A Comparative Study on the Elastic Characteristics of an Aluminum Thin-Film Using Laser Optical Measurement Techniques

Abstract

:1. Introduction

2. Materials and Methods

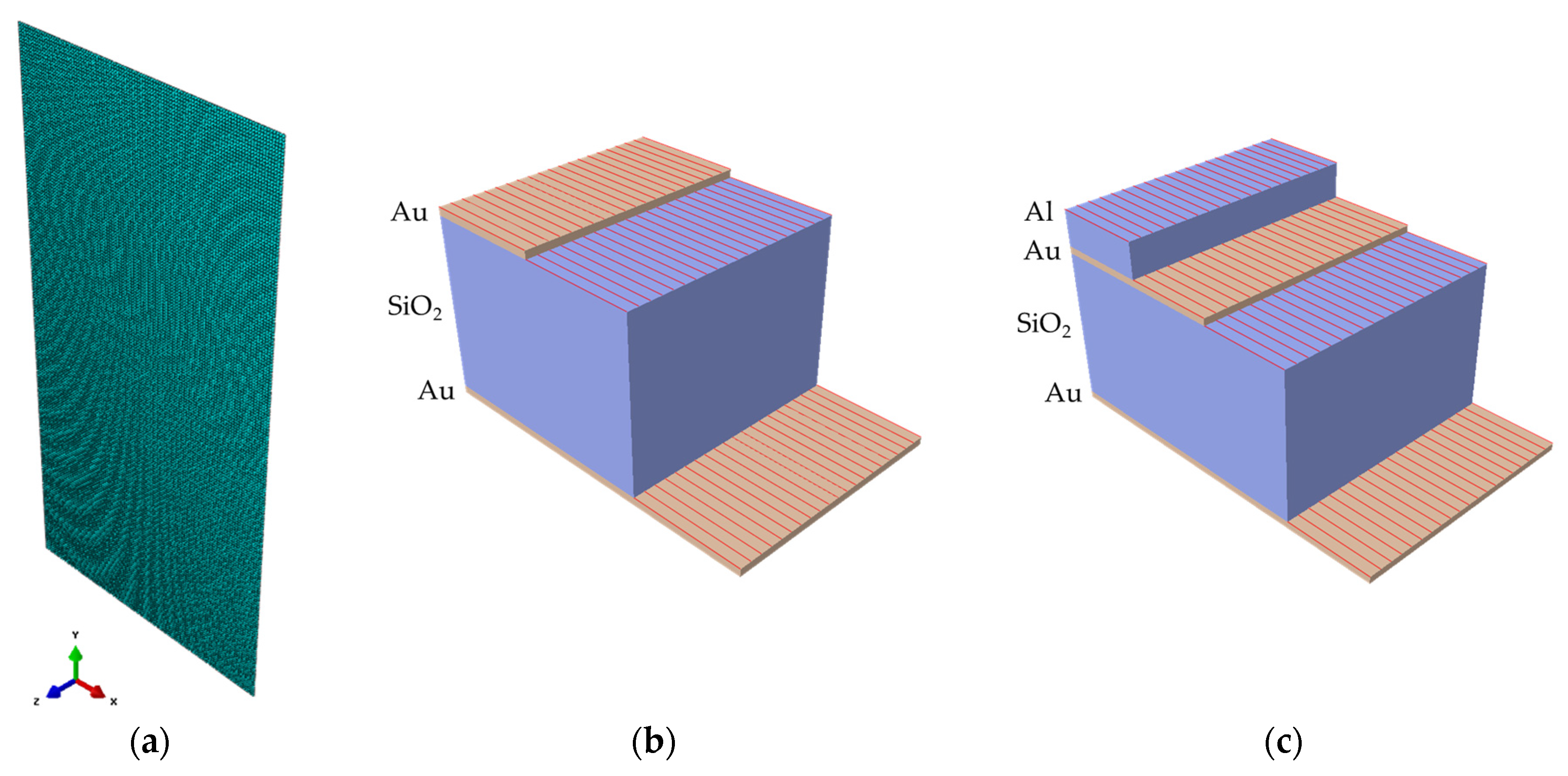

2.1. Sample Preparation

