Bio-Organic Electronics—Overview and Prospects for the Future

Abstract

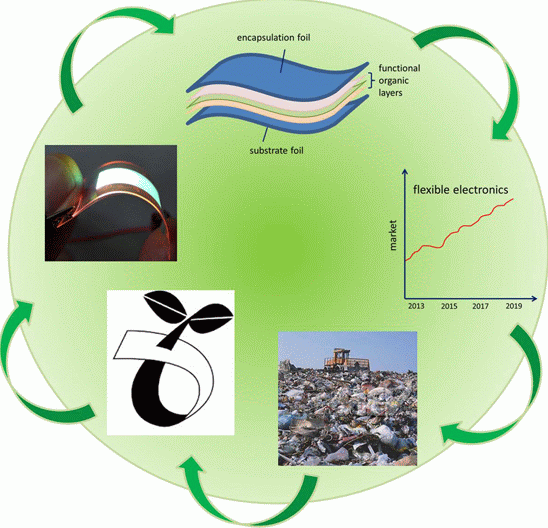

:1. Introduction

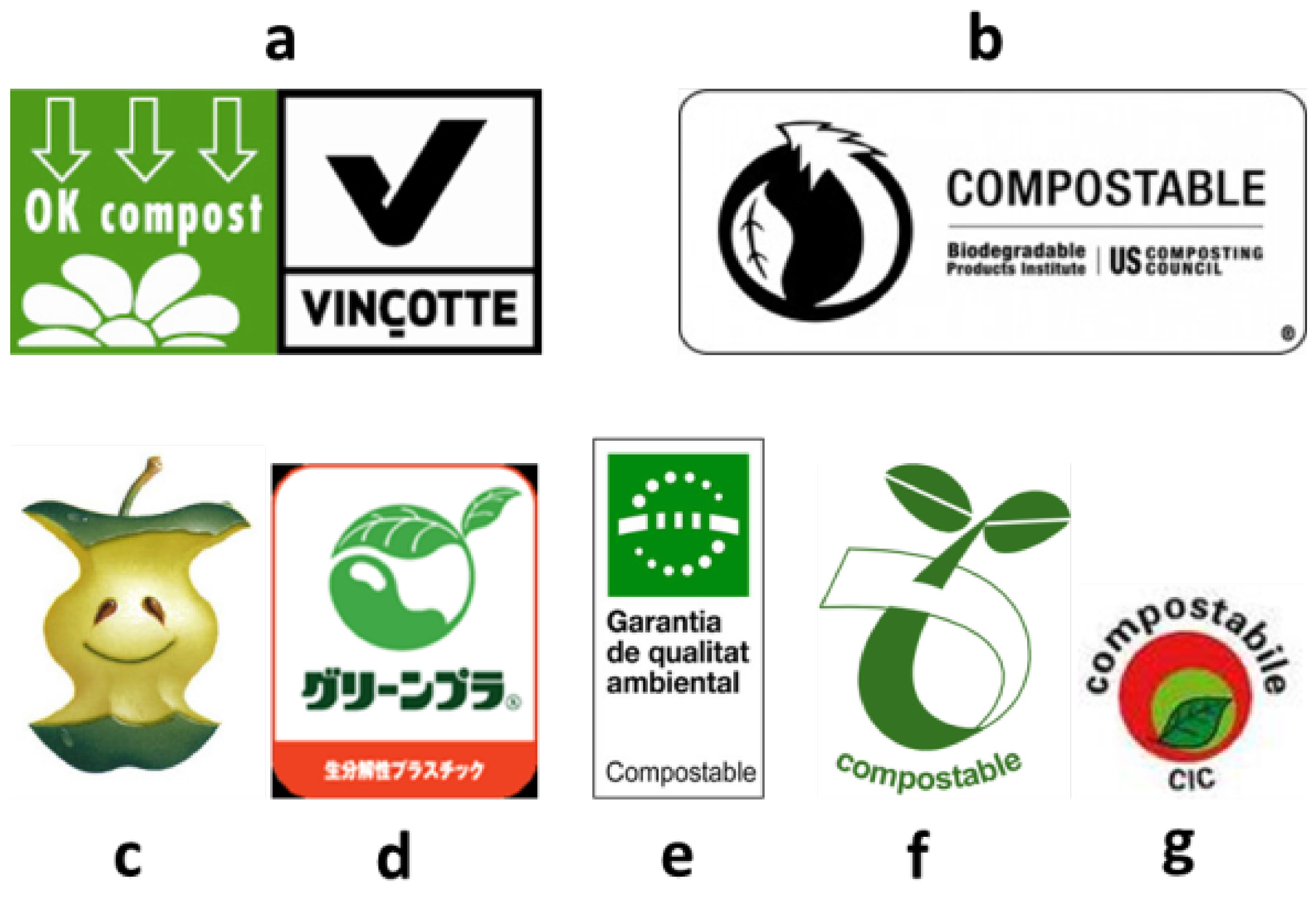

2. Policies and Guidelines

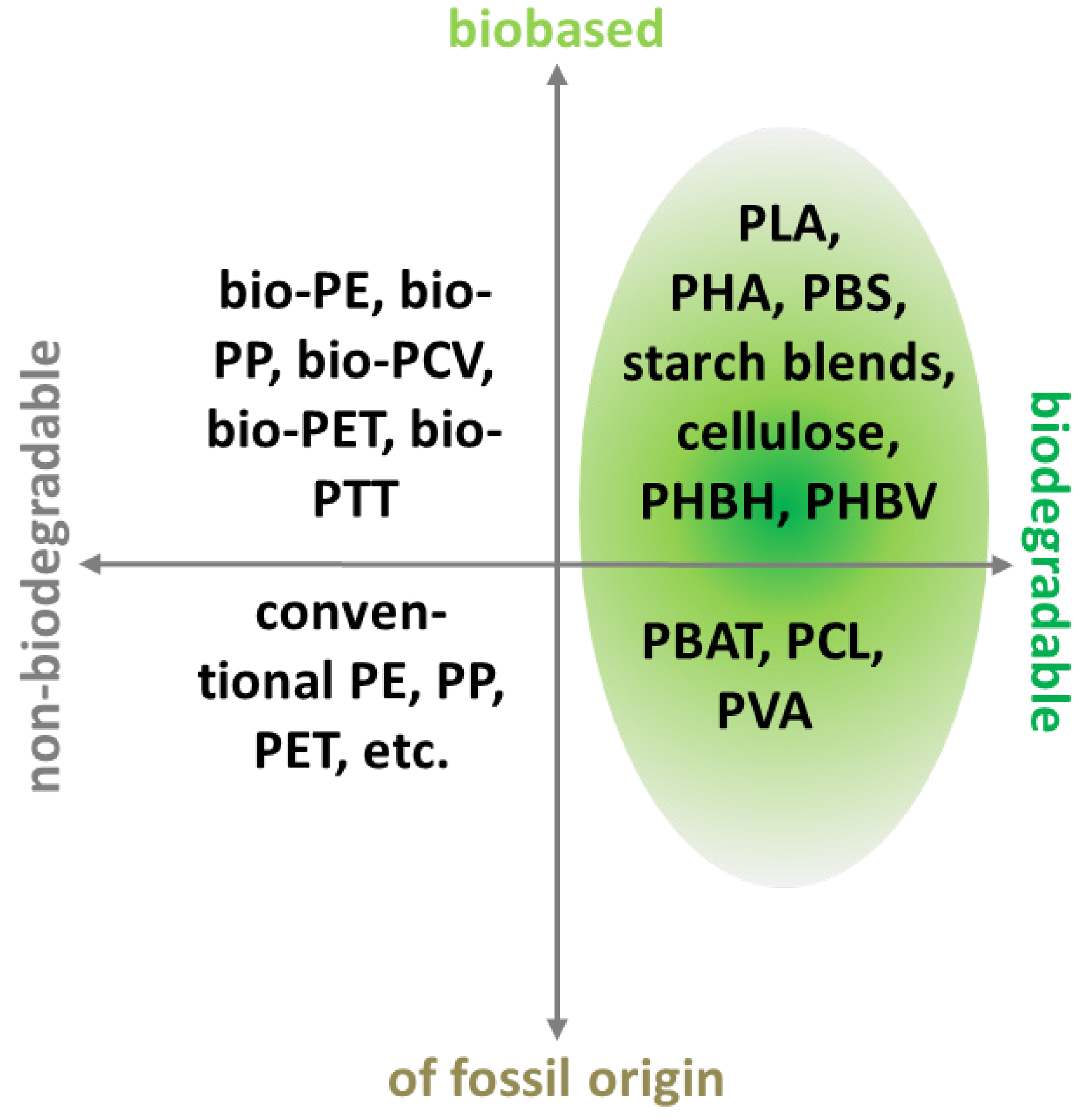

2.1. Definitions and Standards

2.2. Environmental Impact and Biotoxicity

3. Components

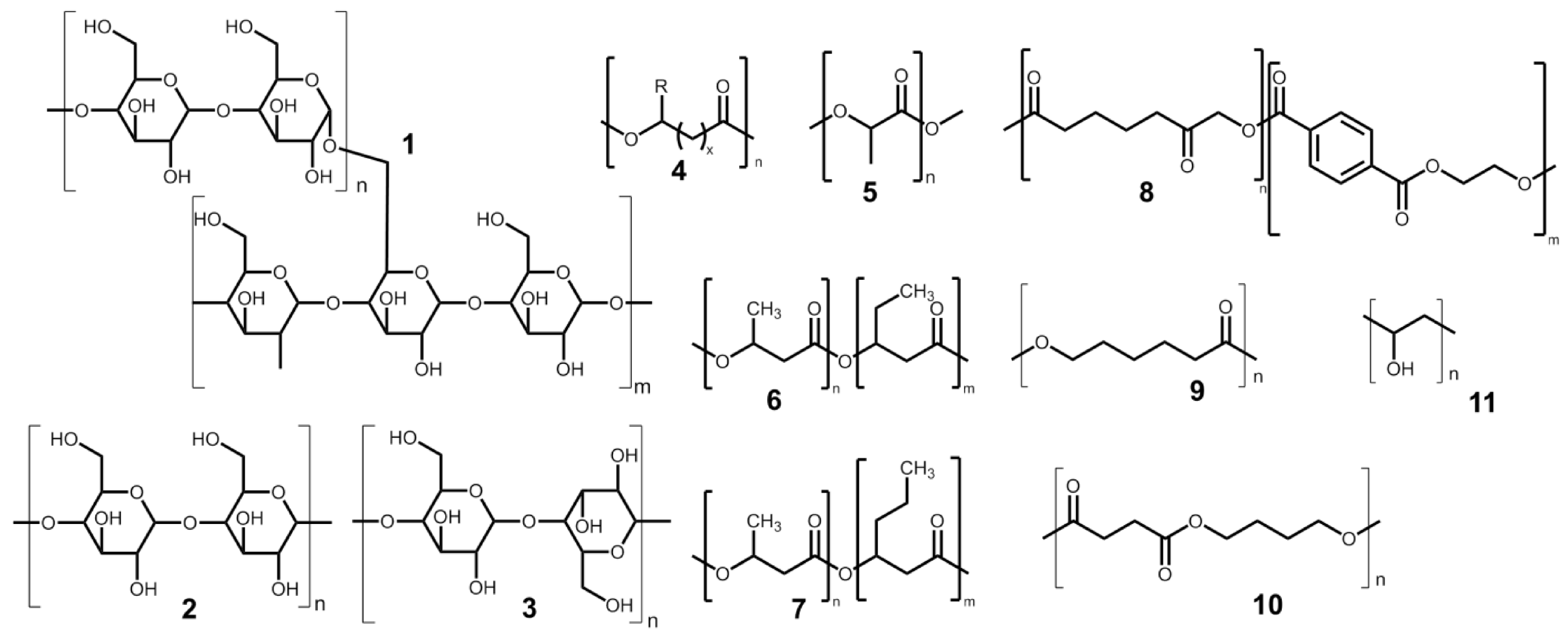

3.1. Substrate Materials

3.2. Adhesives

3.3. Organic Semiconductors

