Effect of Continuous Multi-Walled Carbon Nanotubes on Thermal and Mechanical Properties of Flexible Composite Film

Abstract

:1. Introduction

2. Methods

2.1. Materials

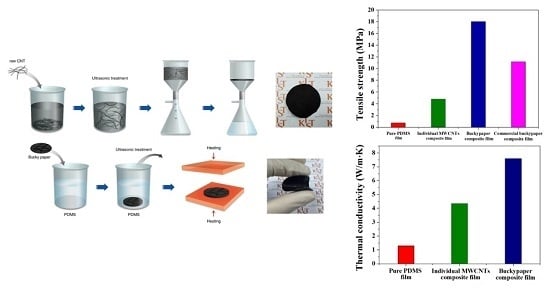

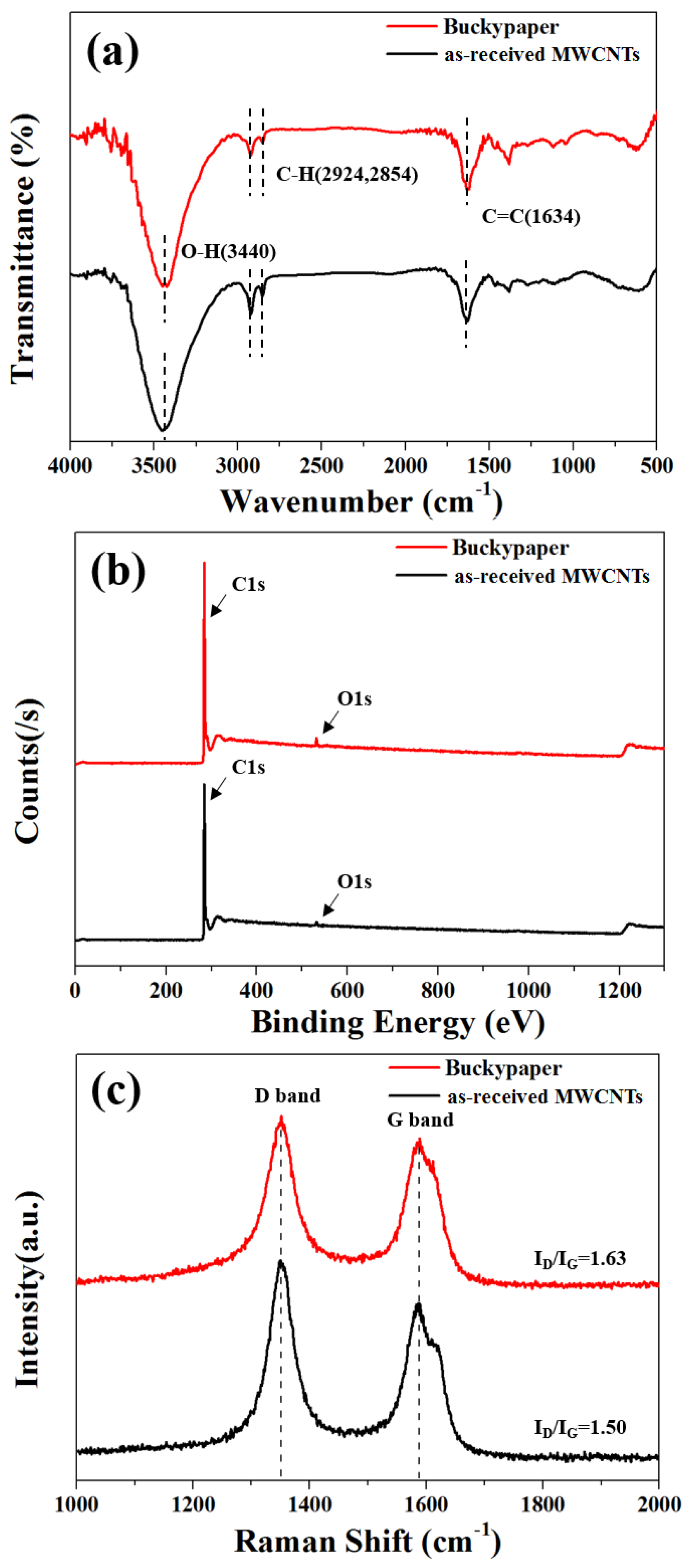

2.2. Preparation of MWCNT Buckypaper

2.3. Fabrication of Composite Film

2.4. Characterization

2.4.1. Morphology

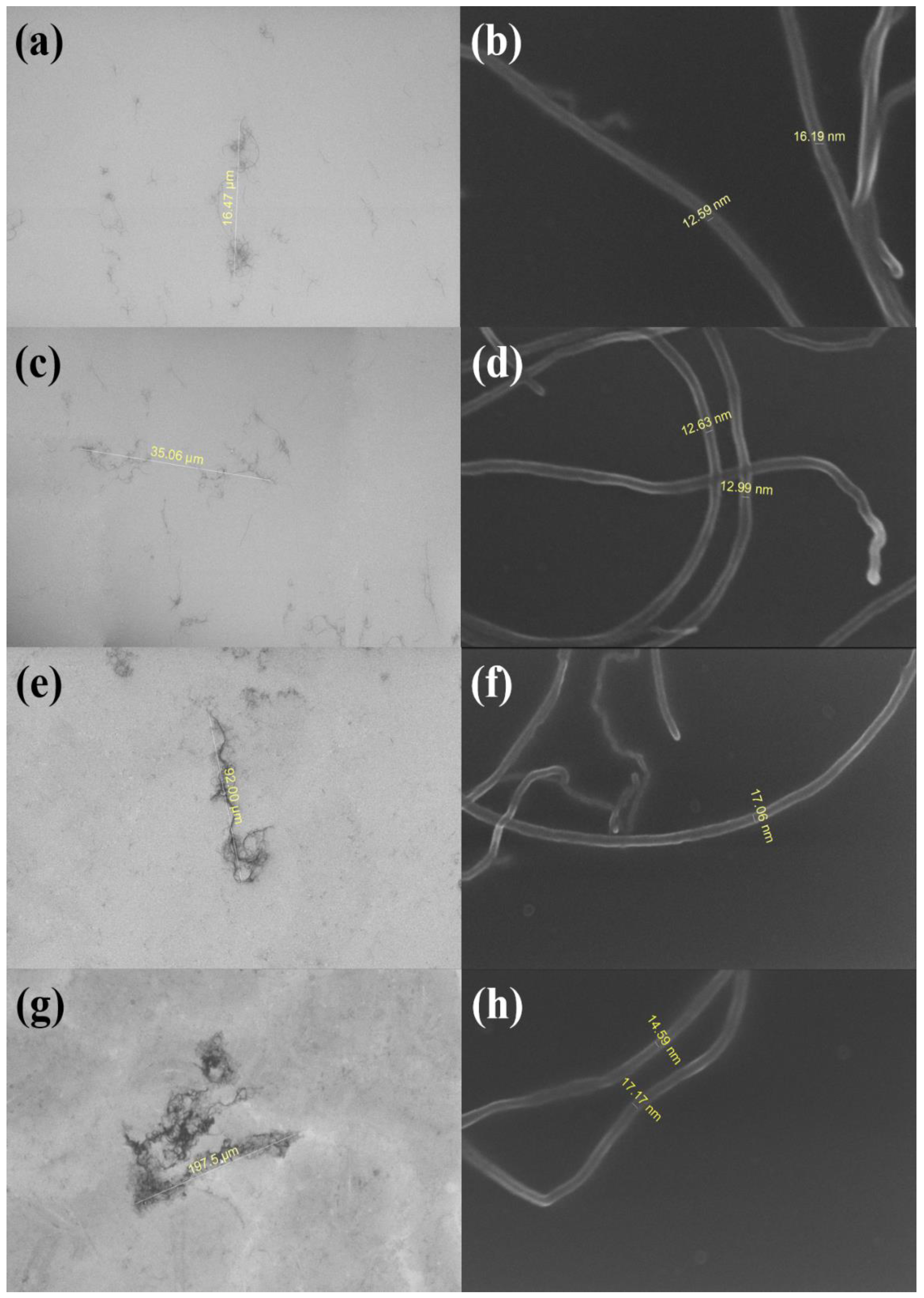

