An Experimental Study on Nano-Carbon Films as an Anti-Wear Protection for Drilling Tools

Abstract

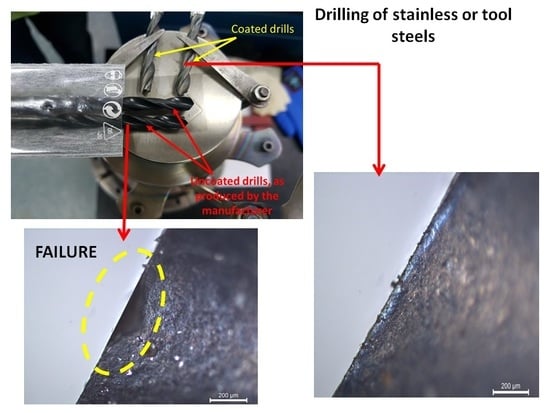

:1. Introduction

2. Materials and Methods

2.1. PLD Deposition

2.2. Characterization of Synthesized Structures

2.3. Functional Tests

3. Results

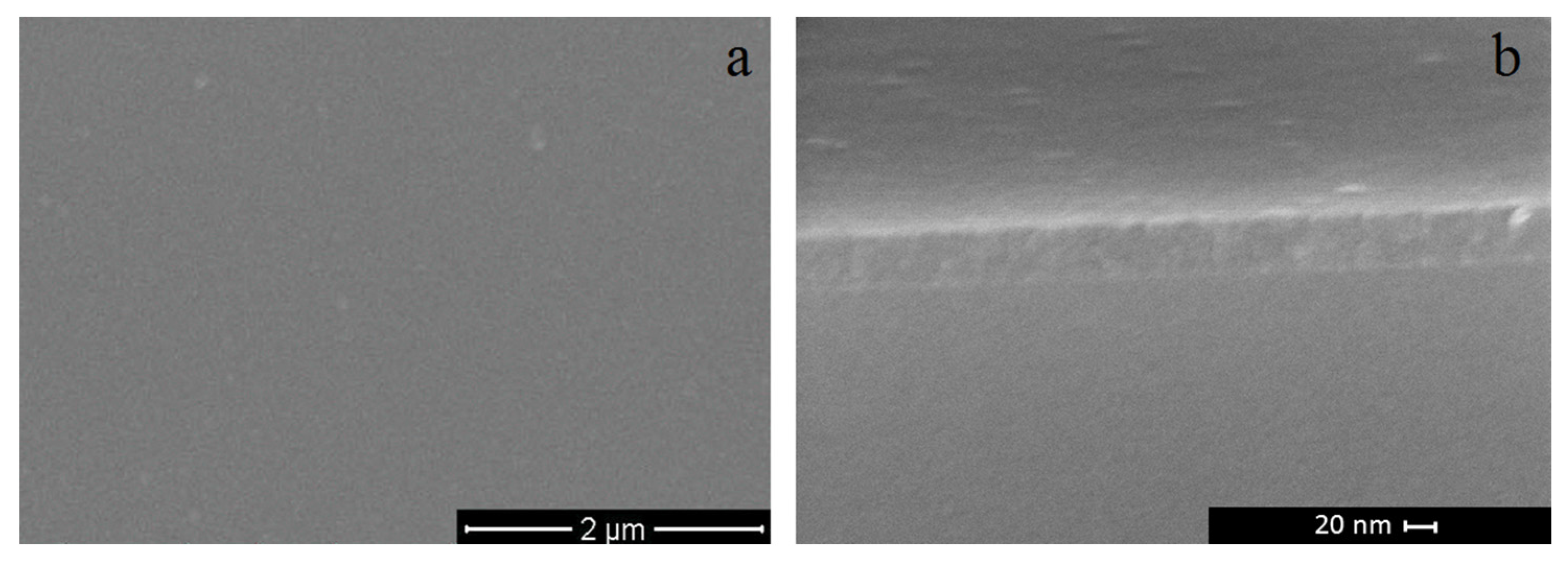

3.1. Films Morphology and Composition

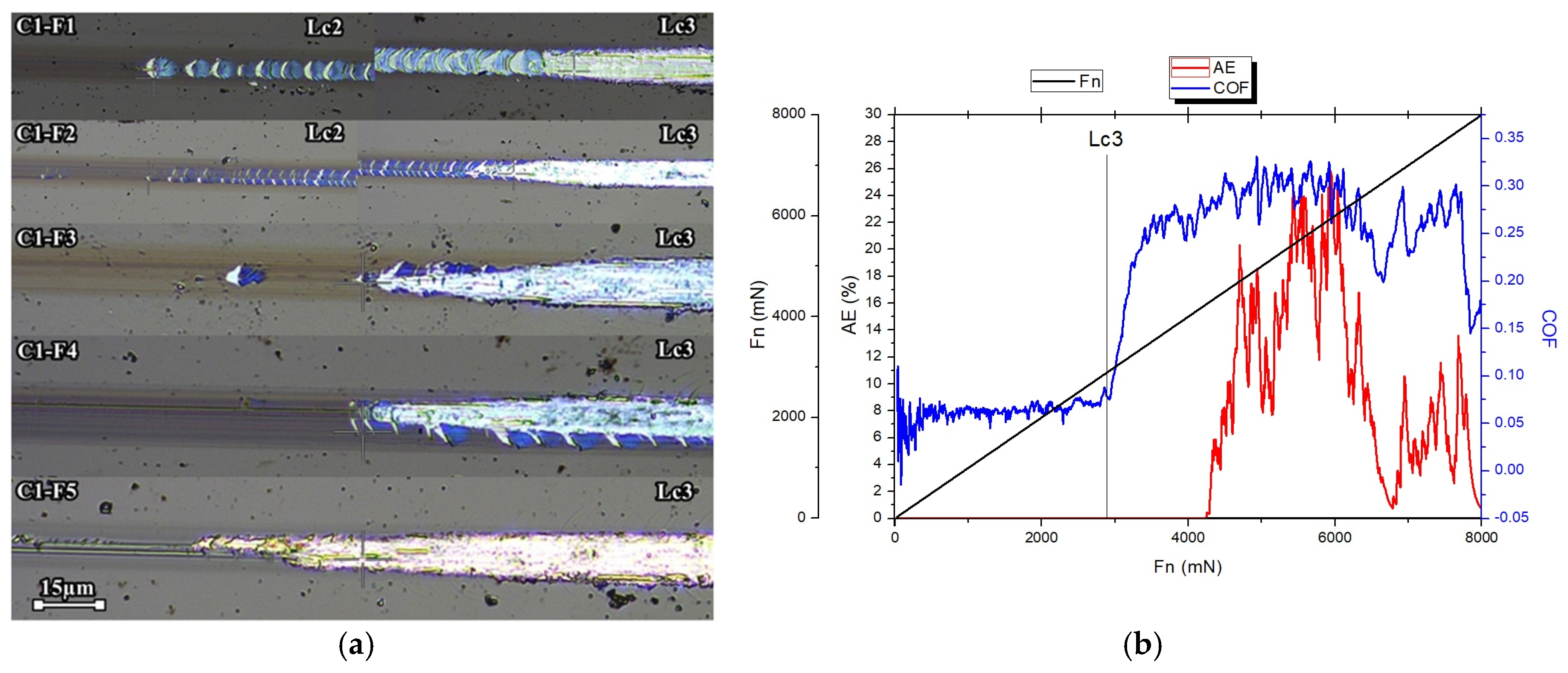

3.2. Scratch Testing

3.3. Nanoindentation Tests

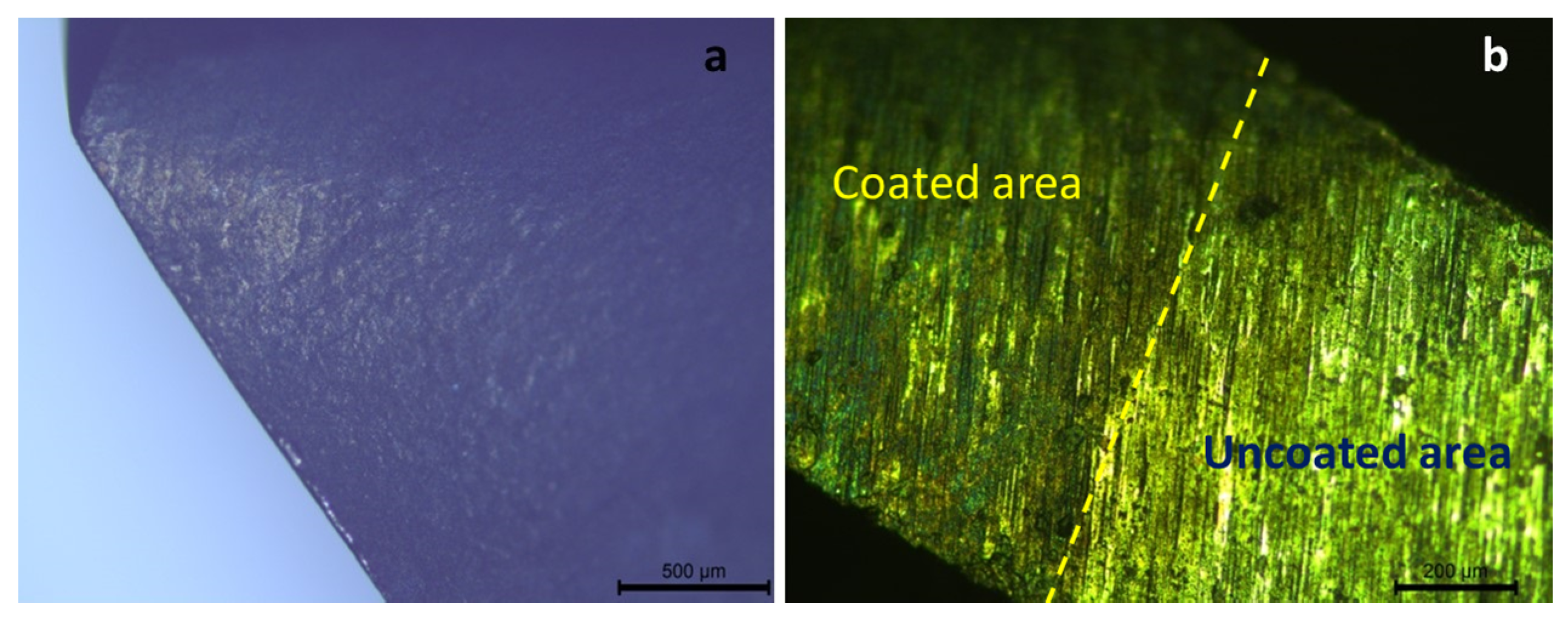

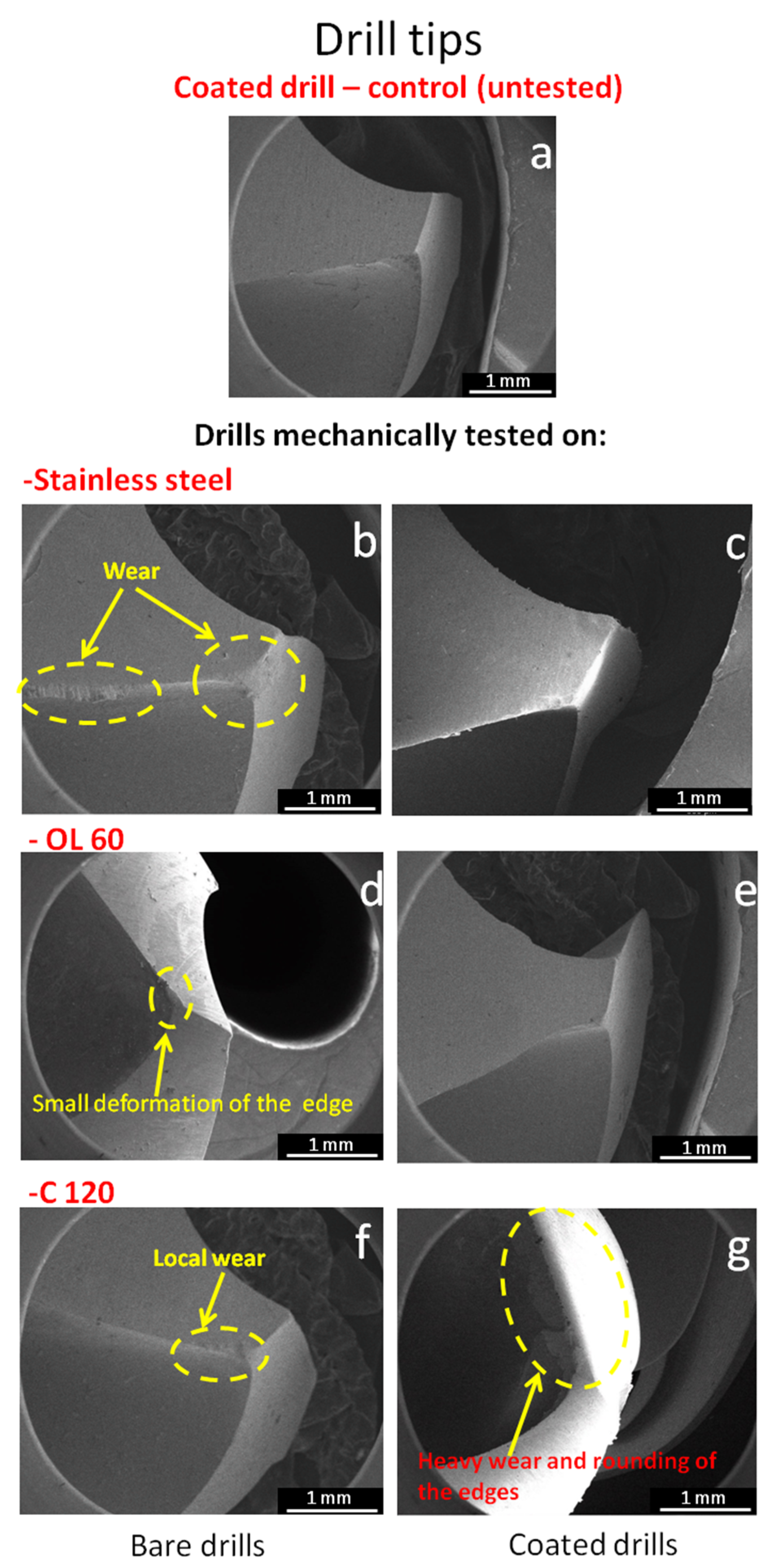

