A.; Dossa, A.A.; Patrício, D.I. Economically Motivated Food Fraud and Adulteration in Brazil: Incidents and Alternatives to Minimize Occurrence. J. Food Sci. 2018, 83, 2028–2038. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Jablonski, J.E. Targeted and non-targeted detection of lemon juice adulteration by LC-MS and chemometrics. Food Addit. Contam. Part A 2016, 33, 560–573. [Google Scholar] [CrossRef]

- Mohammadian, A.; Barzegar, M.; Mani-Varnosfaderani, A. Detection of fraud in lime juice using pattern recognition techniques and FT-IR spectroscopy. Food Sci. Nutr. 2021, 9, 3026–3038. [Google Scholar] [CrossRef]

- Lyu, W.; Yuan, B.; Liu, S.; Simon, J.E.; Wu, Q. Assessment of lemon juice adulteration by targeted screening using LC-UV-MS and untargeted screening using UHPLC-QTOF/MS with machine learning. Food Chem. 2022, 373, 131424. [Google Scholar] [CrossRef]

- Gupta, S.; Rahman, M.A.; Sundaram, S. Citrus fruit as A potential source of phytochemical, antioxidant and pharmacological ingredients. J. Sci. Healthc. Explor. 2021, 2581, 8473. [Google Scholar]

- Rodríguez-García, C.; Sánchez-Quesada, C.; Gaforio, J.J. Dietary flavonoids as cancer chemopreventive agents: An updated review of human studies. Antioxidants 2019, 8, 137. [Google Scholar] [CrossRef]

- Zorpeykar, S.; Mirzaee-Ghaleh, E.; Karami, H.; Ramedani, Z.; Wilson, A.D. Electronic Nose Analysis and Statistical Methods for Investigating Volatile Organic Compounds and Yield of Mint Essential Oils Obtained by Hydrodistillation. Chemosensors 2022, 10, 486. [Google Scholar] [CrossRef]

- Bononi, M.; Quaglia, G.; Tateo, F. Preliminary LC-IRMS Characterization of Italian Pure Lemon Juices and Evaluation of Commercial Juices Distributed in the Italian Market. Food Anal. Methods 2016, 9, 2824–2831. [Google Scholar] [CrossRef]

- Cautela, D.; Laratta, B.; Santelli, F.; Trifirò, A.; Servillo, L.; Castaldo, D. Estimating Bergamot Juice Adulteration of Lemon Juice by High-Performance Liquid Chromatography (HPLC) Analysis of Flavanone Glycosides. J. Agric. Food Chem. 2008, 56, 5407–5414. [Google Scholar] [CrossRef]

- Guyon, F.; Auberger, P.; Gaillard, L.; Loublanches, C.; Viateau, M.; Sabathié, N.; Salagoïty, M.-H.; Médina, B. 13C/12C isotope ratios of organic acids, glucose and fructose determined by HPLC-co-IRMS for lemon juices authenticity. Food Chem. 2014, 146, 36–40. [Google Scholar] [CrossRef]

- Gaiad, J.E.; Hidalgo, M.J.; Villafañe, R.N.; Marchevsky, E.J.; Pellerano, R.G. Tracing the geographical origin of Argentinean lemon juices based on trace element profiles using advanced chemometric techniques. Microchem. J. 2016, 129, 243–248. [Google Scholar] [CrossRef]

- Alizadeh, M.; Pirsa, S.; Faraji, N. Determination of Lemon Juice Adulteration by Analysis of Gas Chromatography Profile of Volatile Organic Compounds Extracted with Nano-Sized Polyester-Polyaniline Fiber. Food Anal. Methods 2017, 10, 2092–2101. [Google Scholar] [CrossRef]

- Brendel, R.; Schwolow, S.; Rohn, S.; Weller, P. Volatilomic Profiling of Citrus Juices by Dual-Detection HS-GC-MS-IMS and Machine Learning-An Alternative Authentication Approach. J. Agric. Food Chem. 2021, 69, 1727–1738. [Google Scholar] [CrossRef]

- Khorramifar, A.; Sharabiani, V.R.; Karami, H.; Kisalaei, A.; Lozano, J.; Rusinek, R.; Gancarz, M. Investigating Changes in pH and Soluble Solids Content of Potato during the Storage by Electronic Nose and Vis/NIR Spectroscopy. Foods 2022, 11, 4077. [Google Scholar] [CrossRef]