2.2. Microscale Beam Testing

2.2.1. Experimental Setup

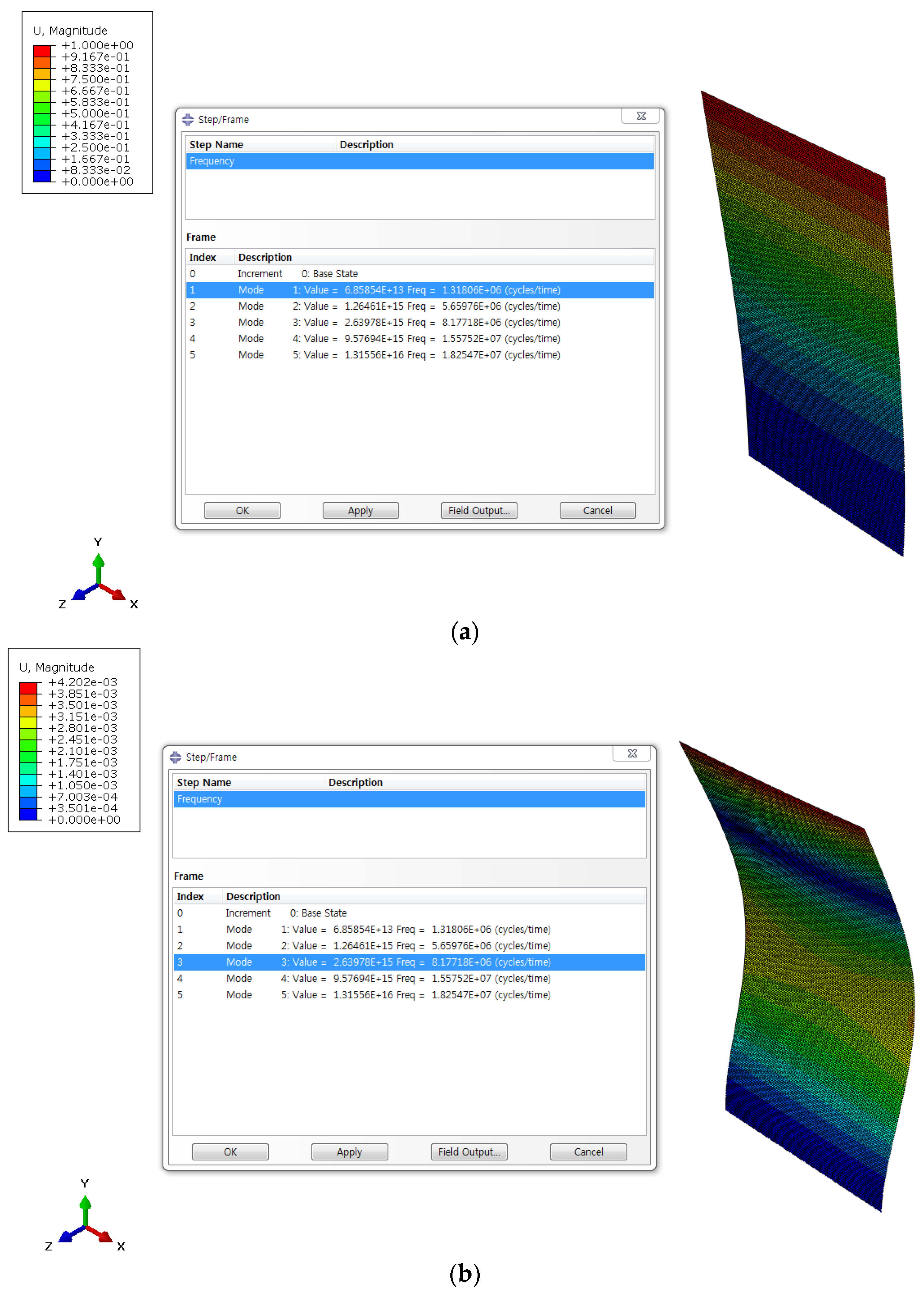

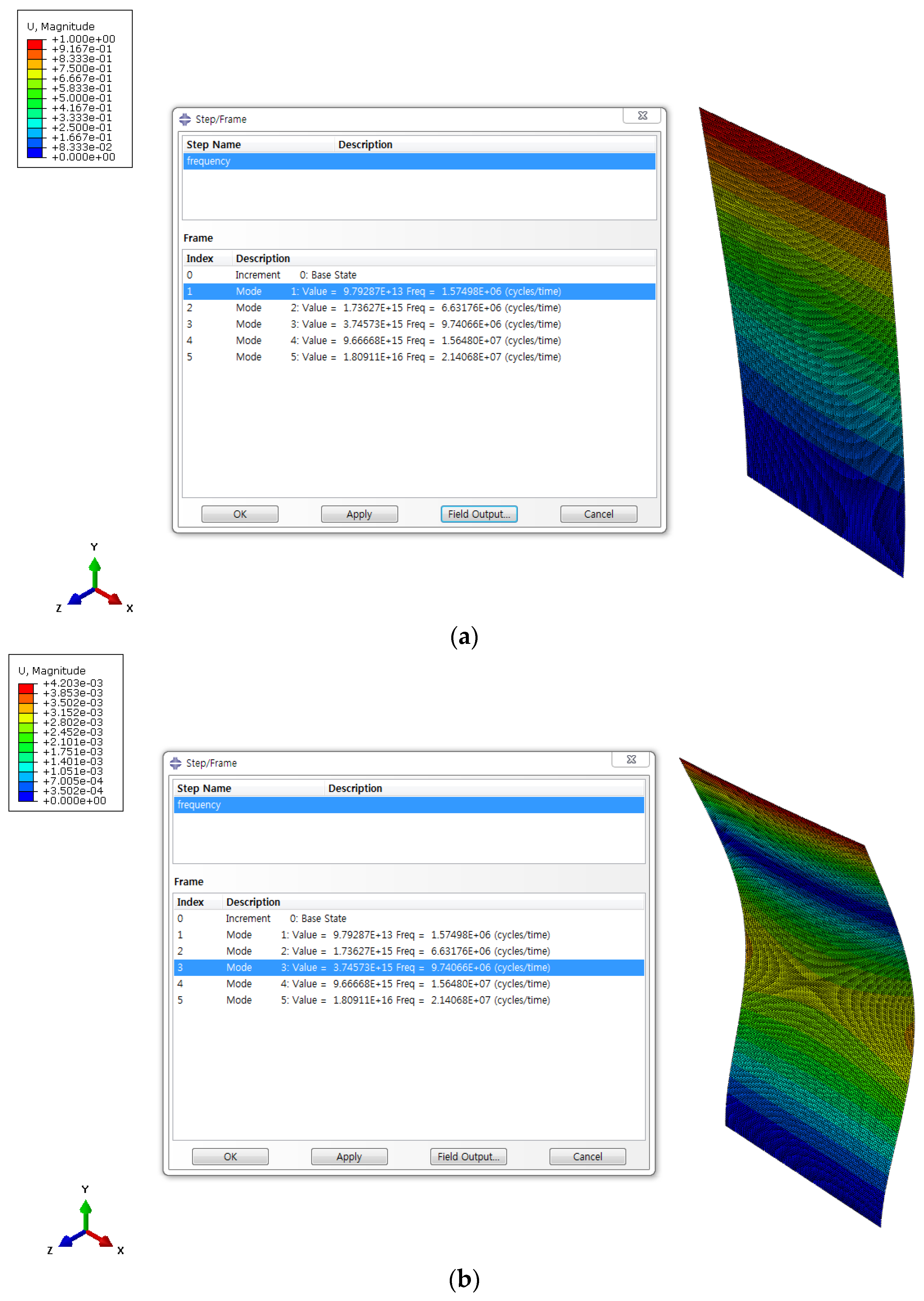

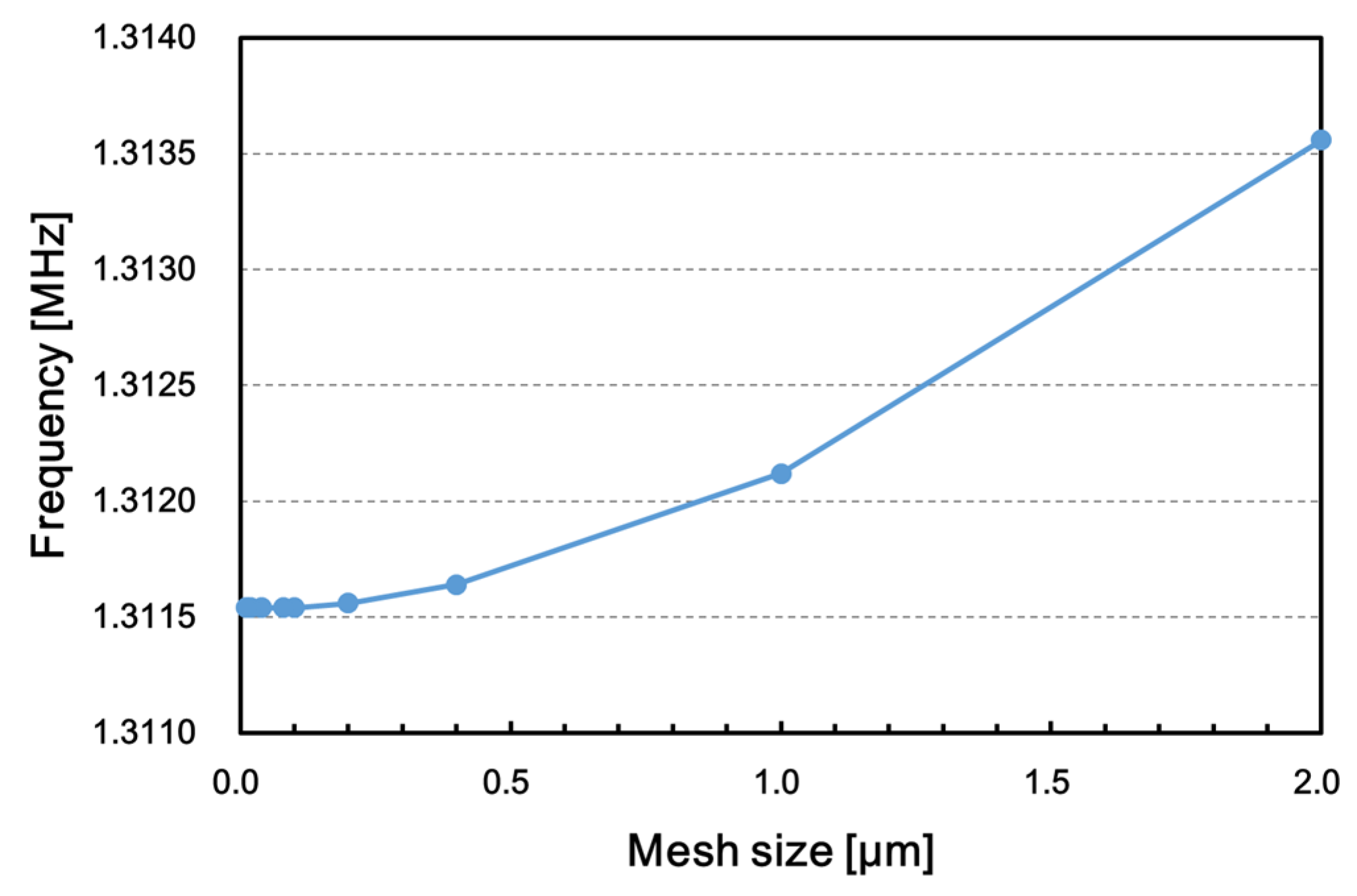

2.2.2. Numerical Analysis

