Graphene Coating on Copper by Electrophoretic Deposition for Corrosion Prevention

Abstract

:1. Introduction

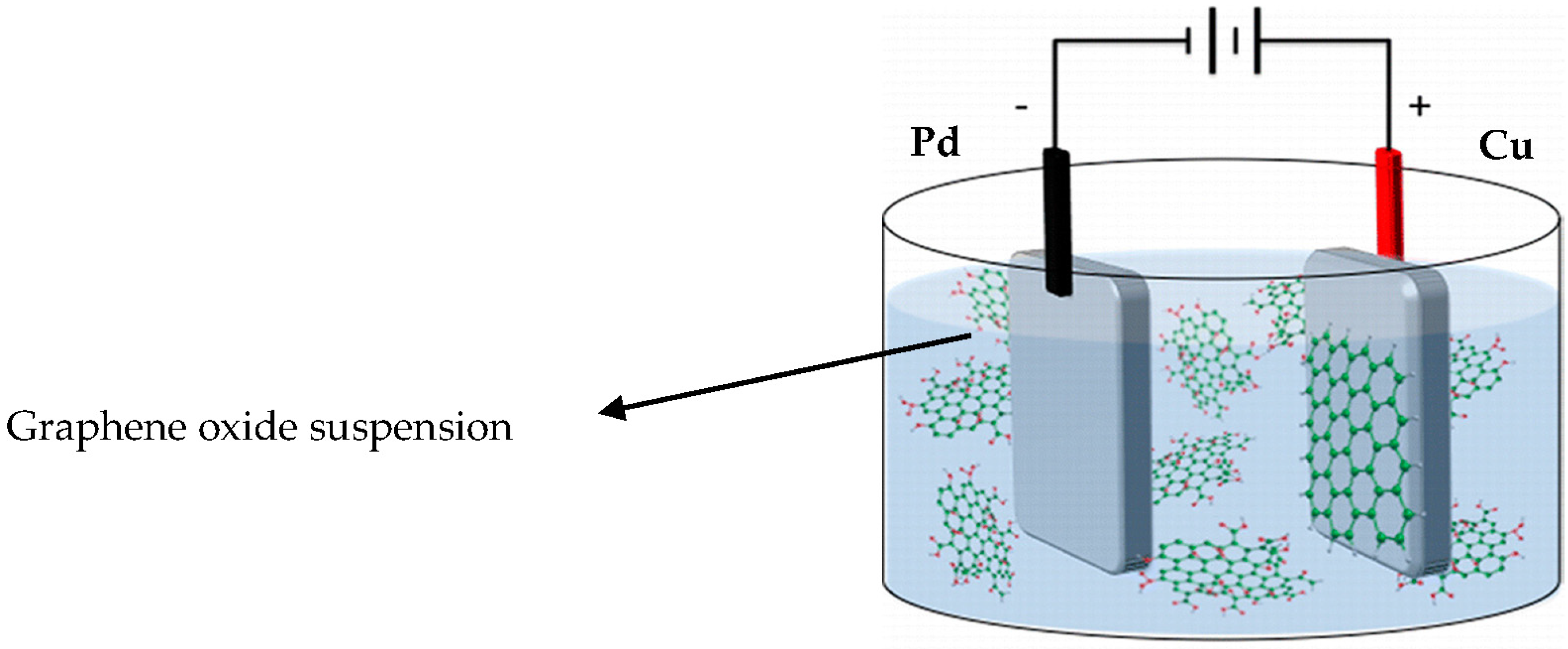

2. Materials and Methods

3. Results and Discussion

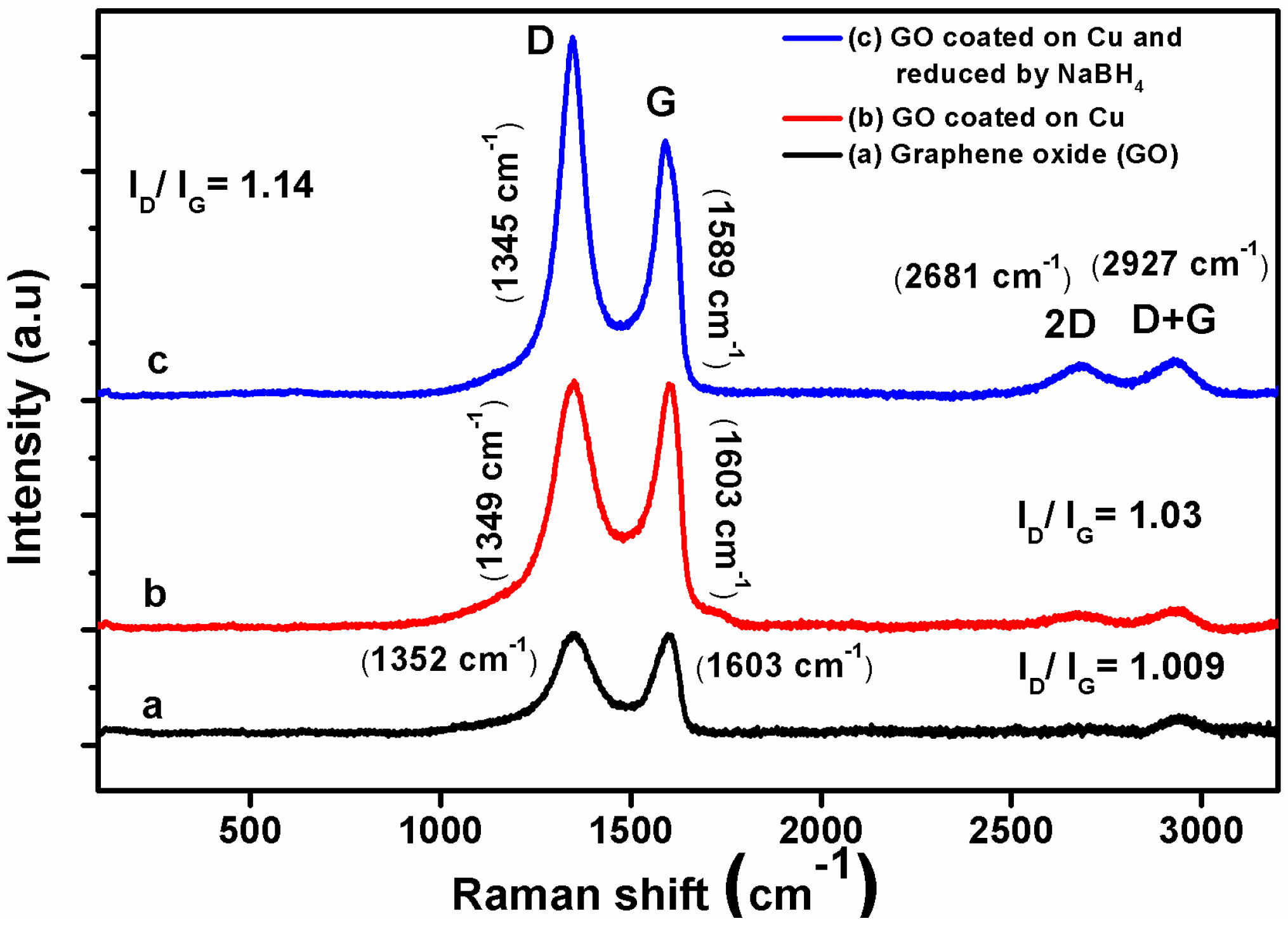

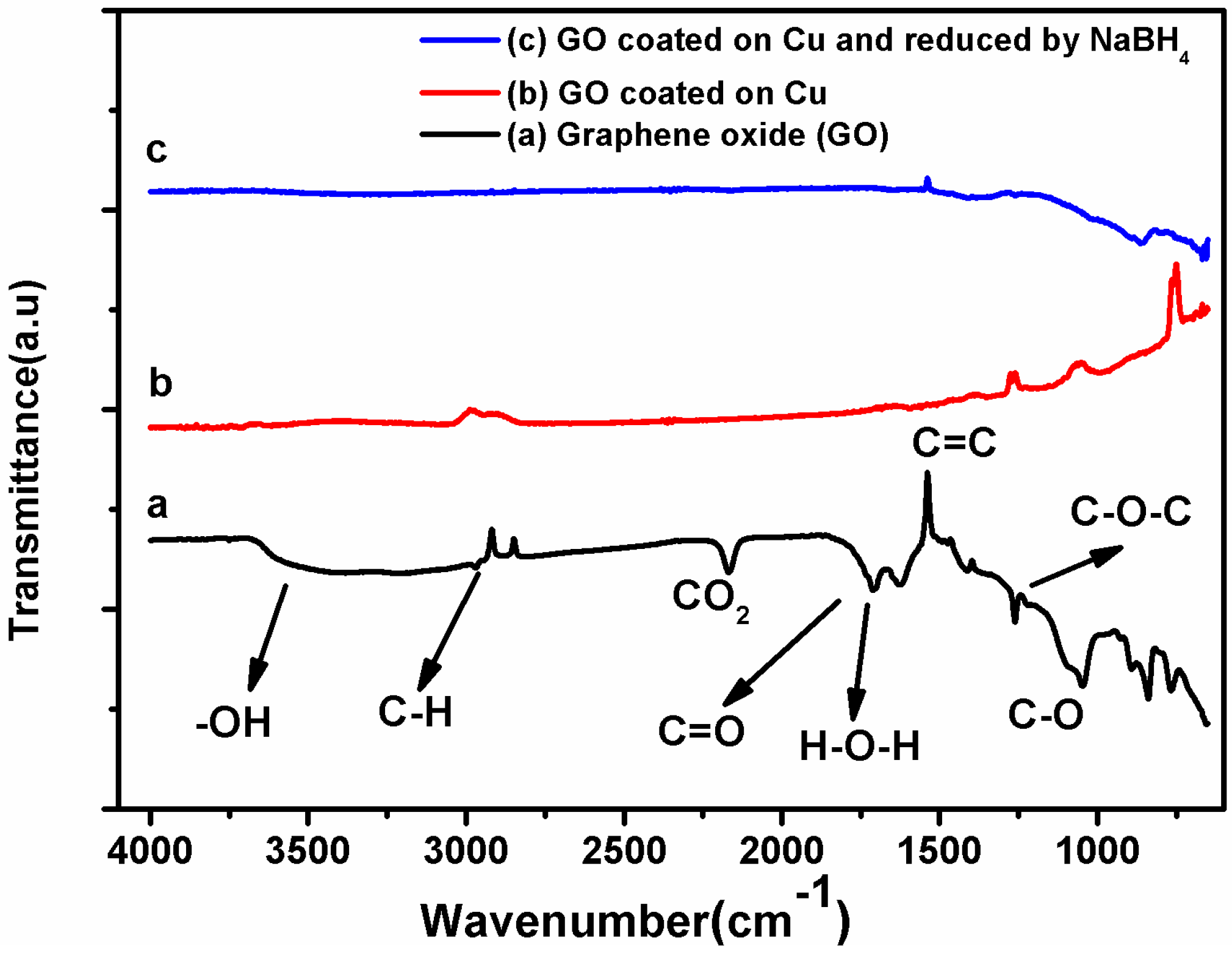

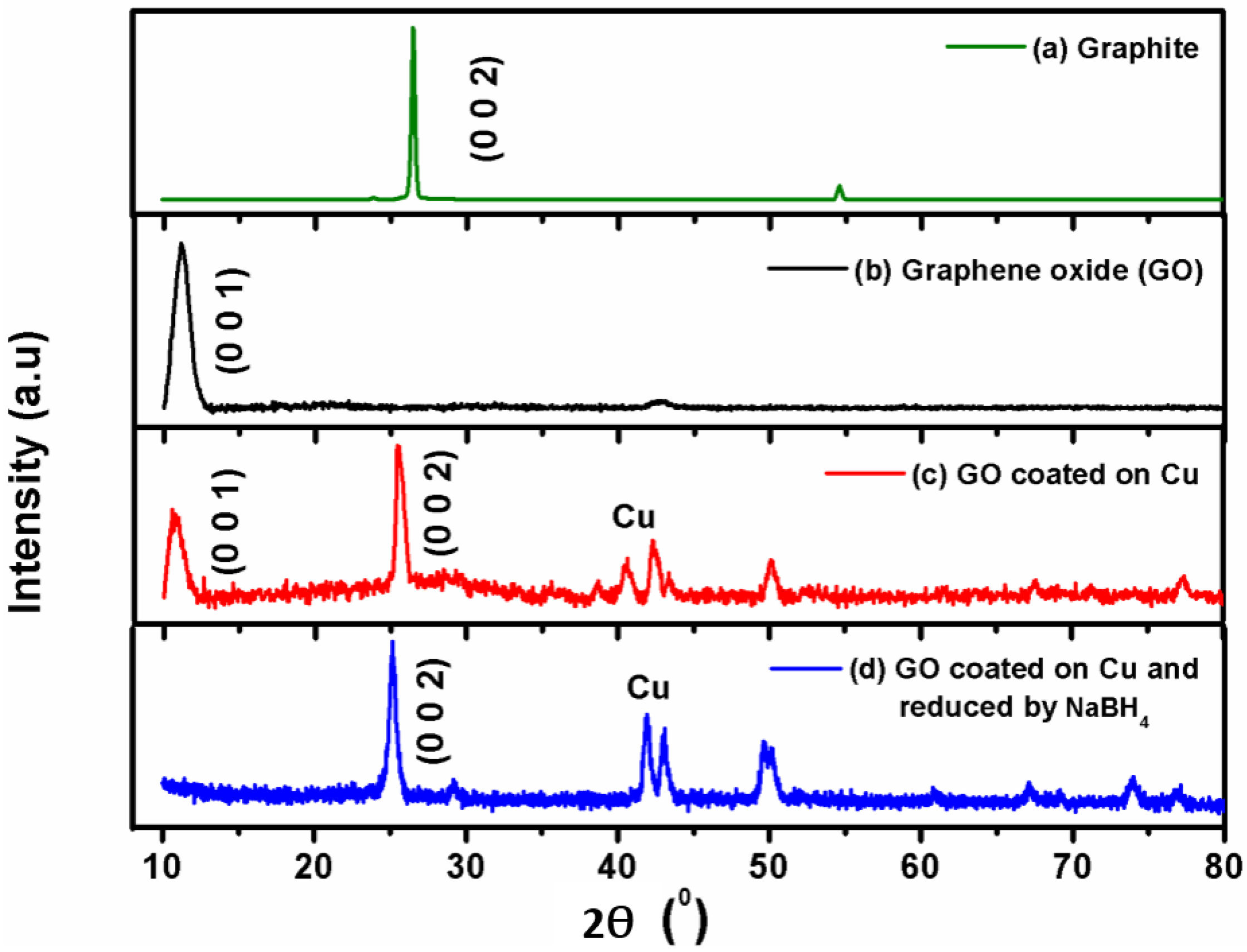

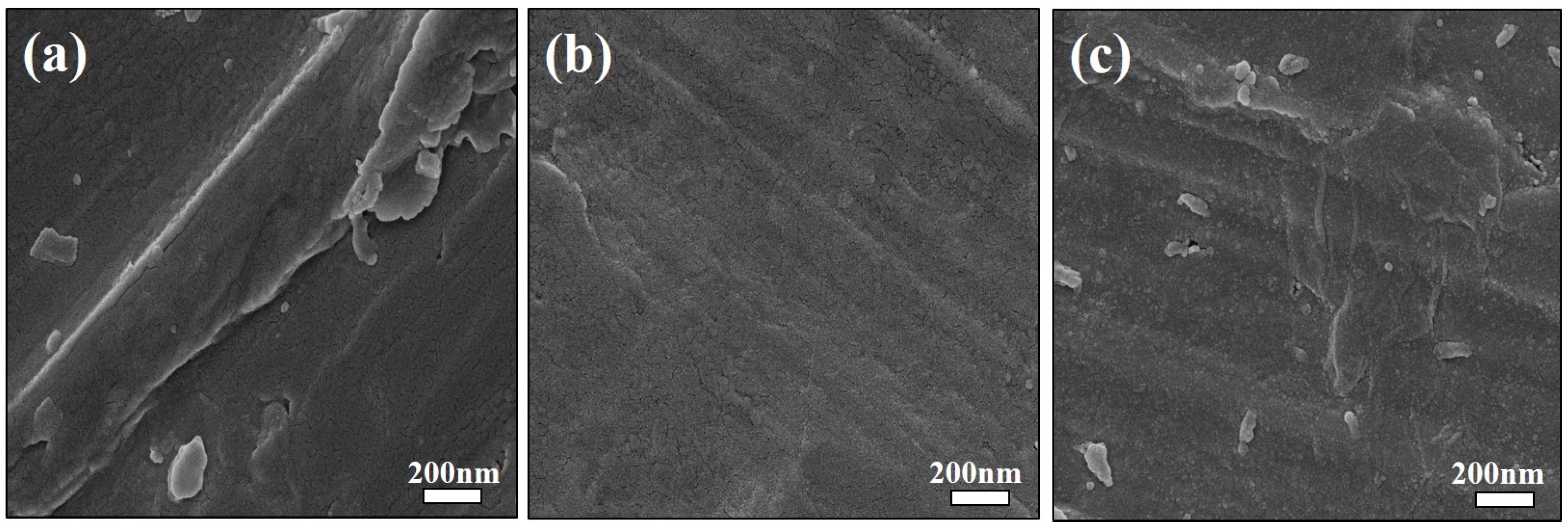

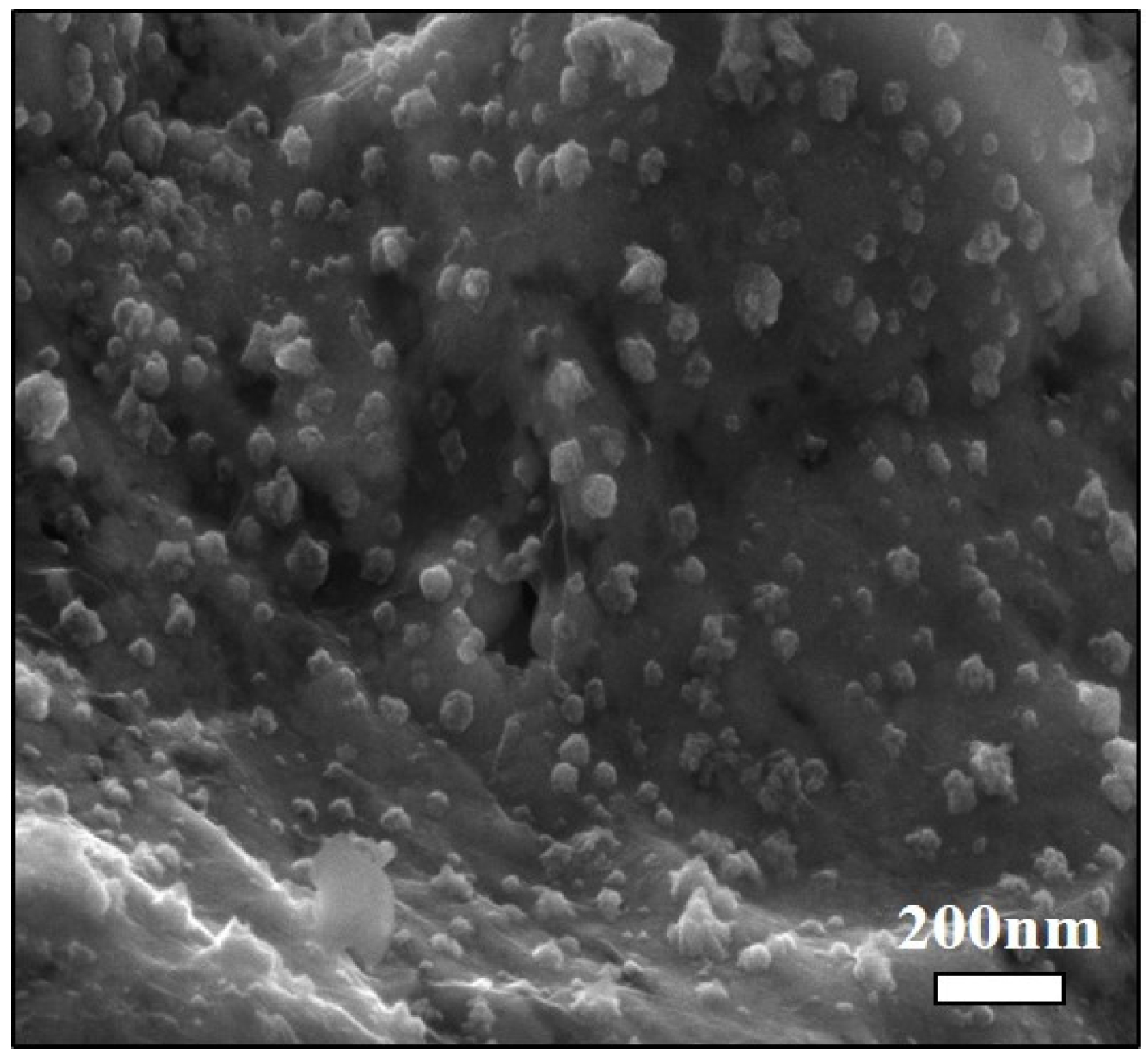

3.1. Characterization of Coating

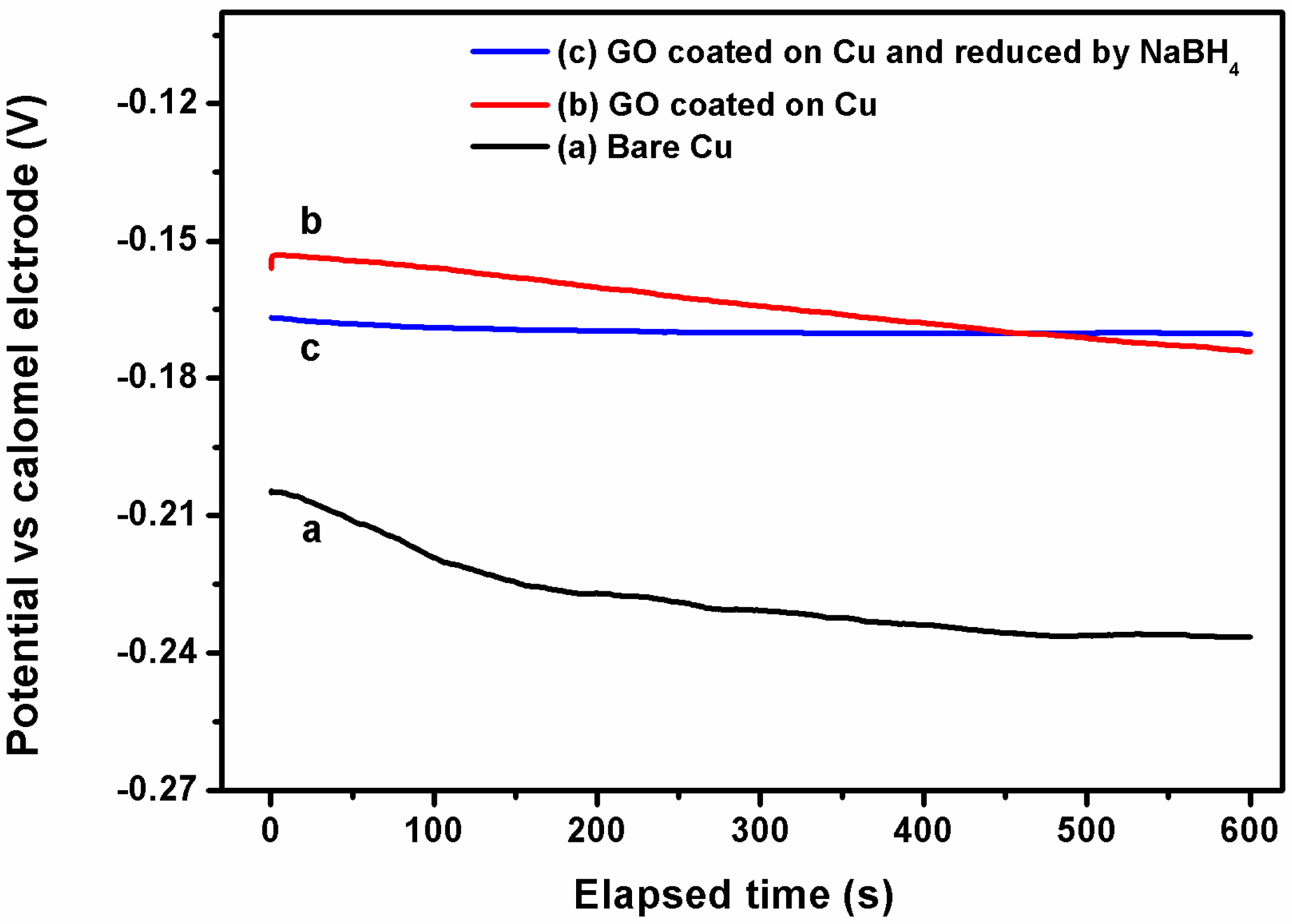

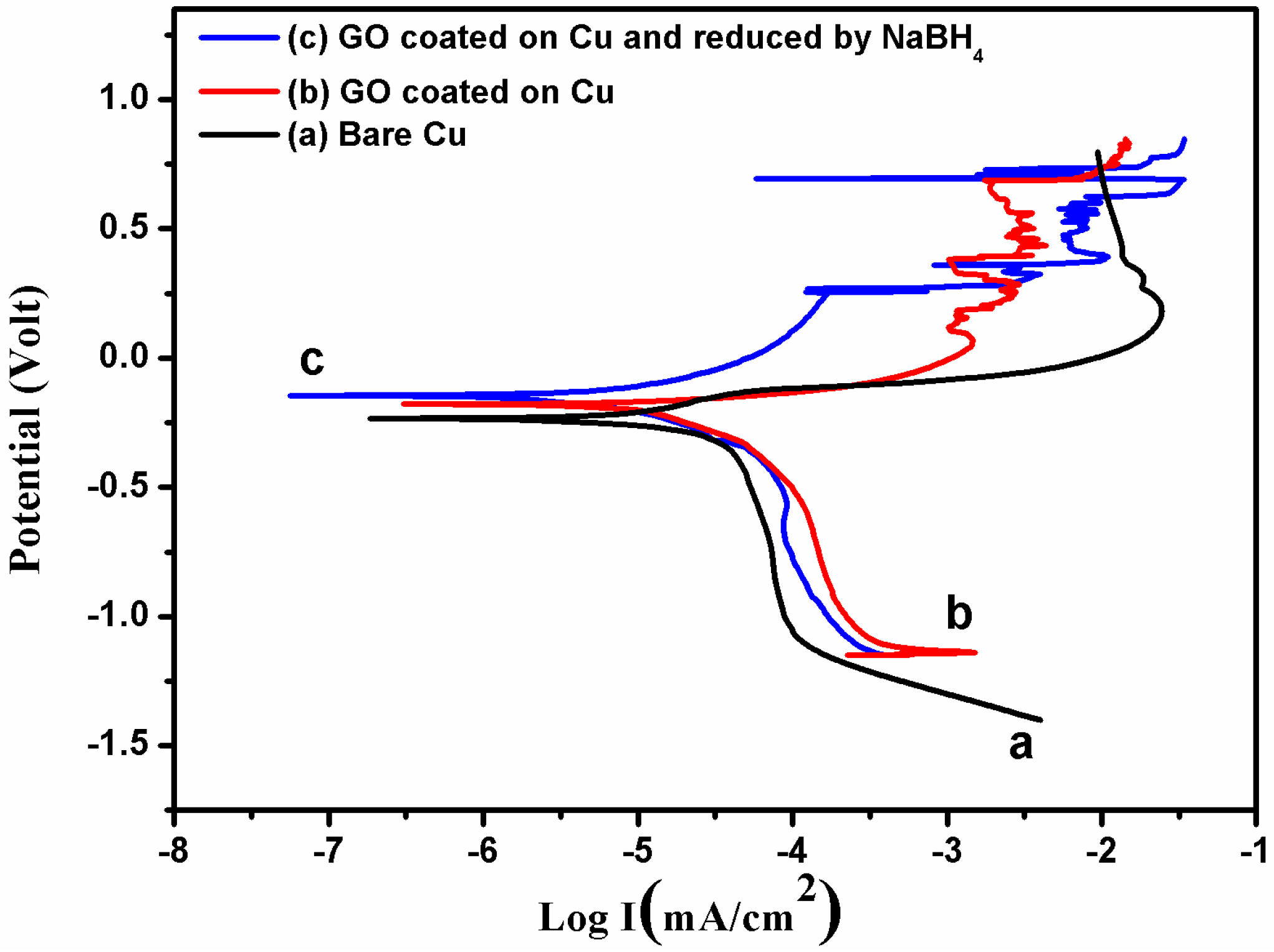

3.2. Corrosion Resistance

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rahmanto, W.H.; Gunawan, R.N. Corrosion rate of copper and iron in seawater based on resistance measurement. J. Coast. Dev. 2002, 5, 67–74. [Google Scholar]

