An Injectable Glass Polyalkenoate Cement Engineered for Fracture Fixation and Stabilization

Abstract

:1. Introduction

2. Materials and Methods

2.1. Glass Synthesis

2.1.1. Polyacrylic Acid

2.1.2. Bovine Serum Albumin

2.2. Glass Characterization

2.3. Scanning Electron Microscopy and Energy Dispersive X-ray Analysis

2.4. Particle Size Analysis

2.5. Cement Preparation

2.6. Handling Characteristics

2.6.1. Working Time

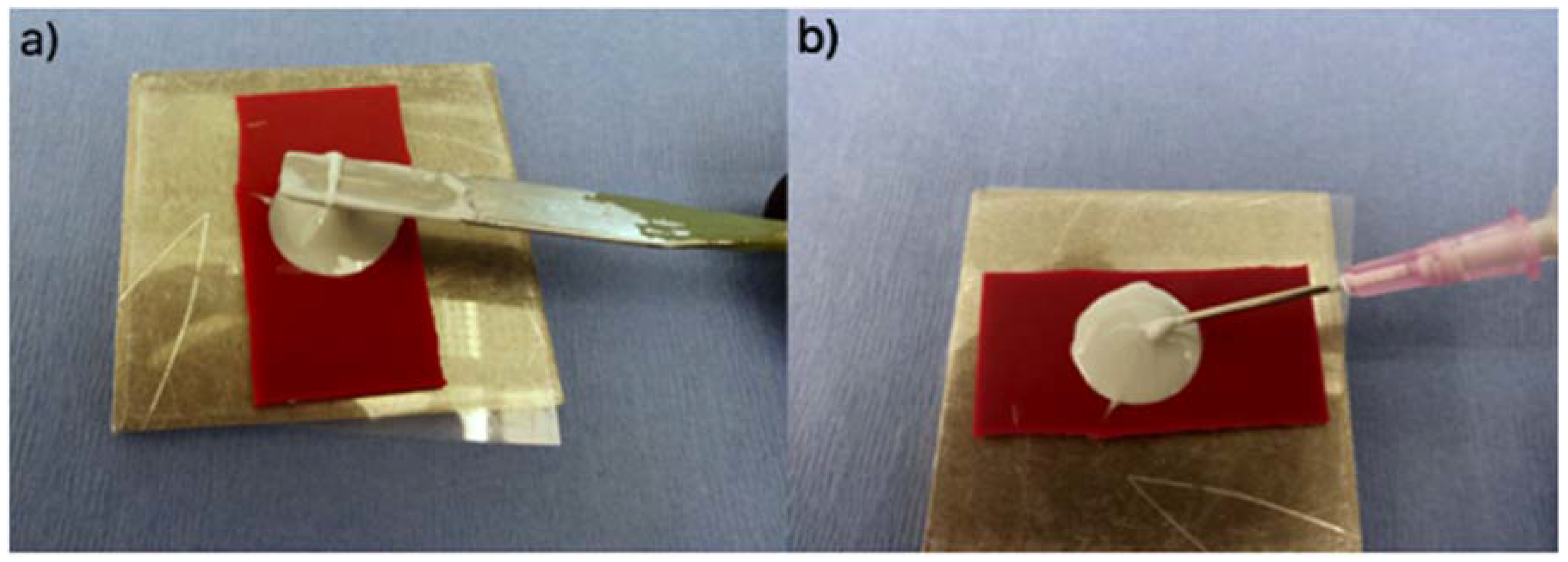

2.6.2. Setting Time Measurement and the Preparation of GPCs

2.6.2.1. Setting Time Measurement

2.6.2.2. Preparation of GPCs

2.7. Mechanical Properties

2.7.1. Compressive Strength Measurement

2.7.2. Biaxial Flexural Strength

2.8. Ion and Bovine Serum Albumin Release Profile

2.9. Statistical Analysis

3. Results and Discussion

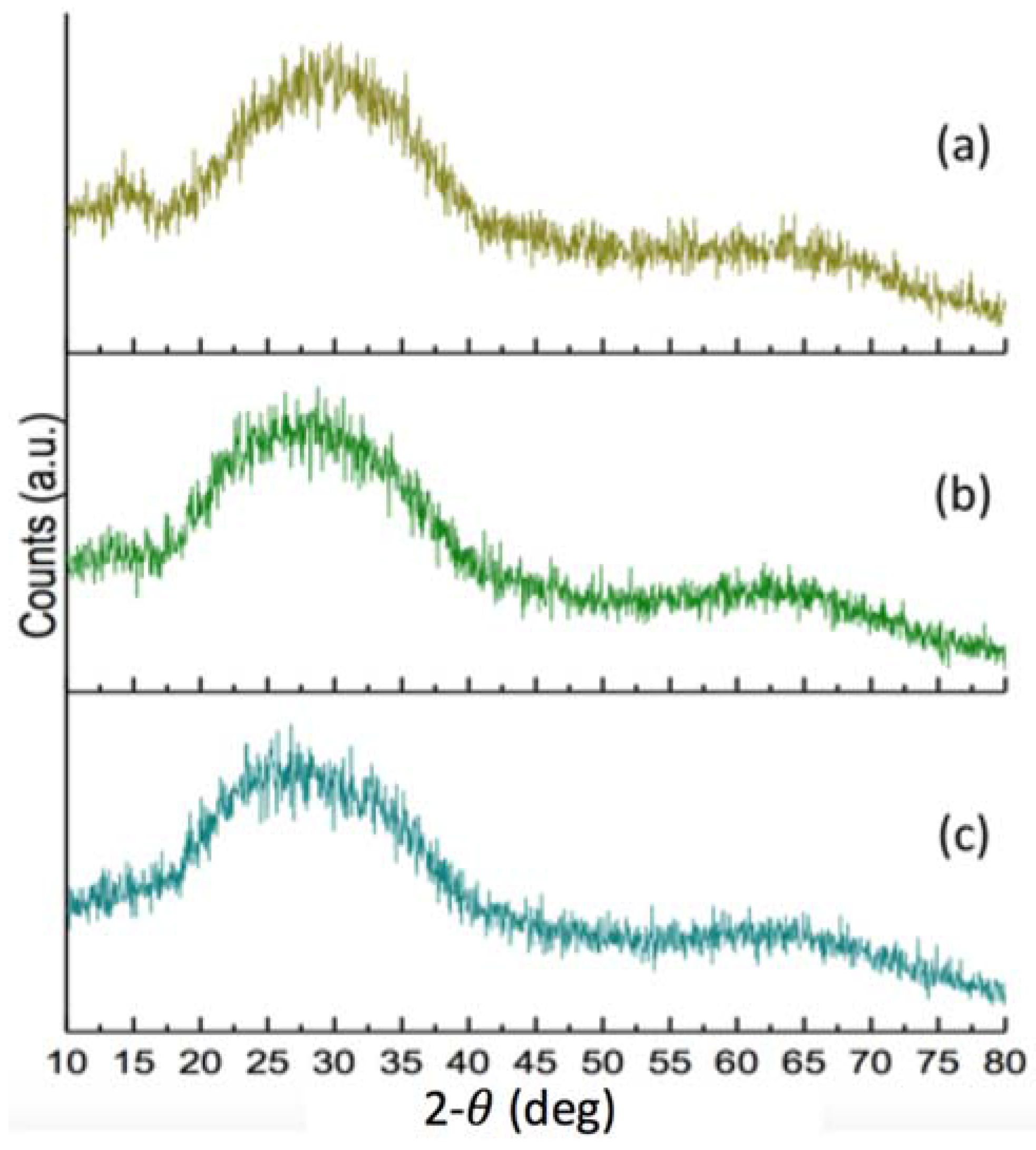