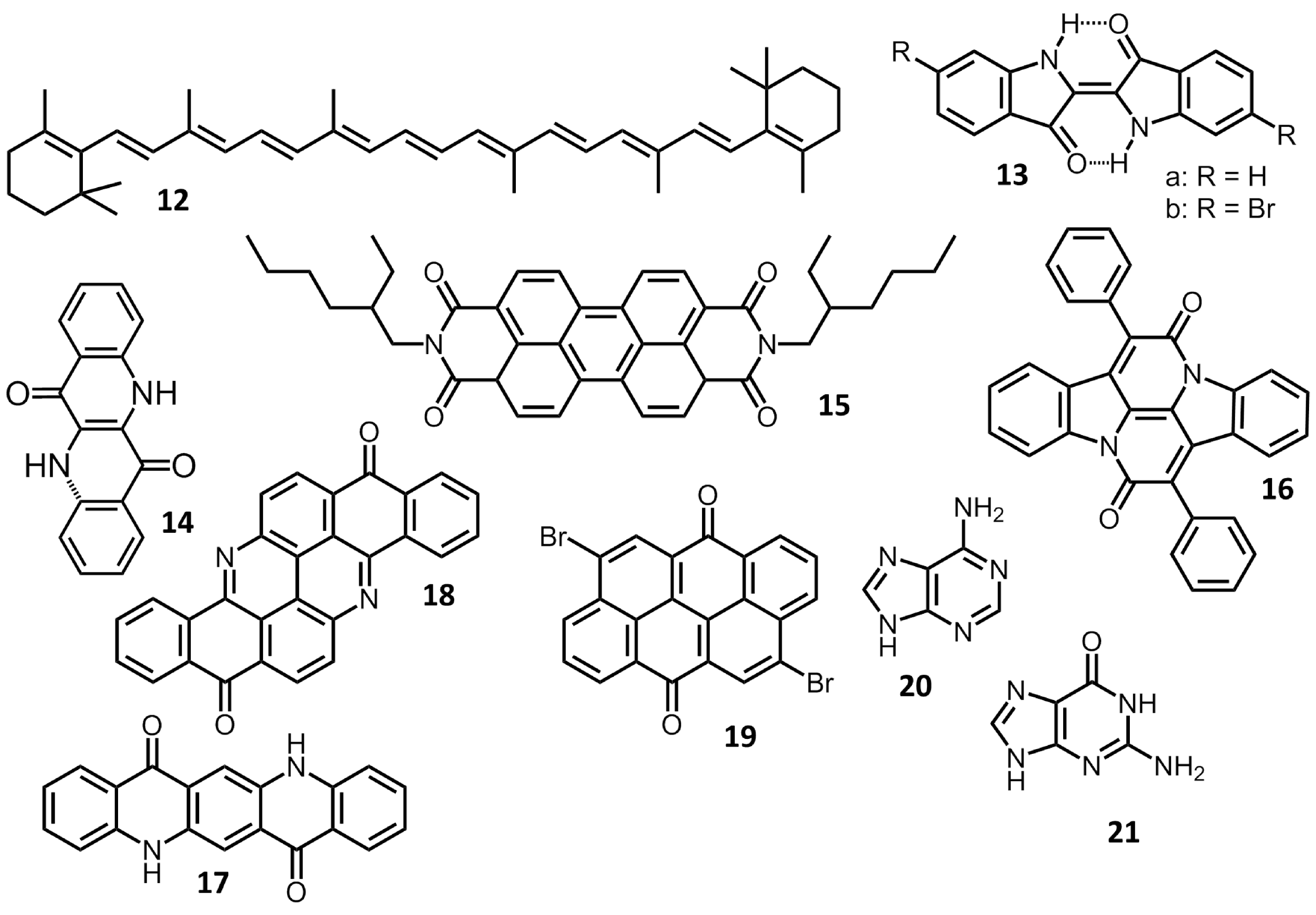

| Material | HOMO (eV) | LUMO (eV) | Eg CV (eV) | Eg Optical (eV) | µ (cm2/VS) | εr |

|---|---|---|---|---|---|---|

| Indigo (13a) | −5.5 | −3.8 | 1.7 | 1.7 | µe = 1 × 10−2, μh = 1 × 10−2 | 4.3 |

| Tyrian Purple (13b) | −5.8 | −4.0 | 1.8 | 1.9 | µe = 0.3 [28], μh = 0.2 | 6.2 |

| Cibalackrot (16) | −5.6 | −3.5 | 2.1 | 2.0 | µe = 9.3 × 10−3, μh = 5.3 × 10−3 | 4.8 |

| Quinacridone (17) | −5.4 | −2.9 | 2.5 | 2.0 | μh = 0.1 | 5.2 |

| Vat Yellow 1 (18) | −6.3 | −3.6 | 2.7 | 2.3 | μe = 4.2 × 10−2 | 3.8 |

| Vat Orange 3 (19) | −6.2 | −3.8 | 2.4 | 2.1 | µe = 8.8 × 10−3 | 3.8 |

| β-carotene (12) | −5.84 | −3.54 | NA | 2.3 | μh = 4 × 10−4 | 2.5 |

3.4. Electrode Materials

3.5. Dielectric Materials

4. Applications and Markets

4.1. Consumer Organic Electronics

4.2. Medicine

4.3. Agriculture/Horticulture

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Seymour, R.B.; Deanin, R.D. History of Polymer Composites, 1st ed.; VNU Science Press BV: Utrecht, The Netherlands, 1987. [Google Scholar]

- Singh, B.; Sharma, N. Mechanistic implications of plastic degradations. Polym. Degrad. Stab. 2008, 93, 561–584. [Google Scholar] [CrossRef]

- BIOPLASTICS—facts and figures. Available online: http://en.european-bioplastics.org/wp-content/uploads/2013/publications/EuBP_FactsFigures_bioplastics_2013.pdf, last (access on 4 March 2014).

