Zircon-Based Ceramic Coatings Formed by a New Multi-Chamber Gas-Dynamic Accelerator

Abstract

:1. Introduction

2. Materials and Methods

3. Results

4. Conclusions

- The zircon-based ceramic coatings were characterized by low porosity (0.1%), a relatively high hardness of 526 ± 65 HV0.2 and fracture toughness of 2.5 ± 0.6 МPа∙m1/2;

- The coatings showed a low specific wear rate, 11.75 × 10−5 mm3·(m∙N)−1;

- The XRD results revealed that the coating consisted of the monoclinic and cubic ZrO2 phases, and SiO2 phase;

- The coating layer showed a low average erosion rate;

- The cohesion strength between the zircon-based ceramic coating and substrate was evaluated as 13.0 ± 0.5 MPa.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chráska, P.; Neufuss, K.; Herman, H. Plasma spraying of zircon. J. Therm. Spray Technol. 1997, 6, 445–448. [Google Scholar] [CrossRef]

- Rendtorff, N.M.; Grasso, S.; Hu, C.; Suarez, G.; Aglietti, E.F.; Sakka, Y. Dense zircon (ZrSiO4) ceramics by high energy ball milling and spark plasma sintering. Ceram. Int. 2012, 38, 1793–1799. [Google Scholar] [CrossRef]

- Suárez, G.; Acevedo, S.; Rendtorff, N.M.; Garrido, L.B.; Aglietti, E.F. Colloidal processing, sintering and mechanical properties of zircon (ZrSiO4). Ceram. Int. 2015, 41, 1015–1021. [Google Scholar] [CrossRef]

- Rendtorff, N.M.; Garrido, L.B.; Aglietti, E.F. Mechanical and fracture properties of zircon-mullite composites obtained by direct sintering. Ceram. Int. 2009, 35, 2907–2913. [Google Scholar] [CrossRef]

- Rudajevova, A. Thermal properties of plasma-sprayed ZrSiO4 material. Ceram. Int. 1994, 64, 47–51. [Google Scholar] [CrossRef]

- Ramaswamy, P.; Seetharamu, S.; Varma, K.B.R.; Rao, K.J. Thermal barrier coating application of zircon sand. J. Therm. Spray Technol. 1999, 8, 447–453. [Google Scholar] [CrossRef]

- Subbarao, E.C. Zirconia—An overview. In Science and Technology of Zirconia; Advances in Ceramics; Heuer, A.H., Hobbs, L.W., Eds.; American Ceramic Society: Westerville, OH, USA, 1981; Volume 3, pp. 1–24. [Google Scholar]

- Vincenzini, P. Zirconia thermal barrier coatings for engine applications. Ind. Ceram. 1990, 10, 113–126. [Google Scholar]

- Suzuki, M.; Inoue, S.S.; Ueno, K. Effect of heat treatment on plasma-sprayed zircon (ZrSiO∙ZrSiO4). Mater. Manuf. Process. 1998, 13, 575–580. [Google Scholar] [CrossRef]

- Sun, C.; Li, H.-J.; Fu, Q.-G.; Li, H.-L.; Wang, Y.-J.; Wu, H. ZrSiO4 oxidation protective coating for SiC-coated carbon/carbon composites prepared by supersonic plasma spraying. J. Therm. Spray Technol. 2013, 22, 525–530. [Google Scholar] [CrossRef]

- Suzuki, M.; Sodeoka, S.; Inoue, T. Zircon-based ceramics composite coating for environmental barrier coating. J. Therm. Spray Technol. 2008, 17, 404–409. [Google Scholar] [CrossRef]

- Okubo, T.; Yonemochi, O.; Maeda, M.; Nakamura, K. Reports of the Government Industrial Research Institute; Government Industrial Research Institute: Nagoya, Japan, 1967; Volume 16.

- Krauth, A.; Meyer, H. Modifications produced by chilling and their crystal growth in the system containing zirconium dioxide. Ber. Deut. Keram. Ges. 1965, 42, 61–72. (In German) [Google Scholar]

- McPherson, R. The Relationship between the mechanism of formation, microstructure and properties of plasma-sprayed coatings. Thin Solid Films 1981, 83, 297–310. [Google Scholar] [CrossRef]

- Evans, A.M.; Williamson, J.P.H. Composition and microstructure of dissociated zircon produced in a plasma furnace. J. Mater. Sci. 1977, 12, 779–790. [Google Scholar] [CrossRef]

