Thermal Analysis of Tantalum Carbide-Hafnium Carbide Solid Solutions from Room Temperature to 1400 °C

Abstract

:1. Introduction

2. Experimental Details

2.1. Materials

2.2. TGA Testing and Post-Oxidation Characterization

3. Results and Discussions

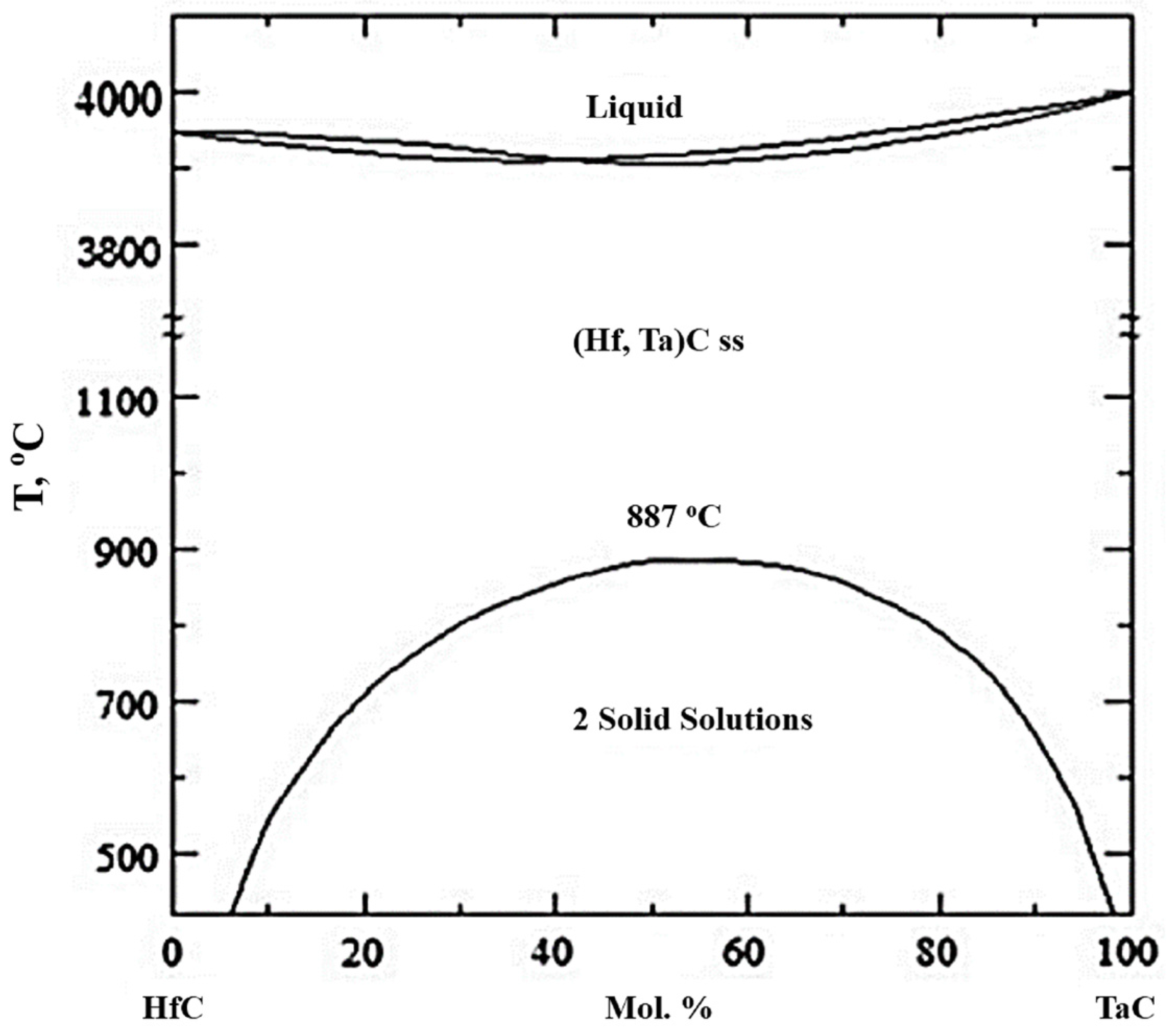

3.1. Microstructure and Phases in Sintered TaC, HfC, and TaC-HfC Solid Solutions

3.2. Macro State Morphology of Post-Oxidation TaC-HfC Solid Solutions

3.3. Mass Change during Thermogravimetric Analysis of Carbide Solid Solutions

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Fahrenholtz, W.G.; Wuchina, E.J.; Lee, W.E.; Zhou, Y. Ultra-High Temperature Ceramics: Materials for Extreme Environment Applications; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014. [Google Scholar]