3.1. Glass Characterization

3.2. Scanning Electron Microscopy and Energy Dispersive X-ray Analysis Particle Size Analysis

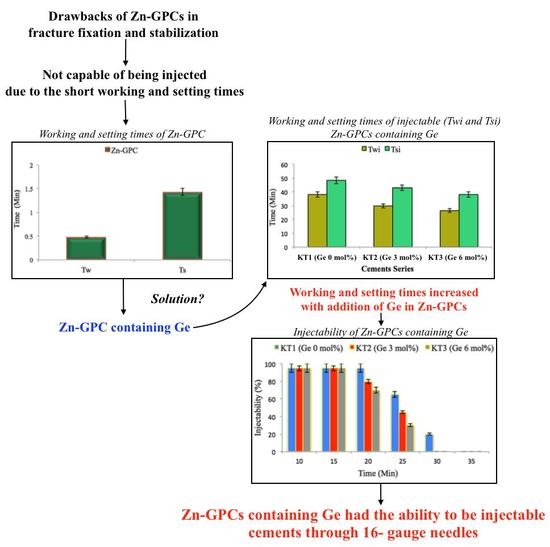

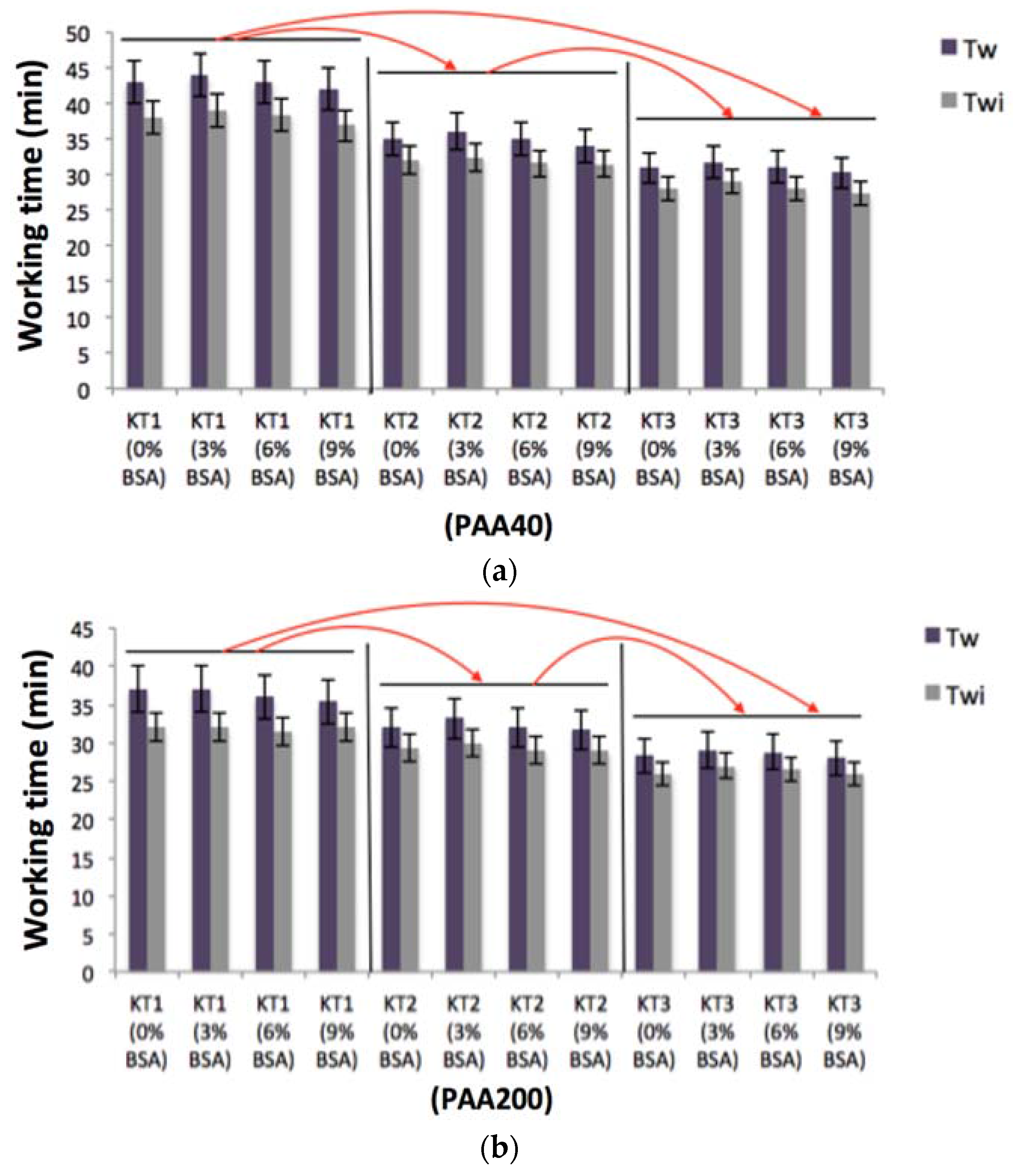

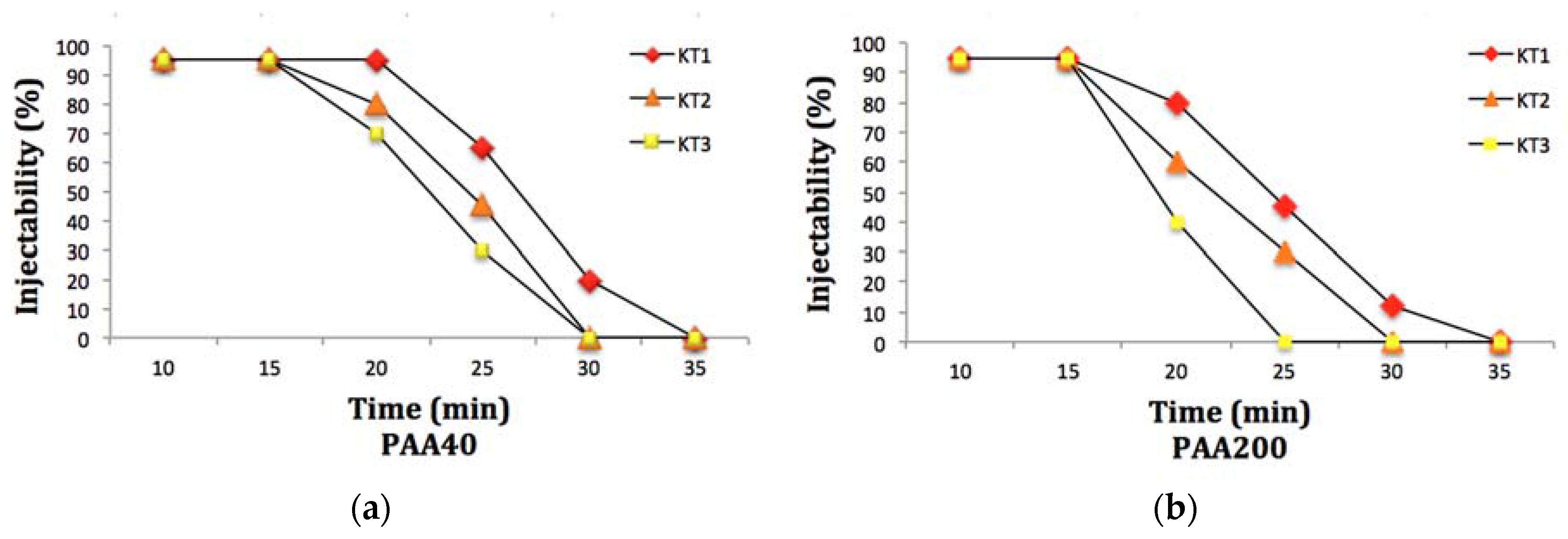

3.3. The Influence of GeO Incorporation and Acid Concentration on Working and Setting Times Measurement of GPCs and Injectability of the Cements

