4.1. Architectural and Engineering Concepts for Kesennuma

We would also propose the “floating platform” scheme to be included in the recovery plan for the destroyed Kesennuma Bay area shown in

Figure 13. Here great numbers of residences and commercial buildings including fishery-related businesses and workplaces were located. The fundamental difference between the recovery of Arahama and Kesennuma Bay area is that the latter regards a much greater population. In addition, as Kesennumma Bay encompasses many fishery-based workplaces and tourist attractions its reconstruction will be more complicated. The scheme that we propose for the restoration of the Uo-machi/Minami-machi area of Kessennuma City is based on some architectural and engineering studies that are presented in this paper. While mitigation of adverse effects is important, the idea is to also maintain Kessennuma’s historical and cultural facilities and ensure that industries, namely fishery and tourism in which about 40% of Kessennuma’s inhabitants are involved, are restored. Furthermore, it is important to ensure a comfortable and intimate environment, provide space for different community schools, and restore important architectural landmarks damaged by disasters as memorial centerpieces.

Moreover, to ensure safety against major tsunamis, we simultaneously propose to raise the ground level up to 2.0 m for regional access roads like the so-called Kessennuma Bay Road to produce a first line of defense, in addition to the shoring up of the bay area comprising eight district blocks using the floating platform system—able to withstand strong earthquakes and huge tsunami—to be placed on the excavated artificial water areas.

Figure 13.

Damaged Kesennuma Bay area.

Figure 13.

Damaged Kesennuma Bay area.

Architectural functions, mainly public spaces such as the commercial/office facilities, restaurants/coffeeshops and so forth will be situated on the first and second floors while residential spaces will be situated beyond the third floor residential space to produce an integrated floating complex where work and habitation are integrated [

11]. In the Fiscal Year prior to the great disaster, the region’s population was recorded as being 840 people (340 households). Looking at future development possibilities however, we propose a population of 1280 people (520 households, though for the floating complexes a total of 268 households was set) as the maximum population. Additionally, this development proposal proposes to have 124 of 274 fishery facilities to be located on the floating platforms together with some 20 community schools.

Meanwhile, according to a guideline produced by the Ministry of Land, Infrastructure, Transport and Tourism, comprehensive tsunami countermeasures that divided tsunamis into two categories—frequent tsunami and giant tsunami. A frequent tsunami occurs in a range of from once in several decades to once in about 150 years and meets the Level 1 height of 6.2 m. A giant tsunami occurs infrequently but causes massive damage. Flooding behind seawalls and/or dike of 6.2 m in this case is envisioned and evacuation is a vital part of countermeasures (disaster mitigation) in principle. Regarding Level 2 for dealing with the giant tsunami category, the proposal sees the use of the floating complexes found on the inner portion of the town to realize a mechanism which enables it to ride through a tsunami with a maximum of 12.0 m; as for those located on the periphery, evacuation routes were set in consideration of the fact that there would be enough time to evacuate.