- Gómez, A.H.; Wang, J.; Hu, G.; Pereira, A.G. Electronic nose technique potential monitoring mandarin maturity. Sens. Actuators B Chem. 2006, 113, 347–353. [Google Scholar] [CrossRef]

- Rasekh, M.; Karami, H.; Fuentes, S.; Kaveh, M.; Rusinek, R.; Gancarz, M. Preliminary study non-destructive sorting techniques for pepper (Capsicum annuum L.) using odor parameter. LWT 2022, 164, 113667. [Google Scholar] [CrossRef]

- Majchrzak, T.; Wojnowski, W.; Dymerski, T.; Gębicki, J.; Namieśnik, J. Electronic noses in classification and quality control of edible oils: A review. Food Chem. 2018, 246, 192–201. [Google Scholar] [CrossRef] [PubMed]

- Wasilewski, T.; Migoń, D.; Gębicki, J.; Kamysz, W. Critical review of electronic nose and tongue instruments prospects in pharmaceutical analysis. Anal. Chim. Acta 2019, 1077, 14–29. [Google Scholar] [CrossRef]

- Gardner, J.W.; Bartlett, P.N. A brief history of electronic noses. Sens. Actuators B Chem. 1994, 18, 210–211. [Google Scholar] [CrossRef]

- Karami, H.; Rasekh, M.; Mirzaee-Ghaleh, E. Comparison of chemometrics and AOCS official methods for predicting the shelf life of edible oil. Chemom. Intell. Lab. Syst. 2020, 206, 104165. [Google Scholar] [CrossRef]

- Rüffer, D.; Hoehne, F.; Bühler, J. New Digital Metal-Oxide (MOx) Sensor Platform. Sensors 2018, 18, 1052. [Google Scholar] [CrossRef] [PubMed]

- Van Duy, L.; Nguyet, T.T.; Le, D.T.T.; Van Duy, N.; Nguyen, H.; Biasioli, F.; Tonezzer, M.; Di Natale, C.; Hoa, N.D. Room Temperature Ammonia Gas Sensor Based on p-Type-like V2O5 Nanosheets towards Food Spoilage Monitoring. Nanomaterials 2023, 13, 146. [Google Scholar] [CrossRef] [PubMed]

- Tatli, S.; Mirzaee-Ghaleh, E.; Rabbani, H.; Karami, H.; Wilson, A.D. Rapid Detection of Urea Fertilizer Effects on VOC Emissions from Cucumber Fruits Using a MOS E-Nose Sensor Array. Agronomy 2022, 12, 35. [Google Scholar] [CrossRef]

- Gorsaka-Horczyczak, E.; Guzek, D.; Moleda, Z.; Wojtasik-Kalinowska, I.; Brodowska, M.; Wierzbicka, A. Applications of electronic noses in meat analysis. Food Sci. Technol. 2016, 36, 389–395. [Google Scholar] [CrossRef]

- Karami, H.; Rasekh, M.; Mirzaee-Ghaleh, E. Qualitative analysis of edible oil oxidation using an olfactory machine. J. Food Meas. Charact. 2020, 14, 2600–2610. [Google Scholar] [CrossRef]

- Wojnowski, W.; Majchrzak, T.; Dymerski, T.; Gebicki, J.; Namieśnik, J. Portable Electronic Nose Based on Electrochemical Sensors for Food Quality Assessment. Sensors 2017, 17, 2715. [Google Scholar] [CrossRef]

- Niu, B.; Zhang, H.; Zhou, G.; Zhang, S.; Yang, Y.; Deng, X.; Chen, Q. Safety risk assessment and early warning of chemical contamination in vegetable oil. Food Control 2021, 125, 107970. [Google Scholar] [CrossRef]

- Luo, Y.; Li, Z.; Yuan, Y.; Yue, T. Bioadsorption of patulin from kiwi fruit juice onto a superior magnetic chitosan. J. Alloy Compd. 2016, 667, 101–108. [Google Scholar] [CrossRef]