3.4. Functional Tests

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Robertson, J. Diamond-like amorphous carbon. Mater. Sci. Eng. R 2002, 37, 129–281. [Google Scholar] [CrossRef]

- Dai, W.; Liu, J.; Geng, D.; Guo, P.; Zheng, J.; Wang, Q. Microstructure and property of diamond-like carbon films with Al and Cr co-doping deposited using a hybrid beams system. Appl. Surf. Sci. 2016, 388, 503–509. [Google Scholar] [CrossRef]

- Popescu, A.C.; Stan, G.E.; Duta, L.; Nita, C.; Popescu, C.; Surdu, V.A.; Husanu, M.A.; Bita, B.; Ghisleni, R.; Himcinschi, C.; et al. The role of ambient gas and pressure on the structuring of hard diamond-like carbon films synthesized by pulsed laser deposition. Materials 2015, 8, 3284–3305. [Google Scholar] [CrossRef]

- Suschke, K.; Hubner, R.; Murmu, P.P.; Gupta, P.; Futter, J.; Markwitz, A. High energy radial deposition of diamond-like carbon coatings. Coatings 2015, 5, 326–337. [Google Scholar] [CrossRef]

- Silva, W.M.; Jesus, L.M.; Carneiro, J.R.; Souza, P.S.; Martins, P.S.; Trava-Airoldi, V.J. Performance of carbide tools coated with DLC in the drilling of SAE 323 aluminum alloy. Surf. Coat. Technol. 2015, 284, 404–409. [Google Scholar] [CrossRef]

- Bhowmick, S.; Banerji, A.; Alpas, A.T. Tribological behavior of Al–6.5%, –12%, –18.5% Si alloys during machining using CVD diamond and DLC coated tools. Surf. Coat. Technol. 2015, 284, 353–364. [Google Scholar] [CrossRef]

- Ciniero, A.; Le Rouzic, J.; Reddyhoff, T. The use of triboemission imaging and charge measurements to study DLC coating failure. Coatings 2017, 7, 129. [Google Scholar] [CrossRef]