2.4.2. Fourier Transform Infrared (FT-IR) Measurements

2.4.3. X-ray photoelectron spectroscopy (XPS) Measurements

2.4.4. Raman Measurements

2.4.5. Thermal Conductivity

2.4.6. Heat Dissipation Property

2.4.7. Mechanical Property

3. Results and Discussion

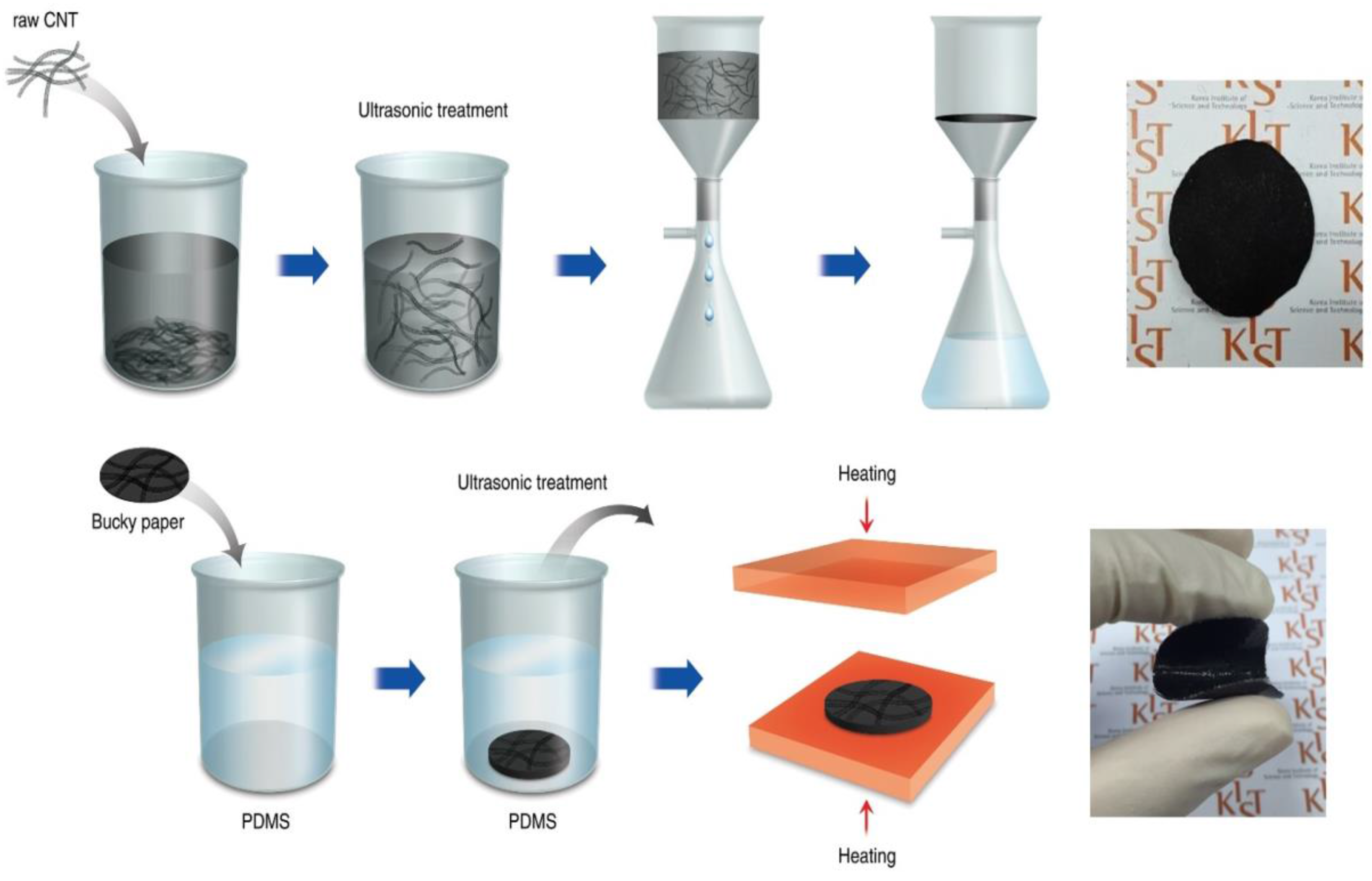

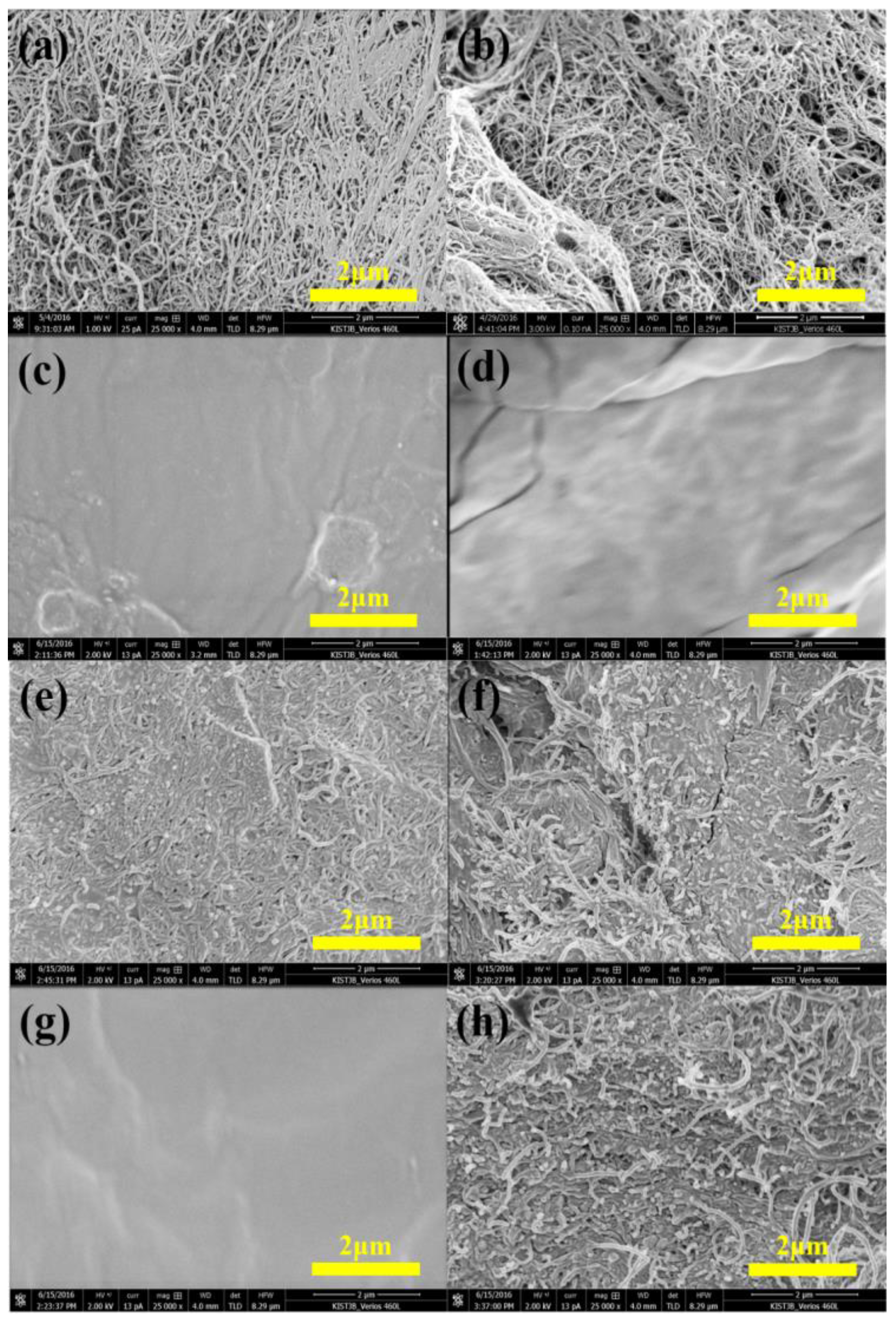

3.1. Effect of Processing Conditions on Buckypaper Structure

