A Feeding Quantity Monitoring System for a Combine Harvester: Design and Experiment

Abstract

:1. Introduction

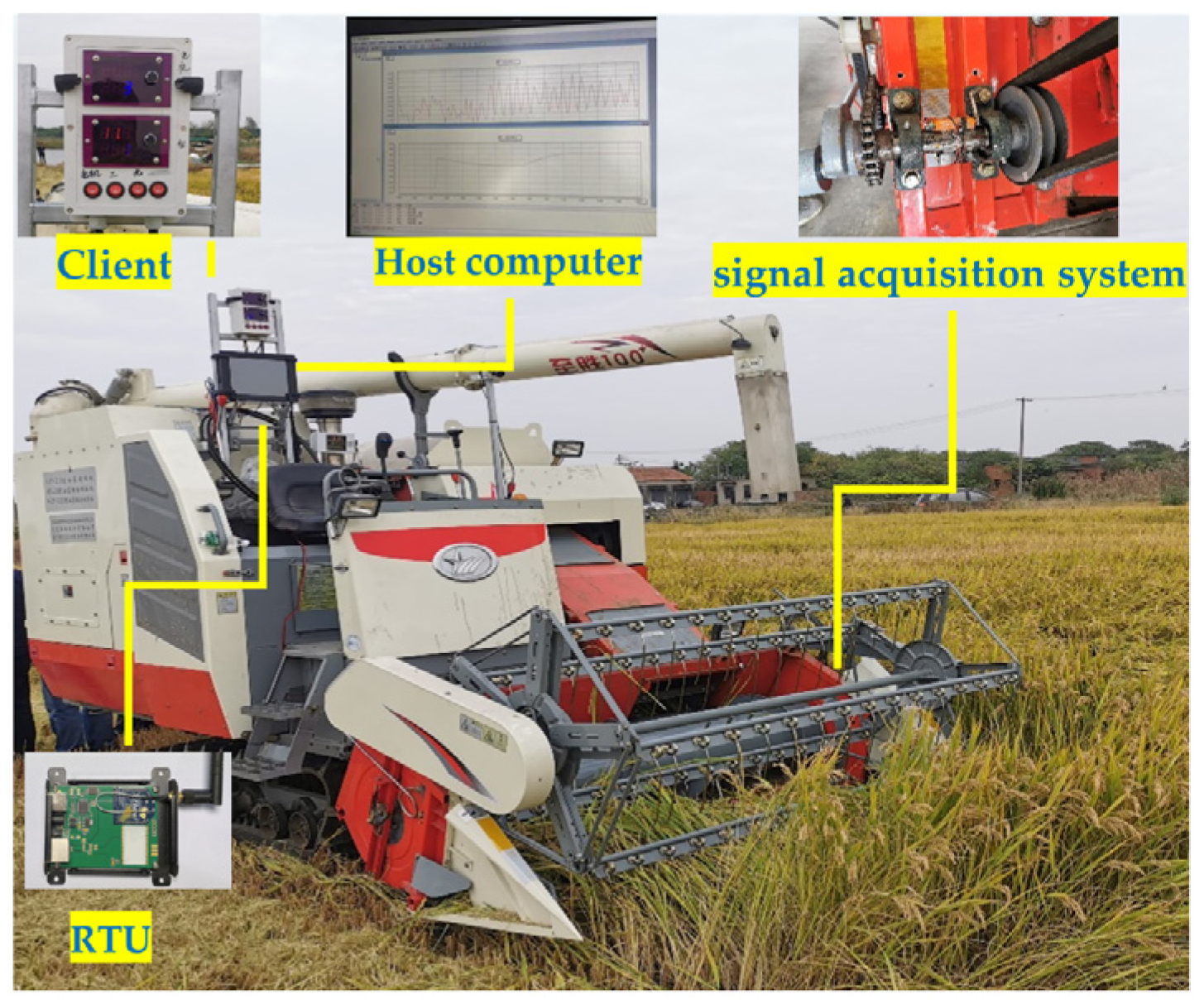

2. Materials and Methods

2.1. Feeding Quantity Measurement Principle

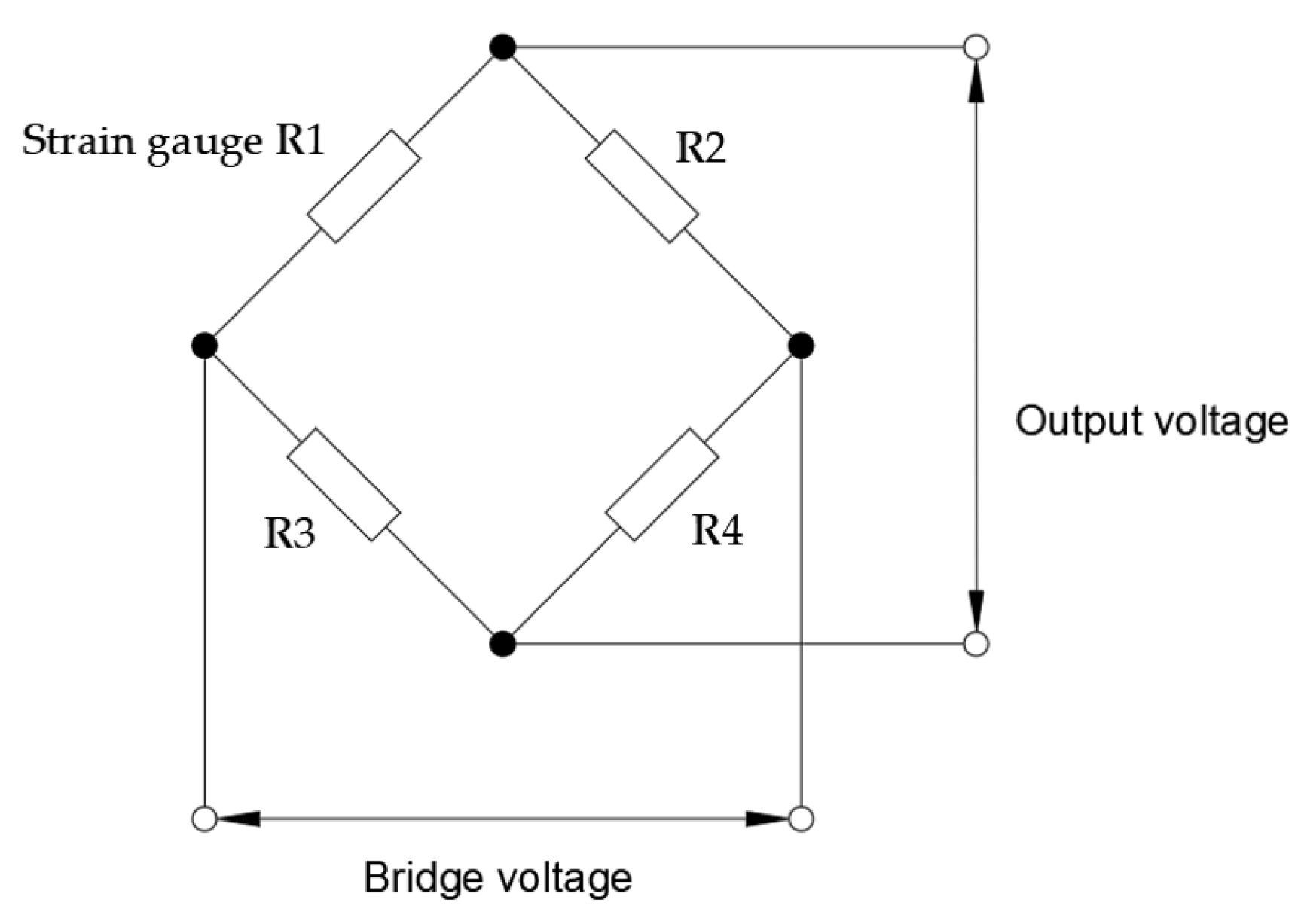

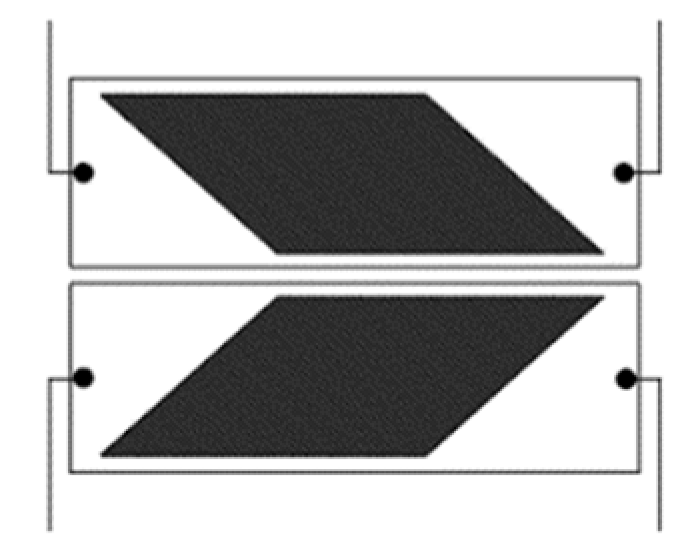

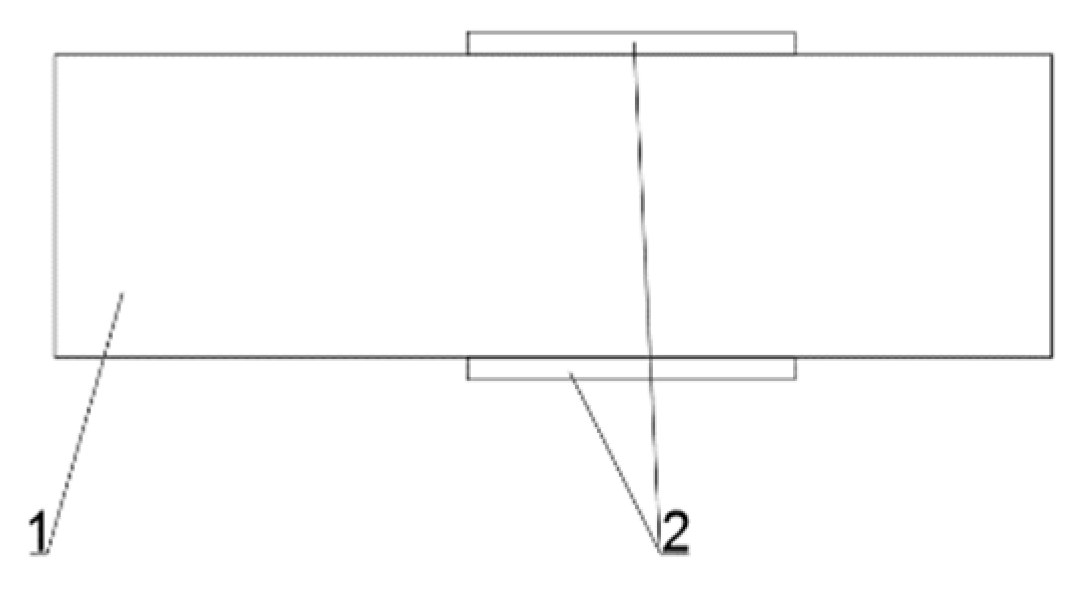

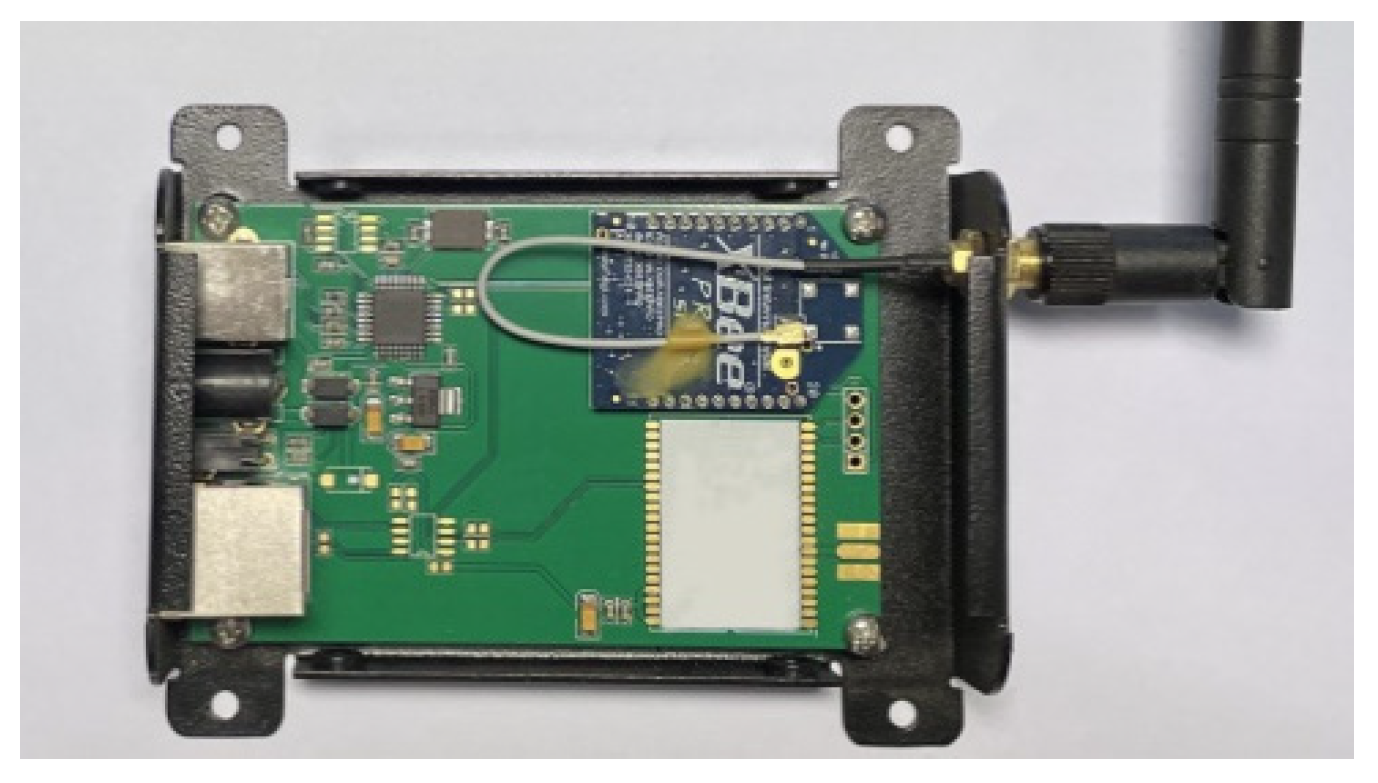