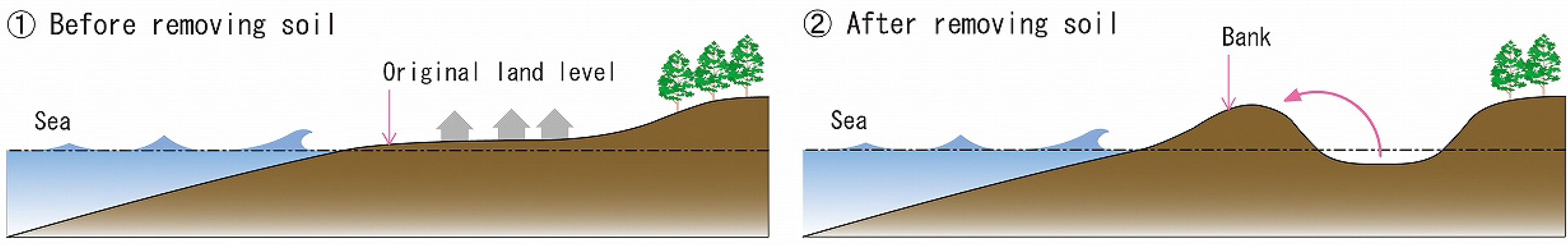

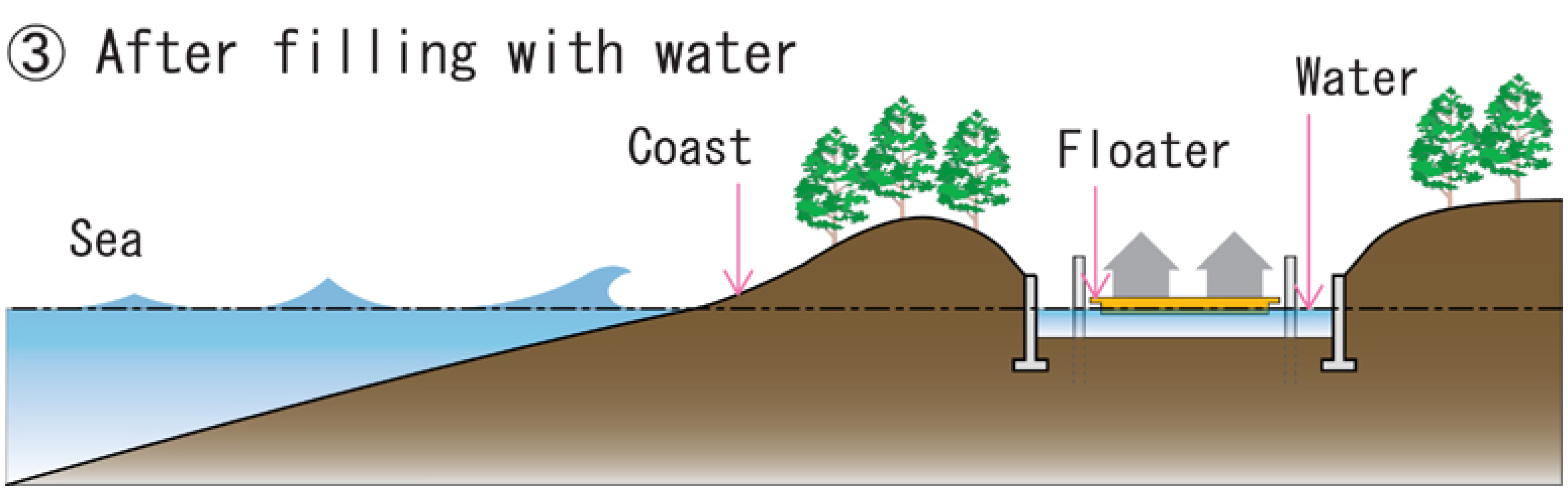

First of all, as is shown in

Figure 14, this narrow bay area divided into eight district blocks is to be excavated to a depth of 5 m and the topsoil removed. The total area for this wide-ranging region along the bay, which is developed by excavating soil from low-lying land areas, is approximately 30,000 m

2.; the topsoil of about 150,000 m

3 removed from the location is to be relocated in order to raise the other area where the ground had sunk by more than 80 cm due to the huge earthquake in 2011 with the excavated area being filled with water until a man-made lagoon and/or basin is produced. Secondly, eight floating platforms (Site 1 to Site 8) will be built at the shipyard and towed and situated inside the man-made lagoon. The construction process of the Kesennuma Bay area is shown in

Figure 15. The left portion in this figure shows the condition of the 8 excavated areas with water and the floating platforms are situated at these water areas shown in the central figure. Meanwhile the one on right is the final stage of the reconstruction process for the destroyed Kesennuma Bay area. These floating platforms in 8 district blocks range in size and shape but due to this paper’s limited length, Site 2 floating platform which is seen having stability issues which are considered to be the worst upon facing natural disasters was selected as a representative platform among the 8 floating platforms for the foregoing study.

Figure 14.

Site plan of eight district blocks in Kesennuma Bay area.

Figure 14.

Site plan of eight district blocks in Kesennuma Bay area.

Figure 15.

Different construction stages of Kesennuma Bay area.