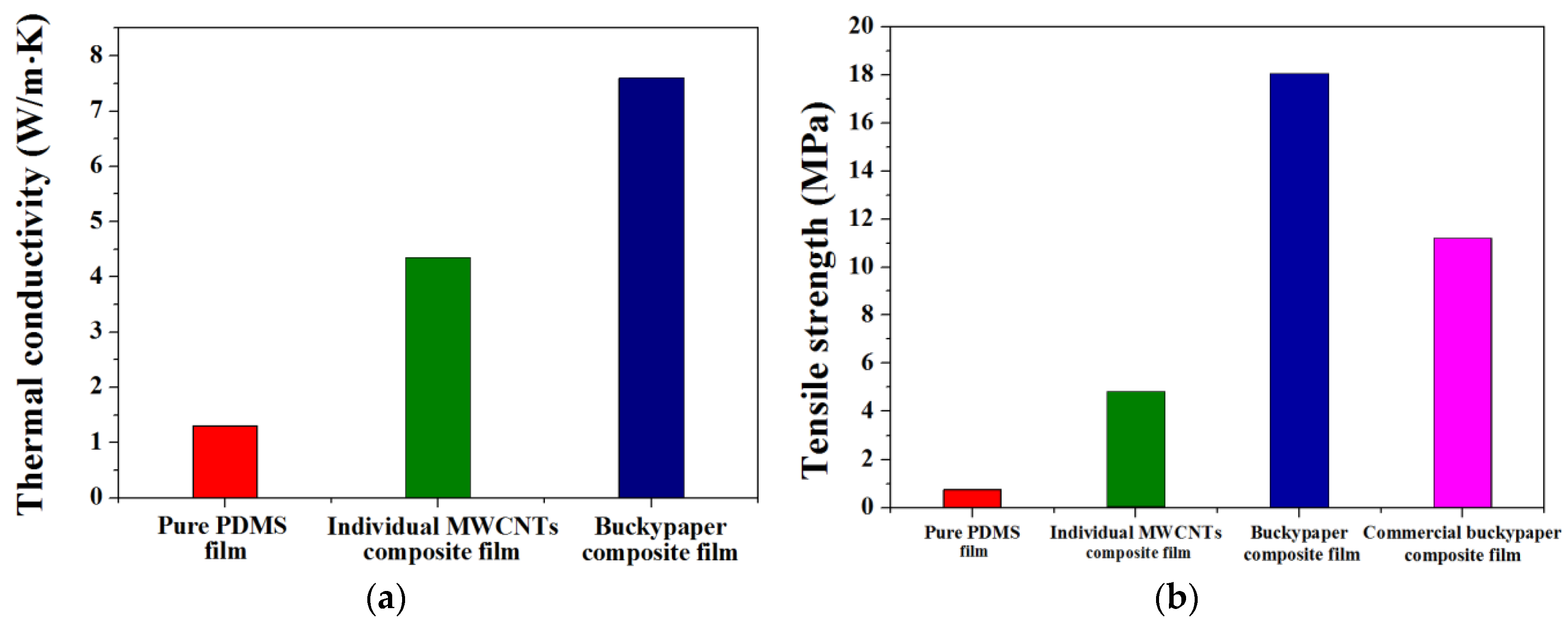

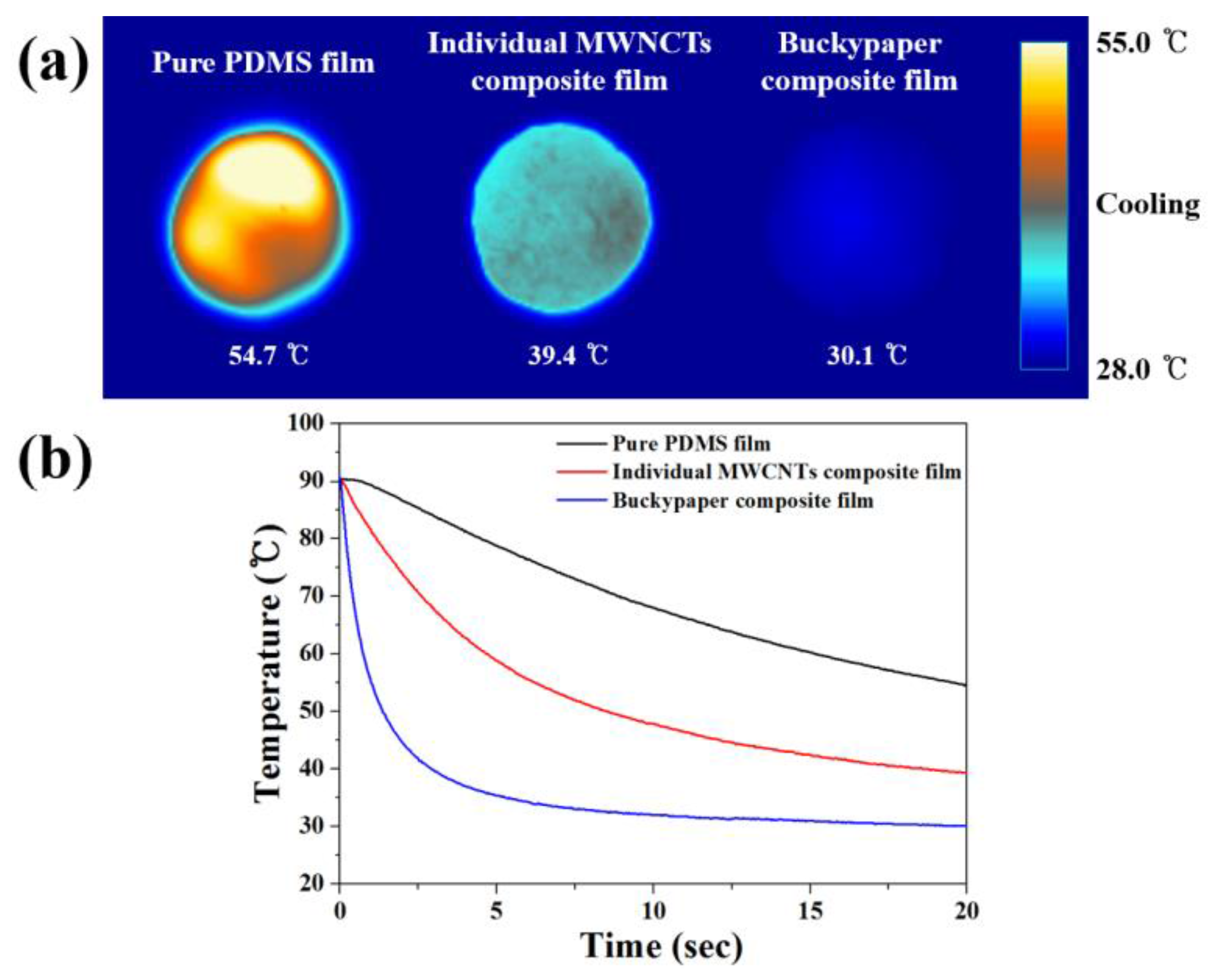

3.2. Properties of Composite Films

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| MWCNTs | multi-walled carbon nanotubes |

