Phase and Microstructural Correlation of Spark Plasma Sintered HfB2-ZrB2 Based Ultra-High Temperature Ceramic Composites

Abstract

:1. Introduction

2. Materials and Method

2.1. Processing of Composites

2.2. Phase, Microstructural and Mechanical Characterization

3. Results and Discussion

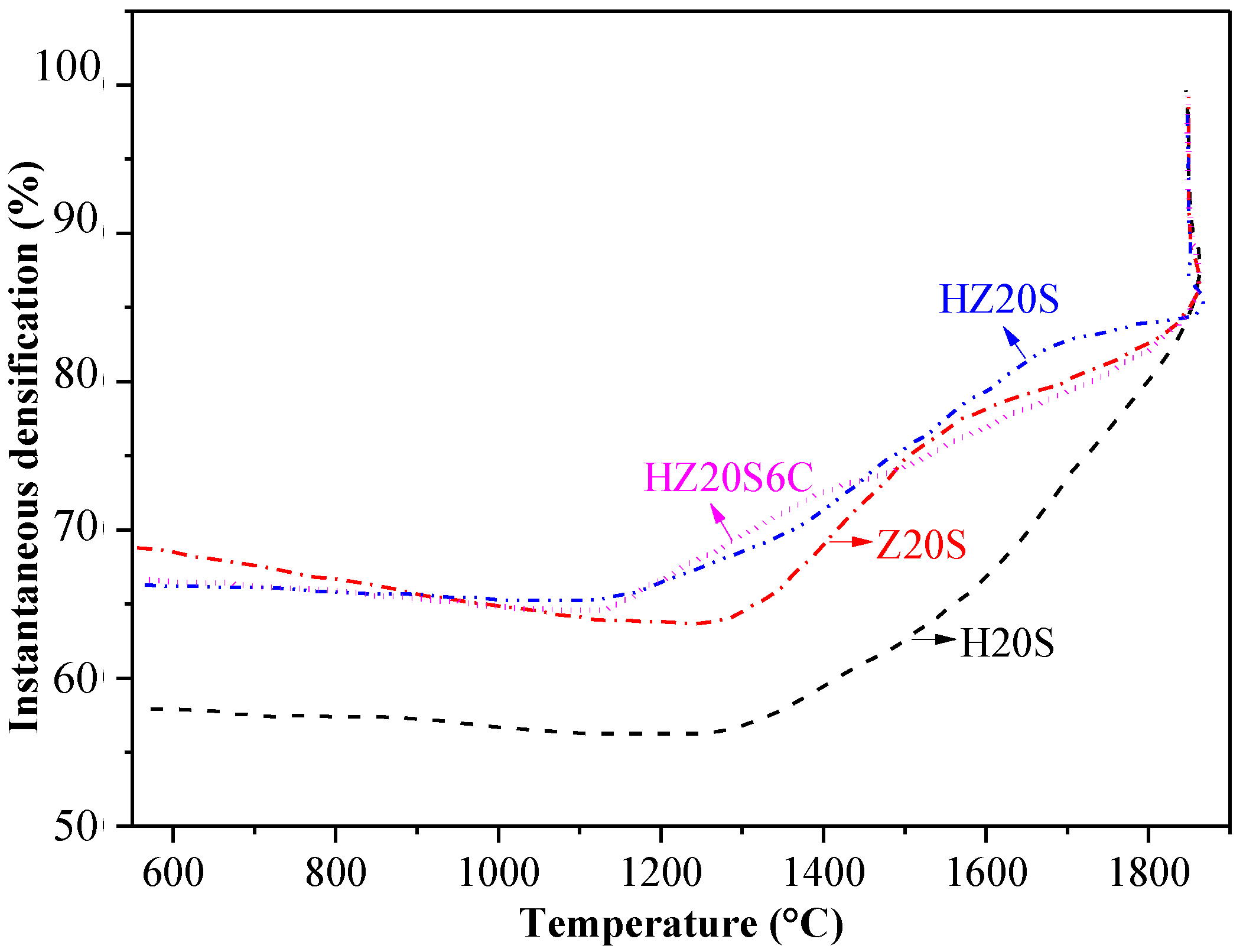

3.1. Densification of HfB2-ZrB2-SiC-CNT Composites

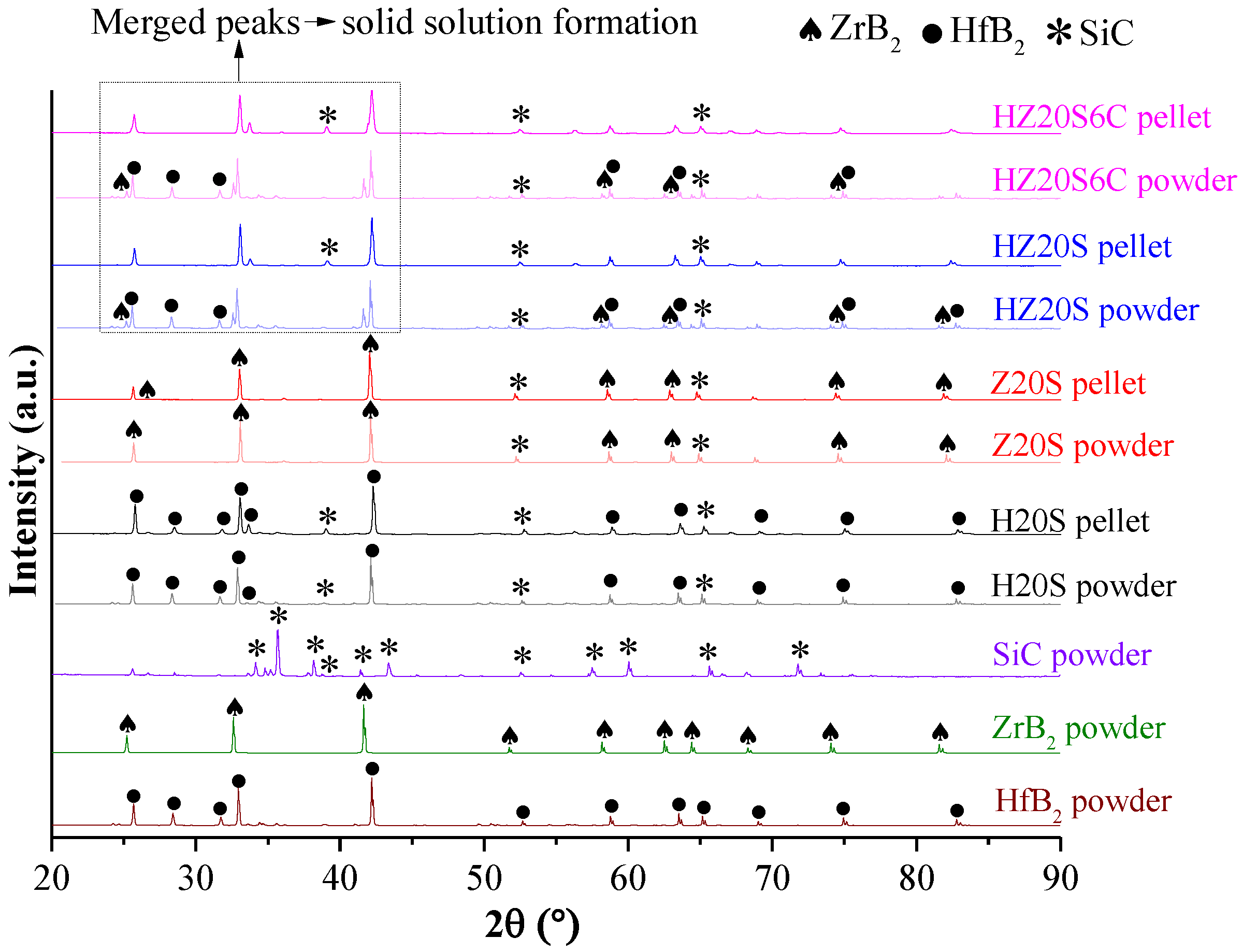

3.2. Phase Analysis of HfB2-ZrB2-SiC-CNT Composites

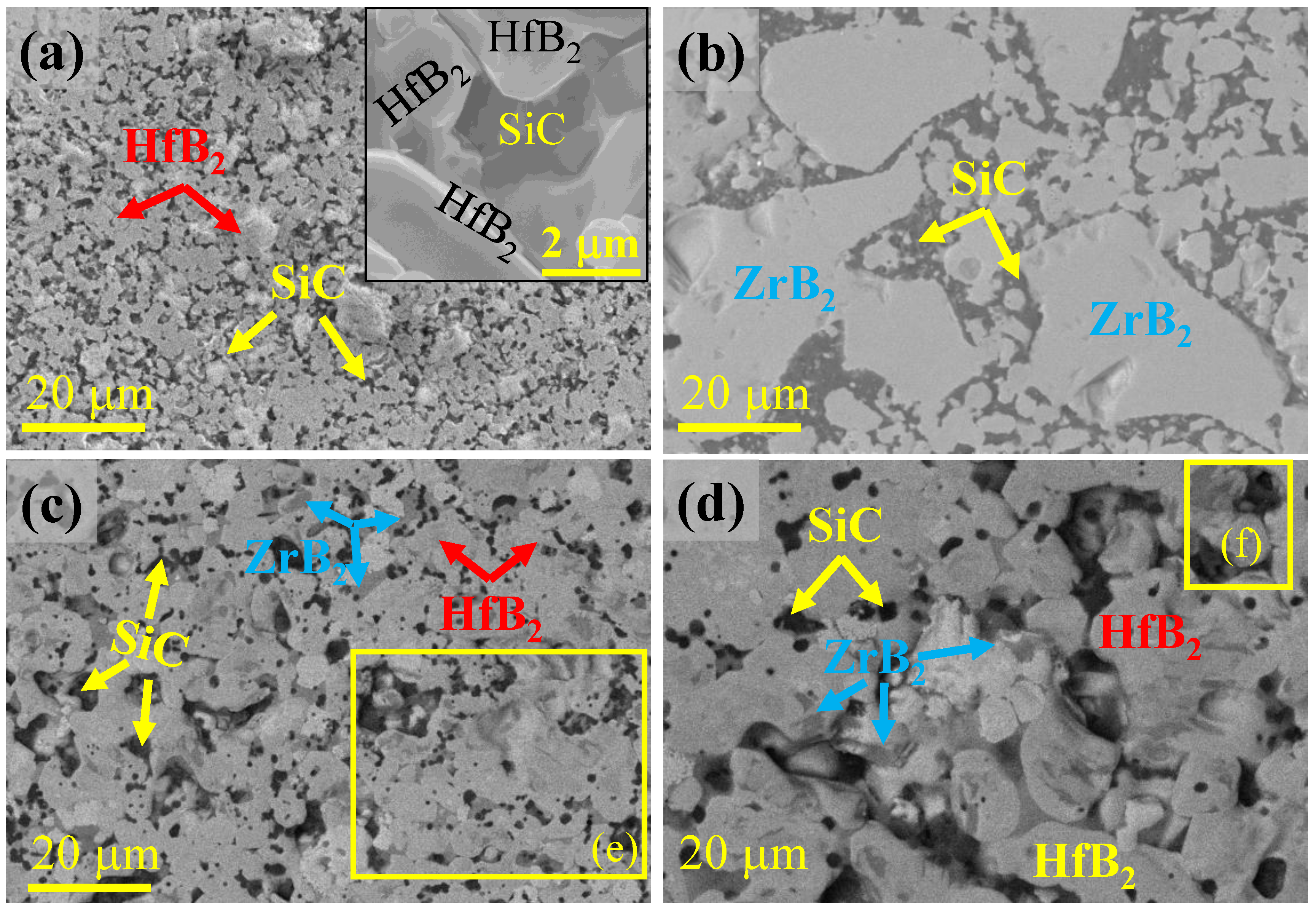

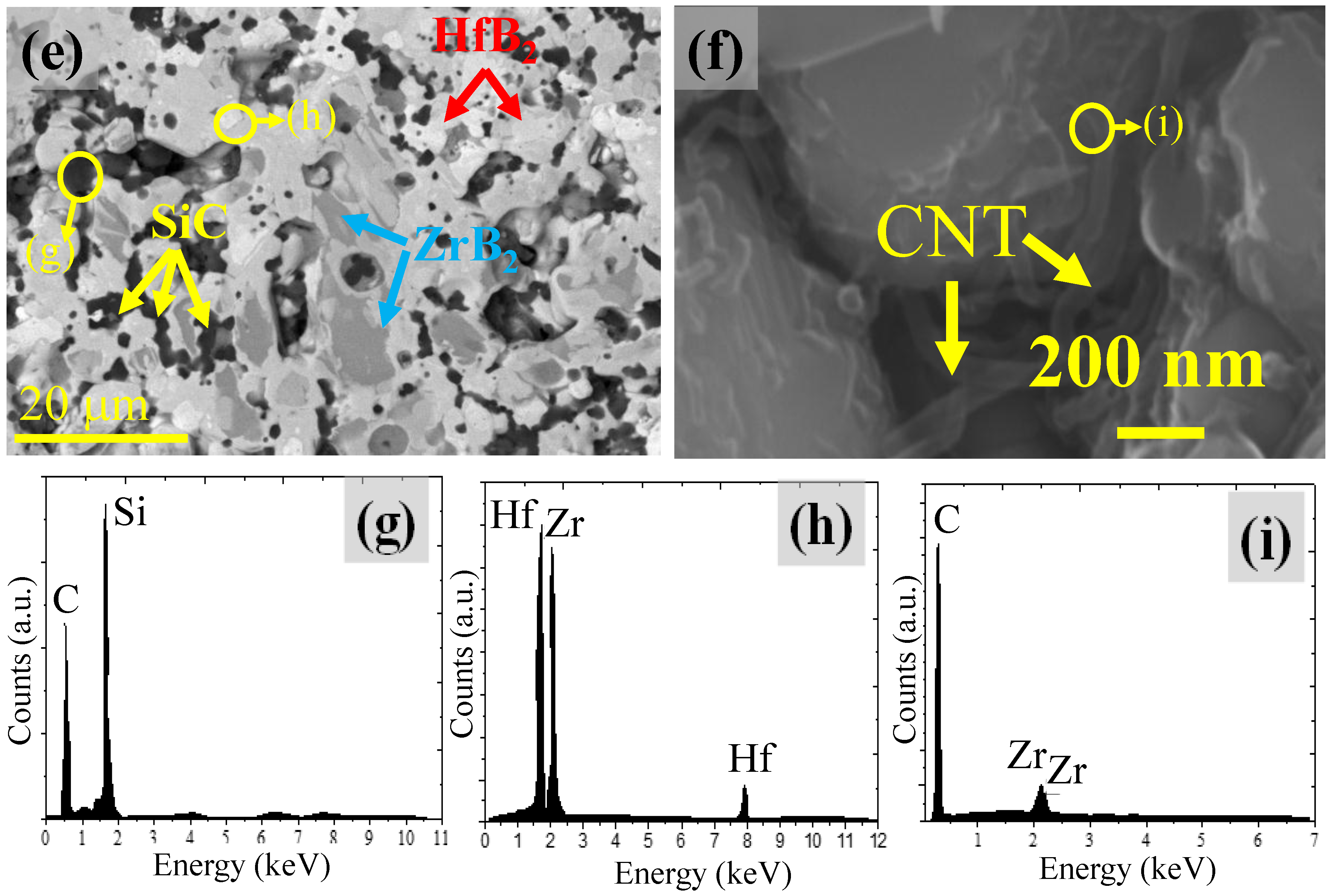

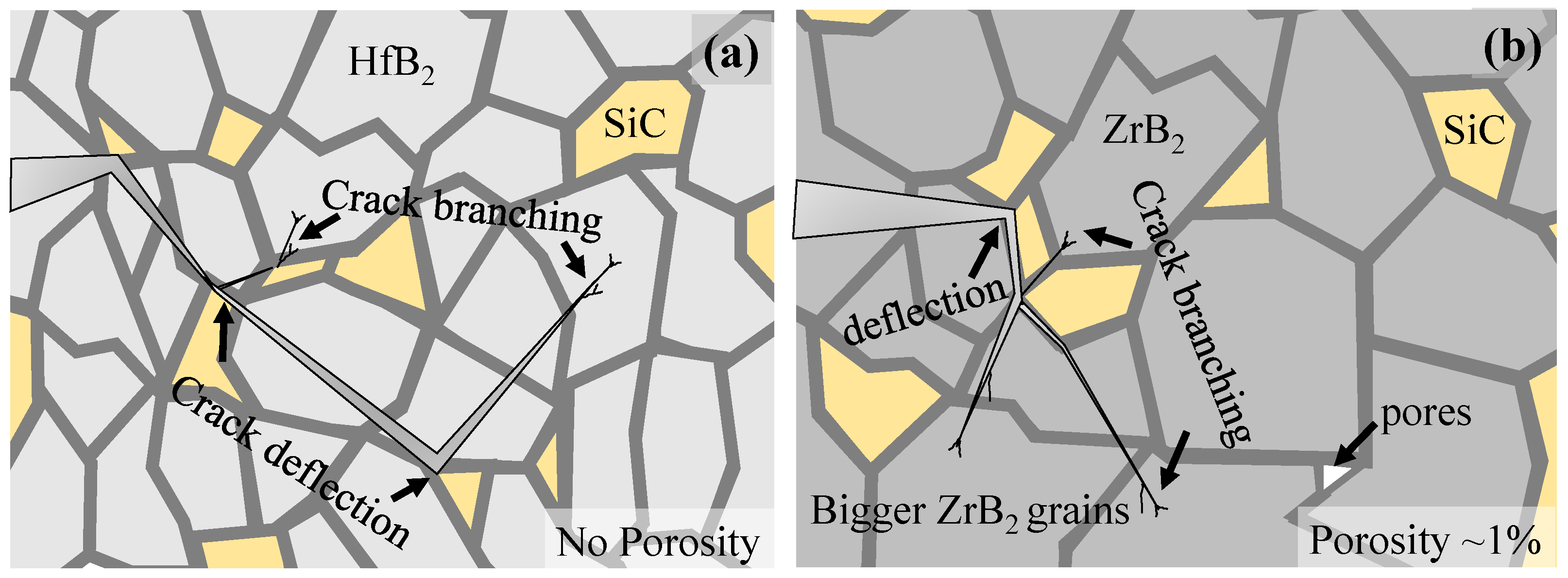

3.3. Microstructural Analysis of HfB2-ZrB2-SiC-CNT Composites

3.4. Mechanical Characterization of HfB2-ZrB2-SiC-CNT Composites

