Oxide Thin-Film Transistors on Fibers for Smart Textiles

Abstract

:1. Introduction

2. Fabrication of TFTs on Fibers

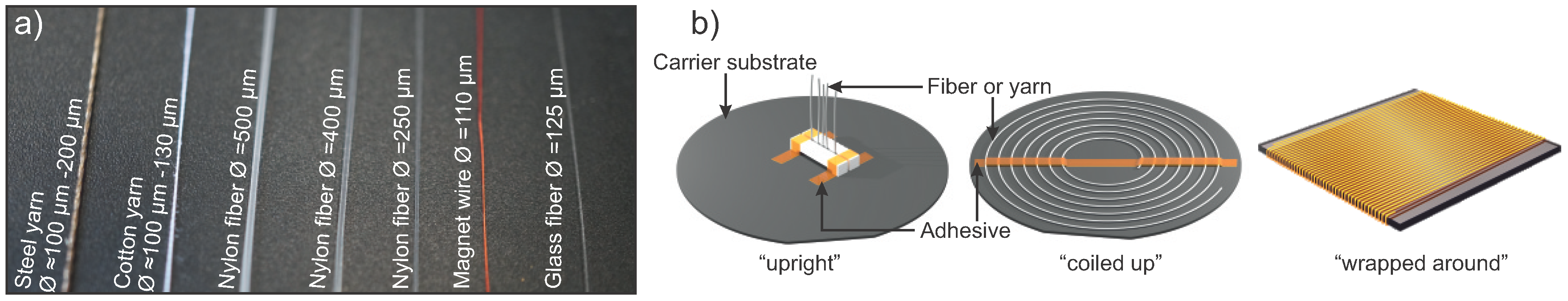

2.1. Micro Processing on Yarns and Fibers

- Chemical properties: The chemical stability of the fiber material is a key aspect since the fibers have to resist the etchants and solvents used during the fabrication process. In this respect the metal and glass fibers exhibit the most beneficial properties.

- Temperature resistance: Similar to the chemical properties, the melting or glass transition temperature of the evaluated materials can significantly limit the choice of usable deposition technologies. While the maximum temperature of cotton and nylon is in the range of 200 , the glass fiber can be processed at temperatures above 1000 .

- Fiber surface: Thin-film devices are made from active layers with thickness in the nanometer range, hence the surface of the fibers has to be as flat as possible. While the steel and cotton yarns do not exhibit a continuous surface, also the surface roughness of the other fibers varies strongly. The rms value of the employed glass fibers is <10 , but the corresponding values for nylon and the insulated Cu wire reach values of 10 μm and 1 μm, respectively.

- Conductivity: Non-conductive fibers (glass, cotton, nylon) have the advantage that no additional insulation layer is needed, and all electronic devices on their surface are decoupled from each other. Metallic substrate fibers at the same time, could simplify the device structure by providing electronic functionality themselves. Here an interesting option could be the use the insulated Cu wire as substrate fiber, gate contact and gate insulator simultaneously.

- Textile properties: Unobtrusive smart textiles call for electronic fibers which are soft, bendable, and with dimensions comparable to the textile yarns of the fabric. In this respect cotton but also steel yarns have beneficial properties. Similarly, polymer fibers such as nylon are common. Anyway, the diameter of the nylon fibers should not be too large (≲750 μm [20]). Furthermore, thin Cu wires are bendable and can be imperceptible when integrated into a textile [21]. Glass fibers on the other hand exhibit a small diameter, but their minimum bending radius is limited to ≈5 .

