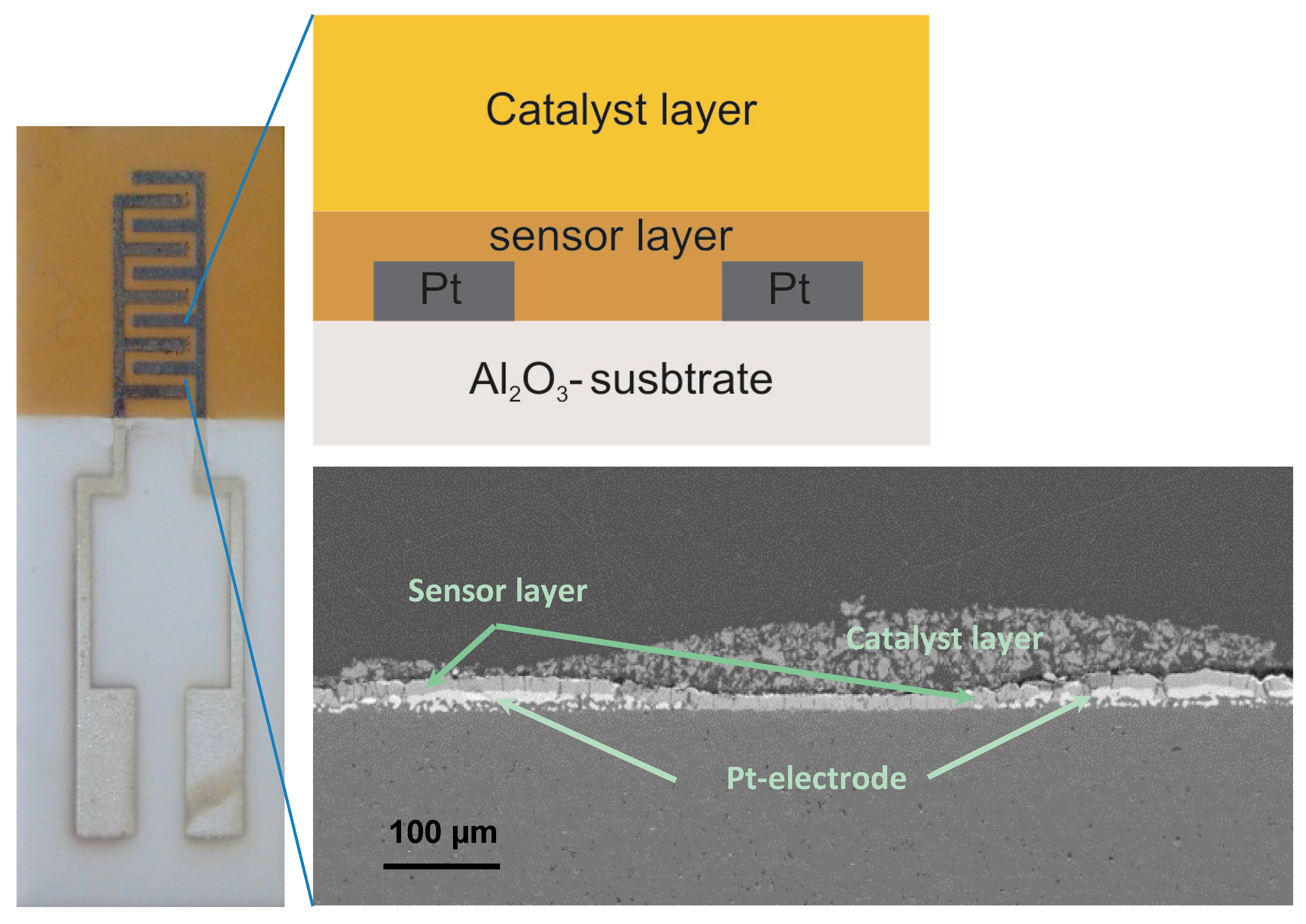

3.1. Al-Doped TiO2 Sensor Layer

As the XRD investigation of the as-coated and

ex situ at 500 °C, 800 °C, and 1000 °C heat-treated Al-doped TiO

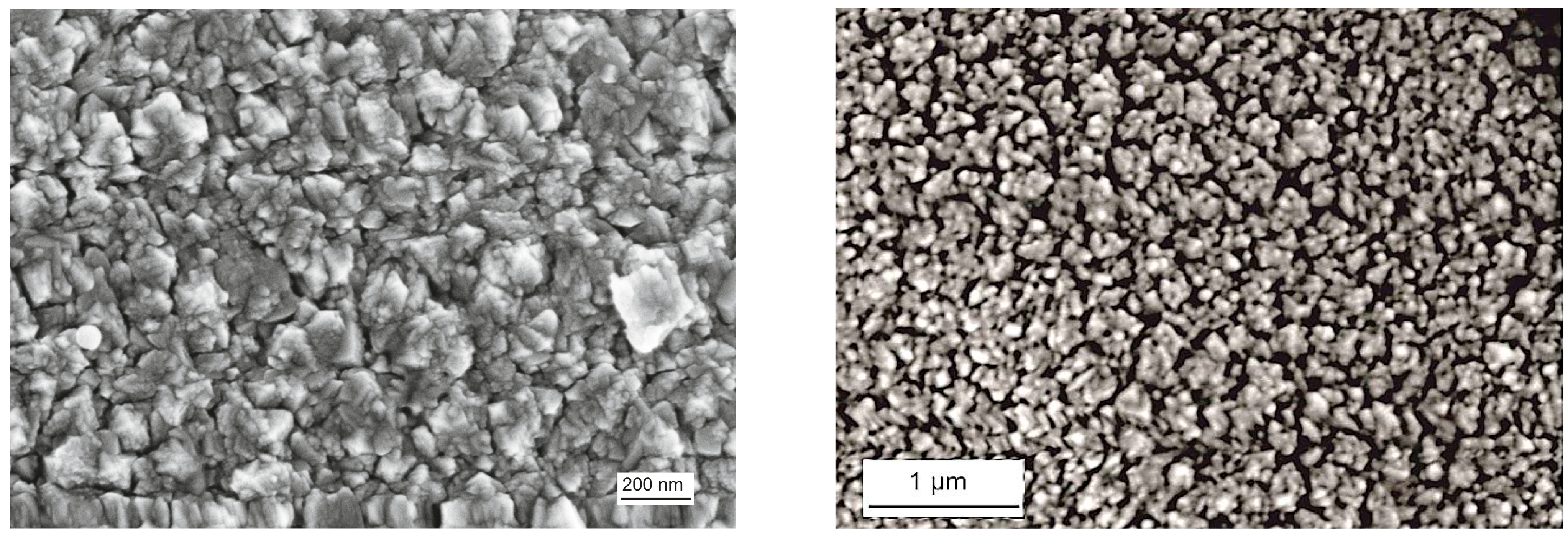

2 layers indicate, the layer is weakly crystalline and contains the anatase phase in the as-coated case. The top-view SEM image of the as-coated layer displays densely packed fine columnar morphology of the layer (

