Corrosion Resistance of Pipeline Steel with Damaged Enamel Coating and Cathodic Protection

Abstract

:1. Introduction

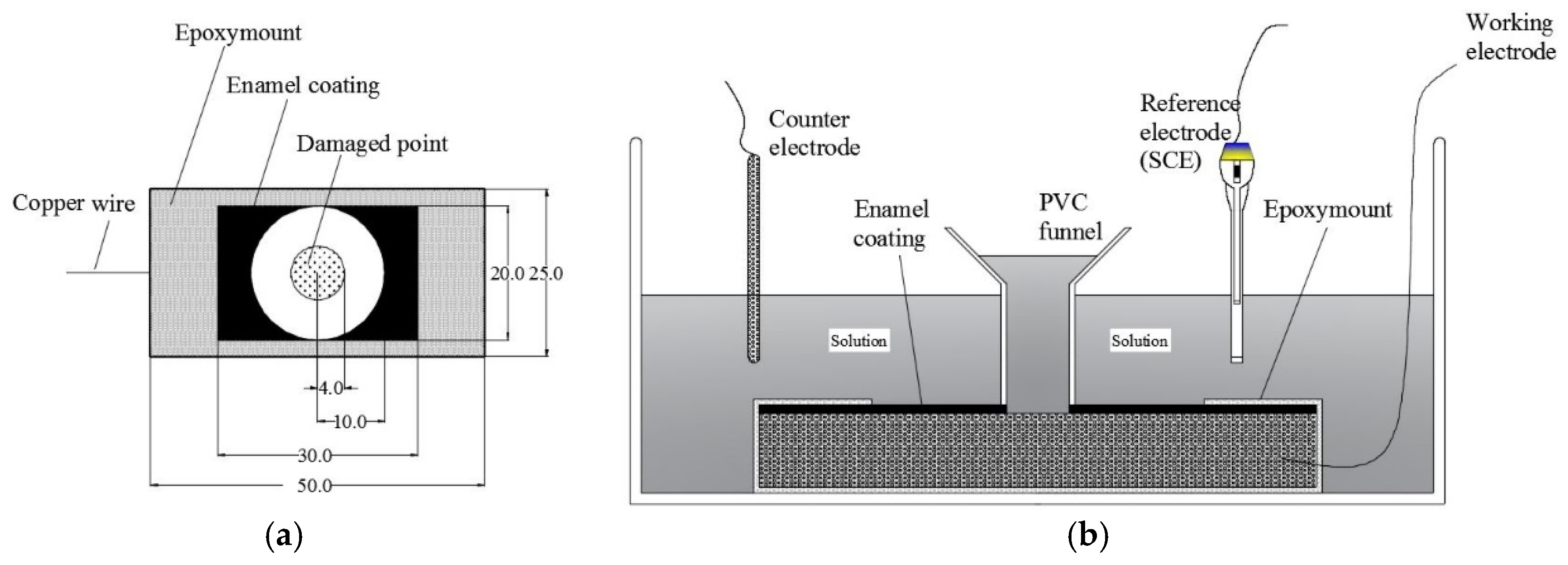

2. Materials and Methods

2.1. Sample Preparation

2.2. Characterization of Enamel Coatings

2.3. Electrochemical Tests

3. Results and Discussion

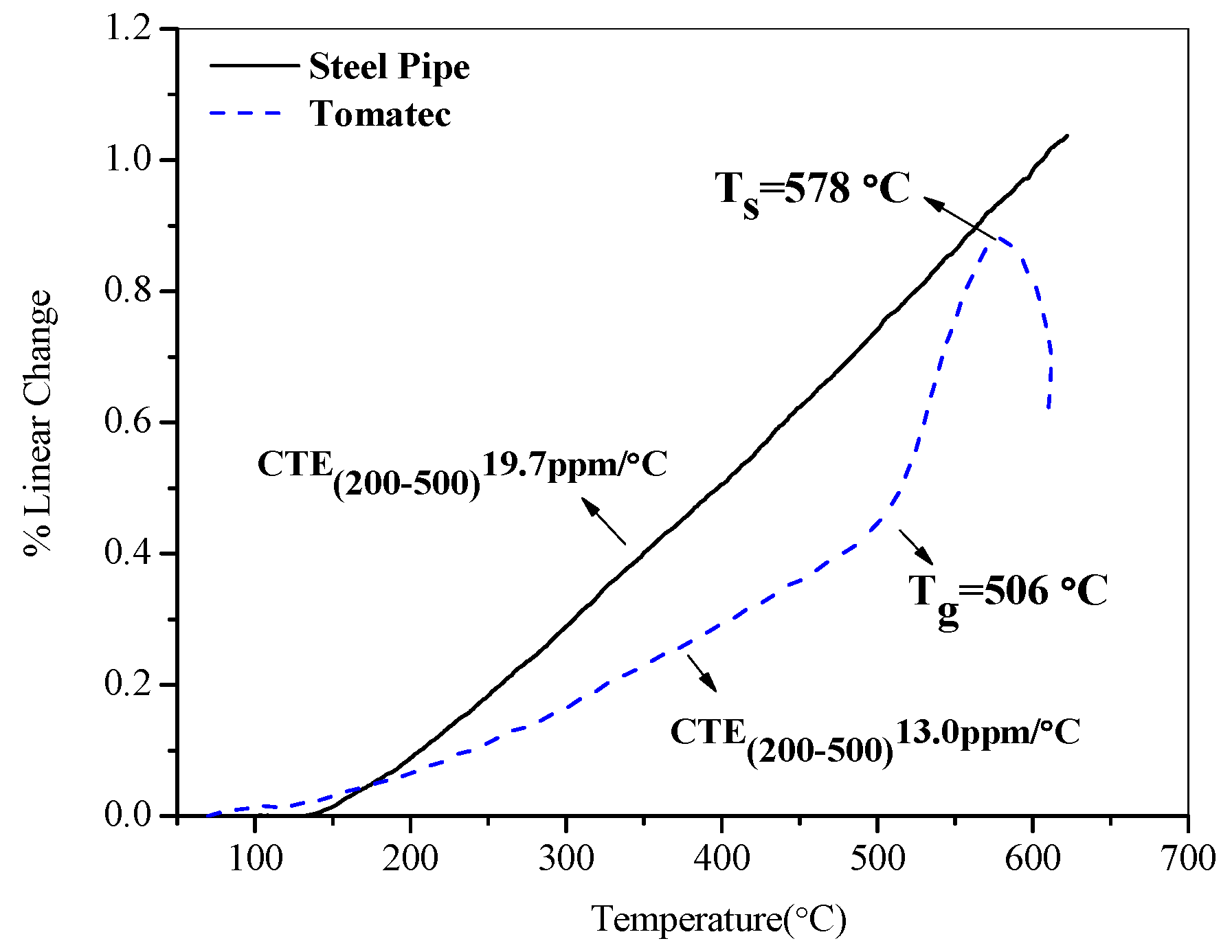

3.1. Thermal Properties

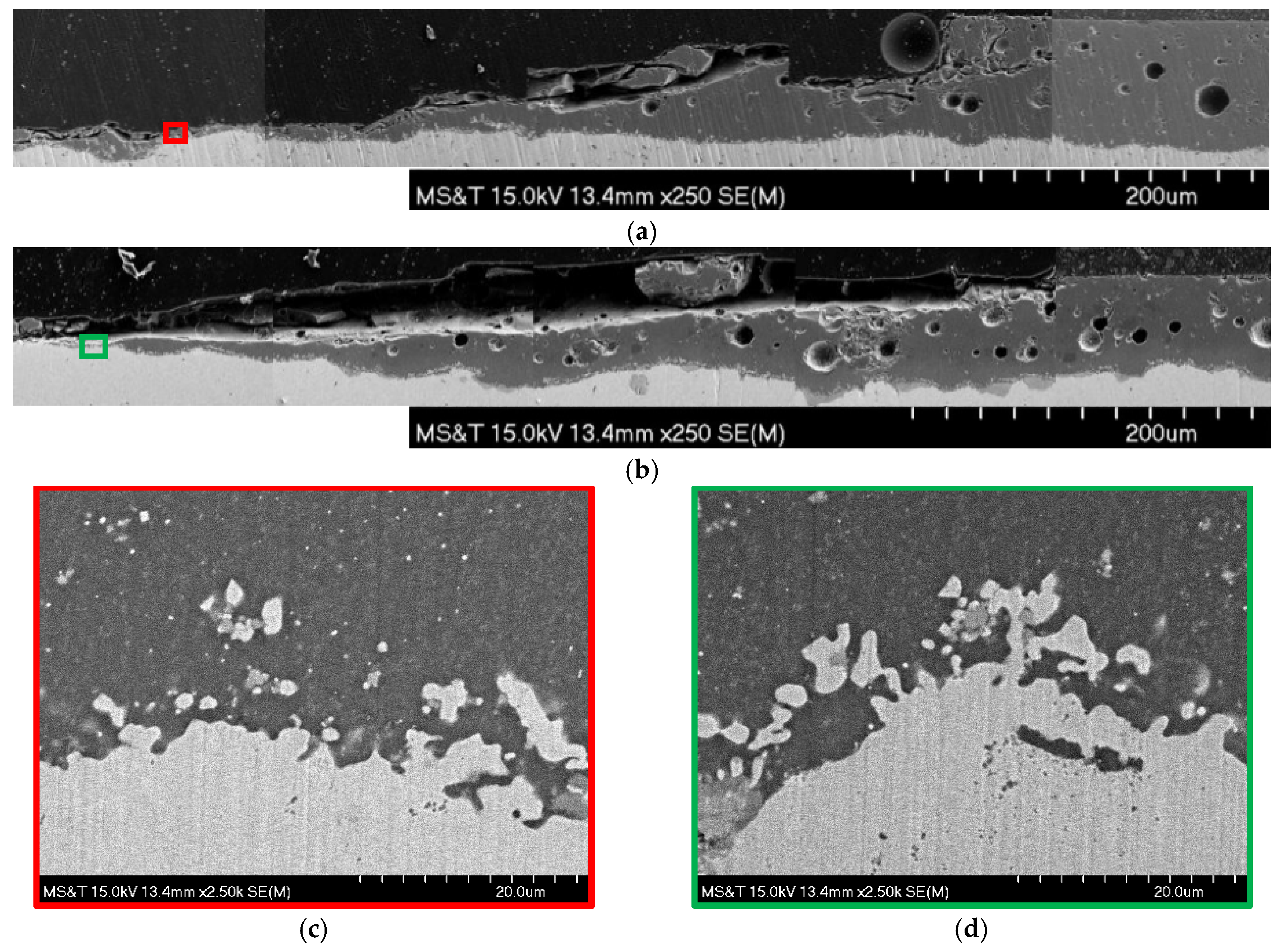

3.2. Coating Microstructure

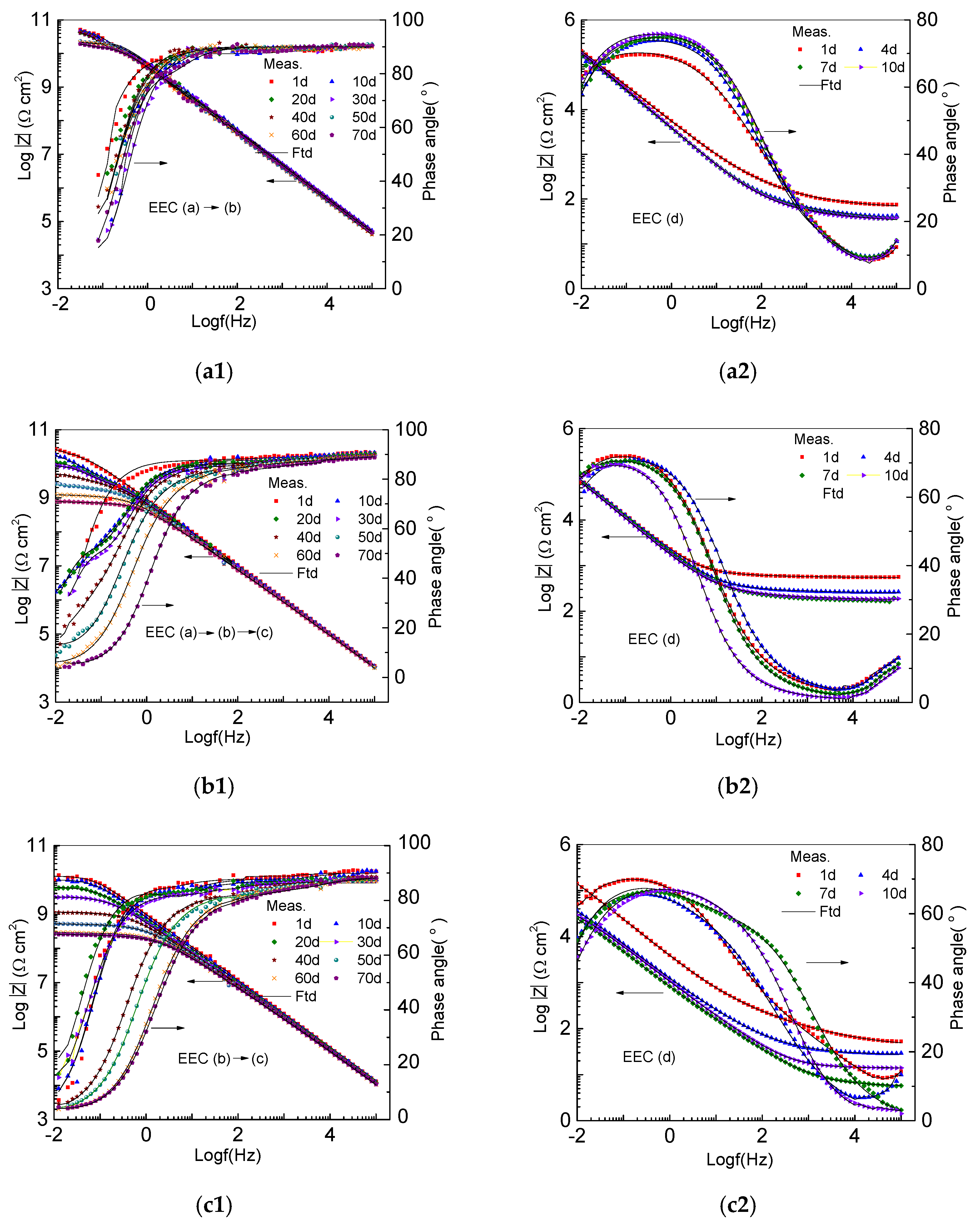

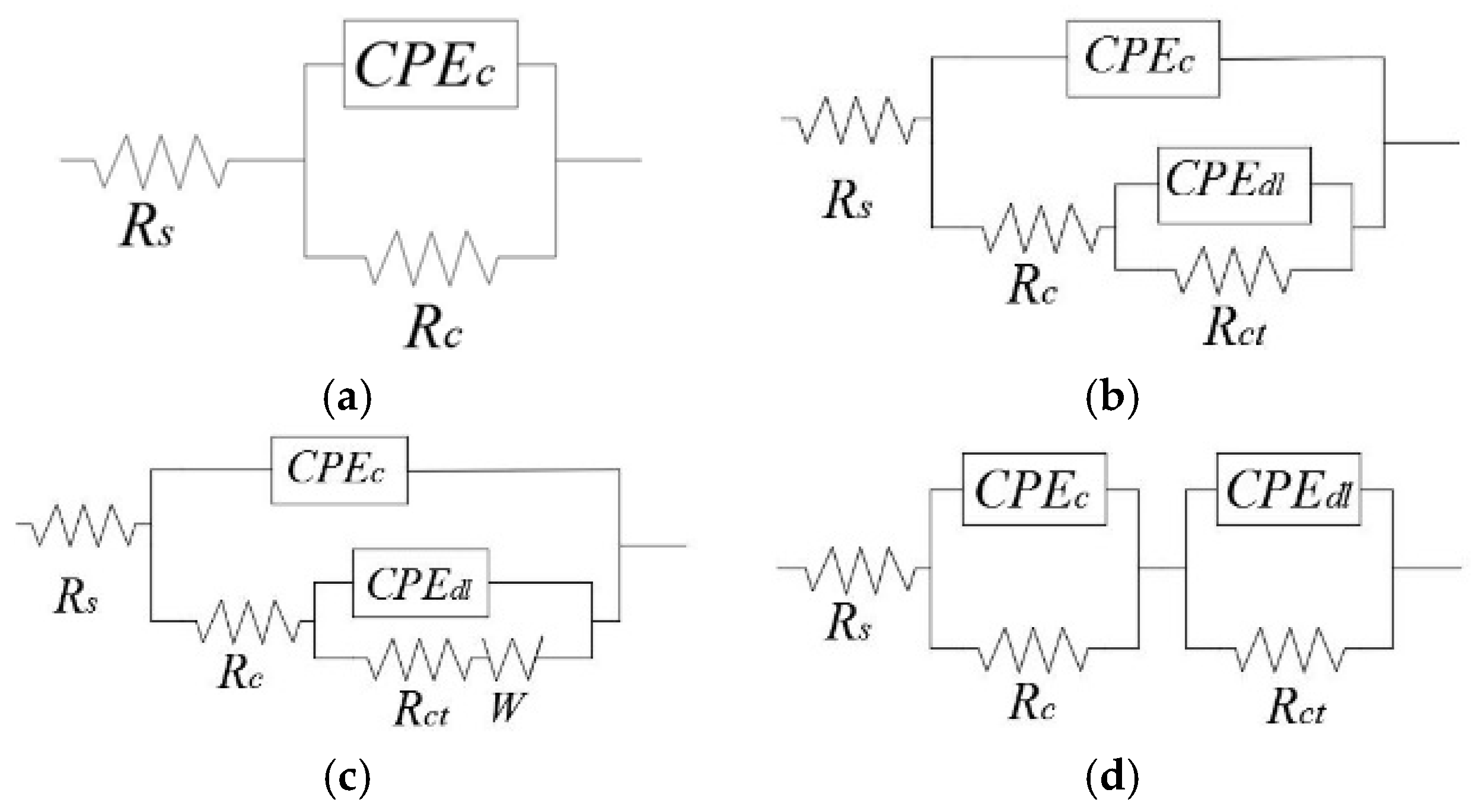

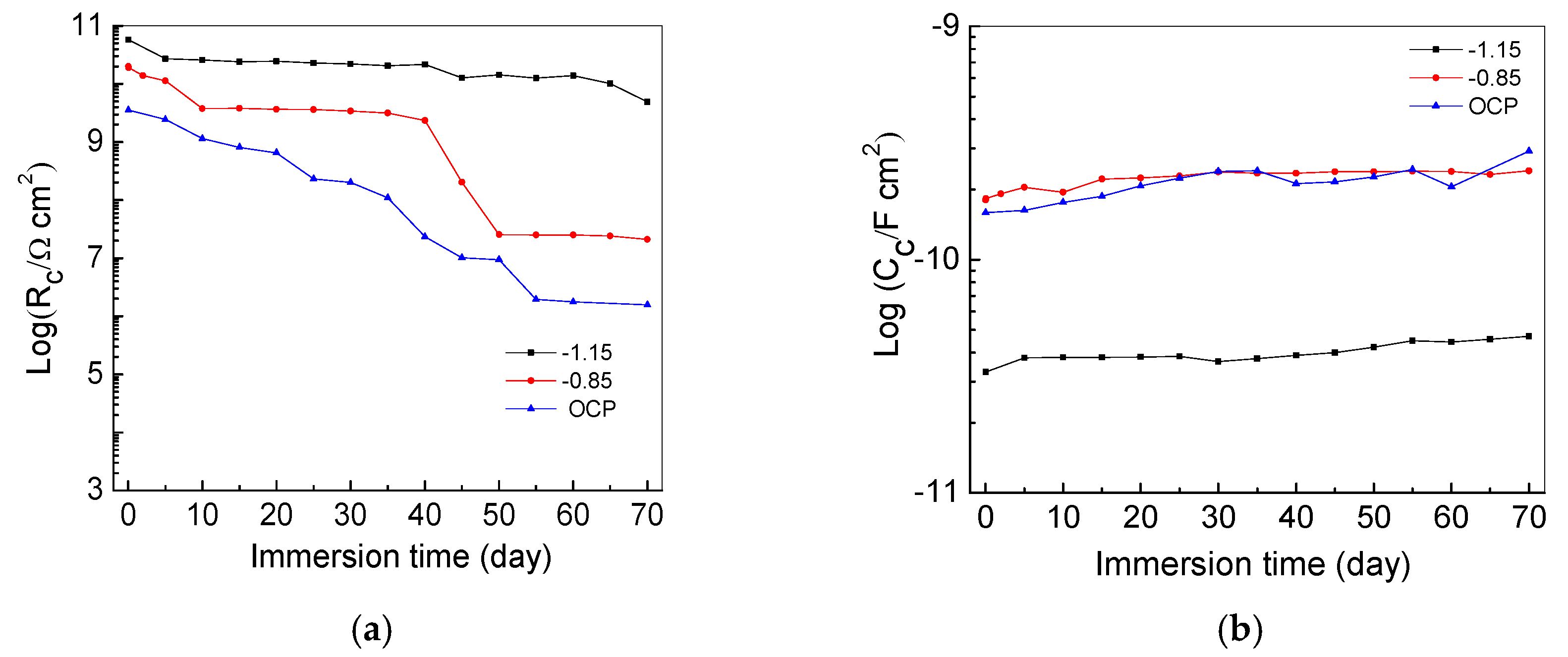

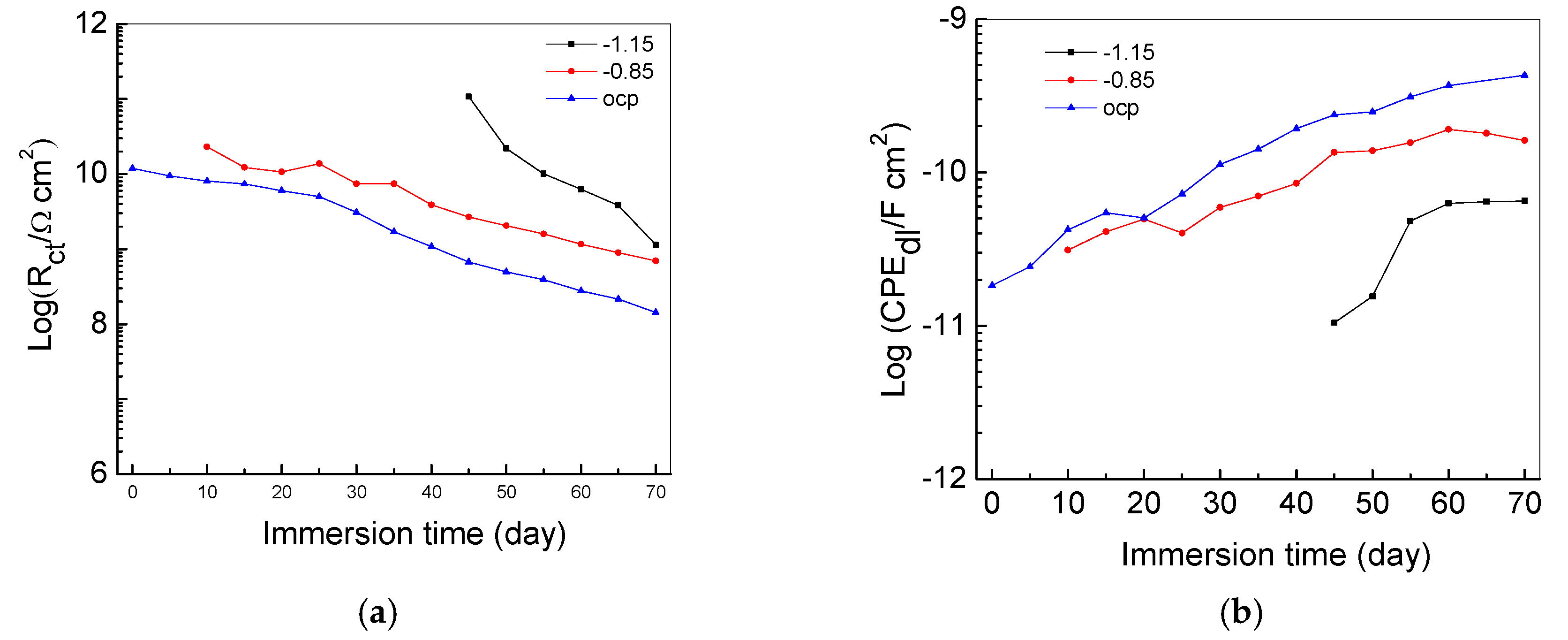

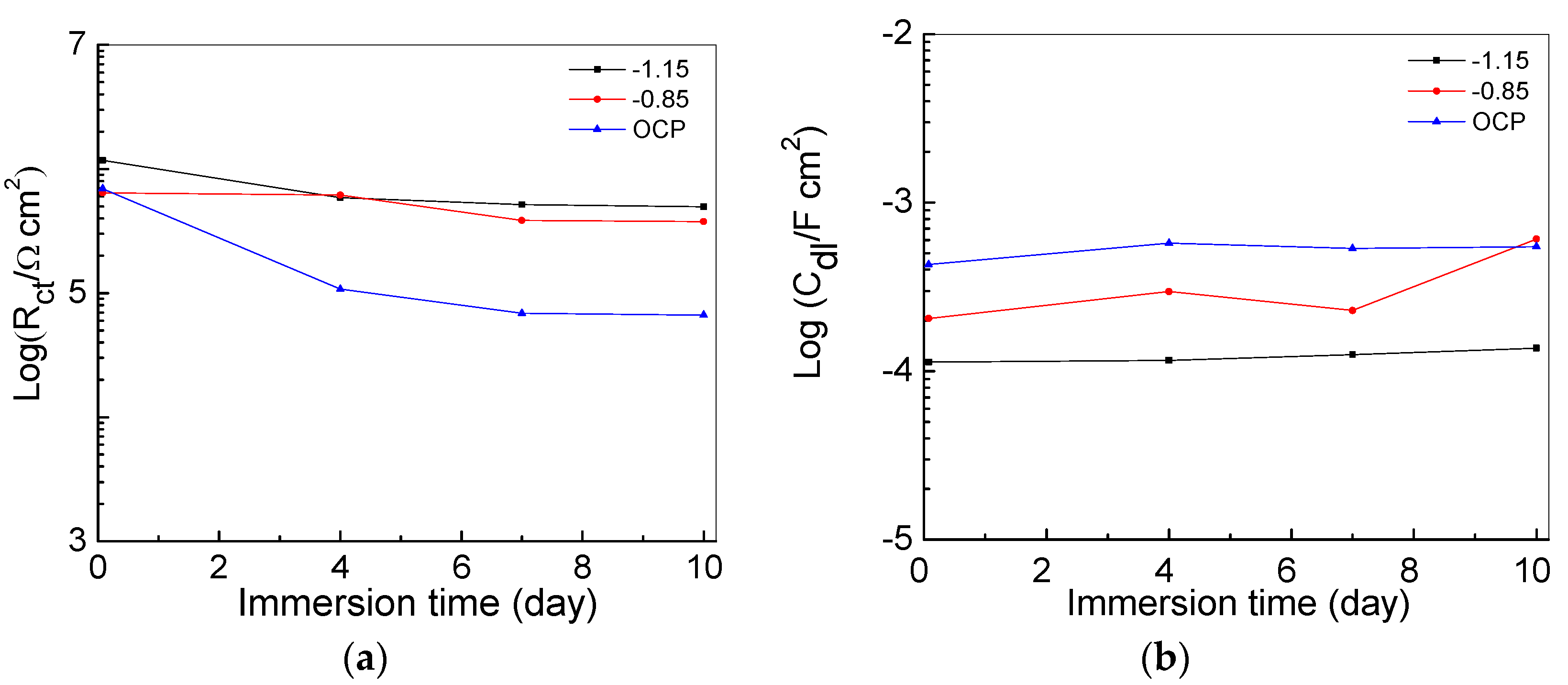

3.3. EIS