| CNTs | carbon nanotubes |

| PDMS | Polydimethylsiloxane |

| DMF | Dimethylformamide |

| PTFE | Polytetrafluoroethylene |

| FE-SEM | field emission scanning electron microscopy |

| FT-IR | Fourier transform infrared |

| XPS | X-ray photoelectron spectroscopy |

References

- Han, Z.; Fina, A. Thermal conductivity of carbon nanotubes and their polymer nanocomposites: A review. Prog. Polym. Sci. 2011, 36, 914–944. [Google Scholar] [CrossRef]

- Ruoff, R.S.; Lorents, D.C. Mechanical and thermal properties of carbon nanotubes. Carbon 1995, 33, 925–930. [Google Scholar] [CrossRef]

- Yu, M.-F.; Lourie, O.; Dyer, M.J.; Moloni, K.; Kelly, T.F.; Ruoff, R.S. Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science 2000, 287, 637–640. [Google Scholar] [CrossRef] [PubMed]

- Berber, S.; Kwon, Y.-K.; Tománek, D. Unusually high thermal conductivity of carbon nanotubes. Phys. Rev. Lett. 2000, 84, 4613–4616. [Google Scholar] [CrossRef] [PubMed]

- Osman, M.A.; Srivastava, D. Temperature dependence of the thermal conductivity of single-wall carbon nanotubes. Nanotechnology 2001, 12, 21–24. [Google Scholar] [CrossRef]

- Kim, P.; Shi, A.; Majumdar, A.; McEuen, P.L. Thermal Transport Measurements of Individual Multiwalled Nanotubes. Phys. Rev. Lett. 2001, 87. [Google Scholar] [CrossRef] [PubMed]

- Mickelson, E.T.; Huffman, C.B.; Rinzler, A.G.; Smalley, R.E.; Hauge, R.H.; Margrave, J.L. Fluorination of single-wall carbon nanotubes. Chem. Phys. Lett. 1998, 296, 188–194. [Google Scholar] [CrossRef]

- Garg, A.; Sinnott, S.B. Effect of chemical functionalization on the mechanical properties of carbon nanotubes. Chem. Phys. Lett. 1998, 295, 273–278. [Google Scholar] [CrossRef]

- Bogdanovich, A.E.; Bradford, P.D. Carbon nanotube yarn and 3-D braid composites. Part I: Tensile testing and mechanical properties analysis. Compos. Part A 2010, 41, 230–237. [Google Scholar] [CrossRef]

- Bradford, P.D.; Bogdanovich, A.E. Carbon nanotube yarn and 3-D braid composites. Part II: Dynamic mechanical analysis. Compos. Part A 2010, 41, 238–246. [Google Scholar] [CrossRef]

- Mora, R.J.; Vilatela, J.J.; Windle, A.H. Properties of composites of carbon nanotube fibres. Compos. Sci. Technol. 2009, 69, 1558–1563. [Google Scholar] [CrossRef]

- Zhang, J.; Jiang, D. Influence of geometries of multi-walled carbon nanotubes on the pore structures of Buckypaper. Compos. Part A 2012, 43, 469–474. [Google Scholar] [CrossRef]

- Frizzell, C.J.; in het Panhuis, M.; Coutinho, D.H.; Balkus, K.J., Jr.; Minett, A.I.; Blau, W.J.; Coleman, J.N. Reinforcement of macroscopic carbon nanotube structures by polymer intercalation: The role of polymer molecular weight and chain conformation. Phys. Rev. B 2005, 72. [Google Scholar] [CrossRef]

- Li, C.; Thostenson, E.T.; Chou, T.-W. Dominant role of tunneling resistance in the electrical conductivity of carbon nanotube–based composites. Appl. Phys. Lett. 2007, 91. [Google Scholar] [CrossRef]

- Kaiser, A.B.; Skákalová, V. Electronic conduction in polymers, carbon nanotubes and graphene. Chem. Soc. Rev. 2011, 40, 3786–3801. [Google Scholar] [CrossRef] [PubMed]

- Itkis, M.E.; Borondics, F.; Yu, A.; Haddon, R.C. Thermal conductivity measurements of semitransparent single-walled carbon nanotube films by a bolometric technique. Nano Lett. 2007, 7, 900–904. [Google Scholar] [CrossRef] [PubMed]