2.2. Signal Acquisition Method

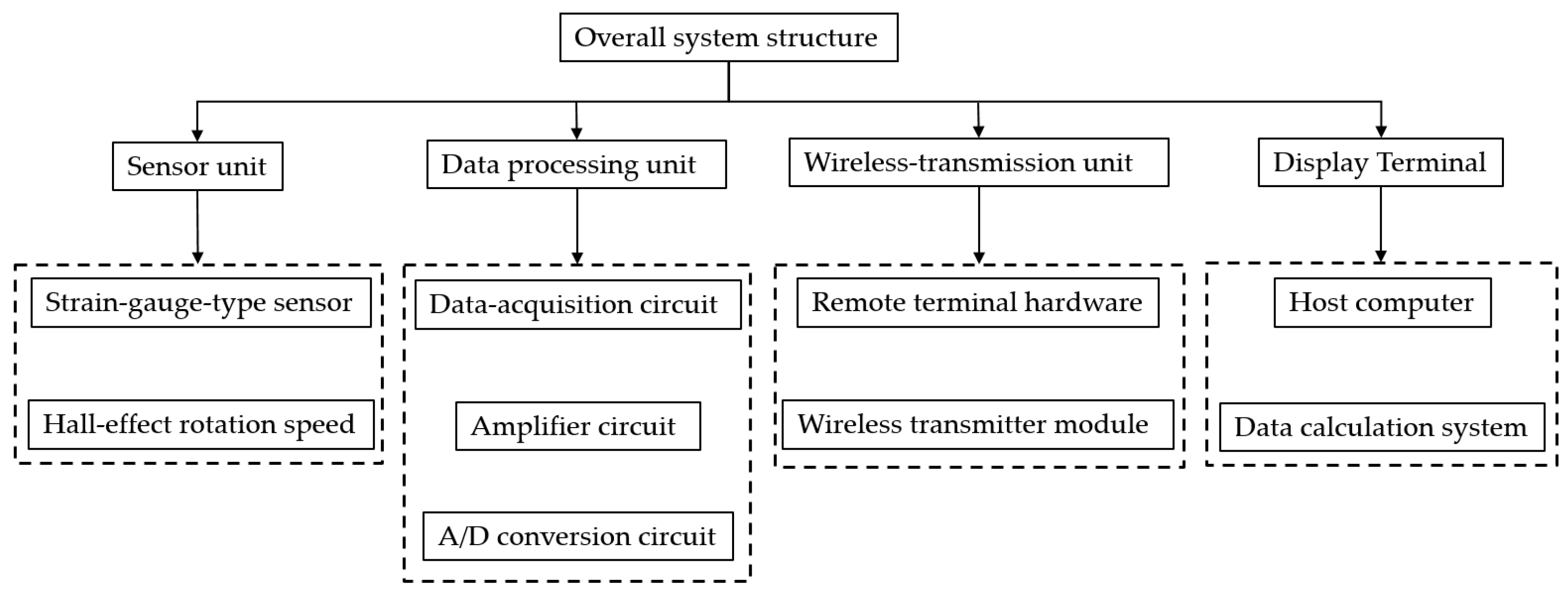

2.3. Overall Structure of the Monitoring System

2.4. Bench Calibration Experiment

3. Results of Signal Analysis

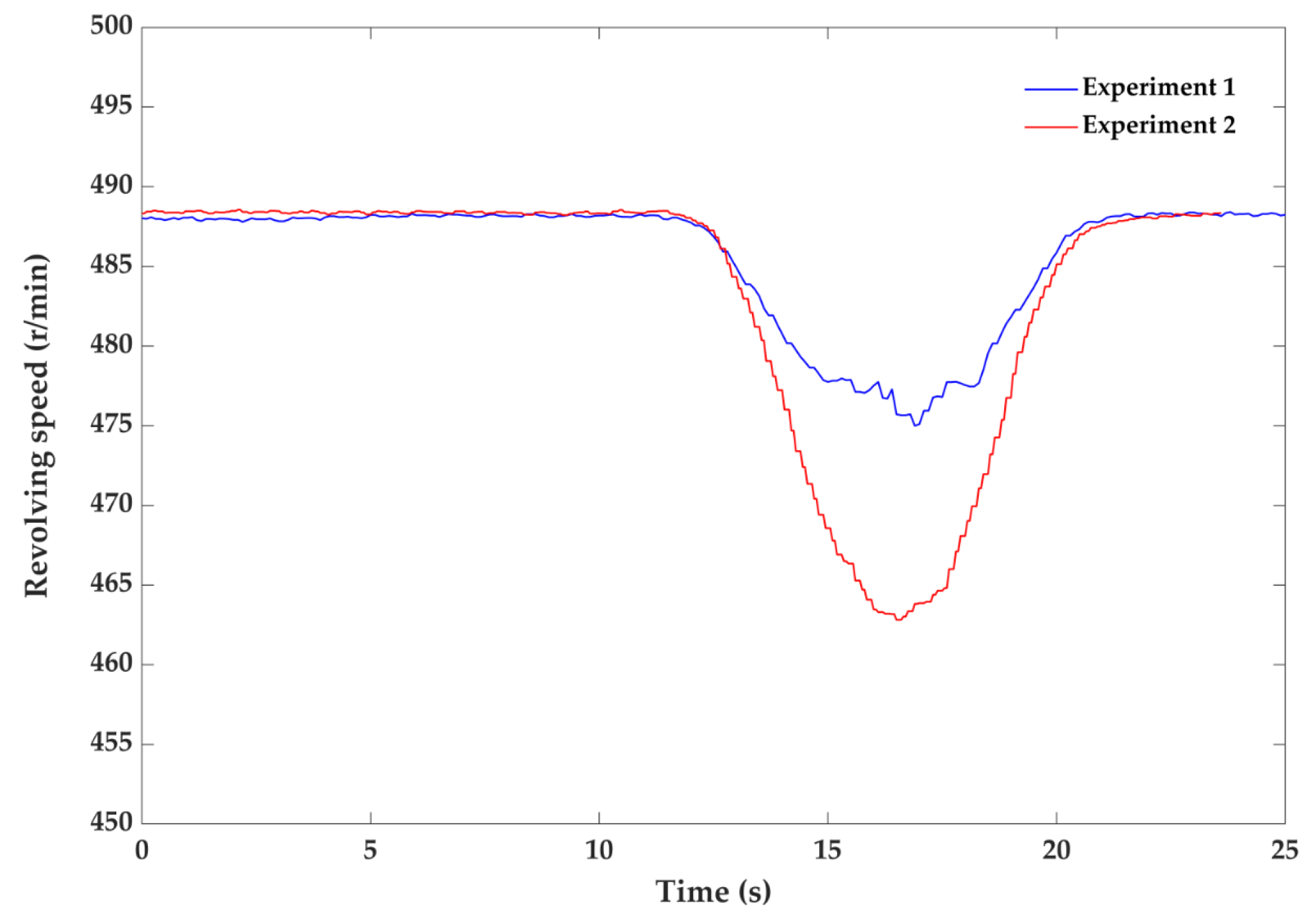

3.1. System Characterization

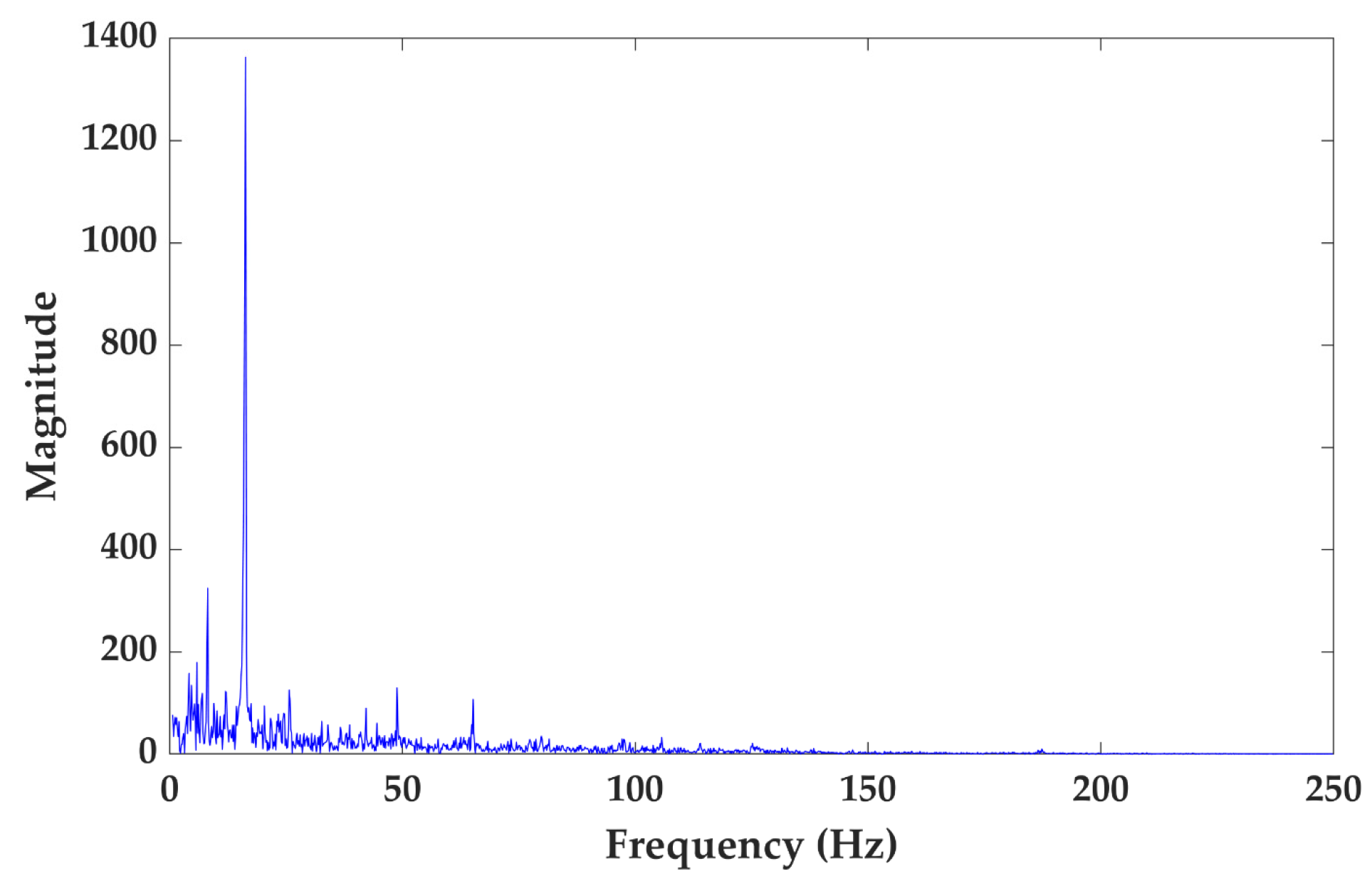

3.2. Noise Analysis of No-Load Signal

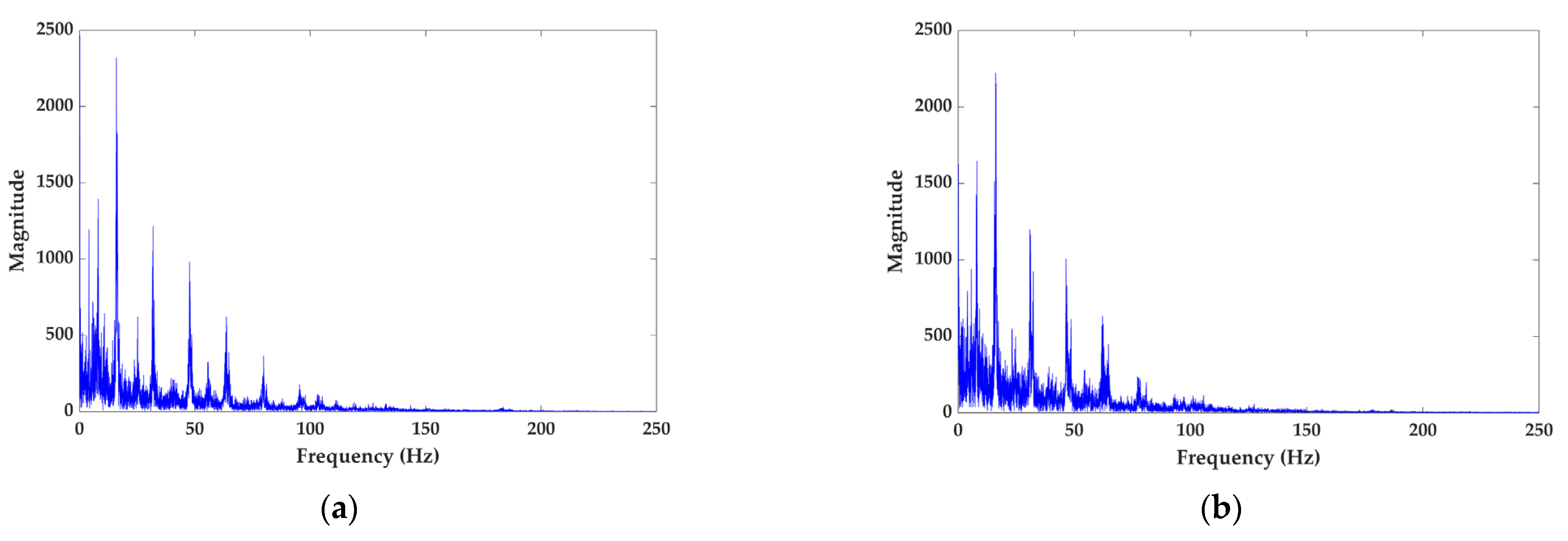