Figure 15.

Different construction stages of Kesennuma Bay area.

4.2. Structural Design of Floating Platforms for Kesennuma Bay

The floating platform in the proposal is of a barge-type construction, similar to that used in the Mega-Float Project that was carried out in Japan between 1995 and 2000 [

12]. During the 1990s, attempting to realize facilitated construction of an offshore airport, the Technological Research Association of Mega-Float (TRAM) was established and centered upon the Japanese shipbuilding industry. In the final stage of this research project, a 1000-meter-long floating airport model was actually built and floated on the sea. The construction procedure of such a super-large floating platform had been constructed by welding many pieces of floating modular unit at sea and was verified successfully (see

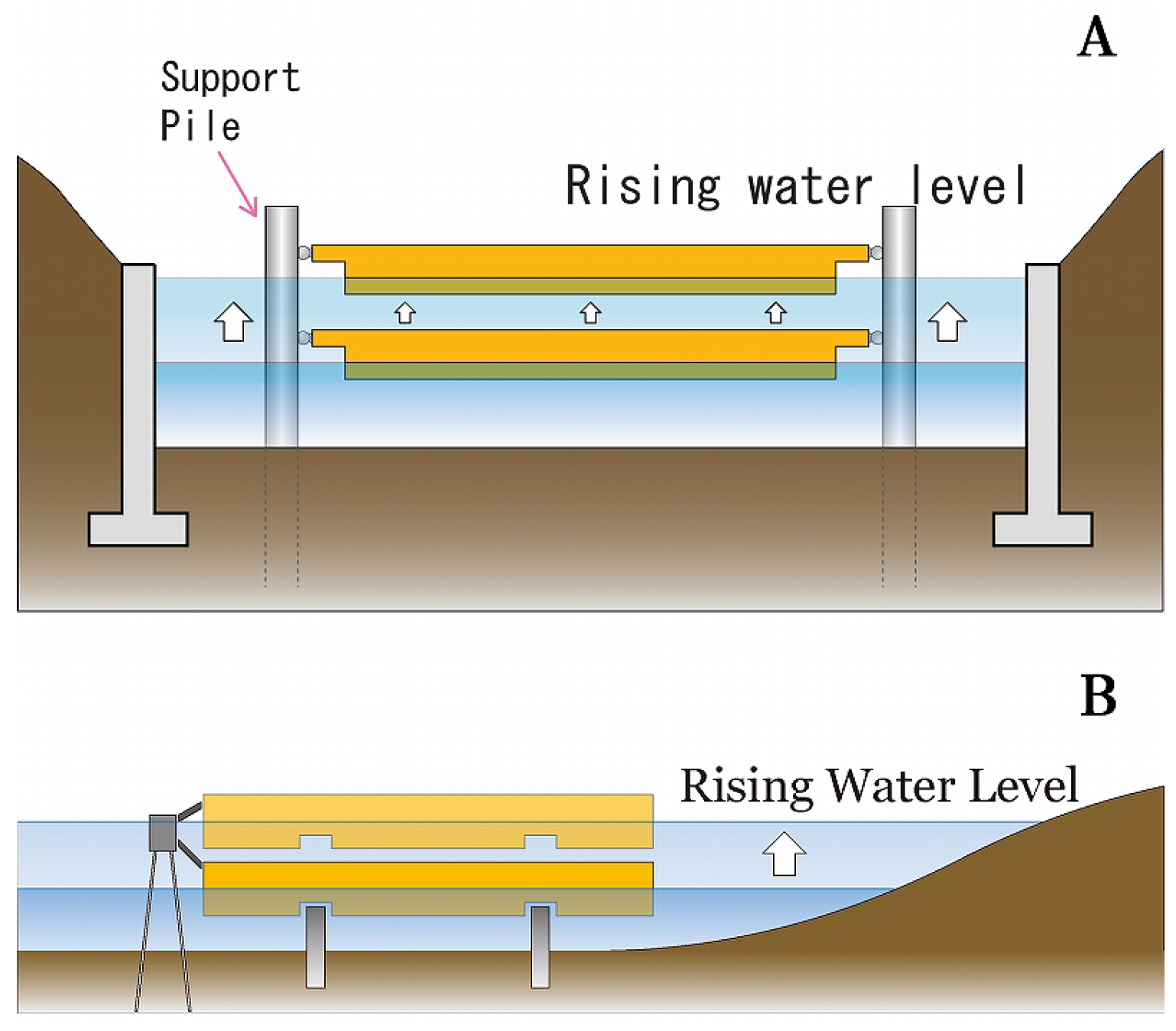

Figure 16). The authors are considering how to make best use of the valuable data and findings of the experiments as well as development of construction techniques for the project. In principle, the floating platform “floats by itself”; however, the proposal calls for what is known as the “Soft-landing System” explained already in

Section 2. In this system, the floating platforms are partially supported by support piles located beneath them. Since a floating platform stays afloat independently, it can be freely and easily moved in the horizontal direction within the man-made lagoon and, when connecting the floating platform and its supporting piles, vertical adjustment can be precisely controlled through changes in the weight of the ballast water inside the floating platform.

Figure 16.

Picture of “Mega-Float Project” (courtesy of the Marine Technology and Development Dept. at the Shipbuilding Research Center of Japan).

Figure 16.

Picture of “Mega-Float Project” (courtesy of the Marine Technology and Development Dept. at the Shipbuilding Research Center of Japan).

Figure 17 explains the simplified construction scheme for both the towing condition of the floating foundation without the ballast water as well as the fixed condition on the supporting pile (after filling water inside of the ballast water tank, following construction). The detailed section of the floating platform for “Soft-landing System” is shown in

Figure 17 (right portion). The floating platform is partially supported in its weight by 3.5 m piles with rubber fenders. The rubber fender located underneath of the floating platform works to cushion from the earthquakes and so on. About one tenth of the floating complex’s total weight is placed upon the supporting pile in this case. Meanwhile, the buoyancy force supports the displacement of the floating complex the most. Bird’s-eye view of a floating complex in Site 2 of the Kesennuma Bay area is shown in