Figure 2, left). Further heat-treatment increases the anatase crystallinity. At around 800 °C, the first indication of anatase-rutile transformation can be seen (

Figure 3). After 3 h of heat-treatment at 1000 °C, full conversion to rutile takes place. The Al-doped TiO

2 layers which were used for sensor testing were calcined at 800 °C and, thus, contained mainly anatase phase and some minor amounts of rutile. The SEM top-view micrograph of the 800 °C heat-treated Al-doped layer indicates the crystallization development yielding some porosity at the grain and column boundaries (

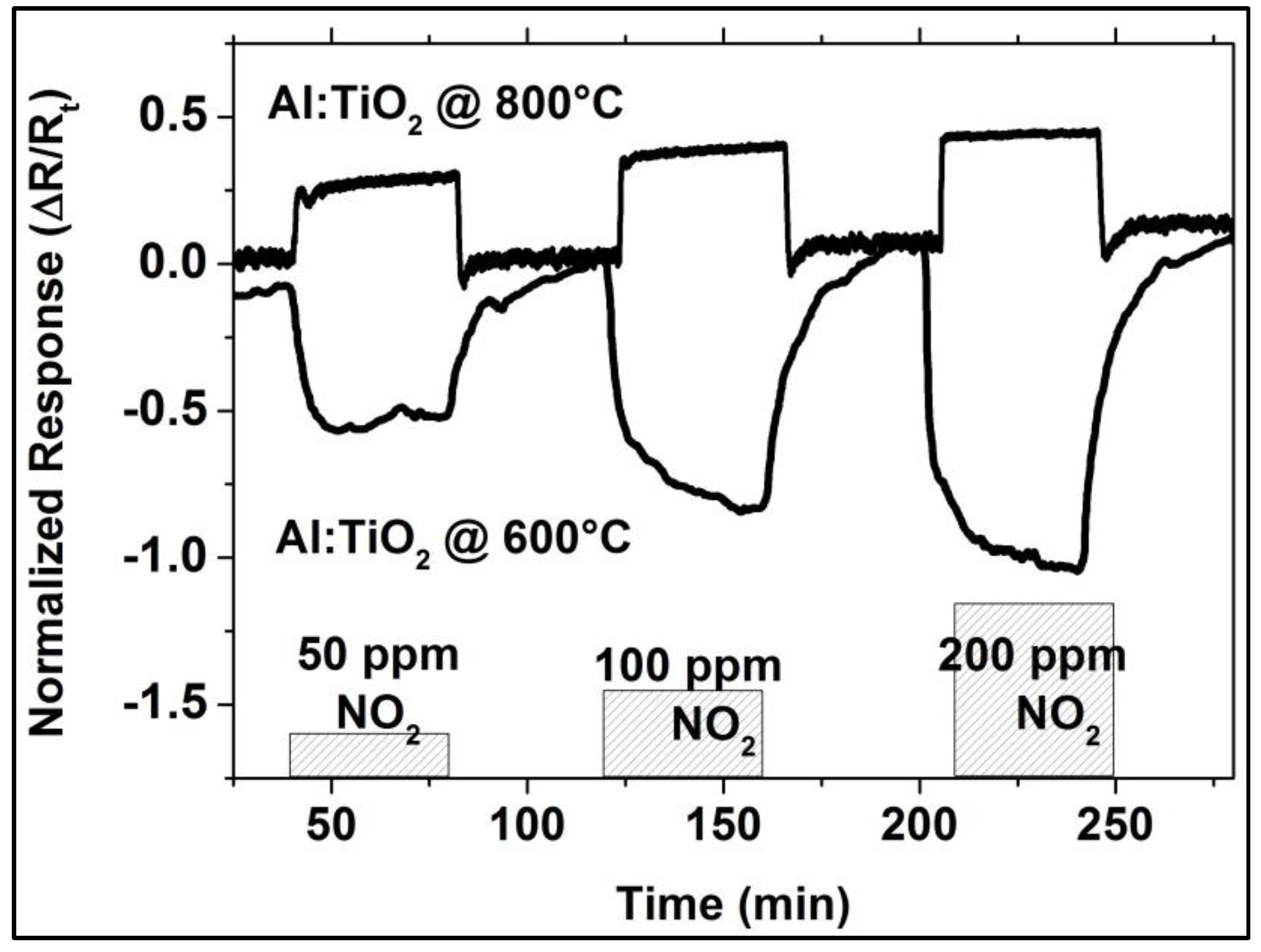

Figure 2, right). The sensor tests of Al-doped TiO

2 layers towards NO

2 were published in details elsewhere [

10]. The most striking observation with this high-temperature sensor material was the alteration of the sensor signal direction at 800 °C yielding a resistance decrease under NO

2 exposure being opposite to the resistance increase observed at 600 °C (see

Figure 4). No significant effect of humidity on the sensor response was observed at these temperatures.

This behavior can be assumed to be due to the conversion of NO

2 to NO because of the above-mentioned and the

Figure 5 illustrated thermodynamic equilibrium conditions which may result in the formation of ionized oxygen species (e.g., O

2−-ion) taking over the control of sensing mechanism through surface adsorption (see Equation (2) and [

10]):

This behavior of the Al-doped TiO

2 layer indicates poor NO

2-sensing capability at temperatures above 600 °C. On the other hand, Al-doped TiO

2 shows negligible sensitivity towards CO concentrations varying from 50 to 200 ppm in the given temperature range. Moreover, these layers are more sensitive to NO

2 when NO

2 and CO are simultaneously present in the test environment, indicating a minimized cross-sensitivity towards CO [

9].

In order to overcome the NO

2 sensing deficit of the Al-doped TiO

2 layer, a perovskite layer as a catalytic filter is employed. This Rh-incorporating perovskite has a self-regenerative property which results in the segregation of Rh nanoparticles on the reduction and re-incorporation into the lattice upon oxidation [

25]. Relying on the NO oxidizing capability of Rh, the effects caused on a sensor due to the high-temperature deviations in NO

2 containing gas environments can be eliminated.