- Raus, P.; Chriska, P. Transmission electron microscope study of a plasma-sprayed zircon coating. Ceram. Silik. 1989, 33, 325–332. (In Czech) [Google Scholar]

- Chniska, P.; Dubsky, J.; Kolman, B.; Ilavsky, J.; Forman, J. Study of phase changes in plasma sprayed deposits. J. Therm. Spray Tech. 1992, 1, 301–306. [Google Scholar] [CrossRef]

- Schelz, S.; Enguehard, F.; Caron, N.; Plessis, D.; Minot, B.; Guillet, F.; Longuet, J.-L.; Teneze, N.; Bruneton, E. Recombination of silica and zirconia into zircon by means of laser treatment of plasma-sprayed coatings. J. Mater. Sci. 2008, 43, 1948–1957. [Google Scholar] [CrossRef]

- Ault, N.N. Characteristics of refractory oxide coatings produced by flame-spraying. J. Eur. Ceram. Soc. 1957, 40, 69–74. [Google Scholar] [CrossRef]

- Li, Y.; Khor, K.A. Microstructure and composition analysis in plasma sprayed coatings of Al2O3/ZrSiO4 mixtures. Surf. Coat. Technol. 2002, 150, 125–132. [Google Scholar] [CrossRef]

- Vasilik, N.; Tyurin, Y.; Kolisnichenko, O. Method for Gas-Dynamic Detonating Speedup of Powders and Device for Its Implementation. RU Patent 2506341, 11 July 2012. [Google Scholar]

- Kovaleva, M.; Tyurin, Y.; Kolisnichenko, O.; Prozorova, M.; Arseenko, M. Properties of detonation nanostructured titanium-based coatings. J. Therm. Spray Tech. 2013, 22, 518–524. [Google Scholar] [CrossRef]

- Kovaleva, M.; Tyurin, Y.; Vasilik, N.; Kolisnichenko, O.; Prozorova, M.; Arseenko, M.; Danshina, E. Deposition and characterization of Al2O3 coatings by multi-chamber gas-dynamic accelerator. Surf. Coat. Technol. 2013, 232, 719–725. [Google Scholar] [CrossRef]

- Kovaleva, M.; Tyurin, Y.; Vasilik, N.; Kolisnichenko, O.; Prozorova, M.; Arseenko, M.; Yapryntsev, M.; Sirota, V.; Pavlenko, I. Effect of processing parameters on the microstructure and properties of WC-10Co-4Cr coatings formed by a new multi-chamber gas-dynamic accelerator. Ceram. Int. 2015, 41, 15067–15074. [Google Scholar] [CrossRef]

- Kovaleva, M.; Tyurin, Y.; Vasilik, N.; Kolisnichenko, O.; Prozorova, M.; Arseenko, M.; Sirota, V.; Pavlenko, I. Effect of heat treatment on the microstructure and microhardness of nanostructural Al2O3 coatings. J. Therm. Spray Technol. 2014, 23, 1199–1209. [Google Scholar] [CrossRef]

- Kovaleva, M.; Prozorova, M.; Arseenko, M.; Tyurin, Y.; Kolisnichenko, O.; Vasilik, N.; Sirota, V.; Pavlenko, I. Deposition and characterization of alumina-titania coating by multi-chamber gas-dynamic sprayer. Results Phys. 2015, 5, 1–2. [Google Scholar] [CrossRef]

- Prozorova, M.; Kovaleva, M.; Arseenko, M.; Tyurin, Y.; Kolisnichenko, O.; Vasilik, N.; Sirota, V.; Yapryntsev, M.; Pavlenko, I.; Mamunin, K. Microstructure and mechanical properties of alumina powder coatings by a new multi-chamber detonation sprayer. Surf. Rev. Lett. 2016, 23, 1550088. [Google Scholar] [CrossRef]

- Kovaleva, M.G.; Prozorova, M.S.; Arseenko, M.Y.; Yapryntsev, M.N.; Vagina, O.N. Properties and peculiarities of ceramic coatings on the Al2O3 and ZrSiO4 basis formed by a new multi-chamber gas-dynamic accelerator. IJAC 2016, 12, 593–601. [Google Scholar]

- Sridhar, G.; Ghosh, S.; Chowdhury, N.G. Materials Characterization Techniques: Principles and Applications; National Metallurgical Laboratory (Council of Scientific & Industrial Research): Jamshedpur, India, 1999; pp. 163–176. [Google Scholar]

- ASTM-E-3-86 Standard Methods of Preparing Metallographic Specimens; American Society for Metals: Geauga, OH, USA, 1986; Volume 03.01, p. 12.