2.2. Fabrication Approaches

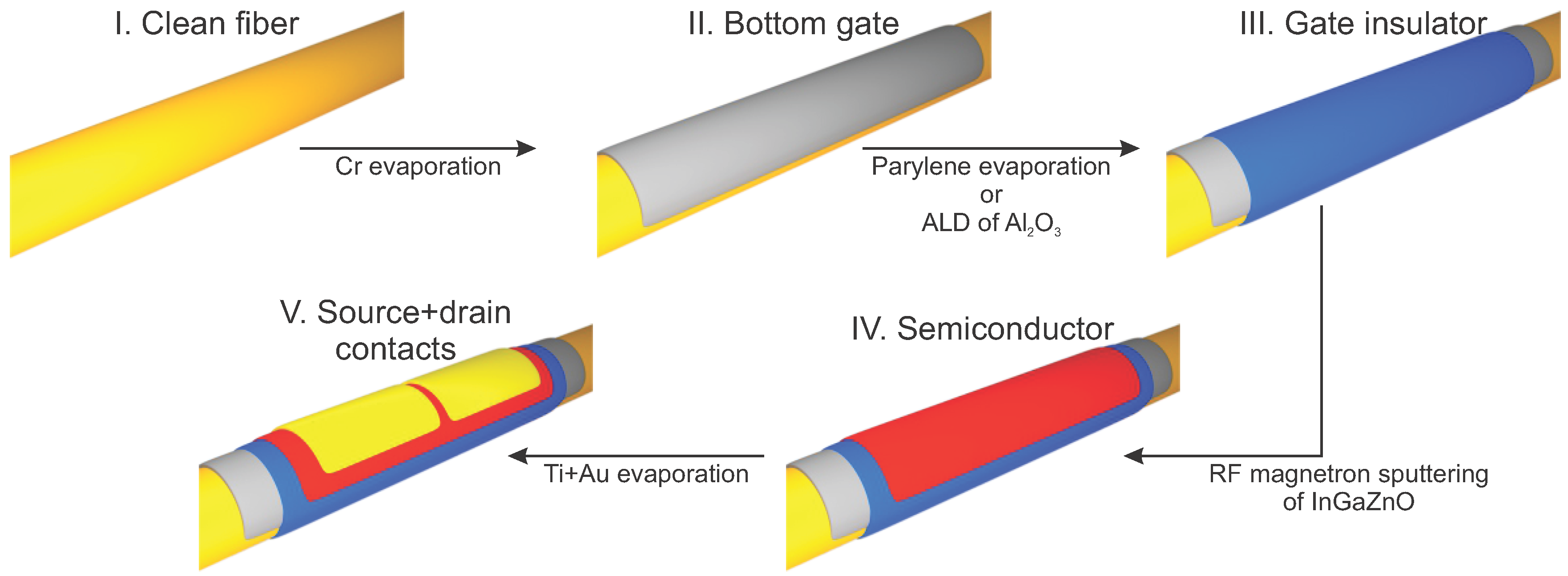

2.2.1. Direct Fabrication

2.2.2. Transfer Fabrication

3. Results and Discussion

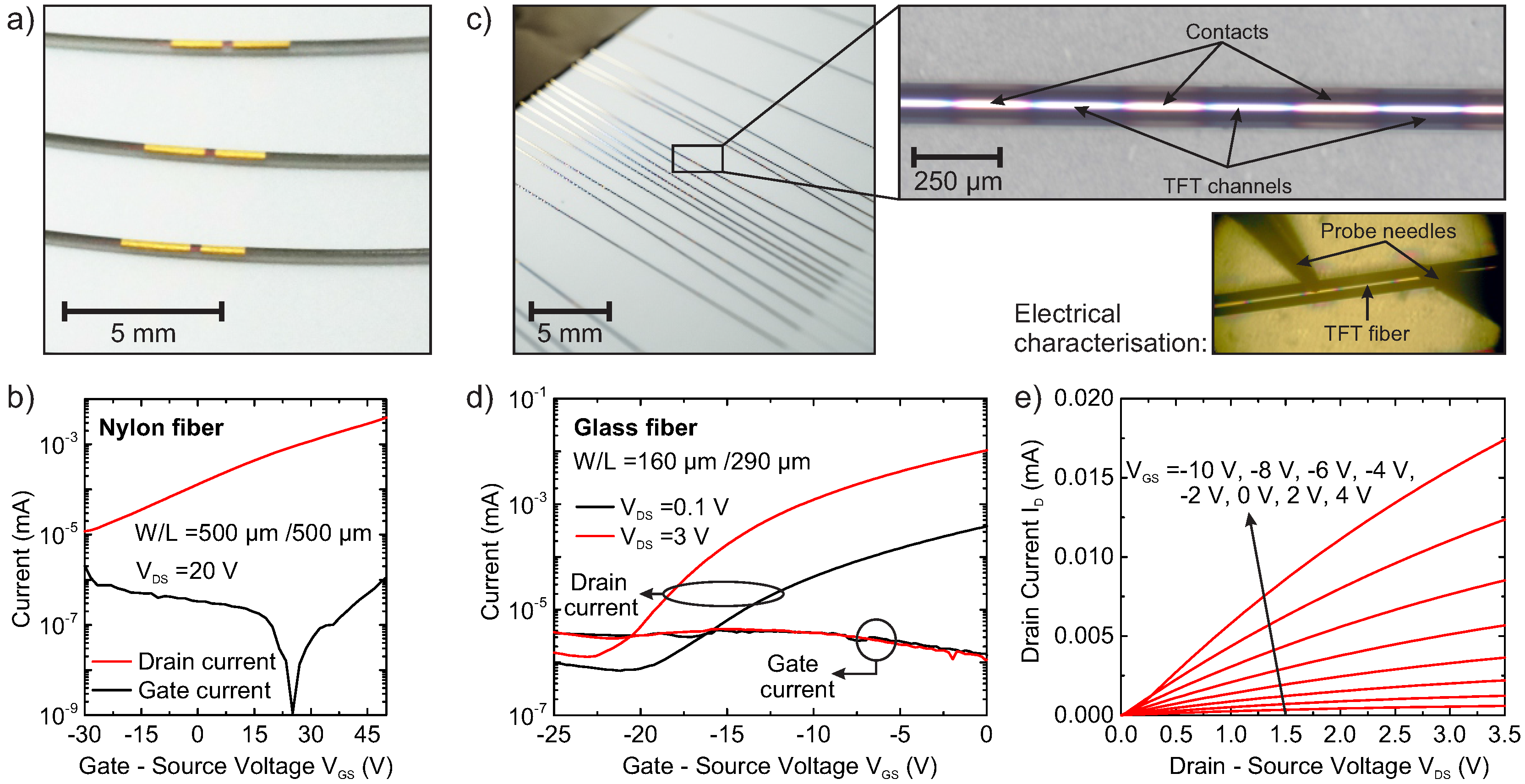

3.1. Directly Fabricated TFTs

3.1.1. TFTs on Polymer Fibers

3.1.2. TFTs on Glass Fibers

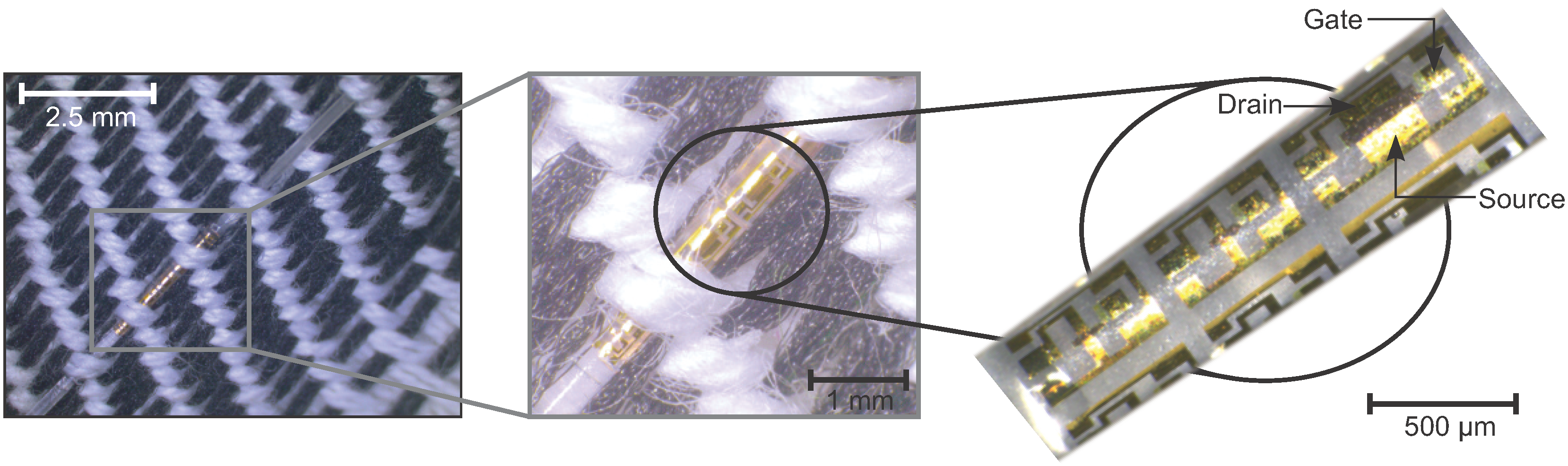

3.2. Transferred TFTs

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Nathan, A.; Ahnood, A.; Cole, M.T.; Lee, S.; Suzuki, Y.; Hiralal, P.; Bonaccorso, F.; Hasan, T.; Garcia-Gancedo, L.; Dyadyusha, A.; et al. Flexible electronics: The next ubiquitous platform. Proc IEEE 2012, 100, 1486–1517. [Google Scholar] [CrossRef]