3.2. Catalytic BaTi0.95Rh0.05O3 Powder

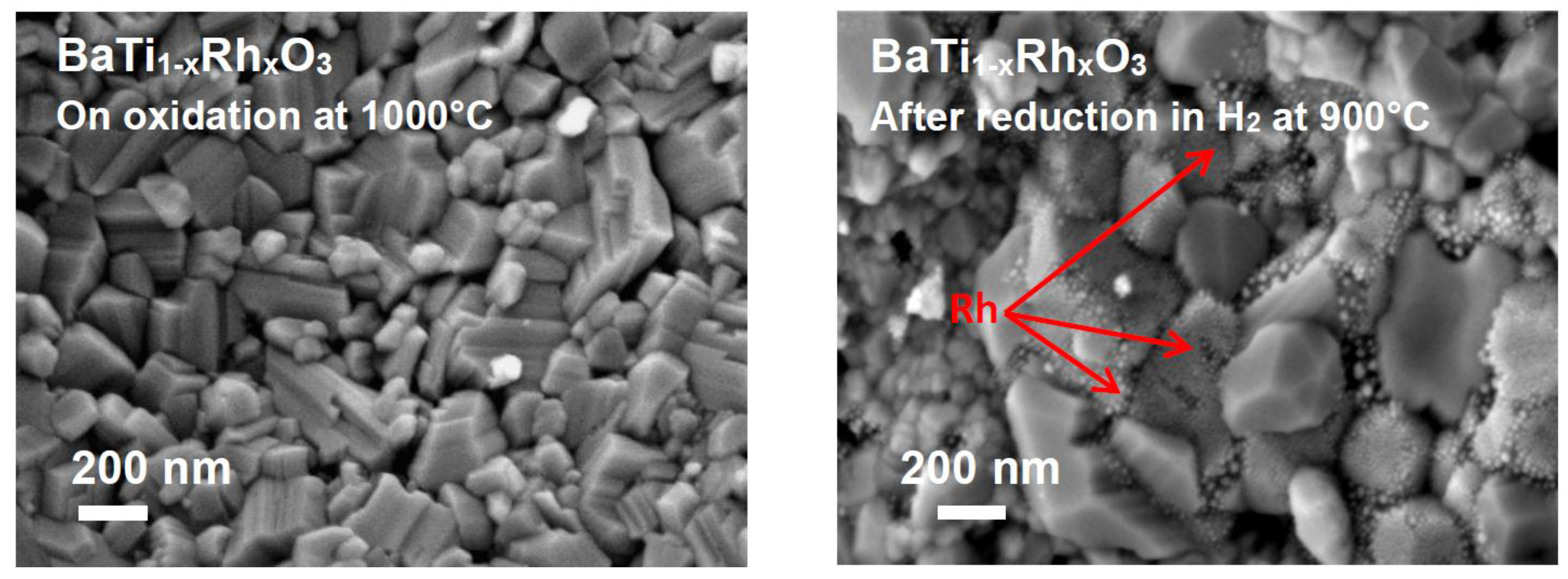

The SEM observations of the BaTi

0.95Rh

0.05O

3 catalytic material exhibited that under oxidized conditions (e.g., after calcining at 1000 °C in air), large prismatic grains of perovskite were formed. In turn, on heat-treatment of the oxidized powder, this time under reduced conditions (e.g., 900 °C in 2.5 vol.% H

2), Rh metallic particles segregates at the grain boundaries of the perovskite (

Figure 6, left and right, respectively).

In situ high-temperature XRD analysis of pre-calcined powder in the range of RT-1000 °C-RT showed that the increase of temperature results in shifting of all X-ray diffraction peak positions of BaTi

0.95Rh

0.05O

3 to lower Bragg angles (2θ) due to expansion of the lattice (see

Figure 7). After heating to 700 °C in air, the BaTi

0.95Rh

0.05O

3 powder yields the BaTiO

3 perovskite, BaTi

2O

5, and BaCO

3 phases.

BaCO3 disappears at around 800 °C, probably due to the low melting point of the compound. In turn, at this temperature, Ba2TiO4 phase appears to form. On heating to 1000 °C, next to the well-crystallized BaTiO3, the BaTi2O5, and Ba2TiO4 phases at lower intensity, and a trace TiO2 phase are detected. At this stage, the presence of some trace amounts of RhO2 cannot be ruled out even though the matching peak positions were not identified due to the overlapping. After cooling down to RT, the in situ to 1000 °C heated powder contains BaTiO3, BaTi2O5, and the (111) plane of Ba2TiO4 phases.

In summary, it can be concluded that heating to 1000 °C and cooling down to RT in air of the BaTi0.95Rh0.05O3 catalytic powder results in full decomposition of BaCO3 and the formation of BaTi2O5 and Ba2TiO4 through the irreversible phase conversion. These phases may contain partially-incorporated Rh. No clear identification of the presence of metallic Rh or RhO2 was possible during in situ X-ray of this in air heat-treated powder.

After reduction treatment in H

2, BaTi

0.95Rh

0.05O

3 perovskite powder displays fine agglomerates which are associated with the presence of metallic Rh (

Figure 6, right). The presence of cubic Rh with the 2θ position of 47.8° in the X-ray diffraction pattern of the reduced perovskite powder indicates that the hexagonal perovskite decreased upon reduction in H

2. The sensor tests were carried out with a BaTi

0.95Rh

0.05O

3 powder which was calcined in air at 1000 °C.