- Moskal, G.J. The porosity assessment of thermal barrier coatings obtained by APS method. J. Achiev. Mater. Manuf. Eng. 2007, 20, 483–486. [Google Scholar]

- Evans, A.G.; Wilshaw, T.R. Quasi-static solid particle damage in brittle solids—I. Observations analysis and implications. Acta Metall. 1976, 24, 939–956. [Google Scholar] [CrossRef]

- ASTM-G-99-05 Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus; ASTM: West Conshohocken, PA, USA, 2010; Volume 03.02, p. 6.

- Vershinin, D.S.; Smolyakova, M.Y.; Manokhin, S.S.; Druchinina, O.A.; Akhmadeev, Y.K. Study of tribological properties of VT16 nitrated titanium alloy with use automated friction machine. Zavod. Labor. Diagn. Mater. 2010, 76, 45–49. [Google Scholar]

- ASTM G76-13 Standard Test Method for Conducting Erosion Tests by Solid Particle Impingement Using Gas Jets; ASTM: West Conshohocken, PA, USA, 2013; Volume 03.02, p. 12.

- Ruff, A.W.; Ives, L.K. Measurement of solid particle velocity in erosive wear. Wear 1975, 35, 195–199. [Google Scholar] [CrossRef]

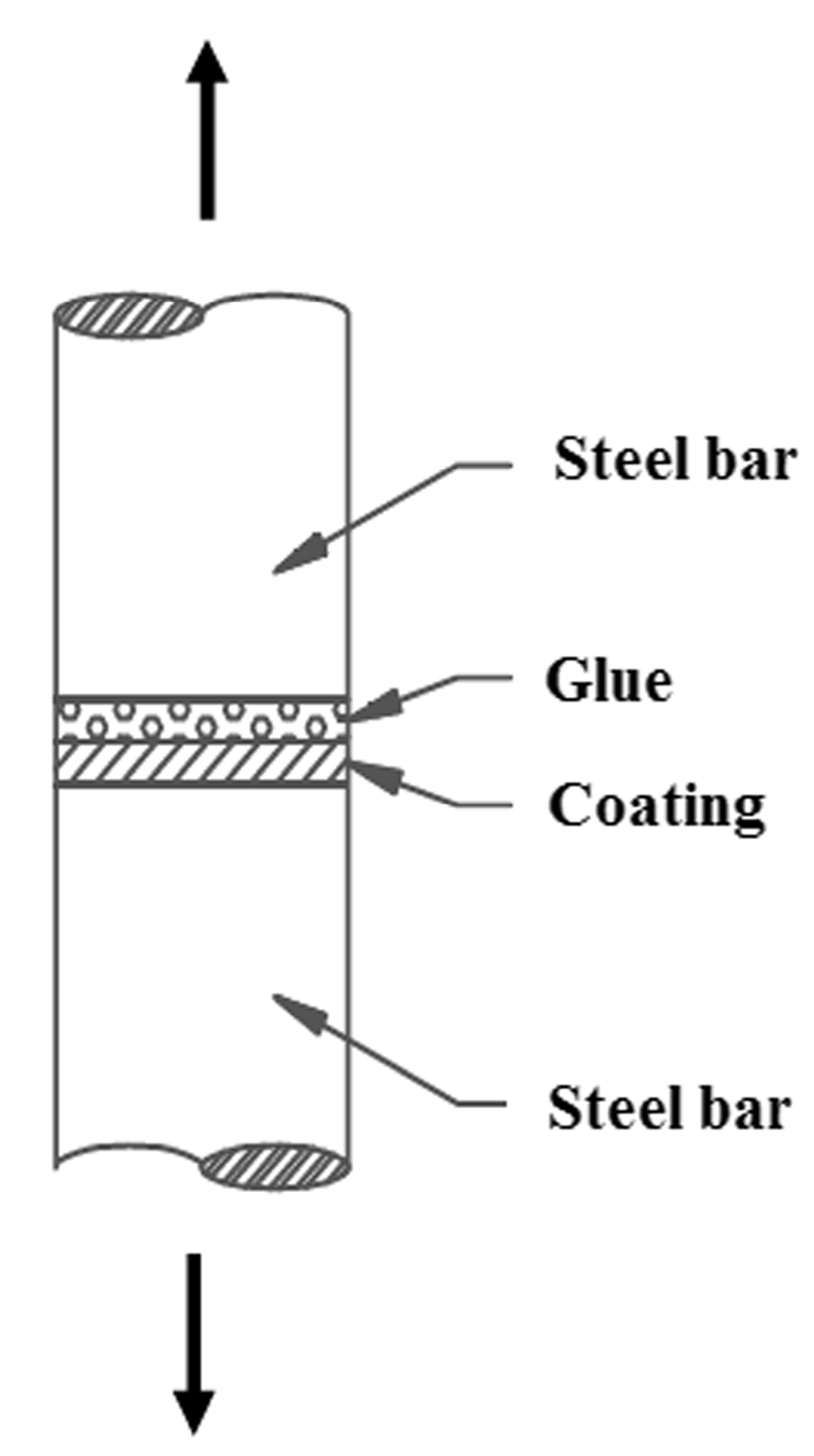

- ASTM C 633-79 Standard Test Method for Adhesion or Cohesion Strength of Thermal Spray Coatings; ASTM: West Conshohocken, PA, USA, 1985; Volume 15.02, pp. 340–346.

- Li, Y.; Khor, K.A. Plasma spray processing of alumina + zircon mixtures. Process. Fabr. Adv. Mater. VIII. 2001, 469–476. [Google Scholar] [CrossRef]

- Attar, H.; Ehtemam-Haghighi, S.; Kent, D.; Okulov, I.V.; Wendrock, H.; Bӧnisch, M.; Volegov, A.S.; Calin, M.; Eckert, J.; Dargusch, M.S. Nanoindentation and wear properties of Ti and Ti-TiB composite materials produced by selective laser melting. Mater. Sci. Eng. A 2017, 688, 20–26. [Google Scholar] [CrossRef]

- Prashanth, K.; Scudino, S.; Chaubey, A.; Löber, L.; Wang, P.; Attar, H.; Attar, H.; Schimansky, F.P.; Pyczak, F.; Eckert, J. Processing of Al-12Si-TNM composites by selective laser melting and evaluation of compressive and wear properties. J. Mater. Res. 2016, 31, 55–65. [Google Scholar] [CrossRef]