3.3. Analysis of Load Signal

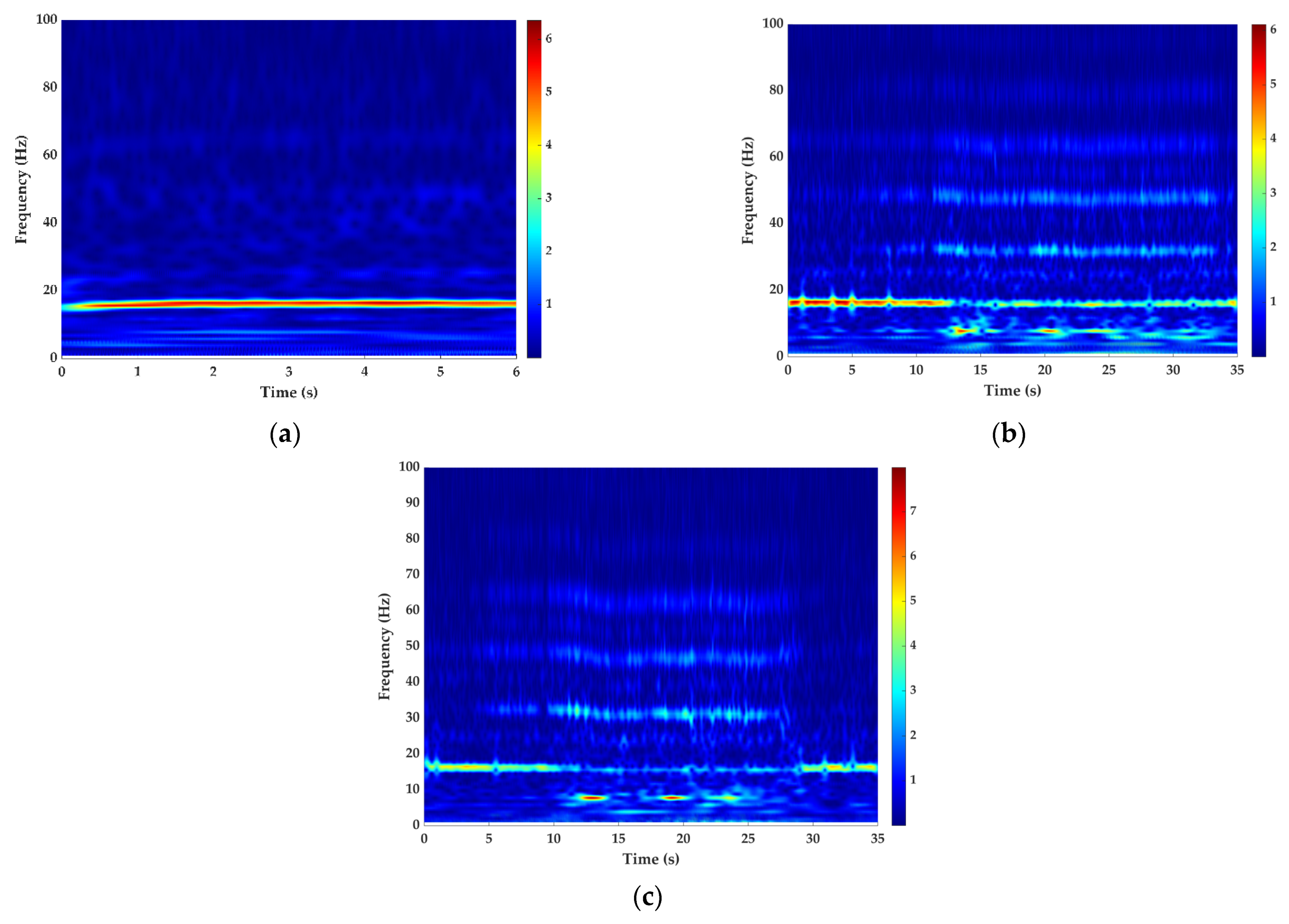

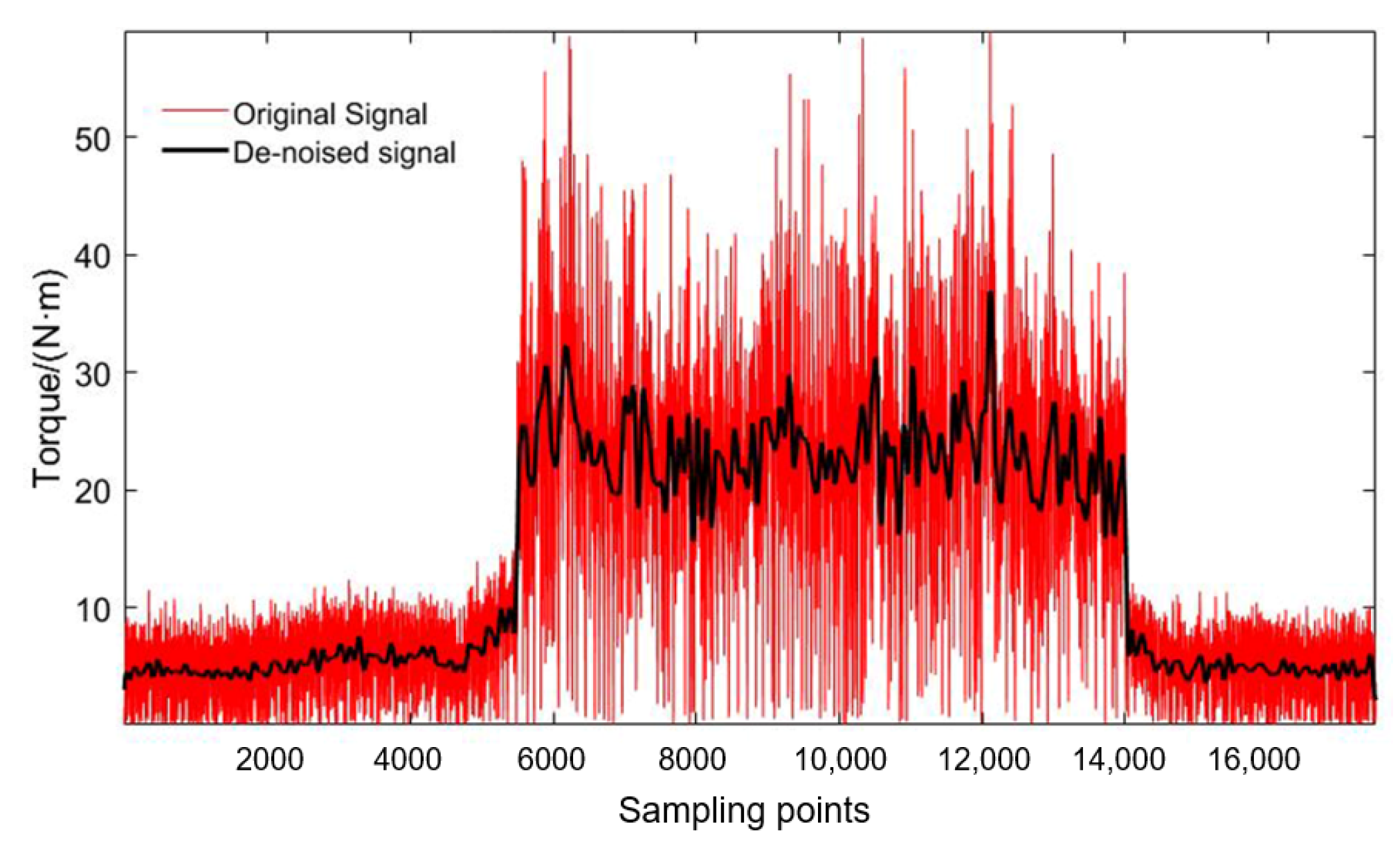

3.4. Time-Frequency Analysis, Filtering, and Denoising of Signal

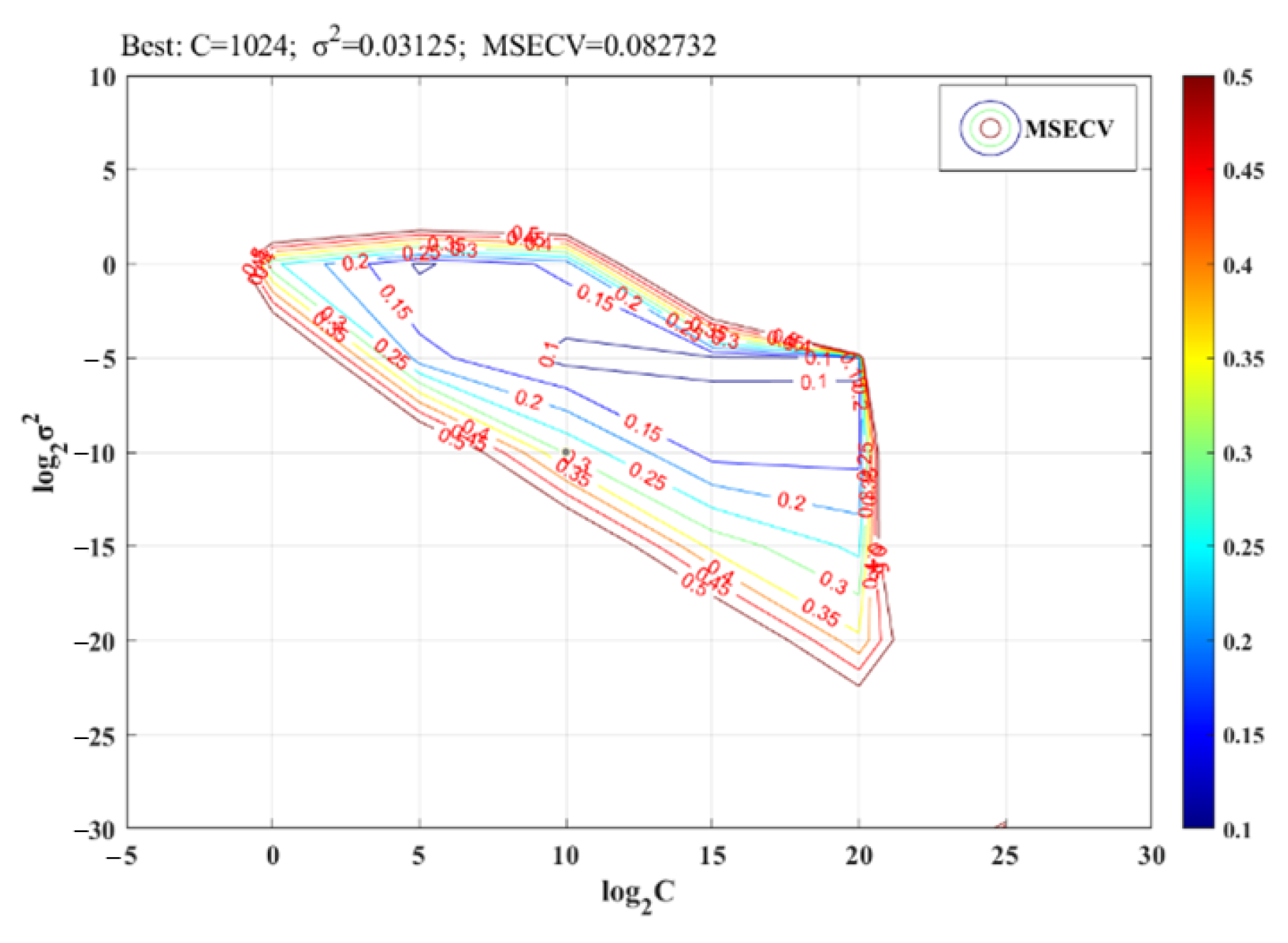

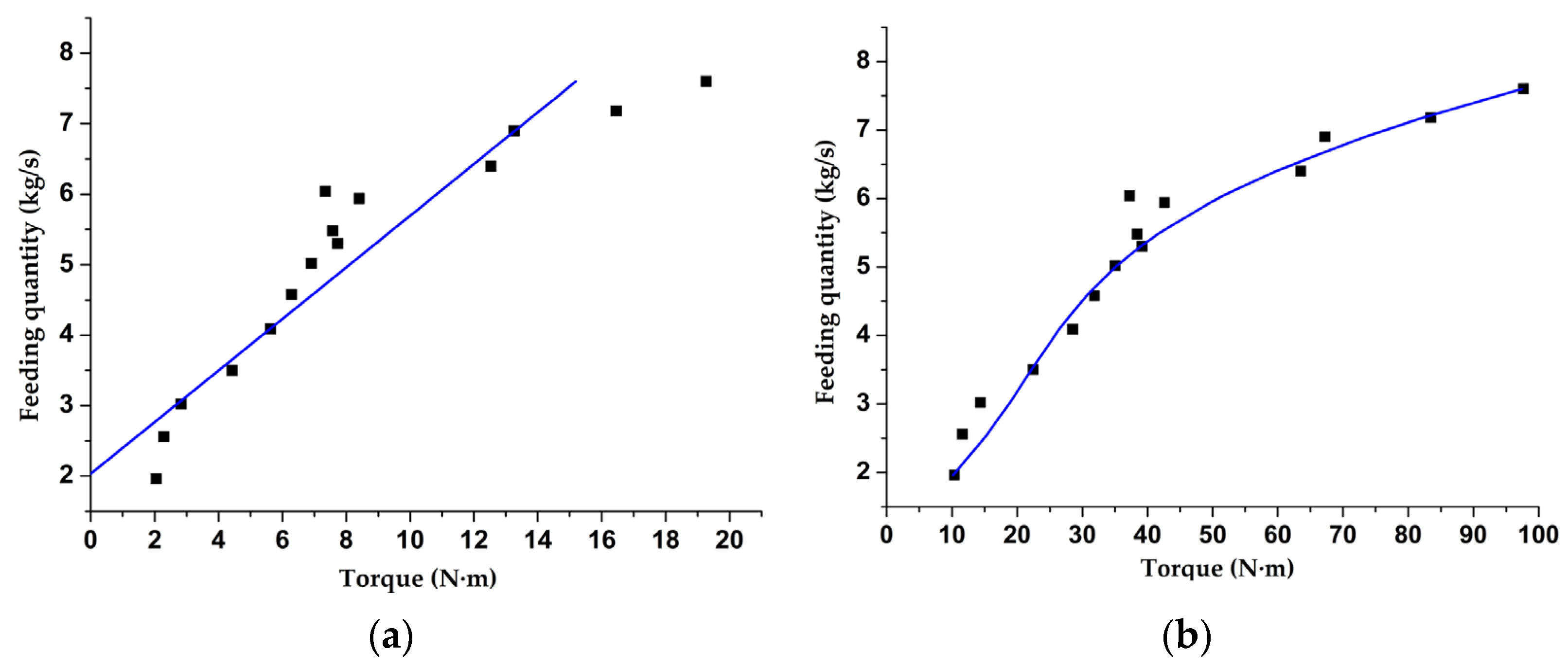

3.5. Fitting of Feed Quantity–Torque Relationship

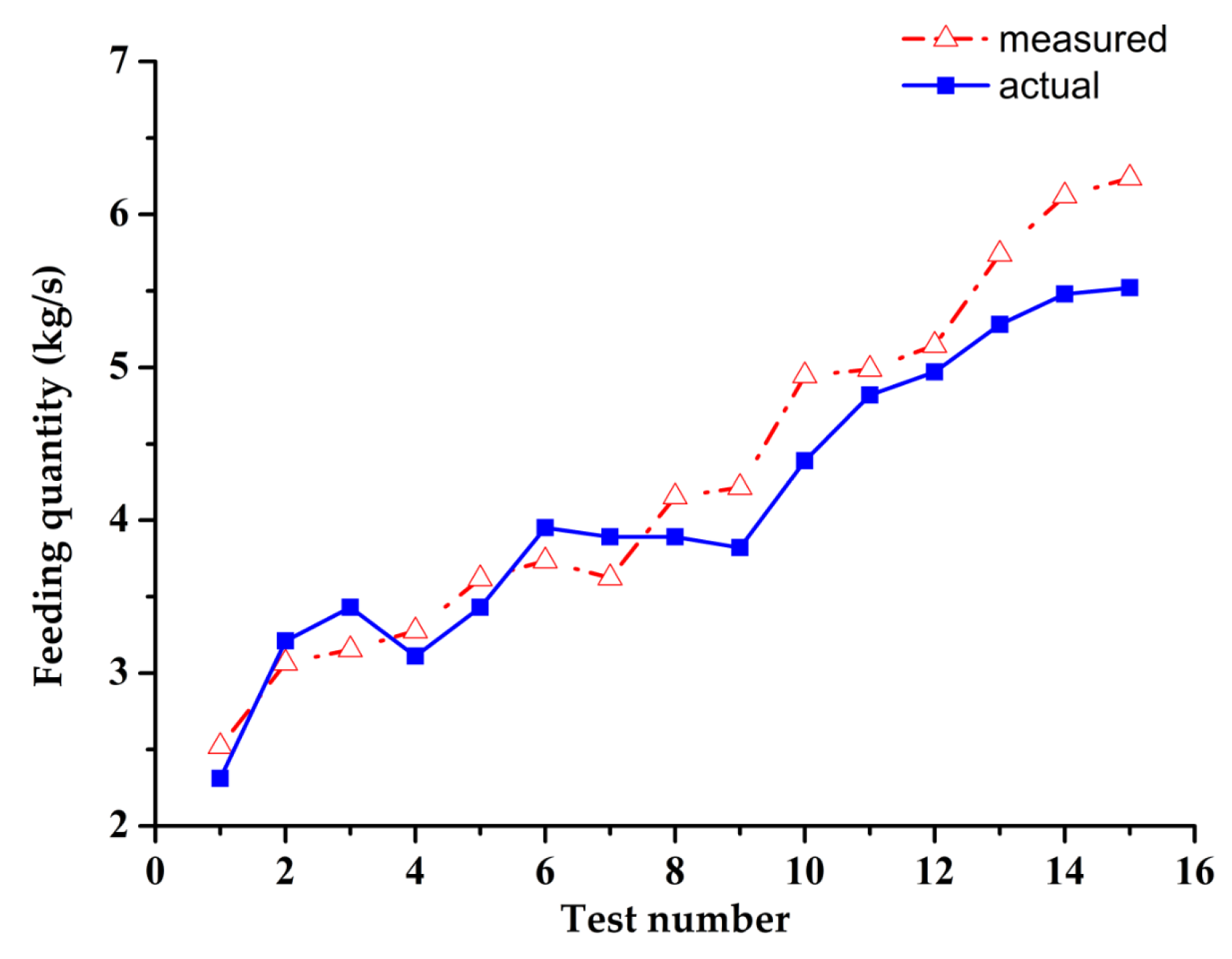

4. Field Experiment

