Utilization of Blended Waste Materials in Bricks

Abstract

:1. Introduction

2. Methodology

2.1. Materials

2.1.1. Ordinary Portland Cement (OPC)

2.1.2. Palm Oil Fuel Ash (POFA)

2.1.3. Fly Ash (FA)

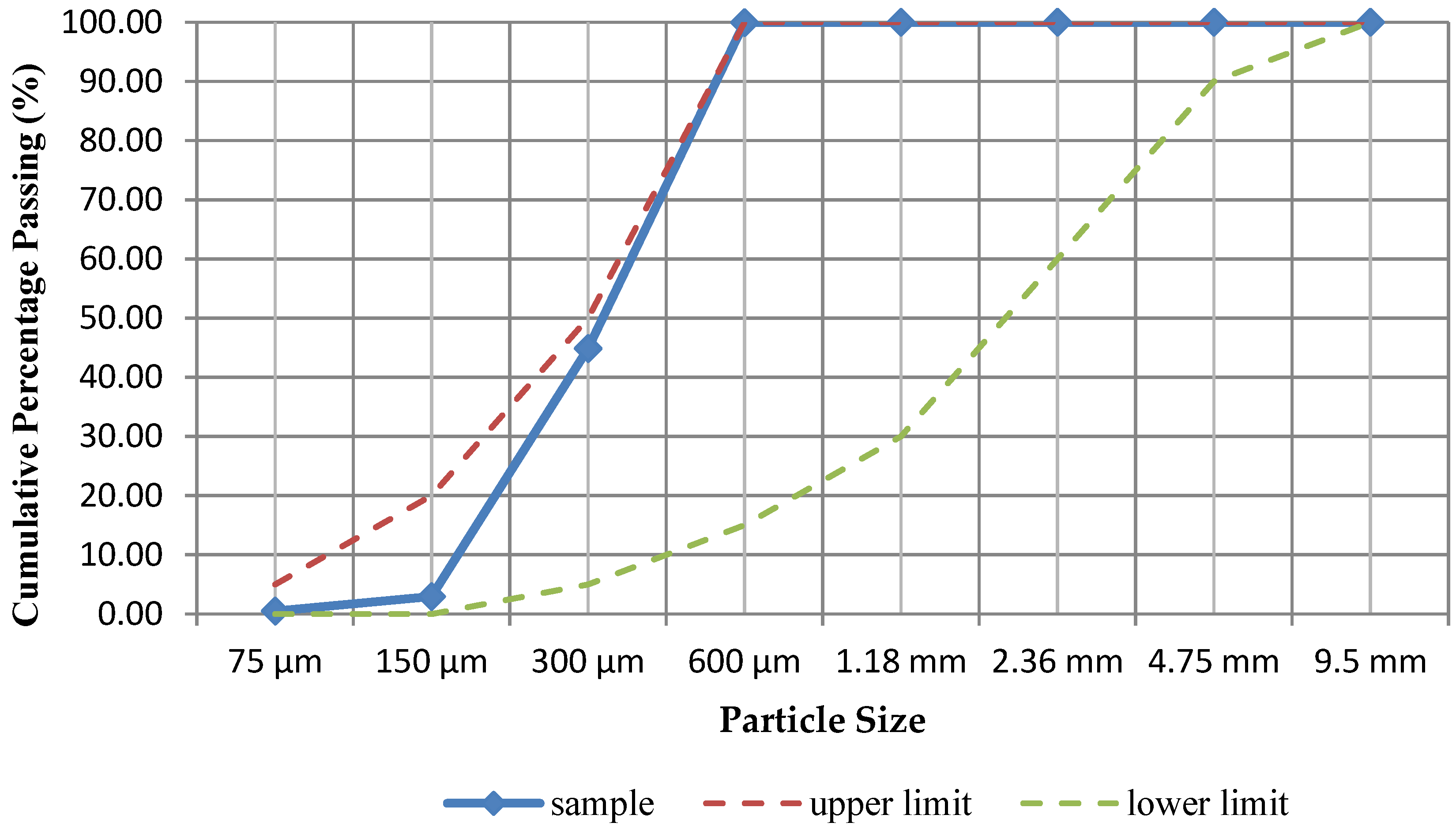

2.1.4. Local River Sand

2.2. Brick Mix

2.3. Preparation of Bricks