- Shah, A.A.; Hasan, F.; Hameed, A.; Ahmed, S. Biological degradation of plastics: A comprehensive review. Biotechnol. Adv. 2008, 26, 246–265. [Google Scholar] [CrossRef]

- Rifkin, J. The Third Industrial Revolution: How lateral Power is Transforming Energy, the Economy, and the World, 1st ed.; Palgrave Macmillan: New York, NY, USA, 2011; pp. 1–32. [Google Scholar]

- Griese, H.; Stobbe, L.; Middendorf, A.; Reichl, H. Environmental compatibility of electronics—A key towards local and global sustainable development. In Proceedings of the 2004 International IEEE Conference on the Asian Green Electronics AGEC, Hong Kong, China, 5–6 January 2004; pp. 158–163.

- Fahlteich, J.; Amberg-Schwab, S.; Weber, U.; Noller, K.; Miesbauer, O.; Boeffel, C.; Schiller, N. 29.1: Ultra-high barriers for encapsulation of flexible displays and lighting devices. SID 2013, 44, 354–357. [Google Scholar] [CrossRef]

- Tress, T.; Leo, K.; Riede, M. Influence of hole-transport layers and donor materials on open-circuit voltage and shape of I–V curves of organic solar cells. Adv. Funct. Mater. 2011, 21, 2140–2149. [Google Scholar] [CrossRef]

- Zhou, Y.; Fuentes-Hernandez, C.; Khan, T.M.; Liu, J.-C.; Hsu, J.; Shim, J.W.; Dindar, A.; Youngblood, J.P.; Moon, R.J.; Kippelen, B. Recyclable organic solar cells on cellulose nanocrystal substrates. Sci. Rep. 2013, 3, 1–5. [Google Scholar]

- Martins, R.F.P.; Ahnood, A.; Correia, N.; Pereira, L.M.N.P.; Barros, R.; Barquinha, P.M.C.B.; Costa, R; Ferreira, I.M.M.; Nathan, A.; Fortunato, E.E.M.C. Recyclable, flexible, low-power oxide electronics. Adv. Funct. Mater. 2013, 23, 2153–2161. [Google Scholar] [CrossRef]

- Legnani, C.; Vilani, C.; Calil, V.L.; Barud, H.S.; Quirino, W.G.; Achete, C.A.; Ribeiro, J.L.; Cremona, M. Bacterial cellulose membrane as flexible substrate for organic light emitting devices. Thin Solid Films 2008, 517, 1016–1020. [Google Scholar] [CrossRef]

- Shah, J.; Brown, R.M., Jr. Towards electronic paper displays made from microbial cellulose. Appl. Microbiol. Biotechnol. 2005, 66, 352–355. [Google Scholar] [CrossRef]

- Kim, D.Y.; Steckl, A.J. Electrowetting on paper for electronic paper display. ACS Appl. Mater. Interfaces 2010, 2, 3318–3323. [Google Scholar] [CrossRef]

- Fukuhira, Y.; Kitazonoa, E.; Hayashia, T.; Kanekoa, H.; Tanakab, M.; Shimomurac, M.; Sumi, Y. Biodegradable honeycomb-patterned film composed of poly(lactic acid) and dioleoylphosphatidylethanolamine. Biomaterials 2006, 27, 1797–1802. [Google Scholar] [CrossRef]

- Breulmann, M.; Künkel, A.; Philipp, S.; Reimer, V.; Siegenthaler, K.O.; Skupin, G.; Ymamoto, M. Polymers, Biodegradable. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH: Weinheim, Germany, 2009. [Google Scholar]

- Oosterhoff, R.H. Biodegradable Diacrylates and Adhesives Based Thereon. U.S. 005580940A, 3 December 1996. [Google Scholar]

- Kumar, R.; Choudhary, V.; Mishra, S.; Varma, I.K.; Mattiason, B. Adhesives and plastics based on soy protein products. Ind. Crop. Prod. 2002, 16, 155–172. [Google Scholar]

- Mahdavi, A.; Ferreira, L.; Sundback, C.; Nichol, J.W.; Chan, E.P.; Carter, D.J.D.; Bettinger, C.J.; Patanavanich, S.; Chignozha, L.; Ben-Joseph, E.; et al. A biodegradable and biocompatible gecko-inspired tissue adhesive. Proc. Natl. Acad. Sci. USA 2008, 105, 2307–2312. [Google Scholar] [CrossRef]