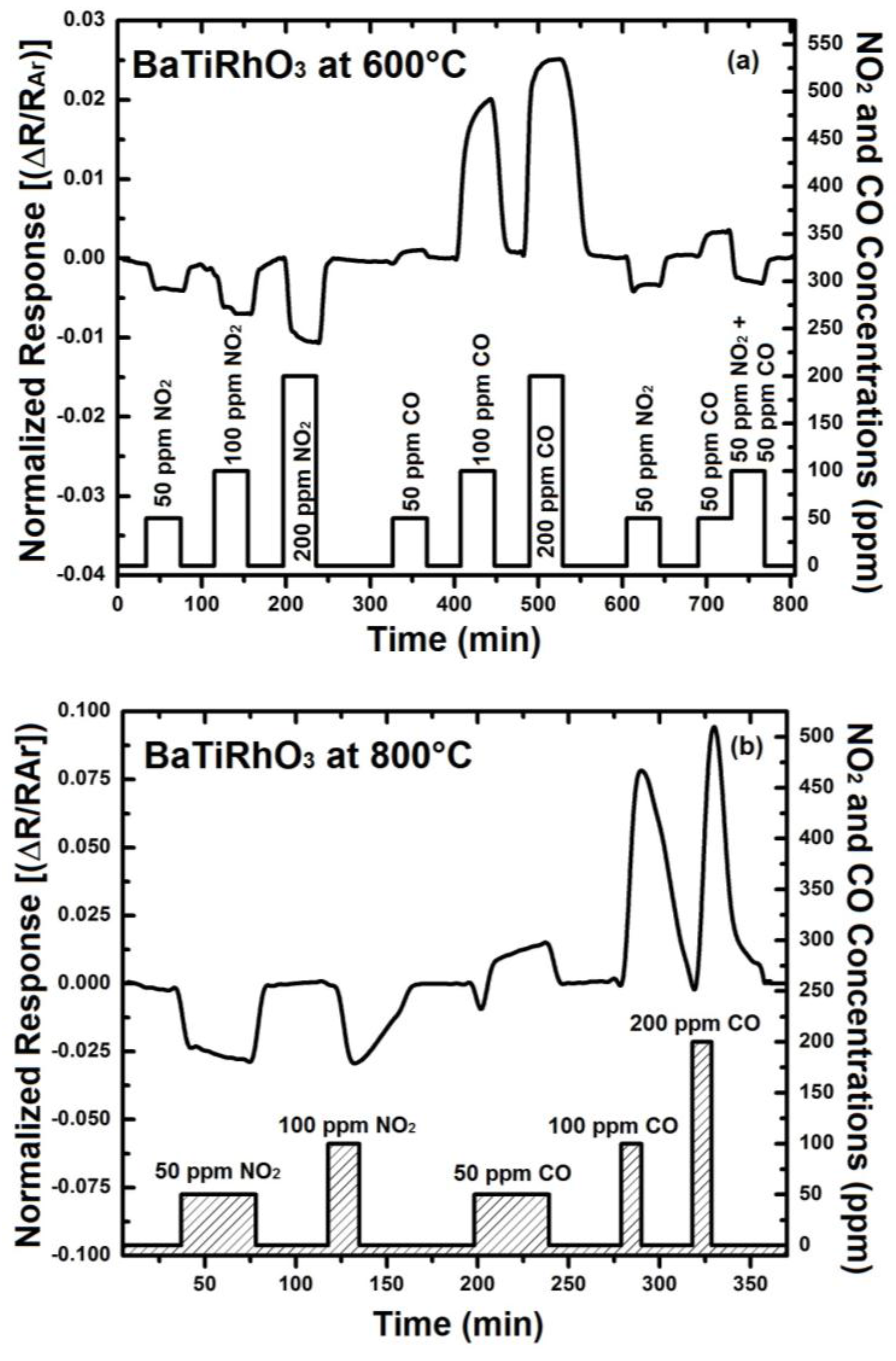

In order to understand the contribution of BaTi

0.95Rh

0.05O

3 perovskite to the sensor response, initially the sensor response of this perovskite has been recorded. For that, some interdigital sensor platforms were coated by screen-printing with a thick BaTi

0.95Rh

0.05O

3 perovskite powder. These sensors were tested towards NO

2 and CO in the form of single gas exposures having different concentrations at 600 °C to 900 °C in a dry argon environment (see

Figure 8).

Thick layers of BaTi

0.95Rh

0.05O

3 perovskite catalyst yield remarkable response towards NO

2 at the temperatures of 600 °C to 900 °C and in dry argon, but also a high sensor response towards CO (50 to 200 ppm). As the sensor response towards NO

2 and CO improves with the temperature, the CO response alters to the opposite direction at 900 °C (see

Figure 8). This behavior of the catalytic layer may be due to the CO-oxidation capability. Our previous unpublished tests carried out with this catalytic perovskite by using 1% CO, 5000 ppm O

2 diluted in He indicated a very low light-off temperature for CO oxidation (below 210 °C). While under less oxygen-containing conditions,

i.e., by exposing the perovskite to 1000 ppm CO and 1000 ppm NO in He, it was observed that CO conversion occurs at significantly higher temperatures.

