Improvement of Aluminium Film Adhesion on PMMA Using Pre-Layer and Specific Annealing

Abstract

:1. Introduction

2. Theory

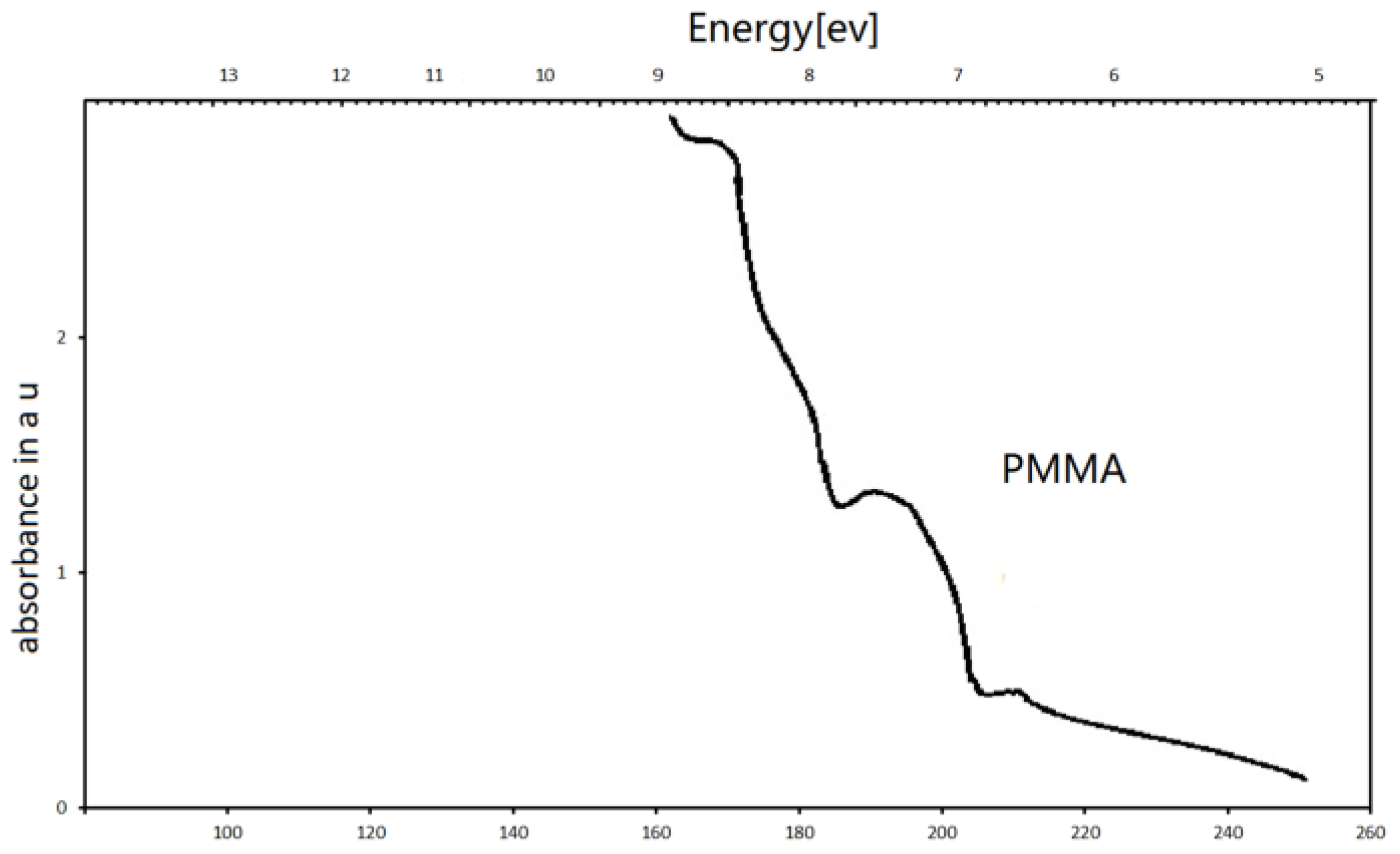

2.1. Photon Induced Damage of PMMA

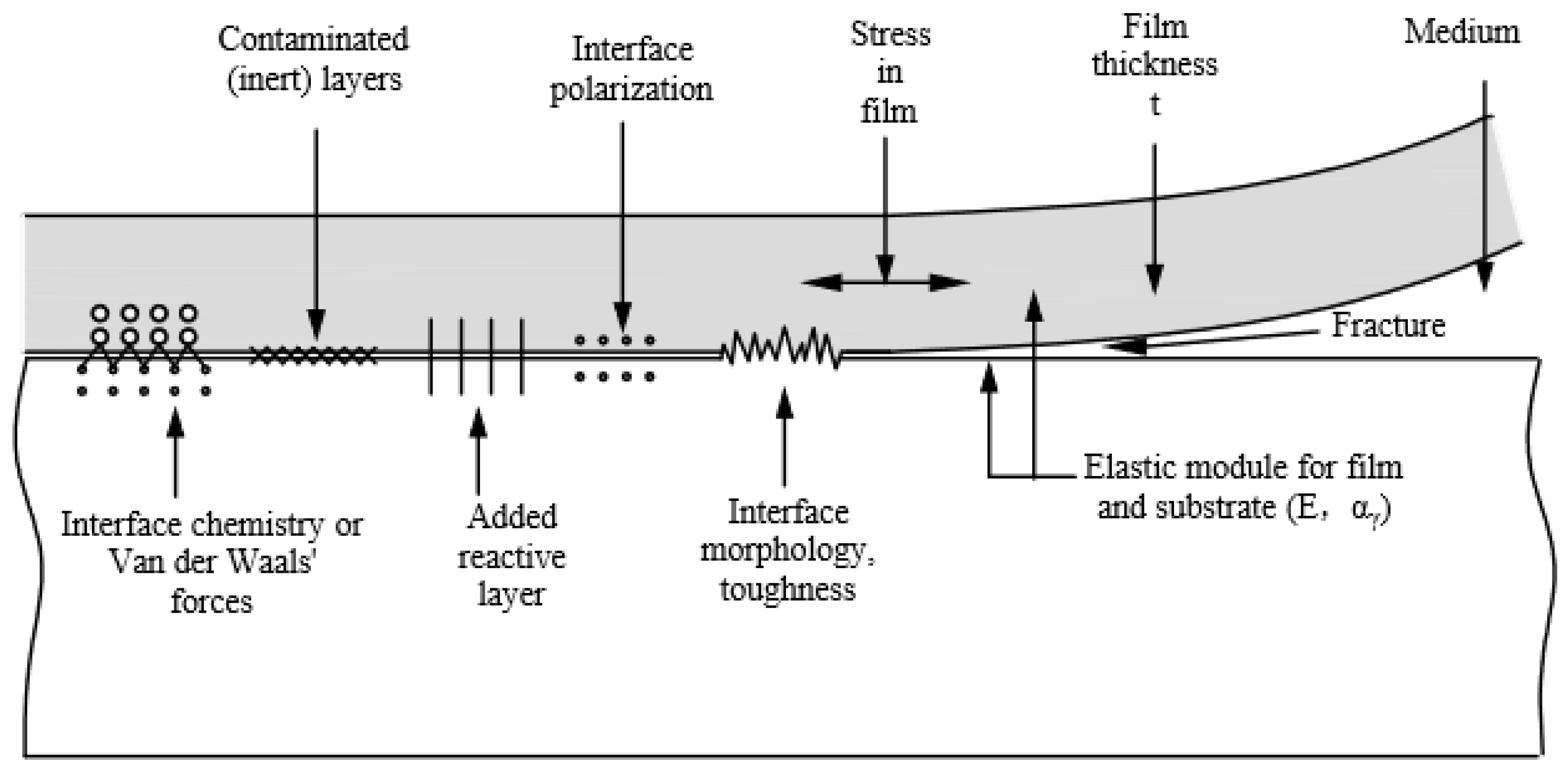

2.2. Mechanism of Thin Film Adhesion

2.3. Photon Radiation and Weak Boundary Layer Theory

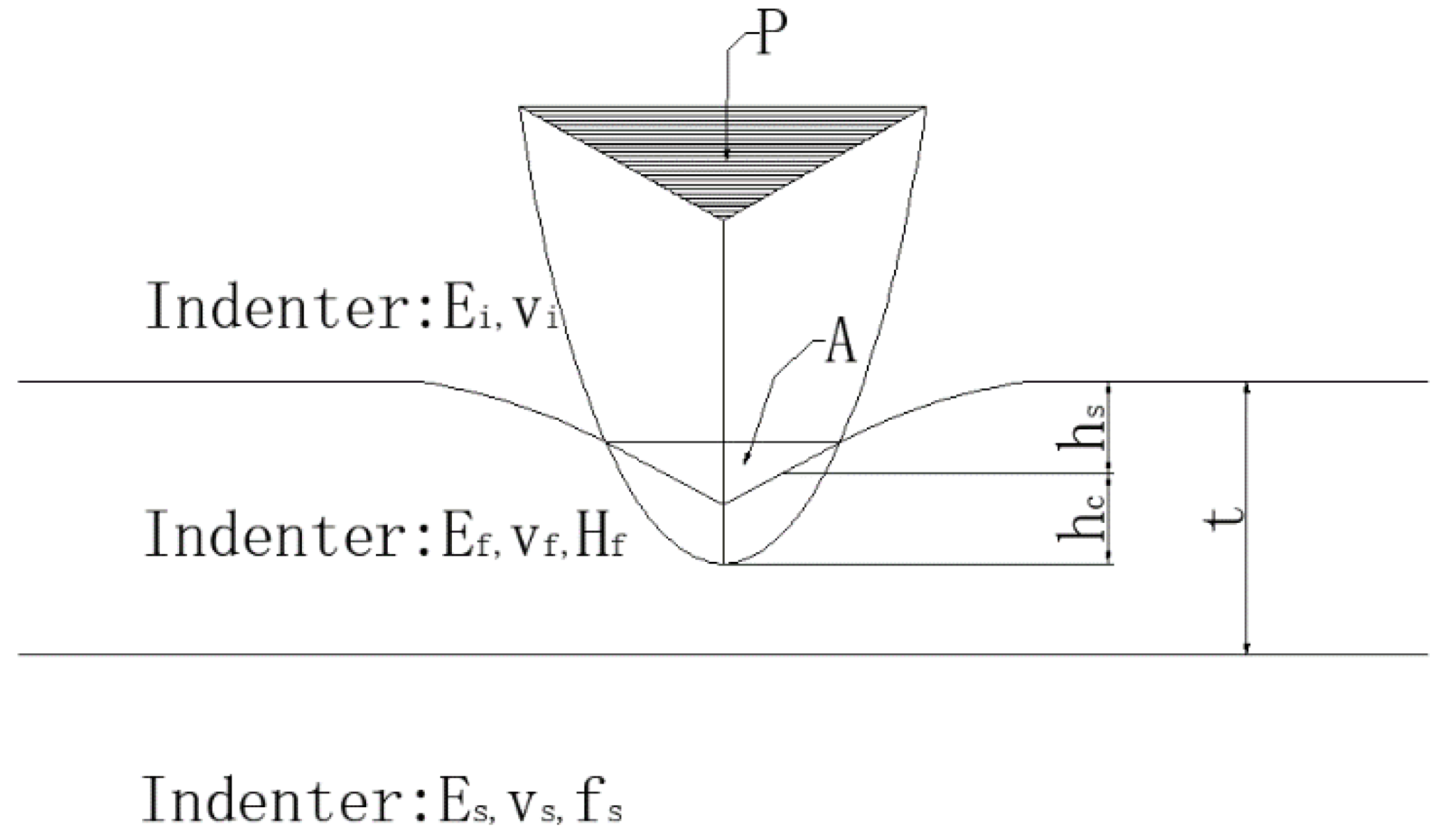

2.4. Hardness, Indentation Test

3. Experimental Procedures

4. Results and Discussion

4.1. Water Contact Angle Test of PMMA Surface