- Singh, B.P.; Nayak, S.; Nanda, K.K.; Jena, B.K.; Bhattacharjee, S.; Besra, L. The production of a corrosion resistant graphene reinforced composite coating on copper by electrophoretic deposition. Carbon 2013, 61, 47–56. [Google Scholar] [CrossRef]

- Basu, S.; Singh, P.K.; Huang, J.-J.; Wang, Y.-H. Liquid-Phase Deposition of Al2O3 Thin Films on GaN. J. Electrochem. Soc. 2007, 154, H1041–H1046. [Google Scholar] [CrossRef]

- Silickas, P.; Valiulis, A.V. Liquid-phase deposition and the properties of thin zirconium dioxide films on different substrates. Mater. Sci. 2008, 44, 211–215. [Google Scholar] [CrossRef]

- Talo, A.; Passiniemi, P.; Forsén, O.; Yläsaari, S. Polyaniline/epoxy coatings with good anti-corrosion properties. Synth. Met. 1997, 85, 1333–1334. [Google Scholar] [CrossRef]

- Li, X.; Yu, X.; Han, Y. Polymer thin films for antireflection coatings. J. Mater. Chem. C 2013, 1, 2266–2285. [Google Scholar] [CrossRef]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Singh, V.; Joung, D.; Zhai, L.; Das, S.; Khondaker, S.I.; Seal, S. Graphene based materials: Past, present and future. Prog. Mater. Sci. 2011, 56, 1178–1271. [Google Scholar] [CrossRef]