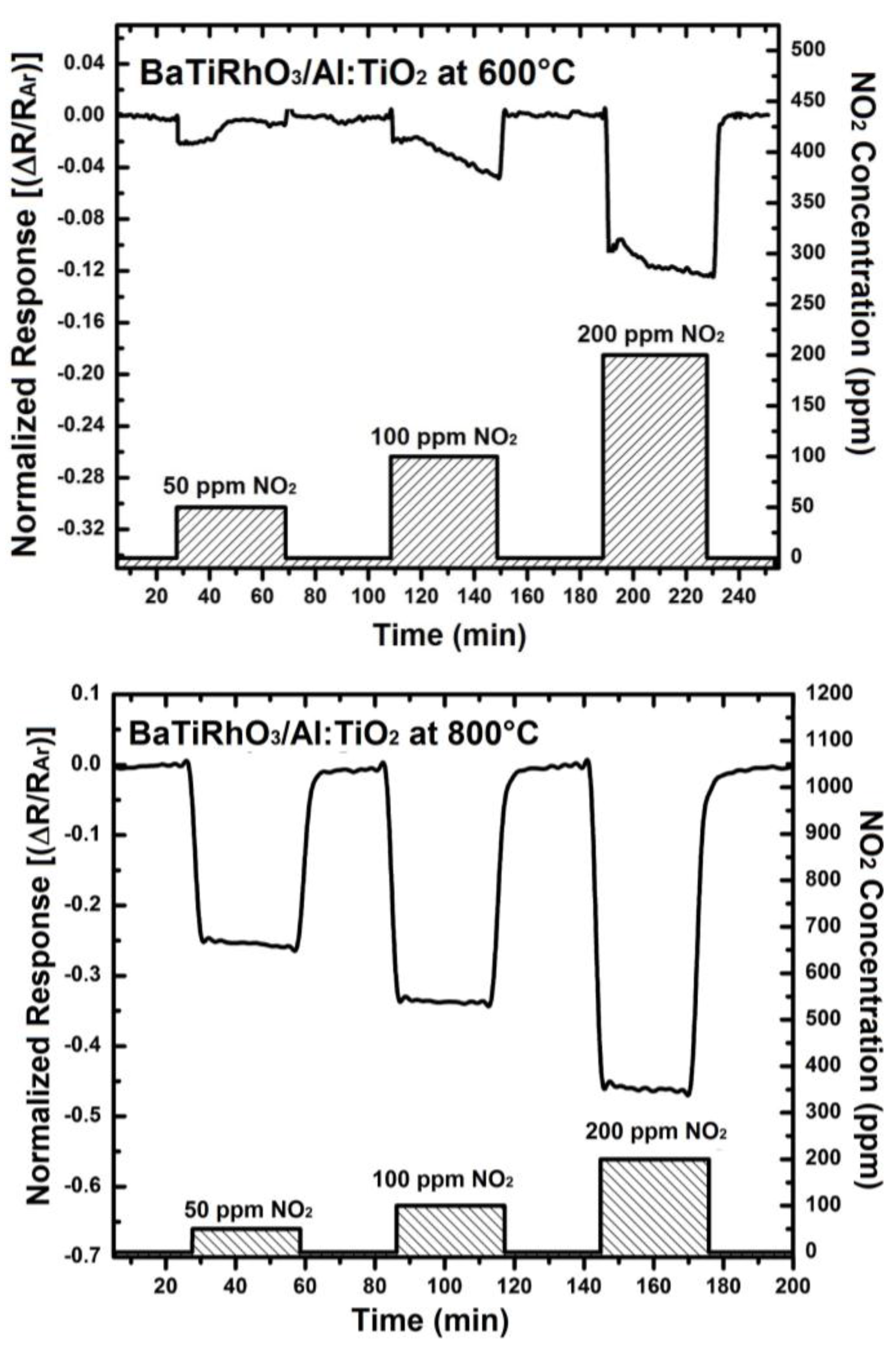

The addition of 5% humidity to the argon environment results in an improvement of the NO

2 response of BaTi

0.95Rh

0.05O

3 perovskite by a factor of two at 800 °C (e.g., 0.02

vs. 0.04 for 100 ppm at 800 °C) and somewhat less at 900 °C (see

Figure 9). Similarly, CO response in the presence of humidity yields resistance increase at 900 °C, as observed under dry conditions, indicating an adsorption promotion effect of OH

−δ ions (see [

14]). The discrepancy, concerning CO response at 900 °C under dry conditions, can be explained with the facts that water vapor or OH-ions at this temperature may either react with CO during adsorption on the catalyst surfaces or the BaTi

0.95Rh

0.05O

3 influences catalytically the adsorption mechanism of CO under oxidizing conditions. All sensor responses with BaTi

0.95Rh

0.05O

3 were p-type at all test temperatures with the exception of CO exposure at 900 °C. Nevertheless, the sensor response towards CO is significant. Thus, considering this fact, it is expected that the BaTi

0.95Rh

0.05O

3 layers as a gas sensing material may display a high CO cross-interference under exposure to CO concentrations higher than 50 ppm at high temperatures.

3.3. NO2 Response of BaTi0.9Rh0.1O3 Catalyst + Al-Doped TiO2 Duplex Layers

According to the concept presented above in

Section 2.1, duplex sensor layers having catalytic BaTi

0.95Rh

0.05O

3 perovskite and Al-doped TiO

2 are tested for their NO

2-response in the temperature range of 600 °C to 900 °C.