- Nakazawa, H.; Kamata, R.; Okuno, S. Deposition of silicon-doped diamond-like carbon films by plasma-enhanced chemical vapor deposition using an intermittent supply of organosilane. Diam. Relat. Mater. 2015, 51, 7–13. [Google Scholar] [CrossRef]

- Popa, A.C.; Stan, G.E.; Husanu, M.A.; Pasuk, I.; Popescu, I.D.; Popescu, A.C.; Mihailescu, I.N. Multi-layer haemocompatible diamond-like carbon coatings obtained by combined radio frequency plasma enhanced chemical vapor deposition and magnetron sputtering. J. Mater. Sci. Mater. Med. 2013, 24, 2695–2707. [Google Scholar] [CrossRef] [PubMed]

- Wiatrowski, A.; Kijaszek, W.; Posadowski, W.M.; Oleszkiewicz, W.; Jadczak, J.; Kunicki, P. Deposition of diamond-like carbon thin films by the high power impulse magnetron sputtering method. Diam. Relat. Mater. 2017, 72, 71–76. [Google Scholar] [CrossRef]

- Bewilogua, K.; Hofmann, D. History of diamond-like carbon films—From first experiments to worldwide applications. Surf. Coat. Technol. 2014, 242, 214–225. [Google Scholar] [CrossRef]

- Qin, F.; Chou, Y.K.; Nolen, D.; Thompson, R.G. Coating thickness effects on diamond coated cutting tools. Surf. Coat. Technol. 2009, 204, 1056–1060. [Google Scholar] [CrossRef]

- Dorner, A.; Schürer, C.; Reisel, G.; Irmer, G.; Seidel, O.; Müller, E. Diamond-like carbon-coated Ti6Al4V: Influence of the coating thickness on the structure and the abrasive wear resistance. Wear 2001, 249, 489–497. [Google Scholar] [CrossRef]

- Yang, D. Applications of Laser Ablation—Thin Film Deposition, Nanomaterial Synthesis and Surface Modification; InTech: Rijeka, Croatia, 2016; p. 426. [Google Scholar]

- Rau, J.V.; Teghil, R.; De Bonis, A.; Generosi, A.; Paci, B.; Generosi, R.; Fosca, M.; Ferro, D.; Rossi Albertini, V.; Chilingarov, N.S. Pulsed laser deposition of hard and superhard carbon thin films from C60 targets. Diam. Relat. Mater. 2010, 19, 7–14. [Google Scholar] [CrossRef]

- Voevodin, A.A.; Donley, M.S.; Zabinski, J.S. Pulsed laser deposition of diamond-like carbon wear protective coatings: A review. Surf. Coat. Technol. 1997, 92, 42–49. [Google Scholar] [CrossRef]

- Qian, F.; Craciun, V.; Singh, R.K.; Dutta, S.D.; Pronko, P.P. High intensity femtosecond laser deposition of diamond-like carbon thin films. J. Appl. Phys. 1999, 86, 2281–2290. [Google Scholar] [CrossRef]

- Eason, R. Pulsed Laser Deposition of Thin Films: Applications-Led Growth of Functional Materials; Wiley: New York, NY, USA, 2007; p. 682. [Google Scholar]

- Hino, T.; Mustofa, S.; Nishida, M.; Araki, T. Reduction of droplet of tantalum oxide using double slit in pulsed laser deposition. Vacuum 2003, 70, 47–52. [Google Scholar] [CrossRef]

- Craciun, V.; Craciun, D. Evidence for volume boiling during laser ablation of single crystalline targets. Appl. Surf. Sci. 1999, 138, 218–223. [Google Scholar] [CrossRef]

- Lescoute, E.; Hallo, L.; Hébert, D.; Chimier, B.; Etchessahar, B.; Tikhonchuk, V.T.; Chevalier, J.M.; Combis, P. Experimental observations and modeling of nanoparticle formation in laser-produced expanding plasma. Phys. Plasma 2008, 15, 063507. [Google Scholar] [CrossRef]