- Li, S.; Hu, Y.; Liu, W.; Chen, Y.; Wang, F.; Lu, X.; Zheng, W. Untargeted volatile metabolomics using comprehensive two-dimensional gas chromatography-mass spectrometry—A solution for orange juice authentication. Talanta 2020, 217, 121038. [Google Scholar] [CrossRef] [PubMed]

- Qiu, S.; Hou, P.; Huang, J.; Han, W.; Kang, Z. The Monitoring of Black-Odor River by Electronic Nose with Chemometrics for pH, COD, TN, and TP. Chemosensors 2021, 9, 168. [Google Scholar] [CrossRef]

- Hong, X.; Wang, J.; Qi, G. E-nose combined with chemometrics to trace tomato-juice quality. J. Food Eng. 2015, 149, 38–43. [Google Scholar] [CrossRef]

- Torri, L.; Sinelli, N.; Limbo, S. Shelf life evaluation of fresh-cut pineapple by using an electronic nose. Postharvest Biol. Technol. 2010, 56, 239–245. [Google Scholar] [CrossRef]

- Qiu, S.; Wang, J.; Gao, L. Qualification and quantisation of processed strawberry juice based on electronic nose and tongue. LWT-Food Sci. Technol. 2015, 60, 115–123. [Google Scholar] [CrossRef]

- Gobbi, E.; Falasconi, M.; Concina, I.; Mantero, G.; Bianchi, F.; Mattarozzi, M.; Musci, M.; Sberveglieri, G. Electronic nose and Alicyclobacillus spp. spoilage of fruit juices: An emerging diagnostic tool. Food Control 2010, 21, 1374–1382. [Google Scholar] [CrossRef]

- Rasekh, M.; Karami, H.; Wilson, A.D.; Gancarz, M. Classification and Identification of Essential Oils from Herbs and Fruits Based on a MOS Electronic-Nose Technology. Chemosensors 2021, 9, 142. [Google Scholar] [CrossRef]

- Rasekh, M.; Karami, H. Application of electronic nose with chemometrics methods to the detection of juices fraud. J. Food Process. Preserv. 2021, 45, e15432. [Google Scholar] [CrossRef]

- Pelosi, P.; Zhu, J.; Knoll, W. From Gas Sensors to Biomimetic Artificial Noses. Chemosensors 2018, 6, 32. [Google Scholar] [CrossRef]

- Ayari, F.; Mirzaee- Ghaleh, E.; Rabbani, H.; Heidarbeigi, K. Using an E-nose machine for detection the adulteration of margarine in cow ghee. J. Food Process Eng. 2018, 41, e12806. [Google Scholar] [CrossRef]

- Karami, H.; Rasekh, M.; Mirzaee-Ghaleh, E. Identification of olfactory characteristics of edible oil during storage period using metal oxide semiconductor sensor signals and ANN methods. J. Food Process. Preserv. 2021, 45, e15749. [Google Scholar] [CrossRef]

- Khorramifar, A.; Rasekh, M.; Karami, H.; Malaga-Toboła, U.; Gancarz, M. A Machine Learning Method for Classification and Identification of Potato Cultivars Based on the Reaction of MOS Type Sensor-Array. Sensors 2021, 21, 5836. [Google Scholar] [CrossRef] [PubMed]

- Khorramifar, A.; Karami, H.; Wilson, A.D.; Sayyah, A.H.A.; Shuba, A.; Lozano, J. Grape Cultivar Identification and Classification by Machine Olfaction Analysis of Leaf Volatiles. Chemosensors 2022, 10, 125. [Google Scholar] [CrossRef]

- Latif, G.; Ben Brahim, G.; Iskandar, D.N.F.A.; Bashar, A.; Alghazo, J. Glioma Tumors’ Classification Using Deep-Neural-Network-Based Features with SVM Classifier. Diagnostics 2022, 12, 1018. [Google Scholar] [PubMed]

- Abiodun, O.I.; Jantan, A.; Omolara, A.E.; Dada, K.V.; Mohamed, N.A.; Arshad, H. State-of-the-art in artificial neural network applications: A survey. Heliyon 2018, 4, e00938. [Google Scholar] [CrossRef] [PubMed]