- Amft, O.; Tröster, G. On-body sensing solutions for automatic dietary monitoring. IEEE Pervasive Comput. 2009, 8, 62–70. [Google Scholar] [CrossRef]

- Cherenack, K.; van Pieterson, L. Smart textiles: Challenges and opportunities. J. Appl. Phys. 2012, 112, 091301. [Google Scholar] [CrossRef]

- Zysset, C.; Kinkeldei, T.; Cherenack, K.; Tröster, G. Woven electronic textiles: An enabling technology for health-care monitoring in clothing. In Proceedings of the UbiComp’10, Copenhagen, Denmark, 26–29 September 2010; pp. 1–4. [Google Scholar]

- Codau, T.C.; Onofrei, E.; Bedek, G.; Dupont, D.; Cochrane, C. Embedded textile heat flow sensor characterization and application. Sens. Actuators A Phys. 2015, 235, 131–139. [Google Scholar] [CrossRef]

- Giovanelli, D.; Farella, E. Force Sensing Resistor and Evaluation of Technology for Wearable Body Pressure Sensing. J. Sens. 2016, 2016. [Google Scholar] [CrossRef]

- Castano, L.M.; Flatau, A.B. Smart fabric sensors and e-textile technologies: A review. Smart Mater. Struct. 2014, 23, 053001. [Google Scholar] [CrossRef]

- Pu, X.; Li, L.; Song, H.; Du, C.; Zhao, Z.; Jiang, C.; Cao, G.; Hu, W.; Wang, Z.L. A Self-Charging Power Unit by Integration of a Textile Triboelectric Nanogenerator and a Flexible Lithium-Ion Battery for Wearable Electronics. Adv. Mater. 2015, 27, 2472–2478. [Google Scholar] [CrossRef] [PubMed]

- Dai, M.; Xiao, X.; Chen, X.; Lin, H.; Wu, W.; Chen, S. A low-power and miniaturized electrocardiograph data collection system with smart textile electrodes for monitoring of cardiac function. Australas. Phys. Eng. Sci. Med. 2016, 39, 1029–1040. [Google Scholar] [CrossRef] [PubMed]

- Locher, I.; Kirstein, T.; Tröster, G. Temperature profile estimation with smart textiles. In Proceedings of the International Conference on Intelligent textiles, Smart clothing, Well-being, and Design, Tampere, Finland, 19–20 September 2005; p. 8. [Google Scholar]

- Lee, J.B.; Subramanian, V. Organic transistors on fiber: A first step towards electronic textiles. In Proceedings of the IEEE International Electron Devices Meeting 2003 (IEDM’03 Technical Digest), Washington, DC, USA, 8–10 December 2003; pp. 199–202. [Google Scholar]

- Hamedi, M.; Forchheimer, R.; Inganäs, O. Towards woven logic from organic electronic fibres. Nat. Mater. 2007, 6, 357–362. [Google Scholar] [CrossRef] [PubMed]

- Zeng, W.; Shu, L.; Li, Q.; Chen, S.; Wang, F.; Tao, X.M. Fiber-based wearable electronics: A review of materials, fabrication, devices, and applications. Adv. Mater. 2014, 26, 5310–5336. [Google Scholar] [CrossRef] [PubMed]

- Cherenack, K.; Zysset, C.; Kinkeldei, T.; Münzenrieder, N.; Tröster, G. Wearable Electronics: Woven Electronic Fibers with Sensing and Display Functions for Smart Textiles. Adv. Mater. 2010, 22, 5071. [Google Scholar] [CrossRef]

- Zysset, C.; Kinkeldei, T.; Münzenrieder, N.; Petti, L.; Salvatore, G.; Tröster, G. Combining electronics on flexible plastic strips with textiles. Text. Res. J. 2013, 83, 1130–1142. [Google Scholar] [CrossRef]

- Kinkeldei, T.; Denier, C.; Zysset, C.; Münzenrieder, N.; Tröster, G. 2D Thin Film Temperature Sensors Fabricated onto 3D Nylon Yarn Surface for Smart Textile Applications. Res. J. Text. Appar. 2013, 17, 16–20. [Google Scholar] [CrossRef]

- Nomura, K.; Ohta, H.; Takagi, A.; Kamiya, T.; Hirano, M.; Hosono, H. Room-temperature fabrication of transparent flexible thin-film transistors using amorphous oxide semiconductors. Nature 2004, 432, 488–492. [Google Scholar] [CrossRef] [PubMed]