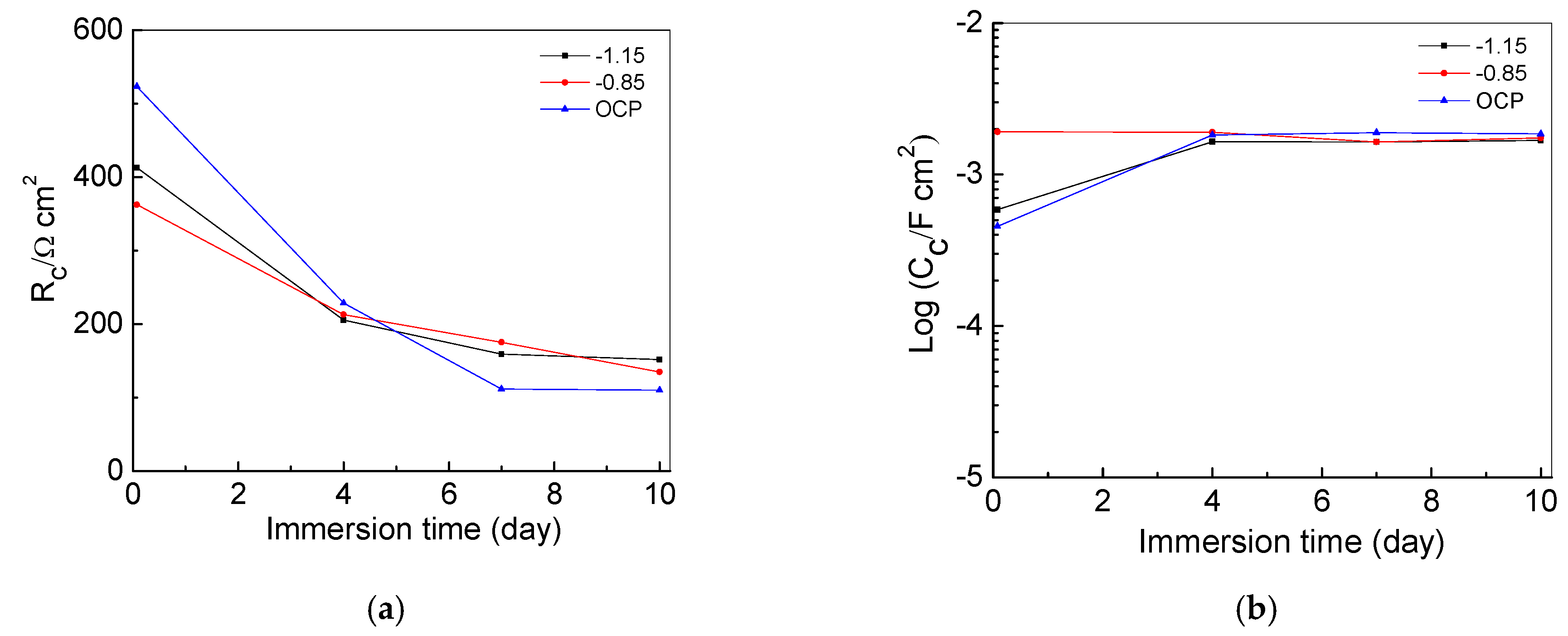

3.4. Potentiostatic

3.5. Visual Observations after Corrosion Tests

4. Conclusions

- The enamel coating is subjected to initial compression due to its lower CTE than steel, thus it is less susceptible to tensile cracks. In comparison with epoxy coating, the enamel coating has a higher glass transition temperature, and thus allows an increase of pipeline operation temperature up to 400 °C, with a safety factor of approximately 1.25.

- Enamel residual remained between anchor points of the steel substrate after the enamel coating had been chipped off, this was due to impact loading. During all the corrosion tests, no further delamination