Figure 18. The plan view of the Site 2 floating platform is basically trapezoidal in shape (27 m in width and 72 to 76 m in length) and the total deck area is 2175 m

2. Since the draft is fixed to be 3.8 m, the volume and the displacement become 8265 m

3 and 8265 t, respectively. In this calculation, it is assumed that the density of liquid is to be 0.001 t/m

3 assuming the liquid inside of reservoir is treated as pure water rather than saltwater. Saltwater can also be used to fill this artificial basin. In case the basin is connected directly to the sea, the floating platform may move up and down due to the tidal change in vertical direction.

Figure 17.

Sectional views of the conditions of floating platform both before and after constructions.

Figure 17.

Sectional views of the conditions of floating platform both before and after constructions.

Figure 18.

Bird’s-eye view of the Site 2 floating complex (Image as represented by architectural model).

Figure 18.

Bird’s-eye view of the Site 2 floating complex (Image as represented by architectural model).

On the other hand, the figure of 0.167 t/m3 is used for the calculation of the approximate deadweight of a floating platform made of steel as estimated as 1816 t from data provided by the Mega-Float Project. The estimated weights for a 4-story commercial complex with residences becomes 6238.9 t according to the data of 1.48 t/m2 for a reinforced concrete building for residential use due to the fundamental study while the live load of items such as trees, asphalt and cars is assumed as 200 t in this study. Moreover, since this live load varies depending upon quantity, materials and so on, the design enables the adjustment of one-fifth of the total live load by regulating the volume of ballast water inside floating platform. Since approximately one-tenth of the total weight is designed to be supported by several support piles of “Soft-landing System” as described before, the final total weight of the Site 2 floating complex becomes 9309 t instead of 8265 t, which is supported by the buoyancy force of the floating platform itself while the supporting piles support 1044 t in weight (under this condition, the weight of ballast water is 1054.1 t). Accordingly, the draft of the floating platform increases to be 4.28 m instead of 3.8 m when the floating platform detaches from the support piles. In another words, the floating platform stays on the same position as long as the water tide goes up more than 0.48 m from the mean water and/or sea level (MWL).