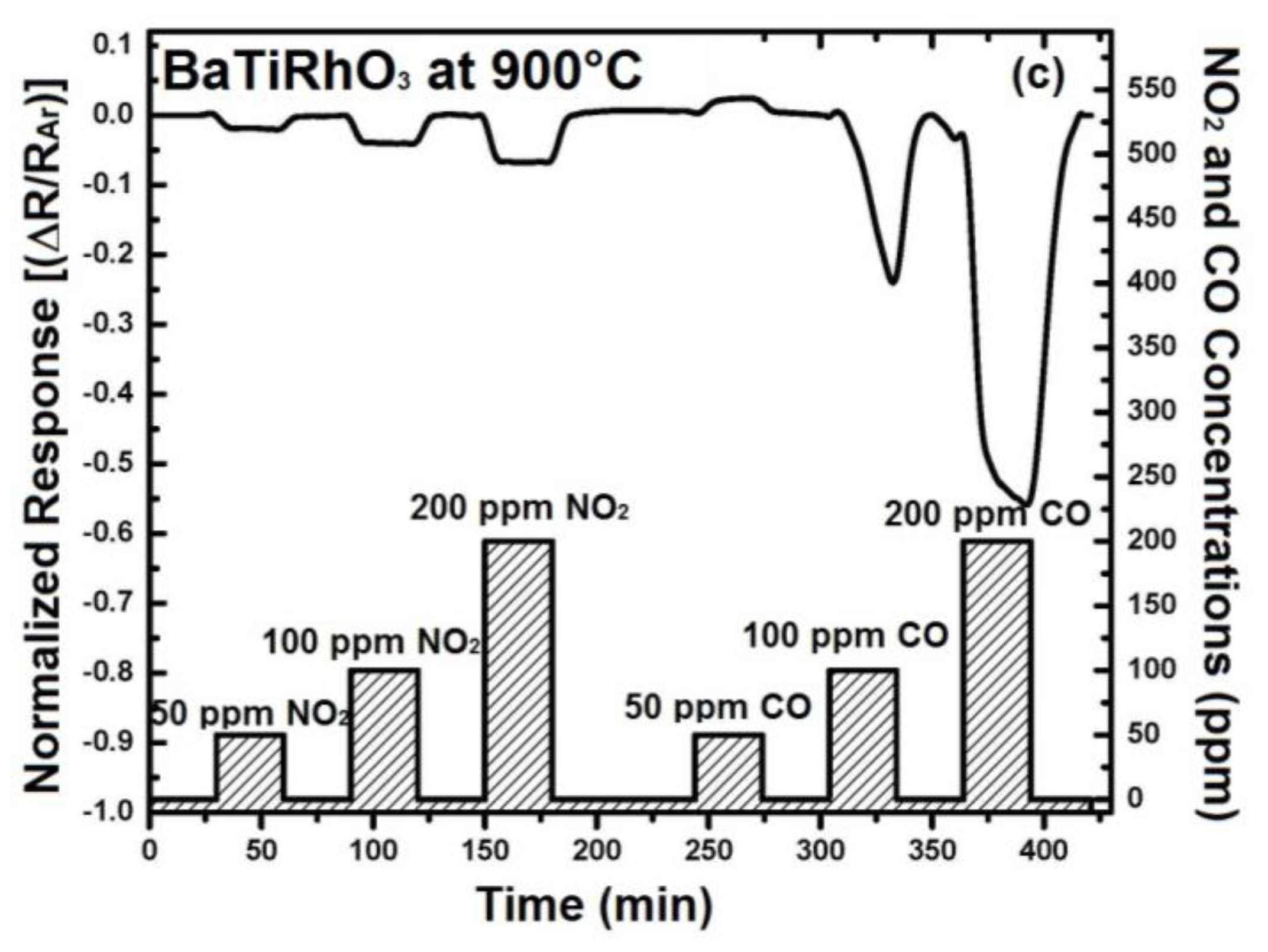

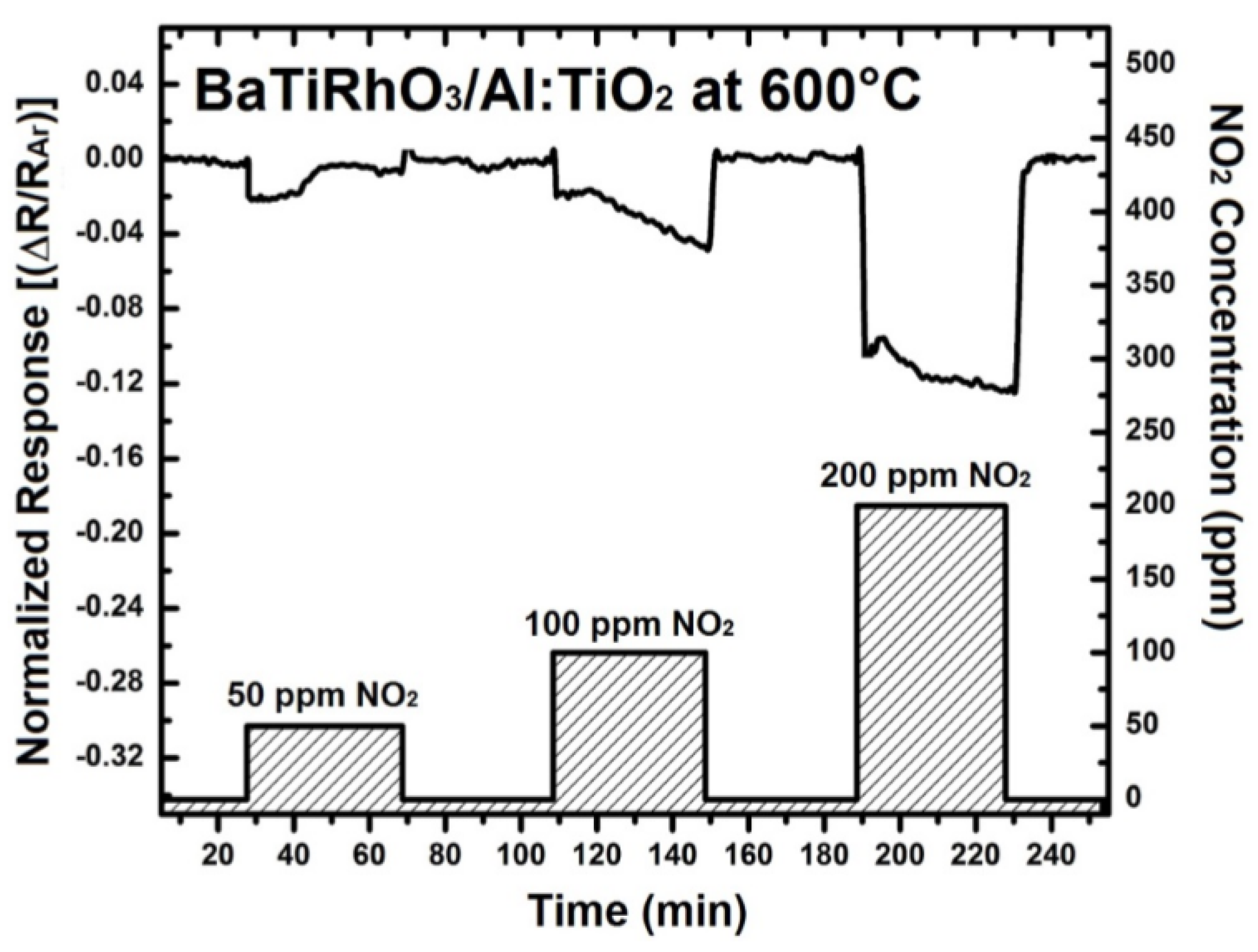

The NO

2 sensor response obtained with these duplex layers display remarkable sensitivity values at 600 °C, 800 °C, and 900 °C despite high gas temperatures (e.g., 0.12 at 600 °C, 0.46 at 800 °C, and 0.92 at 900 °C, upon exposure to 200 ppm), (see

Figure 10). Moreover, the change in signal direction which was observed with the Al-doped TiO

2 layer as indicated with the sensor responses given in

Figure 4 does not occur when duplex sensing layers are employed.