was found, and the CP did not change the coating properties and the mechanical condition at the coating-substrate interface.

- At the intact coating areas, the higher the potential (up to −1.15 V/SCE) applied in CP, the higher the coating resistance and charge transfer resistance. The CP does not cause debonding between the coating and its steel substrate, it decelerates the degradation process of the coating and delays the electrochemical reactions at the steel-electrolyte interface.

- The resistances of all the damaged coatings were less than 1 kΩ cm2, indicating the loss of their barrier effect in protecting the steel substrate from corrosion. The introduction of CP does not improve the coating performance once damaged.

- The resistances against electrolyte penetration into the enamel coating and charge transfer through the steel-electrolyte interface in the intact and damaged enamel coating areas differed by at least 104 times after 70 days of testing. It is thus important to separate the electrochemical processes in the intact and damaged zones during corrosion tests.

Author Contributions

Funding

Conflicts of Interest

References

- Love, C.T.; Xian, G.; Karbhari, V.M. Cathodic disbondment resistance with reactive ethylene terpolymer blends. Prog. Org. Coat. 2007, 60, 287–296. [Google Scholar] [CrossRef]

- Zhu, C.; Xie, R.; Xue, J.; Song, L. Studies of the impedance models and water transport behaviors of cathodically polarized coating. Electrochim. Acta 2011, 56, 5828–5835. [Google Scholar] [CrossRef]

- Martinez, S.; Žulj, L.V.; Kapor, F. Disbonding of underwater-cured epoxy coating caused by cathodic protection current. Corros. Sci. 2009, 51, 2253–2258. [Google Scholar] [CrossRef]

- Rossi, S.; Parziani, N.; Zanella, C. Abrasion resistance of vitreous enamel coatings in function of frit composition and particles presence. Wear 2015, 332, 702–709. [Google Scholar] [CrossRef]

- Lazutkina, O.R.; Kostenko, M.G.; Komarova, S.A.; Kazak, A.K. Highly reliable energy-efficient glass coatings for pipes transporting energy carriers, liquids, and gases. Glass Ceram. 