- Hu, A.; Rybachuk, M.; Lu, Q.B.; Duley, W.W. Femtosecond pulsed laser deposition and optical properties of diamond-like amorphous carbon films embedded with SP-bonded carbon chains. Diam. Relat. Mater. 2008, 17, 1643–1646. [Google Scholar] [CrossRef]

- De Barros, M.I.; Vandenbulcke, L. Plasma-assisted chemical vapor deposition process for depositing smooth diamond coatings on titanium alloys at moderate temperature. Diam. Relat. Mater. 2000, 9, 1862–1866. [Google Scholar] [CrossRef]

- Morshed, M.M.; McNamara, B.P.; Cameron, D.C.; Hashmi, M.S.J. Stress and adhesion in DLC coatings on 316L stainless steel deposited by a neutral beam source. J. Mater. Process. Technol. 2003, 143, 922–926. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Interpretation of Raman spectra of disordered and amorphous carbon. Phys. Rev. B 2000, 61, 14095–14107. [Google Scholar] [CrossRef]

- Irmer, G.; Dorner-Reisel, A. Micro-Raman studies on DLC coatings. Adv. Eng. Mater. 2005, 7, 694–705. [Google Scholar] [CrossRef]

- McCann, R.; Roy, S.S.; Papakonstantinou, P.; McLaughlin, J.A.; Ray, S.C. Spectroscopic analysis of a-C and a-CNx films prepared by ultrafast high repetition rate pulsed laser deposition. J. Appl. Phys. 2005, 97, 073522. [Google Scholar] [CrossRef]

- Misra, R.D.K.; Zhang, Z.; Jia, Z.; Surya, P.V.; Somani, M.C.; Karjalainen, L.P. Nanomechanical insights into the deformation behavior of austenitic alloys with different stacking fault energies and austenitic stability. Mater. Sci. Eng. A 2011, 528, 6958–6963. [Google Scholar] [CrossRef]

- Fischer-Cripps, A.C. Nanoindentation, 3rd ed.; Springer: Berlin, Germany, 2011; p. 279. [Google Scholar]

- Hay, J.L.; O’Hern, M.E.; Oliver, W.C. The importance of contact radius for substrate independent property measurement of thin films. Mater. Res. Soc. Symp. Proc. 1998, 522, 27–32. [Google Scholar] [CrossRef]

- Carbon—Graphite Materials. Available online: https://www.azom.com/properties.aspx?ArticleID=516 (accessed on 3 October 2017).

- Bonelli, M.; Fioravanti, A.P.; Miotello, A.; Ossi, P.M. Structural and mechanical properties of Ta-C films grown by pulsed laser deposition. Europhys. Lett. 2000, 50, 501–506. [Google Scholar] [CrossRef]

- Bonelli, M.; Ferrari, A.C.; Fioravanti, A.P.; Bassi, A.L.; Miotello, A.; Ossi, P.M. Structure and mechanical properties of low stress tetrahedral amorphous carbon films prepared by pulsed laser deposition. Eur. Phys. J. B 2002, 25, 269–280. [Google Scholar] [CrossRef]

- Liu, X.; Metcalf, T.H.; Mosaner, P.; Miotello, A. Laser fluence dependence of the elastic properties of diamond-like carbon films prepared by pulsed-laser deposition. Appl. Surf. Sci. 2007, 253, 6480–6486. [Google Scholar] [CrossRef]

- Salah, N.; Alshahrie, A.; Iqbal, J.; Hasan, P.M.Z.; Abdel-wahab, M.S. Tribological behavior of diamond-like carbon thin films deposited by the pulse laser technique at different substrate temperatures. Tribol. Int. 2016, 103, 274–280. [Google Scholar] [CrossRef]

- Gayathri, S.; Kumar, N.; Krishnan, R.; Ravindran, T.R.; Dash, S.; Tyagi, A.K.; Sridharan, M. Influence of Cr content on the micro-structural and tribological properties of PLD grown nanocomposite DLC-Cr thin films. Mater. Chem. Phys. 2015, 167, 194–200. [Google Scholar] [CrossRef]

- Constantinou, M.; Pervolaraki, M.; Koutsokeras, M.; Prouskas, C.; Patsalas, P.; Kelires, P.; Giapintzakis, J.; Constantinides, G. Enhancing the nanoscratch resistance of pulsed laser deposited DLC films through molybdenum-doping. Surf. Coat. Tehnol. 2015, 330, 185–195. [Google Scholar] [CrossRef]