- Jenkins, E.K.; DeChant, M.T.; Perry, E.B. When the Nose Doesn’t Know: Canine Olfactory Function Associated with Health, Management, and Potential Links to Microbiota. Front. Vet. Sci. 2018, 5, 56. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez Viejo, C.; Tongson, E.; Fuentes, S. Integrating a Low-Cost Electronic Nose and Machine Learning Modelling to Assess Coffee Aroma Profile and Intensity. Sensors 2021, 21, 2016. [Google Scholar] [CrossRef]

- Kulkarni, A.; Chong, D.; Batarseh, F.A. 5-Foundations of data imbalance and solutions for a data democracy. In Data Democracy; Batarseh, F.A., Yang, R., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 83–106. [Google Scholar]

- Ting, K.M. Confusion Matrix. In Encyclopedia of Machine Learning and Data Mining; Sammut, C., Webb, G.I., Eds.; Springer: Boston, MA, USA, 2017; p. 260. [Google Scholar]

- Khairunniza-Bejo, S.; Shahibullah, M.S.; Azmi, A.N.N.; Jahari, M. Non-Destructive Detection of Asymptomatic Ganoderma boninense Infection of Oil Palm Seedlings Using NIR-Hyperspectral Data and Support Vector Machine. Appl. Sci. 2021, 11, 10878. [Google Scholar] [CrossRef]

- Bieganowski, A.; Józefaciuk, G.; Bandura, L.; Guz, Ł.; Łagód, G.; Franus, W. Evaluation of Hydrocarbon Soil Pollution Using E-Nose. Sensors 2018, 18, 2463. [Google Scholar] [CrossRef] [PubMed]

- Novakovic, J.; Veljovi, A.; Iiic, S.; Papic, Z.; Tomovic, M. Evaluation of classification models in machine learning. Theory Appl. Math. Comput. Sci. 2017, 7, 39–46. [Google Scholar]

- Melo, F. Area under the ROC Curve. In Encyclopedia of Systems Biology; Dubitzky, W., Wolkenhauer, O., Cho, K.-H., Yokota, H., Eds.; Springer: New York, NY, USA, 2013; pp. 38–39. [Google Scholar]

- Aghili, N.S.; Rasekh, M.; Karami, H.; Azizi, V.; Gancarz, M. Detection of fraud in sesame oil with the help of artificial intelligence combined with chemometrics methods and chemical compounds characterization by gas chromatography—Mass spectrometry. LWT 2022, 167, 113863. [Google Scholar] [CrossRef]

- Fuadah, Y.N.; Lim, K.M. Classification of Blood Pressure Levels Based on Photoplethysmogram and Electrocardiogram Signals with a Concatenated Convolutional Neural Network. Diagnostics 2022, 12, 2886. [Google Scholar] [CrossRef]

- Celdrán, A.C.; Oates, M.J.; Molina Cabrera, C.; Pangua, C.; Tardaguila, J.; Ruiz-Canales, A. Low-Cost Electronic Nose for Wine Variety Identification through Machine Learning Algorithms. Agronomy 2022, 12, 2627. [Google Scholar] [CrossRef]

- Lelono, D.; Triyana, K.; Hartati, S.; Istiyanto, J.E. Classification of Indonesia black teas based on quality by using electronic nose and principal component analysis. AIP Conf. Proc. 2016, 1755, 20003. [Google Scholar] [CrossRef]

- Han, L.; Chen, M.; Li, Y.; Wu, S.; Zhang, L.; Tu, K.; Pan, L.; Wu, J.; Song, L. Discrimination of different oil types and adulterated safflower seed oil based on electronic nose combined with gas chromatography-ion mobility spectrometry. J. Food Compos. Anal. 2022, 114, 104804. [Google Scholar] [CrossRef]

- Tian, X.; Wang, J.; Ma, Z.; Li, M.; Wei, Z. Combination of an E-Nose and an E-Tongue for Adulteration Detection of Minced Mutton Mixed with Pork. J. Food Qual. 2019, 2019, 4342509. [Google Scholar] [CrossRef]

- Centonze, V.; Lippolis, V.; Cervellieri, S.; Damascelli, A.; Casiello, G.; Pascale, M.; Logrieco, A.F.; Longobardi, F. Discrimination of geographical origin of oranges (Citrus sinensis L. Osbeck) by mass spectrometry-based electronic nose and characterization of volatile compounds. Food Chem. 2019, 277, 25–30. [Google Scholar] [CrossRef] [PubMed]