- Whitten, P.G.; Spinks, G.M.; Wallace, G.G. Mechanical properties of carbon nanotube paper in ionic liquid and aqueous electrolytes. Carbon 2005, 43, 1891–1896. [Google Scholar] [CrossRef]

- Wang, Z.; Liang, Z.; Wang, B.; Zhang, C.; Kramer, L. Processing and property investigation of single-walled carbon nanotube (SWNT) buckypaper/epoxy resin matrix nanocomposites. Compos. Part A 2004, 35, 1225–1232. [Google Scholar] [CrossRef]

- Lee, J.; Kim, W.; Kim, W. Stretchable carbon nanotube/ion-gel supercapacitors with high durability realized through interfacial microroughness. ACS Appl. Mater. Interfaces 2014, 6, 13578–13586. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Wang, W.; Li, C.; Wei, L.; Chen, X.; Tong, Y.; Mai, K.; Lu, X. Highly conductive ethylene-vinyl acetate copolymer/carbon nanotube paper for lightweight and flexible supercapacitors. J. Power Sources 2014, 248, 1248–1255. [Google Scholar] [CrossRef]

- Chen, P.; Fu, Y.; Aminirad, R.; Wang, C.; Zhang, J.; Wang, K.; Galatsis, K.; Zhou, C. Fully printed separated carbon nanotube thin film transistor circuits and its application in organic light emitting diode control. Nano Lett. 2011, 11, 5301–5308. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.; Wei, B. Direct fabrication of single-walled carbon nanotube macro-films on flexible substrates. Chem. Commun. 2007, 3042–3044. [Google Scholar] [CrossRef] [PubMed]

- Feng, J.-M.; Wang, R.; Li, Y.-L.; Zhong, X.-H.; Cui, L.; Guo, Q.-J.; Hou, F. One-step fabrication of high quality double-walled carbon nanotube thin films by a chemical vapor deposition process. Carbon 2010, 48, 3817–3824. [Google Scholar] [CrossRef]

- Dumée, L.F.; Sears, K.; Schütz, J.; Finn, N.; Huynh, C.; Hawkins, S.; Duke, M.; Gray, S. Characterization and evaluation of carbon nanotube Bucky-Paper membranes for direct contact membrane distillation. J. Membr. Sci. 2010, 351, 36–43. [Google Scholar] [CrossRef] [Green Version]

- Suppiger, D.; Busato, S.; Ermanni, P. Characterization of single-walled carbon nanotube mats and their performance as electromechanical actuators. Carbon 2008, 46, 1085–1090. [Google Scholar] [CrossRef]

- Chen, H.; Zeng, S.; Chen, M.; Zhang, Y.; Li, Q. Fabrication and functionalization of carbon nanotube films for high-performance flexible supercapacitors. Carbon 2015, 92, 271–296. [Google Scholar] [CrossRef]

- Zhang, X.; Jiang, K.; Feng, C.; Liu, P.; Zhang, L.; Kong, J.; Zhang, T.; Li, Q.; Fan, S. Spinning and processing continuous yarns from 4-inch wafer scale super-aligned carbon nanotube arrays. Adv. Mater. 2006, 18, 1505–1510. [Google Scholar] [CrossRef]

- Liu, M.; Sun, J.; Sun, Y.; Bock, C.; Chen, Q. Thickness-dependent mechanical properties of polydimethylsiloxane membranes. J. Micromech. Microeng. 2009, 19. [Google Scholar] [CrossRef]

- Liu, M.; Sun, J.; Chen, Q. Influences of heating temperature on mechanical properties of polydimethylsiloxane. Sens. Actuator A 2009, 151, 42–45. [Google Scholar] [CrossRef]

- Schneider, F.; Fellner, T.; Wilde, J.; Wallrabe, U. Mechanical properties of silicones for MEMS. J. Micromech. Microeng. 2008, 18. [Google Scholar] [CrossRef]

- Kuo, A.C.M. Polymer Data Handbook; Mark, J.E., Ed.; Oxford University Press: Oxford, UK, 1999; pp. 411–435. [Google Scholar]

- Sim, L.C.; Ramanan, S.R.; Ismail, H.; Seetharamu, K.N.; Goh, T.J. Thermal characterization of Al2O3 and ZnO reinforced silicone rubber as thermal pads for heat dissipation purposes. Thermochim. Acta 2005, 430, 155–165. [Google Scholar] [CrossRef]

- Inam, F.; Yan, H.; Reece, M.J.; Peijs, T. Dimethylformamide: An effective dispersant for making ceramic-carbon nanotube composites. Nanotechnology 2008, 19. [Google Scholar] [CrossRef] [PubMed]