2.3. Picosecond Ultrasonic Measurement

2.3.1. Experimental Setup

2.3.2. Theory/Calculation

3. Results

3.1. Microstructural Characteristics

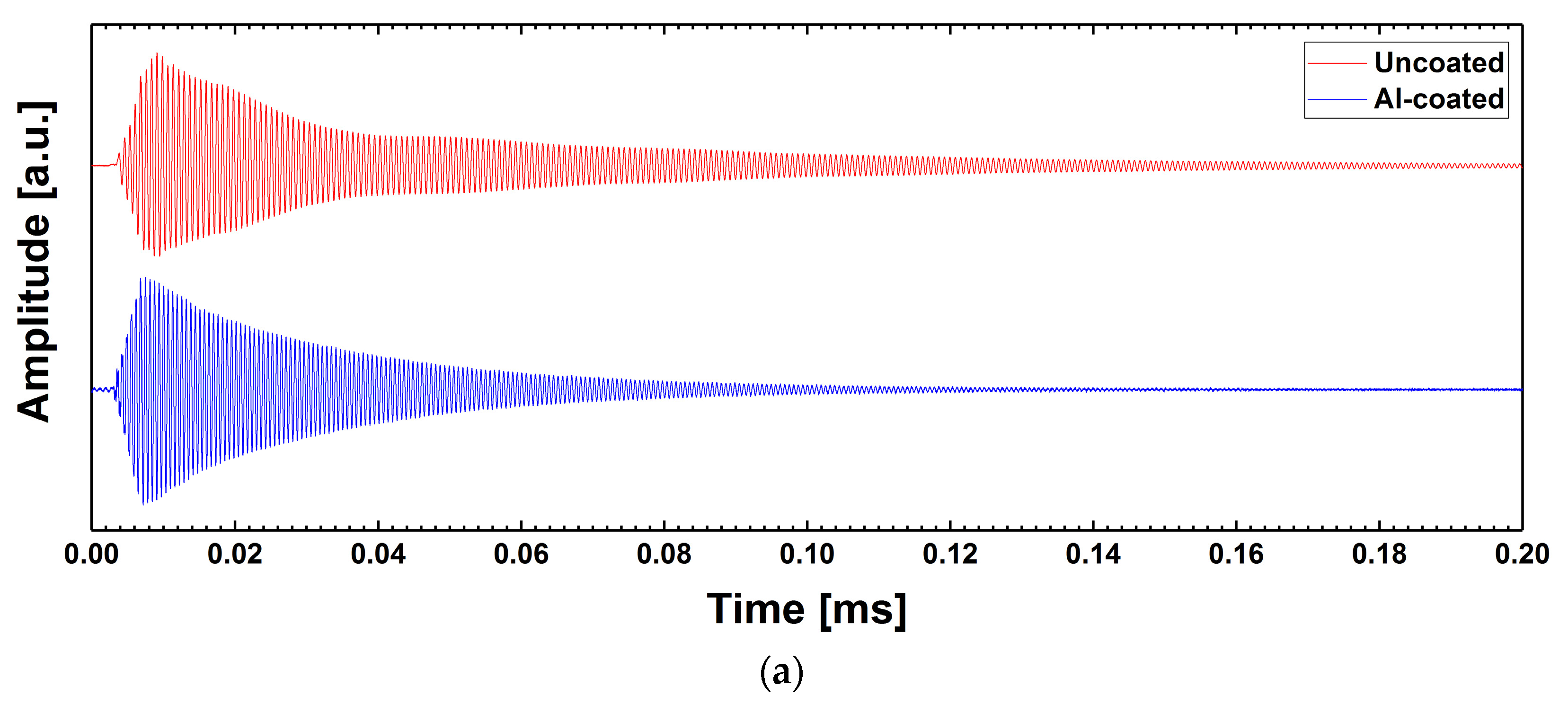

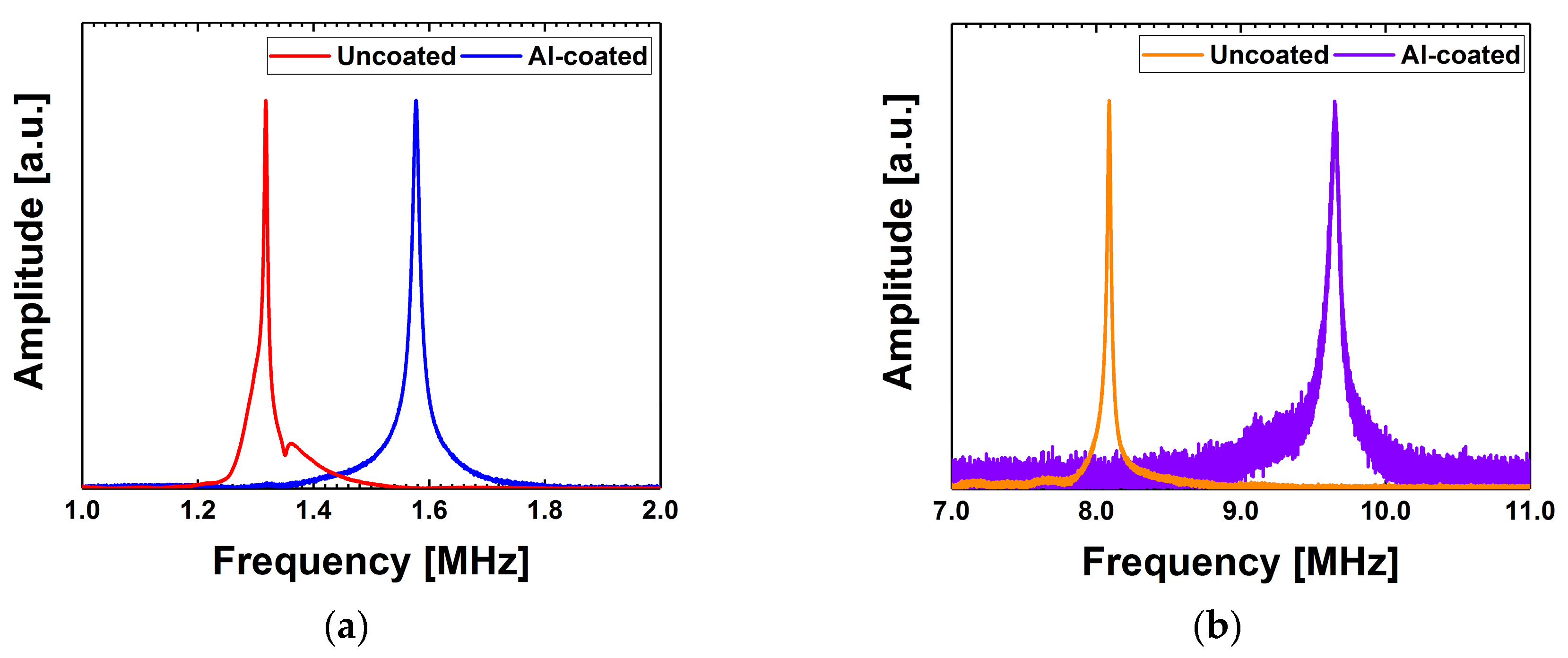

3.2. Microscale Beam Testing