- Mohammad-Razdari, A.; Ghasemi-Varnamkhasti, M.; Yoosefian, S.H.; Izadi, Z.; Siadat, M. Potential application of electronic nose coupled with chemometric tools for authentication assessment in tomato paste. J. Food Process Eng. 2019, 42, e13119. [Google Scholar] [CrossRef]

- Gomez, A.H.; Wang, J.; Hu, G.; Pereira, A.G. Monitoring storage shelf life of tomato using electronic nose technique. J. Food Eng. 2008, 85, 625–631. [Google Scholar] [CrossRef]

- Gu, S.; Wang, Z.; Chen, W.; Wang, J. Early identification of Aspergillus spp. contamination in milled rice by E-nose combined with chemometrics. J. Sci. Food Agric. 2021, 101, 4220–4228. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, W.; Gu, S.; Wang, Y.; Wang, J. Evaluation of trunk borer infestation duration using MOS E-nose combined with different feature extraction methods and GS-SVM. Comput. Electron. Agric. 2020, 170, 105293. [Google Scholar] [CrossRef]

- Du, D.; Xu, M.; Wang, J.; Gu, S.; Zhu, L.; Hong, X. Tracing internal quality and aroma of a red-fleshed kiwifruit during ripening by means of GC-MS and E-nose. RSC Adv. 2019, 9, 21164–21174. [Google Scholar] [CrossRef] [PubMed]

- Payman, S.H.; Bakhshipour Ziaratgahi, A.; Sanaeifar, A. Applying Electronic Nose System for Qualitative Classification of Iranian Black Tea. Innov. Food Technol. 2019, 6, 351–362. [Google Scholar] [CrossRef]

- Ghasemi-Varnamkhasti, M.; Mohammad-Razdari, A.; Yoosefian, S.H.; Izadi, Z.; Rabiei, G. Selection of an optimized metal oxide semiconductor sensor (MOS) array for freshness characterization of strawberry in polymer packages using response surface method (RSM). Postharvest Biol. Technol. 2019, 151, 53–60. [Google Scholar] [CrossRef]

- Qiao, J.; Su, G.; Liu, C.; Zou, Y.; Chang, Z.; Yu, H.; Wang, L.; Guo, R. Study on the Application of Electronic Nose Technology in the Detection for the Artificial Ripening of Crab Apples. Horticulturae 2022, 8, 386. [Google Scholar] [CrossRef]

- Rusinek, R.; Dobrzański, B.; Oniszczuk, A.; Gawrysiak-Witulska, M.; Siger, A.; Karami, H.; Ptaszyńska, A.A.; Żytek, A.; Kapela, K.; Gancarz, M. How to Identify Roast Defects in Coffee Beans Based on the Volatile Compound Profile. Molecules 2022, 27, 8530. [Google Scholar] [CrossRef]

- Velička, A.; Tarasevičienė, Ž.; Hallmann, E.; Kieltyka-Dadasiewicz, A. Impact of Foliar Application of Amino Acids on Essential Oil Content, Odor Profile, and Flavonoid Content of Different Mint Varieties in Field Conditions. Plants 2022, 11, 2938. [Google Scholar] [CrossRef]

- Srinath, K.; Kiranmayee, A.H.; Bhanot, S.; Panchariya, P.C. Detection of Palm Oil Adulteration in Sunflower Oil Using ATR-MIR Spectroscopy Coupled with Chemometric Algorithms. MAPAN 2022, 37, 483–493. [Google Scholar] [CrossRef]

- Teixeira, G.G.; Dias, L.G.; Rodrigues, N.; Marx, Í.M.G.; Veloso, A.C.A.; Pereira, J.A.; Peres, A.M. Application of a lab-made electronic nose for extra virgin olive oils commercial classification according to the perceived fruitiness intensity. Talanta 2021, 226, 122122. [Google Scholar] [CrossRef]

- Cruz-Domínguez, O.; Carrera-Escobedo, J.L.; Guzmán-Valdivia, C.H.; Ortiz-Rivera, A.; García-Ruiz, M.; Durán-Muñoz, H.A.; Vidales-Basurto, C.A.; Castaño, V.M. A novel method for dried chili pepper classification using artificial intelligence. J. Agric. Food Res. 2021, 3, 100099. [Google Scholar] [CrossRef]