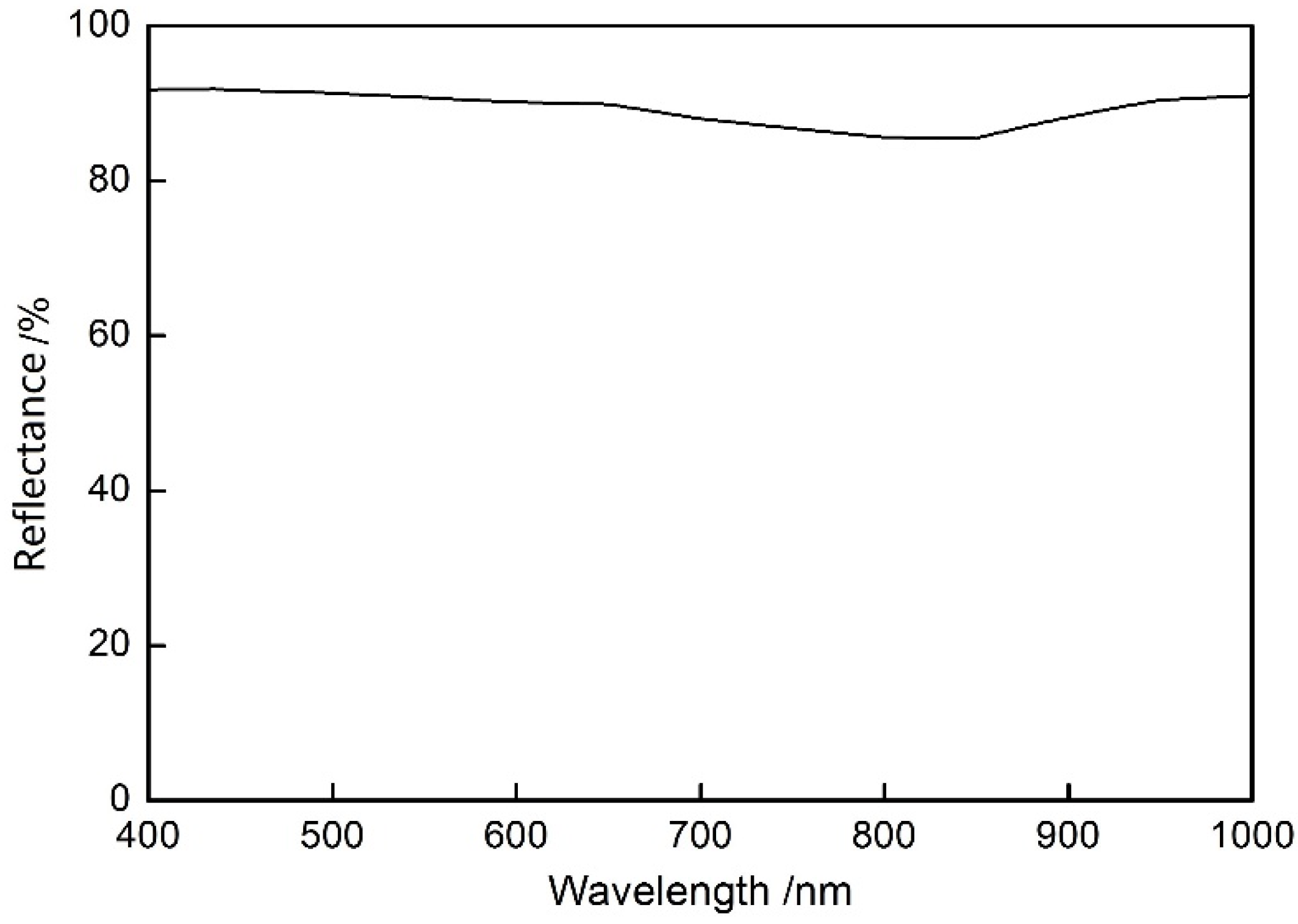

4.2. Spectral Analysis

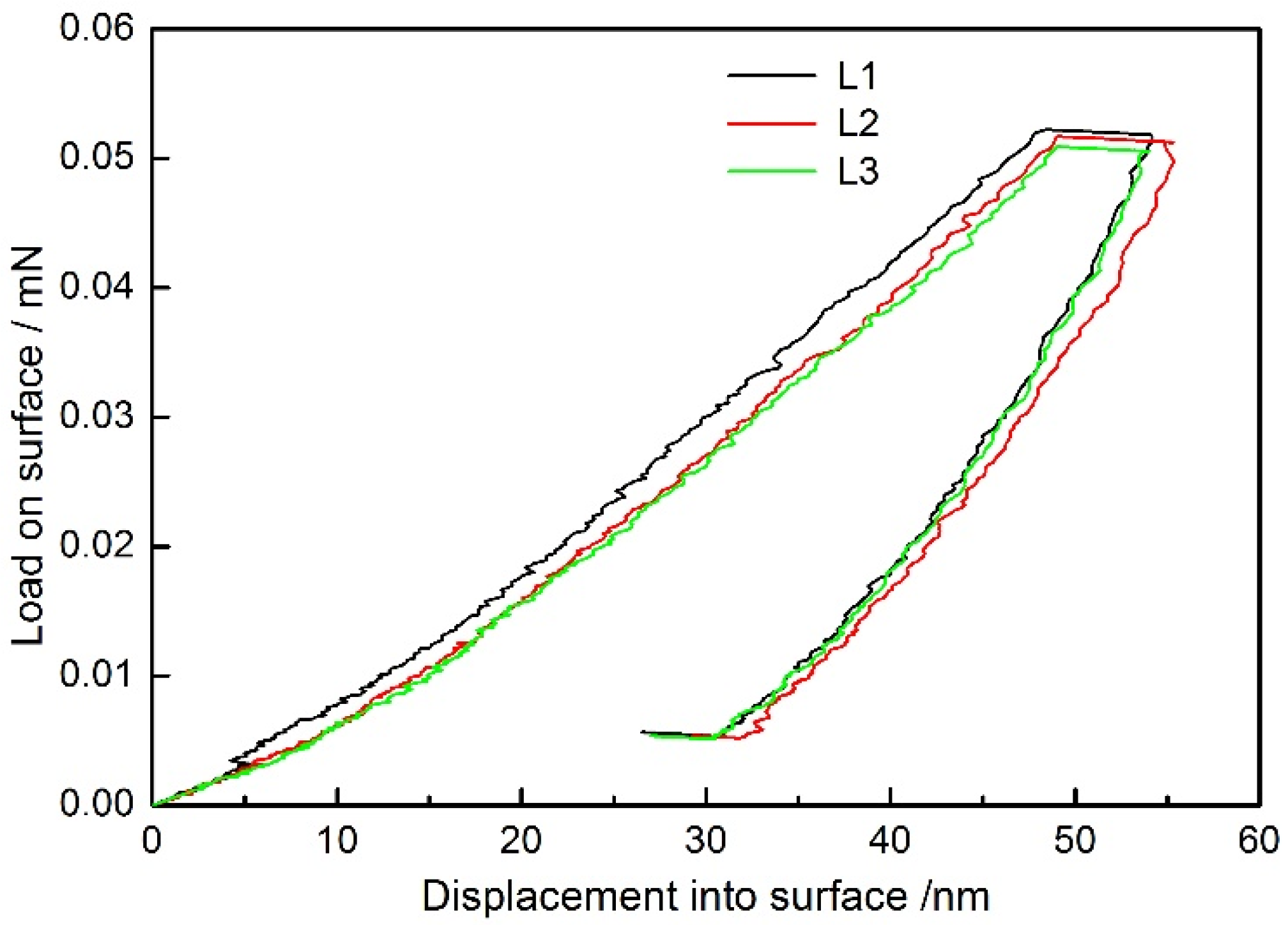

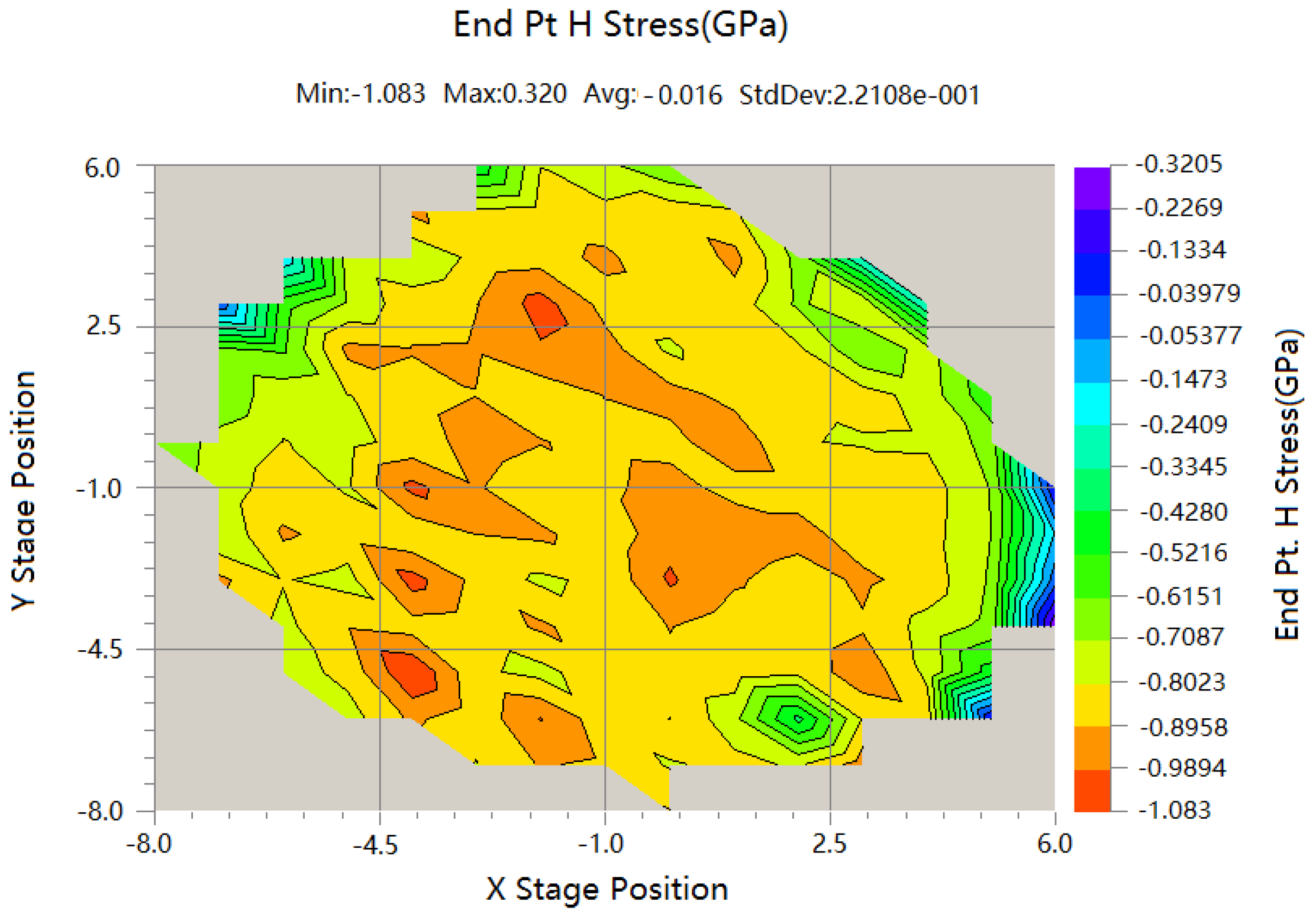

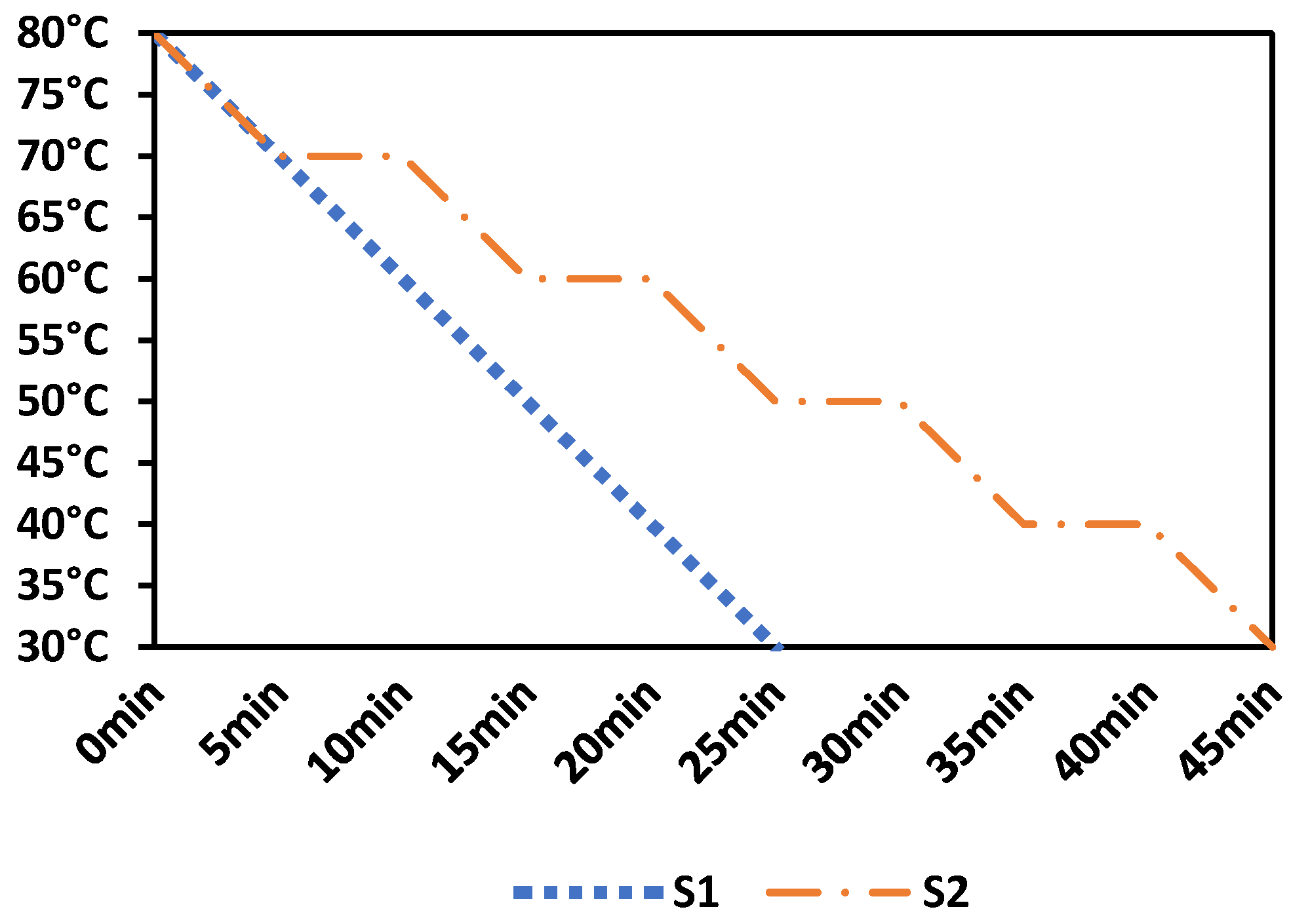

4.3. Elastic Modulus and Hardness Test

4.4. Adhesion Test

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Baldini, F.; Carloni, A. Optical PMMA chip suitable for multianalyte detection. IEEE Sens. J. 2008, 8, 1305–1309. [Google Scholar] [CrossRef]