2007, 64, 93–95. [Google Scholar] [CrossRef]

- Fan, L.; Tang, F.; Reis, S.T.; Chen, G.; Koenigstein, M.L. Corrosion resistance of transmission pipeline steel coated with five types of enamels. Acta Metall. Sin. (Engl. Lett.) 2017, 30, 390–398. [Google Scholar] [CrossRef]

- Fan, L.; Tang, F.; Reis, S.T.; Chen, G.; Koenigstein, M.L. Corrosion resistances of steel pipes internally coated with enamel. Corrosion 2017, 73, 1335–1345. [Google Scholar] [CrossRef]

- Lauer, R.S. Advancements in the abrasion resistance of internal plastic coatings. Mater. Perform. 2014, 53, 52–55. [Google Scholar]

- Deflorian, F.; Rossi, S. An EIS study of ion diffusion through organic coatings. Electrochim. Acta 2006, 51, 1736–1744. [Google Scholar] [CrossRef]

- Le Thu, Q.; Takenouti, H.; Touzain, S. EIS characterization of thick flawed organic coatings aged under cathodic protection in seawater. Electrochim. Acta 2006, 51, 2491–2502. [Google Scholar] [CrossRef]

- ASTM D4541–09(2009) Standard Test Method for Pull-Off Strength of Coatings Using Portable Adhesion Testers; ASTM Standards: West Conshohocken, PA, USA, 2009.

- ASTM G14-04(2010)e1 Standard Test Method for Impact Resistance of Pipeline Coatings (Falling Weight Test); ASTM Standards: West Conshohocken, PA, USA, 2010.