- Sanjinés, R.; Vâju, C.; Smajda, R.; Mionić, M.; Magrez, A. Electrical properties and applications of carbon based nanocomposite materials: An overview. Surf. Coat. Technol. 2011, 206, 727–733. [Google Scholar] [CrossRef]

- Jeon, I.-Y.; Choi, H.-J.; Bae, S.-Y.; Change, D.W.; Baek, J.-B. Wedging graphite into graphene and graphene-like platelets by dendritic. J. Mater. Chem. 2011, 21, 7820–7826. [Google Scholar] [CrossRef] [Green Version]

- Singh, B.P.; Jena, B.K.; Bhattacharjee, S.; Besra, L. Development of oxidation and corrosion resistance hydrophobic graphene oxide-polymer composite coating on copper. Surf. Coat. Technol. 2013, 232, 475–481. [Google Scholar] [CrossRef]

- Tong, Y.; Bohmb, S.; Song, M. Graphene Based Materials and Their Composites as Coatings. Aust. J. Nanomed. Nanotechnol. 2013, 1, 1003. [Google Scholar]

- Yivlialin, R.; Bussetti, G.; Brambilla, L.; Castiglioni, C.; Tommasini, M.; Duò, L.; Passoni, M.; Ghidelli, M.; Casari, C.S.; Li Bassi, A. Microscopic Analysis of the Different Perchlorate Anions Intercalation Stages of Graphite. J. Phys. Chem. C 2017, 121, 14246–14253. [Google Scholar] [CrossRef]

- Dikin, D.A.; Stankovich, S.; Zimney, E.J.; Piner, R.D.; Dommett, G.H.B.; Evmenenko, G.; Nguyen, S.T.; Ruoff, R.S. Preparation and characterization of graphene oxide paper. Nature 2007, 448, 457–460. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Zhi, L.; Müllen, K. Transparent, conductive graphene electrodes for dye-sensitized solar cells. Nano Lett. 2008, 8, 323–327. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Zhang, G.; Bai, X.; Sun, X.; Wang, X.; Wang, E.; Dai, H. Highly conducting graphene sheets and Langmuir–Blodgett films. Nat. Nanotechnol. 2008, 3, 538–542. [Google Scholar] [CrossRef] [PubMed]

- Gilje, S.; Han, S.; Wang, M.; Wang, K.L.; Kaner, R.B. A chemical route to graphene for device applications. Nano Lett. 2007, 7, 3394–3398. [Google Scholar] [CrossRef] [PubMed]

- Tung, V.C.; Allen, M.J.; Yang, Y.; Kaner, R.B. High-throughput solution processing of large-scale graphene. Nat. Nanotechnol. 2009, 4, 25–29. [Google Scholar] [CrossRef] [PubMed]

