Modification of the Interfacial Interaction between Carbon Fiber and Epoxy with Carbon Hybrid Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Fillers/Epoxy/Carbon Fiber Composites

2.2. Characterizations

3. Results and Discussions

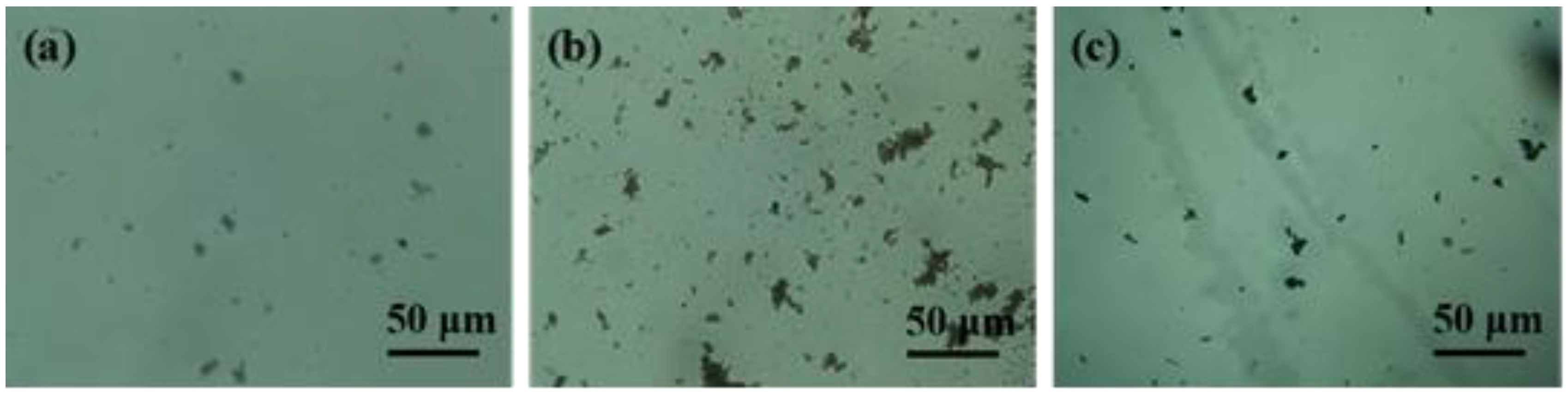

3.1. The Microstructure Characterization of Carbon Hybrid Dispersions

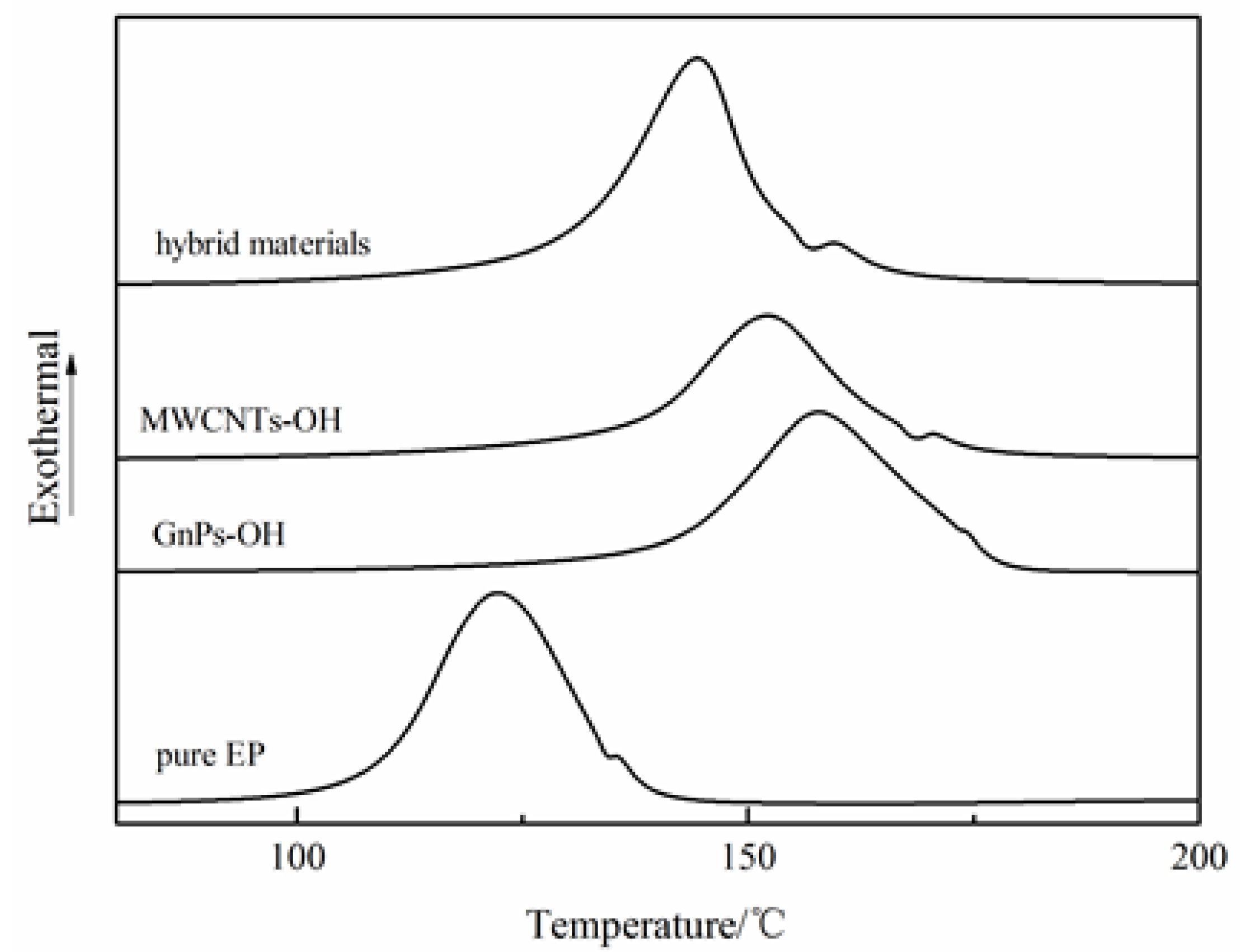

3.2. Differential Scanning Calorimetry (DSC) of Epoxy Composites

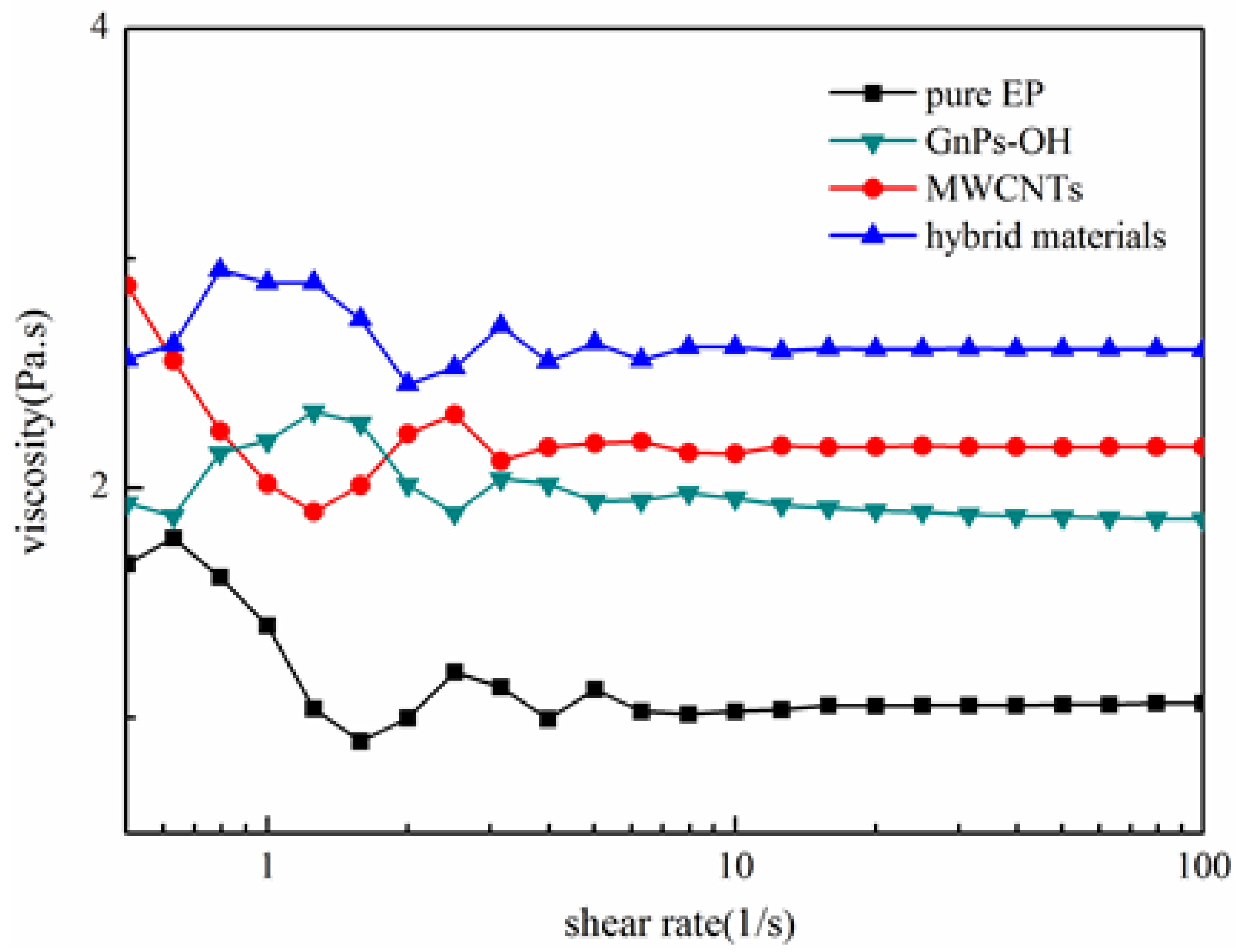

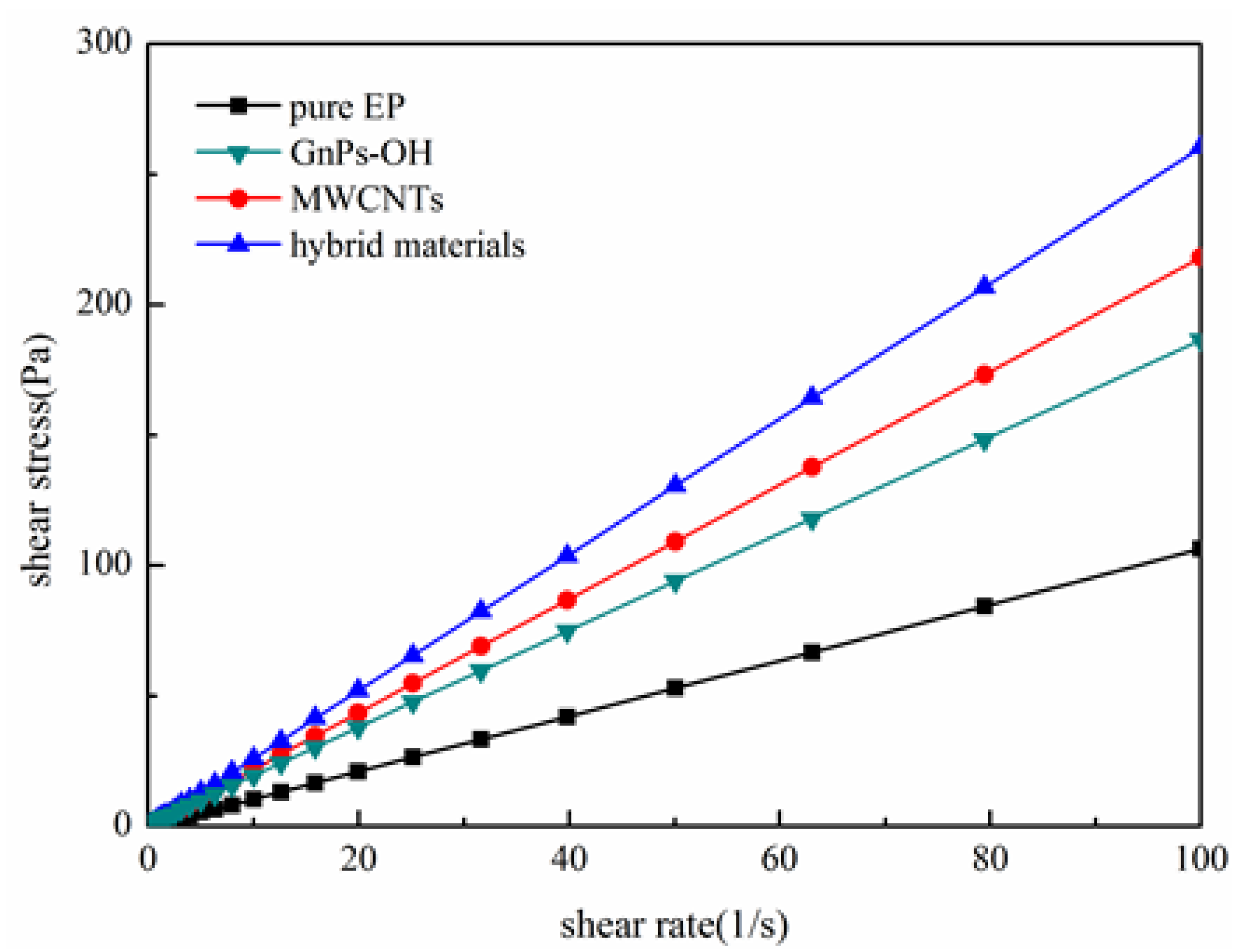

3.3. Rheological Behaviors of Epoxy Composites

3.4. Dynamic Mechanical Thermal Analysis (DMA) of Epoxy Composites