2.4. Testing Methods

2.4.1. Compression Test

2.4.2. Water Absorption Test

2.4.3. Thermogravimetric Analysis Test

3. Results and Discussion

3.1. Density

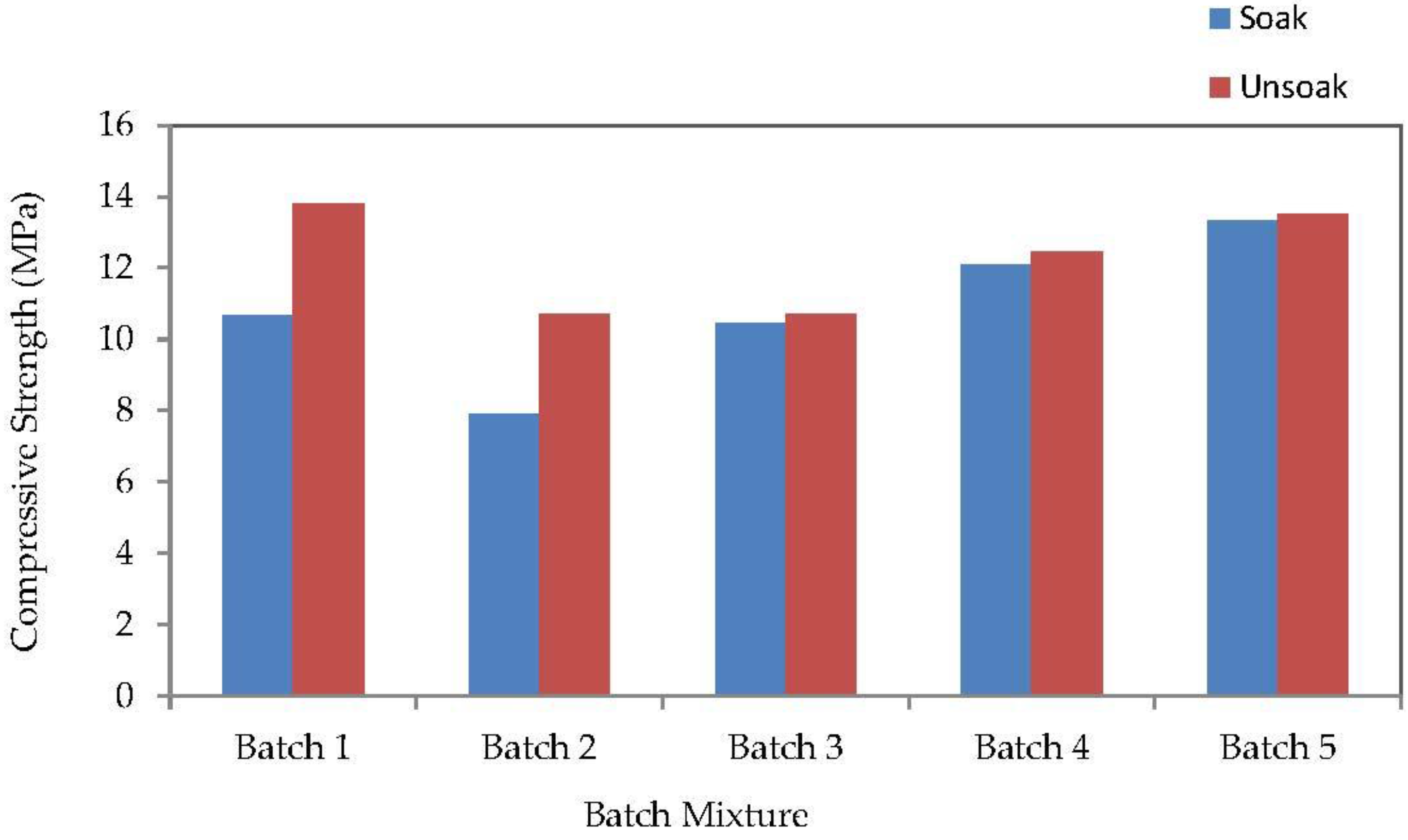

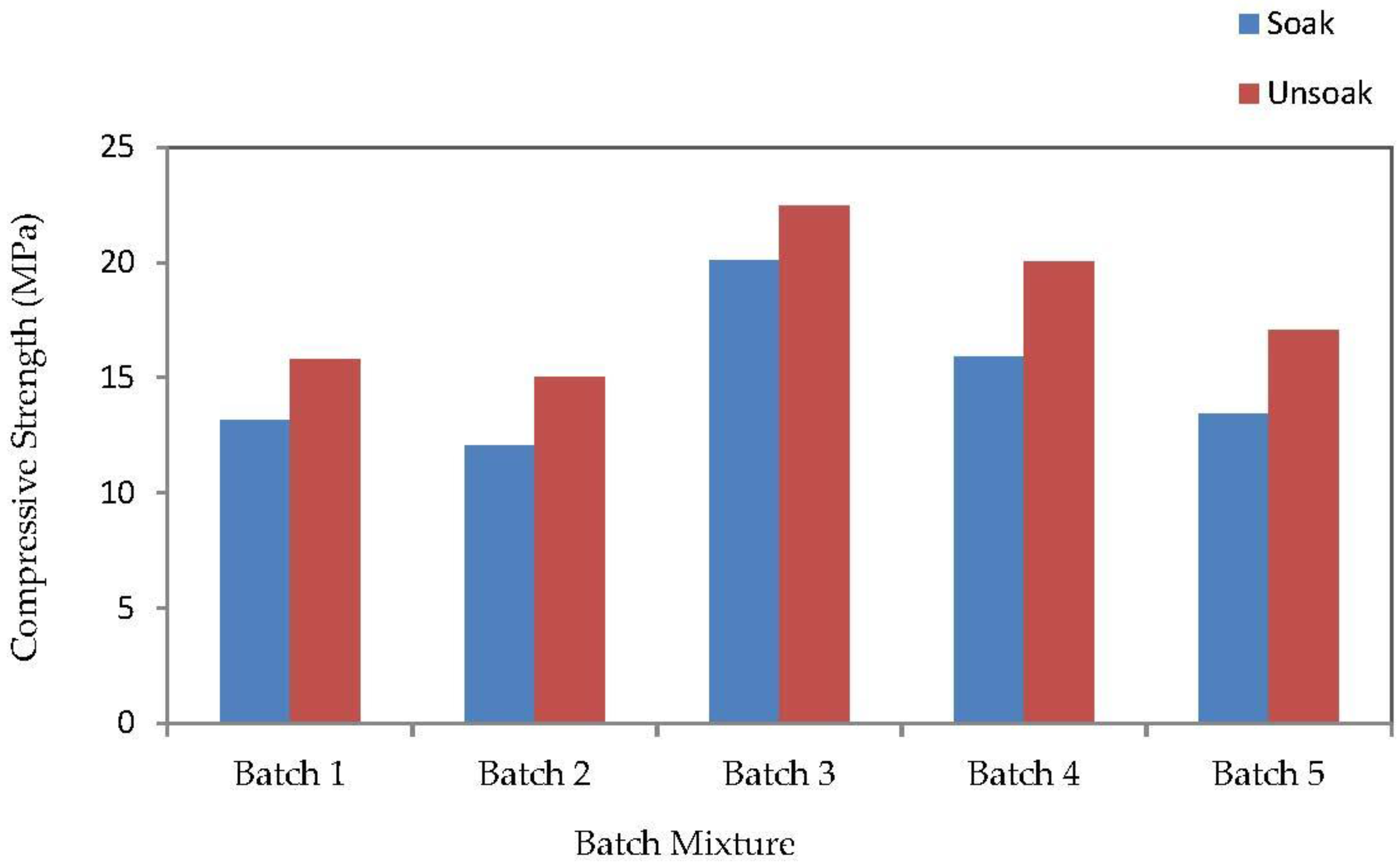

3.2. Compressive Strength