3.5. Effect of Residual Stress on the Mechanical Properties of HfB2-ZrB2-SiC-CNT Composites

4. Conclusions

Acknowledgements

Author Contributions

Conflicts of Interest

References

- Corral, E.L.; Loehman, R.E. Ultra-high-temperature ceramic coatings for oxidation protection of carbon–carbon composites. J. Am. Ceram. Soc. 2008, 91, 1495–1502. [Google Scholar] [CrossRef]

- Balani, K.; Gonzalez, G.; Agarwal, A.; Hickman, R.; O’Dell, J.S.; Seal, S. Synthesis, microstructural characterization, and mechanical property evaluation of vacuum plasma sprayed tantalum carbide. J. Am. Ceram. Soc. 2006, 89, 1419–1425. [Google Scholar] [CrossRef]

- Levine, S.R.; Opila, E.J.; Halbig, M.C.; Kiser, J.D.; Singh, M.; Salem, J.A. Evaluation of ultra-high temperature ceramics foraeropropulsion use. J. Eur. Ceram. Soc. 2002, 22, 2757–2767. [Google Scholar] [CrossRef]

- Zapata-Solvas, E.; Jayaseelan, D.D.; Lin, H.T.; Brown, P.; Lee, W.E. Mechanical properties of ZrB2- and HfB2-based ultra-high temperature ceramics fabricated by spark plasma sintering. J. Eur. Ceram. Soc. 2013, 33, 1373–1386. [Google Scholar] [CrossRef]

- Fahrenholtz, W.G.; Hilmas, G.E.; Talmy, I.G.; Zaykoski, J.A. Refractory diborides of zirconium and hafnium. J. Am. Ceram. Soc. 2007, 90, 1347–1364. [Google Scholar] [CrossRef]

- Mallik, M.; Kailath, A.J.; Ray, K.; Mitra, R. Electrical and thermophysical properties of ZrB2 and HfB2 based composites. J. Eur. Ceram. Soc. 2012, 32, 2545–2555. [Google Scholar] [CrossRef]