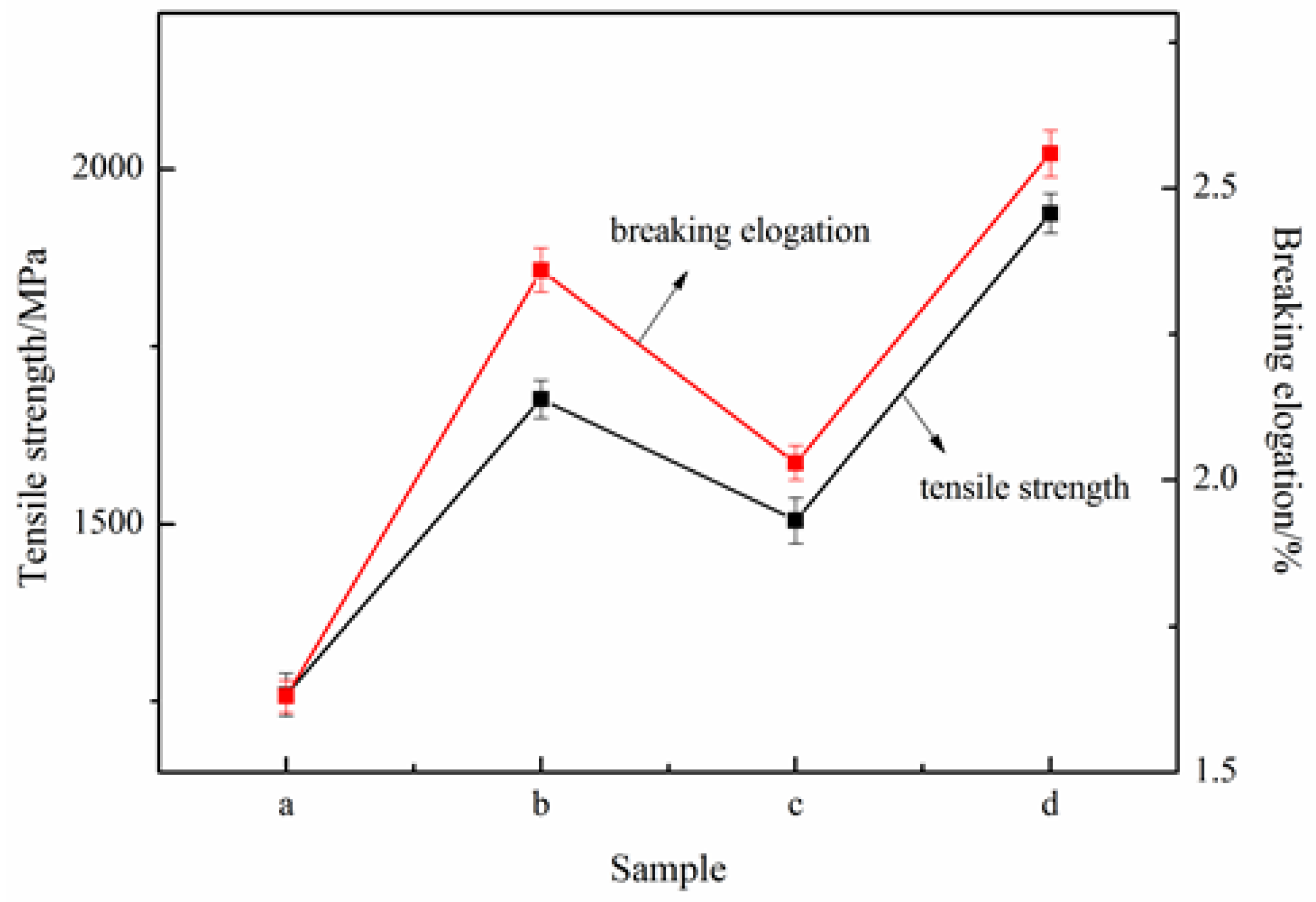

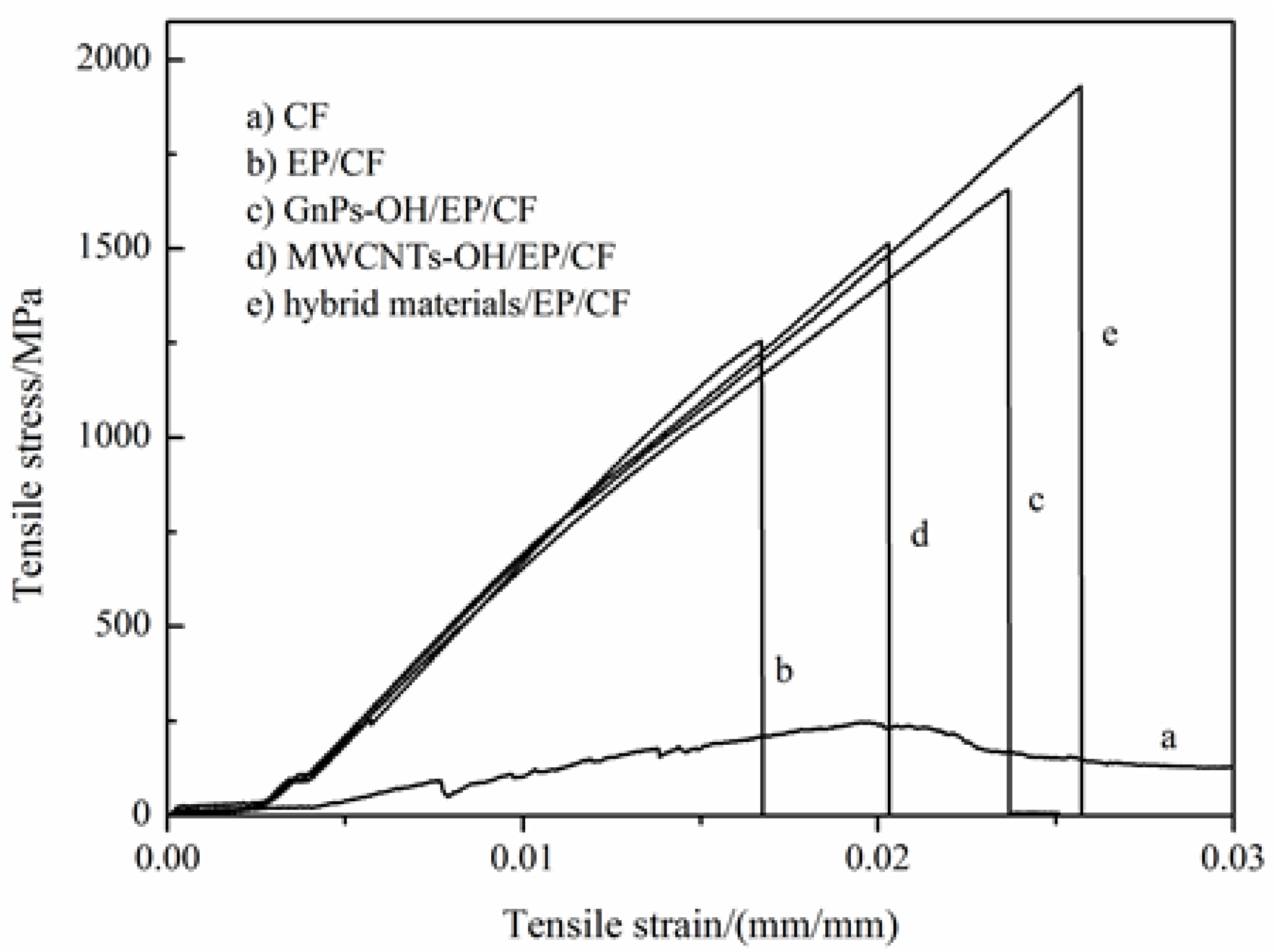

3.5. Mechanical Property of Carbon Fiber Composites

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Cecen, V.; Sarikanat, M.; Yildiz, H.; Tavman, I.H. Comparison of mechanical properties of epoxy composites reinforced with stitched glass and carbon fabrics: Characterization of mechanical anisotropy in composites and investigation on the interaction between fiber and epoxy matrix. Polym. Compos. 2008, 29, 840–853. [Google Scholar] [CrossRef]