- Prasai, D.; Tuberquia, J.C.; Harl, R.R.; Jennings, G.K.; Rogers, B.R.; Bolotin, K.I. Graphene: Corrosion-inhibiting coating. ACS Nano 2012, 6, 1102–1108. [Google Scholar] [CrossRef] [PubMed]

- Narula, U.; Tan, C. Determining the Parameters of Importance of a Graphene Synthesis Process Using Design-of-Experiments Method. Appl. Sci. 2016, 6, 204. [Google Scholar] [CrossRef]

- Singh Raman, R.K.; Chakraborty Banerjee, P.; Lobo, D.E.; Gullapalli, H.; Sumandasa, M.; Kumar, A.; Choudhary, L.; Tkacz, R.; Ajayan, P.M.; Majumder, M. Protecting copper from electrochemical degradation by graphene coating. Carbon 2012, 50, 4040–4045. [Google Scholar] [CrossRef]

- Kirkland, N.T.; Schiller, T.; Medhekar, N.; Birbilis, N. Exploring graphene as a corrosion protection barrier. Corros. Sci. 2012, 56, 1–4. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, M.; Zhu, Y.; Ding, G.; Jiang, D.; Guo, Q.; Liu, S.; Xie, X.; Chu, P.K.; Di, Z.; et al. Direct growth of graphene film on germanium substrate. Sci. Rep. 2013, 3, 2465. [Google Scholar] [CrossRef] [PubMed]

- Geckle, R.J.; Mroczkowski, R.S. Corrosion of Precious Metal Plated Copper Alloys Due to Mixed Flowing Gas Exposure. IEEE Trans. Compon. Hybrids Manuf. Technol. 1991, 14, 162–169. [Google Scholar] [CrossRef]

- Chen, S.; Brown, L.; Levendorf, M.; Cai, W.; Ju, S.-Y.; Edgeworth, J.; Li, X.; Magnuson, C.W.; Velamakanni, A.; Piner, R.D.; et al. Oxidation resistance of graphene-coated Cu and Cu Ni alloy. ACS Nano 2011, 5, 1321–1327. [Google Scholar] [CrossRef] [PubMed]

- Yang, L. Coatings for Corrosion Protection of Metals and Alloys. Master’s Thesis, McMaster University, Hamilton, ON, Canada, 2012. [Google Scholar]

- Zhou, X. Graphene Oxidation Barrier Coating. Bachelor’s Thesis, University of Colorado, Boulder, CO, USA, 2011. [Google Scholar]

- Besra, L.; Liu, M. A review on fundamentals and applications of electrophoretic deposition (EPD). Prog. Mater. Sci. 2007, 52, 1–61. [Google Scholar] [CrossRef]

- Besra, L.; Uchikoshi, T.; Suzuki, T.S.; Sakka, Y. Bubble-free aqueous electrophoretic deposition (EPD) by pulse-potential application. J. Am. Ceram. Soc. 2008, 91, 3154–3159. [Google Scholar] [CrossRef]

- Ferrari, B.; Moreno, R. Electrophoretic deposition of aqueous alumina slips. J. Eur. Ceram. Soc. 1997, 17, 549–556. [Google Scholar] [CrossRef]

- An, S.J.; Zhu, Y.; Lee, S.H.; Stoller, M.D.; Emilsson, T.; Park, S.; Velamakanni, A.; An, J.; Ruoff, R.S. Thin film fabrication and simultaneous anodic reduction of deposited graphene oxide platelets by electrophoretic deposition. J. Phys. Chem. Lett. 2010, 1, 1259–1263. [Google Scholar] [CrossRef]

- Park, J.H.; Park, J.M. Electrophoretic deposition of graphene oxide on mild carbon steel for anti-corrosion application. Surface Coat. Technol. 2014, 254, 167–174. [Google Scholar] [CrossRef]

- He, W.; Zhu, L.; Chen, H.; Wang, Y.; Li, W.; Liu, H.; Wang, Y. Electrophoretic deposition of graphene oxide as a corrosion inhibitor for sintered NdFeB. Appl. Surface Sci. 2013, 279, 416–423. [Google Scholar] [CrossRef]

- Singh, D. Electrophoretic Deposition of Graphene on Copper and its Corrosion Behaviour. Master’s Thesis, NIT Rourkela, Odisha, India, 2017. [Google Scholar]

- Raza, M.A.; Rehman, Z.U.; Ghauri, F.A.; Ahmad, A.; Ahmad, R.; Raffi, M. Corrosion study of electrophoretically deposited graphene oxide coatings on copper metal. Thin Solid Films 2016, 620, 150–159. [Google Scholar] [CrossRef]

- Raza, M.A.; Ali, A.; Ghauri, F.A.; Aslam, A.; Yaqoob, K.; Wasay, W.; Raffi, M. Electrochemical behavior of graphene coatings deposited on copper metal by electrophoretic deposition and chemical vapor deposition. Surface Coat. Technol. 2017. In press. [Google Scholar] [CrossRef]

- Al-Sammarraie, A.M.A.; Raheema, M.H. Electrodeposited Reduced Graphene Oxide Films on Stainless Steel, Copper, and Aluminum for Corrosion Protection Enhancement. Int. J. Corros. 2017, 2017, 6939354. [Google Scholar] [CrossRef]

- Diba, M.; Fam, D.W.H.; Boccaccini, A.; Shaffer, M.S.P. Electrophoretic deposition of graphene-related materials: A review of the fundamentals. Prog. Mater. Sci. 2016, 82, 83–117. [Google Scholar] [CrossRef]