- Heinemann, R.K.; Hinduja, S. Investigating the feasibility of DLC-coated twist drills in deep-hole drilling. Int. J. Adv. Manuf. Technol. 2009, 44, 862–869. [Google Scholar] [CrossRef]

- Kao, W.H.; Su, Y.L.; Yao, S.H. Tribological property and drilling application of Ti–C:H and Cr–C:H coatings on high-speed steel substrates. Vacuum 2006, 80, 604–614. [Google Scholar] [CrossRef]

| Target | Substrate | Target-Substrate Distance (cm) | T (°C) | Pressure (Pa) | Fluence (J/cm2) | Energy (mJ) | No. of Pulses | Sample Code |

|---|---|---|---|---|---|---|---|---|

| Carbon graphite | Si(100) (20 × 20) mm2 | 5 | 200 | 2 × 10−5 | 2 | 500 | 5000 | C1-F1 |

| 3 | C1-F2 | |||||||

| 4 | C1-F3 | |||||||

| 5 | C1-F4 | |||||||

| 6 | C1-F5 |

| Samples | Layer No. | Layer Type | Density (g/cm3) | Thickness (nm) | Roughness (nm) |

|---|---|---|---|---|---|

| C1-F1 | 2, 0 | C | 1.8 | 72.7 | 0.4 |

| 1, 0 | SiO2 | 2.3 | 2 | 2 | |

| C1-F2 | 2, 0 | C | 1.9 | 60.8 | 0.2 |

| 1, 0 | SiO2 | 2.3 | 6 | 2.7 | |

| C1-F3 | 2, 0 | C | 2.1 | 55.2 | 0.4 |

| 1, 0 | SiO2 | 2.3 | 6.7 | 3 | |

| C1-F4 | 2, 0 | C | 2 | 58 | 0.3 |

| 1, 0 | SiO2 | 2.3 | 3.8 | 2 | |

| C1-F5 | 2, 0 | C | 2 | 96 | 0.2 |

| 1, 0 | SiO2 | 2.3 | 4 | 3 |

| Samples | LC2 (mN) | StdDev | LC3 (mN) | StdDev | Friction Coefficient (μ) |

|---|---|---|---|---|---|

| C1-F1 | 3542 | 235.601 | 5436 | 203.5 | 0.06 |

| C1-F2 | 3025 | 316.429 | 3937 | 439.6 | 0.06 |

| C1-F3 | – | – | 3319 | 514.9 | 0.07 |

| C1-F4 | – | – | 3248 | 473 | 0.075 |

| C1-F5 | – | – | 3251 | 528 | 0.09 |

| Surface Condition | Stainless Steel | OL60 | C120 |

|---|---|---|---|

| Uncoated drill tips temperature (°C) | 72 | 68 | 69 |

| Coated drills tips temperature (°C) | 63 | 60 | 78 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Popescu, C.; Cristea, D.; Bita, B.; Cristescu, R.; Craciun, D.; Chioibasu, G.D.; Luculescu, C.; Paun, I.; Duta, L.; Popescu, A.C. An Experimental Study on Nano-Carbon Films as an Anti-Wear Protection for Drilling Tools. Coatings 2017, 7, 228. https://doi.org/10.3390/coatings7120228

Popescu C, Cristea D, Bita B, Cristescu R, Craciun D, Chioibasu GD, Luculescu C, Paun I, Duta L, Popescu AC. An Experimental Study on Nano-Carbon Films as an Anti-Wear Protection for Drilling Tools. Coatings. 2017; 7(12):228. https://doi.org/10.3390/coatings7120228

Chicago/Turabian StylePopescu, Camelia, Daniel Cristea, Bogdan Bita, Rodica Cristescu, Doina Craciun, Georgiana Diana Chioibasu, Catalin Luculescu, Irina Paun, Liviu Duta, and Andrei C. Popescu. 2017. "An Experimental Study on Nano-Carbon Films as an Anti-Wear Protection for Drilling Tools" Coatings 7, no. 12: 228. https://doi.org/10.3390/coatings7120228