3.2.1. Effect of Blended POFA and Fly Ash Replacement

3.2.2. Effect of Immersion

3.3. Water Absorption

3.4. Thermogravimetric Analysis

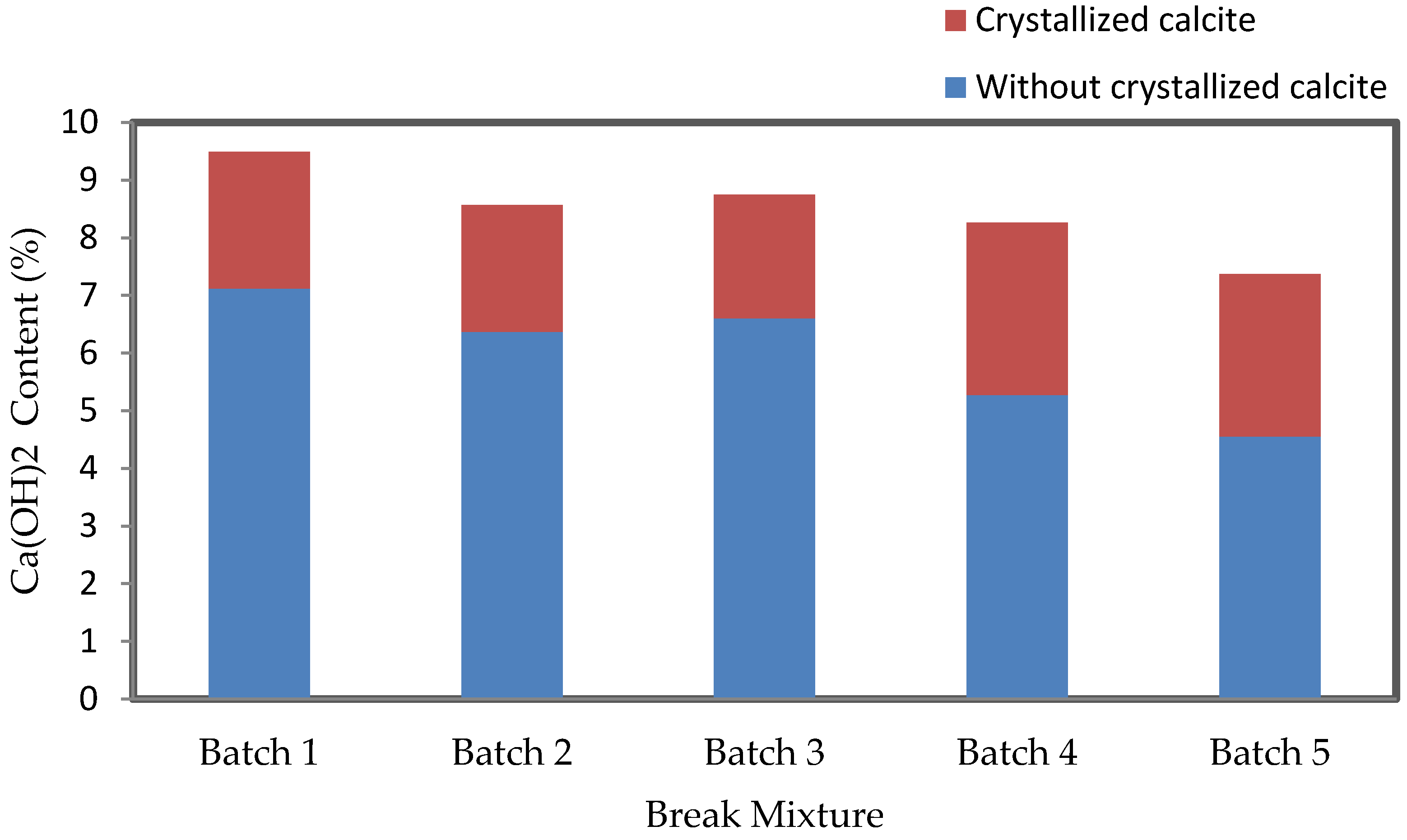

3.4.1. Hydrated Phase of Cement Pastes Containing Blended POFA and Fly Ash

3.4.2. Ca(OH)2 Content

3.5. Cost of Brick

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Da Silva Almeida, G.; Da Silva, J.B.; Silva, C.J.; Swarnakar, R.; De Araújo Neves, G.; De Lima, A.G. Heat and mass transport in an industrial tunnel dryer: Modeling andsimulation applied to hollow bricks. Appl. Therm. Eng. 2013, 55, 78–86. [Google Scholar] [CrossRef]