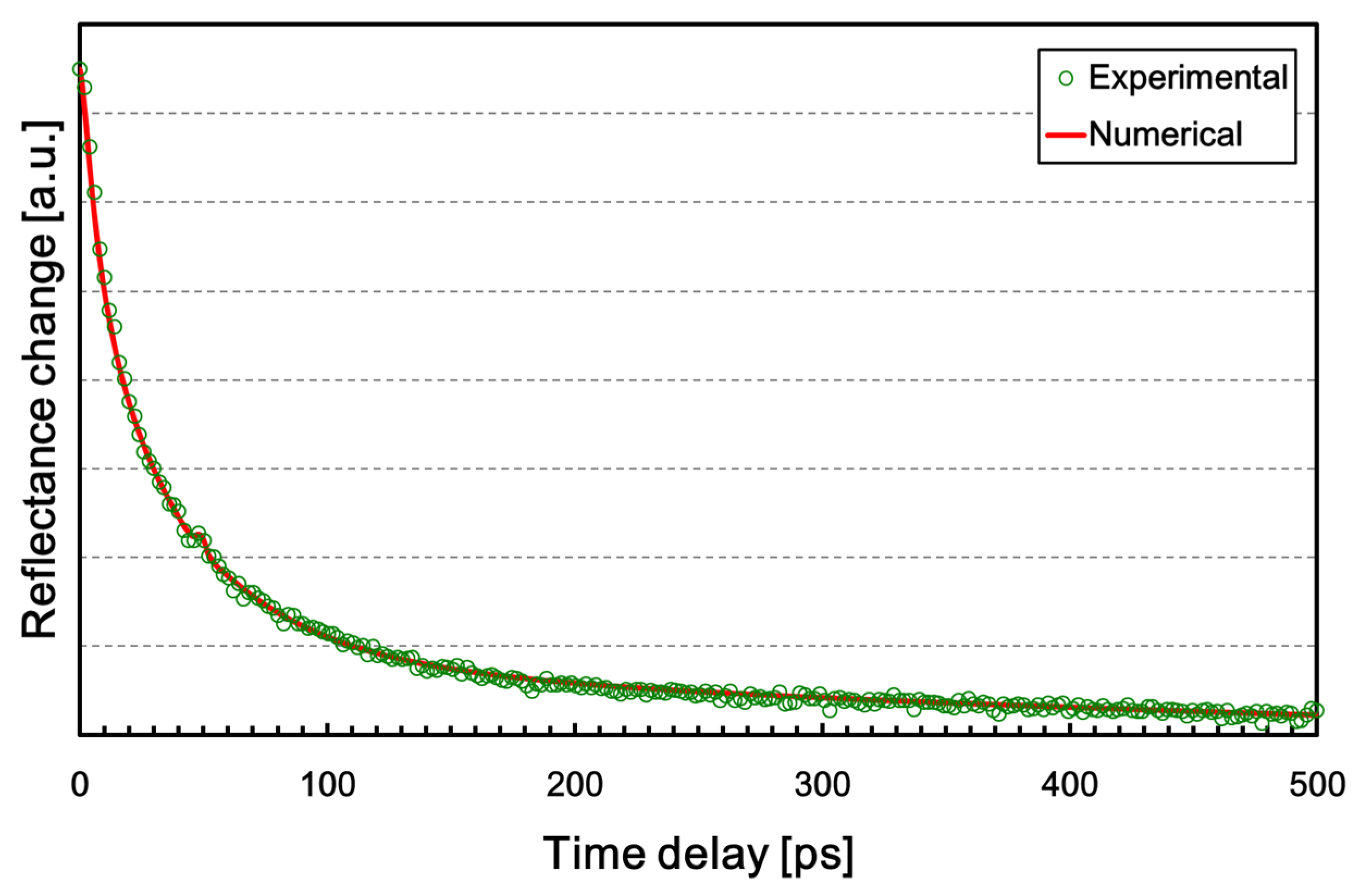

3.3. Picosecond Ultrasonic Measurement

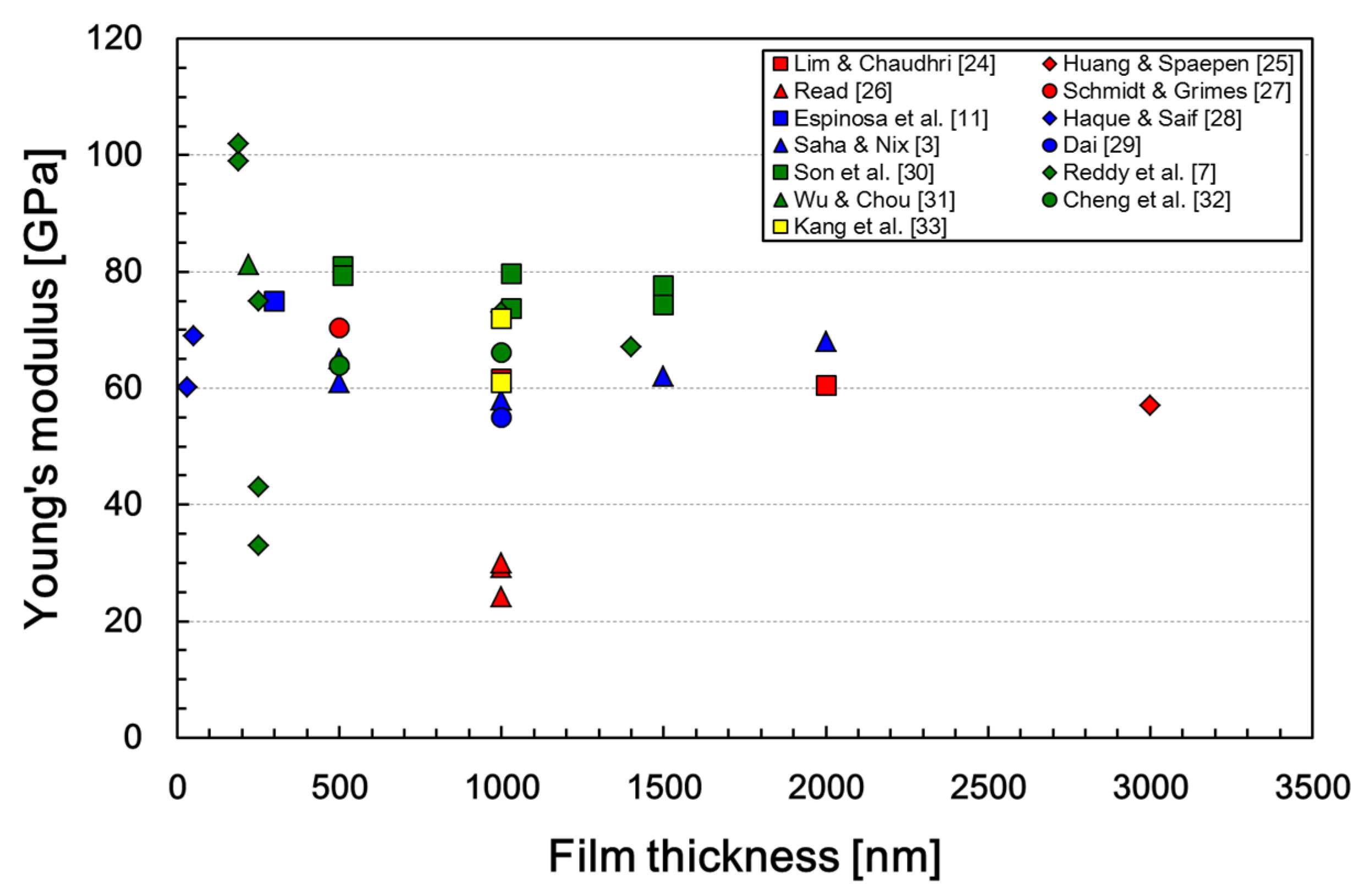

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix

References

- Zhang, F.; Krishnaswamy, S.; Lilley, C.M. Bulk-wave and guided-wave photoacoustic evaluation of the mechanical properties of aluminum/silicon nitride double-layer thin films. Ultrasonics 2006, 45, 66–76. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.Y.; Alwi, H.A.; Awang, R.; Krishnaswamy, S. Influence of radio frequency power on thermal diffusivity of plasma enhanced chemical vapor deposition-grown hydrogenated amorphous carbon thin-films. J. Appl. Phys. 2011, 109, 113503. [Google Scholar]