4.3. Some Engineering Evaluations on Floating Complex

Usually, waves are treated as most influential upon causing excitations for the floating platforms at sea, wind and current forces are dominant upon analysis in the present case since waves lose most of their energy in shallow waters, being blocked by the surrounding land. Therefore, the wave force can be neglected for the present case. The schematic sectional view of the Site 2 floating complex against wind and current loads is shown in

Figure 19. In this figure, CG indicates the location of the center of gravity while M is the location of the metacentric height of the floating complex. The floating complex moves up due to increased water depth in this figure. In general, both wind and current drag forces are calculated by multiplying four components: namely the liquid density, the projected area perpendicular to the flow, the drag coefficient and the square of the flow speed; this is divided by two. First of all, the current force due to tsunami, storm surge and/or wind driven current on the floating platforms was taken into account as dangerous factor. However, in principle, the horizontal load of the current due to tsunami on a barge-type floating platform is not too large, since the floating platform’s aspect ratio (draft-length ratio) is small. In other words, both the drag coefficient for the underwater portion of the floating platform and the wetted projected area are small. In addition, most of the tsunami flow passes underneath the floating platform, which is just riding on tsunami flow. Actually, video of the floating sea berth struck by the huge tsunami on 11 March 2011 have been recorded (available via YouTube) depicting the floating sea berth, “Marine Gate Shiogama”. This visual record proves that floating platforms moored properly are extremely stable and safe against tsunamis. The tsunami had not risen quickly (estimated about 0.04 m/s from footage) but even if it had a 10 m wave height, the vertical excursion of the floating sea berth, the vertical speed is only about threefold this speed at most, not that fast. The total horizontal load for tsunami against the Site 2 floating platform and 12 m high concrete piles is estimated as 1701 t (or 16,670 KN) based on the assumption that the horizontal velocity is 10.0 m/s observed at the water depth of 10 m on land during the huge tsunami in the Indian Ocean in 2004. Here in above calculations of the horizontal current force on the wetted portion of the floating platform, we assumed the drag coefficients of the wetted part of the floating platform as 1.0 for current force due to tsunami while the aspect ratio between the draft and the length of the floating platform is 1:20 [

13].

Figure 19.

Schematic sectional view of upright condition of the floating complex.

Figure 19.

Schematic sectional view of upright condition of the floating complex.

Another environmental load is wind force and the resulting moment especially in the storm condition. Next, the inclination of floating complex due to the strong wind force must be determined for the safety of the floating complex. Basically, two factors are involved for the computation for the inclination of the floating complex; one is the overturning moment due to wind force and the other is the stability of the floating complex. The overturning moment due to wind or the wind heeling moment is obtained as a product of the wind force and the corresponding lever arm between the centroid of the wind force on the floating complex and the location of center of gravity. The vertical location of center of gravity of the Site 2 floating complex with ballast waters is calculated to be 8.08 m (vertical distance between the bottom of the floating platform and the location of CG) while the meta-centric heights (vertical distance between CG and the location of M) in transverse and longitudinal directions for the Site 2 floating complex are 10.22 m and 99.26 m, respectively. Meanwhile the restoring moment against the wind heeling moment is calculated as a product of the displacement of the floating complex, and the meta-centric height and the heeling angle assuming the angle is small enough. Then the heeling angle due to wind can be obtained by these relations. When the wind-speed is assumed to be 70.0 m/s which is close to be 69.8 m/s, this maximum in Japan having been reached during a typhoon at the Muroto Peninsula of Kochi Prefecture in September of 1965, the approximate horizontal wind load and the heeling angle of the floating complex in the transverse direction are calculated as 295.9 t (or 2899.5 KN) and only 0.569 deg., respectively while heeling angle of longitudinal direction is less than one tenth of that of transverse direction, thus showing that there is a small effect generated due to strong wind. Here in above calculations of the horizontal natural load on the structure, we assumed the drag coefficients as 1.5 for wind.