Microstructure and Cavitation Erosion Resistance of HVOF Deposited WC-Co Coatings with Different Sized WC

Abstract

:1. Introduction

2. Experimental Procedure

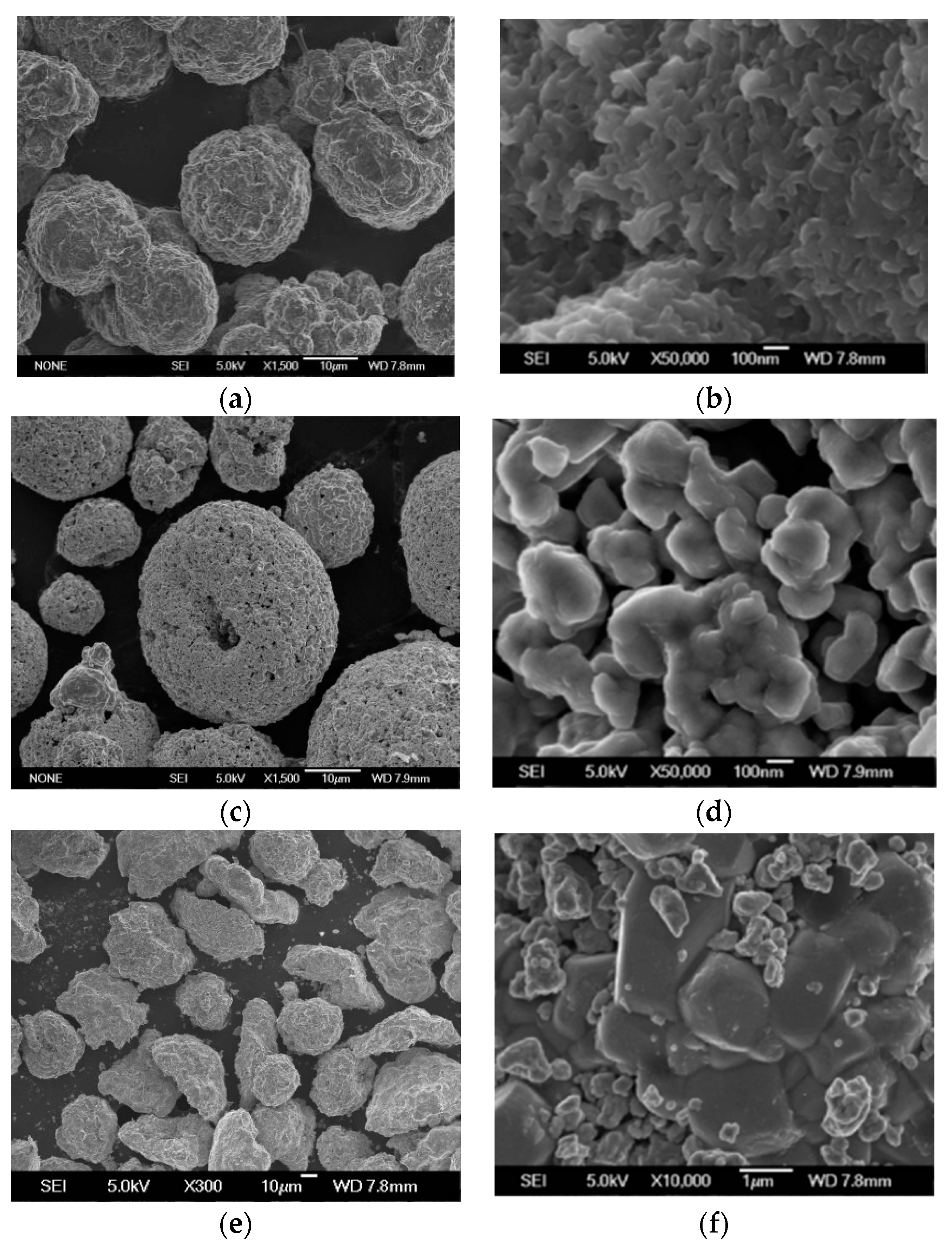

2.1. Coating Materials

2.2. Coating Fabrication

2.3. Characterization

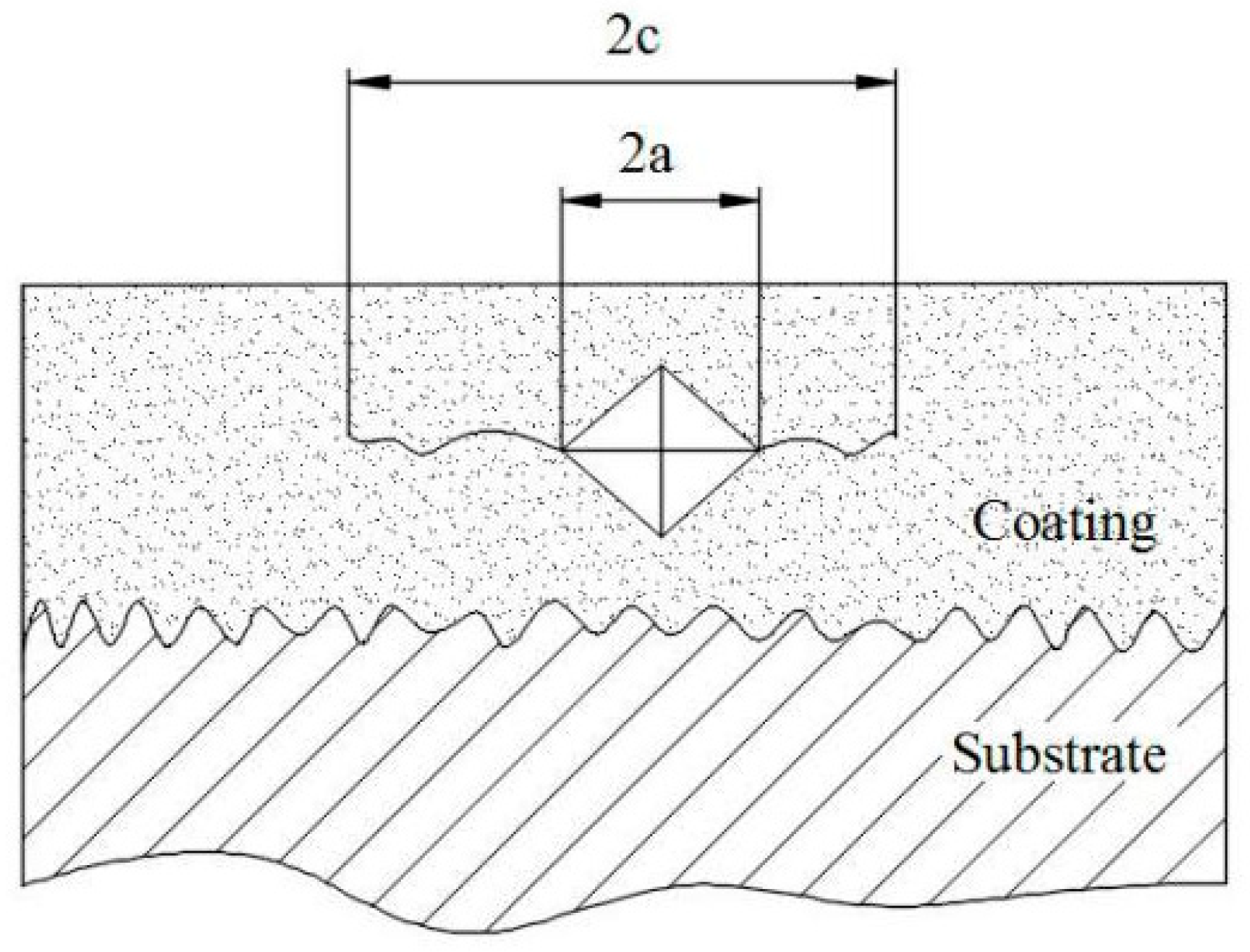