- Louis, L.E. Transition Metal Carbides and Nitrides; Academic Press: New York, NY, USA, 1971. [Google Scholar]

- Upadhya, K.; Yang, J.; Hoffman, W.P. Materials for Ultrahigh Temperature Structural Applications. Am. Ceram. Soc. Bull. 1997, 76, 51–56. [Google Scholar]

- Pierson, H.O. Handbook of Refractory Carbides and Nitrides; William Andrew Publishing: Westwood, NJ, USA, 1996. [Google Scholar]

- Opeka, M.M.; Talmy, I.G.; Zaykoski, J.A. Oxidation-based Materials Selection for 2000 °C + Hypersonic Aerosurfaces: Theoretical Considerations and Historical Experience. J. Mater. Sci. 2004, 39, 5887–5904. [Google Scholar] [CrossRef]

- Simonenko, E.P.; Sevast’yanov, D.V.; Simonenko, N.P.; Sevast’yanov, V.G.; Kuznetsov, N.T. Promising Ultra-high Temperature Ceramic Materials for Aerospace Applications. Russ. J. Inorg. Chem. 2013, 58, 1669–1693. [Google Scholar] [CrossRef]

- Gary, S.P.; Krishnamurthy, N.; Awasthi, A.; Venkatraman, M. The O-Ta (Oxygen-Tantalum) System. J. Phase Equilib. 1996, 17, 63–77. [Google Scholar]

- Fahrenholtz, W.G.; Hilmas, G.E. Oxidation of Ultra-high Temperature Transition Metal Diboride Ceramics. Int. Mater. Rev. 2012, 57, 61–72. [Google Scholar] [CrossRef]

- Gasch, M.; Ellerby, D.; Irby, E.; Beckman, S.; Gusman, M.; Johnson, S. Processing, Properties and Arc Jet Oxidation of Hafnium Diboride/Silicon Carbide Ultra High Temperature Ceramics. J. Mater. Sci. 2004, 39, 5925–5937. [Google Scholar] [CrossRef]

- Agte, C.; Alterhum, H. Investigations of the High-Melting Carbide Systems Connected with Problem of the Carbon Melting. Z. Technol. Phyzik 1930, 11, 182–191. [Google Scholar]

- Coutright, E.L.; Prater, J.T.; Holcomb, G.R.; Stpierre, G.R.; Rapp, R.A. Oxidation of Hafnium Carbide and Hafnium Carbide with Additions of Tantalum and Praseodymium. Oxid. Met. 1991, 36, 423–437. [Google Scholar] [CrossRef]

- Ghaffari, S.A.; Faghihi-Sani, M.A.; Golestani-Fard, F.; Ebrahimi, S. Pressureless Sintering of Ta0.8Hf0.2C UHTC in the Presence of MoSi2. Ceram. Int. 2013, 39, 1985–1989. [Google Scholar] [CrossRef]

- Patterson, M.C.L. Advanced HfC-TaC Oxidation Resistance Composite Rocket Thruster. Mater. Manuf. Process. 1996, 11, 367–379. [Google Scholar] [CrossRef]

- Rudy, E. Ternary Phase Equilibria in Transition Metal-Boron-Carbon-Silicon System. Part II. Ternary Systems, Vol I. Ta-HfC-C System; Technical Report: AFML-TR-65-2 Part II Vol. 1; Wright-Patterson Air Force Base, Air Force Systems Command, Air Force Materials Laboratory: Dayton, OH, USA, 1969. [Google Scholar]