- Nisar, A.; Ariharan, S.; Venkateswaran, T.; Sreenivas, N.; Balani, K. Effect of carbon nanotube on processing, microstructural, mechanical and ablation behavior of ZrB2–20SiC based ultra-high temperature ceramic composites. Carbon 2017, 111, 269–282. [Google Scholar] [CrossRef]

- Nisar, A.; Ariharan, S.; Venkateswaran, T.; Sreenivas, N.; Balani, K. Oxidation studies on tac based ultra-high temperature ceramic composites under plasma arc jet exposure. Corros. Sci. 2016, 109, 50–61. [Google Scholar] [CrossRef]

- Gild, J.; Zhang, Y.; Harrington, T.; Jiang, S.; Hu, T.; Quinn, M.C.; Mellor, W.M.; Zhou, N.; Vecchio, K.; Luo, J. High-entropy metal diborides: A new class of high-entropy materials and a new type of ultrahigh temperature ceramics. Sci. Rep. 2016, 6, 37946. [Google Scholar] [CrossRef] [PubMed]

- Anselmi-Tamburini, U.; Kodera, Y.; Gasch, M.; Unuvar, C.; Munir, Z.A.; Ohyanagi, M.; Johnson, S. Synthesis and characterization of dense ultra-high temperature thermal protection materials produced by field activation through spark plasma sintering (SPS): I. Hafnium diboride. J. Mater. Sci. 2006, 41, 3097–3104. [Google Scholar] [CrossRef]

- Wang, H.; Wang, C.-A.; Yao, X.; Fang, D. Processing and mechanical properties of zirconium diboride-based ceramics prepared by spark plasma sintering. J. Am. Ceram. Soc. 2007, 90, 1992–1997. [Google Scholar] [CrossRef]

- Nisar, A.; Ariharan, S.; Balani, K. Synergistic reinforcement of carbon nanotubes and silicon carbide for toughening tantalum carbide based ultrahigh temperature ceramic. J. Mater. Res. 2016, 31, 682–692. [Google Scholar] [CrossRef]