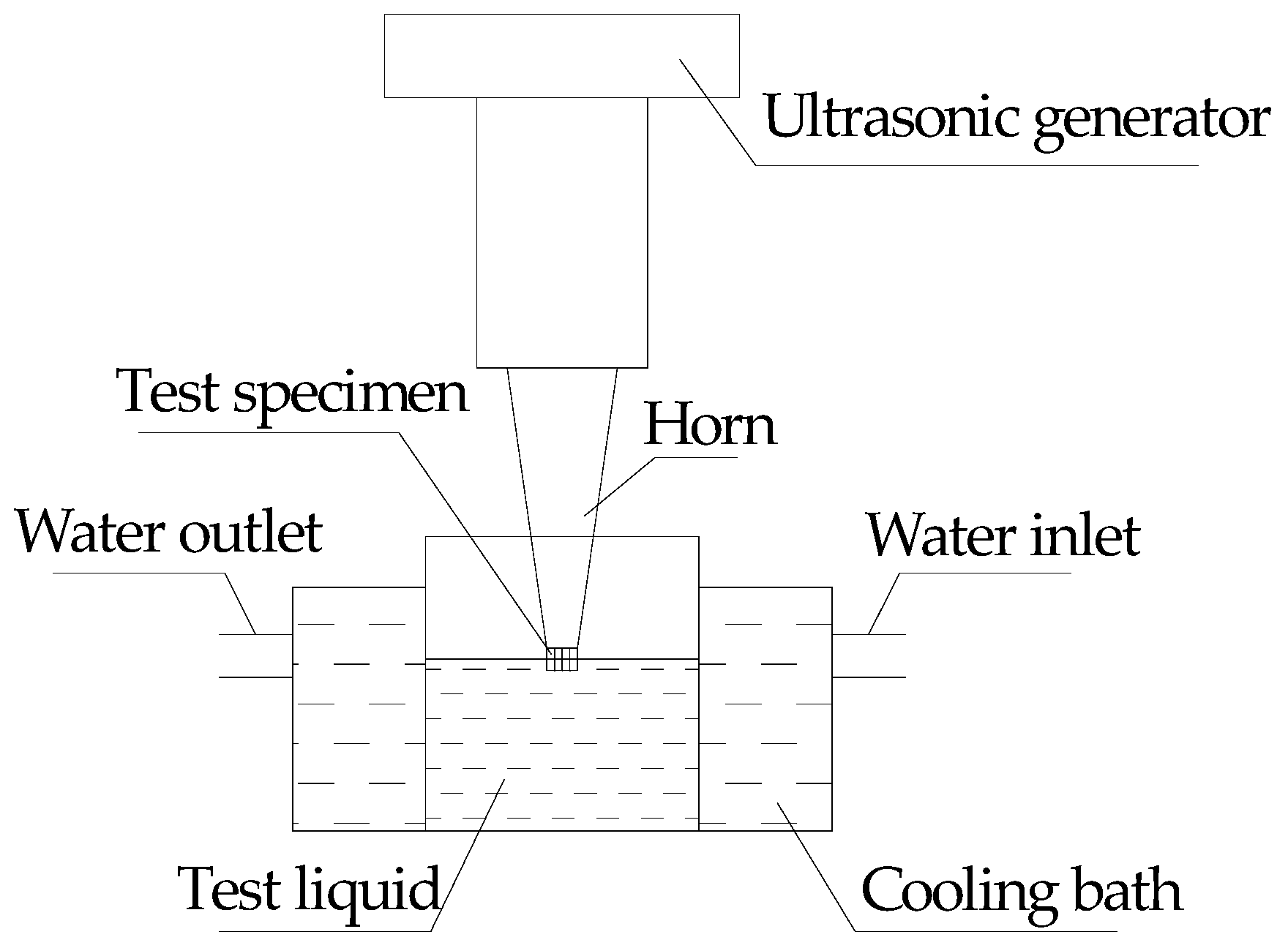

2.4. Cavitation Erosion Tests

3. Results and Discussion

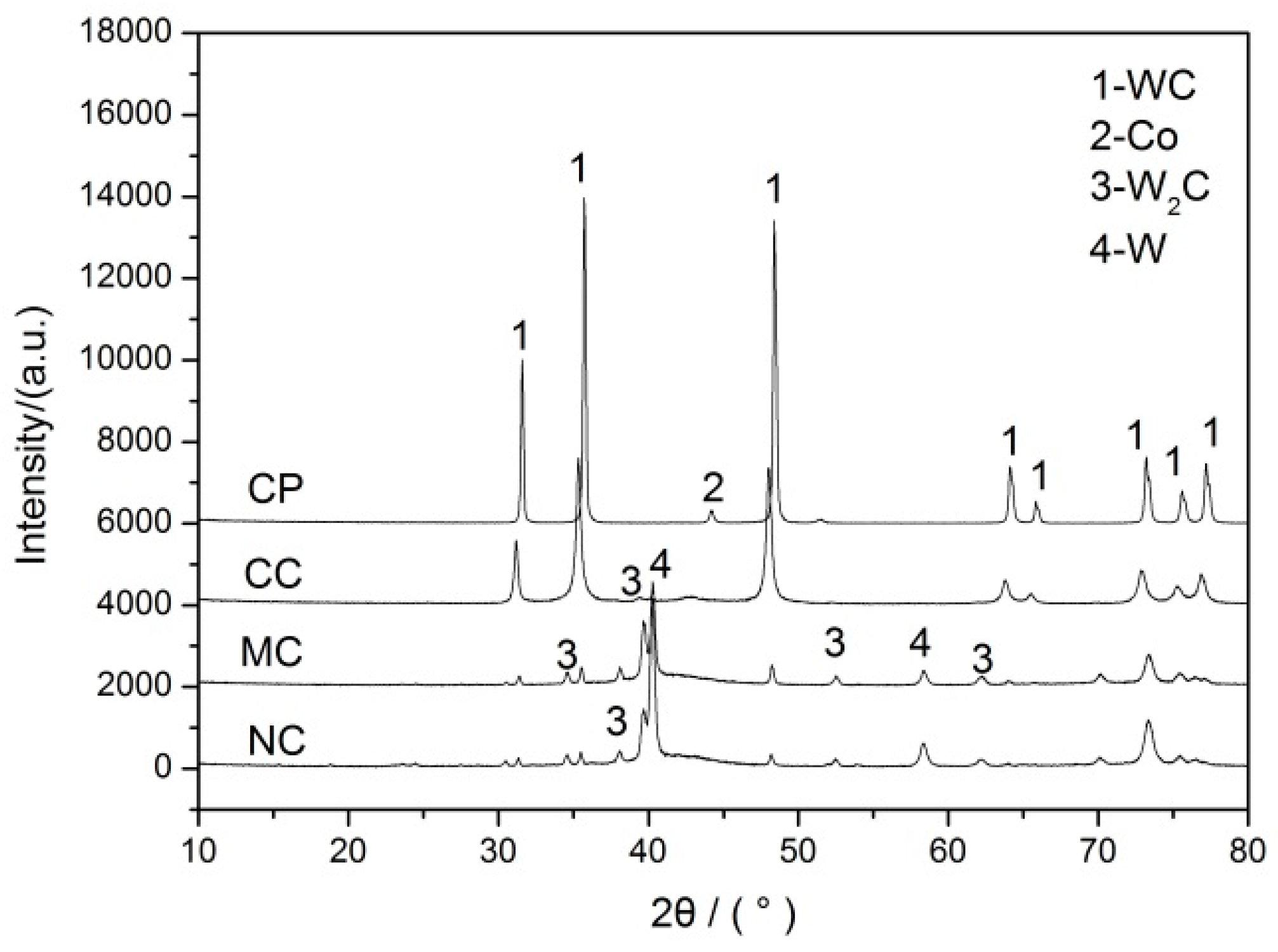

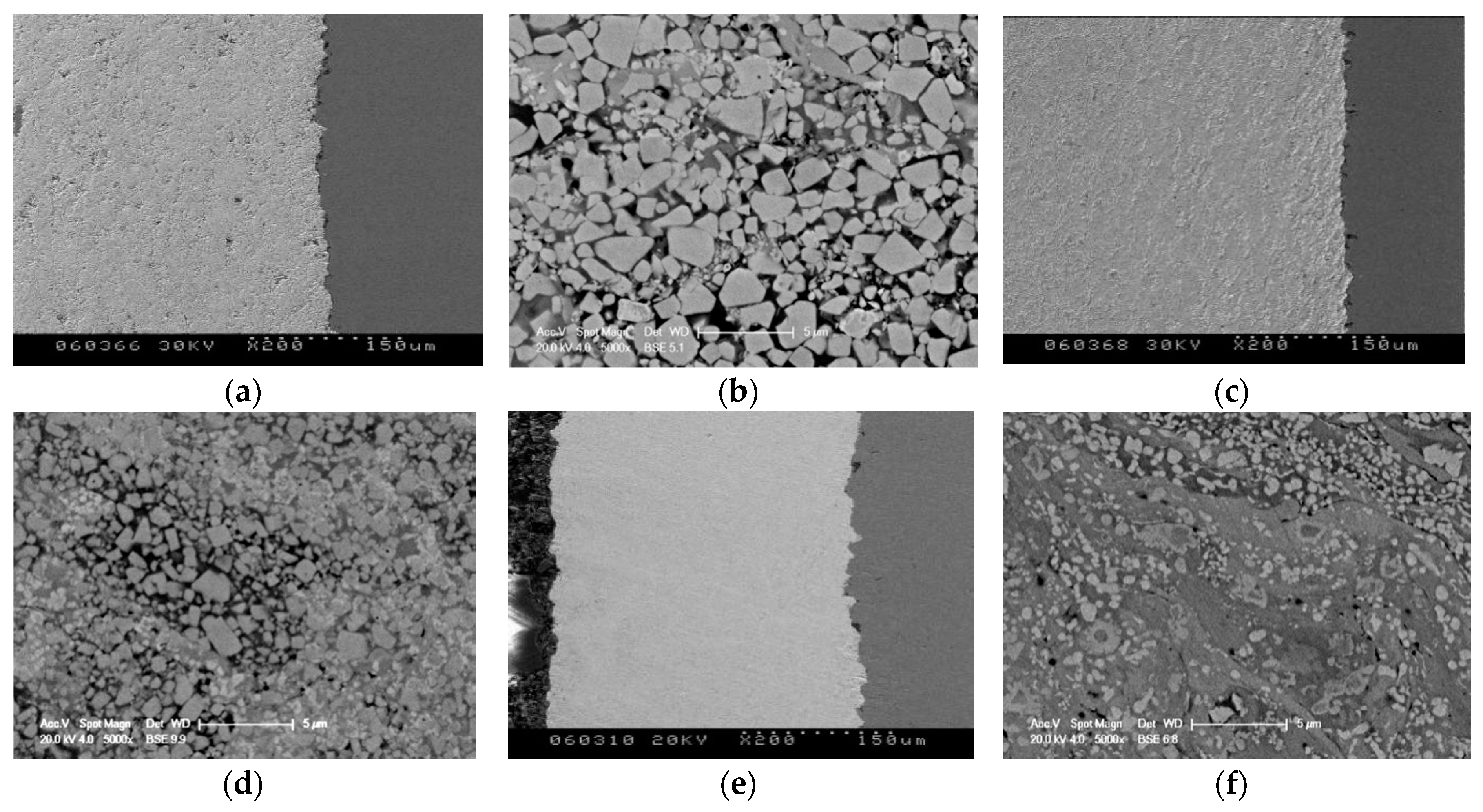

3.1. Microstructure of WC-12Co Powders and Coatings

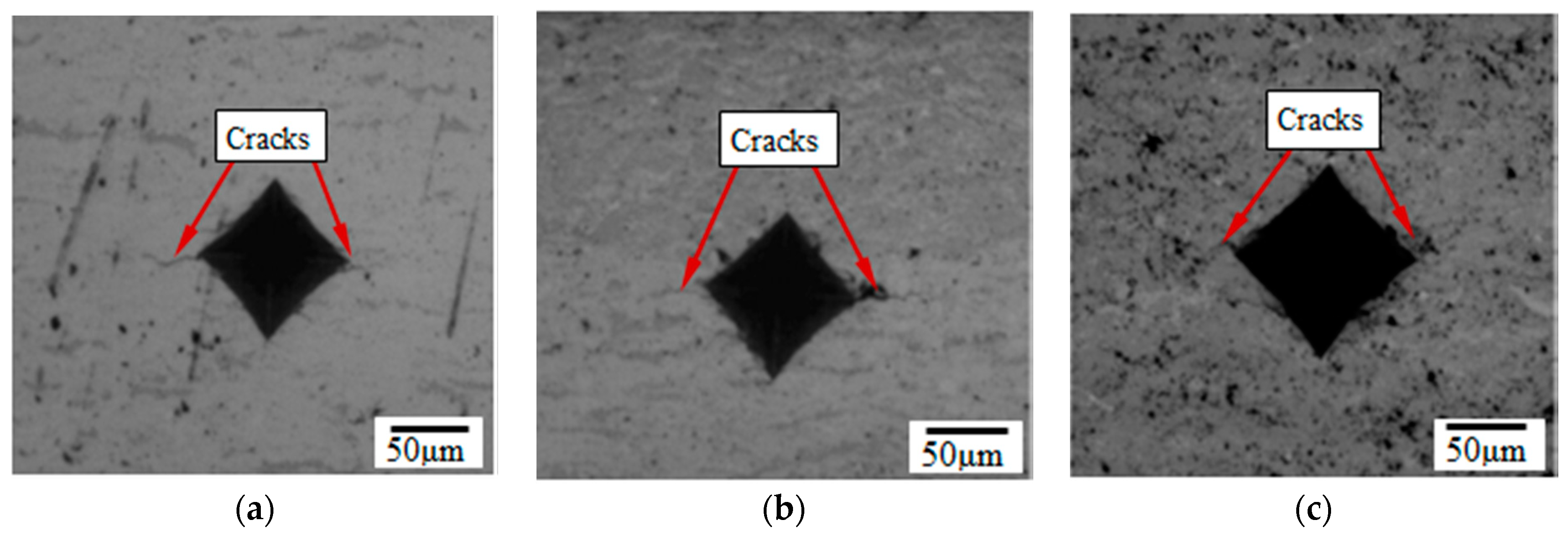

3.2. Mechanical Properties of WC-12Co Coatings