- Ghaffari, S.A.; Faghihi-Sani, M.A.; Golestani-Fard, F.; Nojabayy, M. Diffusion and Solid Solution Formation Between the Binary Carbides of TaC, HfC, ZrC. Int. J. Refract. Met. Hard Mater. 2013, 41, 180–184. [Google Scholar] [CrossRef]

- Cedillos-Barraza, O.; Grasso, S.; Nasiri, N.A.; Jayaseelan, D.D.; Reece, M.J.; Lee, W.E. Sintering Behavior, Solid Solution Formation and Characterization of TaC, HfC and TaC-HfC Fabricated by Spark Plasma Sintering. J. Eur. Ceram. Soc. 2016, 36, 1539–1548. [Google Scholar] [CrossRef]

- Zhang, C.; Gupta, A.; Seal, S.; Boesl, B.; Agarwal, A. Solid Solution Synthesis of Tantalum Carbide-Hafnium Carbide by Spark Plasma Sintering. J. Am. Ceram. Soc. 2017, 100, 1773–2308. [Google Scholar] [CrossRef]

- Zhang, C. High Temperature Oxidation Study of Tantalum Carbide-Hafnium Carbide Solid Solutions Synthesized By Spark Plasma Sintering. Ph.D. Thesis, Florida International University, Miami, FL, USA, 18 October 2016. [Google Scholar]

- Desmaison-Brut, M.; Alexandre, N.; Desmaison, J. Comparison of the Oxidation Behavior of Two Dense Hot Isostatically Pressed Tantalum Carbide (TaC and Ta2C) Materials. J. Eur. Ceram. Soc. 1997, 17, 1325–1334. [Google Scholar] [CrossRef]

- Zhang, X.; Hilmas, G.E.; Fahrenholtz, W.G. Densification, Mehcanical Properties, and Oxidation Reistance of TaC-TaB2 Creamics. J. Am. Ceram. Soc. 2008, 91, 4129–4132. [Google Scholar]

- Cramer, S.D.; Covino, B.S., Jr. ASM Handbook Volume 13A: Corrosion: Fundamentals, Testing, and Protection; ASM International: Geauga County, OH, USA, 2013. [Google Scholar]

- Bargeron, C.B.; Benson, R.C.; Jette, A.N.; Phillips, T.E. Oxidation of Hafnium Carbide in the Temperature Range 1400° to 2060 °C. J. Am. Ceram. Soc. 1993, 76, 1040–1046. [Google Scholar] [CrossRef]

- Liu, D.; Deng, J.; Jin, Y.; He, C. Adsorption of Atomic Oxygen on HfC and TaC (110) Surface From Firtst Principles. Appl. Surf. Sci. 2012, 261, 214–218. [Google Scholar] [CrossRef]

| Name | Pellet Density (×103 kg/m3) | Densification (%) | Average Grain Size (µm) |

|---|---|---|---|

| Pure TaC | 14.14 | 96.7 | 6.8 ± 1.4 |

| T80H20 | 13.85 | 97.8 | 6.2 ± 2.1 |

| T50H50 | 13.26 | 98.2 | 3.8 ± 1.2 |

| T20H80 | 12.68 | 98.8 | 3.1 ± 1.1 |

| Pure HfC | 12.21 | 98.5 | 2.3 ± 0.7 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Loganathan, A.; Boesl, B.; Agarwal, A. Thermal Analysis of Tantalum Carbide-Hafnium Carbide Solid Solutions from Room Temperature to 1400 °C. Coatings 2017, 7, 111. https://doi.org/10.3390/coatings7080111

Zhang C, Loganathan A, Boesl B, Agarwal A. Thermal Analysis of Tantalum Carbide-Hafnium Carbide Solid Solutions from Room Temperature to 1400 °C. Coatings. 2017; 7(8):111. https://doi.org/10.3390/coatings7080111

Chicago/Turabian StyleZhang, Cheng, Archana Loganathan, Benjamin Boesl, and Arvind Agarwal. 2017. "Thermal Analysis of Tantalum Carbide-Hafnium Carbide Solid Solutions from Room Temperature to 1400 °C" Coatings 7, no. 8: 111. https://doi.org/10.3390/coatings7080111