- Nisar, A.; Balani, K. Role of interfaces on multi-length scale wear mechanics of tac-based composites. Adv. Eng. Mater. 2017, 19. [Google Scholar] [CrossRef]

- Sciti, D.; Silvestroni, L.; Celotti, G.; Melandri, C.; Guicciardi, S. Sintering and mechanical properties of ZrB2–TaSi2 and HfB2–TaSi2 ceramic composites. J. Am. Ceram. Soc. 2008, 91, 3285–3291. [Google Scholar] [CrossRef]

- Musa, C.; Orrù, R.; Sciti, D.; Silvestroni, L.; Cao, G. Synthesis, consolidation and characterization of monolithic and SiC whiskers reinforced HfB2 ceramics. J. Eur. Ceram. Soc. 2013, 33, 603–614. [Google Scholar] [CrossRef]

- Bull, J.; Kolodziej, P.; Salute, J.; Keese, D. Design, Instrumentation and Preflight Testing of a Sharp Ultra-High Temperature Ceramic Nosetip; NASA TM-1998-112229; NASA: Washington, DC, USA, October 1998.

- Fahrenholtz, W.G.; Wuchina, E.J.; Lee, W.E.; Zhou, Y. Ultra-High Temperature Ceramics: Materials for Extreme Environment Applications; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Yadhukulakrishnan, G.B.; Rahman, A.; Karumuri, S.; Stackpoole, M.M.; Kalkan, A.K.; Singh, R.P.; Harimkar, S.P. Spark plasma sintering of silicon carbide and multi-walled carbon nanotube reinforced zirconium diboride ceramic composite. Mater. Sci. Eng. A 2012, 552, 125–133. [Google Scholar] [CrossRef]

- Tian, W.-B.; Kan, Y.-M.; Zhang, G.-J.; Wang, P.-L. Effect of carbon nanotubes on the properties of ZrB2–SiC ceramics. Mater. Sci. Eng. A 2008, 487, 568–573. [Google Scholar] [CrossRef]

- Wang, Z.; Hong, C.; Zhang, X.; Sun, X.; Han, J. Microstructure and thermal shock behavior of ZrB2–SiC–graphite composite. Mater. Chem. Phys. 2009, 113, 338–341. [Google Scholar] [CrossRef]

- Balani, K.; Bakshi, S.R.; Mungole, T.; Agarwal, A. Ab-initio molecular modeling of interfaces in tantalum-carbon system. J. Appl. Phys. 2012, 111, 063521–063527. [Google Scholar] [CrossRef]

- Liu, L.; Ye, F.; Zhang, Z.; Zhou, Y. Microstructure and mechanical properties of the spark plasma sintered TaC/SiC composites. Mater. Sci. Eng. A 2011, 529, 479–484. [Google Scholar] [CrossRef]

- Balak, Z.; Zakeri, M. Effect of HfB2 on microstructure and mechanical properties of ZrB2–SiC-based composites. Int. J. Refract. Metals Hard Mater. 2016, 54, 127–137. [Google Scholar] [CrossRef]

- Hu, P.; Guolin, W.; Wang, Z. Oxidation mechanism and resistance of ZrB2–SiC composites. Corros. Sci. 2009, 51, 2724–2732. [Google Scholar] [CrossRef]

- Squire, T.H.; Marschall, J. Material property requirements for analysis and design of UHTC components in hypersonic applications. J. Eur. Ceram. Soc. 2010, 30, 2239–2251. [Google Scholar] [CrossRef]

- Kumar, A.; Biswas, K.; Basu, B. On the toughness enhancement in hydroxyapatite-based composites. Acta Mater. 2013, 61, 5198–5215. [Google Scholar] [CrossRef]

- Anstis, G.R.; Chantiklul, P.; Lawn, B.R.; Marshall, D.B. A critical evaluation of indentation techniques for measuring fracture toughness: I, dircet crack measurements. J. Am. Ceram. Soc. 1981, 64, 533–538. [Google Scholar] [CrossRef]

- Awaji, H.; Sakaida, Y. V-notch technique for single-edge notched beam and chevron notch methods. J. Am. Ceram. Soc. 1990, 73, 3522–3523. [Google Scholar] [CrossRef]

- Wang, X.; Padture, N.P.; Tanaka, H. Contact-damage-resistant ceramic/single-wall carbon nanotubes and ceramic/graphite composites. Nat. Mater. 2004, 3, 539–544. [Google Scholar] [CrossRef] [PubMed]

- Chantikul, P.; Anstis, G.R.; Lawn, B.R.; Marshall, D.B. A critical evaluation of indentation techniques for measuring fracture toughness: II, strength method. J. Am. Ceram. Soc. 1981, 64, 539–543. [Google Scholar] [CrossRef]