- Taguchi, T.; Saito, H.; Iwasashi, M.; Sakane, M.; Ochiai, N. Biodegradable adhesives composed of human serum albumin and organic acid-based crosslinkers with active ester groups. J. Bioact. Compat. Pol. 2009, 24, 546–559. [Google Scholar] [CrossRef]

- Yang, C.; Lin, W.; Li, Z.; Zhang, R.; Wen, H.; Gao, B.; Chen, G.; Gao, P.; Yuen, M.M.F.; Wong, C.P. Water-based isotropically conductive adhesives: Towards green and low-cost flexible electronics. Adv. Funct. Mater. 2011, 21, 4582–4588. [Google Scholar] [CrossRef]

- Bettinger, C.J.; Bao, Z. Biomaterials-based organic electronic devices. Polym. Int. 2010, 59, 563–567. [Google Scholar]

- Mostert, A.B.; Powell, B.J.; Pratt, F.L.; Hanson, G.R.; Sarna, T.; Gentle, I.R.; Meredith, P. Role of semiconductivity and ion transport in the electrical conduction of melanin. Proc. Natl. Acad. Sci. USA 2012, 109, 8943–8947. [Google Scholar]

- Irimia-Vladu, M.; Troshin, P.A.; Reisinger, M.; Shmygleva, L.; Kanbur, Y; Schwabegger, G.; Bodea, M.; Schwödiauer, R.; Mumyatov, A.; Fergus, J.W.; et al. Biocompatible and biodegradable materials for organic field-effect transistors. Adv. Funct. Mater. 2010, 20, 4069–4076. [Google Scholar] [CrossRef]

- Irimia-Vladu, M.; Sariciftcib, N.S.; Bauer, S. Exotic materials for bio-organic electronics. J. Mater. Chem. 2011, 21, 1350–1361. [Google Scholar] [CrossRef]

- Głowacki, E.D.; Irimia-Vladu, M.; Kaltenbrunner, M.; Gąsiorowski, J.; White, M.S.; Monkowius, U.; Romanazzi, G.; Suranna, G.P.; Mastrorilli, P.; Sekitani, T.; et al. Hydrogen-bonded semiconducting pigments for air-stable field-effect transistors. Adv. Mater. 2013, 25, 1563–1569. [Google Scholar] [CrossRef]

- Irimia-Vladu, M.; Troshin, P.A.; Reisinger, M.; Schwabegger, G.; Ullah, M.; Schwoediauer, R.; Mumyatov, A.; Bodea, M.; Fergus, J.W.; Razumov, V.F.; et al. Environmentally sustainable organic field effect transistors. Org. Electron. 2010, 11, 1974–1990. [Google Scholar] [CrossRef]

- Głowacki, E.D.; Leonat, L.; Voss, G.; Bodea, M.; Bozkurt, Z.; Irimia-Vladu, M.; Bauer, S.; Sariciftci, N.S. Natural and nature-inspired semiconductors for organic electronics. Proc. SPIE 2011, 8118, 81180M:1–81180M:10. [Google Scholar]

- Kanbur, Y.; Irimia-Vladu, M.; Głowacki, E.D.; Voss, G.; Baumgartner, M.; Schwabegger, G.; Leonat, L.; Ullah, M.; Sarica, H.; Erten-Ela, S.; et al. Vacuum-processed polyethylene as a dielectric for low operating voltage organic field effect transistors. Org. Electron. 2012, 13, 919–924. [Google Scholar] [CrossRef]

- Nudejima, S.-I.; Miyazawa, K.I.; Okuda-Shimazaki, J.; Taniguchi, A. Biodegradation of C60 fullerene nanowhiskers by macrophage-like cells. Adv. Biomed. Res. 2010, 89–94. [Google Scholar]

- Partha, R.; Conyers, J.L. Biomedical applications of functionalized fullerene-based nanomaterials. Int. J. Nanomed. 2009, 4, 261–275. [Google Scholar] [CrossRef]

- Chiappini, C.; Liu, X.; Fakhoury, J.R.; Ferrari, M. Biodegradable porous silicon barcode nanowires with defined geometry. Adv. Funct. Mater. 2010, 20, 2231–2239. [Google Scholar] [CrossRef]

- Irimia-Vladua, M.; Głowackib, E.D.; Vossb, G.; Bauera, S.; Sariciftci, N.S. Green and biodegradable electronics. Mater. Today 2012, 15, 7–8. [Google Scholar]