- Attar, H.; Prashanth, K.G.; Chaubey, A.K.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Comparison of wear properties of commercially pure titanium prepared by selective laser melting and casting processes. Mat. Lett. 2015, 142, 38–41. [Google Scholar] [CrossRef]

- Ehtemam-Haghighi, S.; Prashanth, K.G.; Attar, H.; Chaubey, A.K.; Cao, G.H.; Zhang, L.C. Evaluation of mechanical and wear properties of TixNb7Fe alloys designed for biomedical applications. Mater. Des. 2016, 111, 592–599. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, P.-Z.; Wei, D.-B.; Chen, X.-H.; Wang, R.-N.; Wang, H.-Y.; Feng, K.-T. Microstructure and sliding wear behavior of pure titanium surface modified by double-glow plasma surface alloying with Nb. Mater. Des. 2013, 52, 265–273. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and rubbing of flat surface. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Praveen, A.S. Erosion wear behavior of plasma sprayer NiCrSiB/Al2O3. Int. J. Refract. Metals Hard Mat. 2015, 52, 209–218. [Google Scholar] [CrossRef]

- Zhang, Y.; Cheng, Y.B.; Lathabai, S. Erosion of alumina ceramics by air and water-suspended garnet particles. Wear 2000, 240, 40–51. [Google Scholar] [CrossRef]

- Pawlowski, L. The Science and Engineering of Thermal Spray Coating, 2nd ed.; John Wiley & Sons: New York, NY, USA, 2008. [Google Scholar]

- Hjorhhede, A.; Nylund, A. Adhesion testing of thermally sprayed and laser deposited coatings. Surf. Coat. Technol. 2004, 28, 208–218. [Google Scholar] [CrossRef]

| Spray Distance, mm | Barrel Length, mm | Barrel Diameter, mm | Powder Feed Rate, g/h | Flow Rate of Fuel Mixture Components, m3/h | Oxygen/Fuel Ratio | ||

|---|---|---|---|---|---|---|---|

| Oxygen | Propane (100%) | Air | |||||

| 55 | 500 | 16 | 550 | * 3.9/** 3.6 | * 0.75/** 0.7 | * 0.1/** 0.11 | 5.2 |

| Erodent Velocity, m/s | Erodent Feed Rate, g/min | Impingement Angle, ° | Nozzle Diameter, mm |