- Goyal, S.; Goyal, G. Heuristic Machine Learning Feedforward Algorithm for Predicting Shelf Life of Processed Cheese. Int. J. Basic Appl. Sci. 2012, 1, 458–467. [Google Scholar] [CrossRef]

- Rasekh, M.; Karami, H.; Wilson, A.D.; Gancarz, M. Performance Analysis of MAU-9 Electronic-Nose MOS Sensor Array Components and ANN Classification Methods for Discrimination of Herb and Fruit Essential Oils. Chemosensors 2021, 9, 243. [Google Scholar] [CrossRef]

| Sensor Type | Main Applications | Typical Detection Ranges (ppm) |

|---|---|---|

| MQ3 | Alcohol | 10–300 |

| TGS822 | Steam organic solvents | 50–5000 |

| MQ-136 | Sulfur dioxide (SO2) | 1–200 |

| MQ-9 | CO and combustible gas | Co 10–1000, Cg 100–10,000 |

| TGS813 | CH4, C3H8, C4H10 | 500–10,000 |

| MQ135 | Steam ammonia, benzene, sulfide | 10–10,000 |

| TGS2602 | Sulfide, hydrogen sulfide, ammonia, toluene | 1–30 |

| TGS2620 | Alcohol, steam organic solvents | 50–5000 |

| LJ | LW1 | LW2 | LW3 | P | LP1 | LP2 | LP3 | S | LS1 | LS2 | LS3 | Accuracy | Precision | Recall | Specificity | AUC | F | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LJ | 15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| LW1 | 0 | 12 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.983 | 1.000 | 0.800 | 1.000 | 1.000 | 0.889 |

| LW2 | 0 | 0 | 15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| LW3 | 0 | 0 | 0 | 15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| P | 0 | 0 | 0 | 0 | 15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| LP1 | 0 | 0 | 0 | 0 | 0 | 15 | 0 | 0 | 0 | 0 | 0 | 0 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| LP2 | 0 | 3 | 0 | 0 | 0 | 0 | 15 | 0 | 0 | 0 | 0 | 0 | 0.983 | 0.833 | 1.000 | 0.982 | 0.908 | 0.909 |

| LP3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 15 | 0 | 0 | 0 | 0 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| S | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 15 | 0 | 0 | 0 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| LS1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 15 | 0 | 0 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| LS2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 15 | 0 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| LS3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 15 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Average | 0.997 | 0.986 | 0.983 | 0.998 | 0.992 | 0.983 | ||||||||||||

| Kernel Function | C-SVM | Nu-SVM | ||||||

|---|---|---|---|---|---|---|---|---|

| C | γ | Train | Validation | Nu | γ | Train | Validation | |

| Linear | 100 | 1 | 97.77 | 94.44 | 0.1 | 0.255 | 99.44 | 96.11 |

| Polynomial | 1 | 10 | 90.55 | 87.77 | 0.5 | 1 | 96.11 | 91.66 |

| Radial basis function | 1 | 100 | 93.33 | 85.55 | 0.1 | 0.5 | 97.22 | 95.55 |

| Sigmoid | 0.1 | 100 | 92.22 | 86.11 | 0.1 | 0.255 | 89.44 | 88.88 |

| LJ | LW1 | LW2 | LW3 | P | LP1 | LP2 | LP3 | S | LS1 | LS2 | LS3 | Accuracy | Precision | Recall | Specificity | AUC | F | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LJ | 15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| LW1 | 0 | 14 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.994 | 1.000 | 0.933 | 1.000 | 1.000 | 0.966 |

| LW2 | 0 | 0 | 15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| LW3 | 0 | 0 | 0 | 15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| P | 0 | 0 | 0 | 0 | 15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| LP1 | 0 | 0 | 0 | 0 | 0 | 15 | 0 | 0 | 0 | 0 | 0 | 0 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| LP2 | 0 | 1 | 0 | 0 | 0 | 0 | 15 | 0 | 0 | 0 | 0 | 0 | 0.994 | 0.938 | 1.000 | 0.994 | 0.966 | 0.968 |