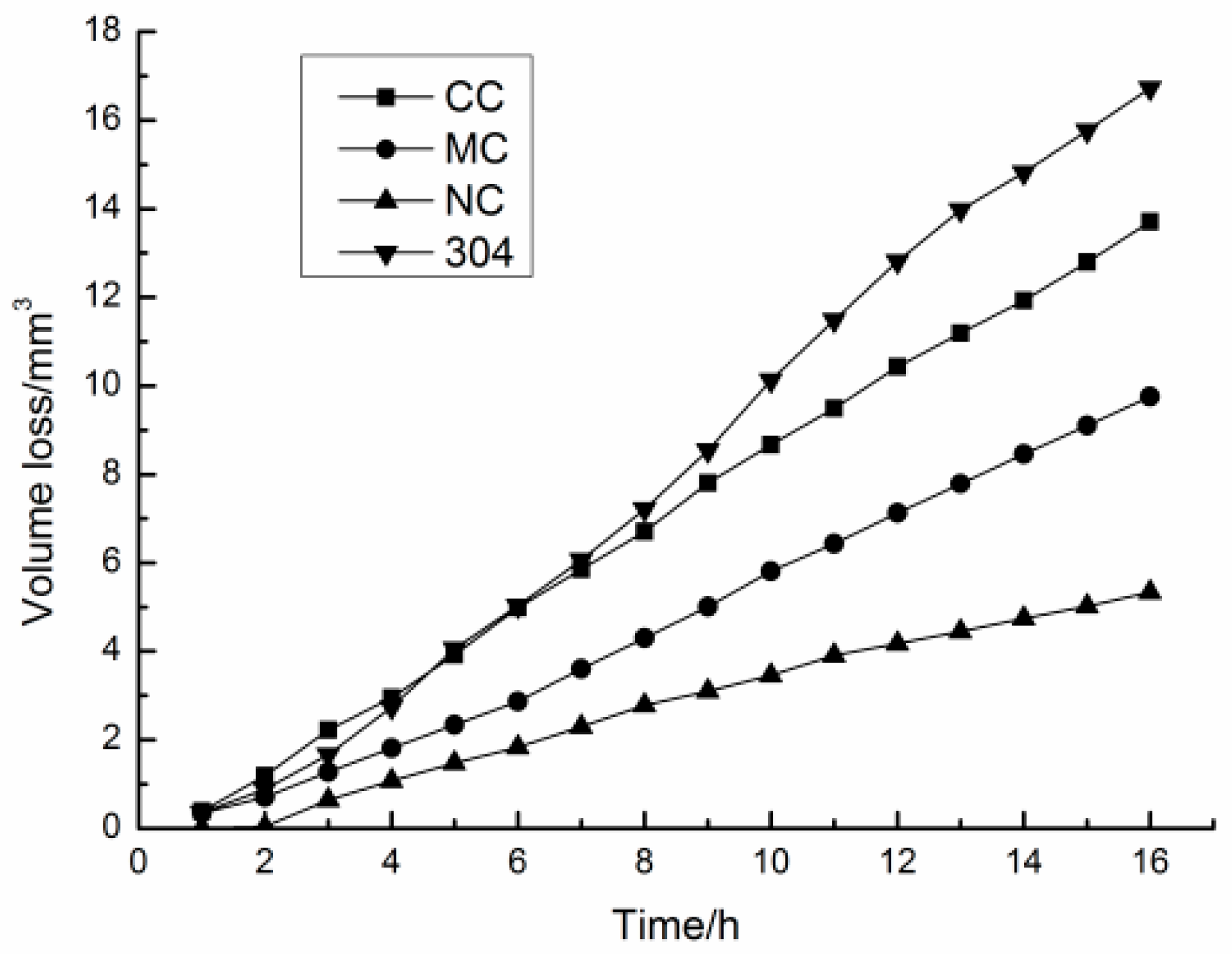

3.3. Cavitation Erosion Resistance

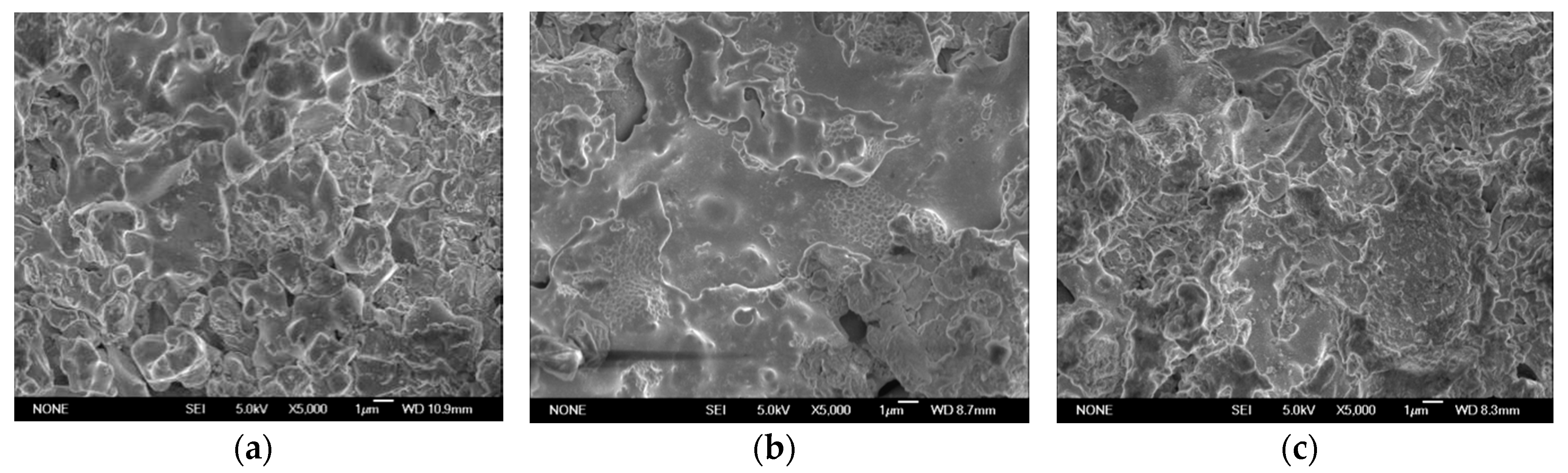

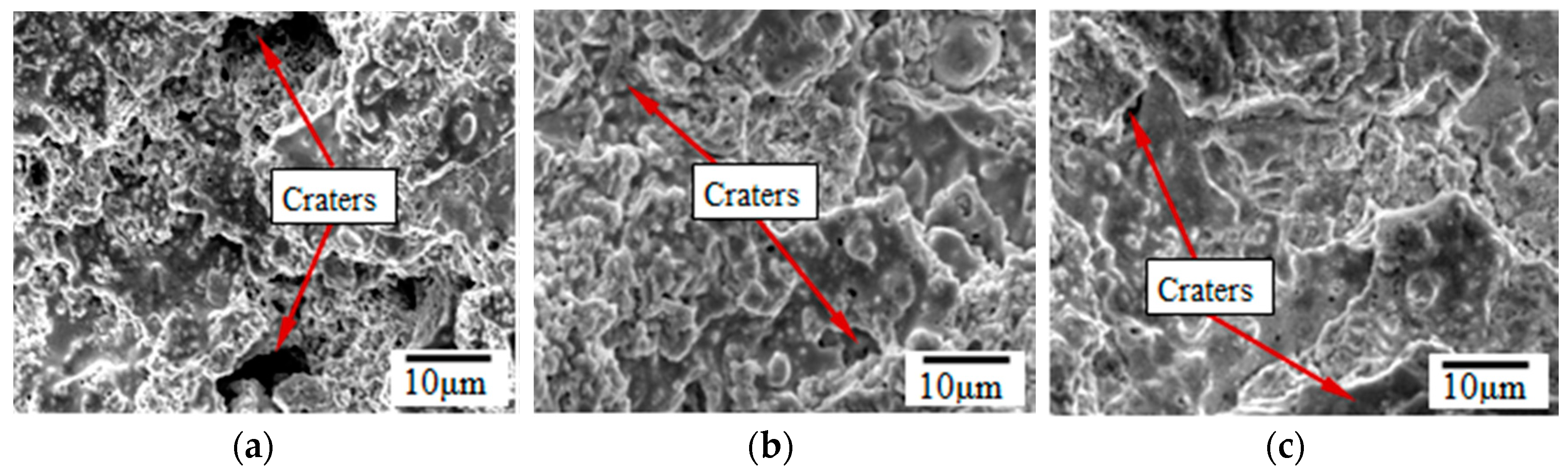

3.4. Cavitation Erosion Mechanisms

4. Conclusions

- WC decarburization occurs during HVOF spraying nanostructured and multimodal WC-12Co powders by forming W2C and W phases, while no apparent decarburization can be observed using conventional WC-12Co powder. Nanostructured WC-12Co coating suffers the most serious decarburization but possesses the lowest porosity.

- Average microhardness values of nanostructured and multimodal WC-12Co coatings exceed 1500 HV0.2, which is 50% higher than the conventional coating. Both coatings also show higher fracture toughness, especially the nanostructured coating.

- Nanostructured and multimodal WC-12Co coatings exhibit the best and intermediate CE resistance, respectively, and the CE rate of nanostructured coating is only approximately one third of that of conventional coating.

- The enhanced CE resistance of the nanostructured WC-12Co coating originates from its superb fracture toughness and microhardness, which makes the microcracks form and propagate with more difficulty. Meanwhile, the coatings dense nanostructure and strong cohesive strength are also factors for the excellent cavitation erosion performance.