|---|---|---|---|

| 60 | 2.2 | 30, 60 and 90 | 1.5 |

| Nozzle to Sample Distance, mm | Test Time, min | Samples Size, mm3 | |

| 10 | 60 | (25 × 20 × 5), (25 × 25 × 5), (25 × 25 × 5) | |

| Chemical Composition and Mechanical Features | Powder | Coating | Steel | |

|---|---|---|---|---|

| Chemical Composition (wt %) | ||||

| Zr | 77.48 | 61.03 | ||

| Si | 8.23 | 11.17 | ||

| O | 13.77 | 12.75 | ||

| Fe | 0.46 | 7.40 | ||

| Al | 0.07 | 0.73 | ||

| C | 6.92 | 0.12 | ||

| Fe | base | |||

| Mn | 0.90 | |||

| P | 0.025 | |||

| S | 0.01 | |||

| Cr | 16.0 | |||

| Cu | 0.20 | |||

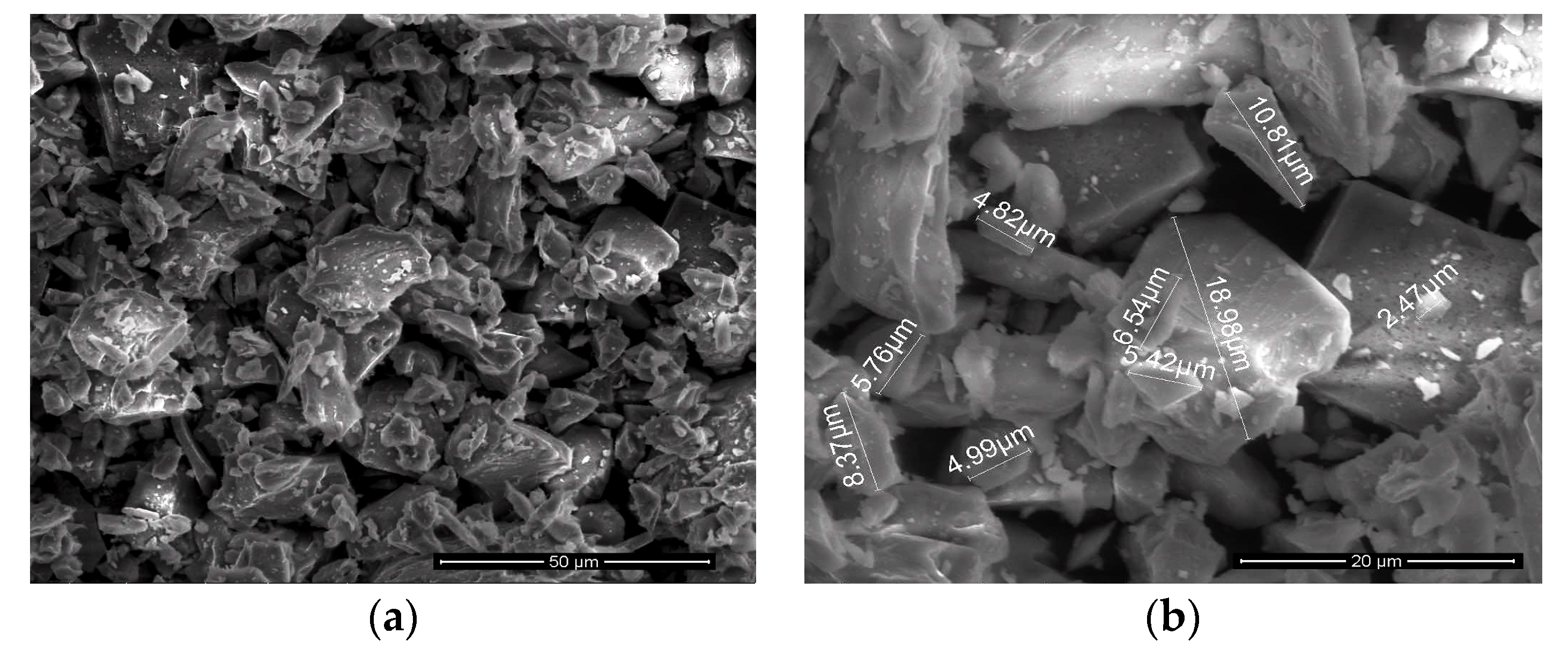

| Particle size Distribution (μm) | ||||

| d(0.1) | 2.56 | |||

| d(0.5) | 18.29 | |||

| d(0.9) | 46.68 | |||

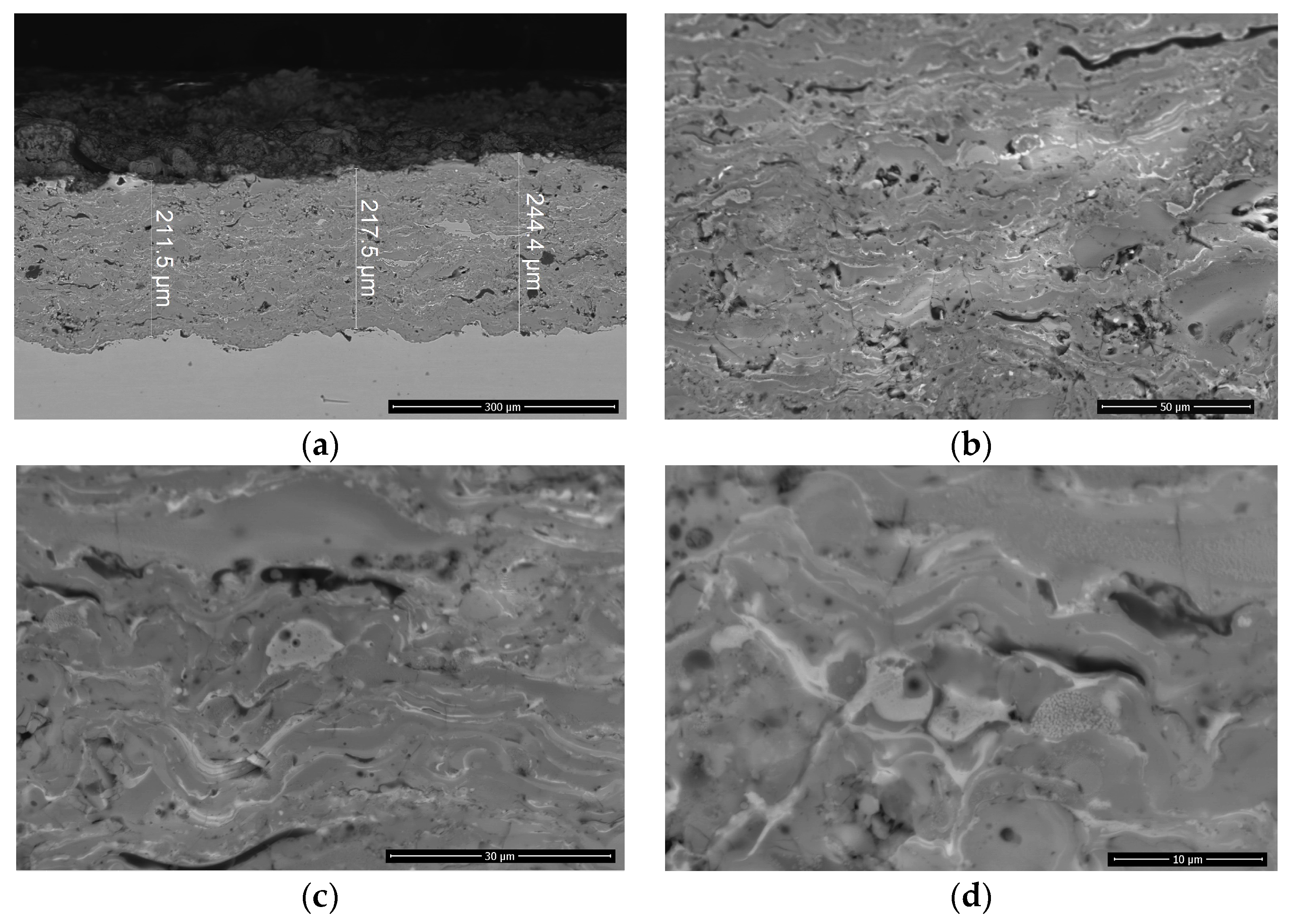

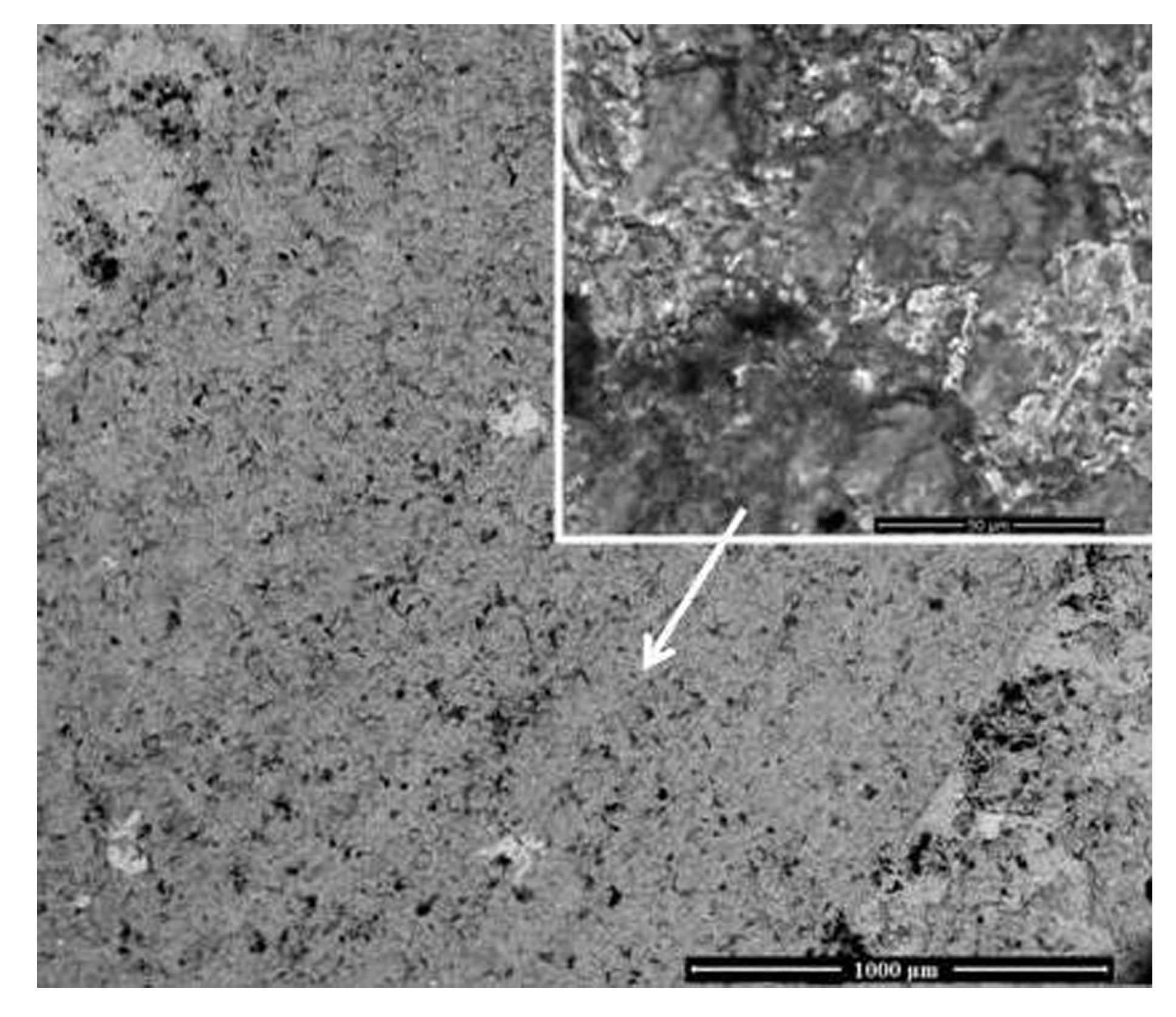

| Porosity, ± 0.05% | 0.10 | |||

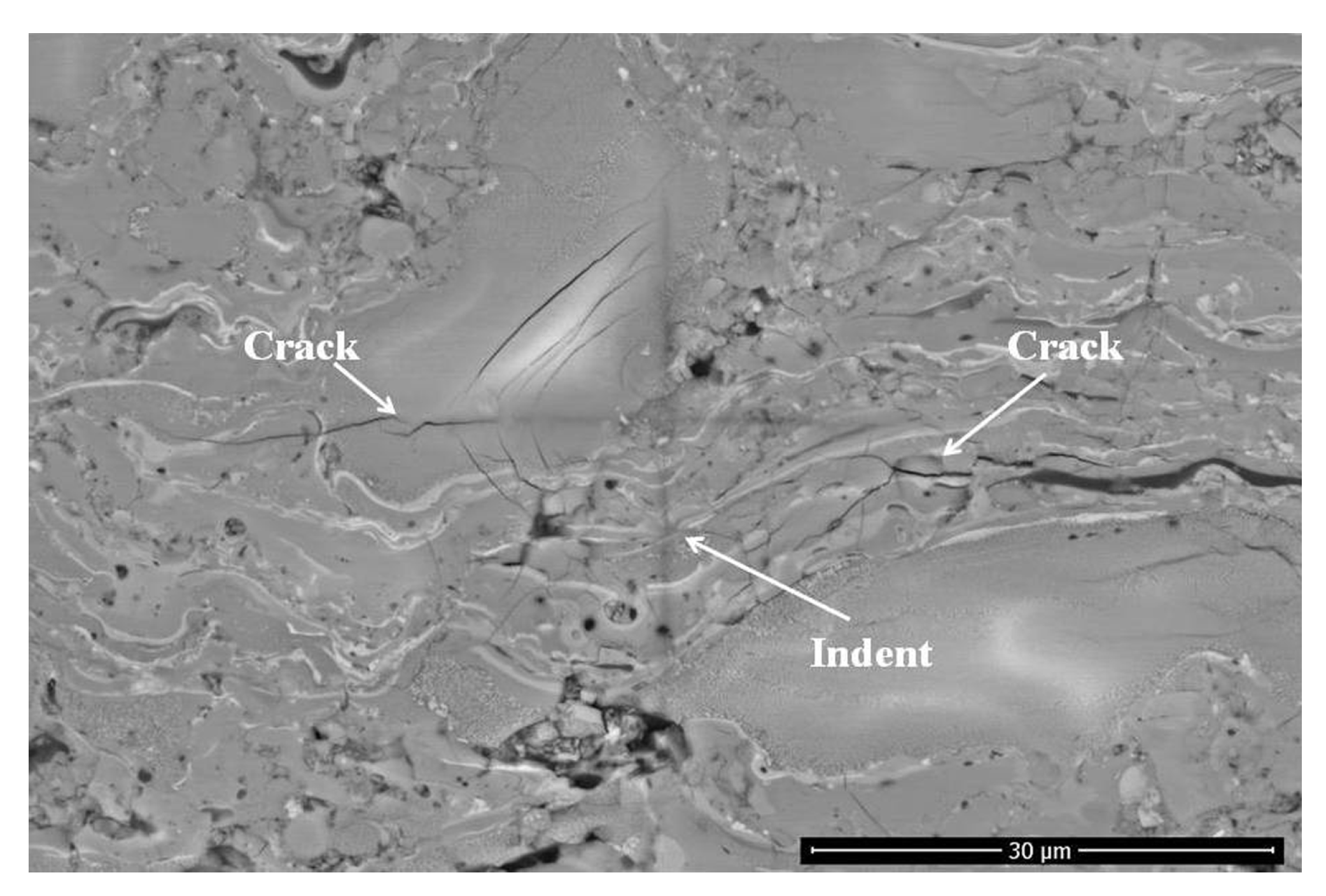

| Microhardness (HV0.2) | 526 ± 65 | 187 ± 12 | ||

| Fracture Toughness, ± 0.6 МPа∙m1/2 | 2.5 | – | ||

| Specific Wear Rate∙(× 10−5) *, ** [mm3·(m∙N)−1] | 11.75 | 48.54 | ||