- Sheldon, B.W.; Curtin, W.A. Nanoceramic composites: Tough to test. Nat. Mater. 2004, 3, 505–506. [Google Scholar] [CrossRef] [PubMed]

- Bakshi, S.R.; Musaramthota, V.; Virzi, D.A.; Keshri, A.K.; Lahiri, D.; Singh, V.; Seal, S.; Agarwal, A. Spark plasma sintered tantalum carbide–carbon nanotube composite: Effect of pressure, carbon nanotube length and dispersion technique on microstructure and mechanical properties. Mater. Sci. Eng. A 2011, 528, 2538–2547. [Google Scholar] [CrossRef]

- Rudy, E. Ternary Phase Equilibria in Transition Metal-Boron-Carbon-Silicon Systems. Part 5. Compendium of Phase Diagram Data; AD0689843; DTIC: Washington, WA, USA, 30 April 1969. [Google Scholar]

- Silvestroni, L.; Sciti, D.; Bellosi, A. Microstructure and properties of pressureless sintered HfB2-based composites with additions of ZrB2 or HfC. Adv. Eng. Mater. 2007, 9, 915–920. [Google Scholar] [CrossRef]

- Post, B.; Glaser, F.W.; Moskowitz, D. Transition metal diborides. Acta Metall. 1954, 2, 20–25. [Google Scholar] [CrossRef]

- Bakshi, S.R.; Musaramthota, V.; Lahiri, D.; Singh, V.; Seal, S.; Agarwal, A. Spark plasma sintered tantalum carbide: Effect of pressure and nano-boron carbide addition on microstructure and mechanical properties. Mater. Sci. Eng. A 2011, 528, 1287–1295. [Google Scholar] [CrossRef]

- Dresselhaus, M.S.; Jorio, A.; Hofmann, M.; Dresselhaus, G.; Saito, R. Perspectives on carbon nanotubes and graphene Raman Spectroscopy. Nano Lett. 2010, 10, 751–758. [Google Scholar] [CrossRef] [PubMed]

- Sonber, J.K.; Murthy, T.S.R.C.; Subramanian, C.; Krishnamurthy, N.; Hubli, R.C.; Suri, A.K. Effect of CrSi2 and HfB2 addition on densification and properties of ZrB2. Int. J. Refract. Metals Hard Mater. 2012, 31, 125–131. [Google Scholar] [CrossRef]

- Marschall, J.; Erlich, D.C.; Manning, H.; Duppler, W.; Ellerby, D.; Gasch, M. Microhardness and high-velocity impact resistance of HfB2/SiC and ZrB2/SiC composites. J. Mater. Sci. 2004, 39, 5959–5968. [Google Scholar] [CrossRef]

- Gasch, M.; Ellerby, D.; Irby, E.; Beckman, S.; Gusman, M.; Johnson, S. Processing, properties and arc jet oxidation of hafnium diboride/silicon carbide ultra high temperature ceramics. J. Mater. Sci. 2004, 39, 5925–5937. [Google Scholar] [CrossRef]

- Licheri, R.; Orrù, R.; Musa, C.; Locci, A.M.; Cao, G. Consolidation via spark plasma sintering of HfB2/SiC and HfB2/HfC/SiC composite powders obtained by self-propagating high-temperature synthesis. J. Alloys Compd. 2009, 478, 572–578. [Google Scholar] [CrossRef]

- Asl, M.S.; Kakroudi, M.G.; Noori, S. Hardness and toughness of hot pressed ZrB2–SiC composites consolidated under relatively low pressure. J. Alloys Compd. 2015, 619, 481–487. [Google Scholar] [CrossRef]

- Zhu, C.; Guo, W.; Yu, T.X.; Woo, C.H. Radial compression of carbon nanotubes: Deformation and damage, super-elasticity and super-hardness. Nanotechnology 2005, 16, 1035. [Google Scholar] [CrossRef]

- Hu, C.; Sakka, Y.; Byungkoog, J.; Tanaka, H.; Nishimura, T.; Shuqi, G.; Grasso, S. Microstructure and properties of ZrB2–SiC and HfB2–SiC composites fabricated by spark plasma sintering (SPS) using TaSi2 as sintering aid. J. Ceram. Soc. Jpn. 2010, 118, 997–1001. [Google Scholar] [CrossRef]

- Rosen, B.W.; Hashin, Z. Effective thermal expansion coefficients and specific heats of composite materials. Int. J. Eng. Sci. 1970, 8, 157–173. [Google Scholar] [CrossRef]