- Hermawan, H. Biodegradable Metals: From Concept to Application; Springer: Heidelberg, Germany, 2012; pp. 13–22. [Google Scholar]

- Cheng, J.; Liu, B.; Wu, Y.H.; Zheng, Y.F. Comparative in vitro study on pure metals (Fe, Mn, Mg, Zn and W) as biodegradable metals. J. Mater. Sci. Technol. 2013, 29, 619–627. [Google Scholar] [CrossRef]

- Irimia-Vladu, M.; Głowacki, E.D.; Schwabegger, G.; Leonat, L.; Akpinar, H.Z.; Sitter, H.; Bauer, S.; Sariciftci, N.S. Natural resin shellac as a substrate and a dielectric layer for organic field-effect transistors. Green Chem. 2013, 15, 1473–1476. [Google Scholar] [CrossRef]

- Capelli, R.; Amsden, J.J.; Generali, G.; Toffanin, S.; Benfenati, V.; Muccini, M.; Kaplan, D.L.; Omenetto, F.G.; Zamboni, R. Integration of silk protein in organic and light-emitting transistors. Org. Electron. 2011, 12, 1146–1151. [Google Scholar] [CrossRef]

- Chang, J.-W.; Wang, C.-G.; Huang, C.-Y.; Tsai, T.-D.; Guo, T.-F.; Wen, T.-C. Chicken albumen dielectrics in organic field-effect transistors. Adv. Mater. 2011, 23, 4077–4081. [Google Scholar] [CrossRef]

- Petritz, A.; Wolfberger, A.; Fian, A.; Irimia-Vladu, M.; Haase, A.; Gold, H.; Rothländer, T.; Griesser, T.; Stadlober, B. Cellulose as biodegradable high-k dielectric layer in organic complementary inverters. Appl. Phys. Lett. 2013, 103, 153303:1–153303:5. [Google Scholar]

- Khor, L.Q.; Cheong, K.Y. Aloe vera gel as natural organic dielectric in electronic application. J. Mater. Sci.: Mater. Electron. 2013, 24, 2646–2652. [Google Scholar] [CrossRef]

- Kosbar, L.L.; Gelorme, J.D.; Japp, R.M.; Fotorny, W.T. Introducing biobased materials into the electronics industry—Developing a Lignin-based resin for printed wiring boards. J. Ind. Ecol. 2001, 4, 93–105. [Google Scholar]

- Zhu, H.; Xiao, Z.; Liu, D.; Li, Y.; Weadock, N.J.; Fang, Z.; Huang, J.; Hu, L. Biodegradable transparent substrates for flexible organic-light-emitting diodes. Energy Environ. Sci. 2013, 6, 2105–2111. [Google Scholar] [CrossRef]

- Hu, L.; Choi, J.W.; Yang, Y.; Jeong, S.; la Mantia, F.; Cui, L.-F.; Cui, Y. Highly conductive paper for energy-storage devices. Proc. Natl. Acad. Sci. USA 2009, 106, 21490–21494. [Google Scholar] [CrossRef]

- Nyholm, L.; Nyström, G.; Mihranyan, A.; Strømme, M. Toward flexible polymer and paper-based energy storage devices. Adv. Mater. 2011, 23, 3751–3769. [Google Scholar]

- Barr, M.C.; Rowehl, J.A.; Lunt, R.R.; Xu, J.; Wang, A.; Boyce, C.M.; Im, S.G.; Bulovic, V.; Gleason, K.K. Direct monolithic integration of organic photovoltaic circuits on unmodified paper. Adv. Mater. 2011, 23, 3500–3505. [Google Scholar] [CrossRef]

- Zschieschang, U.; Yamamoto, T.; Takimiya, K.; Kuwabara, H.; Ikeda, M.; Sekitani, T.; Someya, T.; Klauk, H. Organic electronics on banknotes. Adv. Mater. 2011, 23, 654–658. [Google Scholar] [CrossRef]

- Irimia-Vladu, M.; Głowacki, E.D.; Troshin, P.A.; Schwabegger, G.; Leonat, L.; Susarova, D.K.; Krystal, O.; Ullah, M.; Kanbur, Y.; Bodea, M.A.; et al. Indigo—A natural pigment for high performance ambipolar organic field effect transistors and circuits. Adv. Mater. 2012, 24, 375–380. [Google Scholar] [CrossRef]

- Kim, D.-H.; Kim, Y.-S.; Amsden, J.; Panilaitis, B.; Kaplan, D.L.; Omenetto, F.G.; Zakin, M.R.; Rogers, J.A. Silicon electronics on silk as a path to bioresorbable, implantable devices. Appl. Phys. Lett. 2009, 95, 133701:1–133701:3. [Google Scholar]