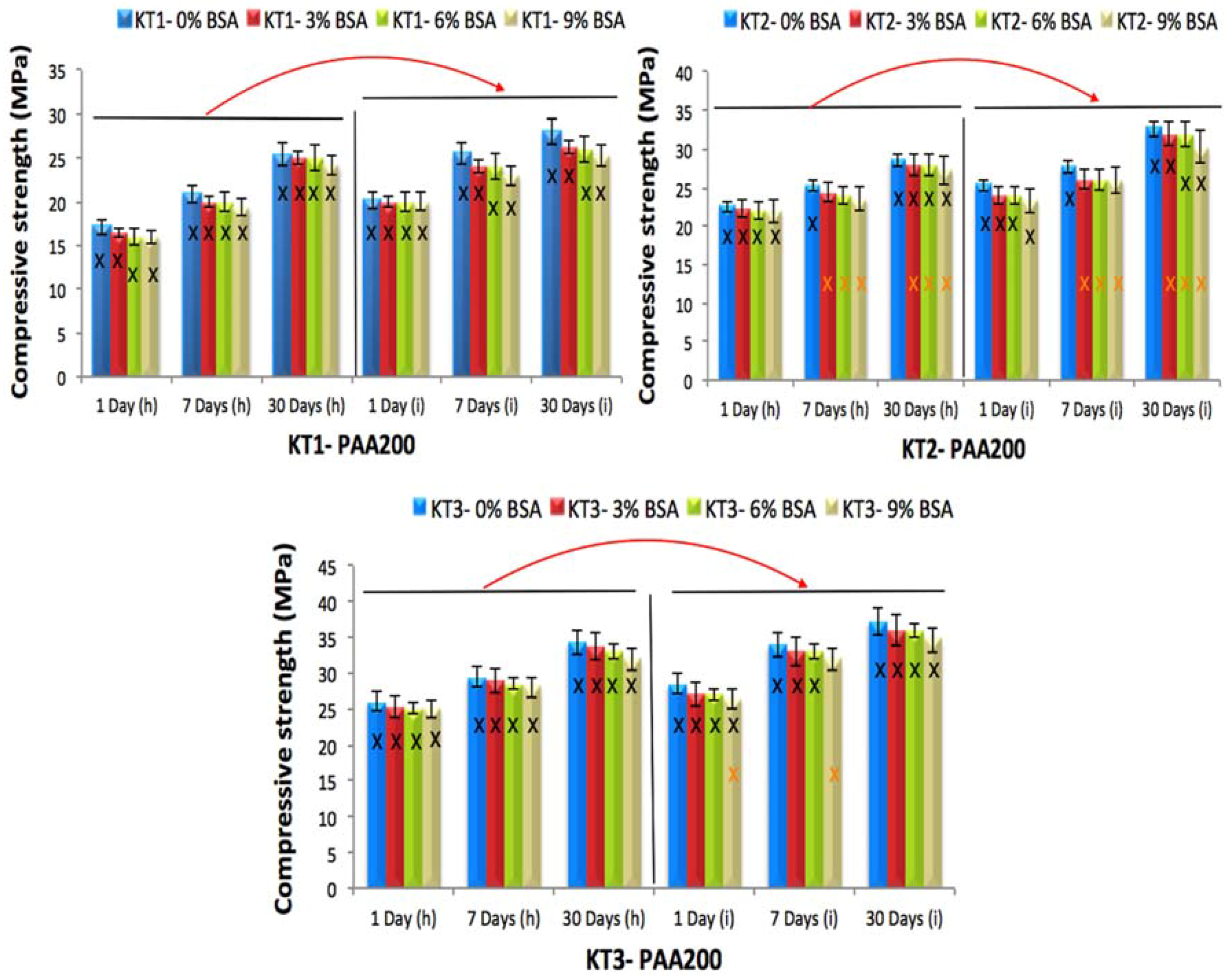

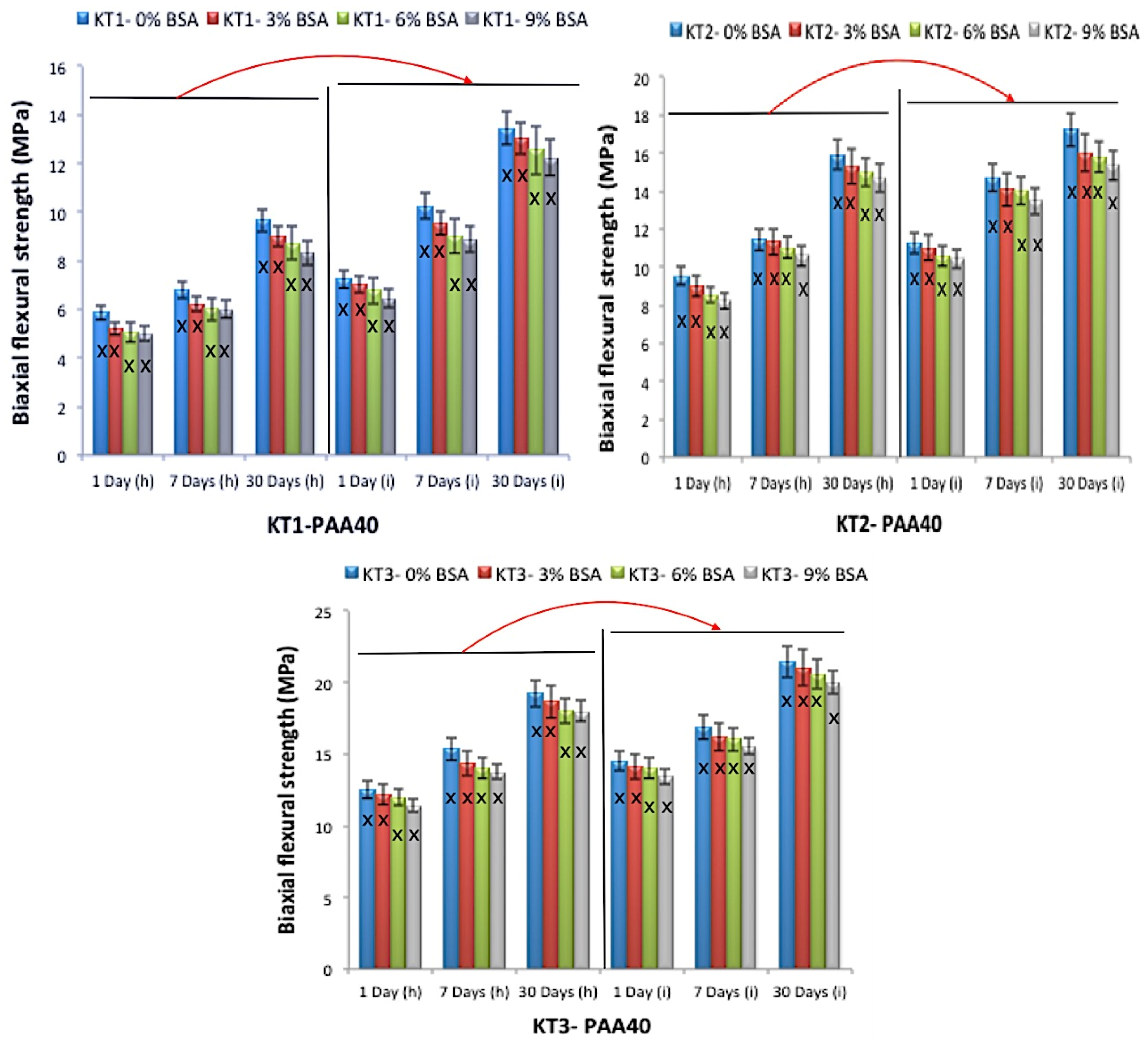

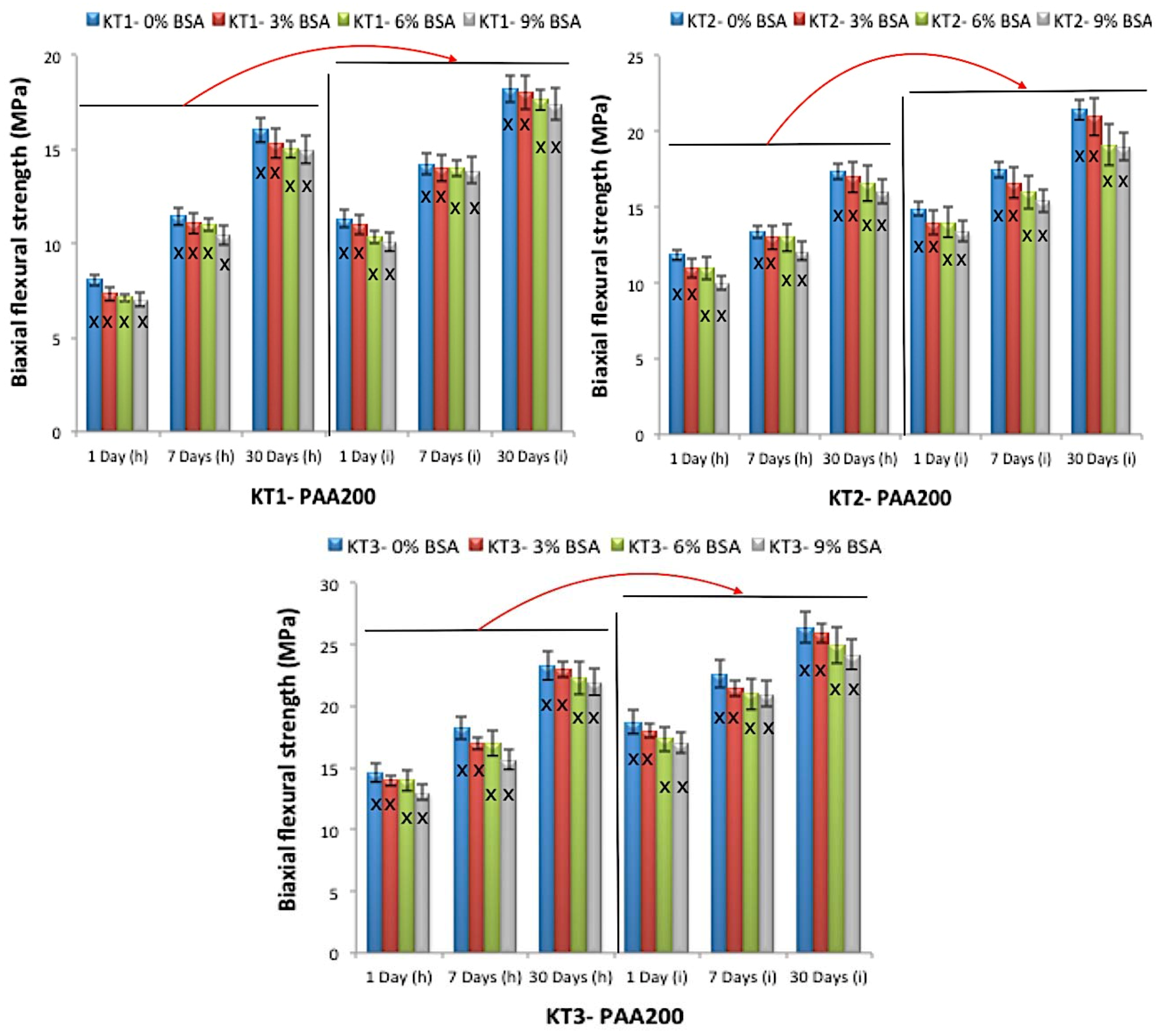

3.4. The Influence of GeO, BSA Incorporation and Acid Concentration on Compressive (σc) and Biaxial Flexural (σf) Strengths of KT Cements