- Saha, R.; Nix, W.D. Effects of the substrate on the determination of thin film mechanical properties by nanoindentation. Acta Mater. 2002, 50, 23–38. [Google Scholar] [CrossRef]

- Chen, S.; Liu, L.; Wang, T. Investigation of the mechanical properties of thin films by nanoindentation, considering the effects of thickness and different coating–substrate combinations. Surf. Coat. Technol. 2005, 191, 25–32. [Google Scholar] [CrossRef]

- Zhao, D.; Qian, X.; Gu, X.; Jajja, S.A.; Yang, R. Measurement techniques for thermal conductivity and interfacial thermal conductance of bulk and thin film materials. J. Electron. Packag. 2016, 138, 040802. [Google Scholar] [CrossRef]

- Chaudhary, M.; Gupta, A. Microcantilever-based sensors. Def. Sci. J. 2009, 59, 634–641. [Google Scholar] [CrossRef]

- Reddy, A.; Kahn, H.; Heuer, A.H. A mems-based evaluation of the mechanical properties of metallic thin films. J. Microelectromech. Syst. 2007, 16, 650–658. [Google Scholar] [CrossRef]

- Strandjord, A.J.; Popelar, S.; Jauernig, C. Interconnecting to aluminum-and copper-based semiconductors (electroless-nickel/gold for solder bumping and wire bonding). Microelectron. Reliab. 2002, 42, 265–283. [Google Scholar] [CrossRef]

- Hamon, Y.; Brousse, T.; Jousse, F.; Topart, P.; Buvat, P.; Schleich, D. Aluminum negative electrode in lithium ion batteries. J. Power Sour. 2001, 97, 185–187. [Google Scholar] [CrossRef]

- Shaheen, S.E.; Radspinner, R.; Peyghambarian, N.; Jabbour, G.E. Fabrication of bulk heterojunction plastic solar cells by screen printing. Appl. Phys. Lett. 2001, 79, 2996–2998. [Google Scholar] [CrossRef]

- Espinosa, H.; Zhu, Y.; Fischer, M.; Hutchinson, J. An experimental/computational approach to identify moduli and residual stress in mems radio-frequency switches. Exp. Mech. 2003, 43, 309–316. [Google Scholar] [CrossRef]

- Stephanou, P.; Pisano, A. PS-4 GHZ contour extensional mode aluminum nitride MEMS resonators. In Proceedings of the 2006 IEEE Ultrasonics Symposium, Vancouver, BC, Canada, 3–6 October 2006; pp. 2401–2404. [Google Scholar]

- Kim, Y.Y. An advanced characterization method for the elastic modulus of nanoscale thin-films using a high-frequency micromechanical resonator. Materials 2017, 10, 806. [Google Scholar] [CrossRef] [PubMed]

- Richardson, C.; Ehrlich, M.; Wagner, J. Interferometric detection of ultrafast thermoelastic transients in thin films: Theory with supporting experiment. J. Opt. Soc. Am. B Opt. Phys. 1999, 16, 1007–1015. [Google Scholar] [CrossRef]

- Stevens, R.J.; Smith, A.N.; Norris, P.M. Measurement of thermal boundary conductance of a series of metal-dielectric interfaces by the transient thermoreflectance technique. J. Heat Transfer 2005, 127, 315–322. [Google Scholar] [CrossRef]

- Miklós, A.; Bozóki, Z.; Lörincz, A. Picosecond transient reflectance of thin metal films. J. Appl. Phys. 1989, 66, 2968–2972. [Google Scholar] [CrossRef]

- Shackelford, J.F.; Han, Y.-H.; Kim, S.; Kwon, S.-H. CRC Materials Science and Engineering Handbook; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Huh, Y.-H.; Kim, D.-I.; Kim, D.-J.; Lee, H.-M.; Park, J.-H. Dependency of micro-mechanical properties of gold thin films on grain size. In Engineering against Fracture; Springer: Berlin, Germany, 2009; pp. 339–346. [Google Scholar]

- Pamula, V.K.; Jog, A.; Fair, R.B. Mechanical property measurement of thin-film gold using thermally actuated bimetallic cantilever beams. In Proceedings of the Fourth International Conference on Modeling and Simulation of Microsystems, Hilton Head, SC, USA, 19–21 March 2001. [Google Scholar]

- Stojanovic, N.; Yun, J.; Washington, E.B.; Berg, J.M.; Holtz, M.W.; Temkin, H. Thin-film thermal conductivity measurement using microelectrothermal test structures and finite-element-model-based data analysis. J. Microelectromech. Syst. 2007, 16, 1269–1275. [Google Scholar] [CrossRef]

- Xiang, Y.; Tsui, T.; Vlassak, J.J. The mechanical properties of freestanding electroplated Cu thin films. J. Mater. Res. 2006, 21, 1607–1618. [Google Scholar] [CrossRef]