- Shahriary, L.; Athawale, A. Graphene Oxide Synthesized by using Modified Hummers Approach. Int. J. Renew. Energy Environ. Eng. 2014, 2, 58–63. [Google Scholar]

- Kang, J.H.; Kim, T.; Choi, J.; Park, J.; Kim, Y.S.; Chang, M.S.; Jung, H.; Park, K.T.; Yang, S.J.; Park, C.R. Hidden Second Oxidation Step of Hummers Method. Chem. Mater. 2016, 28, 756–764. [Google Scholar] [CrossRef]

- Yang, Z.; Zheng, Q.; Qiu, H.; LI, J.; Yang, J. A simple method for the reduction of graphene oxide by sodium borohydride with CaCl2 as a catalyst. New Carbon Mater. 2015, 30, 41–47. [Google Scholar] [CrossRef]

- De, D.; Chakraborty, M.; Majumdar, S.; Giri, S. Bandgap engineering through nanocrystalline magnetic alloy grafting on reduced graphene oxide. Phys. Chem. Chem. Phys. 2014, 16, 19661–19667. [Google Scholar] [CrossRef] [PubMed]

- Lih, E.T.Y.; Zaid, R.B.M.; Ling, T.L.; Chong, K.F. Facile Corrosion Protection Coating from Graphene. Int. J. Chem. Eng. Appl. 2012, 3, 453. [Google Scholar] [CrossRef]

- Sobon, G.; Sotor, J.; Jagiello, J.; Kozinski, R.; Zdrojek, M.; Holdynski, M.; Paletko, P.; Boguslawski, J.; Lipinska, L.; Abramski, K.M. Graphene oxide vs. reduced graphene oxide as saturable absorbers for Er-doped passively mode-locked fiber laser. Opt. Express 2012, 20, 19463–19473. [Google Scholar] [CrossRef] [PubMed]

- Loryuenyong, V.; Totepvimarn, K.; Eimburanapravat, P.; Boonchompoo, W.; Buasri, A. Preparation and Characterization of Reduced Graphene Oxide Sheets via Water-Based Exfoliation and Reduction Methods. Adv. Mater. Sci. Eng. 2013, 2013, 923403. [Google Scholar] [CrossRef]

- Fu, C.; Zhao, G.; Zhang, H.; Li, S. Evaluation and Characterization of Reduced Graphene Oxide Nanosheets as Anode Materials for Lithium-Ion Batteries. Int. J. Electrochem. Sci 2013, 8, 6269–6280. [Google Scholar] [CrossRef]

- Thema, F.T.; Moloto, M.J.; Dikio, E.D.; Nyangiwe, N.N.; Kotsedi, L.; Maaza, M.; Khenfouch, M. Synthesis & characterization of graphene thin films by chemical reduction of exfoliated and intercalated graphite oxide. J. Chem. 2013, 2013, 150536. [Google Scholar] [CrossRef]

- Antony, R.P.; Preethi, L.K.; Gupta, B.; Mathews, T.; Dash, S.; Tyagi, A.K. Efficient electrocatalytic performance of thermally exfoliated reduced graphene oxide-Pt hybrid. Mater. Res. Bull. 2015, 70, 60–67. [Google Scholar] [CrossRef]

- Mišković-Stanković, V.; Jevremović, I.; Jung, I.; Rhee, K. Electrochemical study of corrosion behavior of graphene coatings on copper and aluminum in a chloride solution. Carbon 2014, 75, 335–344. [Google Scholar] [CrossRef]

- ASTM G102-89(2015)e1 Standard Practice for Calculation of Corrosion Rates and Related Information from Electrochemical Measurements; ASTM (American Society for Testing and Materials) International: West Conshohocken, PA, USA, 2015.

- Qi, Y.; Xia, T.; Li, Y.; Duan, L.; Chen, W. Colloidal Stability of Reduced Graphene Oxide Materials Prepared Using Different Reducing Agents. Environ. Sci. Nano 2016, 3, 1062–1071. [Google Scholar] [CrossRef]

- Krishnamoorthy, K.; Ramadoss, A.; Kim, S.-J. Graphene Oxide Nanosheets for Corrosion-Inhibiting Coating. Sci. Adv. Mater. 2013, 5, 406–410. [Google Scholar] [CrossRef]

- Sai Pavan, A.S.; Ramanan, S.R. A study on corrosion resistant graphene films on low alloy steel. Appl. Nanosci. 2016, 6, 1175–1181. [Google Scholar] [CrossRef]

| Sample | Ecorr (mV) | Icorr (µA/cm2) | Corrosion Rate (mm/year) | Inhibition Efficiency (%) |

|---|---|---|---|---|

| Bare copper | −235.3 | 15.375 | 0.18 | – |

| GO Coated copper | −182.2 | 12.44 | 0.15 | 19.08 |

| GO Coated Cu after reduction | −145.4 | 7.01 | 0.08 | 54.40 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Usha Kiran, N.; Dey, S.; Singh, B.P.; Besra, L. Graphene Coating on Copper by Electrophoretic Deposition for Corrosion Prevention. Coatings 2017, 7, 214. https://doi.org/10.3390/coatings7120214

Usha Kiran N, Dey S, Singh BP, Besra L. Graphene Coating on Copper by Electrophoretic Deposition for Corrosion Prevention. Coatings. 2017; 7(12):214. https://doi.org/10.3390/coatings7120214

Chicago/Turabian StyleUsha Kiran, N., Sanjukta Dey, Bimal P. Singh, and Laxmidhar Besra. 2017. "Graphene Coating on Copper by Electrophoretic Deposition for Corrosion Prevention" Coatings 7, no. 12: 214. https://doi.org/10.3390/coatings7120214