3.5. Morphology of Cement Fracture Surfaces

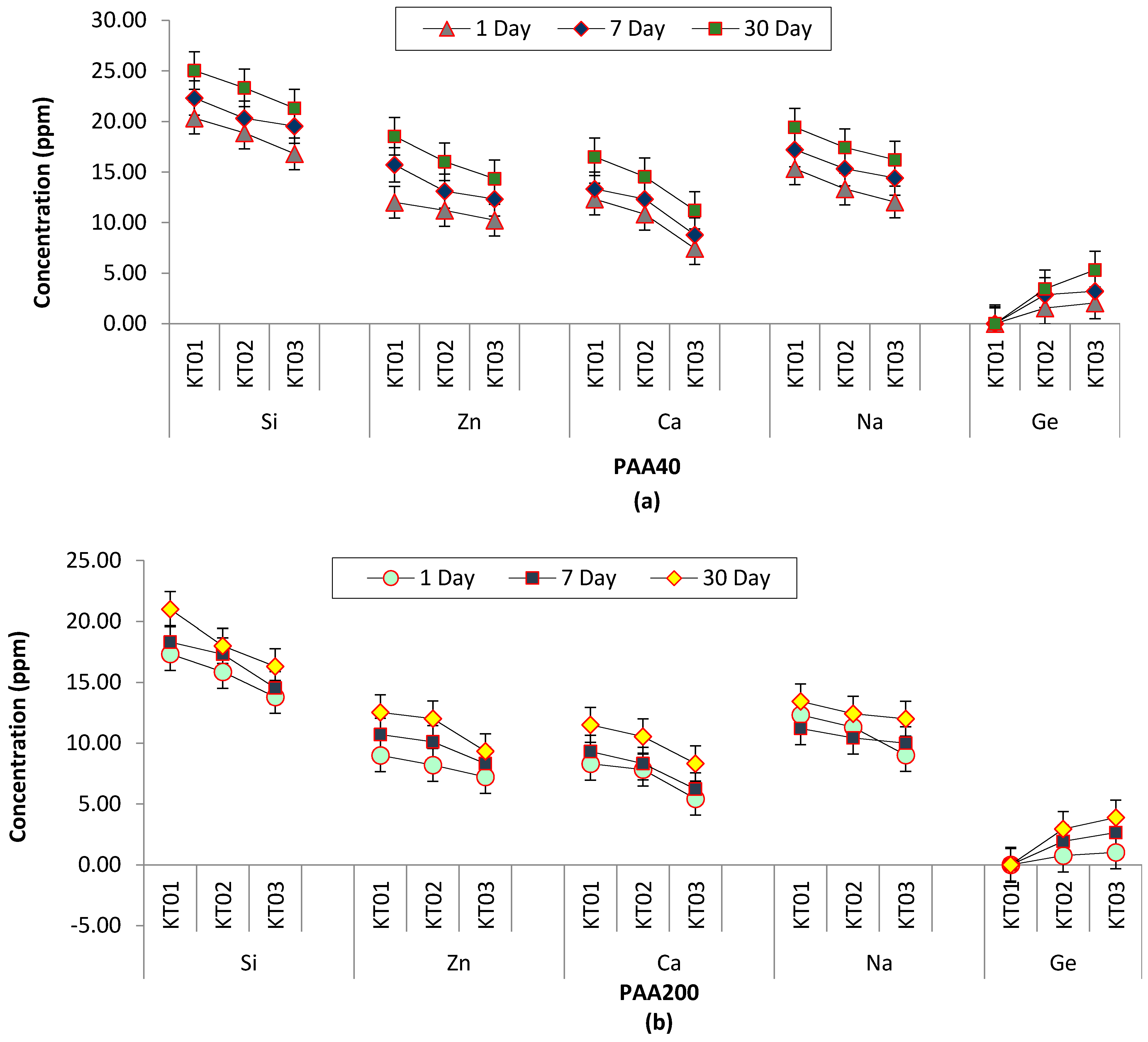

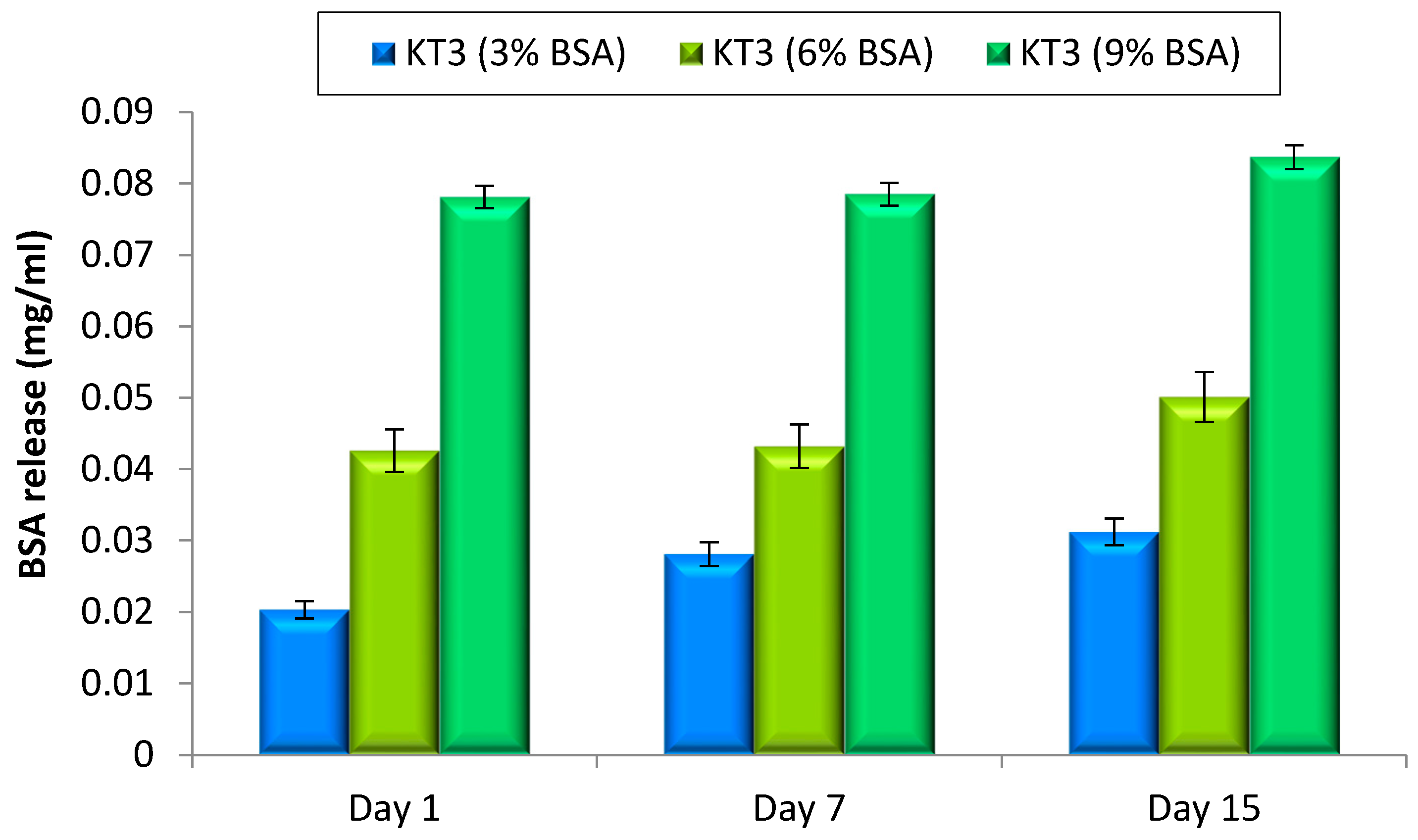

3.6. Ion and Bovine Serum Albumin Release Profile

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Qui, Y.; Hamilton, S.K.; Temenoff, J. Improving mechanical properties of injectable polymers and composites. Inject. Biomater. Sci. Appl. 2011, 61–91. [Google Scholar] [CrossRef]

- Laurencin, C.T.; Ambrosio, A.M.A.; Borden, M.D.; Cooper, J.A., Jr. Tissue Engineering: Orthopedic Applications. Annu. Rev. Biomed. Eng. 1999, 1, 19–46. [Google Scholar] [CrossRef] [PubMed]