- Tambe, N.S.; Bhushan, B. Micro/nanotribological characterization of PDMS and PMMA used for BioMEMS/NEMS applications. Ultramicroscopy 2005, 105, 238–247. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, R.; Liu, X.; Liang, Y.; Zhang, X.; Zhu, M. Fabrication of PMMA superhydrophobic surface coating by hot embossing/spray method. J. Tianjin Univ. 2015, 12, 1071–1076. (In Chinese) [Google Scholar] [CrossRef]

- Hegemann, D.; Brunner, H.; Oehr, C. Plasma treatment of polymers for surface and adhesion improvement. Nucl. Inst. Methods Phys. Res. B 2003, 208, 281–286. [Google Scholar] [CrossRef]

- Laurens, P.; Petit, S.; Arefi-Khonsari, F. Study of PET surfaces after laser or plasma treatment: surface modifications and adhesion properties towards Al deposition. Plasmas Polym. 2003, 8, 281–295. [Google Scholar] [CrossRef]

- Wang, L. Study on the Adhesion Strength of Metal Films on PMMA Substrate by UV Surface Treatment; Dalian University of Technology: Dalian, China, 2015. [Google Scholar]

- Mitsubishi Rayon Acrypet®. Available online: http://www.matweb.com/search/QuickText.aspx?SearchText=7.%09MitsubishiRayon%20Acrypet (accessed on 14 May 2018).

- Jaboski, A. Efficiency of anti-stokes fluorescence in dyes. Nature 1933, 131, 839–840. [Google Scholar] [CrossRef]

- Scaiano, J.C.; Stamplecoskie, K.G.; Hallett-Tapley, G.L. Photochemical norrish type I reaction as a tool for metal nanoparticle synthesis: importance of proton coupled electron transfer. Chem. Commun. 2012, 48, 4798–4808. [Google Scholar] [CrossRef] [PubMed]

- Cui, G.; Sun, Z.; Fang, W. Adiabatic and nonadiabatic bond cleavages in Norrish type I reaction. J. Phys. Chem. A 2011, 115, 10146–10153. [Google Scholar] [CrossRef] [PubMed]

- Dekhtyar, Y.; Griva, A.; Lancere, L.; Andersons, B.; Sansonetti, E. Wettability of the PMMA surface caused by its polarization due to UV radiation. In Proceedings of the Applications of Ferroelectrics Held Jointly with 2012 European Conference on the Applications of Polar Dielectrics and 2012 International Symp Piezoresponse Force Microscopy and Nanoscale Phenomena in Polar Materials (ISAF/ECAPD/PFM), Aveiro, Portugal, 9–13 July 2012; pp. 1–3. [Google Scholar] [CrossRef]

- Strobel, M.; Corn, S.; Lyons, C.S.; Korba, G.A. Plasma fluorination of polyolefins. J. Polym. Sci. Part A Polym. Chem. 1987, 25, 539–545. [Google Scholar] [CrossRef]

- Bikerman, J.J. Cause of poor adhesion boundary. Ind. Eng. Chem. 1967, 59, 40–44. [Google Scholar] [CrossRef]