| LP3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 15 | 0 | 0 | 0 | 0 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| S | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 15 | 0 | 0 | 0 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| LS1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 15 | 0 | 0 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| LS2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 15 | 0 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| LS3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 15 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Average | 0.999 | 0.995 | 0.994 | 0.999 | 0.997 | 0.994 | ||||||||||||

| Topology | Train | Test | CCR (%) | ||

|---|---|---|---|---|---|

| RMSE | R2 | RMSE | R2 | ||

| 8-5-12 | 0.411 | 0.672 | 0.456 | 0.634 | 66.4 |

| 8-6-12 | 0.346 | 0.731 | 0.460 | 0.632 | 70.0 |

| 8-7-12 | 0.278 | 0.808 | 0.368 | 0.725 | 78.2 |

| 8-8-12 | 0.221 | 0.835 | 0.350 | 0.736 | 80.3 |

| 8-9-12 | 0.203 | 0.864 | 0.245 | 0.824 | 85.5 |

| 8-10-12 | 0.090 | 0.932 | 0.215 | 0.852 | 89.8 |

| 8-11-12 | 0.117 | 0.923 | 0.185 | 0.871 | 89.1 |

| 8-12-12 | 0.080 | 0.945 | 0.227 | 0.861 | 90.0 |

| 8-13-12 | 0.047 | 0.9967 | 0.219 | 0.857 | 91.4 |

| 8-14-12 | 0.093 | 0.978 | 0.268 | 0.904 | 94.2 |

| 8-15-12 | 0.027 | 0.981 | 0.061 | 0.959 | 97.8 |

| LJ | LW1 | LW2 | LW3 | P | LP1 | LP2 | LP3 | S | LS1 | LS2 | LS3 | Accuracy | Precision | Recall | Specificity | AUC | F | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LJ | 15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| LW1 | 0 | 15 | 0 | 0 | 0 | 0 | 3 | 0 | 0 | 0 | 0 | 0 | 0.983 | 0.833 | 1.000 | 0.982 | 0.908 | 0.909 |

| LW2 | 0 | 0 | 15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| LW3 | 0 | 0 | 0 | 15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| P | 0 | 0 | 0 | 0 | 15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| LP1 | 0 | 0 | 0 | 0 | 0 | 15 | 0 | 0 | 0 | 0 | 0 | 0 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| LP2 | 0 | 0 | 0 | 0 | 0 | 0 | 12 | 0 | 0 | 0 | 0 | 0 | 0.983 | 1.000 | 0.800 | 1.000 | 1.000 | 0.889 |

| LP3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 15 | 0 | 0 | 0 | 0 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| S | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 15 | 0 | 0 | 0 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| LS1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 15 | 0 | 0 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| LS2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 15 | 1 | 0.994 | 0.938 | 1.000 | 0.994 | 0.966 | 0.968 |

| LS3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 14 | 0.994 | 1.000 | 0.933 | 1.000 | 1.000 | 0.966 |

| Average | 0.996 | 0.981 | 0.978 | 0.998 | 0.989 | 0.978 | ||||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammadian, N.; Ziaiifar, A.M.; Mirzaee-Ghaleh, E.; Kashaninejad, M.; Karami, H. Nondestructive Technique for Identifying Adulteration and Additives in Lemon Juice Based on Analyzing Volatile Organic Compounds (VOCs). Processes 2023, 11, 1531. https://doi.org/10.3390/pr11051531

Mohammadian N, Ziaiifar AM, Mirzaee-Ghaleh E, Kashaninejad M, Karami H. Nondestructive Technique for Identifying Adulteration and Additives in Lemon Juice Based on Analyzing Volatile Organic Compounds (VOCs). Processes. 2023; 11(5):1531. https://doi.org/10.3390/pr11051531

Chicago/Turabian StyleMohammadian, Nasim, Aman Mohammad Ziaiifar, Esmaeil Mirzaee-Ghaleh, Mahdi Kashaninejad, and Hamed Karami. 2023. "Nondestructive Technique for Identifying Adulteration and Additives in Lemon Juice Based on Analyzing Volatile Organic Compounds (VOCs)" Processes 11, no. 5: 1531. https://doi.org/10.3390/pr11051531