- Yang, X.; Jha, A.; Brydson, R.; Cochrane, R.C. An analysis of the microstructure and interfacial chemistry of steel–enamel interface. Thin Solid Films 2003, 443, 33–45. [Google Scholar] [CrossRef]

- Samiee, L.; Sarpoolaky, H.; Mirhabibi, A. Microstructure and adherence of cobalt containing and cobalt free enamels to low carbon steel. Mater. Sci. Eng. A 2007, 458, 88–95. [Google Scholar] [CrossRef]

- Liu, H.H.; Shueh, Y.; Yang, F.S.; Shen, P. Microstructure of the enamel-steel interface: Cross-sectional TEM and metallographic studies. Mater. Sci. Eng. A 1992, 149, 217–224. [Google Scholar] [CrossRef]

- Presa, M.R.; Tucceri, R.I.; Florit, M.I.; Posadas, D. Constant phase element behavior in the poly(o-toluidine) impedance response. J. Electroanal. Chem. 2001, 502, 82–90. [Google Scholar] [CrossRef]

- Yao, Z.P.; Jiang, Z.H.; Wang, F.P. Study on corrosion resistance and roughness of micro-plasma oxidation ceramic coatings on Ti alloy by EIS technique. Electrochim. Acta 2007, 52, 4539–4546. [Google Scholar] [CrossRef]

- Orazem, M.E.; Tribollet, B. Equivalent circuit analogs. In Electrochemical Impedance Spectroscopy, 1st ed.; John Wiley & Sons: Hoboken, NJ, USA, 2008; p. 233. ISBN 978-0-470-04140-6. [Google Scholar]

- Zhang, J.T.; Hu, J.M.; Zhang, J.Q.; Cao, C.N. Studies of water transport behavior and impedance models of epoxy-coated metals in NaCl solution by EIS. Prog. Org. Coat. 2004, 51, 145–151. [Google Scholar] [CrossRef]

- Zhang, J.T.; Hu, J.M.; Zhang, J.Q.; Cao, C.N. Studies of impedance models and water transport behaviors of polypropylene coated metals in NaCl solution. Prog. Org. Coat. 2004, 49, 293–301. [Google Scholar] [CrossRef]

- Hu, J.M.; Zhang, J.Q.; Cao, C.N. Determination of water uptake and diffusion of Cl− ion in epoxy primer on aluminum alloys in NaCl solution by electrochemical impedance spectroscopy. Prog. Org. Coat. 2003, 46, 273–279. [Google Scholar] [CrossRef]

- Walter, G.W. A review of impedance plot methods used for corrosion performance analysis of painted metals. Corros. Sci. 1986, 26, 681–703. [Google Scholar] [CrossRef]

- Tang, F.J.; Chen, G.; Brow, R.K.; Volz, J.S.; Koenigstein, M.L. Corrosion resistance and mechanism of steel rebar coated with three types of enamel. Corros. Sci. 2012, 59, 157–168. [Google Scholar] [CrossRef]

- Tang, F.J.; Cheng, X.M.; Chen, G.; Brow, R.K.; Volz, J.S.; Koenigstein, M.L. Electrochemical behavior of enamel-coated carbon steel in simulated concrete pore water solution with various chloride concentrations. Electrochim. Acta 2013, 92, 36–46. [Google Scholar] [CrossRef]

- Ranade, S.; Forsyth, M.; Tan, M.Y.J. In situ measurement of pipeline coating integrity and corrosion resistance losses under simulated mechanical strains and cathodic protection. Prog. Org. Coat. 2016, 101, 111–121. [Google Scholar] [CrossRef]

| Element | C | Mn | P | S | Si | Cu | Ni | Cr | Mo | Al | V | Fe | Others |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| wt % | 0.17 | 1.15 | 0.07 | 0.02 | 0.26 | 0.10 | 0.04 | 0.07 | 0.07 | 0.024 | 0.02 | 98 | 0.006 |

| Elements | SiO2 | B2O3 | Na2O | CaO | MnO2 | Al2O3 | TiO2 | K2O | Fe2O3 | MgO | BaO | Others |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T-001 | 60.3 | 12.84 | 7.20 | 2.37 | 5.37 | 4.49 | 0.14 | 2.12 | 3.48 | 0.17 | 1.47 | 0.05 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, L.; Reis, S.T.; Chen, G.; Koenigstein, M.L. Corrosion Resistance of Pipeline Steel with Damaged Enamel Coating and Cathodic Protection. Coatings 2018, 8, 185. https://doi.org/10.3390/coatings8050185

Fan L, Reis ST, Chen G, Koenigstein ML. Corrosion Resistance of Pipeline Steel with Damaged Enamel Coating and Cathodic Protection. Coatings. 2018; 8(5):185. https://doi.org/10.3390/coatings8050185

Chicago/Turabian StyleFan, Liang, Signo T. Reis, Genda Chen, and Michael L. Koenigstein. 2018. "Corrosion Resistance of Pipeline Steel with Damaged Enamel Coating and Cathodic Protection" Coatings 8, no. 5: 185. https://doi.org/10.3390/coatings8050185