Author Contributions

Funding

Conflicts of Interest

References

- Singh, R.; Tiwari, S.K.; Mishra, S.K. Cavitation erosion in hydraulic turbine components and mitigation by coatings: Current status and future needs. J. Mater. Eng. Perform. 2012, 21, 1539–1551. [Google Scholar] [CrossRef]

- Jasionowski, R.; Zasada, D.; Przetakiewicz, W. Cavitation erosion resistance of alloys used in cathodic protection of hulls of ships. Arch. Metall. Mater. 2014, 59, 241–245. [Google Scholar] [CrossRef]

- Kim, J.H.; Yang, H.S.; Baik, K.H.; Seong, B.G.; Lee, C.H.; Hwang, S.Y. Development and properties of nanostructured thermal spray coatings. Curr. Appl. Phys. 2006, 6, 1002–1006. [Google Scholar] [CrossRef]

- Kamdi, Z.; Shipway, P.H.; Voisey, K.T.; Sturgeon, A.J. Abrasive wear behavior of conventional and large-particle tungsten carbide-based cermet coatings as a function of abrasive size and type. Wear 2011, 271, 1264–1272. [Google Scholar] [CrossRef]

- Tillmann, W.; Baumann, I.; Hollingsworth, P.S.; Hagen, L. Sliding and rolling wear behavior of HVOF-sprayed coatings derived from conventional, fine and nanostructured WC-12Co powders. J. Therm. Spray Technol. 2014, 23, 262–280. [Google Scholar] [CrossRef]

- Krebs, S.; Grtner, F.; Klassen, T. Cold spraying of Cu-Al-Bronze for cavitation protection in marine environments. J. Therm. Spray Technol. 2015, 45, 708–716. [Google Scholar]

- Wang, Y.; Liu, J.; Kang, N.; Darut, G.; Poirier, T.; Stella, J.; Liao, H.; Planche, M.H. Cavitation erosion of plasma-sprayed CoMoCrSi coatings. Tribol. Int. 2016, 102, 429–435. [Google Scholar] [CrossRef]

- Ma, N.; Guo, L.; Cheng, Z.; Wu, H.; Ye, F.; Zhang, K. Improvement on mechanical properties and wear resistance of HVOF sprayed WC-12Co coatings by optimizing feedstock structure. Appl. Surf. Sci. 2014, 320, 364–371. [Google Scholar] [CrossRef]

- Guilemany, J.M.; Dosta, S.; Miguel, J.R. The enhancement of the properties of WC-Co HVOF coatings through the use of nanostructured and microstructured feedstock powders. Surf. Coat. Technol. 2006, 201, 1180–1190. [Google Scholar] [CrossRef]

- Lekatou, A.; Sioulas, D.; Karantzalis, A.E.; Grimanelis, D. A comparative study on the microstructure and surface property evaluation of coatings produced from nanostructured and conventional WC-Co powders HVOF-sprayed on Al7075. Surf. Coat. Technol. 2015, 276, 539–556. [Google Scholar] [CrossRef]

- Babua, P.S.; Basub, B.; Sundararajan, G. Abrasive wear behavior of detonation sprayed WC-12Co coatings: Influence of decarburization and abrasive characteristics. Wear 2010, 268, 1387–1399. [Google Scholar] [CrossRef]

- Cho, T.Y.; Yoon, J.H.; Kim, K.S.; Song, K.O.; Joo, Y.K.; Fang, W.; Zhang, S.H.; Youn, S.J.; Chun, H.G.; Hwang, S.Y. A study on HVOF coatings of micron and nano WC-Co powders. Surf. Coat. Technol. 2008, 202, 5556–5559. [Google Scholar] [CrossRef]

- Yang, Q.; Senda, T.; Ohmori, A. Effect of carbide grain size on microstructure and sliding wear behavior of HVOF-sprayed WC-12%Co coatings. Wear 2003, 254, 23–34. [Google Scholar] [CrossRef]

- He, J.; Lavernia, E.J.; Liu, Y.; Qiao, Y.; Fischer, T.E. Near-nanostructured WC-18 pct Co coatings with low amounts of non-WC carbide phase: Part I. synthesis and characterization. Metall. Mater. Trans. A 2002, 33, 145–157. [Google Scholar] [CrossRef]

- Ji, G.C.; Wang, H.T.; Chen, X.; Bai, X.B.; Dong, Z.X.; Yang, F.G. Characterization of cold-sprayed multimodal WC-12Co coating. Surf. Coat. Technol. 2013, 235, 536–543. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, Z.H.; Li, L.X.; Yang, G.B. The parameters optimization and abrasion wear mechanism of liquid fuel HVOF sprayed bimodal WC-12Co coating. Surf. Coat. Technol. 2012, 206, 2233–2241. [Google Scholar] [CrossRef]

- Ding, Z.X.; Chen, W.; Wang, Q. Resistance of cavitation erosion of multimodal WC-12Co coatings sprayed by HVOF. Trans. Nonferrous Met. Soc. China 2011, 21, 2231–2236. [Google Scholar] [CrossRef]

- Ding, X.; Cheng, X.D.; Shi, J.; Li, C.; Yuan, C.Q.; Ding, Z.X. Influence of WC size and HVOF process on erosion wear performance of WC-10Co4Cr coatings. Int. J. Adv. Manuf. Technol. 2018, 96, 1615–1624. [Google Scholar] [CrossRef]

- Hu, Y.M. Structure and Resistance of Cavitation Erosion Micro-Nano WC-Based Coatings Sprayed by HVOF. Master’s Thesis, Wuhan University of Technology, Wuhan, Hubei, China, 2015. (In Chinese). [Google Scholar]

- Ghabchi, A.; Varis, T.; Turunen, E.; Suhonen, T.; Liu, X.; Hannula, S.P. Behavior of HVOF WC-10Co4Cr coatings with different carbide size in fine and coarse particle abrasion. J. Therm. Spray Technol. 2010, 19, 368–377. [Google Scholar] [CrossRef]

- Wang, H.T.; Ji, G.C.; Chen, Q.Y.; Du, X.F.; Fu, W. Microstructure characterization and abrasive wear performance of HVOF sprayed WC-Co coatings. Adv. Mater. Res. 2011, 189–193, 707–710. [Google Scholar] [CrossRef]