- Chow, C.L.; Takagi, S. A natural bone cement—A laboratory novelty led to the development of revolutionary new biomaterials. J. Res. Natl. Inst. Tech. 2001, 106, 1029–1033. [Google Scholar] [CrossRef] [PubMed]

- Wren, A.W. Strontium Substituted Glass Ionomer Cements for Skeletal Applications. Ph.D. Thesis, University of Limerick, Limerick, Ireland, 2008. [Google Scholar]

- Wang, X.; May, J.; Wang, Y.; He, B. Bone repair in radii and tibias of rabbits with phosphorylated chitosan reinforced calcium phosphate cements. Biomaterials 2002, 23, 4167–4176. [Google Scholar] [CrossRef] [PubMed]

- Higgins, T.F.; Dodds, S.D.; Wolfe, S.W. A biomechanical analysis of fixation of intra-articular distal radial fractures with calcium phosphate bone cement. J. Bone Jt. Surg. Am. Vol. 2002, 84, 1579–1586. [Google Scholar] [CrossRef]

- Hidaka, N.; Yamano, Y.; Kadoya, Y.; Nishimura, N. Calcium phosphate bone cement for treatment of distal radius fractures: A preliminary report. J. Orthop. Sci. 2002, 7, 182–187. [Google Scholar] [CrossRef] [PubMed]

- Aoki, H.; Ukegawa, Y. Ceramic biomaterial. In Manual of Orthopaedic Materials; Yamamuro, T., Onishi, H., Eds.; Kanehara & Co., Ltd.: Tokyo, Japan, 1992; pp. 39–47. (In Japanese) [Google Scholar]

- Niwa, S.; Yamamoto, H. Biological reaction and clinical application of calcium phosphate cement. Kansetugeka. J. Jt. Surg. 1998, 17, 82–88. (In Japanese) [Google Scholar]

- Khairoun, I.; Driessens, F.C.; Boltong, M.G.; Planell, J.A.; Wenz, R. Addition of cohesion promotors to calcium phosphate cements. Biomaterials 1999, 20, 393–398. [Google Scholar] [CrossRef]

- Cattani-Lorente, M.A.; Godin, C.; Meyer, J.M. Early strength of glass ionomer cements. Dent. Mater. 1993, 9, 57–62. [Google Scholar] [CrossRef]

- Nicholson, J.W. Adhesive dental materials–A review. Int. J. Adhes. Adhes. 1998, 18, 229–236. [Google Scholar] [CrossRef]

- Zimehl, R.; Hannig, M. Non metallic restorative materials based on glass ionomer cements-recent trends and developments. Colloids Surf. A 2000, 163, 55–62. [Google Scholar] [CrossRef]

- Nicholson, J.W. Chemistry of glass-ionomer cements: A review. Biomaterials 1998, 19, 485–494. [Google Scholar] [CrossRef]

- Towler, M.R.; Kenny, S.; Boyd, D.; Pembroke, T.; Buggy, M.; Hill, R.G. Zinc ion release from novel hard tissue biomaterials. Biomed. Mater. Eng. 2004, 14, 565–572. [Google Scholar] [PubMed]

- Endotherapeutics: Serenocem Ear Cement and Granules. Available online: http://www.endotherapeutics.com.au/serenocem (accessed on 10 October 2016).

- Invotec International®: SerenocemTM Ostologic Cement. Available online: http://www.mundinc.com/uploads/serenocem_otologic_cement.pdf (accessed on 10 October 2016).

- Wren, A.W.; Kidari, A.; Cummins, N.M.; Towler, M.R. A spectroscopic investigation into the setting and mechanical properties of titanium containing glass polyalkenoate cements. J. Mater. Sci. Mater. Med. 2010, 21, 2355–2364. [Google Scholar] [CrossRef] [PubMed]

- Sawai, J. Quantitative evaluation of antibacterial activities of metallic oxide powders (ZnO, MgO and CaO) by conductimetric assay. J. Microbiol. Methods 2003, 54, 177–182. [Google Scholar] [CrossRef]

- Catelan, A.; Padilha, A.C.; Salzedas, L.M.; Coclete, G.A.; dos Santos, P.H. Effect of radiotherapy on the radiopacity and flexural strength of a composite resin. Acta Odontol. Latinoam. 2008, 21, 159–162. [Google Scholar] [PubMed]

- Boyd, D.; Towler, M.R.; Watts, S.; Hill, R.G.; Wren, A.W.; Clarkin, O.M. The role of Sr2+ on the structure and reactivity of SrO-CaO-ZnO-SiO2 ionomer glasses. J. Mater. Sci. Mater. Med. 2008, 19, 953–957. [Google Scholar] [CrossRef] [PubMed]

- Clarkin, O.; Boyd, D.; Towler, M.R. Comparison of failure mechanisms for cements used in skeletal luting applications. J. Mater. Sci. Mater. Med. 2009, 20, 1585–1594. [Google Scholar] [CrossRef] [PubMed]

- Varshneya, A.K. Fundamentals of Inorganic Glasses, 1st ed.; Gulf Professional Publishing Academic Press: Boston, MA, USA, 1994. [Google Scholar]

- Khader, B.A.; Curran, D.J.; Peel, S.; Towler, M.R. Glass Polyalkenoate Cements Designed for Cranioplasty Applications: An Evaluation of Their Physical and Mechanical Properties. J. Funct. Biomater. 2016, 7, 8. [Google Scholar] [CrossRef] [PubMed]

- Towler, M.R.; Stanton, K.T.; Mooney, P.; Hill, R.G.; Moreno, N.; Querol, X. Modelling of the glass phase in fly ashes using network connectivity theory. J. Chem. Technol. Biotechnol. 2002, 77, 240–245. [Google Scholar] [CrossRef]

- Dentistry—Water-Based Cements-Part 1: Powder/Liquid Acid-Base Cements, ISO 9917-1; ISO: Geneva, Switzerland, 2007.