- Cheng, G.; Sun, X.; Wang, Y.; Tay, S.L.; Gao, W. Nanoindentation study of electrodeposited ag thin coating: An inverse calculation of anisotropic elastic-plastic properties. Surf. Coat. Technol. 2017, 310, 43–50. [Google Scholar] [CrossRef]

- Hong, S.; Kim, K.; Kim, Y.-M.; Hahn, J.-H.; Lee, C.-S.; Park, J.-H. Characterization of elastic moduli of Cu thin films using nanoindentation technique. Compos. Sci. Technol. 2005, 65, 1401–1408. [Google Scholar] [CrossRef]

- Lim, Y.; Chaudhri, M.; Enomoto, Y. Accurate determination of the mechanical properties of thin aluminum films deposited on sapphire flats using nanoindentations. J. Mater. Res. 1999, 14, 2314–2327. [Google Scholar] [CrossRef]

- Huang, H.; Spaepen, F. Tensile testing of free-standing Cu, Ag and Al thin films and Ag/Cu multilayers. Acta Mater. 2000, 48, 3261–3269. [Google Scholar] [CrossRef]

- Read, D.T.; Cheng, Y.-W.; Keller, R.R.; McColskey, J.D. Tensile properties of free-standing Aluminum thin films. Scr. Mater. 2001, 45, 583–589. [Google Scholar] [CrossRef]

- Schmidt, S.; Grimes, C.A. Characterization of nano-dimensional thin-film elastic moduli using magnetoelastic sensors. Sens. Actuators A Phys. 2001, 94, 189–196. [Google Scholar] [CrossRef]

- Haque, M.; Saif, M.A. Mechanical behavior of 30–50 nm thick Aluminum films under uniaxial tension. Scr. Mater. 2002, 47, 863–867. [Google Scholar] [CrossRef]

- Dai, C.-L. In situ electrostatic microactuators for measuring the Young’s modulus of CMOS thin films. J. Micromech. Microeng. 2003, 13, 563. [Google Scholar] [CrossRef]

- Son, D.; Jeong, J.-H.; Kwon, D. Film-thickness considerations in microcantilever-beam test in measuring mechanical properties of metal thin film. Thin Solid Films 2003, 437, 182–187. [Google Scholar] [CrossRef]

- Wu, L.-C.; Chou, Y.-F. On-wafer characterization of thermomechanical properties of isotropic thin films deposited on anisotropic substrates. Jpn. J. Appl. Phys. 2008, 47, 5623. [Google Scholar] [CrossRef]

- Cheng, Y.-C.; Tong, C.-J.; Lin, M.-T. Measurement of static and dynamic mechanical behavior of micro and nano-scale thin metal films: Using micro-cantilever beam deflection. Microsyst. Technol. 2011, 17, 721–730. [Google Scholar] [CrossRef]

- Kang, T.J.; Kim, J.-G.; Lee, H.-Y.; Lee, J.-S.; Lee, J.-H.; Hahn, J.-H.; Kim, Y.H. Modification of optical and mechanical surface properties of sputter-deposited aluminum thin films through ion implantation. Int. J. Precis. Eng. Manuf. 2014, 15, 889–894. [Google Scholar] [CrossRef]

| Property | Material | ||

|---|---|---|---|

| SiO2 | Au | Al | |

| Young’s modulus (GPa) | 72.0 | 79.0 | – |

| Poisson’s ratio | 0.17 | 0.44 | 0.35 |

| Density (kg/m3) | 2200 | 19,300 | 2700 |

| Method | Sample | Resonant Frequency | |

|---|---|---|---|

| 1st Order | 2nd Order | ||

| Experiment | Uncoated | 1.317 | 8.089 |

| Al-coated | 1.577 | 9.652 | |

| Finite element analysis | Uncoated | 1.318 | 8.177 |

| Al-coated 1 | 1.575 | 9.741 | |

| Property | Material | |

|---|---|---|

| Al | Si | |

| Density (kg/m3) | 2700 | 2330 |

| Specific heat (J/kg·K) | 900 | 700 |

| Thermal conductivity (W/m·K) | 140 | 148 |

| Coefficient of thermal expansion (μ/K) | 24.0 | 2.6 |

| Young’s modulus (GPa) | – | 130 |

| Poisson’s ratio | 0.35 | 0.25 |

| Refractive index | 2.23 | – |

| Extinction coefficient | 7.60 | – |

| Surface reflectivity | 0.88 | – |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.; Kim, Y.Y.; Cho, Y. A Comparative Study on the Elastic Characteristics of an Aluminum Thin-Film Using Laser Optical Measurement Techniques. Coatings 2017, 7, 143. https://doi.org/10.3390/coatings7090143

Lee S, Kim YY, Cho Y. A Comparative Study on the Elastic Characteristics of an Aluminum Thin-Film Using Laser Optical Measurement Techniques. Coatings. 2017; 7(9):143. https://doi.org/10.3390/coatings7090143

Chicago/Turabian StyleLee, Seonwook, Yun Young Kim, and Younho Cho. 2017. "A Comparative Study on the Elastic Characteristics of an Aluminum Thin-Film Using Laser Optical Measurement Techniques" Coatings 7, no. 9: 143. https://doi.org/10.3390/coatings7090143