- Yusoff, S. Renewable energy from palm oil—Innovation on effectiveutilization of waste. J. Clean. Prod. 2006, 14, 87–93. [Google Scholar] [CrossRef]

- Ng, W.P.Q.; Lam, H.L.; Foo, F.Y.; Kamal, M.; Lim, J.H.E. Waste-to-wealth: Green potential from palm biomass in Malaysia. J. Clean. Prod. 2012, 34, 57–65. [Google Scholar] [CrossRef] [Green Version]

- Agensi Inovasi Malaysia. National Biomass Strategy 2020: New Wealth Creation for Malaysia’s Palm Oil Industry; Agensi Inovasi Malaysia: Kualalumpur, Malaysia, 2011; pp. 1–32. [Google Scholar]

- AL-Oqla, F.M.; Sapuan, S.M. Natural fiber reinforced polymer composites in industrial applications: Feasibility of date palm fibers for sustainable automotive Industry. J. Clean. Prod. 2014, 66, 347–354. [Google Scholar] [CrossRef]

- Rahman, M.E.; Boon, A.; Muntohar, A.S.; Tanim, M.N.H.; Pakrashi, V. Performance of Bricks Incorporating Palm Oil Fuel Ash. J. Clean. Prod. 2014, 78, 195–201. [Google Scholar] [CrossRef]

- AL-Oqla, F.M.; Sapuan, S.M. Polymer Selection Approach for Commonly and Uncommonly Used Natural Fibers under Uncertainty Environments. J. Miner. Metals Mater. Soc. 2015, 67, 2450–2463. [Google Scholar] [CrossRef]

- Al-Oqla, F.M.; Sapuan, M.S.; Ishak, M.R.; Aziz, N.A. Combined Multi-criteria Evaluation Stage Technique as an agro Waste Evaluation Indicator for Polymeric Composites: Date Palm Fibers as a Case Study. BioResources 2014, 9, 4608–4621. [Google Scholar] [CrossRef]

- Al-Oqla, F.M.; Sapuan, M.S.; Ishak, M.R.; Aziz, N.A. A Novel Evaluation Tool for Enhancing the Selection of Natural Fibers for Polymeric Composites Based on Fiber Moisture Content Criterion. BioResources 2015, 10, 299–312. [Google Scholar] [CrossRef]

- Tangchirapat, W.; Saeting, T.; Jaturapitakkul, C.; Kiattikomol, K.; Siripanichgorn, A. Use of waste ash from palm oil industry in concrete. Waste Manag. 2007, 27, 81–88. [Google Scholar] [CrossRef] [PubMed]

- Cicek, T.; Tanrıverdi, M. Lime based steam autoclaved fly ash bricks. Constr. Build. Mater. 2007, 21, 1295–1300. [Google Scholar] [CrossRef]

- Tay, J.H. Ash from oil-palm waste as concrete material. J. Mater. Civ. Eng. 1990, 2, 94–105. [Google Scholar] [CrossRef]

- Muntohar, A.S.; Rahman, M.E. Lightweight masonry block from oil palm kernel shell. Constr. Build. Mater. 2014, 54, 477–484. [Google Scholar] [CrossRef]

- Shakir, A.A.; Sivakumar, N.; Mustapha, K.N. Properties of bricks made using fly ash, quarry dust and billet scale. Constr. Build. Mater. 2013, 41, 131–138. [Google Scholar] [CrossRef]

- Turgut, P. Manufacturing of building bricks without Portland cement. J. Clean. Prod. 2012, 37, 361–367. [Google Scholar] [CrossRef]

- Gokhan, G.; Osman, S. Porous clay bricks manufactured with rice husks. Constr. Build. Mater. 2013, 40, 390–396. [Google Scholar]

- Rahman, M.A. Properties of clay-sand-rice husk ash mixed bricks. Int. J. Cem. Compos. Lightweight Concr. 1987, 9, 105–108. [Google Scholar] [CrossRef]

- Malhotra, S.K.; Tehri, S.I. Development of bricks from granulated blastfurnace slag. Constr. Build. Mater. 1996, 10, 191–193. [Google Scholar] [CrossRef]