- Ausman, K.D.; O’Connell, M.J.; Boul, P.; Ericson, L.M.; Casavant, M.J.; Walters, D.A.; Huffman, C.; Saini, R.; Wang, Y.; Haroz, E.; et al. Roping and wrapping carbon nanotubes. AIP Conf. Proc. 2001, 591, 226–230. [Google Scholar]

- Okpalugo, T.I.T.; Papakonstantinou, P.; Murphy, H.; McLaughlin, J.; Brown, N.M.D. High resolution XPS characterization of chemical functionalised MWCNTs and SWCNTs. Carbon 2005, 43, 153–161. [Google Scholar] [CrossRef]

- Osswald, S.; Havel, M.; Gogotsi, Y. Monitoring oxidation of multiwalled carbon nanotubes by Raman spectroscopy. J. Raman Spectrosc. 2007, 38, 728–736. [Google Scholar] [CrossRef]

- Shenogina, N.; Shenogin, S.; Xue, L.; Keblinskia, P. On the lack of thermal percolation in carbon nanotube composites. Appl. Phys. Lett. 2005, 87. [Google Scholar] [CrossRef]

- Huxtable, S.T.; Cahill, D.G.; Shenogin, S.; Xue, L.; Ozisik, R.; Barone, P.; Usrey, M.; Strano, M.S.; Siddons, G.; Shim, M.; et al. Interfacial heat flow in carbon nanotube suspensions. Nat. Mater. 2003, 2, 731–734. [Google Scholar] [CrossRef] [PubMed]

- Shenogin, S.; Xue, L.; Ozisik, R.; Keblinski, P.; Cahill, D.G. Role of thermal boundary resistance on the heat flow in carbon-nanotube composites. J. Appl. Phys. 2004, 95, 8136–8144. [Google Scholar] [CrossRef]

- Pak, S.Y.; Kim, H.M.; Kim, S.Y.; Youn, J.R. Synergistic improvement of thermal conductivity of thermoplastic composites with mixed boron nitride and multi-walled carbon nanotube fillers. Carbon 2012, 50, 4830–4838. [Google Scholar] [CrossRef]

| Sample | Types of MWCNT | MWCNT Content (mg/50 mL) | Sonication Time (min) | Dispersion Medium | Types of Filter | Thickness (μm) | Tensile Strength (MPa) |

|---|---|---|---|---|---|---|---|

| (a) | CM-130 | 50 | 20 | Ethanol | Nylon | 220 | - |

| (b) | CM-150 | 50 | 20 | Ethanol | Nylon | 100 | - |

| (c) | CM-250 | 50 | 20 | Ethanol | Nylon | 150 | 0.68 |

| (d) | CM-280 | 50 | 20 | Ethanol | Nylon | 150 | 1.98 |

| (e) | CM-280 | 10 | 20 | Ethanol | Nylon | 100 | - |

| (f) | CM-280 | 30 | 20 | Ethanol | Nylon | 130 | 1.96 |

| (g) | CM-280 | 70 | 20 | Ethanol | Nylon | 200 | 1.20 |

| (h) | CM-280 | 90 | 20 | Ethanol | Nylon | 240 | 0.74 |

| (i) | CM-280 | 50 | 10 | Ethanol | Nylon | 170 | 0.75 |

| (j) | CM-280 | 50 | 30 | Ethanol | Nylon | 160 | 1.13 |

| (k) | CM-280 | 50 | 20 | DMF 1 | Nylon | 150 | 2.08 |

| (l) | CM-280 | 50 | 20 | DMF | PTFE 2 | 130 | 3.70 |

| Element | Peak Position (eV) | Atomic Concentration (%) | |

|---|---|---|---|

| As-received MWCNTs | O1s | 532.36 | 1.6 |

| C1s | 284.37 | 98.4 | |

| Buckypaper fabricated under the optimized conditions | O1s | 533.21 | 1.69 |

| C1s | 285.31 | 98.31 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cha, J.E.; Kim, S.Y.; Lee, S.H. Effect of Continuous Multi-Walled Carbon Nanotubes on Thermal and Mechanical Properties of Flexible Composite Film. Nanomaterials 2016, 6, 182. https://doi.org/10.3390/nano6100182

Cha JE, Kim SY, Lee SH. Effect of Continuous Multi-Walled Carbon Nanotubes on Thermal and Mechanical Properties of Flexible Composite Film. Nanomaterials. 2016; 6(10):182. https://doi.org/10.3390/nano6100182

Chicago/Turabian StyleCha, Ji Eun, Seong Yun Kim, and Seung Hee Lee. 2016. "Effect of Continuous Multi-Walled Carbon Nanotubes on Thermal and Mechanical Properties of Flexible Composite Film" Nanomaterials 6, no. 10: 182. https://doi.org/10.3390/nano6100182