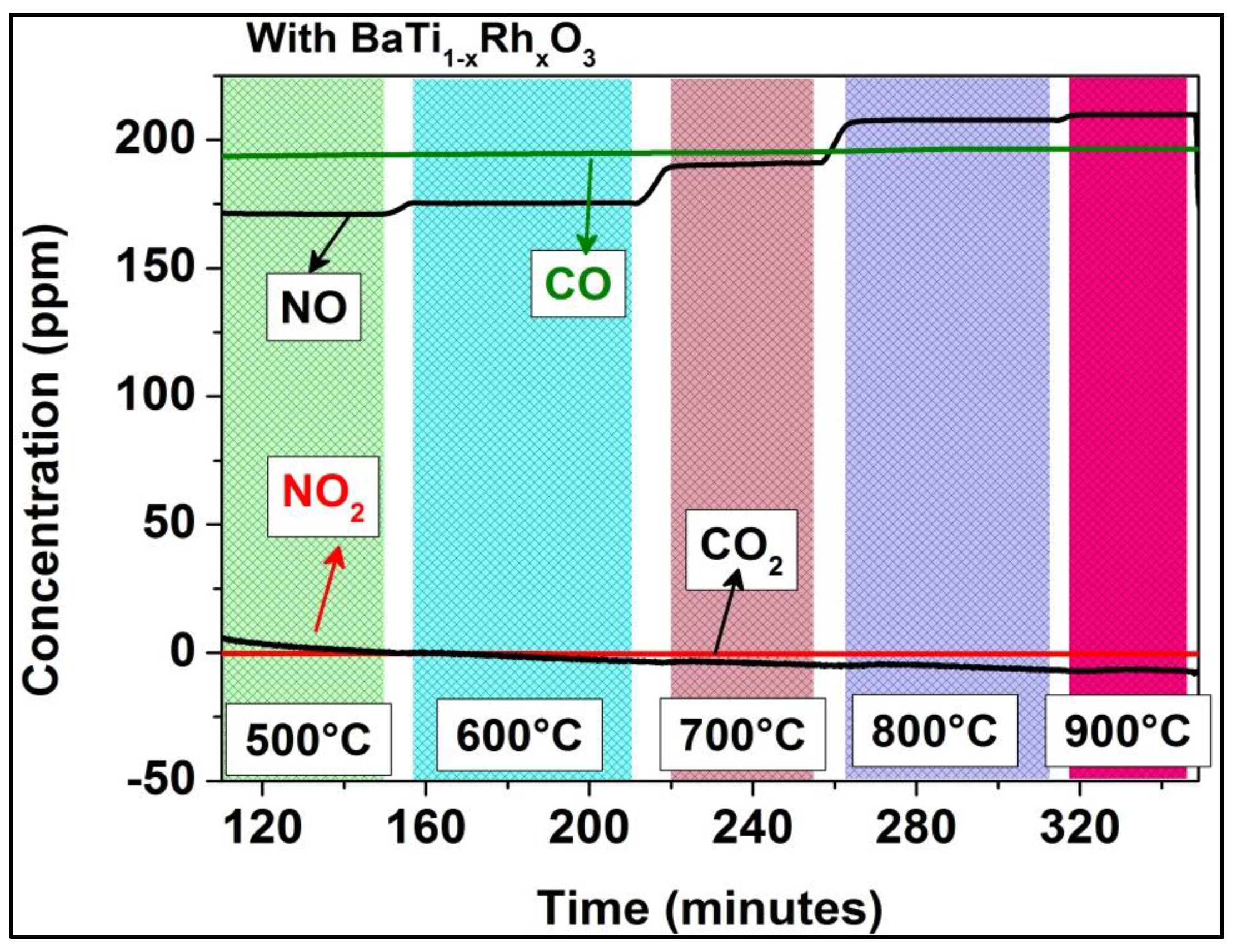

In order to clarify whether this response at such elevated temperatures is from NO

2 or from NO, the sensor response of this duplex layer towards NO was recorded in dry synthetic air (see

Figure 11). Normally as shown with

Figure 5, above 600 °C under dry conditions, a temperature-dependent conversion of NO

2 to NO occurs.

The sensor tests of the BaTi

0.95Rh

0.05O

3 perovskite and Al-doped TiO

2 duplex layer carried out toward NO in a dry synthetic air environment at 600 °C exhibited significantly lower sensitivity values (e.g., 0.018 and 0.023 under exposure to 50 ppm and 200 ppm, respectively). Further analyses, which were carried out to observe the effect of catalytic perovskite powder on NO

2/NO conversion at high temperatures, indicated that full NO

2 to NO conversion already occurs at 300 °C if BaTi

0.95Rh

0.05O

3 catalytic powder was exposed to 200 ppm NO

2 in the sensor chamber (see

Figure 12). In turn, when the chamber is empty,

i.e., without the perovskite catalyst, the NO

2-to-NO conversion develops gradually, starting from 500 °C, and is completed above 800 °C as, at that temperature, no more NO

2 can be measured in the system’s output (see

Figure 5). Thus, it is reasonable to assume that the BaTi

0.95Rh

0.05O

3 catalytic top layer conditions the test environment to have NO+O

2− at all test temperatures and catalytically oxidizes NO to NO

2 at the interface of the perovskite and the Al-doped TiO

2 layer [

10]. Thus it can be concluded that exposure of the sensor to NO

2 at higher temperatures yields a sensor signal which cannot be correlated to NO and to molecular oxygen from the synthetic air, but to NO

2.

Table 1 summarizes a selection of sensor properties of single and duplex sensor layers investigated in this study. For comparison purposes, only the responses toward 200 ppm NO

2 are considered. Sensitivities of Al:TiO

2 single layer and BaTiRhO

3/Al:TiO

2 duplex layer are relatively high at 600 °C (0.70 and 0.92, respectively), but the recovery of sensor response with the single Al:TiO

2 layer requires extremely longer times. At higher temperatures, and in a humid environment, this appears to be shortened. The sensor with the single BaTiRhO

3 layer exhibits, in turn, the lowest sensitivities (0.11 and 0.05) at all test temperatures (600–900 °C). No further NO

2-sensing measurement is carried out at 900 °C with the single Al:TiO

2 layer because of the lack of reliability of its sensor signal.

The sensitivity of the sensor with the duplex layer reduces down to 0.16 at 800 °C, and further to 0.06 at 900 °C. Although the sensitivity of the duplex layer sensor (i.e., BaTiRhO3/Al:TiO2) is lower than that of the Al:TiO2 single layer, the reaction and recovery times of the sensor with the duplex layer is partly to half as short than those of the Al:TiO2 single layer sensor (reaction times = 2.0 min vs. 2.5 min at 600 °C and 1.6 min vs. 3.8 min at 800 °C, recovery times = 4.3 min vs. 17 min at 600 °C and 2.5 min vs. 4.2 min at 800 °C, respectively). The sensitivities and the reaction and recovery times of the BaTiRhO3/Al:TiO2 duplex layer sensor remain in the same range at all test temperatures, indicating a maintained reliability with this sensor.

Humidity shows no significant effect on sensitivity, although some influence on reaction and recovery times are observed favoring humidity at 800 °C, and oppositely at 600 °C. Therefore, it is not possible to identify any specific trend regarding the humidity influence. Although it is obvious that the BaTiRhO3 catalytic layer intervenes in the thermodynamic equilibrium condition of NO2/NO environment by lowering the conversion temperature significantly, as a single sensor layer, the sensor with the BaTiRhO3 single layer does not yield good performance for NO2-sensing.

The literature indicates that perovskites with different formulations give great opportunity to detect gas mixtures by means of sensor arrays. Doping elements either in the lattice of perovskite or on the surface of perovskite could help to improve sensing performance of perovskite oxide and to decrease the sensing temperature [

27,

28]. La-based, Ce and Pd-doped perovskites are proven to yield good sensing behavior toward CO and CH

4, respectively. No other sensor study is known to date with the BaTiRhO

3 catalytic layer to confirm its behavior. However,

Figure 9 displays that the sensor with a single BaTiRhO

3 layer yields greater signals toward CO than NO

2.