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, D.; Wang, S.M.; Kang, F.; Zhu, Q.Y.; Li, X.H. Mathematical model of feeding rate and processing loss for combine harvester. Trans. Chin. Soc. Agric. Eng. 2011, 27, 18–21. [Google Scholar]

- Jie, Z.; Chen, J.X.; Liu, H.J. Research on fuzzy control of random feed quantity of GPS combine. Trans. Chin. Soc. Agric. Mach. 2006, 37, 55–58. [Google Scholar]

- Wang, S.Y.; Hu, Z.C.; Yao, L.J.; Peng, B.L.; Wang, B.; Wang, Y.W. Simulation and parameter optimization of pickup device for full-feed peanut combine harvester. Comput. Electron. Agric. 2022, 192, 106602. [Google Scholar] [CrossRef]

- Zhang, Y.W.; Chen, D.; Yin, Y.X.; Wang, X.; Wang, S.M. Experimental Study of Feed Rate Related Factors of Combine Harvester Based on Grey Correlation. In Proceedings of the 6th IFAC Conference on Bio-Robotics, Beijing, China, 13–15 July 2018; Volume 51, pp. 402–407. [Google Scholar]

- Miu, P.I. Modeling and simulation of grain threshing and separation in axial threshing units, part II, application to tangential feeding. Comput. Electron. Agric. 2008, 60, 105–109. [Google Scholar] [CrossRef]

- Chai, X.Y.; Zhou, Y.; Xu, L.Z.; Li, Y.; Li, Y.M.; Lv, L.Y. Effect of guide strips on the distribution of threshed outputs and cleaning losses for a tangential-longitudinal flow rice combine harvester. Biosyst. Eng. 2020, 198, 223–234. [Google Scholar] [CrossRef]

- Jie, Z.; Luo, S.B.; Zhou, X.J. LabVIEW-based telemetering experiments of rice feed quantity for combined harvester. Trans. Chin. Soc. Agric. Eng. 2009, 25, 87–91. [Google Scholar]