| Avg. Erosion Rate (10−3) (mm3/g) | ||||

| Impact Angle | 30° | 2.9 | 21.7 | |

| 60° | 3.4 | 26.0 | ||

| 90° | 8.1 | 28.0 | ||

| Average Adhesion (MPa), Fracture Mechanism | 13, Cohesive | |||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kovaleva, M.; Prozorova, M.; Arseenko, M.; Tyurin, Y.; Kolisnichenko, O.; Yapryntsev, M.; Novikov, V.; Vagina, O.; Sirota, V. Zircon-Based Ceramic Coatings Formed by a New Multi-Chamber Gas-Dynamic Accelerator. Coatings 2017, 7, 142. https://doi.org/10.3390/coatings7090142

Kovaleva M, Prozorova M, Arseenko M, Tyurin Y, Kolisnichenko O, Yapryntsev M, Novikov V, Vagina O, Sirota V. Zircon-Based Ceramic Coatings Formed by a New Multi-Chamber Gas-Dynamic Accelerator. Coatings. 2017; 7(9):142. https://doi.org/10.3390/coatings7090142

Chicago/Turabian StyleKovaleva, Marina, Mayya Prozorova, Maria Arseenko, Yuri Tyurin, Oleg Kolisnichenko, Maxim Yapryntsev, Vseslav Novikov, Olga Vagina, and Viacheslav Sirota. 2017. "Zircon-Based Ceramic Coatings Formed by a New Multi-Chamber Gas-Dynamic Accelerator" Coatings 7, no. 9: 142. https://doi.org/10.3390/coatings7090142