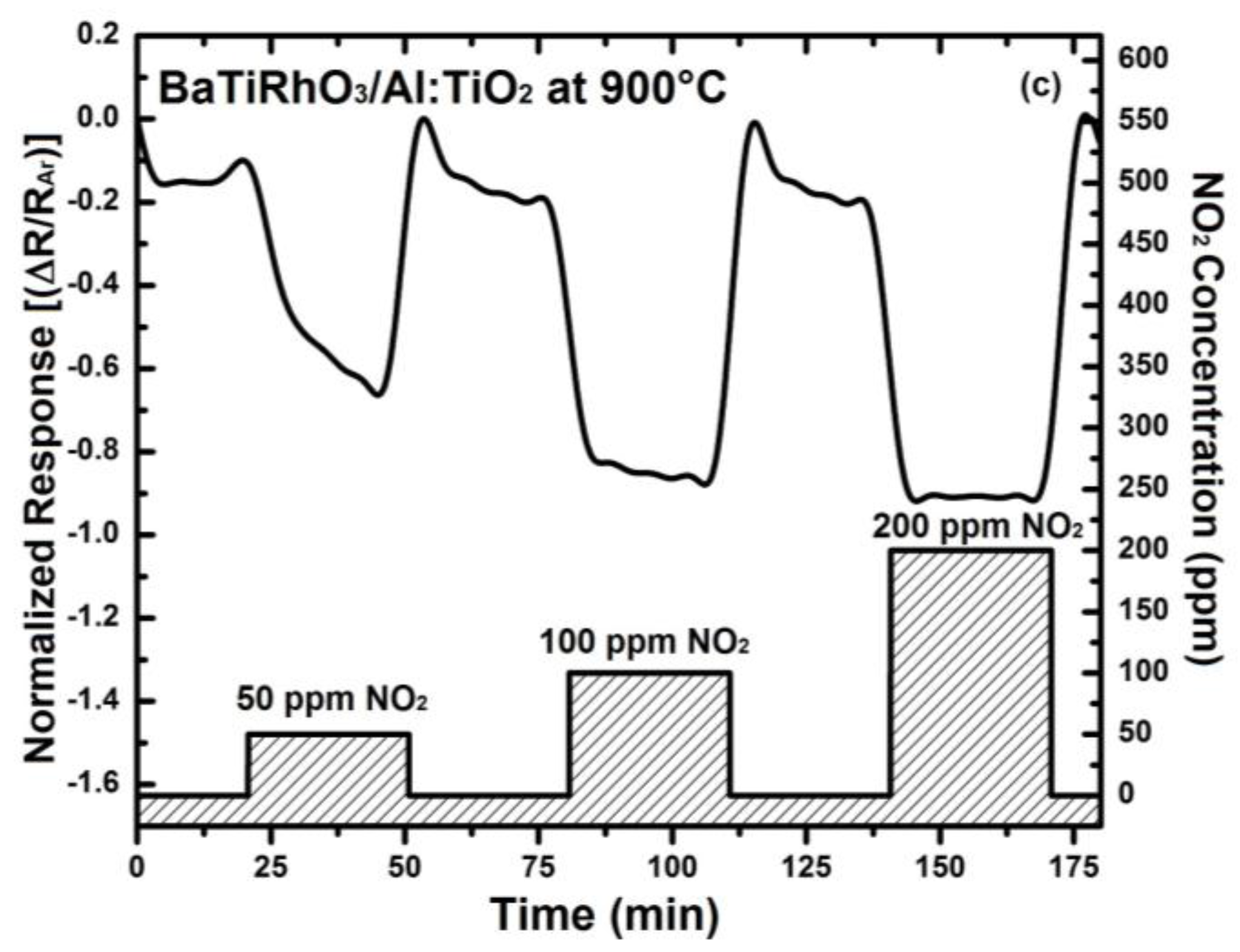

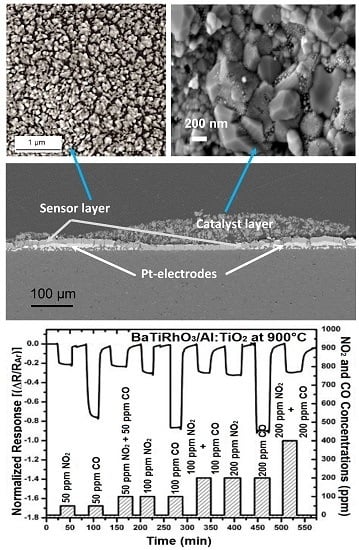

The sensors with the BaTiRhO

3/Al:TiO

2 duplex layers, in turn, exhibit a NO

2-selective sensing as exposed to CO + NO

2 mixed gas environments in the temperature range of 600 °C and 900 °C. Although stronger signals are observed by exposure only to CO, it appears that these signals are in the same direction as those toward NO

2 (

Figure 13). Usually, the semiconducting sensors yield signals in opposite directions when exposed to oxidizing (e.g., NO

2, O

2) and reducing gases (e.g., CO, CH

4).

Previous studies which used XPS to determine the nature of CO adsorption on the surface of doped LaCoO

3 perovskite formulations as the sensor material have revealed that CO preferentially adsorbs on the lattice oxygen in the form of mono-dentate carbonate on the surface of perovskite-type oxide. Ce (e.g., La

0.9Ce

0.1CoO

3) doping changed not only the total amount of adsorbed CO but also the nature of adsorption phenomena. By adding Ce, in addition to the mono-dentate form, the bi-dentate carbonate form was also appeared on the surface resulting in an increase of the total adsorbed CO [

27]. In the case of Pd-doped LaFeO

3, the noble metal gives an active site on the metal oxide to adsorb methane species. Pd is well known for its H dissolving capacity, which could help to create PdH pair in methane adsorption phenomena [

28].

In our case, it is likely that under single CO gas exposure in dry argon, CO adsorption rapidly consumes the surface-adsorbed oxygen of the sensing layer forming CO

2 and excess electrons according to Equation (3):

Hence, it is probable that the sensors with the duplex layer exhibit CO cross-interference. In order to test this, the sensor response of the BaTi

0.95Rh

0.05O

3 catalyst + Al-doped TiO

2 duplex layers was recorded under NO

2 and CO single-gas exposure, followed by NO

2 and CO mixed gas exposure at 800 °C and 900 °C (

Figure 13 left and right). These tests displayed that the duplex layer is more sensitive to NO

2 in the presence of CO, while under CO single-gas exposure, relatively high sensor sensitivity is recorded. The resistance decrease obtained on exposure to gas mixtures of 50 ppm NO

2 + 50 ppm CO, 100 ppm NO

2 + 100 ppm CO, and 200 ppm NO

2 + 200 ppm CO equals to that obtained by exposure only to NO

2 at concentrations of 50, 100, and 200 ppm, respectively. In turn, under NO

2 + CO gas mixture exposure, NO

2 is converted to NO + O

2− at temperatures above 300 °C through the BaTi

0.95Rh

0.05O

3 catalytic layer and this ionized oxygen may readily react with CO without being in interaction with the sensor surface and is removed as CO

2, while the converted NO reacts with the oxygen adsorbed on the surface of Al-doped TiO

2 sensing layer. Thus, at temperatures as high as 800 °C and 900 °C, the sensor with the BaTiRhO

3/Al:TiO

2-duplex layer gives signals preferentially corresponding to NO

2, despite being exposed to CO + NO

2 gas mixtures at relatively higher concentrations (

Figure 13, left and right).