- Wang, W.W.; Li, J.C.; Chen, L.Q.; Liang, X.T. Effects of key parameters of straw chopping device on qualified rate, non-uniformity and power consumption. Int. J. Agric. Biol. Eng. 2018, 11, 122–128. [Google Scholar] [CrossRef]

- Li, Y.M.; Wang, J.P.; Xu, L.Z.; Tang, Z.; Xu, Z.H.; Wang, K.J. Design and experiment on adjusting mechanism of concave clearance of combine harvester cylinder. Trans. Chin. Soc. Agric. Mach. 2018, 49, 68–75. [Google Scholar]

- Chen, J.; Ning, X.B.; Li, Y.M.; Yang, G.J.; Wu, P. Fuzzy adaptive control system of forward speed for combine harvester based on model reference. Trans. Chin. Soc. Agric. Mach. 2014, 45, 87–91. [Google Scholar]

- Ning, X.B.; Chen, J.; Li, Y.M.; Wang, K.; Wang, Y.F. Kinetic model of combine harvester threshing system and simulation and experiment of speed control. Trans. Chin. Soc. Agric. Eng. 2015, 31, 25–34. [Google Scholar]

- Wei, X.H.; Li, Y.M.; Chen, J.; Song, S.P.; Gu, J.; Zuo, Z.Y.; Ni, J. System integration of working process intelligent monitoring and controlling devices for combine harvester. Trans. Chin. Soc. Agric. Eng. 2009, 25, 56–60. [Google Scholar]

- Chen, J.; Li, Y.M.; Ji, B.B. Study on measurement method of combine feed quantity. Trans. Chin. Soc. Agric. Mach. 2006, 12, 76–78. [Google Scholar]

- Tang, Z.; Li, Y.M.; Xu, L.Z.; Pang, J.; Li, H.C. Experimental study on wheat feed rate of tangential-axial combine harvester. Trans. Chin. Soc. Agric. Eng. 2012, 28, 26–31. [Google Scholar]

- Liang, X.X.; Chen, Z.; Zhang, X.C.; Wei, L.G.; Li, W. Design and experiment of on-line monitoring system for feed quantity of combine harvester. Trans. Chin. Soc. Agric. Mach. 2013, 44, 1–6. [Google Scholar]

- Lu, W.T.; Deng, Z.G.; Zhang, D.X.; Gao, H.T.; You, H.Y. Combine feed rate modeling research. J. Agric. Mech. Res. 2013, 35, 129–132. [Google Scholar]

- You, H.Y.; Lu, W.T. Fuzzy control system for feed quantity of combine harvester. J. Northwest AF Univ. (Nat. Sci. Ed.) 2015, 43, 229–234. [Google Scholar]

- Zhao, S.H.; Zhang, G.Z.; Zhang, S.J.; Fu, J.W.; Mohamed, A. Designing a real-time feed measurement system for horizontal axial flow threshing drum based on thin film sensor. J. Huazhong Agric. Univ. 2020, 39, 160–169. [Google Scholar]

- Huynh, V.M.; Powell, T.; Siddall, J.N. Threshing and separating process-a mathematical model. Trans. Am. Soc. Agric. Biol. Eng. 1982, 20, 65–73. [Google Scholar] [CrossRef]

- Wang, S.Y.; Hu, Z.C.; Wu, F.; Yu, Z.Y.; Cao, M.Z.; Gao, X.M. Modeling and experiment of feeding rate for full-feed peanut pickup harvester. Trans. Chin. Soc. Agric. Eng. 2019, 35, 29–36. [Google Scholar]

- Liu, Y.Y.; Liu, H.; Yin, Y.X.; An, X.F. Feeding assessment method for combine harvester based on power measurement. J. China Agric. Univ. 2017, 22, 157–163. [Google Scholar]

- Zhang, Z.Q.; Sun, Y.F.; Liu, R.J.; Zhang, M.; Li, H.; Li, M.Z. Design and test of feed rate monitoring system for combine harvester. Trans. Chin. Soc. Agric. Mach. 2019, 50, 85–92. [Google Scholar]

| No. | Total Material Mass (kg) | Feeding Quantity (kg·s−1) |

|---|---|---|

| 1 | 9.8 | 1.96 |

| 2 | 12.8 | 2.56 |

| 3 | 15.1 | 3.02 |

| 4 | 17.5 | 3.5 |

| 5 | 20.45 | 4.09 |

| 6 | 22.9 | 4.58 |

| 7 | 25.1 | 5.02 |

| 8 | 26.5 | 5.3 |

| 9 | 27.4 | 5.48 |

| 10 | 29.7 | 5.94 |

| 11 | 30.2 | 6.04 |

| 12 | 32 | 6.4 |

| 13 | 34.5 | 6.9 |

| 14 | 35.9 | 7.18 |

| 15 | 38 | 7.6 |

| Decision Factor | Average Error | Root Mean Square Error | |

|---|---|---|---|

| PLSR | 0.853 | 16.2% | 1.877 |

| SVM | 0.967 | 5.21% | 0.573 |

| No. | Measured Feeding Quantity (kg·s−1) | Actual Feeding Quantity (kg·s−1) | Deviation |

|---|---|---|---|

| 1 | 2.52 | 2.31 | 9.1% |

| 2 | 3.06 | 3.21 | 4.5% |

| 3 | 3.15 | 3.43 | 8.1% |

| 4 | 3.28 | 3.11 | 5.3% |

| 5 | 3.62 | 3.43 | 5.5% |

| 6 | 3.73 | 3.95 | 5.5% |

| 7 | 3.62 | 3.89 | 6.9% |

| 8 | 4.15 | 3.89 | 6.8% |

| 9 | 4.22 | 3.82 | 10.4% |

| 10 | 4.94 | 4.39 | 12.6% |

| 11 | 4.99 | 4.82 | 3.5% |

| 12 | 5.14 | 4.97 | 3.5% |

| 13 | 5.74 | 5.28 | 8.7% |

| 14 | 6.12 | 5.48 | 11.7% |

| 15 | 6.24 | 5.52 | 13.0% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, T.; Guan, Z.; Li, H.; Mu, S.; Wu, C.; Zhang, M.; Wang, G.; Chen, X. A Feeding Quantity Monitoring System for a Combine Harvester: Design and Experiment. Agriculture 2022, 12, 153. https://doi.org/10.3390/agriculture12020153

Jiang T, Guan Z, Li H, Mu S, Wu C, Zhang M, Wang G, Chen X. A Feeding Quantity Monitoring System for a Combine Harvester: Design and Experiment. Agriculture. 2022; 12(2):153. https://doi.org/10.3390/agriculture12020153

Chicago/Turabian StyleJiang, Tao, Zhuohuai Guan, Haitong Li, Senlin Mu, Chongyou Wu, Min Zhang, Gang Wang, and Xu Chen. 2022. "A Feeding Quantity Monitoring System for a Combine Harvester: Design and Experiment" Agriculture 12, no. 2: 153. https://doi.org/10.3390/agriculture12020153