- Munzenrieder, N.; Petti, L.; Zysset, C.; Salvatore, G.; Kinkeldei, T.; Perumal, C.; Carta, C.; Ellinger, F.; Troster, G. Flexible a-IGZO TFT amplifier fabricated on a free standing polyimide foil operating at 1.2 MHz while bent to a radius of 5 mm. In Proceedings of the 2012 IEEE International the Electron Devices Meeting (IEDM), San Francisco, CA, USA, 10–13 December 2012; pp. 96–99. [Google Scholar]

- Petti, L.; Münzenrieder, N.; Vogt, C.; Faber, H.; Büthe, L.; Cantarella, G.; Bottacchi, F.; Anthopoulos, T.D.; Tröster, G. Metal oxide semiconductor thin-film transistors for flexible electronics. Appl. Phys. Rev. 2016, 3, 021303. [Google Scholar] [CrossRef]

- Issum, B.V.; Chamberlain, N. The free diameter and specific volume of textile yarns. J. Text. Inst. Trans. 1959, 50, T599–T623. [Google Scholar] [CrossRef]

- Zysset, C.; Nasseri, N.; Büthe, L.; Münzenrieder, N.; Kinkeldei, T.; Petti, L.; Kleiser, S.; Salvatore, G.A.; Wolf, M.; Tröster, G. Textile integrated sensors and actuators for near-infrared spectroscopy. Opt. Express 2013, 21, 3213–3224. [Google Scholar] [CrossRef] [PubMed]

- Service, R.F. Patterning electronics on the cheap. Science 1997, 278, 383–384. [Google Scholar] [CrossRef]

- Hegemann, D.; Amberg, M.; Ritter, A.; Heuberger, M. Recent developments in Ag metallised textiles using plasma sputtering. Mater. Technol. 2009, 24, 41–45. [Google Scholar] [CrossRef]

- Salvatore, G.A.; Münzenrieder, N.; Kinkeldei, T.; Petti, L.; Zysset, C.; Strebel, I.; Büthe, L.; Tröster, G. Wafer-scale design of lightweight and transparent electronics that wraps around hairs. Nat. Commun. 2014, 5, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Kinkeldei, T.; Munzenrieder, N.; Zysset, C.; Cherenack, K.; Tröster, G. Encapsulation for flexible electronic devices. IEEE Electron Device Lett. 2011, 32, 1743–1745. [Google Scholar] [CrossRef]

- Shichman, H.; Hodges, D.A. Modeling and simulation of insulated-gate field-effect transistor switching circuits. IEEE J. Solid-State Circuits 1968, 3, 285–289. [Google Scholar] [CrossRef]

- Kondo, M.; Uemura, T.; Matsumoto, T.; Araki, T.; Yoshimoto, S.; Sekitani, T. Ultraflexible and ultrathin polymeric gate insulator for 2 V organic transistor circuits. Appl. Phys. Express 2016, 9, 061602. [Google Scholar] [CrossRef]

- Münzenrieder, N.; Cherenack, K.; Tröster, G. The Effects of Mechanical Bending and Illumination on the Performance of Flexible IGZO TFTs. Trans. Electron Devices IEEE 2011, 58, 2041–2048. [Google Scholar] [CrossRef]

- Zysset, C.; Munzenrieder, N.; Kinkeldei, T.; Cherenack, K.; Troster, G. Woven active-matrix display. IEEE Trans. Electron Devices 2012, 59, 721–728. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Münzenrieder, N.; Vogt, C.; Petti, L.; Salvatore, G.A.; Cantarella, G.; Büthe, L.; Tröster, G. Oxide Thin-Film Transistors on Fibers for Smart Textiles. Technologies 2017, 5, 31. https://doi.org/10.3390/technologies5020031

Münzenrieder N, Vogt C, Petti L, Salvatore GA, Cantarella G, Büthe L, Tröster G. Oxide Thin-Film Transistors on Fibers for Smart Textiles. Technologies. 2017; 5(2):31. https://doi.org/10.3390/technologies5020031

Chicago/Turabian StyleMünzenrieder, Niko, Christian Vogt, Luisa Petti, Giovanni A. Salvatore, Giuseppe Cantarella, Lars Büthe, and Gerhard Tröster. 2017. "Oxide Thin-Film Transistors on Fibers for Smart Textiles" Technologies 5, no. 2: 31. https://doi.org/10.3390/technologies5020031