- Yu, B.; Jiang, Z.Y.; Tang, X.Z.; Yue, C.Y.; Yang, J.L. Enhanced interphase between epoxy matrix and carbon fiber with carbon nanotube-modified silane coating. Compos. Sci. Technol. 2014, 99, 131–140. [Google Scholar] [CrossRef]

- Zhang, X.Q.; Xu, H.B.; Fan, X.Y. Grafting of amine-capped cross-linked polyphosphazenes onto carbon fiber surfaces: A novel coupling agent for fiber reinforced composites. RSC Adv. 2014, 4, 12198–12205. [Google Scholar] [CrossRef]

- Razaqpur, A.G.; Spadea, S. Shear strength of FRP reinforced concrete members with stirrups. J. Compos. Constr. 2015, 19. [Google Scholar] [CrossRef]

- Spadea, G.; Bencardino, F.; Sorrenti, F.; Swamy, R.N. Structural effectiveness of FRP materials in strengthening RC beams. Eng. Struct. 2015, 99, 631–641. [Google Scholar] [CrossRef]

- Hughes, J.D.H. The carbon-fiber epoxy interface—A review. Compos. Sci. Technol. 1991, 41, 13–45. [Google Scholar] [CrossRef]

- Vautard, F.; Ozcan, S.; Meyer, H. Properties of thermo-chemically surface treated carbon fibers and of their epoxy and vinyl ester composites. Composites A 2012, 43, 1120–1133. [Google Scholar] [CrossRef]

- Lee, S.H.; Wang, S.Q. Biodegradable polymers/bamboo fiber biocomposite with bio-based coupling agent. Composites A 2006, 37, 80–91. [Google Scholar] [CrossRef]