- Brown, H.L.; Armstrong, P.E.; Kempter, C.P. Elastic properties of some polycrystalline transition-metal monocarbides. J. Chem. Phys. 1966, 45, 547–549. [Google Scholar] [CrossRef]

- Taya, M.; Hayashi, S.; Kobayashi, A.S.; Yoon, H.S. Toughening of a particulate-reinforced ceramic-matrix composite by thermal residual stress. J. Am. Ceram. Soc. 1990, 73, 1382–1391. [Google Scholar] [CrossRef]

- Ghosh, D.; Subhash, G.; Orlovskaya, N. Measurement of scratch-induced residual stress within sic grains in ZrB2–SiC composite using micro-Raman Spectroscopy. Acta Mater. 2008, 56, 5345–5354. [Google Scholar] [CrossRef]

- Watts, J.; Hilmas, G.; Fahrenholtz, W.G.; Brown, D.; Clausen, B. Measurement of thermal residual stresses in ZrB2–SiC composites. J. Eur. Ceram. Soc. 2011, 31, 1811–1820. [Google Scholar] [CrossRef]

- Zhang, C.; Gupta, A.; Seal, S.; Boesl, B.; Agarwal, A. Solid solution synthesis of tantalum carbide-hafnium carbide by spark plasma sintering. J. Am. Ceram. Soc. 2017, 100, 1853–1862. [Google Scholar] [CrossRef]

| Compositions | Sample ID | Theoretical Density (g/cc) | Archimedes Density (g/cc) | % Relative Densification |

|---|---|---|---|---|

| HfB2 + 20 vol % SiC | H20S | 9.04 | 9.04 | 100.0 |

| ZrB2 + 20 vol % SiC | Z20S | 5.51 | 5.46 | 99.0 |

| HfB2-ZrB2 (1:1) + 20 vol % SiC | HZ20S | 7.27 | 6.98 | 96.0 |

| HfB2-ZrB2 (1:1) + 20 vol % SiC + 6 vol % CNT | HZ20S6C | 6.92 | 6.85 | 99.5 |

| Sample ID | Hardness (GPa) | E (GPa) | re | rd | KIC (MPa·m0.5) | GIC (J·m−2) | |

|---|---|---|---|---|---|---|---|

| ROM | Experimental | ||||||

| H20S | 21.6 ± 0.2 | 23.4 ± 1.9 | 456 ± 10 | 0.560 | 0.440 | 5.2 ± 0.5 | 57.1 ± 3.3 |

| Z20S | 19.2 ± 0.3 | 23.6 ± 2.1 | 503 ± 13 | 0.656 | 0.344 | 5.7 ± 0.4 | 63.0 ± 2.1 |

| HZ20S | 20.4 ± 0.3 | 20.4 ± 4.9 | 425 ± 07 | 0.658 | 0.342 | 8.7 ± 0.8 | 176.8 ± 4.8 |

| HZ20S6C | 19.5 ± 0.3 | 28.1 ± 1.2 | 528 ± 08 | 0.666 | 0.335 | 10.2 ± 0.3 | 192.6 ± 1.6 |

| Composition | CTE (×10−6/K) | Modulus (GPa) | Residual Stress (MPa) | |||||

|---|---|---|---|---|---|---|---|---|

| ROM | HS Model | Em | Er | Hsueh’s Model σ0 | Taya’s Model | |||

| U.B. | L.B. | σm | σr | |||||

| H20S | 5.74 | 5.74 | 5.73 | 433 | 360 | 950.5 | 669.1 | −29.2 |

| Z20S | 5.42 | 5.42 | 5.40 | 366 | 555 | 878.5 | 806.3 | −32.8 |

| HZ20S | 5.58 | 5.59 | 5.58 | 394 | 185 | 591.3 | 214.5 | −40.2 |

| HZ20S6C | 5.36 | 5.36 | 5.34 | 485 | 650 | 176.4 | 139.0 | −42.8 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nisar, A.; Balani, K. Phase and Microstructural Correlation of Spark Plasma Sintered HfB2-ZrB2 Based Ultra-High Temperature Ceramic Composites. Coatings 2017, 7, 110. https://doi.org/10.3390/coatings7080110

Nisar A, Balani K. Phase and Microstructural Correlation of Spark Plasma Sintered HfB2-ZrB2 Based Ultra-High Temperature Ceramic Composites. Coatings. 2017; 7(8):110. https://doi.org/10.3390/coatings7080110

Chicago/Turabian StyleNisar, Ambreen, and Kantesh Balani. 2017. "Phase and Microstructural Correlation of Spark Plasma Sintered HfB2-ZrB2 Based Ultra-High Temperature Ceramic Composites" Coatings 7, no. 8: 110. https://doi.org/10.3390/coatings7080110