- Bilgin, N.; Yeprem, H.A.; Arslan, S.; Bilgin, A.; Gunay, E.; Marsoglu, M. Use of waste marble powder in brick industry. Constr. Build. Mater. 2012, 29, 449–457. [Google Scholar] [CrossRef]

- Weng, C.H.; Lin, D.F.; Chiang, P.C. Utilization of sludge as brick materials. Adv. Environ. Res. 2003, 7, 679–685. [Google Scholar] [CrossRef]

- Faria, K.C.P.; Gurgel, R.F.; Holanda, J.N.F. Recycling of sugarcane bagasse ash waste in the production of clay bricks. J. Environ. Manag. 2012, 101, 7–12. [Google Scholar] [CrossRef] [PubMed]

- Gencel, O.; Sutcu, M.; Erdogmus, E.; Koc, V.; Cay, V.V.; Gok, M.S. Properties of bricks with waste ferrochromium slag and zeolite. J. Clean. Prod. 2013, 59, 111–119. [Google Scholar] [CrossRef]

- Zhang, L. Production of Bricks from Waste Materials—A review. Constr. Build. Mater. 2013, 47, 643–655. [Google Scholar] [CrossRef]

- Taaffe, J.; O’Sullivan, S.; Rahman, M.E.; Pakrashi, V. Experimental Characterisation of Polyethylene Terephthalate (PET) Bottle Eco-Bricks. Mater. Des. 2014, 60, 50–56. [Google Scholar] [CrossRef]

- Rahman, M.E.; Muntohar, A.S.; Pakrashi, V.; Nagaratnam, B.H.; Sujan, D. Self Compacting Concrete from Uncontrolled Burning of Rice Husk & Blended Fine Aggregate. Mater. Des. 2014, 55, 410–415. [Google Scholar]

- ASTM International. Standard Specification for Portland Cement; ASTM C150/C150M-12; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- ASTM International. Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM C618-12a; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Nagaratnam, B.H.; Rahman, M.E.; Mannan, M.A. A Study on Hardened State Properties Using Fly Ash and Blended Fine Aggregate. Adv. Mater. Res. 2012, 587, 21–25. [Google Scholar] [CrossRef]

- Australian Standard. Aggregates and Rock for Engineering Purposes—Concrete Aggregates; AS 2758.1; Australian Standard: Sydney, Australia, 1998. [Google Scholar]

- ASTM International. Standard Test Methods for Sampling and Testing Brick and Structural Clay Tile; ASTM C67-11; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- ASTM International. Standard Test Method for Compositional Analysis by Thermogravimetry; ASTM E1131-08; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Borges, P.H.R.; Costa, J.O.; Milestone, N.B.; Lynsdale, C.J.; Streatfield, R.E. Carbonation of CH and C-S-H in composite cement pastes containing high amounts of BFS. Cem. Concr. Res. 2010, 40, 284–292. [Google Scholar] [CrossRef]

- Ranjbar, N.; Mehrali, M.; Behnia, A.; Alengaram, U.J.; Jumaat, M.J. Compressive Strength and Microstructural Analysis of Fly Ash/Palm Oil Fuel Ash Based Geopolymer Mortar. Mater. Des. 2014, 59, 532–539. [Google Scholar] [CrossRef]

- ASTM International. Standard Specification for Concrete Building Brick; ASTM C55-11; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- Altwair, N.M.; Johari, A.M.; Hashim, S.F.S. Strength Activity Index and Microstructural Characteristics of Treated Palm Oil Fuel Ash. Int. J. Civ. Environ. Eng. 2011, 11, 100–107. [Google Scholar]

- Chindaprasirt, P.; Homwuttiwong, S.; Jaturapitakkul, C. Strength and water permeability of concrete containing palm oil fuel ash and rice husk. Constr. Build. Mater. 2007, 21, 1492–1499. [Google Scholar] [CrossRef]

- Naganathan, S.; Linda, T. Effect of Fly Ash Fineness on the Performance of Cement Mortar. Jordan J. Civ. Eng. 2013, 7, 326–331. [Google Scholar]