- Matuana, L.M.; Woodhams, R.T.; Balatinecz, J.J.; Park, C.B. Influence of interfacial interactions on the properties of PVC cellulosic fiber composites. Polym. Compos. 1998, 19, 446–455. [Google Scholar] [CrossRef]

- Tang, L.G.; Kardos, J.L. A review of methods for improving the interfacial adhesion between carbon fiber and polymer matrix. Polym. Compos. 1997, 18, 100–113. [Google Scholar] [CrossRef]

- Park, B.; Lee, W.; Lee, E.; Min, S.H.; Kim, B.S. Highly tunable interfacial adhesion of glass fiber by hybrid multilayers of graphene oxide and aramid nanofiber. ACS Appl. Mater. Interfaces 2015, 7, 3329–3334. [Google Scholar] [CrossRef] [PubMed]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.; Wei, X.D.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef] [PubMed]

- Yue, L.; Pircheraghi, G.; Monemian, S.A.; Manas-Zloczower, I. Epoxy composites with carbon nanotubes and graphene nanoplatelets—Dispersion and synergy effects. Carbon 2014, 78, 268–278. [Google Scholar] [CrossRef]

- Dong, X.C.; Li, B.; Wei, A.; Cao, X.H.; Chan-Park, M.B.; Zhang, H.; Li, L.J.; Huang, W.; Chen, P. One-step growth of grapheme—Carbon nanotube hybrid materials by chemical vapor deposition. Carbon 2011, 49, 2944–2949. [Google Scholar] [CrossRef]