- Volinsky, A.A.; Tymiak, N.I.; Kriese, M.D.; Hutchinson, J.W. Quantitative modelling and measurement of copper thin film adhesion. Mater. Res. Soc. Symp. Proc. 1998, 539, 277–290. [Google Scholar] [CrossRef]

- Furuuchi, S.; Sakata, H.; Aikawa, K. Microhardness of silica films prepared by resistance heating and electron beam evaporation. Jpn. J. Appl. Phys. 1974, 13, 1905–1906. [Google Scholar] [CrossRef]

- Al-Kuhaili, M. Electron Beam Evaporation. Encyclopedia Nanotechnol. 2012, 37, 718. [Google Scholar] [CrossRef]

- Arsenyev, S.A.; Koryagin, S.A. Electromagnetic radiation from positive-energy bound electrons in the Coulomb field of a nucleus at rest in a strong uniform magnetic field. J. Exp. Theor. Phys. 2012, 114, 913–922. [Google Scholar] [CrossRef]

- Kamińska, A.; Kaczmarek, H.; Kowalonek, J. The influence of side groups and polarity of polymers on the kind and effectiveness of their surface modification by air plasma action. Eur. Polym. J. 2002, 38, 1915–1919. [Google Scholar] [CrossRef]

- Bikerman, J.J. The fundamentals of tackiness and adhesion. J. Colloid Sci. 1947, 2, 163–175. [Google Scholar] [CrossRef]

- Li, H.; Vlassak, J.J. Determining the elastic modulus and hardness of an ultra-thin film on a substrate using nanoindentation. J. Mater. Res. 2009, 24, 1114–1126. [Google Scholar] [CrossRef]

- Aouachria, K.; Belhaneche-Bensemra, N. Miscibility of PVC/PMMA blends by vicat softening temperature, viscometry, DSC and FTIR analysis. Polym. Test. 2006, 25, 1101–1108. [Google Scholar] [CrossRef]

- Misra, A.; Nastasi, M. Evolution of tensile residual stress in thin metal films during energetic particle deposition. J. Mater. Res. 1999, 14, 4466–4469. [Google Scholar] [CrossRef]

- Baker, S.P.; Saha, K.; Shu, J.B. Effect of thickness and Ti interlayers on stresses and texture transformations in thin Ag films during thermal cycling. Appl. Phys. Lett. 2013, 103, 191905. [Google Scholar] [CrossRef]

| The Order of Layer | Thickness (nm) | The Way of Evaporation | Vacuum Degree (Pa) | Substrate Temperature (°C) | Deposition Rate (nm/s) | IAD Situation |

|---|---|---|---|---|---|---|

| The first layer | 20 | Resistant Heating | 1.0 × 10−3 | 80 | 1 | Without |

| The second layer | 80 | Electron-beam | 1.0 × 10−3 | 80 | 1.5 | With |

| Parameters | Value |

|---|---|

| Argon flow/sccm | 15 |

| Plate voltage/V | 415 |

| Acceleration/V | 275 |

| Anode voltage/V | 50 |

| Neutralizing current/A | 13.5 |

| Cathodic current/A | 16 |

| Ion beam current/mA | 50 |

| Test | Modulus (GPa) | Drift Coefficient (nm/S) | Load (mN) | Hardness (MPa) |

|---|---|---|---|---|

| 1 | 5.962 | 0.076 | 0.047 | 0.362 |

| 2 | 5.998 | 0.046 | 0.055 | 0.302 |

| 3 | 5.348 | 0.053 | 0.05 | 0.308 |

| Mean | 5.76 | 0.175 | 0.05 | 0.324 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, X.; Zhang, G.; Zhang, J.; Guo, K.; Pan, Y. Improvement of Aluminium Film Adhesion on PMMA Using Pre-Layer and Specific Annealing. Coatings 2018, 8, 186. https://doi.org/10.3390/coatings8050186

Fu X, Zhang G, Zhang J, Guo K, Pan Y. Improvement of Aluminium Film Adhesion on PMMA Using Pre-Layer and Specific Annealing. Coatings. 2018; 8(5):186. https://doi.org/10.3390/coatings8050186

Chicago/Turabian StyleFu, Xiuhua, Gong Zhang, Jing Zhang, Kai Guo, and Yonggang Pan. 2018. "Improvement of Aluminium Film Adhesion on PMMA Using Pre-Layer and Specific Annealing" Coatings 8, no. 5: 186. https://doi.org/10.3390/coatings8050186