- Barhoumi, H.; Maaref, A.; Rammah, M.; Martelet, C.; Jaffrezic-Renault, N.; Mousty, C.; Cosnier, S.; Perez, E.; Rico-Lattes, I. Insulator semiconductor structures coated with biodegradable latexes as encapsulation matrix for urease. Biosens. Bioelectron. 2005, 20, 2318–2323. [Google Scholar] [CrossRef]

- Canham, L. Interview—Nanosilicon for nanomedicine: A step towards biodegradable electronic implants? Nanomedicine 2013, 8, 1573–1576. [Google Scholar] [CrossRef]

- Lendlein, A.; Sisson, A. Handbook of Biodegradable Polymers: Isolation, Synthesis, Characterization and Applications; Wiley-VCH Verlag GmbH Co. KGaA: Weinheim, Germany, 2013; pp. 309–378. [Google Scholar]

- Bazaka, K.; Jacob, M.V. Implantable Devices: Issues and Challenges. Electronics 2013, 2, 1–34. [Google Scholar] [CrossRef]

- Williams, D.F. On the mechanisms of biocompatibility. Biomaterials 2008, 29, 2941–2953. [Google Scholar] [CrossRef]

- Koo, J.H.; Seo, J.; Lee, T. Nanomaterials on flexible substrates to explore innovative functions: From energy harvesting to bio-integrated electronics. Thin Solid Films 2012, 524, 1–19. [Google Scholar] [CrossRef]

- Richards-Grayson, A.C.; Scheidt-Shawgo, R.; Li, Y.; Cima, M.J. Electronic MEMS for triggered delivery. Adv. Drug Deliver. Rev. 2004, 56, 173–184. [Google Scholar] [CrossRef]

- King, K.R.; Wang, C.C.J.; Kaazempur-Mofrad, M.R.; Vacanti, J.P.; Borenstein, J.T. Biodegradable microfluidics. Adv. Mater. 2004, 16, 2007–2012. [Google Scholar] [CrossRef]

- Muskovich, M.; Bettinger, C.L. Biomaterials-based electronics: Polymers and interfaces for biology and medicine. Adv. Healthcare Mater. 2012, 1, 248–266. [Google Scholar] [CrossRef]

- Scarascia-Mugnozza, G.; Schettini, E.; Vox, G.; Malinconico, M.; Immirzi, B.; Pagliara, S. Mechanical properties decay and morphological behaviour of biodegradable films for agricultural mulching in real scale experiment. Polym. Degrad. Stab. 2006, 91, 2801–2808. [Google Scholar] [CrossRef]

- Mormile, P.; Petti, L.; Rippa, M.; Immirzi, B.; Malinconico, M.; Santagata, G. Monitoring of the degradation dynamics of agricultural films by IR thermography. Polym. Degrad. Stab. 2007, 92, 777–784. [Google Scholar] [CrossRef]

- Sozer, N.; Kokini, J.L. Nanotechnology and its applications in the food sector. Trends Biotechnol. 2008, 27, 82–89. [Google Scholar] [CrossRef]

- Theinsthid, P.; Chandrachai, A.; Suwannathep, S.; Keeratipibul, S. Bio-based products: Factors that influence their adoption. In Proceeding of the 2010 IEEE International Conference on Management of Innovation and Technology (ICMIT), Singapore, Singapore, 2–5 June 2010; pp. 354–359.

- Das, R.; Harrop, P. Printed, Organic & Flexible Electronics Forecasts, Players & Opportunities 2012–2022; IDTechEx: Cambridge, UK, 2012; pp. 1–58. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Mühl, S.; Beyer, B. Bio-Organic Electronics—Overview and Prospects for the Future. Electronics 2014, 3, 444-461. https://doi.org/10.3390/electronics3030444

Mühl S, Beyer B. Bio-Organic Electronics—Overview and Prospects for the Future. Electronics. 2014; 3(3):444-461. https://doi.org/10.3390/electronics3030444

Chicago/Turabian StyleMühl, Susan, and Beatrice Beyer. 2014. "Bio-Organic Electronics—Overview and Prospects for the Future" Electronics 3, no. 3: 444-461. https://doi.org/10.3390/electronics3030444

APA StyleMühl, S., & Beyer, B. (2014). Bio-Organic Electronics—Overview and Prospects for the Future. Electronics, 3(3), 444-461. https://doi.org/10.3390/electronics3030444