- Dentistry—Water-Based Cements-Part 1: Powder/Liquid Acid-Base Cements, ISO 9917; ISO: Geneva, Switzerland, 1991.

- Khairoun, I.; Boltong, M.G.; Driessens, F.C.; Planell, J.A. Some factors controlling the injectability of calcium phosphate bone cements. J. Mater. Sci. Mater. Med. 1998, 9, 425–428. [Google Scholar] [CrossRef] [PubMed]

- Williams, J.A.; Billington, R.W.; Pearson, G.J. The effect of the disc support system on biaxial tensile strength of a glass ionomer cement. Dent. Mater. 2002, 18, 376–379. [Google Scholar] [CrossRef]

- Prentice, L.H.; Tyas, M.J.; Burrow, M.F. The effect of particle size distribution on an experimental glass-ionomer cement. Dent. Mater. 2005, 21, 505–510. [Google Scholar] [CrossRef] [PubMed]

- Wren, A.W.; Hansen, J.P.; Hayakawa, S.; Towler, M.R. Aluminum-free glass polyalkenoate cements: Ion release and in vitro antibacterial efficacy. J. Mater. Sci. Mater. Med. 2013, 24, 1167–1178. [Google Scholar] [CrossRef] [PubMed]

- Dickey, B.T.; Kehoe, S.; Boyd, D. Novel adaptations to zinc-silicate glass polyalkenoate cements: The unexpected influences of germanium based glasses on handling characteristics and mechanical properties. J. Mech. Behav. Biomed. Mater. 2013, 23, 8–21. [Google Scholar] [CrossRef] [PubMed]

- Wilson, A.D.; Nicholson, J.W. Acid-Base Cements: Their Biomedical and Industrial Applications (Chemistry of Solid State Materials); West, A.R., Baxter, H., Eds.; Cambridge University Press: Cambridge, UK, 1993. [Google Scholar]

- Wren, A.W.; Coughlan, A.; Palcek, L.; Towler, M.R. Gallium containing glass polyalkenoate anti-cancerous bone cements: Glass characterization and physical properties. J. Mater. Sci. Mater. Med. 2012, 23, 1823–1833. [Google Scholar] [CrossRef] [PubMed]

- Boyd, D.; Towler, M.R. The processing, mechanical properties and bioactivity of zinc based glass ionomer cements. J. Mater. Sci. Mater. Med. 2005, 16, 843–850. [Google Scholar] [CrossRef] [PubMed]

- De Barra, E.; Hill, R.G. Influence of alkali metal ions on the fracture properties of glass polyalkenoate (ionomer) cements. Biomaterials 1998, 19, 495–502. [Google Scholar] [CrossRef]

- Clarkin, O.; Boyd, D.; Towler, M.R. Strontium-based glass polyalkenoate cements for luting applications in the skeleton. J. Biomater. Appl. 2010, 24, 483–502. [Google Scholar] [CrossRef] [PubMed]

- Hill, R.G. The fracture properties of glass polyalkenoate cements as a function of cement age. J. Mater. Sci. 1993, 28, 3851–3858. [Google Scholar] [CrossRef]

- Barkema, G.T.; Panja, D.; van Leeuwen, J.M.J. Structural modes of a polymer in the repton model. J. Chem. Phys. 2011, 134, 154901. [Google Scholar] [CrossRef] [PubMed]

- Rubinstein, M. Discretized model of entangled-polymer dynamics. Phys. Rev. Lett. 1987, 59, 1946–1949. [Google Scholar] [CrossRef] [PubMed]

- McLeish, T.C.B. Tube theory of entangled polymer dynamics. Adv. Phys. 2002, 51, 1379–1527. [Google Scholar] [CrossRef]

- Pourbeik, P.; Beaudoin, J.J.; Alizadeh, A.R.; Raki, L. Mechanical property-porosity relationships of layered calcium silicate hydrate phases. Mater. Struct. 2013, 46, 1489–1495. [Google Scholar] [CrossRef]

| Composition | SiO2 | CaO | ZnO | Na2O | GeO2 |

|---|---|---|---|---|---|

| KT1 | 0.50 | 0.10 | 0.30 | 0.10 | 0 |

| KT2 | 0.50 | 0.10 | 0.27 | 0.10 | 0.03 |

| KT3 | 0.50 | 0.10 | 0.24 | 0.10 | 0.06 |

| Cement Formulations | Powder Components | Liquid Components |

|---|---|---|

| Name | GPCs (g) | PAA40 and PAA200 (wt %) DDI Water (wt %) BSA (wt %) |

| KT1 | 1 g | 0.375/0.375 0.375 0, 3, 6, 9 |

| KT2 | 1 g | 0.375/0.375 0.375 0, 3, 6, 9 |

| KT3 | 1 g | 0.375/0.375 0.375 0, 3, 6, 9 |

| Composition | KT1 | KT2 | KT3 |

|---|---|---|---|

| Si | 31.3 | 29.7 | 28.2 |

| Ca | 8.8 | 8.5 | 7.8 |

| Zn | 26.5 | 22.7 | 22.1 |

| Na | 8.9 | 8.3 | 7.6 |

| Ge | - | 2.2 | 5.2 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khader, B.A.; Peel, S.A.F.; Towler, M.R. An Injectable Glass Polyalkenoate Cement Engineered for Fracture Fixation and Stabilization. J. Funct. Biomater. 2017, 8, 25. https://doi.org/10.3390/jfb8030025

Khader BA, Peel SAF, Towler MR. An Injectable Glass Polyalkenoate Cement Engineered for Fracture Fixation and Stabilization. Journal of Functional Biomaterials. 2017; 8(3):25. https://doi.org/10.3390/jfb8030025

Chicago/Turabian StyleKhader, Basel A., Sean A. F. Peel, and Mark R. Towler. 2017. "An Injectable Glass Polyalkenoate Cement Engineered for Fracture Fixation and Stabilization" Journal of Functional Biomaterials 8, no. 3: 25. https://doi.org/10.3390/jfb8030025