- Du, F.; Yu, D.S.; Dai, L.M.; Ganguli, S.; Varshney, V.; Roy, A.K. Preparation of tunable 3D pillared carbon nanotube-Graphene networks for high-performance capacitance. Chem. Mater. 2011, 23, 4810–4816. [Google Scholar] [CrossRef]

- Cai, D.Y.; Song, M.; Xu, C.X. Highly conductive carbon-nanotube/graphite-oxide hybrid films. Adv. Mater. 2008, 20, 1706–1709. [Google Scholar] [CrossRef]

- Jia, Y.C.; Yu, K.J.; Qian, K. Facile approach to prepare multi-walled carbon nanotubes/graphene nanoplatelets hybrid materials. Nanoscale Res. Lett. 2013, 8. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.Q.; Yu, K.J.; Qian, K.; Jia, Y.C. One step fabrication of multi-walled carbon nanotubes/graphene nanoplatelets hybrid materials with excellent mechanical property. Fibers Polym. 2015, 16, 1540–1546. [Google Scholar] [CrossRef]

- Wu, J.Q.; Yu, K.J.; Qian, K.; Cao, H.J.; Lu, X.F.; Sun, J. Study on Tensile Properties of Epoxy Resin Composites with MWCNTs/f-GN Hybrid Materials. Mater. Rev. 2014, 10, 82–85. [Google Scholar]

- Liu, C.Y.; Yin, X.T.; Lin, Y.; Guan, A.G.; Wu, G.Z. Small molecule-mediated glass transition of acrylic copolymers: Effect of hydrogen bonding strength on glass transition temperature. J. Polym. Sci. Part B 2015, 53, 400–408. [Google Scholar] [CrossRef]

- Zhang, X.; Alloul, O.; He, Q.L.; Zhu, J.H.; Verde, M.J.; Li, Y.T.; Wei, S.Y.; Guo, Z.H. Strengthened magnetic epoxy nanocomposites with protruding nanoparticles on the graphene nanosheets. Polymer 2013, 54, 3594–3604. [Google Scholar] [CrossRef]

- Vennerberg, D.; Hall, R.; Kessler, M.R. Supercritical carbon dioxide-assisted silanization of multi-walled carbon nanotubes and their effect on the thermo-mechanical properties, of epoxy nanocomposites. Polymer 2014, 55, 4156–4163. [Google Scholar] [CrossRef]

- Zhu, J.H.; Wei, S.Y.; Ryu, J.; Budhathoki, M.; Liang, G.; Guo, Z.H. In situ stabilized carbon nanofiber (CNF) reinforced epoxy nanocomposites. J. Mater. Chem. 2010, 20, 4937–4948. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Wang, Y.; Yu, J.R.; Chen, L.; Zhu, J.; Hu, Z.M. Tuning the interface of graphene platelets/epoxy composites by the covalent grafting of polybenzimidazole. Polymer 2014, 55, 4990–5000. [Google Scholar] [CrossRef]

- Xu, Q.W.; Chen, H.X.; Prozzi, J.A. Performance of fiber reinforced asphalt concrete under environmental temperature and water effects. Constr. Build. Mater. 2010, 24, 2003–2010. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, K.; Wang, M.; Wu, J.; Qian, K.; Sun, J.; Lu, X. Modification of the Interfacial Interaction between Carbon Fiber and Epoxy with Carbon Hybrid Materials. Nanomaterials 2016, 6, 89. https://doi.org/10.3390/nano6050089

Yu K, Wang M, Wu J, Qian K, Sun J, Lu X. Modification of the Interfacial Interaction between Carbon Fiber and Epoxy with Carbon Hybrid Materials. Nanomaterials. 2016; 6(5):89. https://doi.org/10.3390/nano6050089

Chicago/Turabian StyleYu, Kejing, Menglei Wang, Junqing Wu, Kun Qian, Jie Sun, and Xuefeng Lu. 2016. "Modification of the Interfacial Interaction between Carbon Fiber and Epoxy with Carbon Hybrid Materials" Nanomaterials 6, no. 5: 89. https://doi.org/10.3390/nano6050089