- Hong, S.; Wu, Y.P.; Zhang, J.F.; Zheng, Y.G.; Zheng, Y.; Lin, J.R. Synergistic effect of ultrasonic cavitation erosion and corrosion of WC-CoCr and FeCrSiBMn coatings prepared by HVOF spraying. Ultrason. Sonochem. 2016, 31, 563–569. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Tang, Z.X.; Cha, L.M. Cavitation and sand slurry erosion resistances of WC-10Co-4Cr coatings. J. Mater. Eng. Perform. 2015, 24, 2435–2443. [Google Scholar] [CrossRef]

- Rodríguez, M.A.; Gil, L.; Camero, S.; Fréty, N.; Santana, Y.; Caro, J. Effects of the dispersion time on the microstructure and wear resistance of WC/Co-CNTs HVOF sprayed coatings. Surf. Coat. Technol. 2014, 258, 38–48. [Google Scholar] [CrossRef]

- Ding, X.; Cheng, X.D.; Li, C.; Yu, X.; Ding, Z.X.; Yuan, C.Q. Microstructure and performance of multi-dimensional WC-CoCr coating sprayed by HVOF. Int. J. Adv. Manuf. Technol. 2018, 96, 1625–1633. [Google Scholar] [CrossRef]

- Hong, S.; Wu, Y.P.; Zhang, J.F.; Zheng, Y.G.; Qin, Y.J.; Gao, W.W.; Li, G.Y. Cavitation erosion behavior and mechanism of HVOF sprayed WC-10Co-4Cr coating in 3.5 wt.% NaCl solution. Trans. Indian Inst. Met. 2015, 68, 151–159. [Google Scholar] [CrossRef]

- Zhao, X.Q.; Zhou, H.D.; Chen, J.M. Comparative study of the friction and wear behavior of plasma sprayed conventional and nanostructured WC-12%Co coatings on stainless steel. Mater. Sci. Eng. A 2006, 431, 290–297. [Google Scholar] [CrossRef]

- Wang, H.T.; Chen, X.; Bai, X.B.; Ji, G.C.; Dong, Z.X.; Yi, D.L. Microstructure and properties of cold sprayed multimodal WC-17Co deposits. Int. J. Refract. Met. Hard Mater. 2014, 45, 196–203. [Google Scholar] [CrossRef]

- Ding, X.; Cheng, X.D.; Yuan, C.Q.; Shi, J.; Ding, Z.X. Structure of micro-nano WC-10Co4Cr coating and cavitation erosion resistance in NaCl solution. Chin. J. Mech. Eng. Engl. Ed. 2017, 30, 1239–1247. [Google Scholar] [CrossRef]

- Ding, X.; Cheng, X.D.; Yu, X.; Li, C.; Yuan, C.Q.; Ding, Z.X. Structure and cavitation erosion behavior of HVOF sprayed multi-dimensional WC-10Co4Cr coating. Trans. Nonferrous Met. Soc. China 2018, 28, 487–494. [Google Scholar] [CrossRef]

- Al-Mutairi, S.; Hashmi, M.S.J.; Yilbas, B.S.; Stokes, J. Microstructural characterization of HVOF/plasma thermal spray of micro/nano WC-12%Co powders. Surf. Coat. Technol. 2015, 264, 175–186. [Google Scholar] [CrossRef]

- Sahraoui, T.; Guessasma, S.; Jeridane, M.L.; Hadji, M. HVOF sprayed WC-Co coatings: Microstructure, mechanical properties and friction moment prediction. Mater. Des. 2010, 31, 1431–1437. [Google Scholar] [CrossRef]

- GB/T 6383-2009 The Method of Vibration Cavitation Erosion Test; Standards Administration of China: Beijing, China, 2009.

| Powder No. | Coating No. | Fuel Flow (m3/h) | Oxygen Flow (m3/h) | Powder Feed Rate (g/min) | Spray Distance (mm) | Horizontal Velocity (mm/s) | Vertical Step (mm) |

|---|---|---|---|---|---|---|---|

| NP | NC | 0.019 | 53.2 | 75 | 370 | 500 | 5 |

| MP | MC | 0.019 | 53.2 | 75 | 370 | 500 | 5 |

| CP | CC | 0.0204 | 61.3 | 75 | 380 | 500 | 5 |

| Coating No. | Microhardness (HV0.2) | Fracture Toughness (MPa·m1/2) |

|---|---|---|

| CC | 1034 ± 77.5 | 3.76 ± 0.38 |

| MC | 1523 ± 157.0 | 4.19 ± 0.65 |

| NC | 1541 ± 80.0 | 4.88 ± 0.47 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, X.; Ke, D.; Yuan, C.; Ding, Z.; Cheng, X. Microstructure and Cavitation Erosion Resistance of HVOF Deposited WC-Co Coatings with Different Sized WC. Coatings 2018, 8, 307. https://doi.org/10.3390/coatings8090307

Ding X, Ke D, Yuan C, Ding Z, Cheng X. Microstructure and Cavitation Erosion Resistance of HVOF Deposited WC-Co Coatings with Different Sized WC. Coatings. 2018; 8(9):307. https://doi.org/10.3390/coatings8090307

Chicago/Turabian StyleDing, Xiang, Du Ke, Chengqing Yuan, Zhangxiong Ding, and Xudong Cheng. 2018. "Microstructure and Cavitation Erosion Resistance of HVOF Deposited WC-Co Coatings with Different Sized WC" Coatings 8, no. 9: 307. https://doi.org/10.3390/coatings8090307