- Gabrovseka, R.; Vukb, T.; Kaucica, V. Evaluation of the hydration of Portland cement containing various carbonates by means of thermal analysis. Acta Chim. Slov. 2006, 53, 159–165. [Google Scholar]

- Dweck, J.; Buchler, P.M.; Vieira Coelho, A.C.; Cartledge, F.K. Hydration of a Portland cement blended with calcium carbonate. Thermochim. Acta 2000, 346, 105–113. [Google Scholar] [CrossRef]

- Li, D.; Shi, H.; Deng, J.; Xu, Y. Study on the thermal decomposition kinetics of nano-sized calcium carbonates. J. Zhejiang Univ. 2003, 4, 363–368. [Google Scholar] [CrossRef]

- Mohammed, M.K.; Dawson, A.R.; Thom, N.H. Production, microstructure and hydration of sustainable self-compacting concrete with different types of filler. Constr. Build. Mater. 2013, 49, 84–92. [Google Scholar] [CrossRef]

- Kroehong, W.; Sinsiri, T.; Jaturapitakkul, C.; Chindaprasirt, P. Effect of Palm Oil Fuel Ash Fineness on the Microstructure of Blended Cement Paste. Constr. Build. Mater. 2011, 25, 4095–4104. [Google Scholar] [CrossRef]

- Scientific and Industrial Research Institute of Malaysia (SIRIM). Specifications for Bricks and Blocks of Fired Brick-Earth Clay or Shale: Part 2: Metric Units; MS 76; SIRIM: Shah Alam, Malaysia, 1972. [Google Scholar]

| Batch | Ratio | Curing Condition |

|---|---|---|

| Batch 1 | C:S = 1:3 | 90 days |

| 28 days | ||

| Batch 2 | C + POFA(10%):S = 1:3 | 90 days |

| 28 days | ||

| Batch 3 | C + POFA(10%) + FA(10%):S = 1:3 | 90 days |

| 28 days | ||

| Batch 4 | C + POFA(10%) + FA(20%):S = 1:3 | 90 days |

| 28 days | ||

| Batch 5 | C + POFA(10%) + FA(30%):S = 1:3 | 90 days |

| 28 days |

| Cement Paste Sample | Second Stage | Third Stage | Fourth Stage | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Temperature Range/°C | Mass Loss/% | Temperature Range/°C | Mass Loss/% | Temperature Range/°C | Mass Loss/% | ||||

| 28 Days | 90 Days | 28 Days | 90 Days | 28 Days | 90 Days | ||||

| Batch 1 | 419–442 | 5.02 | 3.90 | 505–733 | 2.10 | 5.80 | 733–950 | 1.64 | 1.87 |

| Batch 2 | 415–437 | 3.57 | 4.80 | 626–677 | 2.80 | 2.71 | 735–950 | 1.12 | 2.12 |

| Batch 3 | 421–441 | 3.69 | 4.05 | 620–675 | 2.92 | 4.08 | 733–950 | 1.54 | 1.55 |

| Batch 4 | 419–437 | 2.72 | 3.03 | 692–697 | 2.54 | 2.27 | 720–950 | 2.04 | 1.57 |

| Batch 5 | 428–442 | 2.27 | 2.37 | 518–654 | 2.29 | 2.13 | 727–950 | 1.98 | 1.59 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahman, M.E.; Ong, P.J.; Nabinejad, O.; Islam, S.; Khandoker, N.A.N.; Pakrashi, V.; Shorowordi, K.M. Utilization of Blended Waste Materials in Bricks. Technologies 2018, 6, 20. https://doi.org/10.3390/technologies6010020

Rahman ME, Ong PJ, Nabinejad O, Islam S, Khandoker NAN, Pakrashi V, Shorowordi KM. Utilization of Blended Waste Materials in Bricks. Technologies. 2018; 6(1):20. https://doi.org/10.3390/technologies6010020

Chicago/Turabian StyleRahman, Muhammad Ekhlasur, Phang Ji Ong, Omid Nabinejad, Sumaiya Islam, Neamul Ahsan Noman Khandoker, Vikram Pakrashi, and Kazi Md. Shorowordi. 2018. "Utilization of Blended Waste Materials in Bricks" Technologies 6, no. 1: 20. https://doi.org/10.3390/technologies6010020